More Hard Charger Episodes

Detroit Muscle Featured Projects

Detroit Muscle Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

ARP

Cylinder Head Studs, Hex Nuts, Chrysler, Big Block, with Stock, Edelbrock RPM Heads, Kit

Edelbrock

Intake Manifold, 6-Pack, Dual Plane, Aluminum, Natural, Mopar, RB Big Block, 413, 426, 440, Each

Edelbrock

Top End Engine Kit, Power Package, Intake, Cylinder Heads, Cam, Timing Chain, Mopar, 440, Kit

Federal-Mogul Corporation

Engine Rebuild, Forged Flat, 4.350 in. Bore, Standard Rod, Standard Main, Dodge, Chrysler, Plymouth, 440, Kit

Harland Sharp

Rocker Arms, Shaft Mount, 1.5 Ratio, Aluminum, Roller Rockers, Chrysler, Big Block, B/RB, Kit

Automotive Workwear

The Official Workwear of Detroit Muscle

Automotive Workwear

Official Workwear Of Detroit Muscle

Shacklett Automotive Machine

Family-owned and operated machine shop repairs cylinder heads, engines and motors; performance work and dyno testing available.

The Industrial Depot

INDUSTRIAL DEPOT - Fasteners, Hardware, and Shop Supplies

Episode Transcript

(NARRATOR)>> TODAY ON DETROIT MUSCLE WE'RE GONNA GO ALL THE WAY ON A MOTOR REBUILD FOR OUR BIG BLOCK DODGE CHARGER. AT FIRST IT WAS A QUEST FOR A LITTLE MORE POWER BUT AFTER WE FIND A FEW GREMLINS IN THERE, THEN THERE'S NO NEED TO HOLD BACK. FROM THE CRANK TO THE CARB, OR SHOULD WE SAY CARBS?

(MARC)>> HEY GUYS, WELCOME TO DETROIT MUSCLE. TODAY WE ARE CONTINUING THE WORK ON OUR '69 DODGE CHARGER PROJECT. NOW I KNOW IT MAY NOT LOOK LIKE MUCH NOW BUT IT IS A WORK IN PROGRESS, AND WHEN IT'S ALL SAID AND DONE IT'S GONNA BE ONE COOL RIDE.

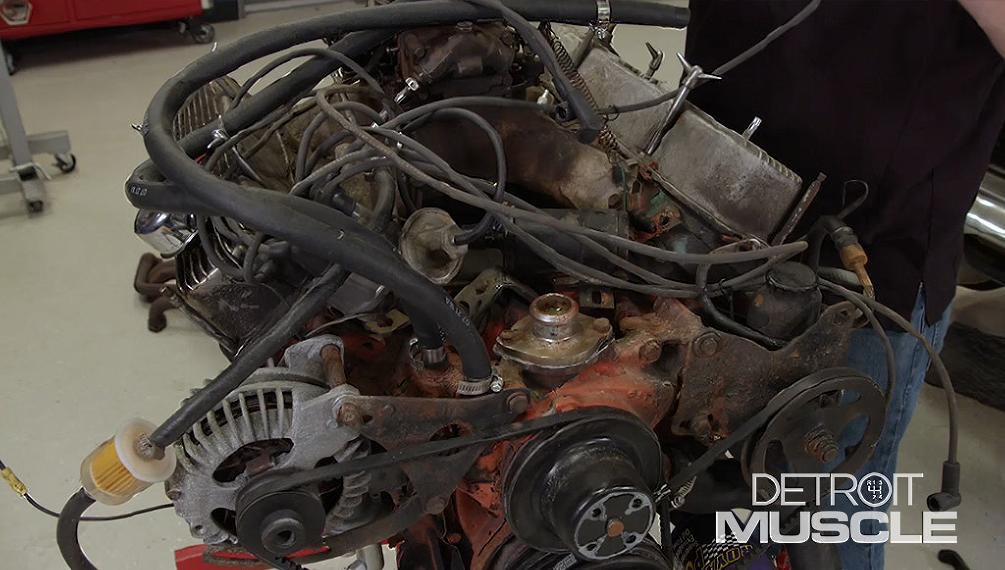

(TOMMY)>> WE WENT AHEAD AND SNATCHED THE ENGINE OUT AND THIS IS GONNA BE OUR TASK FOR THE DAY. WAKING UP AND REBEAUTIFYING THIS BIG OLE HUNK OF GREASY METAL, AND FOR THOSE OF Y'ALL WHO ARE JUST JOINING US THIS IS A LITTLE HISTORY LESSON FOR YOU. WE PICKED UP OUR '69 CHARGER IN ALABAMA, AND SO FAR SHE'S HAD SOME SHEET METAL SWAPPED OUT ALONG WITH A TOP TO BOTTOM REBUILD OF THAT FOUR SPEED GEAR BOX SO THAT IT CAN HOLD UP TO SOME ENGINE UPGRADES.

(MARC)>> NOW WHAT WE WANT TO DO TODAY IS ADD A BIT MORE POWER TO THIS OLD MOPAR BY INSTALLING A NEW TOP END KIT. THE RIGHT COMBINATION OF PROPERLY MATCHED COMPONENTS COULD REALLY DO THIS THING A LOT OF GOOD. IT WASN'T THAT IT RAN BAD BEFORE. IT WAS JUST THAT IT DIDN'T HAVE THAT LOW END GRUNT THAT WE THOUGHT A 440 CUBIC INCH ENGINE SHOULD HAVE.

(TOMMY)>> LOOKING AT THIS ENGINE I BET IT'S GONNA BE A PERFECT EXAMPLE OF A LOT OF MISMATCHED COMPONENTS. THIS INTAKE ON THIS THING HAS A POWER BAND OF ABOUT 3,000 TO 7,800 RPM, AND I'M HERE TO TELL YOU THAT THE REST OF THIS ENGINE DIDN'T SOUND LIKE IT NEEDED THAT BIG OF AN INTAKE, BUT THAT'S OKAY. WE'RE GONNA GO AHEAD AND TEAR IT DOWN TO SEE EXACTLY WHAT WE'RE WORKING WITH.

BEFORE CRACKING IT OPEN IT'S A GOOD IDEA TO BLOW AWAY ANY OF THAT GARBAGE THAT COULD FALL INTO THE ENGINE. WE'LL START BY PULLING THE CARB OFF OF IT, ALONG WITH THE COIL. NEXT UP IS THE INTAKE. THE DISTRIBUTOR CAN COME OUT, AND LATER WE'LL PROBABLY BE REPLACING THAT WITH A NEWER ONE. WE'LL ALSO HAVE TO GET THE FRONT DRIVE ASSEMBLY KNOCKED OFF HERE, AND THAT'S GONNA INCLUDE THE WATER PUMP.

THE CRANK PULLEY COMES OFF WITH A FEW BOLTS...

...AND THEN A PULLER WILL REMOVE THE BALANCER FOR US.

NOW LET'S GET THIS TIMING COVER OFF AND TAKE A LOOK AT THE CHAIN.

YEAH, YOU COULD SAY IT NEEDED A TIMING CHAIN.

TIME TO GET THE VALVE COVERS OFF, AND WE'LL POP OFF THIS VALLEY PAN WHILE WE'RE AT IT.

