More Fat Stack Episodes

Detroit Muscle Featured Projects

Detroit Muscle Builds

Want more content like this?

Join the PowerNation Email NewsletterEpisode Transcript

(Tommy)>> You're watching Powwernation!

(Joel)>> Today on Detroit Muscle Fat Stack gets her body back as well as some added protection.

(Tommy)>> Plus it's a fuel system frenzy as we tackle the plumbing along with a tank refurbishment. [ Music ] [ engines revving ] [ Music ]

(Joel)>> Today we've got our '71 Caprice project that we've christened as Fat Stack back in the shop and we're stoked about it. This candy green paint's looking pretty sharp, but now it's time to address the lingering issue that's lying below the surface. And luckily what we have up our sleeve is fast, easy to do, won't cost a million bucks but it'll sure look like it when it's done.

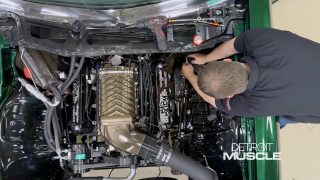

(Tommy)>> Along with that we're gonna conquer our fuel system. We've got to push some petrol from out back toward the front to feed that 800 horsepower supercharged LS. And then finally with these two things taken care of we can drop that green body onto our chassis. We're in kind of a predicament with our old tank here. With that old big body it's kind of an odd duck car, and they don't offer an o-e-m replacement tank for one of them. Our plan is to run an aftermarket in-tank style pump, and what it requires you to do is cut a hole in your tank, and then mount it, and then plumb it accordingly. Now before you go punching holes or throwing sparks you have to remember this thing carries an explosive fuel on the inside, and you don't want to hurt yourself or anyone else. So you need to make sure that you flush one of these things out before you even try to do any kind of modification. We're gonna start off by knocking the locking ring off, and then pulling out the sending unit. This will allow us to drain the tank properly to get everything out of the inside of it. Once that's done and the inspection checks out we can give the inside a good bath.

(Joel)>> We're using a fuel tank repair kit that we got from POR-15. It comes with a cleaner, metal prep, and a sealer. First step is to mix the cleaner with some warm water, and then you're ready to pour it in the tank. After that just slosh it around.

(Tommy)>> With our tank not smelling like fuel any more it's time for us to plan our incision. Now with that there's a couple of things that you need to keep in mind. One is oftentimes there's baffles inside of here and you don't want to make a hole and then next thing you know you're on top of one of those. That just complicates everything. The next thing is your fuel sender. A lot of those have a swinging arm, and if you get too close to it you may run into interference. That's not good either. With our plan we're gonna mount our pump right here toward the back. This is good for a couple of reasons. There's no interference, and it actually makes the installation of the hoses relatively easy. If you were to mount this thing up here you're gonna have to build a big, long trough and hope there's enough clearance between the top of the tank and the bottom of the trunk pan. I'm using some 18-gauge standard old sheet metal to make my panel. Just got to drill a few holes for the mounting ring and slide the pump in. Then it's off to the metal break to bend the tabs. [ Music ]

Now to mark off my little notch, or recess here, I'm gonna use this flat piece of metal. Lay it on top of the tank, slide it across, make her from the bottom of that. That should give us our measurements. My fit is kinda roughed in I guess you would say. What I'm gonna do is tack this thing into place in a couple of spots, grind off this excess lip, and then finish burning everything in. Well with our pocket all welded up and dressed it's time for us to install our fuel pump. We're gonna be using a unit from FiTech. Now this is a pretty significant piece. It will support up to 1,000 horsepower. Now before we can install this thing we need to do some measuring. What you want to do is measure from the top of the tank to the bottom and see where you're at. Now we're at six inches of it. So we need to make sure that we position our pump and the little pickup screen about an eighth of an inch off of the floor of the tank, and we're gonna cut this piece of plastic off right about here and then heat it up so that we can slide the pump into this tube. Once you get the clamp tight all you need to do then is take and zip-tie your pump to the little metal bracket, and then you need to trim off your return tube about a quarter inch from the floor of the tank at a 45. Now to wire up your pump you just have a simple connection that you push together. To attach this pump into the tank it come with this little ring that I used to make that template earlier. We've got a couple of screws that you screw back through here. Then you kinda snake this thing in there, and then you just bolt everything up. [ Music ] A little man handling, nothing crazy though. [ Music ] Well looks like that's gonna do it for a mockup. Now with this little notch that we did you can see that it's considerably lower than just sitting on top of here. Now with this type of modification we did create a small issue. This is just mild steel, and it's gonna flash rust if you were to put fluid inside of here, but I've got the solution for that as well. After cleaning this tank we went ahead and used some of the metal prep to aid in the adhesion of the sealer. The final step to coating our gas tank here is gonna be installing some POR-15 Tank Sealer. You just simply pour it in and then flip the tank around to make sure that you coat the inside of it. Now after you do that this stuff needs to dry for 96 hours before you pour the fuel back into it, and it's that simple. I'm trying to get this stuff coated all over every square inch. You notice I'm moving the tank around in multiple directions giving it time for it to run across everything. We'll do it for a while this way, and then flip the tank over. It works really well when you're in a situation like we are when you have a fuel tank that no one offers. It gives you an opportunity to repair it. I got the tank standing up on its end. That's gonna allow everything to settle to one side. We'll remove the excess. Once that dries like it's supposed to we'll be good to go.

