More Junk Mail DJ5 Episodes

Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

CRC Industries

Heavy Duty Pro-Strength Degreaser

Matco Tools

MATCO Tools are the Official Tool Supplier to PowerNation

The Industrial Depot

Tools, Hardware, Shop Supplies

Episode Transcript

(Pat)>> You're watching Powernation.

(Pat)>> If those old postal Jeep is going to go from carrying the mail to hauling it it's gonna need some engine work, or at the very least an aerosol overhaul. [ MUSIC ]

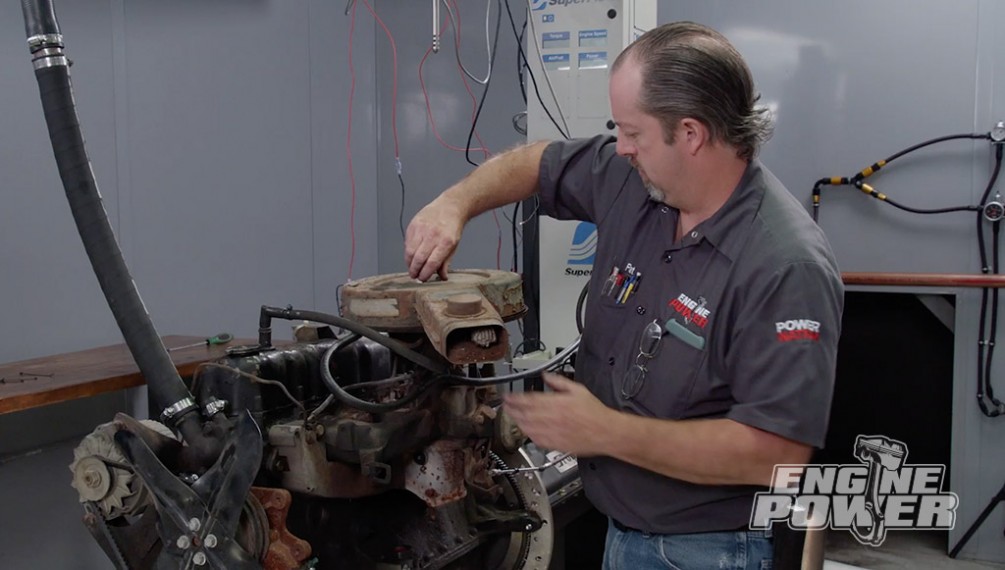

(Pat)>> Welcome to Engine Power. Today we have yet another dare to be different project in the shop to see what we can improve on. We always give the big three manufacturers a lot of love on our projects, and that mainly consists of two valve push rod V-8 stuff because that is what is commonly hot rodded but we have proven that virtually anything can be upgraded to hot rod status with the right parts choice, assembly, and a good old fashioned dyno session. That being said there is an automotive manufacturer from the past that is sometimes overlooked but has produced some formidable power plants that can hold their own. That company is AMC. American Motors Corporation had their own entries into the muscle car arena with stout performers such as the Javelin, AMX, Rambler Rebel, and the Hornet just to name a few. V-8's ranging from 290 cubic inches all the way up to 401 cubic inches put them right in the thick of the horsepower wars of the late '60's to early '70's. Unfortunately this isn't one of them. What we have here is a plain jane 232 cubic inch six banger. It has the same basic architecture as the more popular 258, which later evolved into the modern four liter variant that powered several Jeep models all the way up to 2006. This particular power plant was removed from a rough looking late '70's mail carrier Jeep that is in the building right now. Carcass has some exciting plans for it. Our first task is to see if it will even run, and then make some simple improvements to it and get it back to the guys down in Carcass. Helping out today is the newest member of the Powernation team, Frankie Forman. He's a graduate of UNOH where he built engines for the school's dirt track and drag racing teams. [ drill humming ]

(Pat)>> We had a four liter Jeep on the Superflow docking cart a few years ago. So we know this AMC will bolt up nicely. We used the Jeep four liter flywheel because this engine was originally paired with an automatic transmission.

