More Fat Stack Episodes

Detroit Muscle Featured Projects

Detroit Muscle Builds

Want more content like this?

Join the PowerNation Email NewsletterEpisode Transcript

(Tommy)>> You're watching

Powernation!

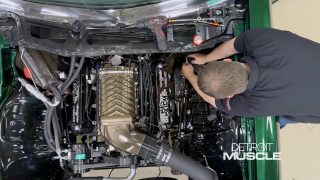

(Joel)>> Today on Detroit Muscle we bust some rust and mend some dents on old Fat Stack.

(Tommy)>> Then we put on our capes and Driveway Rescue a Camaro from catastrophe. [ Music ] [ engines revving ] [ Music ]

(Tommy)>> Hey guys, if you're into throwing sparks, making noise with a grinder, and enjoy the smell of metal in the air you're gonna like what we're doing on Fat Stack today.

(Joel)>> We got our chassis looking like a million bucks, but now it's time to shift our focus over to the body. Sure, she's got a few bumps, bruises, and scars we need to address before it's all pretty again, but it's gonna take a whole lot more than that to scare us.

(Tommy)>> Paint and body work can eat up a lot of time, and it just makes sense why, because it's one of those type of jobs that the more time you spend on it, it allows you to keep making improvements and refine your appearance. So if you've got a project that's in need of some massaging on the body, or you need to take care of some rust, we're gonna show you a few tips and tricks on how to take care of these tasks. All the while with simple processes. [ Music ]

(Joel)>> Now it's no secret that rust in the rear quarter panel area is a common Achilles heel in these old vehicles, and if you've got a project at home that's roughly 25 years or older chances are you're gonna run into this issue. With old Fat Stack we actually got pretty lucky. The fact that this is the only problem area on the entire car is truly a blessing. A lot of that has to do with the big chrome trim piece that used to run along this bottom edge. What happens is eventually over time you get sand, and water, and dirt, all kinds of stuff trapped in between that panel and that trim piece and eventually it rots through. Luckily making this kind of repair isn't all that difficult or complicated, but can be a little intimidating to you guys that have never done it before. If you've got some basic air tools like a wire wheel , grinding stone, and a cutoff wheel you're already in good shape. If you've got a small mig welder like a 110 or a 140 that'll work just fine for this application. First things first, we need to cut the rusty metal out of this car, and there is a way that I like to map it out so that I'm not trimming off more than I need to. Using a roll of masking tape, lay the top edge in the middle of the body panel line. I like to use a marker to trace the bottom edge of the tape just in case it doesn't hold when cutting. [ saw buzzing ]

(Joel)>> Cut all the way across the bottom of the tape, and then use a grinding stone to weaken the spot welds. [ grinder buzzing ]

(Joel)>> You can also use a drill bit, or even a spot weld cutter. [ Music ] Once you've given everything a good once over you can yank the panel until it pops loose. [ Music ] Sometimes in life things don't always turn out as you originally planned. As you can see, we've got some extra corrosion on these inner braces that we need to repair. I've already took the liberty and built a couple of patch panels. We'll get all this nastiness cut out, weld these in, and then we can move on to the outer skin. [ saw buzzing ] [ Music ]

(Joel)>> Now some of you may be wondering why I'm not running any solid beads. If you don't spot weld it can become harder to control the heat of the metal, possibly resulting in warpage. Keep in mind that grinding can create just as much heat as welding. So as you're smooth out your welds be sure to skip around and not spend too much time in one area so that the heat can evenly disperse. [ Music ] [ welder crackling ] [ grinder buzzing ] [ Music ]

