Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterEpisode Transcript

[ Pat ] You're watching Powernation!

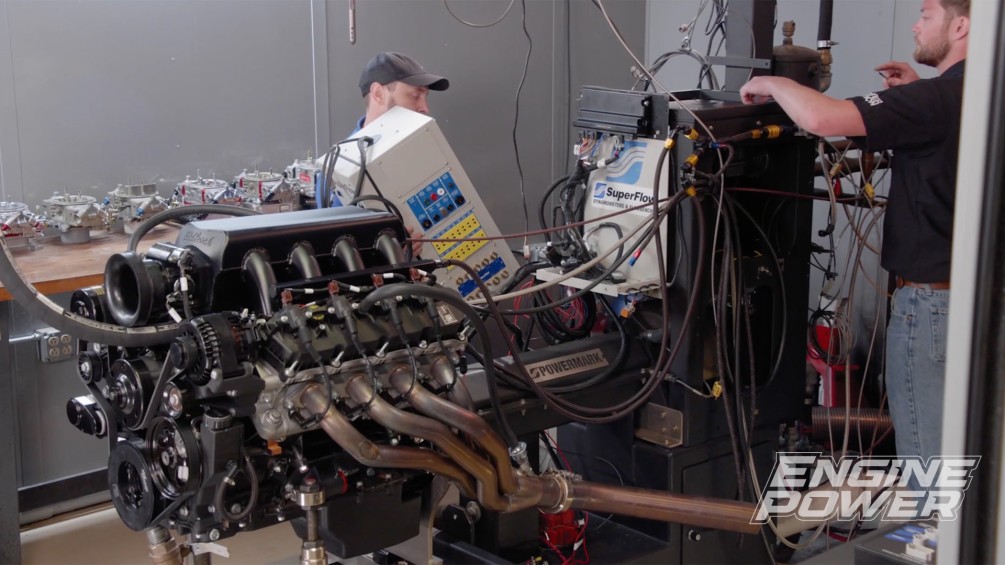

[ Frankie ] Today on Engine Power our SuperFlow dyno gets a massive upgrade in order to keep us on the leading edge of high performance engine testing technology. [ Pat ] We are gonna show you the entire upgrade process, and of course test it out with one of our serious pump gas performers. [ Music ] [ Frankie ] Hey everyone, welcome to a very special episode of Engine Power. Today we have our 7.3-Liter Godzilla on the dyno but we are not upgrading this engine. We're upgrading our dyno system. We are getting a brand new control system from SuperFlow. It's gonna give us a ton of cool functionality and we are very excited to get it installed. [ Pat ] And we are excited to show you the entire process. We're getting a whole new console, a whole new operating system, a new sensor box with increased sensor capability. But before we can do that we're gonna show you the guys from SuperFlow that's gonna make it all happen. Shawn, Cajun, thanks for coming in. [ Frankie ] You guys have a lot of boxes here. It looks like a lot of cool stuff. Tell us about the upgrades we're gonna be doing with our system. [ Shawn ] There's a lot going on here today. First of all, with this system you're getting a brand new sensor, brand new console. You're gonna be getting our new auto throttle as well where you can do both manual and fully automated testing. Eight new channels of lambda and a lot more cool stuff. [ Pat ] Now this is tailored for us. Tell us a little bit about that. [ Kajun ] So we have new valves, new box, a whole lot of new goodies for you guys. Really this is gonna bring you guys up to a modern system. We're gonna be getting rid of your Windows 7 computer. We're gonna be putting on a Windows 11 computer, and that's all part of the upgrade from Win Dyne 3.2 to Win Dyne 5. [ Pat ] Before we do any of that we have to make some pulls on our current system. Tell us why we have to do that. [ Kajun ] We do that to ensure the mechanicals are running good on your dyno. If it runs really well on Win Dyne 3.2 it will run really well on Win Dyne 5. [ Frankie ] Well we have a 600 horse Godzilla as a base line. We'll get some temp in her and make a few pulls. [ engine revving ] Frankie ] Alright, we're gonna run the engine just like we did last time, 3,500 to 6,500 at 300 per second. [ Pat ] How many runs do you actually want? [ Kajun ] Three would be great. [ Frankie ] We'll do at least three. [ engine revving ]

