More Hard Charger Episodes

Detroit Muscle Featured Projects

Detroit Muscle Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Lincoln Electric

Lincoln Electric is the Official Welding Supplier to Detroit Muscle

Matco Tools

MATCO Tools are the Official Tool Supplier to Detroit Muscle

The Industrial Depot

Tools, Hardware, and Shop Supplies

Episode Transcript

(Narrator)>> Today on Detroit Muscle we start assembling the front end of our Hellcat powered '69 Dodge Charger, getting it one step closer to hitting the open road. Plus we head out to rescue a viewer's third gen Camaro from sitting in the garage and get it back on the street.

(Marc)>> Hey everybody welcome to Detroit Muscle. This is a big day for us because we are super excited to get this beautiful Mopar back in the shop. It's our 707 horse Hellcat powered 1969 Dodge Charger. Not only does it have that modern drivetrain but it's got updated suspension with coil overs as well as some big fancy wheels and tires, and a slick black paint job. Basically all the things that dreams are made of.

(Tommy)>> Now it's taken us a really long time to get this car to where it's at now, and we still have a ways to go, but what we're planning to do today is installing one of the most recognizable features of a '69 Charger and that would be its face.

(Marc)>> Now generally speaking you don't need to see the rest of the car to know what this thing came out of. This is the grill and headlight assembly for our '69 Charger. This is actually the one that we pulled out. Now we didn't fix it up because we knew most of this stuff was gonna need to be replaced at some point. The support brace is damaged and rusty. The grille, it's all dry rotted, and cracked, and damaged beyond repair, and the trim well it's seen better days. So basically what I'm trying to say is we can't put this nasty thing in that beautiful car.

(Tommy)>> So we went to Classic Industries for an all-new grille. It comes paint, ready to install. It has your center grille, both left and right extensions, and both headlight doors. Now all these cool parts install into a headlight and grille bracket support. Ours had been sucker punched years ago and was in really bad shape, and it had to be replaced. So I picked up a new one, sprayed on some black paint, and it's ready to go. Now with our old grille we're gonna have to reuse some of the mechanicals in it. So it's time for us to tear it apart and get dirty.

(Marc)>> Now what makes this grille and headlamp assembly so iconic and cool is also what makes it difficult to work on. You've got a lot going on here. You've got the main support that holds all of this together, the grille, the headlamps, and these headlamp doors here, and they're kind of a pain actually. There's a lot of moving parts back here. You've got this main bar that moves. You've got a vacuum pod that moves that as well. Now we're gonna retain some of this and throw the rest of it away, but we need to get it all torn down, get it cleaned up. [ air ratchet humming ]

(Marc)>> Some of these pieces are not remanufactured and hard to find. So we want to take our time and make sure we don't damage any of them in the process of disassembly.

Alright well that's it. We got all the parts we needed to get off of here to make a trip to the blaster. We'll get these parts blasted, get a coat of paint on them.

(Tommy)>> We've got all of our parts cleaned up and we're ready to start spraying them. The first thing we're gonna do is apply some Dupli-Color self-etching primer. And then after that we're gonna spray on some color. Now you could paint these semi-gloss black like a lot of people do, but I'm gonna swap it up a bit and give it a few different colors, and it's gonna add a whole lot of depth to our restoration. We're gonna spray on a few thin coats of primer onto our pieces. This self-etching primer is ideal for bare metal surfaces, and will give us a great base for our primary colors. [ aerosol can hissing ]

(Tommy)>> We'll use cast coat aluminum on the headlight buckets and switch to our case coat for the headlight cover actuator rods. Then I'll use some semi-gloss black on the actuator support bracket. [ aerosol can hissing ]

(Tommy)>> Hey hoss, I get this parts all detailed out, and they're dry and ready for you.

(Marc)>> They look good, thank you. Just in time cause I need these buckets.

(Tommy)>> Well you get busy.

(Marc)>> Alright, thanks. We'll start by installing the headlight buckets that Tommy painted as well as the new adjustor hardware, followed by the headlights and the bezels to tighten them down.

The new Charger emblem goes on next and we'll secure it with some screws. Now we can slide the grille into the support and bolt it together using the supplied hardware we got from Classic Industries.