(Joel)>> Up next, we get "plumb crazy" and fit in Fat Stack's fuel system.

(Joel)>> Well guys we're well on our way of tackling the fuel system on our '71 Caprice project, a-k-a Fat Stack. Now Tommy's already taken care of everything we're gonna need from the fuel tank, but now it's time to address the actual physical plumbing that's gonna be required to draw that fuel from the tank all along the frame rails to the supercharged 840 horsepower LS power plant. Now from the factory this old big body had these pre-bent steel lines that ran along the inside of these frame rails from a low pressure sending unit up to a small block Chevy, and unfortunately for this application that's just not gonna work. A lot of modern day fuel injection systems operate in that 40 to 60 p-s-i range. So you're gonna need adequate plumbing to accommodate that. What you're also gonna need is what is known as a return line running back to your tank. When planning out your fuel system there's common parts that you will be using. First is the fuel tank, which is the reservoir for liquid dinosaur juice. Then there's your pump, your filter, your lines, a regulator, and finally your injection unit. This setup is basic. The pump draws fuel out of the tank and pushes the fluid towards the engine. With an inline unit you want to install the pump within three feet of the tank and mount it as close as possible to the bottom. Usually pumps are pushers, not pullers. If you mount it too high sometimes the pumps can struggle to draw the fuel out of the tank. Fuel filters do just what their name suggests. Filter the fuel as it passes through them. The next connection is determined by the injection system you're planning to run. If your unit doesn't have a pressure regulator built in you will have to install one. Failure to do this can damage components, causing tuning issues and poor performance. Oftentimes regulators have multiple ins, outs, and a return. This return is what bleeds off the excess pressure supplied by the pump and returns it back to the tank. Our plan of attack is to keep the fuel system on ole Fat Stack clean, simple, and serviceable. So we called up the guys at FiTech and they sent us over this black stainless steel fuel line kit that is specifically designed for high performance applications. First thing we're gonna do is mockup our fuel lines along the frame rails, and then we'll move on to pressing on some fittings. Now our new lines are basically gonna run along the same route as the factory ones on the inside of these frame rails but we do have to do some modifying to these frame holes to accommodate the larger size hoses. [ drill humming ] [ Music ]

(Joel)>> After cutting out our holes I went ahead and installed these new grommets to ensure that our new hoses wouldn't get cut by those sharp edges. [ Music ] With our supply line roughed into place now's a good opportunity to see where we want to plumb in our inline filter, and this is kinda where the serviceable side of things comes into play. You want to put this in a spot that's easy to get to, and therefore easy to swap out if you ever need to. Looks like right about here will do just fine. [ Music ]

FiTech offers special tape that keeps the braided material tight for when you're adding your fitting. [ Music ] I like to apply a small amount of assembly oil on the threads of these fittings, and a little bit goes a long way. When tightening this up you want to make sure the nipple seats properly into the socket. Also remember these things are directional. Often they'll have an arrow to indicate flow and show you which direction it needs to be mounted. Now when it comes to physically mounting your lines to the frame you want to use a style of clamp that's not gonna latch in and squeeze them because that's gonna restrict your flow. You want something that's gonna allow enough play for suspension travel but also hold everything in place. [ Music ]

[ Music ] Perfect! Now all we need is a couple of lines running to the tank and the fuel rails and the fuel system is plumbed. It's a lot easier without the body on the chassis.