[ Frankie ] What a nice engine. [ Shawn ] That controlled real nice. [ Frankie ] 596.4, 552 pound feet, exactly what it should be. [ Pat ] From a control standpoint what do you think how it sounded? [ Kajun ] Your data looks great. I think it sounds good. I think we can work with that. [ Pat ] We'll make a couple more here just to say we did. We've never had a control issue with this. It's always worked great. We don't expect anything crazy. [ Frankie ] Just back it up again. [ engine revving ]

[ Shawn ] Nice! [ Frankie ] 554, 597. [ Pat ] Biggest thing with dynos is consistency. Dyno's a tool and you use it for tuning. If you're trying to do things, changing parts and trying to see if it made a difference whether it's good or bad, consistency of the dyno is the most important part. [ Frankie ] Especially dealing with temperatures, and sensor readouts, that's what's great about having all the data that we have and all that stuff we're gonna add. That's gonna be huge for us just tuning engines and having consistent data to work off of. I think this is awesome, and we'll do one more and be ready to go. [ engine revving ]

[ Pat ] You just made three extremely close overlaying graphs. [ Kajun ] Those look really good. [ Frankie ] I don't know who built the engine but it's pretty solid. We've never had any issues and it just works. We just lay into this thing time after time and the dyno just eats it up. [ Pat ] It makes us feel good because we always want the difference to be the parts right and how it's done. So the dyno tells your story, that's all it does. It does exactly what you ask it to. It tells what you've done. [ Frankie ] We have enough data there. I think we'll get her shut down and we'll get started. [ Pat ] Kajun and Shawn dive right into the upgrade, and with almost all of the electronics on the dyno being changed they immediately started getting our new components out of the packaging and prepped to be installed. [ Frankie ] The first thing to go from our Win Dyne 3.2 setup is the entire console, computer, and even the desk with a little extra weight. [ Pat ] Out with the old. [ Frankie ] Since all are being replaced with new components. Our new desk can be raised or lowered so we can stay on our feet as we run in and out of the dyno making adjustments or stay sitting for extended testing periods. [ Kajun ] And we're ready to put the console in. [ Pat ] This new console gets mounted to the desk and it houses our new auto throttle controller that eliminates that long cable connection that had to run inside the dyno cell. We are also increasing the number of monitors to four with each one being individually configurable and allowing us to display a massive amount of live data, which we love. [ Frankie ] With our new computer system in place up next Kajun gets cooking on the upgrades inside our dyno cell.