(Frankie)>> I got it.

(Pat)>> You are like a bull in a china shop. [ MUSIC ] No matter what the engine I always like a clean floor to see what's leaking and where it's leaking from. [ MUSIC ] That is racy right there. Probably should get this flow inhibitor out. Being an older engine the dyno setup is very straight forward and smooth with one minor exception. In order to make the stock throttle linkage work on our dyno we had to do some mild fabrication. A piece of angled aluminum and some one inch d-o-m tubing create a bracket and a spacer. [ MUSIC ]

(Frankie)>> Cool!

(Pat)>> Full throttle, I can feel it. [ engine idling ]

(Pat)>> It loaded down.

(Frankie)>> That's pretty smooth.

(Pat)>> Wide open throttle. [ engine revving ]

(Pat)>> That's more than I expected. That's more than I expected, 88 horsepower.

(Frankie)>> I was thinking like 60 maybe. That's kinda cool.

(Pat)>> 171.8 pound feet of torque. Goal take the air cleaner off but at the same time cut the exhaust off it. Cut that in front of the muffler and we'll re-run it. I'm not saying that's gonna do anything on something that makes this kind of power.

(Frankie)>> It can't hurt though. [ engine revving ]

(Pat)>> That's more!

(Frankie)>> Look at that!

(Pat)>> And it still has oil pressure. 97.8, and 178 pound feet. I know this might sound crazy but if we're gonna try to remove some power robbing things take the fan off it.

(Frankie)>> You read my mind. [ drill humming ]

(Pat)>> It definitely loads better without the air system on there. [ engine revving ]

(Pat)>> What do you think of that?

(Frankie)>> That's what I'm saying.

(Pat)>> That is amazing, 101 horse, 182 pound feet by removing the fan. We backed up that run and the numbers were consistent. 101.8 horsepower at 3,600 and 183.1 pound feet of torque at 2,000. Up next, underneath years of grime and grease we find a pleasant surprise. After that we freshen up the AMC and get it back into the cell block.

(Pat)>> With a modest max horsepower number of around 100 the AMC inline isn't going to wow anyone, but what is impressive about this engine is how well it runs after all of those years in a postal Jeep. Since we don't want to tear into the block but we do want to find out if the cylinders are sealing up nicely we decided to run a compression check. The numbers look great. When you're trying to remove decades worth of caked on grime you'll take all the help you can get. So we grabbed a can of CRC Pro Strength Degreaser. It dissolves oil and grease but is still safe for painted and plastic surfaces. It's water based, leaves behind no residue, and is biodegradable. After letting the degreaser soak for 10 minutes we pressure washed the engine. The results were impressive. [ small engine idling ]

(Pat)>> That is way better.

(Frankie)>> It took a little work but it's all cleaned up now.

(Pat)>> Uh oh! That sounded like something broke. We have our first broken piece. Let's see how this one goes. [ drill humming ] [ MUSIC ]

(Pat)>> Pulleys are in good shape. So that's definitely a re-use, and even though it's a little rusty that's a relatively recent water pump. Very nice! [ MUSIC ]

(Pat)>> Half the time when you're tearing something apart you'll find other things that people have done that may or may not have been correct, like this bolt was too long and it had bottomed out and it started to strip. That's why it looks like it's all galled up on one end. Same thing with half the other fasteners. They've been rounded off or whatever. That's typical of high maintenance things like a mail Jeep. [ MUSIC ] Gutted thermostat. In racing that's usually a restrictor sometimes but I didn't know that the mail Jeeps ran so hot. [ MUSIC ] [ drill humming ] [ MUSIC ] [ drill humming ]

(Pat)>> I love the reveal on the valvetrain because I know how this thing ran. It's always nice to see how it looks. Other than being dirty it looks like it's okay. Interesting that only a few seem to be lubricated. The other ones are not getting oil and it still ran fine. It didn't make any noise. When working on old vehicles sometimes things aren't always what they seem. Case in point this engine. When it was power washed off and we looked up casting numbers it is in fact not a 232 inch engine but a 258, which is great because it will work better with the changes we plan on making, but to make those changes we've got to continue with the teardown and that means remove the cylinder head. [ MUSIC ] [ drill humming ] [ MUSIC ]

