More '01 Mazda B2500/Ford Ranger "Rolling Thunder" Episodes

More Rolling Thunder Episodes

Trucks! Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

American Powertrain Systems

Hydraulic Throwout Bearing Assembly

Factory Five Racing,Inc.

Tubular Front Lower Control Arms

Fore Precision Works, LLC

Dual GSS Fuel Pump and Pickup Assembly

Kimberly-Clark Professional

Blue Nitrile Gloves

Kimberly-Clark Professional

Disposable Microfiber Cloth

Kimberly-Clark Professional

Kimtech PREP Surface Preparation Wipers

Kimberly-Clark Professional

Kimtech PREP Tack Cloths

Matco Tools

Flywheel Turner Tool

Torchmate CNC Cutting Systems

CNC Cutting System

Whitby Motorcars Inc.

Ball Joint Adapters

Episode Transcript

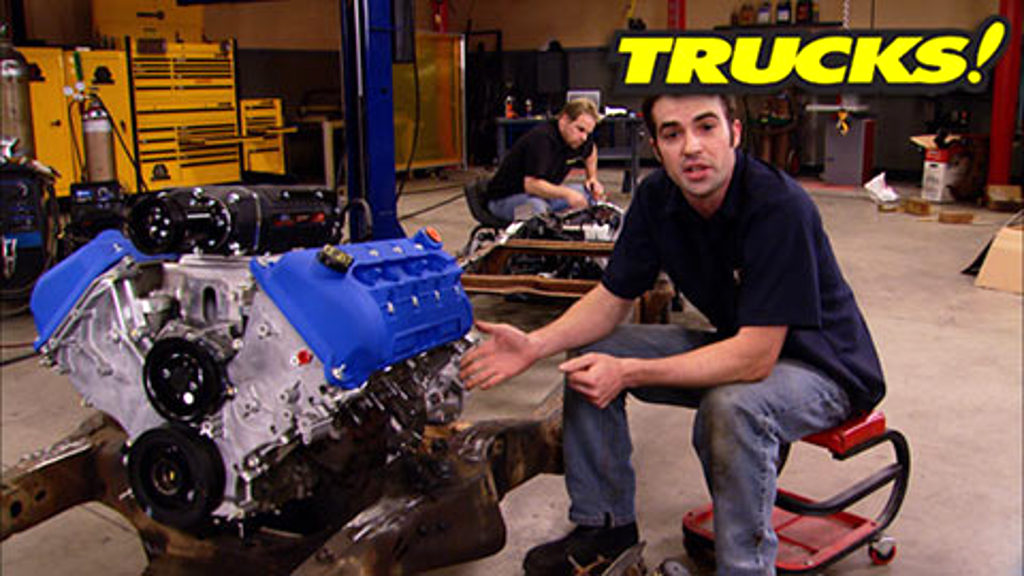

Today, we're installing our supercharged cobra illuminator engine

and six speed transmission and rolling thunder and we're box in the frame while adding speed holes. Then we'll come up with a plan for adding the front suspension in the fuel tank. It's all today here on trucks.

Hey guys, welcome to trucks. Well, today we're gonna be assembling the drive train of project rolling thunder and hopefully for the last time

and that means installing our new fly wheel and clutch, setting up our hydraulic throw out bearing and hanging the 6 ft off the back of our blown 46. Here by the end of the day, we're going to drop the whole thing down in between the frame rails.

And hopefully by the time Ryan has got the engine and transmission assembly ready to drop down in between these frame rails. He got these boxing plates at least ready to tack in. Although right here where our IRS is mounted in, it's going to be pretty stiff, but the rest of it like we showed you before very flexy.

Although Ford did a nice job of boxing up until here, there's this vast expanse in the middle that we've got to do something about.

Now, these Simpson speed holes aren't just for appearance. Check this out.

This is substantial.

That's a lot of weight that we're dropping and not sacrificing any rigidity. Plus, it allows us access in between the rails to run fuel lines, electrical harnesses, things like that.

And

it's gonna look pretty darn cool doing it.

Now, for our application, we knew we were going to need a better than stock replacement clutch. So we went to summit racing and picked up some parts from center force. Now, the disk itself is a dual friction unit with a segmented carbon composite lining that will keep heat down while increasing torque capacity.