[ Frankie ] We have moved inside the dyno cell. So we're gonna start switching stuff out. First thing to do is get all these connections off our sensor box and get it off. [ Music ] [ Pat ] The guys from SuperFlow got our new control console completely assembled and set up. So now we can turn our attention inside the dyno room for the next stage of our Win Dyne 5 upgrade. This box houses all the sensor electronics and control valve electronics, and the entire assembly is being replaced and upgraded. [ Frankie ] So it looks like all the hookups are gonna be pretty easy. Basically the same as all our old stuff, which I think will make it pretty smooth on the transition right? [ Kajun ] Yeah this should be very easy. The bolt pattern is exactly the same on the back of the box. All the sensor connectors are exactly the same. It should go pretty smoothly. [ Pat ] The auto throttle actuator that controls our throttle cable is mounted to the bottom and is adjustable for different linkages and throttle sweeps. [ Kajun ] So I'm setting up the auto throttle in manual mode right now. Going to 100 percent, adjusting the span, making sure that's moving, and going back to our zero position. [ Pat ] The input and output connections are made and our pressure sensor lines can be installed into the new transducer ports. Along with all new sensors we are also getting new servos that pair with the software to help improve the control of the dyno. The upper is located just above the dyno's absorber and controls the water entering the brake, and the other, the outlet, is just below the absorber. With those resealed and connected we can calibrate the load cell on the dyno, which is what physically measures the torque output of the engine. This is a critical process for ensuring accurate torque measurement and horsepower calculation, and if left uncalibrated can give false readings that are too low or too high. [ Frankie ] This hanger mounts to the absorber and gives us a convenient location to apply rotational force on it. Then we can zero out the torque value in the software to remove the weight of the hanger from our reading and hang a known mass to apply a calculated torque to the absorber itself. Our weight is 204 pounds total, and since it hangs 24 inches from the center of the brake we know it is applying 408 pound feet to the absorber. After gently tapping the hanger to prevent any hysteresis, or binding, from effecting the reading we can enter that value to calibrate the sensor in the software. Then we'll remove the weight and the hanger and re-zero the sensor in the software, which will finish calibrating the load zone. [ Pat ] Now we can reinstall the absorber cover, which we've modified to mount our new SuperFlow eight channel oxygen sensor controller. This is a great option we wanted to add to our dyno to improve our analysis and tuning capabilities as it allows us to monitor and tune each cylinder's air/fuel ratio individually. We do have to remove our dyno headers from the engine to tig weld individual stainless oxygen sensor bungs into each primary tube but they only need to be modified once and then we can reap the benefits for years to come. The kit comes with a modern and easily replaceable Bosch LSU-4.9 universal exhaust gas oxygen sensor and long cable extensions for easy and clean routing that keeps them out of harms way. [ Frankie ] Alright Kajun, so we've finished up changing all the hardware inside the dyno cell. Let's talk about some of the software configuration you can do because that's really where Win Dyne 5 shines. [ Kajun ] Like I was saying earlier, the configuration of this has gotten a lot easier compared to previous dyno systems. For one instance, instead of having to open up a separate test editor to change your set points you can now double click and change your test start values and end values and random set points from the main screen. [ Frankie ] With all these sensors as well can those be configured; can they be moved? Talk a little bit about the screen setup here cause this is a pre-loaded screen but we can make our own screens, right? [ Kajun ] Correct, this is the one that came with your guys' dyno system. We can change these things around. We can move any of the sensors anywhere we want. We can resize them, and we're gonna start by doing that by clicking control and "U". That's gonna bring up all these nice purple borders here. That allows us to click and drag things to where we want them to be. [ Frankie ] There are a few final setup configurations that need to be done, and then Kajun can spend a good bit of time showing us through the new software to get us comfortable. This will allow us to take advantage of the new customizable features like screen setup, custom dyno math, additional inputs, and more, but pretty soon we'll be ready to run our engine with our brand new dyno setup. [ Pat ] Coming up, we wrap up and test our new system but first we check out the foundation for SuperFlow's success on a massive scale.

[ Frankie ] Shawn and Kajun are wrapping up the final details on our new dyno software, which will give us the most advanced control and data acquisition that SuperFlow offers. They have been well known throughout the high performance industry for being the standard in dyno technology and that quality is reflected in the parent company Power Test. Where we talk about dynoing engines with 500 to 1,500 pound feet of torque Power Test dynos are custom designed for industrial engine applications that can produce tens of thousands of pound feet like the one at the Cleveland Brothers facility in Evansburg, Pennsylvania. [ Scott ] Cleveland Brothers is a full service Caterpillar dealer. We have several different lines of business which include heavy equipment and power systems. Inside the power systems division includes our truck shops, our commercial engine shops, marine, and our petroleum division. We are a full service engine rebuild center. Our concentration is the petroleum industry. So we will do frack engines. We will do natural gas engines. Our Evansburg facility is our newest facility. It is an engine rebuild shop. When we originally started looking for dynamometers and testing cells for the facility we went to other dealers, other companies, and a common name that kept coming up was Power Test. We reached out and contacted Power Test to come and listen to what we wanted to do with our facilities. From that moment on it was more of a partnership than it was a vendor/supplier. We had used Power Test at another one of our facilities for a smaller dyno that was a pretty straightforward standard installation. So when we were looking at purchasing this facility and putting in test cells we knew that our requirements were gonna be somewhat different. So we went ahead and visited other locations that had other manufacturers of the dynamometers. Power Test name still kept coming up as being the best in the industry. [ Music ] [ Ben ] So Power Test started working with Cleveland Brothers about seven or eight years ago now. So Cleveland Brothers in Evansburg has one of our 45-X-10 dynamometers as well as our H-36-10. Both of those test cells are outfitted with closed loop pulling allowing them to run glycol in their engines. They also have our fuel measurement systems, evaporative coolers, as well as full water recirculation systems in those test cells. [ engine humming ]