(Tommy)>> Coming up, we look back at another big boned bowtie.

(Tommy)>> Our Caprice has a lot of famous relatives but there's one that a lot of Chevy owners put in a league all of its own. First released in '58, the Impala had style, class, and plenty of curves. By '59 GM was building Impalas that were cruising off the dealer's lots with huge wings and teardrop taillights.

(Joel)>> By 1960 the style had been toned down a bit, but in '61 Chevrolet started using a new marketing strategy to make Impalas fly off the car lots and head down the dragstrip. That was the first year the Double-S's appeared on a car, and Chevy felt the Impala was the best fit for the now infamous Super Sport logo. Less than 500 Super Sport Impalas were built in 1961, but they were such a hit that by '62 GM pumped out close to 100,000 of them.

(Tommy)>> The 409 also debuted in '61. However, less than 150 Super Sports were lucky enough to have the iconic motor dropped in it. You can count your lucky stars if you ever get a chance to drive a 409 car, but this '61 Impala is still truly a gem.

(Joel)>> This numbers matching SS is loaded with style inside and out. Four big lamps up front are planted in a chrome grille with smooth body lines on the fenders, blending back into that long and sleek Impala profile.

(Tommy)>> A little bit of chrome trim filled in with some racing red complimented by that unmistakable logo still turns just as many heads today as it did back in '61.

(Joel)>> Six taillights signal the Impala's arrival from the rear. Top that whole thing off with chrome bumpers and you've got one sexy ride.

(Tommy)>> Air conditioning was an option for the Impala, but with a bubble top and no window pillars why would you get it? These cars have so much glass and open room it feels more like a convertible than a hard top. A 348 Chevy coupled with a Powerglide transmission made for a great cruiser.

(Joel)>> Now admittedly these Impalas were not the fastest or the highest performers that Chevy put out during the days of the muscle car, but they were an instant hit and paved the way for other SS cars down the road.

(Tommy)>> The pricey $54-dollar Super Sport package consisted of generous applications of SS badging, sport red interior, a tack on the steering column, and of course a passenger side grab bar just in case you were lucky enough to have one with a 409.

(Joel)>> The Chevrolet Impala is no doubt a hall of fame piece of Detroit Muscle. However, when we're done building our Caprice Fat Stack they're going to have to clear us out a spot on the muscle car Mount Rushmore. Up next, we revitalize the undercarriage before marriage.

(Joel)>> Well guys there's one thing left on the itinerary before we're ready to set Fat Stack's body back on its chassis, and that would be spraying on some undercoating. When it comes to that stuff there's all different kinds out there. What we plan on using is a professional grade truck bed liner for multiple reasons. One, it's tough. Two, it deflects a lot of road debris and moisture and three, looks pretty good when you're done, but there is some extra prep work involved. Step one is to scuff the undercarriage, and that is gonna give the coating a good surface to latch onto. So I'm gonna get to work scrubbing off some ugly. I'm just using a regular red scuff pad to scrub this down and give the bed liner some tooth. You'll probably also want to pressure wash any dirt or debris off of your undercarriage before you start scuffing. [ Music ]

This isn't your run of the mill overspray. We've put hundreds of hours into this paint job, and with that said we're taking special care when masking up old Fat Stack. [ Music ]

[ Music ] Well we got everything masked off, prepped, and ready to go. We do have a couple of bare metal spots that need touched up with some black epoxy primer. We'll get that done, and then this thing's pretty much ready for some bed liner. [ spray gun hissing ] [ Music ] [ spray gun hissing ]

(Joel)>> Now with our epoxy flashed off let's take a minute to talk about the product that we're working with. We went out and got us a two stage urethane base bed liner, and that's gonna give us that stern toughness we need to make this project last a long time. One of the most overlooked advantages of a good undercoating would be the sound deadening aspect. Earlier I took two scrap pieces of sheet metal, and on this one I sprayed some rubberized undercoating, and on this one some industrial bed liner. And just in comparison weight wise this thing is way more dense. Also, check this out. [ metal tapping ]