And the pressure plate features aircraft grade billet, aluminum and a heat treated and replaceable friction surface. It also features their patented ball bearing activated diaphragm and standard descent force centrifugal weight system that'll increase clamping load as RPM increases while still maintaining reasonable pedal pressure.

Now, the aluminum fly wheel we picked up is from center force as well. It's got a mechanically retained starter ring and just like the pressure plate, it's SF I certified and has the heat treated and replaceable friction surface.

Now, these parts are designed for specific road racing applications along with drag racing and while they do cost a little bit more, well, they definitely have benefits. The engine's gonna rev faster, it's easier to match revs while shifting and the engines just gonna plain all accelerate faster due to the lower inertia. Now, we also picked up a billet steel fly wheel for comparisons sake, because we wanted to show you the weight difference check this out.

Now, the steel fly wheel weighs in at nearly 30 pounds. Looks like 28 to be exact.

While the aluminum version looks like

it's less than 13 pounds.

Now to engage and disengage our new clutch. We picked up a hydraulic throw out bearing from American power train.

It features a threaded and adjustable sleeve with O rings that seal to the transmission input shaft along with an additional spacer. So you can get this to work with a variety of transmission and clutch setups. Now, it's also got two braided stainless lines, one with a bleeder on it and the other that we're going to try to adapt to our factory Mazda clutch master cylinder. But before we install it, we got some measurements to take.

The first thing we're doing is installing the bearing assembly and making sure it's sitting flush.

Then we can take our first measurement from the bell housing mating surface to the front of the throw out bearing.

But before we can get our second measurement, there's some installation work we've got to do like getting this pilot bearing installed in the back of the crank shaft.

We're using an impact socket and a mallet.

Next was a bell housing separator plate.

We followed that with the aluminum fly wheel. And since this thing's going on for good. We use some red lock tight on the bolts to make sure it stays put.

And after starting the bolts by hand, we're just snugging them down using the impact wrench, we follow that with an accurate torque

and by using an alignment tool, we can finish up the job getting the clutch disk and the new pressure plate installed.

Now, the first step in tightening down our pressure plate bolts was to torque them to 33 ft pounds. But these are torque to yield factory bolts. So we need to go an additional 60 degrees. But what if you don't have a torque angle gauge? Well, you can do like we're gonna do and just use a template.

You can use a piece of cardboard or whatever you got laying around. But we had this old steering wheel kicking around and we're gonna use it.

Basically, we just marked off 60 degrees on the outside edge of the wheel. We'll line our ratchet handle up with the first hash mark and tighten until we hit the second mark. That way we know we've gone 60 degrees and it's done right

now. Once you get started in this process, you need to make sure that the crank shaft and the fly wheel don't move. If it moves on you while you're turning the ratchet, you'll lose track of where you are and have to start all over again.

Now, to make sure it stays put. Kevin's using a flywheel holding tool we picked up from mad

and with the bell housing installed, we can get that second measurement we needed

and it goes from the bell housing to transmission mating surface to the very top point of the clutch fingers.

And using these measurements and doing a little bit of math, we were able to properly set the height of the adjusting sleeve on the throw out bearing.

It needs to have an eight inch clearance in between the face of the throw out bearing and the clutch fingers to operate properly.

Now, for our application, we ended up using the provided spacer sleeve.

Now, the 20 rings on the throw out bearing are a snug fit. So if you need to lubricate them with brake fluid, only

one final measurement will verify we're still right on the money.

That's it.

Go

and last but not least we can install the bell housing

hopefully for the last time

up next, the magic of speed holes and why they work and later making mods to make it all fit. Stay tuned.

Hey, welcome back to trucks. Well, Project Rolling Thunder is going to be one seriously fast little street truck with a rock solid foundation that handles like a slot car. Part of creating that foundation involves boxing the frame all the way back now, boxing a chassis in is nothing new. There's really nothing new under the sun. This has been done. For years. And it's quite a simple process. It involves using cardboard for templating Tracy out your design, transferring it to metal and then trimming it out and welding it in place. It's pretty simple and can be done with basic tools. So this is a project you guys can do at home. Now, we're gonna box all the way back, leave a little bit of room for suspension travel and go all the way out the back. And since our new fuel cell is gonna sit right here where the spare tire carrier now sits, obviously, this boat anchors gotta go away before we can box these rails in.