[ Scott ] Some of the differences between the automotive testing and the industrial engine testing on the dynos is very similar. You're doing horsepower, torque, r-p-m, torque stall. One of the biggest differences would be the size of our equipment. We have pistons that weigh 500 pounds. We have connecting rods that weigh 200 pounds. So if there's a problem with one of those parts we find it in very fast order and it usually does a considerable amount of damage to a very expensive component. The power test equipment we have in both of our dyno cells we have the dynamometers, the coolers, the motors. It's a complete power test package including the cooling tower outside. At the Evansburg facility we fully test Caterpillar engines to meet all of Caterpillar's specifications, which include engines emissions. So we're able to tune and adjust emissions as needed for these engines so when they leave we're meeting the engine emissions standards as produced. We can test Tier-4 DGB engines and blend gas at this facility and provide all the testing results from those engines. I think the partnership that we have with Power Test has enabled us to develop exceptional capabilities within our testing cells. Power Test helped us throughout the entire design process. We had certain needs and desires that we wanted to highlight within our test cells. There's data that we wanted to extract that maybe was not normally done. We are able to work with Power Test hand in hand to resolve those issues to provide the testing requirements that our customers at Caterpillar demand. All the engines that come through the Evansburg facility will run through our dynamometer. We compare those to Caterpillar as built specifications when they were tested. If they do not meet those specifications the engines are troubleshot for why. Those are repaired and retested until they meet Caterpillar specifications as a new engine. Power Test has been a huge asset to have for their test cells because this is the last stopping point for those engines. The Evansburg shop was solely built and designed as an engine rebuild facility. We rebuilt, remanufacture, and machine all the engine components in house. Nothing leaves our facility. [ Frankie ] When we get back it's dyno time as we test out our innovative dyno software and the SuperFlow guys run us through all of its new features.

[ Frankie ] So we have our Godzilla running with our Win Dyne 5 setup and there are screens everywhere, which I love. There's so much data here. Same as before, 3,500 to 6,500 at 300 per second. Our other values are correct. [ Pat ] There's a lot of familiarity with this because the programming and all that is just so much more easy because it's easier to get at. [ Kajun ] Make sure you go to your contents and set your engine up. [ Frankie ] Got that entered in to make sure all this is right. 4.220 bore, 8 cylinders, 3.976 stroke, four cycle engine. So we know all that is correct. I love this giant screen of data. [ Pat ]The whole thing is it's there and it's easy to find from baro, humidity, air density, a running density altitude change. For race car guys we always look at that. [ Frankie ] Let's make a run and I'm really excited to see how this thing loads in. You watch that, I'll watch this, and we'll make a run. That's nice. [ Pat ] Live 0-2. [ engine revving ] [ Pat ] This is like Christmas. [ Frankie ] The old system would go over the set r-p-m and then drag the engine back down. This just is nicely coming up to meet it. That was so smooth. I mean 548.2 for peak torque and 609.5 for peak power, which is very close. The max we made on this engine when we dyno tested it the first time was 610 and I think it was 550 for torque. I would say that's extremely close. [ Kajun ] And the shape of the curve looks extremely similar to what it did before, which shows us our control is really good on this. [ Pat ] The engine itself doesn't do anything crazy. It's the control part where the dyno's actually controlling what it's doing and smoothing that out is important because otherwise you're gonna get a bunch of erroneous numbers. [ Frankie ] The great part of having this engine as a base line is we can compare them directly and know that if you didn't have that you'd be like what is the shape of that curve? Is that the dyno, the engine? We know it's exactly same, which is perfect cause that's what we want. [ Kajun ] We made a constant in this whole upgrade process. Being that everything else is pretty much brand new we needed to have that one thing that was our constant. [ Frankie ] And this data setup is sweet because we can have 10 screens I think. [ Kajun ] Up to 10. [ Frankie ] We can have our raw numbers, our data. [ Pat ] Just numerical data we always look at. I've very, very impressed. This is essentially a very new system. You've made everything so much more user-friendly, and user adjustable, and user customizable. [ Kajun ] Just so you guys know too just like your main running screens you can float these out too. So you can have multiple screens up at one point in time. [ Frankie ] Only one thing left to do. [ Pat ] Keep dynoing? [ Frankie ] You make a run cause it's so smooth when you go in and the new throttle setup feels totally different. [ Pat ] Let me see if I can get her figured out here. [ Shawn ] Let the old man to the plate. [ Pat ] Let's see if we can figure it out here. Punch start, everything looks good, and button's on top. [ Kajun ] And both of them work. [ engine revving ]