(Pat)>> I can already see that the oil plug has been changed once cause the cajavis that holds it in there, there's an extra one. [ MUSIC ] Whoa! [ MUSIC ] It's not chewed up but it is not supposed to have a cup in it. This is the stuff you're not supposed to see on the bottom of a flat tappet lifter. It is not supposed to be concave. [ MUSIC ] Even though the engine was running well we are seeing some discouraging signs, like the worn out timing chain and cupped lifters. Although this project is called Aerosol Overhaul we're gonna have to dig a little deeper into the 258 to know the true condition of this power plant. Up next, what started as an aerosol overhaul gets a little more complicated.

(Pat)>> The original plan for this six cylinder was to clean it up a little bit, put a few cool parts on it, and get it right back down to the guys in Carcass. Well like any other hot rod project things change rapidly. The more we dug into this project the worse it became so we made the decision to freshen it up a bit. Rings and bearings, and even though it is not a racy V-8 we knew we could get all the parts we needed for it at Summit Racing. This does add a little bit of cost and time to the build but it is well worth it considering what the old parts look like. So we went ahead and polished the crankshaft and ball honed the cylinders for a fresh surface, and put in our new parts. Since we had to replace the cam shaft anyway we decided to go with something a little more sporty. So we called up Summit Racing and got a complete cam kit. It comes with everything we need. This is a hydraulic flat tappet and the duration at 50 thousandths on the intake is 206 degrees. Exhaust is 212 on a 113 degrees of lobe separation. It also came with a timing gear, springs, retainers, and locks, plus lifters. Everything that matches the cam's profile. As far as lift we're gonna have a little bit more because we decided to go with a 1.7 ratio rocker. So the lift at the valve is around 500 thousandths. This Comp Cams hydraulic flat tappet requires specific lube on the lobes for proper break-in, and it comes with a kit. On the journals we're using break-in oil. [ MUSIC ] [ drill humming ]

(Pat)>> The timing set is non-adjustable but we still went ahead and degreed the cam. It comes in at 110 degrees of intake centerline, which is three degrees advanced, spectacular! The freshly sand blasted stock timing cover bolts up, followed by the cleaned and painted stock harmonic balancer. [ MUSIC ] More lubricant is spread on the bottom of the lifters prior to assembly. Then they are gently placed in their lifter bores. It's tempting to use a magnet to install them, but if the magnet has attracted small metal particles they can end up in your engine. The stock replacement head gasket is next. There are no dowels to align the gasket. So you have to do this by hand. Go slowly and check your work making sure both the gasket and the head are properly aligned. Only one head bolt goes into the water jacket. It has to be sealed with thread sealer. [ MUSIC ] The head is torqued in three steps to a final value of 100 pound feet using high pressure lube. The stock push rods ended up being the correct length. So back in they go. These full roller rockers from Scorpion offer increased durability and less friction than the stock rocker setup. They are a bit overkill for this engine but if more high performance mods happen in the future we'll be good to go. After the rockers are torque to 30 pound feet the valves are set to one half turn past zero lash. Before the cork oil pan gasket goes down we'll lay on some black weather strip adhesive. The rubber end gaskets are next. [ MUSIC ] Finally the stock pan goes on. We now have the engine back together to a point where we can apply some color. Hence the name Aerosol Overhaul. What do you think? Because the intake and exhaust are on the same side they share a gasket. Dowels will keep it aligned. The Hedman header has to go on first. It's a six into one style with a one and a half inch primary tube diameter. For induction we chose to splurge a little on Offenhauser's dual port four barrel intake manifold. Make sure the intake and exhaust bolt flange height is the same on both pieces so the manifold bolts up cleanly and seals properly. We're running a one inch spacer for linkage clearance. For good street manners we are running a QFT 450 c-f-m carburetor with an electric choke. [ MUSIC ] Up next, from where we started to where we finish we make a big improvement. It did it!