DANG, PRETTY CLEAN! ROCKER RAILS, WHICH ARE KIND OF A MOPAR SIGNATURE THING, WILL BE THE NEXT THING TO GO, ALONG WITH THE PUSH RODS. AFTER GETTING THE TINS AND THE INTAKE OFF OF THIS THING WE CAN SEE THE INSIDE OF THE ENGINE, AND IT'S ACTUALLY RELATIVELY CLEAN. THE PROBLEM THAT WE DO SEE IS SOMEONE HAS PAINTED THE INSIDE OF HERE. THIS STUFF IS ACTUALLY STARTING TO COME OFF, AND THAT'S WHAT YOU DON'T WANT CAUSE THAT'S GONNA CLOG SOMETHING UP, AND THAT CAN LEAD TO A WHOLE MESS OF PROBLEMS. ONE OF THOSE IS OIL STARVATION, AND YOU DON'T WANT THAT FOR SURE. WE'RE GONNA GO AHEAD AND TEAR THIS THING DOWN, SEE WHAT ELSE WE'RE WORKING WITH.

(MARC)>> WELL WE'VE GOT SOME BAD NEWS. AFTER GETTING THE CYLINDER HEADS OFF WE FOUND ANOTHER PROBLEM. SO WE'VE GOT THE PAINT PEELING ISSUE, STRIKE NUMBER ONE, AND THEN WE CAN TELL HERE INSIDE THE CYLINDER WALL IT'S REALLY WORN. IT'S A GOOD SIGN THAT IT'S BEEN A LONG TIME SINCE THIS THING'S BEEN REBUILT, AND IT'S PRETTY MUCH USED UP. ANOTHER PROBLEM IS THIS TIMING CHAIN, ANOTHER GOOD SIGN THAT THIS THING'S WORN OUT AND NEEDS TO BE REBUILT. SO WE'RE NOT GONNA TAKE IT ANY FARTHER NOW. WE'RE JUST GONNA SEND THIS THING OUT TO A MACHINE SHOP TO HAVE IT REBUILT.

ONCE WE GET THAT BLOCK EMPTIED OUT WE'RE HEADING TO NASHVILLE, TO SEE SHACKLETT AUTO MACHINE. THEY DO SOME MACHINING FOR ENGINE POWER. SO OUR 440 IS IN GOOD HANDS.

NORMALLY THE FIRST STEP WOULD BE TO GET EVERYTHING ALL CLEANED UP, ESPECIALLY AN OLD GREASY ENGINE LIKE OURS, BUT SINCE WE'RE HERE WE ASKED JOHN TO GO AHEAD AND DO US A HUGE FAVOR AND DO THE BORING PROCESS FIRST, AND THAT'S GONNA ALLOW US TO GO AHEAD AND ORDER THE PISTONS THAT WE NEED BECAUSE WE'RE NOT SURE WHICH SIZE WE NEED YET, AND IT'S ALSO GONNA ALLOW US TO SEE HOW THE PROCESS WORKS.

(TOMMY)>> WITH THE MAIN CAPS PULLED OFF, SHE'S READY TO GO ONTO THE BORING MACHINE.

THIS DEVICE CUTS METAL OFF THE CYLINDER WALLS, WHICH IS GONNA DO TWO THINGS. IMPROVE THE CONSISTENCY OF THE CYLINDER SURFACE, AND GIVE US MORE DISPLACEMENT.

(JOHN)>> ALL RIGHT, WE'VE GOT THE FIRST HOLE BORED 30 OVER. WE'LL CHECK IT HERE WITH THE DIAL BORE GAUGE. WE'VE GOT TWO AND HALF THOUSANDTHS TO HONE OUT TO GET TO 30 OVER. SO AT THIS POINT WE'RE GONNA CONTINUE BORING THE OTHER SEVEN CYLINDERS AND FINISH IT UP.

(MARC)>> THIS IS GOING TO CHANGE OUR CUBIC INCH DISPLACEMENT FROM 440 TO ABOUT 446. NOW THAT MAY NOT BE A HUGE LEAP BUT WE'RE NOT BUILDING A MONSTER HERE EITHER.

(TOMMY)>> WELL THEY GOT OUR ENGINE ALL PUNCHED OUT, AND THE NEXT STEP IS REMOVING A FEW OF THESE CAM BEARINGS, THE PIPE LUGS, AND THE FREEZE PLUGS. THEN THEY'RE GONNA SEND IT BACK TO THE FURNACE AND COOK IT AT 750 DEGREES FOR FOUR HOURS.

(MARC)>> AND AFTER IT COMES OUT OF THE FURNACE OUR BLOCK IS GONNA LOOK LIKE THIS ONE HERE. IT'S KINDA RUSTY AND DIRTY LOOKING, AND IT'S FULL OF THIS POWDER HERE AND THAT'S BECAUSE THAT FURNACE TURNS EVERYTHING TO THIS ASH. ALL THE GASKET MATERIAL, PAINT, OIL, AND ANY OTHER IMPURITIES. SO THERE NEEDS TO BE ONE MORE PROCESS BEFORE THAT THING LOOKS REALLY NICE, AND THAT'S GONNA BE THE TUMBLER. AFTER ABOUT 10 MINUTES IN THE TUMBLER IT COMES OUT LOOKING LIKE THIS. THIS IS ANOTHER BIG BLOCK MOPAR THAT JOHN'S DOING FOR ONE OF HIS OTHER CUSTOMERS AND OURS IS GONNA LOOK LIKE THIS IN NO TIME.

(NARRATOR)>> WELL SHE'S MACHINED DOWN AND CLEANED UP. SO WHAT'S GONNA MAKE OUR MOTOR WORK? UP AHEAD WE BEGIN THE REBUILD WITH THE ROTATING ASSEMBLY. THEN LATER ON SEE WHAT KIND OF BUMP STICK, HEADS, AND OTHER GOODIES WE'RE GONNA THROW AT HER.

(MARC)>> HEY WE'RE BACK FROM THE ENGINE SHOP, AND I KNOW IT DOESN'T LOOK LIKE IT BUT THIS IS ACTUALLY THE BLOCK THAT WE SENT OVER TO SHACKLETT'S TO GET CLEANED UP. ALL THE MACHINING PROCESSES ARE DONE AND IT'S READY FOR ASSEMBLY, AND WHEN WE GOT IT BACK HERE WE PUT A COUPLE OF COATS OF OE STYLE PAINT ON IT TO PROTECT IT. NOW SINCE WE HAD THOSE CYLINDERS BORED OUT WE NEEDED NEW PISTONS. SO WE WENT TO SUMMIT RACING FOR THESE 30 OVER PISTONS, BUT THEY ALSO CAME WITH A FULL REBUILD KIT. NEW PISTONS NEED NEW RINGS. WE ALSO GOT CAM BEARINGS, ROD BEARINGS, AND MAIN BEARINGS. THE KIT ALSO COMES WITH NEW FREEZE PLUGS AND PIPE PLUGS FOR THE BLOCK. NOW AS FOR THE REST OF OUR ROTATING ASSEMBLY THE RODS ARE ACTUALLY IN GOOD SHAPE BUT THE CRANK SHAFT WE FOUND OUT HAD BEEN MACHINED BEFORE AND IT NEEDED IT AGAIN. IT WAS PROBABLY CLOSE TO ITS TOLERANCE. SO WE DECIDED TO REPLACE IT, AND THANKFULLY THE GUYS DOWN IN ENGINE POWER HAD THIS STOCK 440 CRANK, AND IT HAD NEVER BEEN MACHINED. SO WE TOOK IT DOWN THERE TO SHACKLETT'S AND THEY TOOK A LOOK AT IT, SAID IT WAS IN GOOD SHAPE. SO ALL THEY DID WAS POLISH ALL THE BEARING JOURNALS. IT'S READY TO GO. WE'LL START OUR REBUILD BY REPLACING THE FREEZE PLUGS THAT WERE REMOVED AT THE MACHINE SHOP, AND WE'LL SLIDE THE NEW BEARINGS INTO THE MAIN CAPS.