Now, weight transfer rearward is one of our main overall goals for this project. So we're going to have to buy back some of the weight that we're losing by removing this spare tire. Well,

but the stainless steel fuel cell that we're installing in its place will more than compensate, especially when it's full. Now, cutting off the factory ribbons is kind of fun and it satisfies some weird primal urge. It's kind of like therapy

now with a big chunk out of the way we could start making our template. That doesn't really matter what you use as long as you can manipulate it and trim it and transfer it on to metal. I'm using some cardboard, but a lot of people use a lighter gauge. I just like this because I can move it around and it's a little more substantial. So basically what you wanna do,

put it up against your work piece and trace around it. And the good thing about a frame is that the rails are usually symmetrical, so you can make one template and just use it for both sides.

Now, templating is a simple process of tracing and trimming

and you want to start off cutting a little bit more than the outside edges of your project and then dialing it back in which is much easier to do on cardboard than it is steel. A little more forgiving too if you make a mistake.

Now, the second most used tool in the whole shop is a black marker and it's used to trace the pattern onto the eight inch plate steel.

We're using our torch MC NC plasma table to cut the speed holes. We just found something round in the right size laying around in the shop to use as a template.

So all of our boxing plates are cut out and trimmed and the speed holes are cut out and we're ready to tack these things in place. I wanted to show you something first.

This is not just for aesthetics, although they do look cool, check this out.

These are the cut outs for about half of the boxing plates for one frame rail

and it's weighing in at eight pounds. So you got 16 pounds worth of weight just from cutting the speed holes without sacrificing strength if that doesn't sound like much think about this. But the rear bumper, the spare tire, well, all the different brackets that we're playing off the point is all of this matters. We get the strength that we want and we get the weight reduction that we want because every little bit helps.

Well, the frame's a little rusty but nothing, a couple passes with the grinding wheel won't fix. Then we're ready to tack our plates in.

Now we're tacking all the plates in individually just in case we have some fine tuning or trimming to do a tacks. A heck of a lot easier to cut out than a fully burned in weld.

Now, the factory formed rails are not square or symmetrical. So you may have to do some forming

with everything looking good.

You can make some fire.

Hey, guys, welcome back to the shop. Well, we've got most of our boxing plates welded in place and we're grinding down those welds for a little bit more finished look. Now we've got some more plates to make and some more welding to do on both the cross members and the bottom side of the frame rails. But we're gonna take a break from this for a second because we wanna drop our new engine and transmission down in between the frame rail

and see where our transmission mount lines up.

Now, the good news is we know the engine is gonna fit because essentially it's exactly the same engine block and we're using the same isolators or engine mounts that we use on stage one with the Mercury Marauder engine.

The problem here is that these are factory and they're rubber and the aftermarket doesn't really support a Mercury Marauder mount. They have cobra mounts. So we're going to have to switch to a cobra mount la

on, we'll cross that bridge when we come to it.

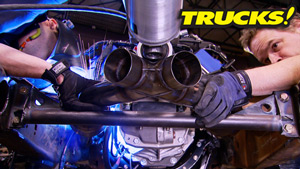

The important thing is knowing where this transmission mount is gonna go and what we're gonna have to fabricate to make this work. The other variable are these long tube headers, Mike and Joe over at horsepower had these flow tag long tubes kicking around. So we just thought we'd throw them on, see if they fit down between the rails or if we're gonna be locked into the factory cobra cast iron manifolds that we know work

and to make sure the transmission ends up in the right spot. We're installing our original Marauder engine mount.

Oh, yeah, that's figures.

Well, just like we suspected these flow tech long tubes are not gonna work unless we do major surgery to the headers themselves or to the frame rails. So we'll probably end up going back with the manifolds we were running, which may not be that big of a deal. The Cobra manifolds are known to support major horsepower numbers. So I think we'll be ok

good on my side.

You in.

Yep.

All right. From the camera point of view. It may look like the mount's gonna line up with the cross member.

But from where I'm sitting, we're a good 2 to 3 inches from having the hall line up, which is no big deal. We wanted to ditch this factory stamped cross member and replace it with a tubular one.

In that way, we can keep it tucked up in between the frame rails and keep it from hanging down too low because ground clearance is gonna be pretty important with our new and much lower ride height. And we've discovered one more thing as well.

There's a difference between the Marauder oil pan and the Ford Racing illuminator pan giving us a few more inches of clearance allowing us to drop the engine down, lowering the all important center of gravity.

But there are plenty of other things to consider before we start making modifications to get that done.

