Episode Transcript

Today, we're taking off a brand new project. We're gonna wedge this dual overhead cam 4.6 L Ford into this. We want to build a smaller version of Ford's Lightning. So Project Rolling Thunder starts today here on tr

Hey guys, welcome to trucks. Well, this is the Kevin Tates grocery Getter. This is my personal truck. I drive it back and forth to work. I haul stuff with it I tow with it and it's even been to the strip a couple of times. It's a 2000 Harley Davidson F 150 but it is not stock underneath. The hood is an 02 lightning drive train with all of the go fast goodies, long tube haters and 373 rear gears. There's a custom

dyno tune on it that's pulling 400 horsepower and 500 ft pounds at the rear wheels and at 5100 and 50 pounds. I've surprised a couple of Mustang gts with this thing. Needless to say it's a fun truck to drive.

I love that truck.

Now, can you imagine a drive train like that with that kind of horsepower and torque in a smaller, more nimble truck that can weigh anywhere between 1,502,000 pounds less. You'd have a little rocket ship on your hands or at least a mini version of a Ford lightning.

And since mini lightning doesn't sound that tough, we're calling this thing project rolling thunder.

Now, we were actually looking for a single cab Ford Ranger when we found our Mazda B 2500 and they look almost identical until you get a little closer. For instance, look at the bedside, it's got this kind of a cool style line that we're actually getting used to sort of sets it apart the doors. Well, Ford Ranger, the cab Ford Ranger, the proofs in the pudding,

you check out the Vin and the sticker

is manufactured by Ford Motor Company in the USA. So for all intents and purposes, it's a ranger.

Now inside,

we got what we want with a stripped down lightweight interior, but most importantly, we got the five speed.

Now, another bonus we found with our truck is that it's wearing its original paint. And even though the paints a little bit on the rough side, it's still better than a couple of other paint jobs, hiding sins of the past. So other than some minor styling changes and Mazda badging, this thing is a

for Ranger, which is also good news because at least on the car lots that we looked at the Mazda trucks were a little bit cheaper. So our B 2500 Ranger Mazda pickup came in at just shy of 3000 bucks. Which way you look at it. It's an awesome start to a great project.

Now, underneath the hood of our well used 160,000 mile pickup is a little 2.5 L four cylinder. Now, it runs fine and I'm sure it would handle commuter duty just fine. Probably get pretty good gas mileage while doing it,

but it is definitely not a high performance power plant and certainly isn't going to cut it for what we have in mind. So there's room for improvement. Literally take a look around the engine. You can see the floor almost all the way around this thing. So we've definitely got space for a bigger engine. Now, if we need even more room, we can ditch the vacuum brake booster in favor of a later model hydro boost set up. We can remove or relocate some of these ac parts along with a couple of the fluid containers.

Now, the 5 L V8 swap, well, it's been done more than a few times. So we're going to stay away from that.

We want to go with the next generation of Ford V8 S the

alert 4.6. Now, they've been around long enough where you can pick up a used engine and transmission combo from a junk yard for a pretty fair price. Heck, you can even buy a complete Lincoln or even cop car and have almost everything you need to complete the swap. Now,

the modular V eights, well, they're smaller displacement but they rev higher and just like the lightning engine in Kevin's Harley truck. Well, they're really receptive to forced induction.

Now, for stage one of this build, the light duty 7.5 inch rear axle and the leaf springs are going to stay put just to get the truck up and running.

But for stage two, those parts are going to hit the scrap pile because that axle is not going to take any abuse from a V8. So it'll be changed out for a stronger 88 or nine inch rear axle. Now, the leaf spring setup would probably be

ok if we were just building a lowered street truck. But we want this thing to handle the twisties. So we're going to go with some sort of adjustable four length or torque arm setup of some sort, something that can plant the power and keep it there. And that'll be one of the biggest challenges we face when putting this truck together. So we're going to have big va power up front and not so much weight out back.