(Pat)>> We've made it to the dyno room to see what the AMC 258 will do. Keeping the timing accurate is an MSD Pro Billet distributor along with their 8.5 millimeter super conductor wires. We also installed a new MSD Blaster 2 coil. It won't be used for the dyno runs but it will see plenty of use later on the street. Alright here comes some fuel. With the fuel level checked we'll fire the engine and set the timing to 32 degrees, check for leaks, and break in the flat tappet cam. That's a good time to let the header paint burn off as well. We run the engine gently from 1,500 to 2,500 r-p-m cycling it for 20 minutes. Alright so we are back to race ready if there is such a thing. Okay here's the deal. We initially thought this engine was a 232 because that's what it said on the fender. The problem with that is it only made 100 horse and like 187 pound feet, but it's actually a 258. We cleaned it off and got everything measured up. So that made the engine even more lame than what it was before. Now the cam was wasted. We had to put some parts in it, re-ring it, re-bearing it, polish the crank, easy stuff. We didn't change a piston or anything like that and we put a couple of goodies on it like the manifold and the carb, racier rocker, but we had to put a cam in it anyway. So we put a little bit bigger cam. 206 at 50 is not a big cam by any stretch of the imagination. So any predictions of what it's going to do? To tell you the truth I don't even know what it's gonna do because it's not a large engine.

(Jeremy)>> I'm going 158.

(Pat)>> I think that probably is a fair assumption. So right now we have 32 degrees of total timing in it. That is a 450 c-f-m QFT carburetor. Very nice carburetor. It's sitting here idling at 14.1 for air/fuel. So it's running nice, it's responsive. [ engine revving ]

(Pat)>> Here we go! [ engine revving ]

(Pat)>> Okay, that's not bad. [ engine revving ]

(Pat)>> Woo, ho! What'd you say it was, 158?

(Jeremy)>> 158, look at this.

(Pat)>> 156 that's pretty good. It's kinda doing the hokey pokey on the bottom because fresh carburetor, untuned for the application. We'll get you tuned back up for that cause it's got a little bit bigger cam in it. We're gonna have to do a little bit of tuning on it but nice and smooth. 156 at 4,500, not falling off what so ever. I'm impressed.

(Jeremy)>> That's easy, super simple. I mean the Jeep itself isn't much to begin with. We didn't ask for much. This is way better than we thought.

(Pat)>> We wanted it to run again. I think we're gonna put a little bit of timing in it. Right now 32 degrees, we're gonna jump it up to 34 degrees of timing. We'll do that right now. Now because this thing's low on compression it's gonna take some time. So here we go! [ engine revving ]

(Pat)>> Alright it made 216 pound feet at 3,500, 163.8 at 4,500.

(Jeremy)>> That's crazy.

(Pat)>> I love doing this stuff!

(Jeremy)>> And you broke the 200 on torque.

(Pat)>> The torque is good. We broke 160 on power and we're still kinda going up. Since the jump to 34 degrees total timing worked so well we're gonna advance it to 36 degrees total timing for the next run. [ engine revving ]

(Jeremy)>> It sounds better! [ engine revving ]

(Pat)>> It did the hokey pokey up there.

(Jeremy)>> Right on the top end there.

(Pat)>> 217 pound feet though. I mean we'll take that. You see how it just gained a little bit. I think we're there on timing but you know what we're gonna do now? We're gonna turn it higher. We'll see if we can get this thing to make 5,000.

(Jeremy)>> So you're starting the pull at 2,500 and you're pulling off at 5,000.

(Pat)>> The brake will grab back a hold of it at 5,000. This is gonna sound way racier, are you ready?

(Jeremy)>> 100 percent.

(Pat)>> I know I get excited. I swear I don't take drugs, I just drink a lot of coffee. Alright here we go. [ engine revving ]

(Pat)>> It did it, it did it! It was kinda complaining. Things with low cylinder pressure like this, this has a calculated compression, a measured compression ratio of 8.13 to one. When you're dealing with something with this amount of power, which is low, any incremental change is a large percentage gain. Okay so we were at 101 horsepower before. Now we're at 162. That's our power difference right there.