(Joel)>> Well guys we got our patch panels welded in. Still got a little bit of surface rust on this back part. I'm just gonna go ahead and rust treat that. Once that's cured we'll spray in some black epoxy primer and call this thing done. [ Music ] Epoxy primer is ideal for sealing out moisture. When it cures it has a thick outer shell that is non-absorbent, unlike self-etching primer, which is porous. Now you may be wondering why I've got an entire quarter panel skin sitting on the table when really all we need is this rear patch. Due to supply chain issues we couldn't find the piece that we needed, but our buddies over at RockAuto had this in stock and they sent it right over. The skin is constructed from high quality sheet metal and features the same dimensions as an original factory replacement. It even has the hole mount pre-cut for the side marker light. Its protective coating also prevents damage during shipping and future corrosion. To some of you it may seem like a waste that we're just cutting out a rear section and scrapping the rest, but this is one of those situations that I want you to consider that your time is your money, and the amount of hours spent building that panel is well worth the cost of a new skin. [ Music ] [ welder crackling ] [ Music ]

(Joel)>> Now if you want to tig weld this piece go right ahead. It's really all about personal preference and the tools you have at your disposal. However, using a mig on these plug welds will give you a sturdier hold in the long run, not to mention make the process much more efficient. [ welding crackling ]

(Joel)>> After your welds are in place you need to evenly smooth out the surface. Just don't get too aggressive with your grinding because you can weaken the structure. [ grinder buzzing ]

(Joel)>> I recommend a 36-grit roll lock because it gives the metal a gritty surface for the filler to latch on to, along with a nice, clean finish. Man oh man, what a difference a few hours of work makes. Doing patch panels can seem really tedious but the more time you spend on your metal work the less time you're gonna have to spend sanding on some filler. Coming up, we identify a couple of small problems.

(Tommy)>> Let's start off saying accidents happen, and usually what's left behind is a dent. Now sometimes they're significant, while others are barely noticeable at all. When you're looking to fix a dent there's several ways you can go about it. One of the main factors is can you get to the back side and push it out. If you can that makes all the difference. You can use hammers, picks, or even wooden blocks to whip it back into shape. But if not you're gonna have to go about things a little bit different. This is an old school dent removing tool, and how it works is you drill a hole here in the panel, screw this thing into it, slide the weight on the puller back and forth, and that will slowly start to pull that dent out. Then you will repeat this process by drilling multiple holes in there and continuing on and on until you get it to the desired shape. Problem with using this tool is it develops a whole other set of problems. That would be you've got a bunch of holes in your panel. So, I'm gonna ask you to hold off on using this thing. A better way is to use what's referred to as a stud gun. Now these have been around for quite a while, and they have multiple uses. To pull the dent it has these small draw pins that you weld to the panel. Then using their slide hammer that clamps to those pins you actuate the weight on it to pull out the dent just like that old school tool but without the holes. To get started we've got to skin that back to bare steel. [ grinder buzzing ]

(Tommy)>> I'm using a 50-grit sanding disc to make light work of stripping down this heavy Chevy. With our tool plugged up we're ready to drop in one of our pull pins and hit the trigger. This tool requires you to push the tip up against the body and to press it. This action completes the circuit for the welding process. [ Music ] That glowing tip you see before you is not a special effect. That metal is molten. [ Music ] Case is getting hot boys! [ Music ]

Obviously the more pins you put on the more points you can pull from, and it may take you a round or two to get this thing dialed in. I'm using this to actually see how deep that dent is, but with our pins in place we can start pulling. What we're trying to do is take this thing from concave and undo what happened. So you'll want to move to move things around slowly. You'll start to see the dent work itself outward as you start to move the metal. Also you don't want to get too eager and pull it out too far or else that will create a whole new problem. Let's check it man, let's check it! Our panel's looking good. Now we just need to remove the pins. You just simply clip them off and grind off the excess. [ Music ] Using a standard set of side cutters, you want to try to trim as close to the tip as possible. Otherwise, you're gonna removing the rest with a grinder. [ Music ] [ sander buzzing ]

(Tommy)>> I'm gonna step it up to 36 grit with the air sander to make sure I get everything nice and smooth. [ sander buzzing ] [ Music ]

(Tommy)>> Just don't over do it and keep the grinder moving to keep the heat low. [ Music ]

Up next, we hit the road and test drive an F-body fave!