(Joel)>> Hear that difference? And even there is a little more prep work and mixing involved in comparison to an aerosol can the overall quality of the product speaks for itself. The viscosity of this bed liner is thick. On a normal paint job most people spray between 15 and 20 p-s-i, and this stuff requires three times that. We're running it in a well ventilated area with plenty of space because you don't want to get this stuff on the wall of your workshop. Guys I have to say for only a few hours of labor this thing has made a complete transformation. Heck looks like a brand new car. Not only does it have the finish we were looking for, it's also gonna add on decades of protection, sound deadening, and even a little bit of insulation. Now comes the fun part. It's finally time to marry this thing back to the chassis. [ Music ]

(Tommy)>> It's been a long time coming, hasn't it?

(Joel)>> It's gonna look pretty sharp I think.

(Tommy)>> Let me know if you see any causes of concern. Think this lift could go any slower?

(Joel)>> Looks good so far, but the suspense is killing me. [ Music ]

(Tommy)>> Be sure to take your time when marrying the body back to the chassis. Keep an eye out for anything catching or not lining up properly. [ mechanical humming ] [ Music ]

(Joel)>> Got those bolts? [ Music ] [ drill humming ]

(Joel)>> Don't forget, you're starting your body bolts into a caged nut. So start slow, and once they're seated go ahead and cinch them down. [ drill humming ] [ Music ]

(Tommy)>> We knew this aged out green relic had a solid foundation for one heck of a build. The floor and trunk pans looking this nice after a simple respray is really saying something.

(Joel)>> Green isn't for everybody. If you can make a green car stand out, to me you've accomplished a rare feat. We've been chomping at the bit to see our '71 Caprice back together just to check out the stance, and I do believe we've nailed it.

(Tommy)>> From where we began, Fat Stack is finally starting to look the part. To make a transformation this drastic, it doesn't happen overnight. It takes a lot of time and effort to get to this point. Now we still have a lot more work to do, but I have to say when we're all said and done this thing is gonna be one impressive piece.

(Joel)>> From the perspective of a couple of car guys this is truly what it's all about. Hitting these big milestones, they can really lift your spirits. When you take a step back and consider all the cool stuff we've still got to put on this car including a vinyl top, some bright work, trick interior. Dude, this thing is gonna look killer.

(Tommy)>> I can't wait to see the chrome, those skirts on the back. This thing definitely is gonna be cool.

(Joel)>> I'm driving first this time though.

Show Full Transcript

(Joel)>> Today on Detroit Muscle Fat Stack gets her body back as well as some added protection.

(Tommy)>> Plus it's a fuel system frenzy as we tackle the plumbing along with a tank refurbishment. [ Music ] [ engines revving ] [ Music ]

(Joel)>> Today we've got our '71 Caprice project that we've christened as Fat Stack back in the shop and we're stoked about it. This candy green paint's looking pretty sharp, but now it's time to address the lingering issue that's lying below the surface. And luckily what we have up our sleeve is fast, easy to do, won't cost a million bucks but it'll sure look like it when it's done.

(Tommy)>> Along with that we're gonna conquer our fuel system. We've got to push some petrol from out back toward the front to feed that 800 horsepower supercharged LS. And then finally with these two things taken care of we can drop that green body onto our chassis. We're in kind of a predicament with our old tank here. With that old big body it's kind of an odd duck car, and they don't offer an o-e-m replacement tank for one of them. Our plan is to run an aftermarket in-tank style pump, and what it requires you to do is cut a hole in your tank, and then mount it, and then plumb it accordingly. Now before you go punching holes or throwing sparks you have to remember this thing carries an explosive fuel on the inside, and you don't want to hurt yourself or anyone else. So you need to make sure that you flush one of these things out before you even try to do any kind of modification. We're gonna start off by knocking the locking ring off, and then pulling out the sending unit. This will allow us to drain the tank properly to get everything out of the inside of it. Once that's done and the inspection checks out we can give the inside a good bath.

(Joel)>> We're using a fuel tank repair kit that we got from POR-15. It comes with a cleaner, metal prep, and a sealer. First step is to mix the cleaner with some warm water, and then you're ready to pour it in the tank. After that just slosh it around.

