More Half Mile Hauler 1963 Galaxie Episodes

Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Magnaflow

Exhaust System, Hot Rod Kit, Header-Back, Stainless Steel, Natural, 3.00 inch Diameter, Universal, Kit

Air Flow Research

Cylinder Heads, Competition Porting, Aluminum, Assembled, 58cc Chamber, 195cc Intake, Ford, Small Block, Pair

Dart

Engine Block, Cast Iron, 4-Bolt Mains, 4.000 in. Diameter Bore, 1-Piece Rear Main Seal, Ford, Small Block,Each

Eagle Specialty Products

Engine Rotating Assembly, Competition,(ESP)Forged Crank, Forged Mahle Pistons, H-Beam Rods, Ford, Small Block, Kit

Edelbrock

Intake Manifold, Super Victor, Single Plane, Aluminum, Natural, Square Bore, Ford, 289/302, Each

FiTech

Fuel Injection System, Go EFI 4 600HP Self-Tuning, Throttle Body, Satin Black, Fuel Rails, Injectors, ECM, Kit

Flaming River

Rack and Pinion Cradle Conversion, Power, New tilt steering column with universal joints, Ford 1962-64, Galaxie, Kit

Jesel Inc.

Rocker System, Full Roller, 1.7 Ratio, Shims, for AFR 165-225cc Outlaw Cylinder Heads, Ford, Small Block, Kit

Jones Machine Racing Products, Inc.

Custom Accessory Drive System Including Water Pump, Alternator, P/S Pump, And Vacuum Pump

Optima

Red Top Optima Battery, Top and Side Terminals, 800 Cold Cranking Amps, 10 in. x 6.875 in. x 7.813 in., Each

American Powertrain Systems

Transmission Kit,1100 Ft Lb Tremec Magnum T-56 Transmission W/ 26-Spline Input, Quicktime Bell Housing, Science Friction Twin-Disc Clutch Kit W/ Billet Flywheel, Hydramax Hydraulic Slave Cylinder System

DSS Racing

Custom Forged Piston Set

Hellion Power Systems

79-93 Mustang Single Turbo System, 76mm Precision Turbo GTS (billet wheel)w/ Ball bearing upgrade, and dual Precision Turbo PW46 46mm wastegates upgrade

PowerTrain Products

One of the nation s leading supplier of remanufactured, rebuilt and used engines, transmissions, differentials, transfer cases & cylinder heads. Providing you with an industry-leading, nationwide parts & labor warranty of up to 4 years

The Industrial Depot

The Industrial Depot - Fasteners, Hardware, and Shop Supplies

WD-40 Specialist

WD-40 300004 Specialist Rust Release Penetrant Spray, 11 oz.

Episode Transcript

(MIKE)>> WE WELCOME

YOU TO ANOTHER EPISODE OF ENGINE POWER. TODAY WE'RE GONNA TAKE CARE OF

YOUR DIY TECH NEEDS WITH A MIX OF NEW TECHNOLOGY AND

OLD SCHOOL HOT RODDING. NOW FIRST UP IS THIS '62 NOVA

THAT'S A WORK IN PROGRESS. NOW WE BORROWED IT FROM A

LOCAL GEAR HEAD WHO'S GETTING

THE JOB DONE AS HIS BUDGET ALLOWS.

UNDER THE HOOD IS AN IRON HEADED SMALL BLOCK CHEVY 350 WITH A NICE LITTLE CAM, INTAKE, AND CARB.

NOW AS PAT LIKES TO SAY, IT'S A MAN'S HOT ROD BECAUSE IT ALSO HAS A FOUR SPEED MANUAL TRANS. NOW THE OWNER SAYS THE CAR HAS A LITTLE HESITATION AND STUMBLED DURING ACCELERATION, BUT NO MATTER WHAT THE ISSUE IS WE'RE NOT MESSING WITH THE CARB. WE ACTUALLY HAVE A LITTLE SURPRISE FOR HIM, BUT FIRST WE'RE GONNA GO OUT, DRIVE IT AROUND, HAVE A LITTLE FUN, AND SEE WHAT HE'S TALKING ABOUT.

AT QUICK ACCELERATION THIS ENGINE IS STRONG. SO THAT'S NOT WHERE THE PROBLEM IS. YEAH, CRUISING EASY, FOURTH GEAR, ABOUT 2,400 RPM. I'LL JUST ROLL INTO THE THROTTLE REAL EASY.

(PAT)>> WHOA!

(MIKE)>> DOWN INTO THIRD. IT'S A LOT WORSE IN THE LOWER GEAR WHEN THE

LOAD ISN'T AS MUCH.