I'll flip the headlamp support over and start putting our headlight assembly together. Starting with the headlight door actuator rod, followed by the actuator mounted bracket. We're gonna replace the old vacuum driven actuators with these electric ones. They bolt right into the factory location and are easy to install.

(Narrator)>> Coming up we start assembling the front of "Project Hard Charger", restoring it to its original glory.

(Marc)>> Hey folks welcome back. Well we're working on getting the grille assembly ready to go into our '69 Charger, and while you were gone we got the trim installed. So this thing is ready to go in the car.

(Tommy)>> Now we've been working on this thing for a long time and I can't wait to see what this piece looks like in there.

(Marc)>> Now with all this fresh paint we want to make sure we take it nice and easy to get it right the first time. We want to get all the bolts started by hand before we tighten any of them for good.

Alright well we got the grille all finished and installed. Everything's tight. Need to move on to the bumper now. We've got original bumper brackets all cleaned up and painted black. Just need to get them installed.

(Tommy)>> You handling it alright over there boss?

(Marc)>> Yeah just about. There's a lot in the way though. [ ratchet clicking ]

(Tommy)>> That's good enough. We're gonna leave these bolts a little loose so that we can make some adjustments before we tighten them down for the final time.

(Marc)>> Now it's time for the shiny stuff. Just look at that reflection.

Amazing what just a few pieces you put on does.

(Tommy)>> You ain't kidding. Once we got all the bumper bolts installed by hand we can make our adjustments and lock it down.

Careful this is shiny.

(Marc)>> I see that. Now it's time for the lower valence. We'll get the center bolted in loosely. Just like the grille support we want to install all the bolts before we tighten them down.

(Tommy)>> You ain't in a bind are you? [ ratchet clicking ]

(Tommy)>> There it is.

(Marc)>> Next we can get the bumperettes installed and they just bolt right in those factory holes.

That looks good.

(Tommy)>> One final thing is our front turn signals and 1

Well mister Marc you definitely do some pretty good work, and it looks like I'm gonna have be doing some work on this hood.

(Marc)>> Yeah I appreciate that, but now it looks like a '69 Charger, and that's the important part. I mean look how far it's come from just what we've done today.

(Tommy)>> Yeah with a little bit of paint, a few pieces of glass, and some interior we're gonna be riding in style.

(Marc)>> Oh I'm ready.

(Tommy)>> A lot of '80's and '90's era muscle cars had interior components that were trimmed out in leather, and as time goes on those leather components dry out, crack, and even fade. Restoring your old parts can be very expensive and finding good used ones is nearly impossible. Classic Industries offers a huge assortment of leather wrapped interior components for third and fourth gen Camaros, like steering wheels, horn caps, shifter knobs, and parking brake handles. Now you can get the interior of your interior of your '82 to '02 Camaro looking good again and it won't break the bank.

(Marc)>> You know here in the shop we use a lot of different tools. We've got hand tools like hammers and chisels, and screw drivers, sockets and ratchets, and wrenches, pliers, and things like that. We've got specific tools for the job, like body working tools, and we've got a bunch of cordless tools and even air tools, but there's one family of tools that we really don't show you that often and that is precision measuring tools, and the reason is that's for things like building an engine, or setting up a rear end, and we normally don't do stuff like that in here. So we really don't get a chance to show you. Well I've got an assortment here on the table. I'm gonna show you what they are and what they do. We've got a set of micrometers. We've got digital calipers, dial calipers, and dial indicator. Now if you don't have any in your box already this small selection of precision measuring tools would be a good place to start, and depending on what you're trying to measure that's gonna determine which one of these tools you're gonna grab. Let's start with the dial indicator. You've seen me use this on the show before. I used it to setup the rear end in our '69 Dodge Charger. This is called a dial indicator because it's got the dial, and as this rod moves up and down it moves the needle and it measures in thousandths of an inch. Let me show you how it works. Once you get your starting point you set it at zero. You can lock that in right here. Then as you move it the outside dial moves in thousandths of an inch and the inside dial measures in tenths of an inch, or hundred thousandths. So if we stop somewhere here. We'll say right there. That's 342 thousandths of an inch from where we started. Now this thing's got several adjustments so you can get it setup where you need it, and it has a magnetic base as well that can turn off and on. So you can stick it to a nice solid surface and get a proper measurement. This thing's great for measuring backlash in a rear end like when I set up our rear for our Charger, or measuring end play for a crankshaft if you're doing an engine build. Well the dial calipers are next and very similar to the way the dial indicator works, this dial right here shows you your measurements. The outside is measured in thousandths of an inch and the inside in millimeters. Now the way it works is you roll this out, these jaws open up. It'll measure outside diameter there or inside diameter here. Now the digital calipers work just like the dial calipers except that as the name suggests has this digital reading here. What's nice about this is you open it up, it shows you right on the screen how far you're moving in thousandths of an inch. Another cool thing about this is you push this button right here, switches back and forth between metric and standard. This is great if you're a novice because it's easier to read. These micrometers measure outside diameter but they do it a little more precisely with this knob, but there are several different types of micrometers that do different jobs and we're gonna have to talk about those another time.