(Tommy)>> With our tank not smelling like fuel any more it's time for us to plan our incision. Now with that there's a couple of things that you need to keep in mind. One is oftentimes there's baffles inside of here and you don't want to make a hole and then next thing you know you're on top of one of those. That just complicates everything. The next thing is your fuel sender. A lot of those have a swinging arm, and if you get too close to it you may run into interference. That's not good either. With our plan we're gonna mount our pump right here toward the back. This is good for a couple of reasons. There's no interference, and it actually makes the installation of the hoses relatively easy. If you were to mount this thing up here you're gonna have to build a big, long trough and hope there's enough clearance between the top of the tank and the bottom of the trunk pan. I'm using some 18-gauge standard old sheet metal to make my panel. Just got to drill a few holes for the mounting ring and slide the pump in. Then it's off to the metal break to bend the tabs. [ Music ]

Now to mark off my little notch, or recess here, I'm gonna use this flat piece of metal. Lay it on top of the tank, slide it across, make her from the bottom of that. That should give us our measurements. My fit is kinda roughed in I guess you would say. What I'm gonna do is tack this thing into place in a couple of spots, grind off this excess lip, and then finish burning everything in. Well with our pocket all welded up and dressed it's time for us to install our fuel pump. We're gonna be using a unit from FiTech. Now this is a pretty significant piece. It will support up to 1,000 horsepower. Now before we can install this thing we need to do some measuring. What you want to do is measure from the top of the tank to the bottom and see where you're at. Now we're at six inches of it. So we need to make sure that we position our pump and the little pickup screen about an eighth of an inch off of the floor of the tank, and we're gonna cut this piece of plastic off right about here and then heat it up so that we can slide the pump into this tube. Once you get the clamp tight all you need to do then is take and zip-tie your pump to the little metal bracket, and then you need to trim off your return tube about a quarter inch from the floor of the tank at a 45. Now to wire up your pump you just have a simple connection that you push together. To attach this pump into the tank it come with this little ring that I used to make that template earlier. We've got a couple of screws that you screw back through here. Then you kinda snake this thing in there, and then you just bolt everything up. [ Music ] A little man handling, nothing crazy though. [ Music ] Well looks like that's gonna do it for a mockup. Now with this little notch that we did you can see that it's considerably lower than just sitting on top of here. Now with this type of modification we did create a small issue. This is just mild steel, and it's gonna flash rust if you were to put fluid inside of here, but I've got the solution for that as well. After cleaning this tank we went ahead and used some of the metal prep to aid in the adhesion of the sealer. The final step to coating our gas tank here is gonna be installing some POR-15 Tank Sealer. You just simply pour it in and then flip the tank around to make sure that you coat the inside of it. Now after you do that this stuff needs to dry for 96 hours before you pour the fuel back into it, and it's that simple. I'm trying to get this stuff coated all over every square inch. You notice I'm moving the tank around in multiple directions giving it time for it to run across everything. We'll do it for a while this way, and then flip the tank over. It works really well when you're in a situation like we are when you have a fuel tank that no one offers. It gives you an opportunity to repair it. I got the tank standing up on its end. That's gonna allow everything to settle to one side. We'll remove the excess. Once that dries like it's supposed to we'll be good to go.

(Joel)>> Up next, we get "plumb crazy" and fit in Fat Stack's fuel system.

(Joel)>> Well guys we're well on our way of tackling the fuel system on our '71 Caprice project, a-k-a Fat Stack. Now Tommy's already taken care of everything we're gonna need from the fuel tank, but now it's time to address the actual physical plumbing that's gonna be required to draw that fuel from the tank all along the frame rails to the supercharged 840 horsepower LS power plant. Now from the factory this old big body had these pre-bent steel lines that ran along the inside of these frame rails from a low pressure sending unit up to a small block Chevy, and unfortunately for this application that's just not gonna work. A lot of modern day fuel injection systems operate in that 40 to 60 p-s-i range. So you're gonna need adequate plumbing to accommodate that. What you're also gonna need is what is known as a return line running back to your tank. When planning out your fuel system there's common parts that you will be using. First is the fuel tank, which is the reservoir for liquid dinosaur juice. Then there's your pump, your filter, your lines, a regulator, and finally your injection unit. This setup is basic. The pump draws fuel out of the tank and pushes the fluid towards the engine. With an inline unit you want to install the pump within three feet of the tank and mount it as close as possible to the bottom. Usually pumps are pushers, not pullers. If you mount it too high sometimes the pumps can struggle to draw the fuel out of the tank. Fuel filters do just what their name suggests. Filter the fuel as it passes through them. The next connection is determined by the injection system you're planning to run. If your unit doesn't have a pressure regulator built in you will have to install one. Failure to do this can damage components, causing tuning issues and poor performance. Oftentimes regulators have multiple ins, outs, and a return. This return is what bleeds off the excess pressure supplied by the pump and returns it back to the tank. Our plan of attack is to keep the fuel system on ole Fat Stack clean, simple, and serviceable. So we called up the guys at FiTech and they sent us over this black stainless steel fuel line kit that is specifically designed for high performance applications. First thing we're gonna do is mockup our fuel lines along the frame rails, and then we'll move on to pressing on some fittings. Now our new lines are basically gonna run along the same route as the factory ones on the inside of these frame rails but we do have to do some modifying to these frame holes to accommodate the larger size hoses. [ drill humming ] [ Music ]