We've got to think about steering rack placement, exhaust clearance and firewall and hood clearance for a now blower equipped V8 engine. So we've got to drop the body back down before we get into all of that. But one thing we do know for sure these factory suspension mounts or pickup points and they're going away.

Now, the upper control arm mounts came off pretty easily, but the lowers were a bear.

They're about a quarter inch thick and they're double layered

and it gives you an indication of how much more stress the lower arms are under in comparison to the upper arm

or didn't want these things going anywhere.

You're watching trucks for a DVD copy of this episode, just go to Power Block tv.com and order your copy for just 595 plus shipping and handling. Start your own trucks, collection delivered right to your door from the power block.

Hey, guys, welcome back to the shop. Well, we've got all the control arm mounts cut off and the top of the frame rails ground clean. Now you might be asking yourself why we didn't utilize the existing pickup points and it's for a couple of reasons. First off, the suspension kits available for late model rangers focus more on aesthetics and just getting the truck to sit lower

and we're after precise handling plus doing it this way, we can relocate the pickup points and move the front axle center line forward about an inch or an inch and a half like we talked about before.

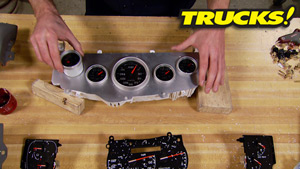

Now doing it this way is gonna take a little bit more research design and engineering, but the time investment is gonna pay off when this thing hits the track as far as components, we check these out.

Now, the upper control arms are rod end equipped and adjustable so we can dial the suspension in

the utilized screw in Chrysler ball joints.

We attach them to these ball joint adapters we picked up from

be motor cars and they allow us to bolt the upper arms to the S N95 mustang spindle, the tubular lower arms, but from factory five racing and feature greasing polyurethane bushings and a built in coil over mount

now by using the mustang spindle. Well, it gives us access to commonly available and reasonably affordable big brake kits

as far as this nasty hub goes. Well, we're gonna get a new one on there. This is just for mock up

and with our frame all boxed in, it really moves this project forward and allows us to do things like mount our custom fuel tank. This tank came from Rick's Hot Rod shops, the Rick's Tank division and it's a custom made stainless steel fuel cell that was made based on the measurements that we emailed to those guys. They also sent us some 90 degree. And so that way we can mount this thing

at

the location and height that we choose.

Now, one of the best features of this fuel cell is the fact that it's internally baffled. And since we're gonna beat on this thing on several road courses, this is gonna take care of any fuel slush issues that we may have and keep us from starving the fuel system.

Now, speaking of fuel delivery, take a look at this. This is our new dual fuel pump set up that's made by four precision works. Now, this is a great upgrade for the 03 and 04 supercharged

Cobras which makes it, the perfect pump system for the arrangement that we've got here. It features 2255 LP H pumps and is fully builded aluminum. And since for precision gives us the option, we opted for a return style system with a dash shade fuel delivery and a dash six return line.

And this ought to make sure

we're gonna feed that hungry monster.

Now, you've heard me say this 1000 times, but one of the biggest secrets to a successful paint job is preparation and that not only includes the materials that you're prepping with but also safety equipment to handle the chemicals.

Well, Kimberly Clark has got you covered with items like these nitro gloves, they're solvent resistant and will keep your skin from absorbing hazardous chemicals.

These surface prep wipes are almost 100% lint free and are a great first step to wiping your surface down.

Now, the last step before actually applying paint is to wipe down with the tag rag.

Well, Kim Tech has a medium low and a no tch tch rack.

So you're good to go no matter what type of paint that you're prepping.

And finally, when the paint's dry, Kim Tech has a disposable micro fiber that makes a great polishing cloth.

Now, if you got any questions over anything we've talked about, give us a shout. Thanks for watching trucks. See you next time.

Show Full Transcript

and six speed transmission and rolling thunder and we're box in the frame while adding speed holes. Then we'll come up with a plan for adding the front suspension in the fuel tank. It's all today here on trucks.

Hey guys, welcome to trucks. Well, today we're gonna be assembling the drive train of project rolling thunder and hopefully for the last time

and that means installing our new fly wheel and clutch, setting up our hydraulic throw out bearing and hanging the 6 ft off the back of our blown 46. Here by the end of the day, we're going to drop the whole thing down in between the frame rails.