THESE HAVE TO BE PREINSTALLED ON OUR REWORKED BLOCK, AND THEN TORQUED TO SPEC. [ hammer tapping ]

(MARC)>> WE'LL DO THIS SO THAT WE CAN CHECK THE CLEARANCE ON THE CRANK JOURNALS AND MAKE SURE THAT EVERYTHING IS WITHIN TOLERANCE. FIRST WE'LL MEASURE THE DIAMETER ON THE CRANK. ALL RIGHT, WE'RE JUST GONNA CHECK FOR MAIN BEARING CLEARANCE HERE BUT WE'RE GONNA GO FOR THE LOWEST NUMBER HERE, WHICH IS TWO THOUSANDTHS. SO WE'VE GOT TWO THOUSANDTHS CLEARANCE, THAT'S GOOD! WE'LL USE SOME ROYAL PURPLE MAX TOUGH ASSEMBLY LUBE ON THESE MAIN BEARINGS. THEN WE CAN STUFF THAT CRANK INTO OUR OLD BIG BLOCK.

SOME MORE MAX TOUGH WILL GET OUR CAPS READY. THEN WE CAN BEGIN INSTALLATION.

WE'LL WRAP THIS PART UP WITH THE REAR SEAL AND GET IT CINCHED DOWN. WELL WE'RE JUST ABOUT READY TO INSTALL OUR RINGS ONTO OUR PISTONS HERE SO WE CAN INSTALL OUR PISTON AND ROD ASSEMBLIES INTO THE BLOCK. A LOT OF YOU AT HOME HAVE SEEN THESE RINGS BEFORE, BUT EACH RING HAS A SPECIFIC JOB. THESE THREE HERE WORK TOGETHER AND THEY ARE THE OIL RINGS. THEY'RE AT THE BOTTOM OF THE PISTON NEAR THE SKIRT, AND THEY SWEEP ALL THE OIL OFF OF THE CYLINDER WALLS AND KEEP IT DOWN IN THE CRANK CASE. THESE TWO ARE THE COMPRESSION RINGS, AND THERE'S A LOWER AND AN UPPER, AND THEY EACH HAVE A TAPERED EDGE, AND THERE'S A LITTLE DOT HERE THAT TELLS YOU WHERE THEY'RE ORIENTED.

(NARRATOR)>> UP NEXT WE GET TO SEE THE SHINY BITS THAT ARE GONNA HELP OUR 440 MAKE MORE POWER. THEN WE'RE GONNA REFURB THOSE OLD VALVE COVERS.

(MARC)>> WELL WE'VE GOT EVERYTHING TORQUED DOWN NOW AND OUR SHORT BLOCK IS COMPLETE, AND WE'RE BACK TO WHERE WE WERE WHEN WE DECIDED WE NEEDED TO REBUILD THIS THING. READY TO MOVE ON TO THE NEXT STEP. WE WENT TO EDELBROCK FOR THIS COMPLETE TOP END KIT, WHICH COMES WITH A PAIR OF ESTREET HEADS, A CAM, LIFTERS, TIMING SET, A WATER PUMP, AND ALL THE GASKETS TO GET IT INSTALLED. THESE ALUMINUM CYLINDER HEADS HAVE 210cc INTAKE RUNNERS AS WELL AS 214 INTAKE VALVES AND 181 EXHAUST VALVES. THE COMBUSTION CHAMBERS ARE 75cc, WHICH IS GONNA BUMP UP OUR COMPRESSION RATIO FROM EIGHTZERO, WHICH IS STOCK, TO AROUND NINE POINT TWO TO ONE. THAT'S GONNA INCREASE DRIVABILITY AS WELL AS PERFORMANCE, BUT IT'S GONNA BE SAFE ENOUGH TO DRIVE AROUND ON PUMP GAS. THIS HYDRAULIC FLAT TAPPET CAM SHAFT IS FROM EDELBROCK'S RPM SERIES. IT'S DESIGNED SPECIFICALLY FOR HIGH PERFORMANCE STREET APPLICATIONS, AND HAS A 1,500 TO 6,500 RPM RANGE, AND THE FIRST THING WE'RE GONNA INSTALL IS GONNA BE THAT BUMP STICK.

ON THE JOURNALS WE'LL USE SOME ROYAL PURPLE MAX TOUGH FOR LUBE, BUT ON THE LOBES WE'LL USE THE BREAK IN COMPOUND THAT EDELBROCK SENT US WITH THE CAM.

WITH THE CAM IN WE CAN PLUG IN THE NEW TIMING SET. A BIG IMPROVEMENT FROM THAT SLOPPY ONE THAT WAS IN IT.

NEXT UP IS THE LIFTERS, WHICH HAVE BEEN SOAKING IN OIL TO PRIME THEM UP. LOOKS LIKE WE'RE AT A GOOD SPOT TO GET THIS THING READY FOR HEADS.

NOW INSTEAD OF USING REGULAR OLD HEAD BOLTS ON THIS WE'VE DECIDED TO GO WITH THESE ARP HEAD STUDS, AND THERE'S A FEW REASONS FOR THAT. THEY ARE COLD FORGED, AND THEY'RE CHROMOLY, AND THEY'RE BUILT TO WITHSTAND 220,000 PSI. IF YOU GO AHEAD AND THREAD A COUPLE OF THEM IN THE BLOCK THAT ALLOWS YOU TO SLIDE ON THE HEAD A LITTLE EASIER AND USE THEM AS ALIGNMENT PINS, AND ALSO IF WE DECIDE TO UPGRADE THIS MOTOR LATER ON THEY'RE REUSABLE. WE'VE SWITCHED TO CUP STYLE PUSH RODS, AND WE'LL LUBE THEM UP ALONG WITH THE STEMS ON OUR VALVES. THE REASON FOR THE CUP STYLE RODS IS WE GOT THIS SET OF HARLAN SHARP ADJUSTABLE ROLLER ROCKERS FROM SUMMIT RACING. THESE ROLLER TIP ROCKERS ARE COOL BECAUSE THEY'RE GONNA FREE UP A LITTLE BIT OF POWER. WE'LL ADJUST THE LASH ON THESE, THEN MOVE ALONG. NEXT UP IS THE VALLEY PAN.

NOW THE ICING ON THE CAKE ON OUR 440 IS GONNA BE THIS SIX PACK INTAKE MANIFOLD THAT WE GOT FROM EDELBROCK. NOW WHAT'S REALLY COOL ABOUT THIS IS EVEN THOUGH OUR '69 CHARGER WAS NEVER EQUIPPED WITH A 440 SIX PACK OURS IS GONNA HAVE ONE.

(MARC)>> ONE MORE THING WE WANT TO DO FOR OUR 440 HERE BEFORE WE WRAP IT UP IS THESE VALVE COVERS. NOW THESE ARE THE ONES WE TOOK OFF OF THE ENGINE BEFORE, AND THEY'VE SEEN BETTER DAYS. THEY'RE A LITTLE DIRTY, AND DINGY LOOKING, BUT STRUCTURALLY THEY'RE REALLY GOOD. SO WE WANT TO CLEAN THEM UP, AND YOU KNOW, BREATHE SOME NEW LIFE INTO THEM. FIRST THINGS FIRST, WE'LL WORK ON GETTING THE BIG GOOBERS CLEANED AWAY. WE'LL ALSO NEED TO GET RID OF ANY OLD GASKETS OR SEALANT THAT WE FIND. THESE THINGS HAVE PROBABLY BEEN ON THAT MOTOR FOR AT LEAST A COUPLE OF DECADES. SO THERE'S PLENTY OF THAT KIND OF STUFF TO BE REMOVED.