(PAT)>> BEFORE WE SHOW YOU OUR SOLUTION TO THE CARB ISSUES WE'RE GONNA GET A BASELINE ON THE DYNO JUST THE WAY IT IS. FOURTH GEAR IS ONE TO ONE, SO THE PULL WILL BE IN FOURTH GEAR TO 5,200 RPM. 235 AND 310 POUND FEET. YOU'VE GOTTA START SOMEWHERE.

(MIKE)>> THAT'S A GOOD ONE.

(PAT)>> GETTING RID OF OUR CARB PROBLEMS IS A SIMPLE SOLUTION AND IT WILL INCLUDE BETTER THROTTLE RESPONSE, FUEL MILEAGE, AND OVERALL DRIVABILITY. THIS IS FITECH EFI'S GO EFI FOUR. IT'S A SELF CONTAINED EFI SYSTEM THAT OFFERS THE FASTEST AND MOST ACCURATE SELF LEARNING AVAILABLE. IT HOUSE FOUR INJECTORS THAT WILL SUPPORT FROM 250 ALL THE WAY UP TO 600 HORSEPOWER, AND THE ECU IS MOUNTED

TO THE THROTTLE BODY. SO NO EXTERNAL BOXES OR HARNESSES WILL CLUTTER

YOUR ENGINE COMPARTMENT. IT HAS A BUILT IN FUEL PRESSURE REGULATOR AND TIMING CONTROL AS WELL AS THE AIR FUEL CAN BE CHANGED ON THE FLY WITH THIS HAND HELD MONITOR, AND AS WE INSTALL IT PAY ATTENTION. THERE ARE SEVERAL MORE OPTIONS WE'LL TELL YOU ABOUT.

(MIKE)>> WITH THE FUEL LINE, CHOKE CABLE, AND THROTTLE LINKAGE REMOVED, THE CARB IS THE FIRST THING TO GO. WE'LL REPLACE THE OLD FOUR HOLE CARBURETOR GASKET

WITH A NEW ONE. NOW THE CROWNING JEWEL IS LAID IN. THE THROTTLE BODY IS DIE CAST AND THE LINKAGE WILL WORK WITH MOST TRANSMISSIONS. THE SENSORS INCLUDE AN AIR IDLE BYPASS MOTOR ON THE BACK, A TWO AND A HALF BAR MAP SENSOR IN THIS VENTURI, AND A TPS SENSOR.

(PAT)>> WE NOTICED THE DISTRIBUTOR CAP WAS BADLY CRACKED. SO A NEW ROTOR AND CAP ARE GOING ON.

(MIKE)>> THE SMALL HARNESS REQUIRES FOUR LOOSE WIRES TO BE HOOKED UP, A HEAVY RED DIRECTLY TO THE BATTERY. THE BLUE WIRE GOES TO THE TACH OUTPUT ON THE HEI DISTRIBUTOR, THE WHITE WIRE GOES TO A SWITCHED 12 VOLT SOURCE. SINCE WE'RE NOT RUNNING A CDI IGNITION BOX IT'LL GO TO THE POSITIVE COIL WIRE. NOW WE CAN INSTALL THE SUPPLIED COOLANT TEMP SENSOR AND MAKE THE CONNECTION. NOW HOOK UP THE HAND HELD CONTROLLER HARNESS AND THE HAND HELD INSIDE THE CAR. FUEL INJECTION REQUIRES HIGHER FUEL PRESSURE

THAN A CARBURETOR DOES. SO FITECH GIVES YOU A COUPLE OF ADD ON OPTIONS. NOW FIRST IS THIS INLINE PUMP THAT REQUIRES A RETURN STYLE REGULATOR AND RETURN LINE BACK TO THE TANK. SECOND IS THEIR AWESOME FUEL COMMAND CENTER. NOW THIS THING ACTS AS A SUMP AND HAS A 340 LITER PER HOUR PUMP INSIDE OF IT. THE FACTORY CARBURETED PUMP FILLS THE SUMP, AND A FLOAT SHUTS THE FUEL FLOW OFF ONCE THE CORRECT LEVEL IS REACHED.

NOW THIS THING SUPPLIES 58 PSI TO THE FITECH UNIT. IT ALSO HAS A LOW PRESSURE GAUGE TO SHOW YOU THE INCOMING PRESSURE FROM THE STOCK PUMP. LET'S GET IT INSTALLED. NOW A LINE IS RAN FROM THE ORIGINAL CARB FEED LINE TO THE INLET OF THE COMMAND CENTER. ANOTHER LINE GOES FROM THE HIGH PRESSURE SIDE THROUGH A FILTER AND TO THE THROTTLE BODY.