(Narrator)>> Stick around and Marc and Tommy head out to look at a viewer's third gen Camaro, lending him a hand getting the car up and running.

(Marc)>> Hey folks welcome back. Well we do something around here called Driveway Rescue. That's where we find a viewer like you that needs some help getting your project back on track. We show up in this van full of tools and parts from our friends at Rock Auto dot com. And we get in there and turn wrenches with you to help get your ride one step closer to where you can enjoy it again, and that's what we're gonna do today. But first I want to introduce you to Tom with Rock Auto dot com. Tom thanks for coming out, and thanks for partnering with us on this. What made you want to get involved in Driveway Rescue?

(Tom)>> Well viewers see what you accomplish in people's driveways and hopefully it gets viewers to get enthusiastic about taking on the project that's maybe been sitting in their garage for a while.

(Marc)>> Yep, I've got one of those myself. I know a lot of viewers do too. We get a ton of submissions for these, and it's a lot of fun for us to get out and do this kind of thing.

(Tom)>> Yeah it emphasizes the variety of cars we have parts for. We have parts for the classics, daily drivers, and vehicles that are just old that people have an emotional attachment to, or they think it's going to be the future classic.

(Marc)>> Yeah, like a third gen Camaro, which is what all these parts are for. Tell us about this.

(Tom)>> Exactly, we have o-e brand parts, we have the famous brands you've known for years. Parts have improved a lot for an old car over the last 30 years, materials have improved. So you have a wide choice of replacements, and we're always adding new parts. We just recently added sun visors for cars back to the '50's. We have chemicals now for new cars that require very specific motor oil and transmission fluid, we have that. We have Dupli-Color touch up paint, Permatex gasket maker and thread locker. So yeah keep checking the Rock Auto dot com catalog. You say yeah I've got an old car. Well we're always adding parts for that old car.

(Marc)>> Awesome, well I need to get this stuff loaded cause Tommy and I need to get out and help this guy get his Camaro back on the road.

(Tom)>> Okay, I'll help you a little bit.

(Marc)>> Oh thanks. Well we got everything loaded in the van and we're on the road to check out this third gen Camaro, and I know Tommy you must be stoked about this.

(Tommy)>> Man I'm pretty jacked up as I usually am.

(Marc)>> I can tell.

(Tommy)>> But either way we had one of you guys write in and tell us about your ride, and he's got this third gen Camaro. It's got a tuned port in it and guess what? It ain't running right.

(Marc)>> And that's right, and those tuned ports often get swapped out for a single plane or dual plane intake and a four barrel carb because people have trouble with them, but that's not what we're gonna do today. We've got all the right parts to get this thing fixed the way it should be, and now all we need to do is get it in our hands, get that thing running.

(Tommy)>> You the proud owner of a Camaro?

(Josh)>> Yes sir.

(Tommy)>> Is that thing close by?

(Josh)>> We've got it right inside.

(Tommy)>> You mind us checking it out?

(Josh)>> Nah, come on in.

(Tommy)>> Looks like a beauty.

(Josh)>> There it is.

(Marc)>> Alright Josh, so what's going on with this thing man?

(Josh)>> Well I've had it for a couple of years, and I was working on it myself, and I've put several parts on it and just got to where I couldn't sink any more money into it because I didn't know exactly what was wrong with it.

(Tommy)>> Well I guess the first thing we need to do is fire it up and see if we can hear it run.