THEN IT'S OVER TO THE PARTS WASHER WHERE CAN START MAKING THESE THINGS LOOK A LITTLE BIT BETTER. ANOTHER REASON WE DO THIS IS BECAUSE YOU DON'T WANT ALL THAT GUNK GETTING INTO YOUR SAND BLASTER BECAUSE YOU'LL NEVER GET IT OUT. FROM JUST THIS LITTLE BIT WASHING YOU CAN ALREADY SEE A HUGE IMPROVEMENT IN THE WAY OUR COVERS LOOK. CHECK IT OUT! YOU CAN SEE THE COLOR THEY WERE SUPPOSED TO BE.

NEXT UP IS THE BLASTING CABINET. THIS WILL GET RID OF ANY LEFTOVER STUFF THAT'S STILL STUCK TO THEM. THESE ARE ALUMINUM THOUGH, SO WE'LL USE THE MEDIUM SETTING TO PREVENT DAMAGING THEM.

WELL THOSE LOOK PRETTY GOOD. NOW THAT THEY'RE BARE ALUMINUM WE COULD PROBABLY JUST RUN THEM LIKE THIS, BUT I'VE GOT SOMETHING EVEN BETTER. WE'LL BUST OUT THE BUFFING WHEEL AND GRAB A LITTLE BIT OF POLISHING ROUGE.

WE'RE GONNA POLISH THE TOPS OF THE FINS TO GET THEM NICE AND SHINY. THIS CAN ALSO BE DONE BY HAND, BUT NO REASON NOT TO USE THE MACHINE IF YOU HAVE ACCESS TO ONE.

WELL NOW THAT WE'VE GOT A NICE POLISH ON THE RIBS AND THE LOGO ON OUR VALVE COVERS WE CAN TAKE THEM OVER TO THE BOOTH AND GET SOME PAINT ON THEM.

FOR PAINT ON THESE WE'RE GONNA USE SOME VHT WRINKLE PLUS. YOU WANT ABOUT THREE MODERATELY HEAVY COATS AND THERE'S A REASON FOR THAT. THE EXTRA PAINT IS WHAT WRINKLES UP FOR THE COOL EFFECT THIS PAINT PROVIDES.

NOW THAT WE'VE GOT OUR THREE COATS OF WRINKLE PLUS ON THESE VALVE COVERS WE'RE GONNA USE THE HEAT GUN TO SPEED UP THAT WRINKLING PROCESS. NOW YOU COULD LET THIS CURE ON ITS OWN, AND IT WOULD GIVE YOU THE SAME EFFECT, BUT WE'RE IMPATIENT. SO THE HEAT GUN WILL SPEED THINGS UP. AFTER ABOUT 10 MINUTES OF HEAT THEY'RE ALL NICE AND WRINKLY.

THE FINAL EFFECT WE'RE GONNA GO FOR IS TO USE A RED SCUFF PAD ON THE TOP OF THE FINS, WHICH COMBINED WITH OUR EARLIER POLISHING WILL GIVE A COOL BRUSHED LOOK. IT JUST TAKES A LITTLE BIT OF ELBOW GREASE. THAT'S IT! WELL I THINK WE'RE GONNA STOP RIGHT THERE. THESE ARE VINTAGE VALVE COVERS AND THEY LOOK REALLY GOOD WITH THAT RED SCUFF PAD FINISH. WE DID LEAVE OURSELVES THE OPTION TO GO BACK AND POLISH BUT I DON'T THINK THEY NEED IT.

(TOMMY)>> HEY GUYS I WANT TO STOP, AND SLOW DOWN, AND TALK ABOUT ONE OF THE MOST POPULAR CENTER SECTIONS OUT THERE, AND THAT IS THE FORD NINE INCH. NOW THEY'RE POPULAR FOR A FEW REASONS. ONE OF THEM IS THAT THEY'RE PRETTY EASY TO FIND CAUSE THEY STARTED MAKING THEM BACK IN 1957, AND USED THEM ALL THE WAY UP INTO THE EARLY '80'S. A SECOND REASON IS THESE THINGS FROM THE FACTORY ARE TOUGHER THAN WOOD PECKER LIPS, AND THIRD, WELL THEY HAVE A DROP OUT CENTER SECTION. SO SWAPPING THE GEAR RATIOS AROUND IS RELATIVELY EASY. INTEGRAL DIFFERENTIALS MUST BE ASSEMBLED IN THE REAR END HOUSING, WHERE NONINTEGRAL, LIKE THIS FORD NINE INCH, CAN BE PREPARED AND ASSEMBLED ON A WORK BENCH. THAT MAKES THEM PERFECT FOR HOT RODDERS AND DRAG RACERS. YOU CAN HAVE MULTIPLE CENTER SECTIONS ALL READY TO GO WITH DIFFERENT GEAR RATIOS, AND THEN THEY CAN BE SWAPPED OUT IN SHORT PERIODS OF TIME. NOW THE AFTERMARKET WORLD REALLY EMBRACED THESE THINGS. YOU CAN PRETTY MUCH BUILD A BRAND NEW ONE STRAIGHT OUT OF THE CATALOG IF YOU WANT TO, OR THERE'S COMPANIES OUT THERE, LIKE CURRIE ENTERPRISES, THAT MANUFACTURES A COMPLETE UNIT FROM BRAKE DRUM TO BRAKE DRUM TO FIT PRETTY MUCH UNDER ANYTHING, FOR ALL TYPES OF CARS AND TRUCKS. NOW IF YOU'RE WONDERING WHAT THAT NINE INCH REFERS TO IT'S THE ACTUAL DIAMETER OF THE RING GEAR. YOU JUST MEASURE IT FROM SIDE TO SIDE. NOW IF YOU'RE GONNA BE BUYING ONE OF THESE THINGS IN A SALVAGE YARD YOU MIGHT WANT TO DO A LITTLE BIT OF HOMEWORK BEFORE YOU PAY THE MAN FOR IT BECAUSE THIS NINE INCH HAS A BIG AND LITTLE BROTHER. THEY MAKE AN EIGHT INCH AND THEY MAKE A NINE AND THREEEIGHTHS, WHICH IS ACTUALLY KNOWN AS A NINE AND A HALF. THE EIGHT INCH, IT COMES IN THE SMALLER CARS USUALLY LIKE A MUSTANG, OR CAN BE EVEN IN LIKE A COMET OR SOMETHING LIKE THAT. THAT BIG NINE AND A HALF, WELL IT CAN COME IN THOSE BIG BODY CARS LIKE A MERCURY OR LINCOLN, AND I'VE ALSO SEEN THEM IN A FOUR BY FOUR TRUCK. JUST MAKE SURE THAT YOU FIGURE OUT WHAT YOU'RE BUYING FIRST. NOW THERE ARE A COUPLE OF TELL TALE SIGNS AND ONE OF THOSE IS UNDER HERE ON THE BOTTOM. TAKE A LOOK AT THE BOTTOM TWO BOLTS UNDER HERE. IF YOU CAN GET A SOCKET ON IT YOU'RE DEALING WITH AN EIGHT INCH. NOW IF YOU'RE FOOLING WITH A STOCK UNIT OFTEN TIMES THERE'S A LITTLE METAL TAG HANGING OFF THE SIDE WITH SOME CODES ON IT, AND THEM CODES CAN HELP YOU OUT. IT'LL TELL YOU LIKE THE GEAR RATIO AND WHETHER OR NOT THIS IS A NINE, EIGHT, OR NINE AND A HALF, BUT LET'S SAY THAT'S TAB'S GONE. WHAT ARE YOU GONNA DO? WELL A GOOD RULE OF THUMB IS TO GO AHEAD AND PULL THIS THING OUT, MEASURE IT ACROSS THERE, THAT'LL TELL YOU FOR SURE. NOW THIS LITTLE HUNK OF METAL HERE IS ACTUALLY FOR DEMONSTRATION PURPOSES OF OUR CUTAWAY, BUT THIS PART THROUGH HERE ACTUALLY SIMULATES THE STUB OF AN AXLE. NOW THE STUB OF THE AXLE HERE IS A 28 SPLINE, AND TO COUNT THEM YOU'D WANT TO COUNT THE PEAKS, NOT THE GROOVES OR THE VALLEYS. NOW FROM THE FACTORY THE NINE INCH DID HAVE A 31 SPLINE BUT IT WAS FOR HEAVIER AND MORE PERFORMANCE ORIENTED APPLICATIONS. NOW THE AFTERMARKET WORLD, WELL THEY HAVE THEM ON UP INTO THE 40'S, AND AS A GENERAL RULE OF THUMB MORE SPLINES, STRONGER THE AXLE. WELL I HOPE THIS INFORMATION HELPED Y'ALL OUT. Y'ALL KNOW THE DEAL, WE'RE ALL OUT OF TIME FOR NOW. SO UNTIL NEXT TIME Y'ALL KEEP IT BETWEEN THE DITCHES.