[ Pat ] Wow! [ Kajun ] Told you it was so easy Pat could do it. [ Shawn ] Look at that overlay. [ Pat ] That's what you want. When you're on your control and it's overlaying. Once the engine is thermally stabilized really it's gonna be onesie twosie right. I cannot believe the amount of detail and the thought process. You went from taking a system that was really really good and totally revamping it. Hat's off to you guys. You did a great job. This is a lot of engineering, a lot of time. I know this is a lot of years in the making. [ Frankie ] I feel like you've thought of everything. All the stuff you would want to be able to change it's all right there. [ Pat ] And that's listening to your customers and saying hey, what can we do to make it better. Along with even the desk that goes up and down. It's the little things. Guys thank you very much. [ Frankie ] We really appreciate it. [ Pat ] It was a pleasure and we're gonna put this thing to the test every time. For us we're data freaks. Anything we can do we're gonna be on here doing what we can on every engine that we have. Thank you very much. [ Shawn ] And I'll be tuning in to watch. [ Pat ] Awesome, we appreciate it!

Show Full Transcript

[ Frankie ] Today on Engine Power our SuperFlow dyno gets a massive upgrade in order to keep us on the leading edge of high performance engine testing technology. [ Pat ] We are gonna show you the entire upgrade process, and of course test it out with one of our serious pump gas performers. [ Music ] [ Frankie ] Hey everyone, welcome to a very special episode of Engine Power. Today we have our 7.3-Liter Godzilla on the dyno but we are not upgrading this engine. We're upgrading our dyno system. We are getting a brand new control system from SuperFlow. It's gonna give us a ton of cool functionality and we are very excited to get it installed. [ Pat ] And we are excited to show you the entire process. We're getting a whole new console, a whole new operating system, a new sensor box with increased sensor capability. But before we can do that we're gonna show you the guys from SuperFlow that's gonna make it all happen. Shawn, Cajun, thanks for coming in. [ Frankie ] You guys have a lot of boxes here. It looks like a lot of cool stuff. Tell us about the upgrades we're gonna be doing with our system. [ Shawn ] There's a lot going on here today. First of all, with this system you're getting a brand new sensor, brand new console. You're gonna be getting our new auto throttle as well where you can do both manual and fully automated testing. Eight new channels of lambda and a lot more cool stuff. [ Pat ] Now this is tailored for us. Tell us a little bit about that. [ Kajun ] So we have new valves, new box, a whole lot of new goodies for you guys. Really this is gonna bring you guys up to a modern system. We're gonna be getting rid of your Windows 7 computer. We're gonna be putting on a Windows 11 computer, and that's all part of the upgrade from Win Dyne 3.2 to Win Dyne 5. [ Pat ] Before we do any of that we have to make some pulls on our current system. Tell us why we have to do that. [ Kajun ] We do that to ensure the mechanicals are running good on your dyno. If it runs really well on Win Dyne 3.2 it will run really well on Win Dyne 5. [ Frankie ] Well we have a 600 horse Godzilla as a base line. We'll get some temp in her and make a few pulls. [ engine revving ] Frankie ] Alright, we're gonna run the engine just like we did last time, 3,500 to 6,500 at 300 per second. [ Pat ] How many runs do you actually want? [ Kajun ] Three would be great. [ Frankie ] We'll do at least three. [ engine revving ]

[ Frankie ] What a nice engine. [ Shawn ] That controlled real nice. [ Frankie ] 596.4, 552 pound feet, exactly what it should be. [ Pat ] From a control standpoint what do you think how it sounded? [ Kajun ] Your data looks great. I think it sounds good. I think we can work with that. [ Pat ] We'll make a couple more here just to say we did. We've never had a control issue with this. It's always worked great. We don't expect anything crazy. [ Frankie ] Just back it up again. [ engine revving ]

[ Shawn ] Nice! [ Frankie ] 554, 597. [ Pat ] Biggest thing with dynos is consistency. Dyno's a tool and you use it for tuning. If you're trying to do things, changing parts and trying to see if it made a difference whether it's good or bad, consistency of the dyno is the most important part. [ Frankie ] Especially dealing with temperatures, and sensor readouts, that's what's great about having all the data that we have and all that stuff we're gonna add. That's gonna be huge for us just tuning engines and having consistent data to work off of. I think this is awesome, and we'll do one more and be ready to go. [ engine revving ]