(Jeremy)>> Holy cow!

(Pat)>> Now is that a different engine or is that a different engine?

(Jimmy)>> That's awesome!

(Pat)>> It's fun but all said and done that's a bad little dude right there.

(Jeremy)>> I don't see why that wouldn't work perfect for us. Any increase is huge for us.

(Pat)>> Now the paint job was my idea because the Jeep is green, and I want it to look cool when you pop the hood and say oh my god. I'm not expecting this to be in there, and plus it'll run a little sportier than it's supposed to.

(Jimmy)>> I think it'll be a perfect engine for us to just cruise around in.

(Pat)>> If you compare where we started to where we ended up the mildly modded 258 is up a little over 61 horsepower and 31 pound feet of torque at peak, and the average output from 2,500 to 4,500 r-p-m is up over 41 horsepower and 68 pound feet of torque. That's a nice gain for some easy bolt on parts. For more information on anything you've seen on today's show go to Powernation TV dot com.

Show Full Transcript

(Pat)>> If those old postal Jeep is going to go from carrying the mail to hauling it it's gonna need some engine work, or at the very least an aerosol overhaul. [ MUSIC ]

(Pat)>> Welcome to Engine Power. Today we have yet another dare to be different project in the shop to see what we can improve on. We always give the big three manufacturers a lot of love on our projects, and that mainly consists of two valve push rod V-8 stuff because that is what is commonly hot rodded but we have proven that virtually anything can be upgraded to hot rod status with the right parts choice, assembly, and a good old fashioned dyno session. That being said there is an automotive manufacturer from the past that is sometimes overlooked but has produced some formidable power plants that can hold their own. That company is AMC. American Motors Corporation had their own entries into the muscle car arena with stout performers such as the Javelin, AMX, Rambler Rebel, and the Hornet just to name a few. V-8's ranging from 290 cubic inches all the way up to 401 cubic inches put them right in the thick of the horsepower wars of the late '60's to early '70's. Unfortunately this isn't one of them. What we have here is a plain jane 232 cubic inch six banger. It has the same basic architecture as the more popular 258, which later evolved into the modern four liter variant that powered several Jeep models all the way up to 2006. This particular power plant was removed from a rough looking late '70's mail carrier Jeep that is in the building right now. Carcass has some exciting plans for it. Our first task is to see if it will even run, and then make some simple improvements to it and get it back to the guys down in Carcass. Helping out today is the newest member of the Powernation team, Frankie Forman. He's a graduate of UNOH where he built engines for the school's dirt track and drag racing teams. [ drill humming ]

(Pat)>> We had a four liter Jeep on the Superflow docking cart a few years ago. So we know this AMC will bolt up nicely. We used the Jeep four liter flywheel because this engine was originally paired with an automatic transmission.

(Frankie)>> I got it.

(Pat)>> You are like a bull in a china shop. [ MUSIC ] No matter what the engine I always like a clean floor to see what's leaking and where it's leaking from. [ MUSIC ] That is racy right there. Probably should get this flow inhibitor out. Being an older engine the dyno setup is very straight forward and smooth with one minor exception. In order to make the stock throttle linkage work on our dyno we had to do some mild fabrication. A piece of angled aluminum and some one inch d-o-m tubing create a bracket and a spacer. [ MUSIC ]

(Frankie)>> Cool!

(Pat)>> Full throttle, I can feel it. [ engine idling ]

(Pat)>> It loaded down.

(Frankie)>> That's pretty smooth.

(Pat)>> Wide open throttle. [ engine revving ]

(Pat)>> That's more than I expected. That's more than I expected, 88 horsepower.

(Frankie)>> I was thinking like 60 maybe. That's kinda cool.

(Pat)>> 171.8 pound feet of torque. Goal take the air cleaner off but at the same time cut the exhaust off it. Cut that in front of the muffler and we'll re-run it. I'm not saying that's gonna do anything on something that makes this kind of power.