Now, it's pretty apparent. Our 2001 Mazda spent a little bit of time up north in the rust belt. It was up there just long enough to put a light surface rust on all the exposed metal, but not long enough to cause any serious rot issues. So we should be in good shape. Now, as far as suspension goes, we're off to a better start up

than we were out back. We've got a short and long a arm set up with tubular arms up top and stamped steel arms down below. We've also got the rack and pinion steering we wanted, it'll give us better steering field and response and also provide more room for our V8 swap. Heck, we've even got a factory power steering cooler

now, like we just told you and showed you earlier in the parking lot, blowing the tires off of a high performance pickup is relatively easy to do.

And that's because of the extreme weight buys to the front of almost every truck out there. And our little Mazda is no different, but there's good news and bad news. Our truck comes in at just under 3100 pounds. But if you take a look at the weight buys, it's 62% to the front of the truck, meaning that

38% of the weight is over the rear axle. Now, ideally, you'd like to have a 5050 weight split, front to back, side to side and corner to corner. Now, we're never going to get there since we started with a pickup truck, but we can try our hardest to get as close as possible. So we'll just have to get creative and relocate as many parts from the front of the truck to the back and put them in the bed and we'll just try to lighten up the front as much as possible and get this thing to hook up.

Now under the hood, we weren't plagued with a whole bunch of messy oil leaks. However, our high mileage drive train, well, it had a bit of road drive on it and it never hurts to clean off your project before you start.

Now, despite having every other tool known to man, the truck shop does not have a wash bait so it doesn't get any more real world than the neighborhood coin off.

Now, here's some interesting trivia. Later model rangers and F 150 already have an aluminum hood. So it gives us a weight savings head start,

get rid of all that schmutz.

Catch your wheel. Now, spin it bit, it's going on.

Hey, welcome back to trucks. Let me introduce you to our little friend.

Actually, not so little. This is a 4.6 L, dual overhead cam modular engine and four rur 70 transmission out of a wrecked 03 mercury marauder. Now we wanted to go modular for a couple of different reasons. The availability of these engines. They've been around long enough and there's lots of them available from the salvage standpoint.

Also the high performance potential of the four valve modular engines. Well, it's proven itself over and over again.

This one starts with a high flowing intake manifold and notoriously high flowing dual overhead cam heads. The same heads that come on the now legendary 2003 and 2004 supercharged Cobras, the Marauder engine has an all aluminum block with six bolton

caps as well as high flowing exhaust manifolds. Now, this package in a stock mercury Marauder in 2003 kicked out just over 300 horsepower in a completely stocked car. So you throw some aftermarket stuff at it, throw a tune on it. Well, you can start to see the potential now just in case you think we reach for this exotic engine. Well, here's a list of potential donor vehicles that can give you guys a four valve modular,

the 93 to 98 Lincoln mark eights, some Lincoln Continentals 99 to 2004 SVT Cobras

Panos Esperanto

2003 and 2004 Mustang Mach one, obviously the 03 and 04 Mercury Marauder and the 03 to 05 Lincoln Aviator just to name a few.

Now, obviously, the original engine and transmission are going away, but here's where you can take a page out of the Ford factory service manual and save yourself some time because unlike an S 10, the Ford Ranger cab aprons and radiator support, well, they're spot welded together. So just like we did when we pulled the in

out and swap the lightning engine into my Harley truck. Well, we're going to take the cab off of the chassis, there's six bolts that hold it on and some engine connections, it comes straight up, you roll the chassis out from underneath it, save yourself a lot of time. Plus it's going to give us the opportunity to give you guys a closer look at what we're doing.

Now, I know that right now there's guys talking back to their television saying you don't have to pull the cab to pull the engine and you're right, you don't have to, however, the ability to do this type of work flat footed and not laying on your back on a creeper. Well, it's definitely worth the extra effort.

And since the air conditioning on our little Mazda still worked well, that means it's full of Freon and the air conditioning compressor is going to stay with the rest of the system and go up with the body when we separate it from the chassis until we can deal with it. The correct way

we may end up reusing our radiator. So we pulled it to keep it from getting damaged.