[ Pat ] You just made three extremely close overlaying graphs. [ Kajun ] Those look really good. [ Frankie ] I don't know who built the engine but it's pretty solid. We've never had any issues and it just works. We just lay into this thing time after time and the dyno just eats it up. [ Pat ] It makes us feel good because we always want the difference to be the parts right and how it's done. So the dyno tells your story, that's all it does. It does exactly what you ask it to. It tells what you've done. [ Frankie ] We have enough data there. I think we'll get her shut down and we'll get started. [ Pat ] Kajun and Shawn dive right into the upgrade, and with almost all of the electronics on the dyno being changed they immediately started getting our new components out of the packaging and prepped to be installed. [ Frankie ] The first thing to go from our Win Dyne 3.2 setup is the entire console, computer, and even the desk with a little extra weight. [ Pat ] Out with the old. [ Frankie ] Since all are being replaced with new components. Our new desk can be raised or lowered so we can stay on our feet as we run in and out of the dyno making adjustments or stay sitting for extended testing periods. [ Kajun ] And we're ready to put the console in. [ Pat ] This new console gets mounted to the desk and it houses our new auto throttle controller that eliminates that long cable connection that had to run inside the dyno cell. We are also increasing the number of monitors to four with each one being individually configurable and allowing us to display a massive amount of live data, which we love. [ Frankie ] With our new computer system in place up next Kajun gets cooking on the upgrades inside our dyno cell.

[ Frankie ] We have moved inside the dyno cell. So we're gonna start switching stuff out. First thing to do is get all these connections off our sensor box and get it off. [ Music ] [ Pat ] The guys from SuperFlow got our new control console completely assembled and set up. So now we can turn our attention inside the dyno room for the next stage of our Win Dyne 5 upgrade. This box houses all the sensor electronics and control valve electronics, and the entire assembly is being replaced and upgraded. [ Frankie ] So it looks like all the hookups are gonna be pretty easy. Basically the same as all our old stuff, which I think will make it pretty smooth on the transition right? [ Kajun ] Yeah this should be very easy. The bolt pattern is exactly the same on the back of the box. All the sensor connectors are exactly the same. It should go pretty smoothly. [ Pat ] The auto throttle actuator that controls our throttle cable is mounted to the bottom and is adjustable for different linkages and throttle sweeps. [ Kajun ] So I'm setting up the auto throttle in manual mode right now. Going to 100 percent, adjusting the span, making sure that's moving, and going back to our zero position. [ Pat ] The input and output connections are made and our pressure sensor lines can be installed into the new transducer ports. Along with all new sensors we are also getting new servos that pair with the software to help improve the control of the dyno. The upper is located just above the dyno's absorber and controls the water entering the brake, and the other, the outlet, is just below the absorber. With those resealed and connected we can calibrate the load cell on the dyno, which is what physically measures the torque output of the engine. This is a critical process for ensuring accurate torque measurement and horsepower calculation, and if left uncalibrated can give false readings that are too low or too high. [ Frankie ] This hanger mounts to the absorber and gives us a convenient location to apply rotational force on it. Then we can zero out the torque value in the software to remove the weight of the hanger from our reading and hang a known mass to apply a calculated torque to the absorber itself. Our weight is 204 pounds total, and since it hangs 24 inches from the center of the brake we know it is applying 408 pound feet to the absorber. After gently tapping the hanger to prevent any hysteresis, or binding, from effecting the reading we can enter that value to calibrate the sensor in the software. Then we'll remove the weight and the hanger and re-zero the sensor in the software, which will finish calibrating the load zone. [ Pat ] Now we can reinstall the absorber cover, which we've modified to mount our new SuperFlow eight channel oxygen sensor controller. This is a great option we wanted to add to our dyno to improve our analysis and tuning capabilities as it allows us to monitor and tune each cylinder's air/fuel ratio individually. We do have to remove our dyno headers from the engine to tig weld individual stainless oxygen sensor bungs into each primary tube but they only need to be modified once and then we can reap the benefits for years to come. The kit comes with a modern and easily replaceable Bosch LSU-4.9 universal exhaust gas oxygen sensor and long cable extensions for easy and clean routing that keeps them out of harms way. [ Frankie ] Alright Kajun, so we've finished up changing all the hardware inside the dyno cell. Let's talk about some of the software configuration you can do because that's really where Win Dyne 5 shines. [ Kajun ] Like I was saying earlier, the configuration of this has gotten a lot easier compared to previous dyno systems. For one instance, instead of having to open up a separate test editor to change your set points you can now double click and change your test start values and end values and random set points from the main screen. [ Frankie ] With all these sensors as well can those be configured; can they be moved? Talk a little bit about the screen setup here cause this is a pre-loaded screen but we can make our own screens, right? [ Kajun ] Correct, this is the one that came with your guys' dyno system. We can change these things around. We can move any of the sensors anywhere we want. We can resize them, and we're gonna start by doing that by clicking control and "U". That's gonna bring up all these nice purple borders here. That allows us to click and drag things to where we want them to be. [ Frankie ] There are a few final setup configurations that need to be done, and then Kajun can spend a good bit of time showing us through the new software to get us comfortable. This will allow us to take advantage of the new customizable features like screen setup, custom dyno math, additional inputs, and more, but pretty soon we'll be ready to run our engine with our brand new dyno setup. [ Pat ] Coming up, we wrap up and test our new system but first we check out the foundation for SuperFlow's success on a massive scale.