(Joel)>> After cutting out our holes I went ahead and installed these new grommets to ensure that our new hoses wouldn't get cut by those sharp edges. [ Music ] With our supply line roughed into place now's a good opportunity to see where we want to plumb in our inline filter, and this is kinda where the serviceable side of things comes into play. You want to put this in a spot that's easy to get to, and therefore easy to swap out if you ever need to. Looks like right about here will do just fine. [ Music ]

FiTech offers special tape that keeps the braided material tight for when you're adding your fitting. [ Music ] I like to apply a small amount of assembly oil on the threads of these fittings, and a little bit goes a long way. When tightening this up you want to make sure the nipple seats properly into the socket. Also remember these things are directional. Often they'll have an arrow to indicate flow and show you which direction it needs to be mounted. Now when it comes to physically mounting your lines to the frame you want to use a style of clamp that's not gonna latch in and squeeze them because that's gonna restrict your flow. You want something that's gonna allow enough play for suspension travel but also hold everything in place. [ Music ]

[ Music ] Perfect! Now all we need is a couple of lines running to the tank and the fuel rails and the fuel system is plumbed. It's a lot easier without the body on the chassis.

(Tommy)>> Coming up, we look back at another big boned bowtie.

(Tommy)>> Our Caprice has a lot of famous relatives but there's one that a lot of Chevy owners put in a league all of its own. First released in '58, the Impala had style, class, and plenty of curves. By '59 GM was building Impalas that were cruising off the dealer's lots with huge wings and teardrop taillights.

(Joel)>> By 1960 the style had been toned down a bit, but in '61 Chevrolet started using a new marketing strategy to make Impalas fly off the car lots and head down the dragstrip. That was the first year the Double-S's appeared on a car, and Chevy felt the Impala was the best fit for the now infamous Super Sport logo. Less than 500 Super Sport Impalas were built in 1961, but they were such a hit that by '62 GM pumped out close to 100,000 of them.

(Tommy)>> The 409 also debuted in '61. However, less than 150 Super Sports were lucky enough to have the iconic motor dropped in it. You can count your lucky stars if you ever get a chance to drive a 409 car, but this '61 Impala is still truly a gem.

(Joel)>> This numbers matching SS is loaded with style inside and out. Four big lamps up front are planted in a chrome grille with smooth body lines on the fenders, blending back into that long and sleek Impala profile.

(Tommy)>> A little bit of chrome trim filled in with some racing red complimented by that unmistakable logo still turns just as many heads today as it did back in '61.

(Joel)>> Six taillights signal the Impala's arrival from the rear. Top that whole thing off with chrome bumpers and you've got one sexy ride.

(Tommy)>> Air conditioning was an option for the Impala, but with a bubble top and no window pillars why would you get it? These cars have so much glass and open room it feels more like a convertible than a hard top. A 348 Chevy coupled with a Powerglide transmission made for a great cruiser.

(Joel)>> Now admittedly these Impalas were not the fastest or the highest performers that Chevy put out during the days of the muscle car, but they were an instant hit and paved the way for other SS cars down the road.

(Tommy)>> The pricey $54-dollar Super Sport package consisted of generous applications of SS badging, sport red interior, a tack on the steering column, and of course a passenger side grab bar just in case you were lucky enough to have one with a 409.