Show Full Transcript

(MARC)>> HEY GUYS, WELCOME TO DETROIT MUSCLE. TODAY WE ARE CONTINUING THE WORK ON OUR '69 DODGE CHARGER PROJECT. NOW I KNOW IT MAY NOT LOOK LIKE MUCH NOW BUT IT IS A WORK IN PROGRESS, AND WHEN IT'S ALL SAID AND DONE IT'S GONNA BE ONE COOL RIDE.

(TOMMY)>> WE WENT AHEAD AND SNATCHED THE ENGINE OUT AND THIS IS GONNA BE OUR TASK FOR THE DAY. WAKING UP AND REBEAUTIFYING THIS BIG OLE HUNK OF GREASY METAL, AND FOR THOSE OF Y'ALL WHO ARE JUST JOINING US THIS IS A LITTLE HISTORY LESSON FOR YOU. WE PICKED UP OUR '69 CHARGER IN ALABAMA, AND SO FAR SHE'S HAD SOME SHEET METAL SWAPPED OUT ALONG WITH A TOP TO BOTTOM REBUILD OF THAT FOUR SPEED GEAR BOX SO THAT IT CAN HOLD UP TO SOME ENGINE UPGRADES.

(MARC)>> NOW WHAT WE WANT TO DO TODAY IS ADD A BIT MORE POWER TO THIS OLD MOPAR BY INSTALLING A NEW TOP END KIT. THE RIGHT COMBINATION OF PROPERLY MATCHED COMPONENTS COULD REALLY DO THIS THING A LOT OF GOOD. IT WASN'T THAT IT RAN BAD BEFORE. IT WAS JUST THAT IT DIDN'T HAVE THAT LOW END GRUNT THAT WE THOUGHT A 440 CUBIC INCH ENGINE SHOULD HAVE.

(TOMMY)>> LOOKING AT THIS ENGINE I BET IT'S GONNA BE A PERFECT EXAMPLE OF A LOT OF MISMATCHED COMPONENTS. THIS INTAKE ON THIS THING HAS A POWER BAND OF ABOUT 3,000 TO 7,800 RPM, AND I'M HERE TO TELL YOU THAT THE REST OF THIS ENGINE DIDN'T SOUND LIKE IT NEEDED THAT BIG OF AN INTAKE, BUT THAT'S OKAY. WE'RE GONNA GO AHEAD AND TEAR IT DOWN TO SEE EXACTLY WHAT WE'RE WORKING WITH.

BEFORE CRACKING IT OPEN IT'S A GOOD IDEA TO BLOW AWAY ANY OF THAT GARBAGE THAT COULD FALL INTO THE ENGINE. WE'LL START BY PULLING THE CARB OFF OF IT, ALONG WITH THE COIL. NEXT UP IS THE INTAKE. THE DISTRIBUTOR CAN COME OUT, AND LATER WE'LL PROBABLY BE REPLACING THAT WITH A NEWER ONE. WE'LL ALSO HAVE TO GET THE FRONT DRIVE ASSEMBLY KNOCKED OFF HERE, AND THAT'S GONNA INCLUDE THE WATER PUMP.

THE CRANK PULLEY COMES OFF WITH A FEW BOLTS...

...AND THEN A PULLER WILL REMOVE THE BALANCER FOR US.

NOW LET'S GET THIS TIMING COVER OFF AND TAKE A LOOK AT THE CHAIN.

YEAH, YOU COULD SAY IT NEEDED A TIMING CHAIN.

TIME TO GET THE VALVE COVERS OFF, AND WE'LL POP OFF THIS VALLEY PAN WHILE WE'RE AT IT.

DANG, PRETTY CLEAN! ROCKER RAILS, WHICH ARE KIND OF A MOPAR SIGNATURE THING, WILL BE THE NEXT THING TO GO, ALONG WITH THE PUSH RODS. AFTER GETTING THE TINS AND THE INTAKE OFF OF THIS THING WE CAN SEE THE INSIDE OF THE ENGINE, AND IT'S ACTUALLY RELATIVELY CLEAN. THE PROBLEM THAT WE DO SEE IS SOMEONE HAS PAINTED THE INSIDE OF HERE. THIS STUFF IS ACTUALLY STARTING TO COME OFF, AND THAT'S WHAT YOU DON'T WANT CAUSE THAT'S GONNA CLOG SOMETHING UP, AND THAT CAN LEAD TO A WHOLE MESS OF PROBLEMS. ONE OF THOSE IS OIL STARVATION, AND YOU DON'T WANT THAT FOR SURE. WE'RE GONNA GO AHEAD AND TEAR THIS THING DOWN, SEE WHAT ELSE WE'RE WORKING WITH.

(MARC)>> WELL WE'VE GOT SOME BAD NEWS. AFTER GETTING THE CYLINDER HEADS OFF WE FOUND ANOTHER PROBLEM. SO WE'VE GOT THE PAINT PEELING ISSUE, STRIKE NUMBER ONE, AND THEN WE CAN TELL HERE INSIDE THE CYLINDER WALL IT'S REALLY WORN. IT'S A GOOD SIGN THAT IT'S BEEN A LONG TIME SINCE THIS THING'S BEEN REBUILT, AND IT'S PRETTY MUCH USED UP. ANOTHER PROBLEM IS THIS TIMING CHAIN, ANOTHER GOOD SIGN THAT THIS THING'S WORN OUT AND NEEDS TO BE REBUILT. SO WE'RE NOT GONNA TAKE IT ANY FARTHER NOW. WE'RE JUST GONNA SEND THIS THING OUT TO A MACHINE SHOP TO HAVE IT REBUILT.