(Josh)>> Yeah we can get the battery hooked back up and we'll see what it'll do.

(Marc)>> Alright Josh, hit it. [ engine idling roughly ]

(Tommy)>> Almost sound like it's got a miss to it. Go ahead and cut it off.

(Josh)>> And that's kind of the problem we've been having.

(Marc)>> I've got a question for you.

(Josh)>> Yep.

(Marc)>> Did you put a throttle position sensor on this thing?

(Josh)>> Yeah.

(Marc)>> Did you calibrate it or adjust it?

(Josh)>> No, it run worse than what it's running right now when that got put on.

(Marc)>> Let's check that, make sure it's dialed in right and go from there.

(Josh)>> Alright, sounds good.

(Narrator)>> Don't go away. We'll see if Tommy and Marc can get this old Camaro's heart pumping again.

(Tommy)>> Hey welcome back. We're elbow deep into Josh's '86 Camaro trying to diagnose its malfunction.

(Marc)>> It's pretty close, four point four-five volts. We need to adjust it a little bit though. This TPS is on five volt reference and needs to be calibrated, and if you skip this step well it's gonna give you a lot of problems. So we'll loosen the bolts, hook our meter back up. Alright Josh turn the key on. Now adjust it for me Tommy. Wiggle it one way, whoa, easy, keeping going that way, keep going, stop, lock it down. That's pretty close. Just for fun let's try it again. [ engine idling rough ]

(Marc)>> I surely didn't fix it.

(Tommy)>> I'm curious what them plugs looks like. We need to get a plug out of this thing and kind of read them. If it was running all crazy like it could have fouled out a couple plugs, causing it to miss like it is, and that's an easy enough thing to check.

(Marc)>> So we'll grab our tune up components that we got from Rock Auto dot com and get busy on swapping out some plugs. Alright let's take a look at this plug right here. You can see on the threads here that it's wet but it looks like it was starting to burn off here. So we're not sure what it's gonna be but we'll definitely put a new set of plugs in it and go from there.

(Tommy)>> It's always a good idea to check the gap on your plugs. We're gonna set these to the factory specs and get them installed. Screw on cap.

(Marc)>> Alright well since the cap and rotor both look fine we got our new plugs in it cause they look bad. We're gonna get these new wires in place and then we're gonna give it a shot and see if we can find the root problem of what caused all this. Alright Josh, hit it. [ engine starting and idling ]

(Tommy)>> Well that definitely didn't fix it. I wonder if that IAC valve on it isn't bad because it's searching around as much as it is.

(Marc)>> It's a common problem. They stick. If we didn't have one I'd say clean it and put it back on there. Since we have one let's put it on there and see if that fixes it. While we're at it let's spray some of that mass air flow sensor cleaner through the maf just to rule that out too, or at least if that is a problem to help eliminate it. Let's do those two things and try it again. [ ratchet spinning ]

(Tommy)>> While he's busy with that I'm gonna give this thing a quick rinse. That should do it.

(Josh)>> This one doesn't move.

(Marc)>> Here you take that one and I'll take that one. Thanks! The IAC screws right into the throttle body and we can get it re-installed as well as the mass air flow sensor. Alright let's try that. Tommy go ahead and hit it. [ engine starting and revving ]

(Tommy)>> Oh yeah, that's way better than it was.

(Marc)>> Well that sounds like it fixed it. What do you think?

(Josh)>> I think it's about time to go out on the road. You ready to take a ride?

(Marc)>> No thanks, I got enough Camaro on me for one day. I think this looks like it's for you.

(Tommy)>> You need to move to the van man.

(Marc)>> Alright I got it.

(Tommy)>> You know it's like funny how cars like this are made for days like today.

(Josh)>> That's right.

(Tommy)>> Mid 80's, sunny!

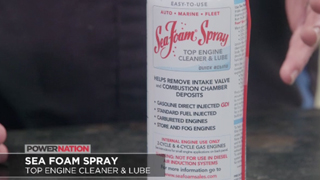

(Marc)>> You're familiar with Sea Foam motor treatment that you pour into your car's fuel tank and crank case to clean and protect your engine. Well they also off an easy to use spray can called Sea Foam Spray. Sea Foam Spray top engine cleaner and lube cleans and lubricates where fuel cleaners can't reach. Cleans intake valves and deposits in the combustion chamber, and lubricates throttle plates and bushings. This is important for direct injection engines and it's safe for all two and four stroke gas engines. They even offer a pack with one can of pour and one can of spray. Well that's all the time we have for today folks. So until next time you know you need to go to our website. Check it out Powernation TV dot com.