And since our four cylinder computer won't exactly work on our new eight cylinder engine, we pulled that as well

and separating the rest of the cab from the chassis. What was simple as pulling the bulkhead connector on the floorboard of the cab

made it really easy.

And with the driver controls and harnesses separated, all that are left are six bolts holding the body to the chassis.

Now, believe it or not, the cab is actually not that heavy. So even without a lift with a few buddies, you can set the cab and nose on some jack stands. Now Ford service se will tell you that everything we've done is standard procedure except the surfing.

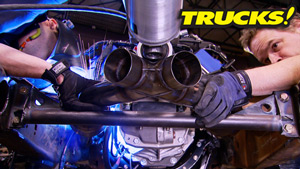

Now, pulling the exhaust system was pretty straightforward and we were able to remove most of the hardware with the help of some penetrating oil.

But separating the down pipe from the exhaust manifold

that took a little heap

with the swap like this, it's kind of uncharted. So you never really know what you're going to reuse and what you're going to throw away. So we're carefully disassembling everything rather than hacking it up and throw it in.

Now, we're not really sure what we're going to do with this four cylinder engine and five speed transmission.

I guess we could sell it as used parts or make a really, really fast go cart.

Now, obviously, weight bias is pretty important with a project like this. So we're weighing everything that we pull out of this truck as well as the new components. We're gonna put in

the stock engine and transmission coming right at

537 pounds, which is actually a little bit lighter than we thought it was gonna be.

Now with the new engine and transmission, unfortunately, we're picking up a couple 100 extra pounds, but we're also picking up a couple 100 extra horsepower and that is a trade off. We'll take any day from there. It becomes a balancing act and trying to effectively plant that power to the rear wheels, get this thing balanced out.

Hey, welcome back to the shop. Well, whether you're building a V8 super truck like we are or just trying to get a little bit of extra life out of your mild up ranger or any other truck. If you've got composite headlights and a bit of age in your vehicle, chances are you've got oxidized headlights. Now, this is an easy problem to fix. There's several ways to do it and we're going to show you how

build on a budget truck projects that save you time and money.

Now, like we said, this is easy. You're just gonna need a few supplies starting with some water, some ultra fine sandpaper. This is 1500 grit, some rubbing compound to polish with and a machine to do the polishing with.

Now, just like a faded paint job or a rusty piece of steel. The oxidation on the headlight is from exposure to the atmosphere

and sanding it off, merely grades the road or cleans the rust off the steel or in this case, removes the yellow plastic layer from the top and exposes cleaner plastic that you can then polish out.

Now, if we weren't just doing a demonstration on how to do this and the benefits of it, I'd obviously be doing the whole headlight, but I want to show you the difference. So we've taped off half of the headlight.

Now, the Mother's polish in a buffer is normally used to restore the gloss on a painted surface. But our goal with the headlight is to restore the clarity in the lens, allowing the light particles to pass through unrestricted and improving your night vision.

Not just a word of caution, be careful around the plastic nebulas on the surface of your headlight. Those need to be there to safely aim your headlights with an aiming and aligning system. So it's pretty important that they stay intact.

There you go. That's a pretty dramatic result for just a few minutes worth of labor. And if you're a paint and body guy, well, you already have these supplies on hand if you know a paint and body guy, well, you can borrow his if neither of those situations apply. Well, there's an even cheaper even easier way to get the same result.

Well, I'm not a body guy and I don't have that stuff laying around. What I do have some good old fashioned toothpaste. So we're gonna show you a way to use this stuff to get results almost as good as the pro level stuff. The price is tough to beat.

Now, it doesn't really matter what type of toothpaste you use, use whatever you have at the house. But the grittier, the better

now the process is the same as the other headlight,

except this side's gonna smell better.

Now, work it back and forth until the toothpaste seems to dry out a little bit.

Now, this is gonna leave a little bit more residue than the rubbing compound would. So you're gonna have to clean it off with a couple of stages using some water to get the big stuff off,

followed up by a good glass cleaner.

