More '01 Mazda B2500/Ford Ranger "Rolling Thunder" Episodes

More Rolling Thunder Episodes

Trucks! Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Ford Performance Parts

Ford Racing 2003-04 Mustang Cobra Upgraded Whipple Supercharger Kit

Accufab,Inc.

High Flow Throttle Body

Fore Precision Works, LLC

Billet Fuel Rails for 2003-2004 Cobra

Fore Precision Works, LLC

Dual GSS Fuel Pump and Pickup Assembly

Fore Precision Works, LLC

F2 Fuel Pressure Regulator

LMC Truck

Chrome 12 Bar Grille Shell

LMC Truck

Euro Style Headlights and Corner Lenses (Black)

LMC Truck

Front Lower Valance with Fog Light Holes

LMC Truck

Grille Reinforcement Panel

LMC Truck

LH Front Fender 98-03 Ranger

LMC Truck

Paintable 12 Bar Grille Shell

LMC Truck

RH Front Fender 98-03 Ranger

Performance Trends Inc.

Suspension Analyzer v2.0

Tremec

Tremec T56 MAGNUM 6-speed

Episode Transcript

Today, we're converting our Mazda B 2500 to the Ford Ranger that it really is Ranger

and we're doing a side by side comparison of our frame stiffening. Finally, it's all the speed parts we need for our illuminator engine. It's all today here on trucks.

Hey guys, welcome to trucks.

Well, today we're back on Project Rolling Thunder, our V8 powered Mazda B 2500 compact truck

when we first started looking for a vehicle to start this project. We were actually looking for a Ford Ranger, but we got a screaming deal on this Mazda 2500 and essentially it is a Ranger. The cab is the same, the doors are the same. Almost every major component in this vehicle is a Ford Ranger. Heck, it even says made by Ford on the door tag,

but we're kind of getting used to the subtle differences that make it a Maza,

but we're still gonna change it.

Well, why would we change it from the Mazda truck? That it is kind of cool looking into a ranger. Well,

check this out,

this rendering was inspired by an actual vehicle that Ford's SVT team put together using an 01 Ford Ranger and a Ford Lightning drive train. Now, this truck looks downright mean and with the power that we've got sitting in the corner waiting to go with it, it's going to back it up too.

Now, one thing we're definitely not gonna change

because it's the same as the Ford Ranger.

This is lightweight aluminum hood. Now, the rest of the swap is pretty straightforward

and since these fenders have a few dings dents and pop knots. Well, it would take a little bit of labor to get them ready for paint anyway. So a sheet metal swap makes even more sense. Now, this would be a great project for you guys to do at home

if you've got a Mazda and you want to turn it into the more popular into some better looking Ford Ranger. Now, we could always do a salvage yard swap. There's plenty of Ford Rangers in the junk yards, but we may end up in the same position as with our Mazda fenders and a little bit of body work to do. So, we went online to L MC trucks website, went through their catalogs picked out some parts and here's what we got.

We started out with brand new sheet metal Ford Ranger fenders and

the one thing that's distinctly Mazda is the header panel and grill. So we got a Ford Ranger header panel that would support everything else.

Now, check these out, there's lots of headlight options in their catalogs. These resemble our rendering almost to A T and will give us nice bright refraction and they're kind of cool looking.

They've got several options with the grill. You can have a painted grill or a chrome grill. Again, the painted grill resembles our rendering. So we're gonna roll with that. Although chrome is an option for you guys. Now, the balance panel has optional fog light ducts. What we're gonna do is utilize those as brake cooling ducts since this is gonna be a road racer. So the rest of it just part swapping.

So it doesn't take much to tear down the nose of one of these trucks. Just a few simple tools will get the job done. But keep this in mind this truck's old enough so that some of the plastic parts and fasteners. Well, they can get a little brittle. So take care, taking it apart.

Trust me, get a hardware box. We'll thank you later.

Now,

all the parts and pieces while they're very lightweight and it might seem like these trucks aren't made of much, but just because the sheet metals, light doesn't mean the underlying structure is not,

it's made to absorb impact on a collision and it's quite strong.