Show Full Transcript

(Marc)>> Hey everybody welcome to Detroit Muscle. This is a big day for us because we are super excited to get this beautiful Mopar back in the shop. It's our 707 horse Hellcat powered 1969 Dodge Charger. Not only does it have that modern drivetrain but it's got updated suspension with coil overs as well as some big fancy wheels and tires, and a slick black paint job. Basically all the things that dreams are made of.

(Tommy)>> Now it's taken us a really long time to get this car to where it's at now, and we still have a ways to go, but what we're planning to do today is installing one of the most recognizable features of a '69 Charger and that would be its face.

(Marc)>> Now generally speaking you don't need to see the rest of the car to know what this thing came out of. This is the grill and headlight assembly for our '69 Charger. This is actually the one that we pulled out. Now we didn't fix it up because we knew most of this stuff was gonna need to be replaced at some point. The support brace is damaged and rusty. The grille, it's all dry rotted, and cracked, and damaged beyond repair, and the trim well it's seen better days. So basically what I'm trying to say is we can't put this nasty thing in that beautiful car.

(Tommy)>> So we went to Classic Industries for an all-new grille. It comes paint, ready to install. It has your center grille, both left and right extensions, and both headlight doors. Now all these cool parts install into a headlight and grille bracket support. Ours had been sucker punched years ago and was in really bad shape, and it had to be replaced. So I picked up a new one, sprayed on some black paint, and it's ready to go. Now with our old grille we're gonna have to reuse some of the mechanicals in it. So it's time for us to tear it apart and get dirty.

(Marc)>> Now what makes this grille and headlamp assembly so iconic and cool is also what makes it difficult to work on. You've got a lot going on here. You've got the main support that holds all of this together, the grille, the headlamps, and these headlamp doors here, and they're kind of a pain actually. There's a lot of moving parts back here. You've got this main bar that moves. You've got a vacuum pod that moves that as well. Now we're gonna retain some of this and throw the rest of it away, but we need to get it all torn down, get it cleaned up. [ air ratchet humming ]

(Marc)>> Some of these pieces are not remanufactured and hard to find. So we want to take our time and make sure we don't damage any of them in the process of disassembly.

Alright well that's it. We got all the parts we needed to get off of here to make a trip to the blaster. We'll get these parts blasted, get a coat of paint on them.

(Tommy)>> We've got all of our parts cleaned up and we're ready to start spraying them. The first thing we're gonna do is apply some Dupli-Color self-etching primer. And then after that we're gonna spray on some color. Now you could paint these semi-gloss black like a lot of people do, but I'm gonna swap it up a bit and give it a few different colors, and it's gonna add a whole lot of depth to our restoration. We're gonna spray on a few thin coats of primer onto our pieces. This self-etching primer is ideal for bare metal surfaces, and will give us a great base for our primary colors. [ aerosol can hissing ]

(Tommy)>> We'll use cast coat aluminum on the headlight buckets and switch to our case coat for the headlight cover actuator rods. Then I'll use some semi-gloss black on the actuator support bracket. [ aerosol can hissing ]

(Tommy)>> Hey hoss, I get this parts all detailed out, and they're dry and ready for you.

(Marc)>> They look good, thank you. Just in time cause I need these buckets.

(Tommy)>> Well you get busy.

(Marc)>> Alright, thanks. We'll start by installing the headlight buckets that Tommy painted as well as the new adjustor hardware, followed by the headlights and the bezels to tighten them down.

The new Charger emblem goes on next and we'll secure it with some screws. Now we can slide the grille into the support and bolt it together using the supplied hardware we got from Classic Industries.

I'll flip the headlamp support over and start putting our headlight assembly together. Starting with the headlight door actuator rod, followed by the actuator mounted bracket. We're gonna replace the old vacuum driven actuators with these electric ones. They bolt right into the factory location and are easy to install.