(Joel)>> The Chevrolet Impala is no doubt a hall of fame piece of Detroit Muscle. However, when we're done building our Caprice Fat Stack they're going to have to clear us out a spot on the muscle car Mount Rushmore. Up next, we revitalize the undercarriage before marriage.

(Joel)>> Well guys there's one thing left on the itinerary before we're ready to set Fat Stack's body back on its chassis, and that would be spraying on some undercoating. When it comes to that stuff there's all different kinds out there. What we plan on using is a professional grade truck bed liner for multiple reasons. One, it's tough. Two, it deflects a lot of road debris and moisture and three, looks pretty good when you're done, but there is some extra prep work involved. Step one is to scuff the undercarriage, and that is gonna give the coating a good surface to latch onto. So I'm gonna get to work scrubbing off some ugly. I'm just using a regular red scuff pad to scrub this down and give the bed liner some tooth. You'll probably also want to pressure wash any dirt or debris off of your undercarriage before you start scuffing. [ Music ]

This isn't your run of the mill overspray. We've put hundreds of hours into this paint job, and with that said we're taking special care when masking up old Fat Stack. [ Music ]

[ Music ] Well we got everything masked off, prepped, and ready to go. We do have a couple of bare metal spots that need touched up with some black epoxy primer. We'll get that done, and then this thing's pretty much ready for some bed liner. [ spray gun hissing ] [ Music ] [ spray gun hissing ]

(Joel)>> Now with our epoxy flashed off let's take a minute to talk about the product that we're working with. We went out and got us a two stage urethane base bed liner, and that's gonna give us that stern toughness we need to make this project last a long time. One of the most overlooked advantages of a good undercoating would be the sound deadening aspect. Earlier I took two scrap pieces of sheet metal, and on this one I sprayed some rubberized undercoating, and on this one some industrial bed liner. And just in comparison weight wise this thing is way more dense. Also, check this out. [ metal tapping ]

(Joel)>> Hear that difference? And even there is a little more prep work and mixing involved in comparison to an aerosol can the overall quality of the product speaks for itself. The viscosity of this bed liner is thick. On a normal paint job most people spray between 15 and 20 p-s-i, and this stuff requires three times that. We're running it in a well ventilated area with plenty of space because you don't want to get this stuff on the wall of your workshop. Guys I have to say for only a few hours of labor this thing has made a complete transformation. Heck looks like a brand new car. Not only does it have the finish we were looking for, it's also gonna add on decades of protection, sound deadening, and even a little bit of insulation. Now comes the fun part. It's finally time to marry this thing back to the chassis. [ Music ]

(Tommy)>> It's been a long time coming, hasn't it?

(Joel)>> It's gonna look pretty sharp I think.

(Tommy)>> Let me know if you see any causes of concern. Think this lift could go any slower?

(Joel)>> Looks good so far, but the suspense is killing me. [ Music ]

(Tommy)>> Be sure to take your time when marrying the body back to the chassis. Keep an eye out for anything catching or not lining up properly. [ mechanical humming ] [ Music ]

(Joel)>> Got those bolts? [ Music ] [ drill humming ]

(Joel)>> Don't forget, you're starting your body bolts into a caged nut. So start slow, and once they're seated go ahead and cinch them down. [ drill humming ] [ Music ]

(Tommy)>> We knew this aged out green relic had a solid foundation for one heck of a build. The floor and trunk pans looking this nice after a simple respray is really saying something.

(Joel)>> Green isn't for everybody. If you can make a green car stand out, to me you've accomplished a rare feat. We've been chomping at the bit to see our '71 Caprice back together just to check out the stance, and I do believe we've nailed it.

(Tommy)>> From where we began, Fat Stack is finally starting to look the part. To make a transformation this drastic, it doesn't happen overnight. It takes a lot of time and effort to get to this point. Now we still have a lot more work to do, but I have to say when we're all said and done this thing is gonna be one impressive piece.

(Joel)>> From the perspective of a couple of car guys this is truly what it's all about. Hitting these big milestones, they can really lift your spirits. When you take a step back and consider all the cool stuff we've still got to put on this car including a vinyl top, some bright work, trick interior. Dude, this thing is gonna look killer.

(Tommy)>> I can't wait to see the chrome, those skirts on the back. This thing definitely is gonna be cool.

(Joel)>> I'm driving first this time though.