There's some obvious differences between a replacement fender and the original fender. The biggest one that you see is the fact that the E coat or the electro deposition primer is black instead of the grayish green color and your eyes are drawn right to the sticker. This just signifies that this fender or this panel has been certified by the Department of Transportation being a safe replacement. Now, this greenish gray E coat is what the factory put on. So, if this is still the color underneath your trucks, skin, well, chances are it hadn't been crashed out. Here's what we're doing. Now, we're gonna transfer this clip and there's an easy way to release these J clips. Just grab a hold of the spring steel tab,

lift it straight up,

that allows you to replace it and it still stays in place. It won't drop off on the floor and it's still movable so you can adjust this panel.

Now, you can clearly see the difference between the Mazda fender and the Ford Ranger fender at least when it comes to styling, but the mounting locations are exactly the same on both pieces.

We had no trouble at all lining up the panel gaps and the stampings were precise

and you want to make sure that there's no interference between the door and the new fender.

This fender passed that test pretty good too.

Looks good, width wise for

the most part looks pretty good.

Now, making sure your fenders are properly aligned is the foundation for the rest of the truck fitting. Well,

if the fenders don't fit, none of this other stuff is going to line up and you're going to be chasing problems around in a circle. So fit your panels from the back to the front. You should be in good shape.

Now, some of the parts come with hardware and clips, some of it you got to repurpose from the old parts that you've taken off.

We reuse the mounting hardware for the headlights and marker lights from the old ones

such as these spring steel headlight mountain clips. They go in from the back side and hold the headlights in, but they can be accessed from the top.

Sometimes it takes some specialty tools. So thanks Metco

all.

Now we're using brand new retainers to hold the grill in from the top. But we transferred the spring steel clips for the bottom from the other header and grill

ranger.

Now with the Mazda front bumper strip down, guess what? It perfectly matches the profile of the Ford Ranger grill and that's just proof that there's some cross breeding going on and this truly was a ranger to start with. Now, the lower balance here, like we said, we want to utilize these fog light ports as some kind of break cooling duct. Now, it doesn't bulk right up. We're gonna have to do some work to it to get it to work. But we wanted to build a chin spoiler or a splitter anyway. So we've got fabrication work ahead of us no matter what we do.

Now, for the minimal time and money investment we've got in this thing. We've turned our plain Jane Mazda B 2500 into a late model Ford Ranger

and a modified one at that

up next, we'll show you just how much difference frame reinforcing can make and later everything you need to make it easy. 600 horsepower. Stay tuned.

Hey, guys, welcome back to the shop.

Well, now that we've got 95% of the boxing done to the frame rails of our ranger. Well, we wanted to take a few minutes and show you what adding about 10 pounds worth of eight inch plate steel can do to the overall stiffness of the chassis because if you remember last time

this frame was way too flexible for the use, we have intended for this truck

with a good 2, 2.5 inches of flex on the frame before any of the other frame points lifted off the jack stand.

And now we've got that number down to about 38 of an inch.

That's before we add in the roll cage.

And it's without the rear bumper and spare tire carrier holding the rear frame rails together.

And with the stiff chassis not doing much flexing or twisting, our coil springs on the suspension will be able to do their job much more effectively.

It's quite the drastic comparison when you stack them up side by side.

Now, we've also done some modifications to the front section of the frame. We've lopped off the factory rack and pinion mount as well as got rid of the coil spring pocket and shock mount along with the upper and lower control arm mounts.

Then we just welded in some eight inch plate along the side and t the holes at the top and the bottom of the frame.

And that'll give us some good flat real estate to work off of when we're building our custom front suspension.

Speaking of which, if you're doing a project like this at home, make sure it's planned out and it's gonna work correctly. The last thing you wanna do is just wing, it could end up in the ditch. Now, if you're gonna do this, try to avoid the trial and error method, not only waste time, it waste materials. So for a better alternative check this out,

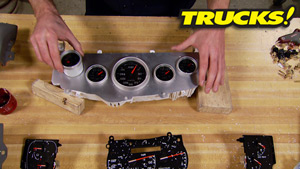

this is suspension, analyzing software that we got from performance trends.

These guys have software applications for circle track racing, engine building drag racing and a whole bunch of others. Now, what you have to do is measure out your frame plot where you think your suspension pick up point need to be, enter the information into the software. It makes some calculations and gives you something like this.

Now, this may look intimidating but just some of these values are inputs. The computer software actually does a lot of the work and calculations for you providing a lot of the outputs.