And hopefully by the time Ryan has got the engine and transmission assembly ready to drop down in between these frame rails. He got these boxing plates at least ready to tack in. Although right here where our IRS is mounted in, it's going to be pretty stiff, but the rest of it like we showed you before very flexy.

Although Ford did a nice job of boxing up until here, there's this vast expanse in the middle that we've got to do something about.

Now, these Simpson speed holes aren't just for appearance. Check this out.

This is substantial.

That's a lot of weight that we're dropping and not sacrificing any rigidity. Plus, it allows us access in between the rails to run fuel lines, electrical harnesses, things like that.

And

it's gonna look pretty darn cool doing it.

Now, for our application, we knew we were going to need a better than stock replacement clutch. So we went to summit racing and picked up some parts from center force. Now, the disk itself is a dual friction unit with a segmented carbon composite lining that will keep heat down while increasing torque capacity.

And the pressure plate features aircraft grade billet, aluminum and a heat treated and replaceable friction surface. It also features their patented ball bearing activated diaphragm and standard descent force centrifugal weight system that'll increase clamping load as RPM increases while still maintaining reasonable pedal pressure.

Now, the aluminum fly wheel we picked up is from center force as well. It's got a mechanically retained starter ring and just like the pressure plate, it's SF I certified and has the heat treated and replaceable friction surface.

Now, these parts are designed for specific road racing applications along with drag racing and while they do cost a little bit more, well, they definitely have benefits. The engine's gonna rev faster, it's easier to match revs while shifting and the engines just gonna plain all accelerate faster due to the lower inertia. Now, we also picked up a billet steel fly wheel for comparisons sake, because we wanted to show you the weight difference check this out.

Now, the steel fly wheel weighs in at nearly 30 pounds. Looks like 28 to be exact.

While the aluminum version looks like

it's less than 13 pounds.

Now to engage and disengage our new clutch. We picked up a hydraulic throw out bearing from American power train.

It features a threaded and adjustable sleeve with O rings that seal to the transmission input shaft along with an additional spacer. So you can get this to work with a variety of transmission and clutch setups. Now, it's also got two braided stainless lines, one with a bleeder on it and the other that we're going to try to adapt to our factory Mazda clutch master cylinder. But before we install it, we got some measurements to take.

The first thing we're doing is installing the bearing assembly and making sure it's sitting flush.

Then we can take our first measurement from the bell housing mating surface to the front of the throw out bearing.

But before we can get our second measurement, there's some installation work we've got to do like getting this pilot bearing installed in the back of the crank shaft.

We're using an impact socket and a mallet.

Next was a bell housing separator plate.

We followed that with the aluminum fly wheel. And since this thing's going on for good. We use some red lock tight on the bolts to make sure it stays put.

And after starting the bolts by hand, we're just snugging them down using the impact wrench, we follow that with an accurate torque

and by using an alignment tool, we can finish up the job getting the clutch disk and the new pressure plate installed.

Now, the first step in tightening down our pressure plate bolts was to torque them to 33 ft pounds. But these are torque to yield factory bolts. So we need to go an additional 60 degrees. But what if you don't have a torque angle gauge? Well, you can do like we're gonna do and just use a template.

You can use a piece of cardboard or whatever you got laying around. But we had this old steering wheel kicking around and we're gonna use it.

Basically, we just marked off 60 degrees on the outside edge of the wheel. We'll line our ratchet handle up with the first hash mark and tighten until we hit the second mark. That way we know we've gone 60 degrees and it's done right

now. Once you get started in this process, you need to make sure that the crank shaft and the fly wheel don't move. If it moves on you while you're turning the ratchet, you'll lose track of where you are and have to start all over again.

Now, to make sure it stays put. Kevin's using a flywheel holding tool we picked up from mad

and with the bell housing installed, we can get that second measurement we needed

and it goes from the bell housing to transmission mating surface to the very top point of the clutch fingers.

And using these measurements and doing a little bit of math, we were able to properly set the height of the adjusting sleeve on the throw out bearing.

It needs to have an eight inch clearance in between the face of the throw out bearing and the clutch fingers to operate properly.

Now, for our application, we ended up using the provided spacer sleeve.

Now, the 20 rings on the throw out bearing are a snug fit. So if you need to lubricate them with brake fluid, only

one final measurement will verify we're still right on the money.

That's it.