(Joel)>> Sometimes we travel far and wide to find our next RockAuto Driveway Rescue. And it isn't always some rusty relic from a dusty barn. Sometimes the car is in near perfect condition, like this '73 Camaro.

(Tommy)>> If you saw this Detroit muscle pass you on the highway you would think that it's in mint condition, but sometimes though looks can be deceiving.

(Joel)>> We hit the trail knowing our buddies at RockAuto would have whatever we needed to help fix up this iconic piece of Detroit Muscle. [ Music ]

(Tommy)>> I feel like I'm lacking a little something back here for one of these things. I don't know what it is.

(Joel)>> These second gen Camaros, they've really come into their own in popularity. The aftermarket support's strong on them, and a lot of guys are building these cars up in really cool ways.

(Tommy)>> Just tooting around in this car right, pretty day like it is.

(Joel)>> Doesn't get much better, does it?

(Tommy)>> It don't suck, I can tell you that! [ Music ]

[ engine revving ]

(Tommy)>> Well the owner did a lot of work on the car, and one of the things that he's found out about the car was there's something wrong with the transmission, or the driveline in it, because once you get it up to speed it starts to make this whining noise. Kinda similar to that old rock crusher four speed sound. He didn't really know if it's in the rear, or in the transmission, or exactly what, but we both know that that kind of repair oftentimes people don't enjoy it because it's kind of so precise of a repair you've got to do.

(Joel)>> It's got to be frustrating for you to put this much time and effort into a car and get it this far, and then it just kinda lays down on you.

(Tommy)>> The goal with these things, as we all know, often times this is the one piece that gives you sanity. Then you do all that work and effort and it can lead you to insanity because its not quite done yet. To fix this one issue with it basically would be finishing the car.

(Joel)>> Did he say if it was a Muncie?

(Tommy)>> He didn't really say. So we'll have to try to crawl up under this thing, or basically just get it back to the shop and see what it is we're working with. It's not crazy loud right now. It's a little noisy from kind of an old car noise, but we'll probably have to get it stretched out on a four lane to see what it is. [ engine revving ]

(Tommy)>> Yeah it's in the transmission.

(Joel)>> You can hear it. And it's not like the M-22 Rock Crusher whine either. It's a little more obnoxious, like there's an issue.

(Tommy)>> But with this thing, when it goes to dead third and its like brrrr, that tells you there's something going on at third because otherwise with speed in it if you're at 29 at the top of second, and shift into third, and you climb 30 instantly it goes brrrr, I bet it's not because you hit 30 mile an hour. It's because you went into third gear.

(Joel)>> We were living every muscle car guy's fantasy cruising around in this old Camaro, but that dream quickly shifted into a nightmare when we dropped it into third gear. We're gonna have to open her up to see what exactly is going on. Luckily RockAuto is a one stop shop where we can get everything we're gonna need to dig into the transmission and get her going again.

(Tommy)>> When you're taking apart a transmission it helps to be in what you could call a sterile environment. So we made the call to just load this thing up and haul it back to the shop.

(Joel)>> Obviously when it comes to transmission issues the more miles you put on the higher the risk of making things worse. So, it's a good thing we brought the enclosed trailer. [ engine rumbling ]

(Joel)>> We'll also make sure everything's strapped down nice and tight. Don't want to have to add paint and body work to the list of issues. [ Music ]

Coming up, we play doctor and open up a Saginaw four speed for a transplant.