Once you have all your information entered the software, it will provide you with a great visual. It will allow you to see a front view

side view

as well as a top view. You can even go in and animate and simulate different suspension dynamics such as dive, steer and roll. And that'll let you see what kind of changes you get in the toe in camber and castor and roll center height

and doing it. This way, you can make sure your suspension is working like you want it to and all dialed in. And that's before you even cut out the first bracket or lay down the first weld. Definitely a time saver.

Now, we're not done with the suspension software yet. We still got to figure out steering rack placement and a couple of other small things. Now, what we've done here is assemble our front suspension. We've got upper and lower control arms, our ball joint adapters and we went ahead and attached them to the spindle.

Then we just welded this jig to our sacrificial hub at a height that mimics the center of the front wheel. And by placing the jig parallel to the front axle, center line, setting the frame at ride height and picking out our front axle width. We can cut in here and determine if we're gonna have any interference issues with the front control, our mounts.

Now, by doing this and using the suspension, analyzing software, we can make sure this is done right the first time and any fine tuning that needs to take place can be done utilizing our adjustable suspension.

Now, I guess we just need to make it happen, but that's another day.

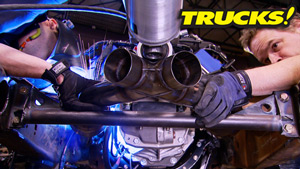

Hey guys, welcome back to trucks. Well, with the solid plan on our suspension well underway, we wanted to talk to you a little bit about the engine swap that we're doing. Now. There's no doubt that there's great aftermarket support for these 4.6 modular engines in particular from Ford racing with our four valve illuminator engine here.

But you gotta keep this in mind. These manufacturers are doing these projects and these products as upgrades and they're assuming that you either have a core or a complete donor and that you're gonna upgrade using their parts and that they may not have every single thing that you need to do to swap in their catalog.

Now, this upper Iler Pulley Bridge and this ac delete pulley, well, they are from Ford Racing. I suggest that you go to Ford Racing's website, search their catalog, see what they do have. But there's two things that we know they don't.

Now, you might just be surprised as to how many of these parts are still available at your Ford parts counter, the engines are new enough and popular enough to where they may have replacement parts in stock or they can find them through their distributors.

The issue is that sometimes over the parts counter, the dealership can get a little bit spendy. So you can do what we did surf a bunch of Ford performance specific forms like stag

net like SV T performance and modular fords and find the guy just like we did that swapping from his root style super charger to a turbo system and he's got all his swap parts available like the charge coolant,

the lower intake

coolant manifold,

the IC coolant pump, which is, by the way, the same for the lightning. So you can find one on a lightning form as well. All the duct work and coolant routing including the lower cage pulley.

My point is this, you're gonna have to do some digging and hunting around and swap meeting to find all of this stuff. But hey, that's kind of fun anyways and what you do have all of the pieces that are gonna make up your terminator and all the accessories. Then the after market kicks in, you can turn to Wicca.

Now

you can pick up a stock eaten super charger for a terminator all day long, fairly reasonable. That's because most of the serious cobra guys are upgrading to this bad boy. Now, this is the whipple 2.3 which incidentally is available from the Ford racing catalog.

They give you a choice of an upper pulley and for a throttle body, we decided to go with this acu

single blade throttle body which gives you 70% more airflow, almost 1700 CFM of airflow

Now, this setup is capable of nearly 20 pounds of boost. So to keep up with those extra atmospheres, you got to give it enough fuel. We're using four precision works beautiful billet, fuel rails, their fuel pressure regulator and their fuel pump hat that we showed you earlier.

Now, since we're beefing everything else up, we certainly didn't want to compromise on the transmission. Now, we wanted a 6 ft but a stock T 56 well, it's rated at 450 ft pounds of torque. This magnum T 56 rated at 700 ft pounds of torque. Now, there's typical trem

options like the choice between a mechanical and electric speedometer. C

but the coolest thing are the multiple shift locations. You can have one on the transmission body and this reversible on the transmission

tail shaft housing, giving you three different shift locations and lots of different options. Now, the magnum T 56 is essentially an after market version of the Tr 6060 which is the same transmission found in Shelby GT 500 Mustangs, Super sport Camaros, Cadillac CTSVS RT eight Challengers and Z six and Z 71 Corvettes. So if it's tough enough for those high performance platforms, it's gonna do just fine in our little ranger.

You're watching trucks for a DVD copy of this episode, just go to power block tv.com and order your copy for just 595 plus shipping and handling, start your own trucks collection delivered right to your door from the power block.