But the results are clear

now, the results we got with just the toothpaste pretty good and they're almost as good as the results we've got with the professional level body shop supplies. And either way you go, well, it's a win because you're gonna be able to see better at night and you're gonna be safer. But you also don't have to replace these expensive headlight assemblies. You can just refurbish the lenses. Now, if you go in the toothpaste route where you can even do it without a rotary tool, just might take a little bit elbow grease, but at least that's free.

You're watching trucks for a DVD copy of this episode. Just go to Power block tv.com and order your copy for just 595 plus shipping and handling. Start your own trucks, collection delivered right to your door from the power block.

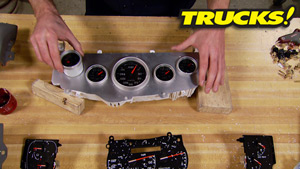

Well, welcome back to the shop now, Kevin and I obviously have quite the challenge ahead of us. Shoe horning this gigantic dual overhead cam 4.6 L engine into an engine bay that was designed to house a 2.5 L four cylinder. Now, there's no doubt about it. It's going to be a tight fit, but we'll make it happen. Now, we'll obviously have to make new engine mounts. We'll probably have to relocate the cross member and we'll more than likely have, make some other modifications as well.

Now, we're going to set the engine back up against the firewall as close as we possibly can to help with weight distribution and speaking of weight. Well, this gigantic engine in trans combo weighs in at 719 pounds, only 183 pounds heavier than the stock combination.

But here's another cool fact, we're picking up 183 horsepower that's gaining one horsepower per,

we'll take that any day of the week.

Now, for stage one, the heavy automatic transmission is going to stick around, but once we go to stage two, we're going to swap it out in favor of a lighter manual transmission because what we're after is the best possible power to weight ratio. We just need to make sure all the power we're making finds its way to the rear tires and onto the ground. And for that, we've got a pretty cool and unique solution.

Now, with our used Marauder engine, we could safely go straight to synthetic engine oil, but with a rebuilt engine or a brand new crate engine, like our illuminator here. You would never break it in with straight synthetic. That is until now. This is Royal Purple's new engine break in oil, which is fortified with zinc and phosphorus making it perfect for breaking in both flat tap it and roller engines.

So with Royal Purple's new break in engine oil no longer, is it necessary to mix old and new technology when you're breaking in your new project's engine?

Now, if you got any questions about this crazy project we're taking on or anything else you saw on today's show? Go to Power Block tv.com guys. Thanks for watching trucks. See you next week.

Show Full Transcript

Hey guys, welcome to trucks. Well, this is the Kevin Tates grocery Getter. This is my personal truck. I drive it back and forth to work. I haul stuff with it I tow with it and it's even been to the strip a couple of times. It's a 2000 Harley Davidson F 150 but it is not stock underneath. The hood is an 02 lightning drive train with all of the go fast goodies, long tube haters and 373 rear gears. There's a custom

dyno tune on it that's pulling 400 horsepower and 500 ft pounds at the rear wheels and at 5100 and 50 pounds. I've surprised a couple of Mustang gts with this thing. Needless to say it's a fun truck to drive.

I love that truck.

Now, can you imagine a drive train like that with that kind of horsepower and torque in a smaller, more nimble truck that can weigh anywhere between 1,502,000 pounds less. You'd have a little rocket ship on your hands or at least a mini version of a Ford lightning.

And since mini lightning doesn't sound that tough, we're calling this thing project rolling thunder.

Now, we were actually looking for a single cab Ford Ranger when we found our Mazda B 2500 and they look almost identical until you get a little closer. For instance, look at the bedside, it's got this kind of a cool style line that we're actually getting used to sort of sets it apart the doors. Well, Ford Ranger, the cab Ford Ranger, the proofs in the pudding,

you check out the Vin and the sticker

is manufactured by Ford Motor Company in the USA. So for all intents and purposes, it's a ranger.

Now inside,

we got what we want with a stripped down lightweight interior, but most importantly, we got the five speed.