ONCE WE GET THAT BLOCK EMPTIED OUT WE'RE HEADING TO NASHVILLE, TO SEE SHACKLETT AUTO MACHINE. THEY DO SOME MACHINING FOR ENGINE POWER. SO OUR 440 IS IN GOOD HANDS.

NORMALLY THE FIRST STEP WOULD BE TO GET EVERYTHING ALL CLEANED UP, ESPECIALLY AN OLD GREASY ENGINE LIKE OURS, BUT SINCE WE'RE HERE WE ASKED JOHN TO GO AHEAD AND DO US A HUGE FAVOR AND DO THE BORING PROCESS FIRST, AND THAT'S GONNA ALLOW US TO GO AHEAD AND ORDER THE PISTONS THAT WE NEED BECAUSE WE'RE NOT SURE WHICH SIZE WE NEED YET, AND IT'S ALSO GONNA ALLOW US TO SEE HOW THE PROCESS WORKS.

(TOMMY)>> WITH THE MAIN CAPS PULLED OFF, SHE'S READY TO GO ONTO THE BORING MACHINE.

THIS DEVICE CUTS METAL OFF THE CYLINDER WALLS, WHICH IS GONNA DO TWO THINGS. IMPROVE THE CONSISTENCY OF THE CYLINDER SURFACE, AND GIVE US MORE DISPLACEMENT.

(JOHN)>> ALL RIGHT, WE'VE GOT THE FIRST HOLE BORED 30 OVER. WE'LL CHECK IT HERE WITH THE DIAL BORE GAUGE. WE'VE GOT TWO AND HALF THOUSANDTHS TO HONE OUT TO GET TO 30 OVER. SO AT THIS POINT WE'RE GONNA CONTINUE BORING THE OTHER SEVEN CYLINDERS AND FINISH IT UP.

(MARC)>> THIS IS GOING TO CHANGE OUR CUBIC INCH DISPLACEMENT FROM 440 TO ABOUT 446. NOW THAT MAY NOT BE A HUGE LEAP BUT WE'RE NOT BUILDING A MONSTER HERE EITHER.

(TOMMY)>> WELL THEY GOT OUR ENGINE ALL PUNCHED OUT, AND THE NEXT STEP IS REMOVING A FEW OF THESE CAM BEARINGS, THE PIPE LUGS, AND THE FREEZE PLUGS. THEN THEY'RE GONNA SEND IT BACK TO THE FURNACE AND COOK IT AT 750 DEGREES FOR FOUR HOURS.

(MARC)>> AND AFTER IT COMES OUT OF THE FURNACE OUR BLOCK IS GONNA LOOK LIKE THIS ONE HERE. IT'S KINDA RUSTY AND DIRTY LOOKING, AND IT'S FULL OF THIS POWDER HERE AND THAT'S BECAUSE THAT FURNACE TURNS EVERYTHING TO THIS ASH. ALL THE GASKET MATERIAL, PAINT, OIL, AND ANY OTHER IMPURITIES. SO THERE NEEDS TO BE ONE MORE PROCESS BEFORE THAT THING LOOKS REALLY NICE, AND THAT'S GONNA BE THE TUMBLER. AFTER ABOUT 10 MINUTES IN THE TUMBLER IT COMES OUT LOOKING LIKE THIS. THIS IS ANOTHER BIG BLOCK MOPAR THAT JOHN'S DOING FOR ONE OF HIS OTHER CUSTOMERS AND OURS IS GONNA LOOK LIKE THIS IN NO TIME.

(NARRATOR)>> WELL SHE'S MACHINED DOWN AND CLEANED UP. SO WHAT'S GONNA MAKE OUR MOTOR WORK? UP AHEAD WE BEGIN THE REBUILD WITH THE ROTATING ASSEMBLY. THEN LATER ON SEE WHAT KIND OF BUMP STICK, HEADS, AND OTHER GOODIES WE'RE GONNA THROW AT HER.

(MARC)>> HEY WE'RE BACK FROM THE ENGINE SHOP, AND I KNOW IT DOESN'T LOOK LIKE IT BUT THIS IS ACTUALLY THE BLOCK THAT WE SENT OVER TO SHACKLETT'S TO GET CLEANED UP. ALL THE MACHINING PROCESSES ARE DONE AND IT'S READY FOR ASSEMBLY, AND WHEN WE GOT IT BACK HERE WE PUT A COUPLE OF COATS OF OE STYLE PAINT ON IT TO PROTECT IT. NOW SINCE WE HAD THOSE CYLINDERS BORED OUT WE NEEDED NEW PISTONS. SO WE WENT TO SUMMIT RACING FOR THESE 30 OVER PISTONS, BUT THEY ALSO CAME WITH A FULL REBUILD KIT. NEW PISTONS NEED NEW RINGS. WE ALSO GOT CAM BEARINGS, ROD BEARINGS, AND MAIN BEARINGS. THE KIT ALSO COMES WITH NEW FREEZE PLUGS AND PIPE PLUGS FOR THE BLOCK. NOW AS FOR THE REST OF OUR ROTATING ASSEMBLY THE RODS ARE ACTUALLY IN GOOD SHAPE BUT THE CRANK SHAFT WE FOUND OUT HAD BEEN MACHINED BEFORE AND IT NEEDED IT AGAIN. IT WAS PROBABLY CLOSE TO ITS TOLERANCE. SO WE DECIDED TO REPLACE IT, AND THANKFULLY THE GUYS DOWN IN ENGINE POWER HAD THIS STOCK 440 CRANK, AND IT HAD NEVER BEEN MACHINED. SO WE TOOK IT DOWN THERE TO SHACKLETT'S AND THEY TOOK A LOOK AT IT, SAID IT WAS IN GOOD SHAPE. SO ALL THEY DID WAS POLISH ALL THE BEARING JOURNALS. IT'S READY TO GO. WE'LL START OUR REBUILD BY REPLACING THE FREEZE PLUGS THAT WERE REMOVED AT THE MACHINE SHOP, AND WE'LL SLIDE THE NEW BEARINGS INTO THE MAIN CAPS.

THESE HAVE TO BE PREINSTALLED ON OUR REWORKED BLOCK, AND THEN TORQUED TO SPEC. [ hammer tapping ]

(MARC)>> WE'LL DO THIS SO THAT WE CAN CHECK THE CLEARANCE ON THE CRANK JOURNALS AND MAKE SURE THAT EVERYTHING IS WITHIN TOLERANCE. FIRST WE'LL MEASURE THE DIAMETER ON THE CRANK. ALL RIGHT, WE'RE JUST GONNA CHECK FOR MAIN BEARING CLEARANCE HERE BUT WE'RE GONNA GO FOR THE LOWEST NUMBER HERE, WHICH IS TWO THOUSANDTHS. SO WE'VE GOT TWO THOUSANDTHS CLEARANCE, THAT'S GOOD! WE'LL USE SOME ROYAL PURPLE MAX TOUGH ASSEMBLY LUBE ON THESE MAIN BEARINGS. THEN WE CAN STUFF THAT CRANK INTO OUR OLD BIG BLOCK.

SOME MORE MAX TOUGH WILL GET OUR CAPS READY. THEN WE CAN BEGIN INSTALLATION.