Hey guys, welcome back to the shop

now, for those of you that have been watching the show for a while. Well, you know, we use this 2000 F 250 for just about everything and it's been that way for about a decade and 140,000 miles and ever since day one, well, it's been wearing the same set of wheels. They're starting to show their age. Now, there's no other single add on that can change the overall appearance of a vehicle than the set of wheels.

So we're gonna use this opportunity to upgrade from the crusty aluminum hoops and the worn out cupped out tires that are pretty much shot and mild up, mostly due to a horrible wheel alignment in favor of these black powder coated Mickey Thompson wheels wrapped in Baha A TZ rubber. Now the Baha A TZ is give you the option of a raised white letter which looks good, but

the black walls look a lot better with these black wheels.

Now, the wheels and tires we're replacing are 3312 fifties on an 11 inch rim and we're replacing them with 3311 fifties or the equivalent thereof on a nine inch wheel, a little bit taller profile and a little bit narrower tread pattern. That's ok because the narrower tread is gonna give us less road noise. So we're just gonna make it a little nicer on a long haul.

Now, when switching wheel sizes like we are, keep in mind that if you're going to a different size lug nut to change the lug wrench, you've got underneath the back seat in the truck.

If you ever get a flat, you might be using your thumb to get home instead of changing the tire.

And after the initial round of tightening the lug

that down with a torch stick, we follow that up with a little bit more accurate torque wrench.

Now, I know we're going to be covering up the selectable hub on this front axle, but we rarely use four wheel drive on this truck anyway,

so we'll just remember to keep the Allen key in with our new size lug wrench just in case.

Well, there you go, a trip to the alignment shop and these tires ought to outlast that worn out 100 and 40,000 mile drive train. But then you know what?

It's just one more project

time for a power stroke.

Now, if you're looking for an alternative to a

billet steel flywheel for your 46, like the one we're building, Hayes has got an option for you.

This flywheel is constructed of 7075 T six forged billet aluminum and features a metal replaceable friction surface for a long life.

It's also precision balanced and sf I certified.

Now, Hayes gives you the option of both the six bolt and the eight bolt crankshaft mounting flash for your Cobra engine and at a 13 pound advantage over its billet steel counterpart, this Hayes flywheel may just give you the performance advantage you're looking for.

Now, Mr Gasket is known for their cool accessories, but one of the neatest things that we found in their catalogs are their anchor track systems.

Now, the tracks and backing strips are powder coated aluminum and the kit comes with stainless steel hardware and the anchors themselves are anodized

and feature a quick release tab for when they're not in use.

Now, Mr Gasket's anchor tracks can be used on just about any vehicle. But if you do use them on a pick up, well, the tracks themselves will, they all but disappear in between the ribs of the bed floor and it doesn't interfere with your load carrying capabilities with 1000 pound payload. It's not just a cool looking accessory. It's practical too.

Hey, thanks for watching. If you got any questions over stuff you've seen on the show, check us out on the web at Power Block tv.com. See you next time.

Show Full Transcript

and we're doing a side by side comparison of our frame stiffening. Finally, it's all the speed parts we need for our illuminator engine. It's all today here on trucks.

Hey guys, welcome to trucks.

Well, today we're back on Project Rolling Thunder, our V8 powered Mazda B 2500 compact truck

when we first started looking for a vehicle to start this project. We were actually looking for a Ford Ranger, but we got a screaming deal on this Mazda 2500 and essentially it is a Ranger. The cab is the same, the doors are the same. Almost every major component in this vehicle is a Ford Ranger. Heck, it even says made by Ford on the door tag,

but we're kind of getting used to the subtle differences that make it a Maza,

but we're still gonna change it.

Well, why would we change it from the Mazda truck? That it is kind of cool looking into a ranger. Well,

check this out,

this rendering was inspired by an actual vehicle that Ford's SVT team put together using an 01 Ford Ranger and a Ford Lightning drive train. Now, this truck looks downright mean and with the power that we've got sitting in the corner waiting to go with it, it's going to back it up too.

Now, one thing we're definitely not gonna change

because it's the same as the Ford Ranger.