Now, another bonus we found with our truck is that it's wearing its original paint. And even though the paints a little bit on the rough side, it's still better than a couple of other paint jobs, hiding sins of the past. So other than some minor styling changes and Mazda badging, this thing is a

for Ranger, which is also good news because at least on the car lots that we looked at the Mazda trucks were a little bit cheaper. So our B 2500 Ranger Mazda pickup came in at just shy of 3000 bucks. Which way you look at it. It's an awesome start to a great project.

Now, underneath the hood of our well used 160,000 mile pickup is a little 2.5 L four cylinder. Now, it runs fine and I'm sure it would handle commuter duty just fine. Probably get pretty good gas mileage while doing it,

but it is definitely not a high performance power plant and certainly isn't going to cut it for what we have in mind. So there's room for improvement. Literally take a look around the engine. You can see the floor almost all the way around this thing. So we've definitely got space for a bigger engine. Now, if we need even more room, we can ditch the vacuum brake booster in favor of a later model hydro boost set up. We can remove or relocate some of these ac parts along with a couple of the fluid containers.

Now, the 5 L V8 swap, well, it's been done more than a few times. So we're going to stay away from that.

We want to go with the next generation of Ford V8 S the

alert 4.6. Now, they've been around long enough where you can pick up a used engine and transmission combo from a junk yard for a pretty fair price. Heck, you can even buy a complete Lincoln or even cop car and have almost everything you need to complete the swap. Now,

the modular V eights, well, they're smaller displacement but they rev higher and just like the lightning engine in Kevin's Harley truck. Well, they're really receptive to forced induction.

Now, for stage one of this build, the light duty 7.5 inch rear axle and the leaf springs are going to stay put just to get the truck up and running.

But for stage two, those parts are going to hit the scrap pile because that axle is not going to take any abuse from a V8. So it'll be changed out for a stronger 88 or nine inch rear axle. Now, the leaf spring setup would probably be

ok if we were just building a lowered street truck. But we want this thing to handle the twisties. So we're going to go with some sort of adjustable four length or torque arm setup of some sort, something that can plant the power and keep it there. And that'll be one of the biggest challenges we face when putting this truck together. So we're going to have big va power up front and not so much weight out back.

Now, it's pretty apparent. Our 2001 Mazda spent a little bit of time up north in the rust belt. It was up there just long enough to put a light surface rust on all the exposed metal, but not long enough to cause any serious rot issues. So we should be in good shape. Now, as far as suspension goes, we're off to a better start up

than we were out back. We've got a short and long a arm set up with tubular arms up top and stamped steel arms down below. We've also got the rack and pinion steering we wanted, it'll give us better steering field and response and also provide more room for our V8 swap. Heck, we've even got a factory power steering cooler

now, like we just told you and showed you earlier in the parking lot, blowing the tires off of a high performance pickup is relatively easy to do.

And that's because of the extreme weight buys to the front of almost every truck out there. And our little Mazda is no different, but there's good news and bad news. Our truck comes in at just under 3100 pounds. But if you take a look at the weight buys, it's 62% to the front of the truck, meaning that

38% of the weight is over the rear axle. Now, ideally, you'd like to have a 5050 weight split, front to back, side to side and corner to corner. Now, we're never going to get there since we started with a pickup truck, but we can try our hardest to get as close as possible. So we'll just have to get creative and relocate as many parts from the front of the truck to the back and put them in the bed and we'll just try to lighten up the front as much as possible and get this thing to hook up.

Now under the hood, we weren't plagued with a whole bunch of messy oil leaks. However, our high mileage drive train, well, it had a bit of road drive on it and it never hurts to clean off your project before you start.

Now, despite having every other tool known to man, the truck shop does not have a wash bait so it doesn't get any more real world than the neighborhood coin off.

Now, here's some interesting trivia. Later model rangers and F 150 already have an aluminum hood. So it gives us a weight savings head start,

get rid of all that schmutz.

Catch your wheel. Now, spin it bit, it's going on.

Hey, welcome back to trucks. Let me introduce you to our little friend.

Actually, not so little. This is a 4.6 L, dual overhead cam modular engine and four rur 70 transmission out of a wrecked 03 mercury marauder. Now we wanted to go modular for a couple of different reasons. The availability of these engines. They've been around long enough and there's lots of them available from the salvage standpoint.