WE'LL WRAP THIS PART UP WITH THE REAR SEAL AND GET IT CINCHED DOWN. WELL WE'RE JUST ABOUT READY TO INSTALL OUR RINGS ONTO OUR PISTONS HERE SO WE CAN INSTALL OUR PISTON AND ROD ASSEMBLIES INTO THE BLOCK. A LOT OF YOU AT HOME HAVE SEEN THESE RINGS BEFORE, BUT EACH RING HAS A SPECIFIC JOB. THESE THREE HERE WORK TOGETHER AND THEY ARE THE OIL RINGS. THEY'RE AT THE BOTTOM OF THE PISTON NEAR THE SKIRT, AND THEY SWEEP ALL THE OIL OFF OF THE CYLINDER WALLS AND KEEP IT DOWN IN THE CRANK CASE. THESE TWO ARE THE COMPRESSION RINGS, AND THERE'S A LOWER AND AN UPPER, AND THEY EACH HAVE A TAPERED EDGE, AND THERE'S A LITTLE DOT HERE THAT TELLS YOU WHERE THEY'RE ORIENTED.

(NARRATOR)>> UP NEXT WE GET TO SEE THE SHINY BITS THAT ARE GONNA HELP OUR 440 MAKE MORE POWER. THEN WE'RE GONNA REFURB THOSE OLD VALVE COVERS.

(MARC)>> WELL WE'VE GOT EVERYTHING TORQUED DOWN NOW AND OUR SHORT BLOCK IS COMPLETE, AND WE'RE BACK TO WHERE WE WERE WHEN WE DECIDED WE NEEDED TO REBUILD THIS THING. READY TO MOVE ON TO THE NEXT STEP. WE WENT TO EDELBROCK FOR THIS COMPLETE TOP END KIT, WHICH COMES WITH A PAIR OF ESTREET HEADS, A CAM, LIFTERS, TIMING SET, A WATER PUMP, AND ALL THE GASKETS TO GET IT INSTALLED. THESE ALUMINUM CYLINDER HEADS HAVE 210cc INTAKE RUNNERS AS WELL AS 214 INTAKE VALVES AND 181 EXHAUST VALVES. THE COMBUSTION CHAMBERS ARE 75cc, WHICH IS GONNA BUMP UP OUR COMPRESSION RATIO FROM EIGHTZERO, WHICH IS STOCK, TO AROUND NINE POINT TWO TO ONE. THAT'S GONNA INCREASE DRIVABILITY AS WELL AS PERFORMANCE, BUT IT'S GONNA BE SAFE ENOUGH TO DRIVE AROUND ON PUMP GAS. THIS HYDRAULIC FLAT TAPPET CAM SHAFT IS FROM EDELBROCK'S RPM SERIES. IT'S DESIGNED SPECIFICALLY FOR HIGH PERFORMANCE STREET APPLICATIONS, AND HAS A 1,500 TO 6,500 RPM RANGE, AND THE FIRST THING WE'RE GONNA INSTALL IS GONNA BE THAT BUMP STICK.

ON THE JOURNALS WE'LL USE SOME ROYAL PURPLE MAX TOUGH FOR LUBE, BUT ON THE LOBES WE'LL USE THE BREAK IN COMPOUND THAT EDELBROCK SENT US WITH THE CAM.

WITH THE CAM IN WE CAN PLUG IN THE NEW TIMING SET. A BIG IMPROVEMENT FROM THAT SLOPPY ONE THAT WAS IN IT.

NEXT UP IS THE LIFTERS, WHICH HAVE BEEN SOAKING IN OIL TO PRIME THEM UP. LOOKS LIKE WE'RE AT A GOOD SPOT TO GET THIS THING READY FOR HEADS.

NOW INSTEAD OF USING REGULAR OLD HEAD BOLTS ON THIS WE'VE DECIDED TO GO WITH THESE ARP HEAD STUDS, AND THERE'S A FEW REASONS FOR THAT. THEY ARE COLD FORGED, AND THEY'RE CHROMOLY, AND THEY'RE BUILT TO WITHSTAND 220,000 PSI. IF YOU GO AHEAD AND THREAD A COUPLE OF THEM IN THE BLOCK THAT ALLOWS YOU TO SLIDE ON THE HEAD A LITTLE EASIER AND USE THEM AS ALIGNMENT PINS, AND ALSO IF WE DECIDE TO UPGRADE THIS MOTOR LATER ON THEY'RE REUSABLE. WE'VE SWITCHED TO CUP STYLE PUSH RODS, AND WE'LL LUBE THEM UP ALONG WITH THE STEMS ON OUR VALVES. THE REASON FOR THE CUP STYLE RODS IS WE GOT THIS SET OF HARLAN SHARP ADJUSTABLE ROLLER ROCKERS FROM SUMMIT RACING. THESE ROLLER TIP ROCKERS ARE COOL BECAUSE THEY'RE GONNA FREE UP A LITTLE BIT OF POWER. WE'LL ADJUST THE LASH ON THESE, THEN MOVE ALONG. NEXT UP IS THE VALLEY PAN.

NOW THE ICING ON THE CAKE ON OUR 440 IS GONNA BE THIS SIX PACK INTAKE MANIFOLD THAT WE GOT FROM EDELBROCK. NOW WHAT'S REALLY COOL ABOUT THIS IS EVEN THOUGH OUR '69 CHARGER WAS NEVER EQUIPPED WITH A 440 SIX PACK OURS IS GONNA HAVE ONE.

(MARC)>> ONE MORE THING WE WANT TO DO FOR OUR 440 HERE BEFORE WE WRAP IT UP IS THESE VALVE COVERS. NOW THESE ARE THE ONES WE TOOK OFF OF THE ENGINE BEFORE, AND THEY'VE SEEN BETTER DAYS. THEY'RE A LITTLE DIRTY, AND DINGY LOOKING, BUT STRUCTURALLY THEY'RE REALLY GOOD. SO WE WANT TO CLEAN THEM UP, AND YOU KNOW, BREATHE SOME NEW LIFE INTO THEM. FIRST THINGS FIRST, WE'LL WORK ON GETTING THE BIG GOOBERS CLEANED AWAY. WE'LL ALSO NEED TO GET RID OF ANY OLD GASKETS OR SEALANT THAT WE FIND. THESE THINGS HAVE PROBABLY BEEN ON THAT MOTOR FOR AT LEAST A COUPLE OF DECADES. SO THERE'S PLENTY OF THAT KIND OF STUFF TO BE REMOVED.

THEN IT'S OVER TO THE PARTS WASHER WHERE CAN START MAKING THESE THINGS LOOK A LITTLE BIT BETTER. ANOTHER REASON WE DO THIS IS BECAUSE YOU DON'T WANT ALL THAT GUNK GETTING INTO YOUR SAND BLASTER BECAUSE YOU'LL NEVER GET IT OUT. FROM JUST THIS LITTLE BIT WASHING YOU CAN ALREADY SEE A HUGE IMPROVEMENT IN THE WAY OUR COVERS LOOK. CHECK IT OUT! YOU CAN SEE THE COLOR THEY WERE SUPPOSED TO BE.

NEXT UP IS THE BLASTING CABINET. THIS WILL GET RID OF ANY LEFTOVER STUFF THAT'S STILL STUCK TO THEM. THESE ARE ALUMINUM THOUGH, SO WE'LL USE THE MEDIUM SETTING TO PREVENT DAMAGING THEM.

WELL THOSE LOOK PRETTY GOOD. NOW THAT THEY'RE BARE ALUMINUM WE COULD PROBABLY JUST RUN THEM LIKE THIS, BUT I'VE GOT SOMETHING EVEN BETTER. WE'LL BUST OUT THE BUFFING WHEEL AND GRAB A LITTLE BIT OF POLISHING ROUGE.