(Frankie)>> It can't hurt though. [ engine revving ]

(Pat)>> That's more!

(Frankie)>> Look at that!

(Pat)>> And it still has oil pressure. 97.8, and 178 pound feet. I know this might sound crazy but if we're gonna try to remove some power robbing things take the fan off it.

(Frankie)>> You read my mind. [ drill humming ]

(Pat)>> It definitely loads better without the air system on there. [ engine revving ]

(Pat)>> What do you think of that?

(Frankie)>> That's what I'm saying.

(Pat)>> That is amazing, 101 horse, 182 pound feet by removing the fan. We backed up that run and the numbers were consistent. 101.8 horsepower at 3,600 and 183.1 pound feet of torque at 2,000. Up next, underneath years of grime and grease we find a pleasant surprise. After that we freshen up the AMC and get it back into the cell block.

(Pat)>> With a modest max horsepower number of around 100 the AMC inline isn't going to wow anyone, but what is impressive about this engine is how well it runs after all of those years in a postal Jeep. Since we don't want to tear into the block but we do want to find out if the cylinders are sealing up nicely we decided to run a compression check. The numbers look great. When you're trying to remove decades worth of caked on grime you'll take all the help you can get. So we grabbed a can of CRC Pro Strength Degreaser. It dissolves oil and grease but is still safe for painted and plastic surfaces. It's water based, leaves behind no residue, and is biodegradable. After letting the degreaser soak for 10 minutes we pressure washed the engine. The results were impressive. [ small engine idling ]

(Pat)>> That is way better.

(Frankie)>> It took a little work but it's all cleaned up now.

(Pat)>> Uh oh! That sounded like something broke. We have our first broken piece. Let's see how this one goes. [ drill humming ] [ MUSIC ]

(Pat)>> Pulleys are in good shape. So that's definitely a re-use, and even though it's a little rusty that's a relatively recent water pump. Very nice! [ MUSIC ]

(Pat)>> Half the time when you're tearing something apart you'll find other things that people have done that may or may not have been correct, like this bolt was too long and it had bottomed out and it started to strip. That's why it looks like it's all galled up on one end. Same thing with half the other fasteners. They've been rounded off or whatever. That's typical of high maintenance things like a mail Jeep. [ MUSIC ] Gutted thermostat. In racing that's usually a restrictor sometimes but I didn't know that the mail Jeeps ran so hot. [ MUSIC ] [ drill humming ] [ MUSIC ] [ drill humming ]

(Pat)>> I love the reveal on the valvetrain because I know how this thing ran. It's always nice to see how it looks. Other than being dirty it looks like it's okay. Interesting that only a few seem to be lubricated. The other ones are not getting oil and it still ran fine. It didn't make any noise. When working on old vehicles sometimes things aren't always what they seem. Case in point this engine. When it was power washed off and we looked up casting numbers it is in fact not a 232 inch engine but a 258, which is great because it will work better with the changes we plan on making, but to make those changes we've got to continue with the teardown and that means remove the cylinder head. [ MUSIC ] [ drill humming ] [ MUSIC ]

(Pat)>> I can already see that the oil plug has been changed once cause the cajavis that holds it in there, there's an extra one. [ MUSIC ] Whoa! [ MUSIC ] It's not chewed up but it is not supposed to have a cup in it. This is the stuff you're not supposed to see on the bottom of a flat tappet lifter. It is not supposed to be concave. [ MUSIC ] Even though the engine was running well we are seeing some discouraging signs, like the worn out timing chain and cupped lifters. Although this project is called Aerosol Overhaul we're gonna have to dig a little deeper into the 258 to know the true condition of this power plant. Up next, what started as an aerosol overhaul gets a little more complicated.