Also the high performance potential of the four valve modular engines. Well, it's proven itself over and over again.

This one starts with a high flowing intake manifold and notoriously high flowing dual overhead cam heads. The same heads that come on the now legendary 2003 and 2004 supercharged Cobras, the Marauder engine has an all aluminum block with six bolton

caps as well as high flowing exhaust manifolds. Now, this package in a stock mercury Marauder in 2003 kicked out just over 300 horsepower in a completely stocked car. So you throw some aftermarket stuff at it, throw a tune on it. Well, you can start to see the potential now just in case you think we reach for this exotic engine. Well, here's a list of potential donor vehicles that can give you guys a four valve modular,

the 93 to 98 Lincoln mark eights, some Lincoln Continentals 99 to 2004 SVT Cobras

Panos Esperanto

2003 and 2004 Mustang Mach one, obviously the 03 and 04 Mercury Marauder and the 03 to 05 Lincoln Aviator just to name a few.

Now, obviously, the original engine and transmission are going away, but here's where you can take a page out of the Ford factory service manual and save yourself some time because unlike an S 10, the Ford Ranger cab aprons and radiator support, well, they're spot welded together. So just like we did when we pulled the in

out and swap the lightning engine into my Harley truck. Well, we're going to take the cab off of the chassis, there's six bolts that hold it on and some engine connections, it comes straight up, you roll the chassis out from underneath it, save yourself a lot of time. Plus it's going to give us the opportunity to give you guys a closer look at what we're doing.

Now, I know that right now there's guys talking back to their television saying you don't have to pull the cab to pull the engine and you're right, you don't have to, however, the ability to do this type of work flat footed and not laying on your back on a creeper. Well, it's definitely worth the extra effort.

And since the air conditioning on our little Mazda still worked well, that means it's full of Freon and the air conditioning compressor is going to stay with the rest of the system and go up with the body when we separate it from the chassis until we can deal with it. The correct way

we may end up reusing our radiator. So we pulled it to keep it from getting damaged.

And since our four cylinder computer won't exactly work on our new eight cylinder engine, we pulled that as well

and separating the rest of the cab from the chassis. What was simple as pulling the bulkhead connector on the floorboard of the cab

made it really easy.

And with the driver controls and harnesses separated, all that are left are six bolts holding the body to the chassis.

Now, believe it or not, the cab is actually not that heavy. So even without a lift with a few buddies, you can set the cab and nose on some jack stands. Now Ford service se will tell you that everything we've done is standard procedure except the surfing.

Now, pulling the exhaust system was pretty straightforward and we were able to remove most of the hardware with the help of some penetrating oil.

But separating the down pipe from the exhaust manifold

that took a little heap

with the swap like this, it's kind of uncharted. So you never really know what you're going to reuse and what you're going to throw away. So we're carefully disassembling everything rather than hacking it up and throw it in.

Now, we're not really sure what we're going to do with this four cylinder engine and five speed transmission.

I guess we could sell it as used parts or make a really, really fast go cart.

Now, obviously, weight bias is pretty important with a project like this. So we're weighing everything that we pull out of this truck as well as the new components. We're gonna put in

the stock engine and transmission coming right at

537 pounds, which is actually a little bit lighter than we thought it was gonna be.

Now with the new engine and transmission, unfortunately, we're picking up a couple 100 extra pounds, but we're also picking up a couple 100 extra horsepower and that is a trade off. We'll take any day from there. It becomes a balancing act and trying to effectively plant that power to the rear wheels, get this thing balanced out.

Hey, welcome back to the shop. Well, whether you're building a V8 super truck like we are or just trying to get a little bit of extra life out of your mild up ranger or any other truck. If you've got composite headlights and a bit of age in your vehicle, chances are you've got oxidized headlights. Now, this is an easy problem to fix. There's several ways to do it and we're going to show you how

build on a budget truck projects that save you time and money.

Now, like we said, this is easy. You're just gonna need a few supplies starting with some water, some ultra fine sandpaper. This is 1500 grit, some rubbing compound to polish with and a machine to do the polishing with.