WE'RE GONNA POLISH THE TOPS OF THE FINS TO GET THEM NICE AND SHINY. THIS CAN ALSO BE DONE BY HAND, BUT NO REASON NOT TO USE THE MACHINE IF YOU HAVE ACCESS TO ONE.

WELL NOW THAT WE'VE GOT A NICE POLISH ON THE RIBS AND THE LOGO ON OUR VALVE COVERS WE CAN TAKE THEM OVER TO THE BOOTH AND GET SOME PAINT ON THEM.

FOR PAINT ON THESE WE'RE GONNA USE SOME VHT WRINKLE PLUS. YOU WANT ABOUT THREE MODERATELY HEAVY COATS AND THERE'S A REASON FOR THAT. THE EXTRA PAINT IS WHAT WRINKLES UP FOR THE COOL EFFECT THIS PAINT PROVIDES.

NOW THAT WE'VE GOT OUR THREE COATS OF WRINKLE PLUS ON THESE VALVE COVERS WE'RE GONNA USE THE HEAT GUN TO SPEED UP THAT WRINKLING PROCESS. NOW YOU COULD LET THIS CURE ON ITS OWN, AND IT WOULD GIVE YOU THE SAME EFFECT, BUT WE'RE IMPATIENT. SO THE HEAT GUN WILL SPEED THINGS UP. AFTER ABOUT 10 MINUTES OF HEAT THEY'RE ALL NICE AND WRINKLY.

THE FINAL EFFECT WE'RE GONNA GO FOR IS TO USE A RED SCUFF PAD ON THE TOP OF THE FINS, WHICH COMBINED WITH OUR EARLIER POLISHING WILL GIVE A COOL BRUSHED LOOK. IT JUST TAKES A LITTLE BIT OF ELBOW GREASE. THAT'S IT! WELL I THINK WE'RE GONNA STOP RIGHT THERE. THESE ARE VINTAGE VALVE COVERS AND THEY LOOK REALLY GOOD WITH THAT RED SCUFF PAD FINISH. WE DID LEAVE OURSELVES THE OPTION TO GO BACK AND POLISH BUT I DON'T THINK THEY NEED IT.

(TOMMY)>> HEY GUYS I WANT TO STOP, AND SLOW DOWN, AND TALK ABOUT ONE OF THE MOST POPULAR CENTER SECTIONS OUT THERE, AND THAT IS THE FORD NINE INCH. NOW THEY'RE POPULAR FOR A FEW REASONS. ONE OF THEM IS THAT THEY'RE PRETTY EASY TO FIND CAUSE THEY STARTED MAKING THEM BACK IN 1957, AND USED THEM ALL THE WAY UP INTO THE EARLY '80'S. A SECOND REASON IS THESE THINGS FROM THE FACTORY ARE TOUGHER THAN WOOD PECKER LIPS, AND THIRD, WELL THEY HAVE A DROP OUT CENTER SECTION. SO SWAPPING THE GEAR RATIOS AROUND IS RELATIVELY EASY. INTEGRAL DIFFERENTIALS MUST BE ASSEMBLED IN THE REAR END HOUSING, WHERE NONINTEGRAL, LIKE THIS FORD NINE INCH, CAN BE PREPARED AND ASSEMBLED ON A WORK BENCH. THAT MAKES THEM PERFECT FOR HOT RODDERS AND DRAG RACERS. YOU CAN HAVE MULTIPLE CENTER SECTIONS ALL READY TO GO WITH DIFFERENT GEAR RATIOS, AND THEN THEY CAN BE SWAPPED OUT IN SHORT PERIODS OF TIME. NOW THE AFTERMARKET WORLD REALLY EMBRACED THESE THINGS. YOU CAN PRETTY MUCH BUILD A BRAND NEW ONE STRAIGHT OUT OF THE CATALOG IF YOU WANT TO, OR THERE'S COMPANIES OUT THERE, LIKE CURRIE ENTERPRISES, THAT MANUFACTURES A COMPLETE UNIT FROM BRAKE DRUM TO BRAKE DRUM TO FIT PRETTY MUCH UNDER ANYTHING, FOR ALL TYPES OF CARS AND TRUCKS. NOW IF YOU'RE WONDERING WHAT THAT NINE INCH REFERS TO IT'S THE ACTUAL DIAMETER OF THE RING GEAR. YOU JUST MEASURE IT FROM SIDE TO SIDE. NOW IF YOU'RE GONNA BE BUYING ONE OF THESE THINGS IN A SALVAGE YARD YOU MIGHT WANT TO DO A LITTLE BIT OF HOMEWORK BEFORE YOU PAY THE MAN FOR IT BECAUSE THIS NINE INCH HAS A BIG AND LITTLE BROTHER. THEY MAKE AN EIGHT INCH AND THEY MAKE A NINE AND THREEEIGHTHS, WHICH IS ACTUALLY KNOWN AS A NINE AND A HALF. THE EIGHT INCH, IT COMES IN THE SMALLER CARS USUALLY LIKE A MUSTANG, OR CAN BE EVEN IN LIKE A COMET OR SOMETHING LIKE THAT. THAT BIG NINE AND A HALF, WELL IT CAN COME IN THOSE BIG BODY CARS LIKE A MERCURY OR LINCOLN, AND I'VE ALSO SEEN THEM IN A FOUR BY FOUR TRUCK. JUST MAKE SURE THAT YOU FIGURE OUT WHAT YOU'RE BUYING FIRST. NOW THERE ARE A COUPLE OF TELL TALE SIGNS AND ONE OF THOSE IS UNDER HERE ON THE BOTTOM. TAKE A LOOK AT THE BOTTOM TWO BOLTS UNDER HERE. IF YOU CAN GET A SOCKET ON IT YOU'RE DEALING WITH AN EIGHT INCH. NOW IF YOU'RE FOOLING WITH A STOCK UNIT OFTEN TIMES THERE'S A LITTLE METAL TAG HANGING OFF THE SIDE WITH SOME CODES ON IT, AND THEM CODES CAN HELP YOU OUT. IT'LL TELL YOU LIKE THE GEAR RATIO AND WHETHER OR NOT THIS IS A NINE, EIGHT, OR NINE AND A HALF, BUT LET'S SAY THAT'S TAB'S GONE. WHAT ARE YOU GONNA DO? WELL A GOOD RULE OF THUMB IS TO GO AHEAD AND PULL THIS THING OUT, MEASURE IT ACROSS THERE, THAT'LL TELL YOU FOR SURE. NOW THIS LITTLE HUNK OF METAL HERE IS ACTUALLY FOR DEMONSTRATION PURPOSES OF OUR CUTAWAY, BUT THIS PART THROUGH HERE ACTUALLY SIMULATES THE STUB OF AN AXLE. NOW THE STUB OF THE AXLE HERE IS A 28 SPLINE, AND TO COUNT THEM YOU'D WANT TO COUNT THE PEAKS, NOT THE GROOVES OR THE VALLEYS. NOW FROM THE FACTORY THE NINE INCH DID HAVE A 31 SPLINE BUT IT WAS FOR HEAVIER AND MORE PERFORMANCE ORIENTED APPLICATIONS. NOW THE AFTERMARKET WORLD, WELL THEY HAVE THEM ON UP INTO THE 40'S, AND AS A GENERAL RULE OF THUMB MORE SPLINES, STRONGER THE AXLE. WELL I HOPE THIS INFORMATION HELPED Y'ALL OUT. Y'ALL KNOW THE DEAL, WE'RE ALL OUT OF TIME FOR NOW. SO UNTIL NEXT TIME Y'ALL KEEP IT BETWEEN THE DITCHES.