(Pat)>> The original plan for this six cylinder was to clean it up a little bit, put a few cool parts on it, and get it right back down to the guys in Carcass. Well like any other hot rod project things change rapidly. The more we dug into this project the worse it became so we made the decision to freshen it up a bit. Rings and bearings, and even though it is not a racy V-8 we knew we could get all the parts we needed for it at Summit Racing. This does add a little bit of cost and time to the build but it is well worth it considering what the old parts look like. So we went ahead and polished the crankshaft and ball honed the cylinders for a fresh surface, and put in our new parts. Since we had to replace the cam shaft anyway we decided to go with something a little more sporty. So we called up Summit Racing and got a complete cam kit. It comes with everything we need. This is a hydraulic flat tappet and the duration at 50 thousandths on the intake is 206 degrees. Exhaust is 212 on a 113 degrees of lobe separation. It also came with a timing gear, springs, retainers, and locks, plus lifters. Everything that matches the cam's profile. As far as lift we're gonna have a little bit more because we decided to go with a 1.7 ratio rocker. So the lift at the valve is around 500 thousandths. This Comp Cams hydraulic flat tappet requires specific lube on the lobes for proper break-in, and it comes with a kit. On the journals we're using break-in oil. [ MUSIC ] [ drill humming ]

(Pat)>> The timing set is non-adjustable but we still went ahead and degreed the cam. It comes in at 110 degrees of intake centerline, which is three degrees advanced, spectacular! The freshly sand blasted stock timing cover bolts up, followed by the cleaned and painted stock harmonic balancer. [ MUSIC ] More lubricant is spread on the bottom of the lifters prior to assembly. Then they are gently placed in their lifter bores. It's tempting to use a magnet to install them, but if the magnet has attracted small metal particles they can end up in your engine. The stock replacement head gasket is next. There are no dowels to align the gasket. So you have to do this by hand. Go slowly and check your work making sure both the gasket and the head are properly aligned. Only one head bolt goes into the water jacket. It has to be sealed with thread sealer. [ MUSIC ] The head is torqued in three steps to a final value of 100 pound feet using high pressure lube. The stock push rods ended up being the correct length. So back in they go. These full roller rockers from Scorpion offer increased durability and less friction than the stock rocker setup. They are a bit overkill for this engine but if more high performance mods happen in the future we'll be good to go. After the rockers are torque to 30 pound feet the valves are set to one half turn past zero lash. Before the cork oil pan gasket goes down we'll lay on some black weather strip adhesive. The rubber end gaskets are next. [ MUSIC ] Finally the stock pan goes on. We now have the engine back together to a point where we can apply some color. Hence the name Aerosol Overhaul. What do you think? Because the intake and exhaust are on the same side they share a gasket. Dowels will keep it aligned. The Hedman header has to go on first. It's a six into one style with a one and a half inch primary tube diameter. For induction we chose to splurge a little on Offenhauser's dual port four barrel intake manifold. Make sure the intake and exhaust bolt flange height is the same on both pieces so the manifold bolts up cleanly and seals properly. We're running a one inch spacer for linkage clearance. For good street manners we are running a QFT 450 c-f-m carburetor with an electric choke. [ MUSIC ] Up next, from where we started to where we finish we make a big improvement. It did it!

(Pat)>> We've made it to the dyno room to see what the AMC 258 will do. Keeping the timing accurate is an MSD Pro Billet distributor along with their 8.5 millimeter super conductor wires. We also installed a new MSD Blaster 2 coil. It won't be used for the dyno runs but it will see plenty of use later on the street. Alright here comes some fuel. With the fuel level checked we'll fire the engine and set the timing to 32 degrees, check for leaks, and break in the flat tappet cam. That's a good time to let the header paint burn off as well. We run the engine gently from 1,500 to 2,500 r-p-m cycling it for 20 minutes. Alright so we are back to race ready if there is such a thing. Okay here's the deal. We initially thought this engine was a 232 because that's what it said on the fender. The problem with that is it only made 100 horse and like 187 pound feet, but it's actually a 258. We cleaned it off and got everything measured up. So that made the engine even more lame than what it was before. Now the cam was wasted. We had to put some parts in it, re-ring it, re-bearing it, polish the crank, easy stuff. We didn't change a piston or anything like that and we put a couple of goodies on it like the manifold and the carb, racier rocker, but we had to put a cam in it anyway. So we put a little bit bigger cam. 206 at 50 is not a big cam by any stretch of the imagination. So any predictions of what it's going to do? To tell you the truth I don't even know what it's gonna do because it's not a large engine.