(Tommy)>> Well we got our four speed out of the Camaro and up here on the table. The first thing we're gonna do is snatch this drain plug out of the bottom of it. You know there's nothing quite like the smell of old 90 weight gear oil. [ Music ] Well to find some metal on a magnet on a drain plug is kind of normal. We're gonna go ahead and remove this side cover to get the disassembly started. [ ratchet clicking ] [ Music ]

(Tommy)>> Good news is we don't have any broken or chipped teeth. So probably just got a bearing going out in it. So go ahead and get this thing apart, and put all these pieces on the table. [ Music ]

Well I'm unboxing the rebuild kit that we got from RockAuto. Whenever you pick up one of these for a standard shift transmission there's usually not a whole lot in it. You've got a couple of synchronizers, some snap rings, thrush washers, bearings, roller bearings, and some seals. Now after getting this thing cleaned up we did find a couple of problems. One of them is our wave washer was broken, chipped up, and extremely fatigued. Second, both bearings are very noisy. You spin them and they make a whole lot of racket. I can feel the vibrations through my fingers. Where if you take these new ones and give them a spin smooth as butter. Now it's time for the fun to begin. [ Music ] Now we're ready to get into what I find is the tricky part of a transmission rebuild, and that is loading the needle bearings into the countershaft, or your input shaft. Now what goes on here is you take these little pieces here and you have to stack them up around the inside of this bore. How that gets even more tricky is you've got to take this, slide it off into that case, and keep all them things from falling out. Cool little tip for you is to use a wooden dowel and some grease. You want to be generous with the grease here because we're trying to keep these little bearings in place. This old school Saginaw is just one of the many transmissions that General Motors offered. And no matter what make or model you're working with you may want to check out RockAuto to repair your application. Little more dab of grease in there to hold that washer. Now let's see if we can get that dude in there. Alright, let's see. [ Music ]

Once you get that in place and knock the dowel rod through you just need to put everything back in its home and get it under the Camaro.

(Joel)>> Driveline's tight, shifter linkage is hooked back up, fresh gear oil. Let's get this thing back on the road. RockAuto has a lot more than just parts to fix your transmission. They've got pretty much anything you might need to get your ride back out on the road. For now it's time to test drive our Camaro and see if we solved the problem. Talk about a night and day difference. After swapping out the old bearings our new RockAuto transmission rebuild kit has this car sounding as good as it looks.

(Tommy)>> You never know what you're gonna get into when you open up a manual transmission. Luckily the repair wasn't that difficult, and with the help of RockAuto we pulled off another successful Driveway Rescue. I'm pretty happy how this one turned out.

(Joel)>> Do we really have to give it back to him today?

(Tommy)>> I told him we wouldn't be done with it until tomorrow.

Show Full Transcript

(Joel)>> Today on Detroit Muscle we bust some rust and mend some dents on old Fat Stack.

(Tommy)>> Then we put on our capes and Driveway Rescue a Camaro from catastrophe. [ Music ] [ engines revving ] [ Music ]

(Tommy)>> Hey guys, if you're into throwing sparks, making noise with a grinder, and enjoy the smell of metal in the air you're gonna like what we're doing on Fat Stack today.

(Joel)>> We got our chassis looking like a million bucks, but now it's time to shift our focus over to the body. Sure, she's got a few bumps, bruises, and scars we need to address before it's all pretty again, but it's gonna take a whole lot more than that to scare us.

(Tommy)>> Paint and body work can eat up a lot of time, and it just makes sense why, because it's one of those type of jobs that the more time you spend on it, it allows you to keep making improvements and refine your appearance. So if you've got a project that's in need of some massaging on the body, or you need to take care of some rust, we're gonna show you a few tips and tricks on how to take care of these tasks. All the while with simple processes. [ Music ]

(Joel)>> Now it's no secret that rust in the rear quarter panel area is a common Achilles heel in these old vehicles, and if you've got a project at home that's roughly 25 years or older chances are you're gonna run into this issue. With old Fat Stack we actually got pretty lucky. The fact that this is the only problem area on the entire car is truly a blessing. A lot of that has to do with the big chrome trim piece that used to run along this bottom edge. What happens is eventually over time you get sand, and water, and dirt, all kinds of stuff trapped in between that panel and that trim piece and eventually it rots through. Luckily making this kind of repair isn't all that difficult or complicated, but can be a little intimidating to you guys that have never done it before. If you've got some basic air tools like a wire wheel , grinding stone, and a cutoff wheel you're already in good shape. If you've got a small mig welder like a 110 or a 140 that'll work just fine for this application. First things first, we need to cut the rusty metal out of this car, and there is a way that I like to map it out so that I'm not trimming off more than I need to. Using a roll of masking tape, lay the top edge in the middle of the body panel line. I like to use a marker to trace the bottom edge of the tape just in case it doesn't hold when cutting. [ saw buzzing ]