This is lightweight aluminum hood. Now, the rest of the swap is pretty straightforward

and since these fenders have a few dings dents and pop knots. Well, it would take a little bit of labor to get them ready for paint anyway. So a sheet metal swap makes even more sense. Now, this would be a great project for you guys to do at home

if you've got a Mazda and you want to turn it into the more popular into some better looking Ford Ranger. Now, we could always do a salvage yard swap. There's plenty of Ford Rangers in the junk yards, but we may end up in the same position as with our Mazda fenders and a little bit of body work to do. So, we went online to L MC trucks website, went through their catalogs picked out some parts and here's what we got.

We started out with brand new sheet metal Ford Ranger fenders and

the one thing that's distinctly Mazda is the header panel and grill. So we got a Ford Ranger header panel that would support everything else.

Now, check these out, there's lots of headlight options in their catalogs. These resemble our rendering almost to A T and will give us nice bright refraction and they're kind of cool looking.

They've got several options with the grill. You can have a painted grill or a chrome grill. Again, the painted grill resembles our rendering. So we're gonna roll with that. Although chrome is an option for you guys. Now, the balance panel has optional fog light ducts. What we're gonna do is utilize those as brake cooling ducts since this is gonna be a road racer. So the rest of it just part swapping.

So it doesn't take much to tear down the nose of one of these trucks. Just a few simple tools will get the job done. But keep this in mind this truck's old enough so that some of the plastic parts and fasteners. Well, they can get a little brittle. So take care, taking it apart.

Trust me, get a hardware box. We'll thank you later.

Now,

all the parts and pieces while they're very lightweight and it might seem like these trucks aren't made of much, but just because the sheet metals, light doesn't mean the underlying structure is not,

it's made to absorb impact on a collision and it's quite strong.

There's some obvious differences between a replacement fender and the original fender. The biggest one that you see is the fact that the E coat or the electro deposition primer is black instead of the grayish green color and your eyes are drawn right to the sticker. This just signifies that this fender or this panel has been certified by the Department of Transportation being a safe replacement. Now, this greenish gray E coat is what the factory put on. So, if this is still the color underneath your trucks, skin, well, chances are it hadn't been crashed out. Here's what we're doing. Now, we're gonna transfer this clip and there's an easy way to release these J clips. Just grab a hold of the spring steel tab,

lift it straight up,

that allows you to replace it and it still stays in place. It won't drop off on the floor and it's still movable so you can adjust this panel.

Now, you can clearly see the difference between the Mazda fender and the Ford Ranger fender at least when it comes to styling, but the mounting locations are exactly the same on both pieces.

We had no trouble at all lining up the panel gaps and the stampings were precise

and you want to make sure that there's no interference between the door and the new fender.

This fender passed that test pretty good too.

Looks good, width wise for

the most part looks pretty good.

Now, making sure your fenders are properly aligned is the foundation for the rest of the truck fitting. Well,

if the fenders don't fit, none of this other stuff is going to line up and you're going to be chasing problems around in a circle. So fit your panels from the back to the front. You should be in good shape.

Now, some of the parts come with hardware and clips, some of it you got to repurpose from the old parts that you've taken off.

We reuse the mounting hardware for the headlights and marker lights from the old ones

such as these spring steel headlight mountain clips. They go in from the back side and hold the headlights in, but they can be accessed from the top.

Sometimes it takes some specialty tools. So thanks Metco

all.

Now we're using brand new retainers to hold the grill in from the top. But we transferred the spring steel clips for the bottom from the other header and grill

ranger.

Now with the Mazda front bumper strip down, guess what? It perfectly matches the profile of the Ford Ranger grill and that's just proof that there's some cross breeding going on and this truly was a ranger to start with. Now, the lower balance here, like we said, we want to utilize these fog light ports as some kind of break cooling duct. Now, it doesn't bulk right up. We're gonna have to do some work to it to get it to work. But we wanted to build a chin spoiler or a splitter anyway. So we've got fabrication work ahead of us no matter what we do.

Now, for the minimal time and money investment we've got in this thing. We've turned our plain Jane Mazda B 2500 into a late model Ford Ranger

and a modified one at that

up next, we'll show you just how much difference frame reinforcing can make and later everything you need to make it easy. 600 horsepower. Stay tuned.

Hey, guys, welcome back to the shop.

Well, now that we've got 95% of the boxing done to the frame rails of our ranger. Well, we wanted to take a few minutes and show you what adding about 10 pounds worth of eight inch plate steel can do to the overall stiffness of the chassis because if you remember last time

this frame was way too flexible for the use, we have intended for this truck

with a good 2, 2.5 inches of flex on the frame before any of the other frame points lifted off the jack stand.