(Narrator)>> Coming up we start assembling the front of "Project Hard Charger", restoring it to its original glory.

(Marc)>> Hey folks welcome back. Well we're working on getting the grille assembly ready to go into our '69 Charger, and while you were gone we got the trim installed. So this thing is ready to go in the car.

(Tommy)>> Now we've been working on this thing for a long time and I can't wait to see what this piece looks like in there.

(Marc)>> Now with all this fresh paint we want to make sure we take it nice and easy to get it right the first time. We want to get all the bolts started by hand before we tighten any of them for good.

Alright well we got the grille all finished and installed. Everything's tight. Need to move on to the bumper now. We've got original bumper brackets all cleaned up and painted black. Just need to get them installed.

(Tommy)>> You handling it alright over there boss?

(Marc)>> Yeah just about. There's a lot in the way though. [ ratchet clicking ]

(Tommy)>> That's good enough. We're gonna leave these bolts a little loose so that we can make some adjustments before we tighten them down for the final time.

(Marc)>> Now it's time for the shiny stuff. Just look at that reflection.

Amazing what just a few pieces you put on does.

(Tommy)>> You ain't kidding. Once we got all the bumper bolts installed by hand we can make our adjustments and lock it down.

Careful this is shiny.

(Marc)>> I see that. Now it's time for the lower valence. We'll get the center bolted in loosely. Just like the grille support we want to install all the bolts before we tighten them down.

(Tommy)>> You ain't in a bind are you? [ ratchet clicking ]

(Tommy)>> There it is.

(Marc)>> Next we can get the bumperettes installed and they just bolt right in those factory holes.

That looks good.

(Tommy)>> One final thing is our front turn signals and 1

Well mister Marc you definitely do some pretty good work, and it looks like I'm gonna have be doing some work on this hood.

(Marc)>> Yeah I appreciate that, but now it looks like a '69 Charger, and that's the important part. I mean look how far it's come from just what we've done today.

(Tommy)>> Yeah with a little bit of paint, a few pieces of glass, and some interior we're gonna be riding in style.

(Marc)>> Oh I'm ready.

(Tommy)>> A lot of '80's and '90's era muscle cars had interior components that were trimmed out in leather, and as time goes on those leather components dry out, crack, and even fade. Restoring your old parts can be very expensive and finding good used ones is nearly impossible. Classic Industries offers a huge assortment of leather wrapped interior components for third and fourth gen Camaros, like steering wheels, horn caps, shifter knobs, and parking brake handles. Now you can get the interior of your interior of your '82 to '02 Camaro looking good again and it won't break the bank.

(Marc)>> You know here in the shop we use a lot of different tools. We've got hand tools like hammers and chisels, and screw drivers, sockets and ratchets, and wrenches, pliers, and things like that. We've got specific tools for the job, like body working tools, and we've got a bunch of cordless tools and even air tools, but there's one family of tools that we really don't show you that often and that is precision measuring tools, and the reason is that's for things like building an engine, or setting up a rear end, and we normally don't do stuff like that in here. So we really don't get a chance to show you. Well I've got an assortment here on the table. I'm gonna show you what they are and what they do. We've got a set of micrometers. We've got digital calipers, dial calipers, and dial indicator. Now if you don't have any in your box already this small selection of precision measuring tools would be a good place to start, and depending on what you're trying to measure that's gonna determine which one of these tools you're gonna grab. Let's start with the dial indicator. You've seen me use this on the show before. I used it to setup the rear end in our '69 Dodge Charger. This is called a dial indicator because it's got the dial, and as this rod moves up and down it moves the needle and it measures in thousandths of an inch. Let me show you how it works. Once you get your starting point you set it at zero. You can lock that in right here. Then as you move it the outside dial moves in thousandths of an inch and the inside dial measures in tenths of an inch, or hundred thousandths. So if we stop somewhere here. We'll say right there. That's 342 thousandths of an inch from where we started. Now this thing's got several adjustments so you can get it setup where you need it, and it has a magnetic base as well that can turn off and on. So you can stick it to a nice solid surface and get a proper measurement. This thing's great for measuring backlash in a rear end like when I set up our rear for our Charger, or measuring end play for a crankshaft if you're doing an engine build. Well the dial calipers are next and very similar to the way the dial indicator works, this dial right here shows you your measurements. The outside is measured in thousandths of an inch and the inside in millimeters. Now the way it works is you roll this out, these jaws open up. It'll measure outside diameter there or inside diameter here. Now the digital calipers work just like the dial calipers except that as the name suggests has this digital reading here. What's nice about this is you open it up, it shows you right on the screen how far you're moving in thousandths of an inch. Another cool thing about this is you push this button right here, switches back and forth between metric and standard. This is great if you're a novice because it's easier to read. These micrometers measure outside diameter but they do it a little more precisely with this knob, but there are several different types of micrometers that do different jobs and we're gonna have to talk about those another time.