Go

and last but not least we can install the bell housing

hopefully for the last time

up next, the magic of speed holes and why they work and later making mods to make it all fit. Stay tuned.

Hey, welcome back to trucks. Well, Project Rolling Thunder is going to be one seriously fast little street truck with a rock solid foundation that handles like a slot car. Part of creating that foundation involves boxing the frame all the way back now, boxing a chassis in is nothing new. There's really nothing new under the sun. This has been done. For years. And it's quite a simple process. It involves using cardboard for templating Tracy out your design, transferring it to metal and then trimming it out and welding it in place. It's pretty simple and can be done with basic tools. So this is a project you guys can do at home. Now, we're gonna box all the way back, leave a little bit of room for suspension travel and go all the way out the back. And since our new fuel cell is gonna sit right here where the spare tire carrier now sits, obviously, this boat anchors gotta go away before we can box these rails in.

Now, weight transfer rearward is one of our main overall goals for this project. So we're going to have to buy back some of the weight that we're losing by removing this spare tire. Well,

but the stainless steel fuel cell that we're installing in its place will more than compensate, especially when it's full. Now, cutting off the factory ribbons is kind of fun and it satisfies some weird primal urge. It's kind of like therapy

now with a big chunk out of the way we could start making our template. That doesn't really matter what you use as long as you can manipulate it and trim it and transfer it on to metal. I'm using some cardboard, but a lot of people use a lighter gauge. I just like this because I can move it around and it's a little more substantial. So basically what you wanna do,

put it up against your work piece and trace around it. And the good thing about a frame is that the rails are usually symmetrical, so you can make one template and just use it for both sides.

Now, templating is a simple process of tracing and trimming

and you want to start off cutting a little bit more than the outside edges of your project and then dialing it back in which is much easier to do on cardboard than it is steel. A little more forgiving too if you make a mistake.

Now, the second most used tool in the whole shop is a black marker and it's used to trace the pattern onto the eight inch plate steel.

We're using our torch MC NC plasma table to cut the speed holes. We just found something round in the right size laying around in the shop to use as a template.

So all of our boxing plates are cut out and trimmed and the speed holes are cut out and we're ready to tack these things in place. I wanted to show you something first.

This is not just for aesthetics, although they do look cool, check this out.

These are the cut outs for about half of the boxing plates for one frame rail

and it's weighing in at eight pounds. So you got 16 pounds worth of weight just from cutting the speed holes without sacrificing strength if that doesn't sound like much think about this. But the rear bumper, the spare tire, well, all the different brackets that we're playing off the point is all of this matters. We get the strength that we want and we get the weight reduction that we want because every little bit helps.

Well, the frame's a little rusty but nothing, a couple passes with the grinding wheel won't fix. Then we're ready to tack our plates in.

Now we're tacking all the plates in individually just in case we have some fine tuning or trimming to do a tacks. A heck of a lot easier to cut out than a fully burned in weld.

Now, the factory formed rails are not square or symmetrical. So you may have to do some forming

with everything looking good.

You can make some fire.

Hey, guys, welcome back to the shop. Well, we've got most of our boxing plates welded in place and we're grinding down those welds for a little bit more finished look. Now we've got some more plates to make and some more welding to do on both the cross members and the bottom side of the frame rails. But we're gonna take a break from this for a second because we wanna drop our new engine and transmission down in between the frame rail

and see where our transmission mount lines up.

Now, the good news is we know the engine is gonna fit because essentially it's exactly the same engine block and we're using the same isolators or engine mounts that we use on stage one with the Mercury Marauder engine.

The problem here is that these are factory and they're rubber and the aftermarket doesn't really support a Mercury Marauder mount. They have cobra mounts. So we're going to have to switch to a cobra mount la

on, we'll cross that bridge when we come to it.

The important thing is knowing where this transmission mount is gonna go and what we're gonna have to fabricate to make this work. The other variable are these long tube headers, Mike and Joe over at horsepower had these flow tag long tubes kicking around. So we just thought we'd throw them on, see if they fit down between the rails or if we're gonna be locked into the factory cobra cast iron manifolds that we know work

and to make sure the transmission ends up in the right spot. We're installing our original Marauder engine mount.

Oh, yeah, that's figures.

Well, just like we suspected these flow tech long tubes are not gonna work unless we do major surgery to the headers themselves or to the frame rails. So we'll probably end up going back with the manifolds we were running, which may not be that big of a deal. The Cobra manifolds are known to support major horsepower numbers. So I think we'll be ok

good on my side.