(Jeremy)>> I'm going 158.

(Pat)>> I think that probably is a fair assumption. So right now we have 32 degrees of total timing in it. That is a 450 c-f-m QFT carburetor. Very nice carburetor. It's sitting here idling at 14.1 for air/fuel. So it's running nice, it's responsive. [ engine revving ]

(Pat)>> Here we go! [ engine revving ]

(Pat)>> Okay, that's not bad. [ engine revving ]

(Pat)>> Woo, ho! What'd you say it was, 158?

(Jeremy)>> 158, look at this.

(Pat)>> 156 that's pretty good. It's kinda doing the hokey pokey on the bottom because fresh carburetor, untuned for the application. We'll get you tuned back up for that cause it's got a little bit bigger cam in it. We're gonna have to do a little bit of tuning on it but nice and smooth. 156 at 4,500, not falling off what so ever. I'm impressed.

(Jeremy)>> That's easy, super simple. I mean the Jeep itself isn't much to begin with. We didn't ask for much. This is way better than we thought.

(Pat)>> We wanted it to run again. I think we're gonna put a little bit of timing in it. Right now 32 degrees, we're gonna jump it up to 34 degrees of timing. We'll do that right now. Now because this thing's low on compression it's gonna take some time. So here we go! [ engine revving ]

(Pat)>> Alright it made 216 pound feet at 3,500, 163.8 at 4,500.

(Jeremy)>> That's crazy.

(Pat)>> I love doing this stuff!

(Jeremy)>> And you broke the 200 on torque.

(Pat)>> The torque is good. We broke 160 on power and we're still kinda going up. Since the jump to 34 degrees total timing worked so well we're gonna advance it to 36 degrees total timing for the next run. [ engine revving ]

(Jeremy)>> It sounds better! [ engine revving ]

(Pat)>> It did the hokey pokey up there.

(Jeremy)>> Right on the top end there.

(Pat)>> 217 pound feet though. I mean we'll take that. You see how it just gained a little bit. I think we're there on timing but you know what we're gonna do now? We're gonna turn it higher. We'll see if we can get this thing to make 5,000.

(Jeremy)>> So you're starting the pull at 2,500 and you're pulling off at 5,000.

(Pat)>> The brake will grab back a hold of it at 5,000. This is gonna sound way racier, are you ready?

(Jeremy)>> 100 percent.

(Pat)>> I know I get excited. I swear I don't take drugs, I just drink a lot of coffee. Alright here we go. [ engine revving ]

(Pat)>> It did it, it did it! It was kinda complaining. Things with low cylinder pressure like this, this has a calculated compression, a measured compression ratio of 8.13 to one. When you're dealing with something with this amount of power, which is low, any incremental change is a large percentage gain. Okay so we were at 101 horsepower before. Now we're at 162. That's our power difference right there.

(Jeremy)>> Holy cow!

(Pat)>> Now is that a different engine or is that a different engine?

(Jimmy)>> That's awesome!

(Pat)>> It's fun but all said and done that's a bad little dude right there.

(Jeremy)>> I don't see why that wouldn't work perfect for us. Any increase is huge for us.

(Pat)>> Now the paint job was my idea because the Jeep is green, and I want it to look cool when you pop the hood and say oh my god. I'm not expecting this to be in there, and plus it'll run a little sportier than it's supposed to.

(Jimmy)>> I think it'll be a perfect engine for us to just cruise around in.

(Pat)>> If you compare where we started to where we ended up the mildly modded 258 is up a little over 61 horsepower and 31 pound feet of torque at peak, and the average output from 2,500 to 4,500 r-p-m is up over 41 horsepower and 68 pound feet of torque. That's a nice gain for some easy bolt on parts. For more information on anything you've seen on today's show go to Powernation TV dot com.