[ Frankie ] Shawn and Kajun are wrapping up the final details on our new dyno software, which will give us the most advanced control and data acquisition that SuperFlow offers. They have been well known throughout the high performance industry for being the standard in dyno technology and that quality is reflected in the parent company Power Test. Where we talk about dynoing engines with 500 to 1,500 pound feet of torque Power Test dynos are custom designed for industrial engine applications that can produce tens of thousands of pound feet like the one at the Cleveland Brothers facility in Evansburg, Pennsylvania. [ Scott ] Cleveland Brothers is a full service Caterpillar dealer. We have several different lines of business which include heavy equipment and power systems. Inside the power systems division includes our truck shops, our commercial engine shops, marine, and our petroleum division. We are a full service engine rebuild center. Our concentration is the petroleum industry. So we will do frack engines. We will do natural gas engines. Our Evansburg facility is our newest facility. It is an engine rebuild shop. When we originally started looking for dynamometers and testing cells for the facility we went to other dealers, other companies, and a common name that kept coming up was Power Test. We reached out and contacted Power Test to come and listen to what we wanted to do with our facilities. From that moment on it was more of a partnership than it was a vendor/supplier. We had used Power Test at another one of our facilities for a smaller dyno that was a pretty straightforward standard installation. So when we were looking at purchasing this facility and putting in test cells we knew that our requirements were gonna be somewhat different. So we went ahead and visited other locations that had other manufacturers of the dynamometers. Power Test name still kept coming up as being the best in the industry. [ Music ] [ Ben ] So Power Test started working with Cleveland Brothers about seven or eight years ago now. So Cleveland Brothers in Evansburg has one of our 45-X-10 dynamometers as well as our H-36-10. Both of those test cells are outfitted with closed loop pulling allowing them to run glycol in their engines. They also have our fuel measurement systems, evaporative coolers, as well as full water recirculation systems in those test cells. [ engine humming ]

[ Scott ] Some of the differences between the automotive testing and the industrial engine testing on the dynos is very similar. You're doing horsepower, torque, r-p-m, torque stall. One of the biggest differences would be the size of our equipment. We have pistons that weigh 500 pounds. We have connecting rods that weigh 200 pounds. So if there's a problem with one of those parts we find it in very fast order and it usually does a considerable amount of damage to a very expensive component. The power test equipment we have in both of our dyno cells we have the dynamometers, the coolers, the motors. It's a complete power test package including the cooling tower outside. At the Evansburg facility we fully test Caterpillar engines to meet all of Caterpillar's specifications, which include engines emissions. So we're able to tune and adjust emissions as needed for these engines so when they leave we're meeting the engine emissions standards as produced. We can test Tier-4 DGB engines and blend gas at this facility and provide all the testing results from those engines. I think the partnership that we have with Power Test has enabled us to develop exceptional capabilities within our testing cells. Power Test helped us throughout the entire design process. We had certain needs and desires that we wanted to highlight within our test cells. There's data that we wanted to extract that maybe was not normally done. We are able to work with Power Test hand in hand to resolve those issues to provide the testing requirements that our customers at Caterpillar demand. All the engines that come through the Evansburg facility will run through our dynamometer. We compare those to Caterpillar as built specifications when they were tested. If they do not meet those specifications the engines are troubleshot for why. Those are repaired and retested until they meet Caterpillar specifications as a new engine. Power Test has been a huge asset to have for their test cells because this is the last stopping point for those engines. The Evansburg shop was solely built and designed as an engine rebuild facility. We rebuilt, remanufacture, and machine all the engine components in house. Nothing leaves our facility. [ Frankie ] When we get back it's dyno time as we test out our innovative dyno software and the SuperFlow guys run us through all of its new features.