You in.

Yep.

All right. From the camera point of view. It may look like the mount's gonna line up with the cross member.

But from where I'm sitting, we're a good 2 to 3 inches from having the hall line up, which is no big deal. We wanted to ditch this factory stamped cross member and replace it with a tubular one.

In that way, we can keep it tucked up in between the frame rails and keep it from hanging down too low because ground clearance is gonna be pretty important with our new and much lower ride height. And we've discovered one more thing as well.

There's a difference between the Marauder oil pan and the Ford Racing illuminator pan giving us a few more inches of clearance allowing us to drop the engine down, lowering the all important center of gravity.

But there are plenty of other things to consider before we start making modifications to get that done.

We've got to think about steering rack placement, exhaust clearance and firewall and hood clearance for a now blower equipped V8 engine. So we've got to drop the body back down before we get into all of that. But one thing we do know for sure these factory suspension mounts or pickup points and they're going away.

Now, the upper control arm mounts came off pretty easily, but the lowers were a bear.

They're about a quarter inch thick and they're double layered

and it gives you an indication of how much more stress the lower arms are under in comparison to the upper arm

or didn't want these things going anywhere.

You're watching trucks for a DVD copy of this episode, just go to Power Block tv.com and order your copy for just 595 plus shipping and handling. Start your own trucks, collection delivered right to your door from the power block.

Hey, guys, welcome back to the shop. Well, we've got all the control arm mounts cut off and the top of the frame rails ground clean. Now you might be asking yourself why we didn't utilize the existing pickup points and it's for a couple of reasons. First off, the suspension kits available for late model rangers focus more on aesthetics and just getting the truck to sit lower

and we're after precise handling plus doing it this way, we can relocate the pickup points and move the front axle center line forward about an inch or an inch and a half like we talked about before.

Now doing it this way is gonna take a little bit more research design and engineering, but the time investment is gonna pay off when this thing hits the track as far as components, we check these out.

Now, the upper control arms are rod end equipped and adjustable so we can dial the suspension in

the utilized screw in Chrysler ball joints.

We attach them to these ball joint adapters we picked up from

be motor cars and they allow us to bolt the upper arms to the S N95 mustang spindle, the tubular lower arms, but from factory five racing and feature greasing polyurethane bushings and a built in coil over mount

now by using the mustang spindle. Well, it gives us access to commonly available and reasonably affordable big brake kits

as far as this nasty hub goes. Well, we're gonna get a new one on there. This is just for mock up

and with our frame all boxed in, it really moves this project forward and allows us to do things like mount our custom fuel tank. This tank came from Rick's Hot Rod shops, the Rick's Tank division and it's a custom made stainless steel fuel cell that was made based on the measurements that we emailed to those guys. They also sent us some 90 degree. And so that way we can mount this thing

at

the location and height that we choose.

Now, one of the best features of this fuel cell is the fact that it's internally baffled. And since we're gonna beat on this thing on several road courses, this is gonna take care of any fuel slush issues that we may have and keep us from starving the fuel system.

Now, speaking of fuel delivery, take a look at this. This is our new dual fuel pump set up that's made by four precision works. Now, this is a great upgrade for the 03 and 04 supercharged

Cobras which makes it, the perfect pump system for the arrangement that we've got here. It features 2255 LP H pumps and is fully builded aluminum. And since for precision gives us the option, we opted for a return style system with a dash shade fuel delivery and a dash six return line.

And this ought to make sure

we're gonna feed that hungry monster.

Now, you've heard me say this 1000 times, but one of the biggest secrets to a successful paint job is preparation and that not only includes the materials that you're prepping with but also safety equipment to handle the chemicals.

Well, Kimberly Clark has got you covered with items like these nitro gloves, they're solvent resistant and will keep your skin from absorbing hazardous chemicals.

These surface prep wipes are almost 100% lint free and are a great first step to wiping your surface down.

Now, the last step before actually applying paint is to wipe down with the tag rag.

Well, Kim Tech has a medium low and a no tch tch rack.

So you're good to go no matter what type of paint that you're prepping.

And finally, when the paint's dry, Kim Tech has a disposable micro fiber that makes a great polishing cloth.

Now, if you got any questions over anything we've talked about, give us a shout. Thanks for watching trucks. See you next time.