And now we've got that number down to about 38 of an inch.

That's before we add in the roll cage.

And it's without the rear bumper and spare tire carrier holding the rear frame rails together.

And with the stiff chassis not doing much flexing or twisting, our coil springs on the suspension will be able to do their job much more effectively.

It's quite the drastic comparison when you stack them up side by side.

Now, we've also done some modifications to the front section of the frame. We've lopped off the factory rack and pinion mount as well as got rid of the coil spring pocket and shock mount along with the upper and lower control arm mounts.

Then we just welded in some eight inch plate along the side and t the holes at the top and the bottom of the frame.

And that'll give us some good flat real estate to work off of when we're building our custom front suspension.

Speaking of which, if you're doing a project like this at home, make sure it's planned out and it's gonna work correctly. The last thing you wanna do is just wing, it could end up in the ditch. Now, if you're gonna do this, try to avoid the trial and error method, not only waste time, it waste materials. So for a better alternative check this out,

this is suspension, analyzing software that we got from performance trends.

These guys have software applications for circle track racing, engine building drag racing and a whole bunch of others. Now, what you have to do is measure out your frame plot where you think your suspension pick up point need to be, enter the information into the software. It makes some calculations and gives you something like this.

Now, this may look intimidating but just some of these values are inputs. The computer software actually does a lot of the work and calculations for you providing a lot of the outputs.

Once you have all your information entered the software, it will provide you with a great visual. It will allow you to see a front view

side view

as well as a top view. You can even go in and animate and simulate different suspension dynamics such as dive, steer and roll. And that'll let you see what kind of changes you get in the toe in camber and castor and roll center height

and doing it. This way, you can make sure your suspension is working like you want it to and all dialed in. And that's before you even cut out the first bracket or lay down the first weld. Definitely a time saver.

Now, we're not done with the suspension software yet. We still got to figure out steering rack placement and a couple of other small things. Now, what we've done here is assemble our front suspension. We've got upper and lower control arms, our ball joint adapters and we went ahead and attached them to the spindle.

Then we just welded this jig to our sacrificial hub at a height that mimics the center of the front wheel. And by placing the jig parallel to the front axle, center line, setting the frame at ride height and picking out our front axle width. We can cut in here and determine if we're gonna have any interference issues with the front control, our mounts.

Now, by doing this and using the suspension, analyzing software, we can make sure this is done right the first time and any fine tuning that needs to take place can be done utilizing our adjustable suspension.

Now, I guess we just need to make it happen, but that's another day.

Hey guys, welcome back to trucks. Well, with the solid plan on our suspension well underway, we wanted to talk to you a little bit about the engine swap that we're doing. Now. There's no doubt that there's great aftermarket support for these 4.6 modular engines in particular from Ford racing with our four valve illuminator engine here.

But you gotta keep this in mind. These manufacturers are doing these projects and these products as upgrades and they're assuming that you either have a core or a complete donor and that you're gonna upgrade using their parts and that they may not have every single thing that you need to do to swap in their catalog.

Now, this upper Iler Pulley Bridge and this ac delete pulley, well, they are from Ford Racing. I suggest that you go to Ford Racing's website, search their catalog, see what they do have. But there's two things that we know they don't.

Now, you might just be surprised as to how many of these parts are still available at your Ford parts counter, the engines are new enough and popular enough to where they may have replacement parts in stock or they can find them through their distributors.

The issue is that sometimes over the parts counter, the dealership can get a little bit spendy. So you can do what we did surf a bunch of Ford performance specific forms like stag

net like SV T performance and modular fords and find the guy just like we did that swapping from his root style super charger to a turbo system and he's got all his swap parts available like the charge coolant,

the lower intake

coolant manifold,

the IC coolant pump, which is, by the way, the same for the lightning. So you can find one on a lightning form as well. All the duct work and coolant routing including the lower cage pulley.

My point is this, you're gonna have to do some digging and hunting around and swap meeting to find all of this stuff. But hey, that's kind of fun anyways and what you do have all of the pieces that are gonna make up your terminator and all the accessories. Then the after market kicks in, you can turn to Wicca.

Now

you can pick up a stock eaten super charger for a terminator all day long, fairly reasonable. That's because most of the serious cobra guys are upgrading to this bad boy. Now, this is the whipple 2.3 which incidentally is available from the Ford racing catalog.