(Narrator)>> Stick around and Marc and Tommy head out to look at a viewer's third gen Camaro, lending him a hand getting the car up and running.

(Marc)>> Hey folks welcome back. Well we do something around here called Driveway Rescue. That's where we find a viewer like you that needs some help getting your project back on track. We show up in this van full of tools and parts from our friends at Rock Auto dot com. And we get in there and turn wrenches with you to help get your ride one step closer to where you can enjoy it again, and that's what we're gonna do today. But first I want to introduce you to Tom with Rock Auto dot com. Tom thanks for coming out, and thanks for partnering with us on this. What made you want to get involved in Driveway Rescue?

(Tom)>> Well viewers see what you accomplish in people's driveways and hopefully it gets viewers to get enthusiastic about taking on the project that's maybe been sitting in their garage for a while.

(Marc)>> Yep, I've got one of those myself. I know a lot of viewers do too. We get a ton of submissions for these, and it's a lot of fun for us to get out and do this kind of thing.

(Tom)>> Yeah it emphasizes the variety of cars we have parts for. We have parts for the classics, daily drivers, and vehicles that are just old that people have an emotional attachment to, or they think it's going to be the future classic.

(Marc)>> Yeah, like a third gen Camaro, which is what all these parts are for. Tell us about this.

(Tom)>> Exactly, we have o-e brand parts, we have the famous brands you've known for years. Parts have improved a lot for an old car over the last 30 years, materials have improved. So you have a wide choice of replacements, and we're always adding new parts. We just recently added sun visors for cars back to the '50's. We have chemicals now for new cars that require very specific motor oil and transmission fluid, we have that. We have Dupli-Color touch up paint, Permatex gasket maker and thread locker. So yeah keep checking the Rock Auto dot com catalog. You say yeah I've got an old car. Well we're always adding parts for that old car.

(Marc)>> Awesome, well I need to get this stuff loaded cause Tommy and I need to get out and help this guy get his Camaro back on the road.

(Tom)>> Okay, I'll help you a little bit.

(Marc)>> Oh thanks. Well we got everything loaded in the van and we're on the road to check out this third gen Camaro, and I know Tommy you must be stoked about this.

(Tommy)>> Man I'm pretty jacked up as I usually am.

(Marc)>> I can tell.

(Tommy)>> But either way we had one of you guys write in and tell us about your ride, and he's got this third gen Camaro. It's got a tuned port in it and guess what? It ain't running right.

(Marc)>> And that's right, and those tuned ports often get swapped out for a single plane or dual plane intake and a four barrel carb because people have trouble with them, but that's not what we're gonna do today. We've got all the right parts to get this thing fixed the way it should be, and now all we need to do is get it in our hands, get that thing running.

(Tommy)>> You the proud owner of a Camaro?

(Josh)>> Yes sir.

(Tommy)>> Is that thing close by?

(Josh)>> We've got it right inside.

(Tommy)>> You mind us checking it out?

(Josh)>> Nah, come on in.

(Tommy)>> Looks like a beauty.

(Josh)>> There it is.

(Marc)>> Alright Josh, so what's going on with this thing man?

(Josh)>> Well I've had it for a couple of years, and I was working on it myself, and I've put several parts on it and just got to where I couldn't sink any more money into it because I didn't know exactly what was wrong with it.

(Tommy)>> Well I guess the first thing we need to do is fire it up and see if we can hear it run.

(Josh)>> Yeah we can get the battery hooked back up and we'll see what it'll do.