Now, just like a faded paint job or a rusty piece of steel. The oxidation on the headlight is from exposure to the atmosphere

and sanding it off, merely grades the road or cleans the rust off the steel or in this case, removes the yellow plastic layer from the top and exposes cleaner plastic that you can then polish out.

Now, if we weren't just doing a demonstration on how to do this and the benefits of it, I'd obviously be doing the whole headlight, but I want to show you the difference. So we've taped off half of the headlight.

Now, the Mother's polish in a buffer is normally used to restore the gloss on a painted surface. But our goal with the headlight is to restore the clarity in the lens, allowing the light particles to pass through unrestricted and improving your night vision.

Not just a word of caution, be careful around the plastic nebulas on the surface of your headlight. Those need to be there to safely aim your headlights with an aiming and aligning system. So it's pretty important that they stay intact.

There you go. That's a pretty dramatic result for just a few minutes worth of labor. And if you're a paint and body guy, well, you already have these supplies on hand if you know a paint and body guy, well, you can borrow his if neither of those situations apply. Well, there's an even cheaper even easier way to get the same result.

Well, I'm not a body guy and I don't have that stuff laying around. What I do have some good old fashioned toothpaste. So we're gonna show you a way to use this stuff to get results almost as good as the pro level stuff. The price is tough to beat.

Now, it doesn't really matter what type of toothpaste you use, use whatever you have at the house. But the grittier, the better

now the process is the same as the other headlight,

except this side's gonna smell better.

Now, work it back and forth until the toothpaste seems to dry out a little bit.

Now, this is gonna leave a little bit more residue than the rubbing compound would. So you're gonna have to clean it off with a couple of stages using some water to get the big stuff off,

followed up by a good glass cleaner.

But the results are clear

now, the results we got with just the toothpaste pretty good and they're almost as good as the results we've got with the professional level body shop supplies. And either way you go, well, it's a win because you're gonna be able to see better at night and you're gonna be safer. But you also don't have to replace these expensive headlight assemblies. You can just refurbish the lenses. Now, if you go in the toothpaste route where you can even do it without a rotary tool, just might take a little bit elbow grease, but at least that's free.

You're watching trucks for a DVD copy of this episode. Just go to Power block tv.com and order your copy for just 595 plus shipping and handling. Start your own trucks, collection delivered right to your door from the power block.

Well, welcome back to the shop now, Kevin and I obviously have quite the challenge ahead of us. Shoe horning this gigantic dual overhead cam 4.6 L engine into an engine bay that was designed to house a 2.5 L four cylinder. Now, there's no doubt about it. It's going to be a tight fit, but we'll make it happen. Now, we'll obviously have to make new engine mounts. We'll probably have to relocate the cross member and we'll more than likely have, make some other modifications as well.

Now, we're going to set the engine back up against the firewall as close as we possibly can to help with weight distribution and speaking of weight. Well, this gigantic engine in trans combo weighs in at 719 pounds, only 183 pounds heavier than the stock combination.

But here's another cool fact, we're picking up 183 horsepower that's gaining one horsepower per,

we'll take that any day of the week.

Now, for stage one, the heavy automatic transmission is going to stick around, but once we go to stage two, we're going to swap it out in favor of a lighter manual transmission because what we're after is the best possible power to weight ratio. We just need to make sure all the power we're making finds its way to the rear tires and onto the ground. And for that, we've got a pretty cool and unique solution.

Now, with our used Marauder engine, we could safely go straight to synthetic engine oil, but with a rebuilt engine or a brand new crate engine, like our illuminator here. You would never break it in with straight synthetic. That is until now. This is Royal Purple's new engine break in oil, which is fortified with zinc and phosphorus making it perfect for breaking in both flat tap it and roller engines.

So with Royal Purple's new break in engine oil no longer, is it necessary to mix old and new technology when you're breaking in your new project's engine?

Now, if you got any questions about this crazy project we're taking on or anything else you saw on today's show? Go to Power Block tv.com guys. Thanks for watching trucks. See you next week.