(Joel)>> Cut all the way across the bottom of the tape, and then use a grinding stone to weaken the spot welds. [ grinder buzzing ]

(Joel)>> You can also use a drill bit, or even a spot weld cutter. [ Music ] Once you've given everything a good once over you can yank the panel until it pops loose. [ Music ] Sometimes in life things don't always turn out as you originally planned. As you can see, we've got some extra corrosion on these inner braces that we need to repair. I've already took the liberty and built a couple of patch panels. We'll get all this nastiness cut out, weld these in, and then we can move on to the outer skin. [ saw buzzing ] [ Music ]

(Joel)>> Now some of you may be wondering why I'm not running any solid beads. If you don't spot weld it can become harder to control the heat of the metal, possibly resulting in warpage. Keep in mind that grinding can create just as much heat as welding. So as you're smooth out your welds be sure to skip around and not spend too much time in one area so that the heat can evenly disperse. [ Music ] [ welder crackling ] [ grinder buzzing ] [ Music ]

(Joel)>> Well guys we got our patch panels welded in. Still got a little bit of surface rust on this back part. I'm just gonna go ahead and rust treat that. Once that's cured we'll spray in some black epoxy primer and call this thing done. [ Music ] Epoxy primer is ideal for sealing out moisture. When it cures it has a thick outer shell that is non-absorbent, unlike self-etching primer, which is porous. Now you may be wondering why I've got an entire quarter panel skin sitting on the table when really all we need is this rear patch. Due to supply chain issues we couldn't find the piece that we needed, but our buddies over at RockAuto had this in stock and they sent it right over. The skin is constructed from high quality sheet metal and features the same dimensions as an original factory replacement. It even has the hole mount pre-cut for the side marker light. Its protective coating also prevents damage during shipping and future corrosion. To some of you it may seem like a waste that we're just cutting out a rear section and scrapping the rest, but this is one of those situations that I want you to consider that your time is your money, and the amount of hours spent building that panel is well worth the cost of a new skin. [ Music ] [ welder crackling ] [ Music ]

(Joel)>> Now if you want to tig weld this piece go right ahead. It's really all about personal preference and the tools you have at your disposal. However, using a mig on these plug welds will give you a sturdier hold in the long run, not to mention make the process much more efficient. [ welding crackling ]

(Joel)>> After your welds are in place you need to evenly smooth out the surface. Just don't get too aggressive with your grinding because you can weaken the structure. [ grinder buzzing ]

(Joel)>> I recommend a 36-grit roll lock because it gives the metal a gritty surface for the filler to latch on to, along with a nice, clean finish. Man oh man, what a difference a few hours of work makes. Doing patch panels can seem really tedious but the more time you spend on your metal work the less time you're gonna have to spend sanding on some filler. Coming up, we identify a couple of small problems.

(Tommy)>> Let's start off saying accidents happen, and usually what's left behind is a dent. Now sometimes they're significant, while others are barely noticeable at all. When you're looking to fix a dent there's several ways you can go about it. One of the main factors is can you get to the back side and push it out. If you can that makes all the difference. You can use hammers, picks, or even wooden blocks to whip it back into shape. But if not you're gonna have to go about things a little bit different. This is an old school dent removing tool, and how it works is you drill a hole here in the panel, screw this thing into it, slide the weight on the puller back and forth, and that will slowly start to pull that dent out. Then you will repeat this process by drilling multiple holes in there and continuing on and on until you get it to the desired shape. Problem with using this tool is it develops a whole other set of problems. That would be you've got a bunch of holes in your panel. So, I'm gonna ask you to hold off on using this thing. A better way is to use what's referred to as a stud gun. Now these have been around for quite a while, and they have multiple uses. To pull the dent it has these small draw pins that you weld to the panel. Then using their slide hammer that clamps to those pins you actuate the weight on it to pull out the dent just like that old school tool but without the holes. To get started we've got to skin that back to bare steel. [ grinder buzzing ]