(Marc)>> Alright Josh, hit it. [ engine idling roughly ]

(Tommy)>> Almost sound like it's got a miss to it. Go ahead and cut it off.

(Josh)>> And that's kind of the problem we've been having.

(Marc)>> I've got a question for you.

(Josh)>> Yep.

(Marc)>> Did you put a throttle position sensor on this thing?

(Josh)>> Yeah.

(Marc)>> Did you calibrate it or adjust it?

(Josh)>> No, it run worse than what it's running right now when that got put on.

(Marc)>> Let's check that, make sure it's dialed in right and go from there.

(Josh)>> Alright, sounds good.

(Narrator)>> Don't go away. We'll see if Tommy and Marc can get this old Camaro's heart pumping again.

(Tommy)>> Hey welcome back. We're elbow deep into Josh's '86 Camaro trying to diagnose its malfunction.

(Marc)>> It's pretty close, four point four-five volts. We need to adjust it a little bit though. This TPS is on five volt reference and needs to be calibrated, and if you skip this step well it's gonna give you a lot of problems. So we'll loosen the bolts, hook our meter back up. Alright Josh turn the key on. Now adjust it for me Tommy. Wiggle it one way, whoa, easy, keeping going that way, keep going, stop, lock it down. That's pretty close. Just for fun let's try it again. [ engine idling rough ]

(Marc)>> I surely didn't fix it.

(Tommy)>> I'm curious what them plugs looks like. We need to get a plug out of this thing and kind of read them. If it was running all crazy like it could have fouled out a couple plugs, causing it to miss like it is, and that's an easy enough thing to check.

(Marc)>> So we'll grab our tune up components that we got from Rock Auto dot com and get busy on swapping out some plugs. Alright let's take a look at this plug right here. You can see on the threads here that it's wet but it looks like it was starting to burn off here. So we're not sure what it's gonna be but we'll definitely put a new set of plugs in it and go from there.

(Tommy)>> It's always a good idea to check the gap on your plugs. We're gonna set these to the factory specs and get them installed. Screw on cap.

(Marc)>> Alright well since the cap and rotor both look fine we got our new plugs in it cause they look bad. We're gonna get these new wires in place and then we're gonna give it a shot and see if we can find the root problem of what caused all this. Alright Josh, hit it. [ engine starting and idling ]

(Tommy)>> Well that definitely didn't fix it. I wonder if that IAC valve on it isn't bad because it's searching around as much as it is.

(Marc)>> It's a common problem. They stick. If we didn't have one I'd say clean it and put it back on there. Since we have one let's put it on there and see if that fixes it. While we're at it let's spray some of that mass air flow sensor cleaner through the maf just to rule that out too, or at least if that is a problem to help eliminate it. Let's do those two things and try it again. [ ratchet spinning ]

(Tommy)>> While he's busy with that I'm gonna give this thing a quick rinse. That should do it.

(Josh)>> This one doesn't move.

(Marc)>> Here you take that one and I'll take that one. Thanks! The IAC screws right into the throttle body and we can get it re-installed as well as the mass air flow sensor. Alright let's try that. Tommy go ahead and hit it. [ engine starting and revving ]

(Tommy)>> Oh yeah, that's way better than it was.

(Marc)>> Well that sounds like it fixed it. What do you think?

(Josh)>> I think it's about time to go out on the road. You ready to take a ride?

(Marc)>> No thanks, I got enough Camaro on me for one day. I think this looks like it's for you.

(Tommy)>> You need to move to the van man.

(Marc)>> Alright I got it.

(Tommy)>> You know it's like funny how cars like this are made for days like today.

(Josh)>> That's right.

(Tommy)>> Mid 80's, sunny!

(Marc)>> You're familiar with Sea Foam motor treatment that you pour into your car's fuel tank and crank case to clean and protect your engine. Well they also off an easy to use spray can called Sea Foam Spray. Sea Foam Spray top engine cleaner and lube cleans and lubricates where fuel cleaners can't reach. Cleans intake valves and deposits in the combustion chamber, and lubricates throttle plates and bushings. This is important for direct injection engines and it's safe for all two and four stroke gas engines. They even offer a pack with one can of pour and one can of spray. Well that's all the time we have for today folks. So until next time you know you need to go to our website. Check it out Powernation TV dot com.