[ Frankie ] So we have our Godzilla running with our Win Dyne 5 setup and there are screens everywhere, which I love. There's so much data here. Same as before, 3,500 to 6,500 at 300 per second. Our other values are correct. [ Pat ] There's a lot of familiarity with this because the programming and all that is just so much more easy because it's easier to get at. [ Kajun ] Make sure you go to your contents and set your engine up. [ Frankie ] Got that entered in to make sure all this is right. 4.220 bore, 8 cylinders, 3.976 stroke, four cycle engine. So we know all that is correct. I love this giant screen of data. [ Pat ]The whole thing is it's there and it's easy to find from baro, humidity, air density, a running density altitude change. For race car guys we always look at that. [ Frankie ] Let's make a run and I'm really excited to see how this thing loads in. You watch that, I'll watch this, and we'll make a run. That's nice. [ Pat ] Live 0-2. [ engine revving ] [ Pat ] This is like Christmas. [ Frankie ] The old system would go over the set r-p-m and then drag the engine back down. This just is nicely coming up to meet it. That was so smooth. I mean 548.2 for peak torque and 609.5 for peak power, which is very close. The max we made on this engine when we dyno tested it the first time was 610 and I think it was 550 for torque. I would say that's extremely close. [ Kajun ] And the shape of the curve looks extremely similar to what it did before, which shows us our control is really good on this. [ Pat ] The engine itself doesn't do anything crazy. It's the control part where the dyno's actually controlling what it's doing and smoothing that out is important because otherwise you're gonna get a bunch of erroneous numbers. [ Frankie ] The great part of having this engine as a base line is we can compare them directly and know that if you didn't have that you'd be like what is the shape of that curve? Is that the dyno, the engine? We know it's exactly same, which is perfect cause that's what we want. [ Kajun ] We made a constant in this whole upgrade process. Being that everything else is pretty much brand new we needed to have that one thing that was our constant. [ Frankie ] And this data setup is sweet because we can have 10 screens I think. [ Kajun ] Up to 10. [ Frankie ] We can have our raw numbers, our data. [ Pat ] Just numerical data we always look at. I've very, very impressed. This is essentially a very new system. You've made everything so much more user-friendly, and user adjustable, and user customizable. [ Kajun ] Just so you guys know too just like your main running screens you can float these out too. So you can have multiple screens up at one point in time. [ Frankie ] Only one thing left to do. [ Pat ] Keep dynoing? [ Frankie ] You make a run cause it's so smooth when you go in and the new throttle setup feels totally different. [ Pat ] Let me see if I can get her figured out here. [ Shawn ] Let the old man to the plate. [ Pat ] Let's see if we can figure it out here. Punch start, everything looks good, and button's on top. [ Kajun ] And both of them work. [ engine revving ]

[ Pat ] Wow! [ Kajun ] Told you it was so easy Pat could do it. [ Shawn ] Look at that overlay. [ Pat ] That's what you want. When you're on your control and it's overlaying. Once the engine is thermally stabilized really it's gonna be onesie twosie right. I cannot believe the amount of detail and the thought process. You went from taking a system that was really really good and totally revamping it. Hat's off to you guys. You did a great job. This is a lot of engineering, a lot of time. I know this is a lot of years in the making. [ Frankie ] I feel like you've thought of everything. All the stuff you would want to be able to change it's all right there. [ Pat ] And that's listening to your customers and saying hey, what can we do to make it better. Along with even the desk that goes up and down. It's the little things. Guys thank you very much. [ Frankie ] We really appreciate it. [ Pat ] It was a pleasure and we're gonna put this thing to the test every time. For us we're data freaks. Anything we can do we're gonna be on here doing what we can on every engine that we have. Thank you very much. [ Shawn ] And I'll be tuning in to watch. [ Pat ] Awesome, we appreciate it!