(Tommy)>> I'm using a 50-grit sanding disc to make light work of stripping down this heavy Chevy. With our tool plugged up we're ready to drop in one of our pull pins and hit the trigger. This tool requires you to push the tip up against the body and to press it. This action completes the circuit for the welding process. [ Music ] That glowing tip you see before you is not a special effect. That metal is molten. [ Music ] Case is getting hot boys! [ Music ]

Obviously the more pins you put on the more points you can pull from, and it may take you a round or two to get this thing dialed in. I'm using this to actually see how deep that dent is, but with our pins in place we can start pulling. What we're trying to do is take this thing from concave and undo what happened. So you'll want to move to move things around slowly. You'll start to see the dent work itself outward as you start to move the metal. Also you don't want to get too eager and pull it out too far or else that will create a whole new problem. Let's check it man, let's check it! Our panel's looking good. Now we just need to remove the pins. You just simply clip them off and grind off the excess. [ Music ] Using a standard set of side cutters, you want to try to trim as close to the tip as possible. Otherwise, you're gonna removing the rest with a grinder. [ Music ] [ sander buzzing ]

(Tommy)>> I'm gonna step it up to 36 grit with the air sander to make sure I get everything nice and smooth. [ sander buzzing ] [ Music ]

(Tommy)>> Just don't over do it and keep the grinder moving to keep the heat low. [ Music ]

Up next, we hit the road and test drive an F-body fave!

(Joel)>> Sometimes we travel far and wide to find our next RockAuto Driveway Rescue. And it isn't always some rusty relic from a dusty barn. Sometimes the car is in near perfect condition, like this '73 Camaro.

(Tommy)>> If you saw this Detroit muscle pass you on the highway you would think that it's in mint condition, but sometimes though looks can be deceiving.

(Joel)>> We hit the trail knowing our buddies at RockAuto would have whatever we needed to help fix up this iconic piece of Detroit Muscle. [ Music ]

(Tommy)>> I feel like I'm lacking a little something back here for one of these things. I don't know what it is.

(Joel)>> These second gen Camaros, they've really come into their own in popularity. The aftermarket support's strong on them, and a lot of guys are building these cars up in really cool ways.

(Tommy)>> Just tooting around in this car right, pretty day like it is.

(Joel)>> Doesn't get much better, does it?

(Tommy)>> It don't suck, I can tell you that! [ Music ]

[ engine revving ]

(Tommy)>> Well the owner did a lot of work on the car, and one of the things that he's found out about the car was there's something wrong with the transmission, or the driveline in it, because once you get it up to speed it starts to make this whining noise. Kinda similar to that old rock crusher four speed sound. He didn't really know if it's in the rear, or in the transmission, or exactly what, but we both know that that kind of repair oftentimes people don't enjoy it because it's kind of so precise of a repair you've got to do.

(Joel)>> It's got to be frustrating for you to put this much time and effort into a car and get it this far, and then it just kinda lays down on you.

(Tommy)>> The goal with these things, as we all know, often times this is the one piece that gives you sanity. Then you do all that work and effort and it can lead you to insanity because its not quite done yet. To fix this one issue with it basically would be finishing the car.

(Joel)>> Did he say if it was a Muncie?

(Tommy)>> He didn't really say. So we'll have to try to crawl up under this thing, or basically just get it back to the shop and see what it is we're working with. It's not crazy loud right now. It's a little noisy from kind of an old car noise, but we'll probably have to get it stretched out on a four lane to see what it is. [ engine revving ]

(Tommy)>> Yeah it's in the transmission.