They give you a choice of an upper pulley and for a throttle body, we decided to go with this acu

single blade throttle body which gives you 70% more airflow, almost 1700 CFM of airflow

Now, this setup is capable of nearly 20 pounds of boost. So to keep up with those extra atmospheres, you got to give it enough fuel. We're using four precision works beautiful billet, fuel rails, their fuel pressure regulator and their fuel pump hat that we showed you earlier.

Now, since we're beefing everything else up, we certainly didn't want to compromise on the transmission. Now, we wanted a 6 ft but a stock T 56 well, it's rated at 450 ft pounds of torque. This magnum T 56 rated at 700 ft pounds of torque. Now, there's typical trem

options like the choice between a mechanical and electric speedometer. C

but the coolest thing are the multiple shift locations. You can have one on the transmission body and this reversible on the transmission

tail shaft housing, giving you three different shift locations and lots of different options. Now, the magnum T 56 is essentially an after market version of the Tr 6060 which is the same transmission found in Shelby GT 500 Mustangs, Super sport Camaros, Cadillac CTSVS RT eight Challengers and Z six and Z 71 Corvettes. So if it's tough enough for those high performance platforms, it's gonna do just fine in our little ranger.

You're watching trucks for a DVD copy of this episode, just go to power block tv.com and order your copy for just 595 plus shipping and handling, start your own trucks collection delivered right to your door from the power block.

Hey guys, welcome back to the shop

now, for those of you that have been watching the show for a while. Well, you know, we use this 2000 F 250 for just about everything and it's been that way for about a decade and 140,000 miles and ever since day one, well, it's been wearing the same set of wheels. They're starting to show their age. Now, there's no other single add on that can change the overall appearance of a vehicle than the set of wheels.

So we're gonna use this opportunity to upgrade from the crusty aluminum hoops and the worn out cupped out tires that are pretty much shot and mild up, mostly due to a horrible wheel alignment in favor of these black powder coated Mickey Thompson wheels wrapped in Baha A TZ rubber. Now the Baha A TZ is give you the option of a raised white letter which looks good, but

the black walls look a lot better with these black wheels.

Now, the wheels and tires we're replacing are 3312 fifties on an 11 inch rim and we're replacing them with 3311 fifties or the equivalent thereof on a nine inch wheel, a little bit taller profile and a little bit narrower tread pattern. That's ok because the narrower tread is gonna give us less road noise. So we're just gonna make it a little nicer on a long haul.

Now, when switching wheel sizes like we are, keep in mind that if you're going to a different size lug nut to change the lug wrench, you've got underneath the back seat in the truck.

If you ever get a flat, you might be using your thumb to get home instead of changing the tire.

And after the initial round of tightening the lug

that down with a torch stick, we follow that up with a little bit more accurate torque wrench.

Now, I know we're going to be covering up the selectable hub on this front axle, but we rarely use four wheel drive on this truck anyway,

so we'll just remember to keep the Allen key in with our new size lug wrench just in case.

Well, there you go, a trip to the alignment shop and these tires ought to outlast that worn out 100 and 40,000 mile drive train. But then you know what?

It's just one more project

time for a power stroke.

Now, if you're looking for an alternative to a

billet steel flywheel for your 46, like the one we're building, Hayes has got an option for you.

This flywheel is constructed of 7075 T six forged billet aluminum and features a metal replaceable friction surface for a long life.

It's also precision balanced and sf I certified.

Now, Hayes gives you the option of both the six bolt and the eight bolt crankshaft mounting flash for your Cobra engine and at a 13 pound advantage over its billet steel counterpart, this Hayes flywheel may just give you the performance advantage you're looking for.

Now, Mr Gasket is known for their cool accessories, but one of the neatest things that we found in their catalogs are their anchor track systems.

Now, the tracks and backing strips are powder coated aluminum and the kit comes with stainless steel hardware and the anchors themselves are anodized

and feature a quick release tab for when they're not in use.

Now, Mr Gasket's anchor tracks can be used on just about any vehicle. But if you do use them on a pick up, well, the tracks themselves will, they all but disappear in between the ribs of the bed floor and it doesn't interfere with your load carrying capabilities with 1000 pound payload. It's not just a cool looking accessory. It's practical too.

Hey, thanks for watching. If you got any questions over stuff you've seen on the show, check us out on the web at Power Block tv.com. See you next time.