(Joel)>> You can hear it. And it's not like the M-22 Rock Crusher whine either. It's a little more obnoxious, like there's an issue.

(Tommy)>> But with this thing, when it goes to dead third and its like brrrr, that tells you there's something going on at third because otherwise with speed in it if you're at 29 at the top of second, and shift into third, and you climb 30 instantly it goes brrrr, I bet it's not because you hit 30 mile an hour. It's because you went into third gear.

(Joel)>> We were living every muscle car guy's fantasy cruising around in this old Camaro, but that dream quickly shifted into a nightmare when we dropped it into third gear. We're gonna have to open her up to see what exactly is going on. Luckily RockAuto is a one stop shop where we can get everything we're gonna need to dig into the transmission and get her going again.

(Tommy)>> When you're taking apart a transmission it helps to be in what you could call a sterile environment. So we made the call to just load this thing up and haul it back to the shop.

(Joel)>> Obviously when it comes to transmission issues the more miles you put on the higher the risk of making things worse. So, it's a good thing we brought the enclosed trailer. [ engine rumbling ]

(Joel)>> We'll also make sure everything's strapped down nice and tight. Don't want to have to add paint and body work to the list of issues. [ Music ]

Coming up, we play doctor and open up a Saginaw four speed for a transplant.

(Tommy)>> Well we got our four speed out of the Camaro and up here on the table. The first thing we're gonna do is snatch this drain plug out of the bottom of it. You know there's nothing quite like the smell of old 90 weight gear oil. [ Music ] Well to find some metal on a magnet on a drain plug is kind of normal. We're gonna go ahead and remove this side cover to get the disassembly started. [ ratchet clicking ] [ Music ]

(Tommy)>> Good news is we don't have any broken or chipped teeth. So probably just got a bearing going out in it. So go ahead and get this thing apart, and put all these pieces on the table. [ Music ]

Well I'm unboxing the rebuild kit that we got from RockAuto. Whenever you pick up one of these for a standard shift transmission there's usually not a whole lot in it. You've got a couple of synchronizers, some snap rings, thrush washers, bearings, roller bearings, and some seals. Now after getting this thing cleaned up we did find a couple of problems. One of them is our wave washer was broken, chipped up, and extremely fatigued. Second, both bearings are very noisy. You spin them and they make a whole lot of racket. I can feel the vibrations through my fingers. Where if you take these new ones and give them a spin smooth as butter. Now it's time for the fun to begin. [ Music ] Now we're ready to get into what I find is the tricky part of a transmission rebuild, and that is loading the needle bearings into the countershaft, or your input shaft. Now what goes on here is you take these little pieces here and you have to stack them up around the inside of this bore. How that gets even more tricky is you've got to take this, slide it off into that case, and keep all them things from falling out. Cool little tip for you is to use a wooden dowel and some grease. You want to be generous with the grease here because we're trying to keep these little bearings in place. This old school Saginaw is just one of the many transmissions that General Motors offered. And no matter what make or model you're working with you may want to check out RockAuto to repair your application. Little more dab of grease in there to hold that washer. Now let's see if we can get that dude in there. Alright, let's see. [ Music ]

Once you get that in place and knock the dowel rod through you just need to put everything back in its home and get it under the Camaro.

(Joel)>> Driveline's tight, shifter linkage is hooked back up, fresh gear oil. Let's get this thing back on the road. RockAuto has a lot more than just parts to fix your transmission. They've got pretty much anything you might need to get your ride back out on the road. For now it's time to test drive our Camaro and see if we solved the problem. Talk about a night and day difference. After swapping out the old bearings our new RockAuto transmission rebuild kit has this car sounding as good as it looks.

(Tommy)>> You never know what you're gonna get into when you open up a manual transmission. Luckily the repair wasn't that difficult, and with the help of RockAuto we pulled off another successful Driveway Rescue. I'm pretty happy how this one turned out.

(Joel)>> Do we really have to give it back to him today?

(Tommy)>> I told him we wouldn't be done with it until tomorrow.