NOW WE'LL RUN A VENT LINE TO OPEN ATMOSPHERE. UNDERNEATH WE CAN INSTALL THE OTWO SENSOR. IT USES A FLANGE AND GASKET SUPPLIED BY FITECH FOR AN EASY INSTALL. FINALLY MAKE THE CONNECTION. WITH THE COMMAND CENTER PRIMED WE CAN SET THE HAND HELD CONTROLLER TO RUN THE ENGINE. BASIC INPUTS ABOUT YOUR ENGINE ARE SELECTED. THIS IS JUST AS EASY AS MAKING A CALL ON A CELL PHONE.

(PAT)>> LOOK AT THAT, FIRST TRY, I LIKE IT.

(MIKE)>> THESE PULLS WILL MIMIC THE ONES WE DID WITH THE CARB. THE SAME EXACT TIMING AND RPM RANGE.

(PAT)>> FIRST PULL RIGHT OFF THE BAT, 250 HORSE, 325 POUND FEET OF TORQUE.

(MIKE)>> THAT'S 15 HORSE UP FROM THAT OLD CARBURETOR.

(PAT)>> YEAH, SOUNDED GREAT, EVERYTHING LOOKED GREAT.

(MIKE)>> THIS THING COMES RIGHT BACK DOWN TO IDLE. THERE WASN'T A HICK UP, A STUMBLE, NOTHING IN IT, WONDERFUL.

(PAT)>> THAT IS AWESOME RIGHT THERE. IT WAS UP 15 HORSEPOWER FROM 235 TO 250 AND UP 15 POUND FEET FROM 310 TO 325.

(MIKE)>> BUT THE PROOF IS ON THE ASPHALT.

YEAH, NIGHT AND DAY DIFFERENCE, NIGHT AND DAY! FITECH OFFERS KITS TO SUPPORT UP TO 1,200 HORSEPOWER, EVEN FOR BOOSTED APPLICATIONS. NOW DIFFERENT FINISHES ARE ALSO AVAILABLE. SIMPLY PUT WE'RE HUGE FANS.

(MIKE)>> WE'RE BACK AND CONTINUING ON PAT'S '63 GALAXIE. NOW THIS CAR IS A TRUE TIME CAPSULE. IT EVEN WEARS THE ORIGINAL PAINT FROM DAY ONE. NOW WHAT IT DOESN'T SPORT ANY MORE IS THE ORIGINAL THREE ON

THE TREE AND 260 CUBIC INCH WEEZER. NOW IF YOU HAVEN'T CAUGHT ANY OF THE SHOWS THAT GOT US TO THIS POINT, HERE'S A QUICK LOOK AT THE PROGRESS.

(PAT)>> THE POWER PLANT IS A SMALL BLOCK FORD WE BUILT TO HANDLE BOOST. ALL THE COMPONENTS REST IN A DART IRON EAGLE BLOCK, AND EAGLE SPECIALTIES COMPETITION ROTATING ASSEMBLY FILLED IT UP AND DSS RACING BUILT US A SET OF CUSTOM PISTONS. AFR COMPETITION CYLINDER HEADS COVERED THEM UP AND JESEL SHAFT ROCKERS WERE BOLTED ON. THE INTAKE MANIFOLD IS AN EDELBROCK SUPER VICTOR CONVERTED TO EFI. JONES RACING SUPPLIED A KILLER FRONT DRIVE, AND A HELLION SINGLE TURBO SYSTEM WAS BOLTED ON. THIS COMBO WAS DYNOED FOR BREAK IN PURPOSES AND MADE 806 HORSEPOWER ON LOW BOOST. THEN IT WAS TIME TO WORK ON THE CAR BY REMOVING ALL OF THE COMPONENTS WE WERE NOT GOING TO USE, LIKE THE ENGINE AND TRANSMISSION. WE NEEDED TO KEEP IT A ROLLER TO MOVE IT AROUND,

SO THE SUSPENSION STAYED. WE HAD A DATE WITH THE PRESSURE WASHER TO CLEAN THE ENGINE BAY AND ENTIRE UNDERNEATH OF THE CAR. IT WAS ROLLED BACK IN THE SHOP AND WORK BEGAN, STARTING WITH A TRICK RACK AND PINION CONVERSION KIT FROM FLAMING RIVER. IT USES A STURDY CRADLE THAT SUPPORTS THE POWER RACK. IT WAS A TRUE BOLT IN INSTALL ANYONE CAN HANDLE. THE KIT EVEN CAME WITH A NEW STEERING COLUMN. WE ORDERED IT BARE TO COLOR MATCH IT TO THE GALAXIE'S INTERIOR. FINALLY WE MADE THE LINK FROM THE COLUMN TO THE RACK WITH THE SUPPLIED DOUBLED SHAFTS AND UJOINTS. NEXT UP WAS LOWERING THE ENGINE IN SO WE COULD GET AN IDEA OF WHAT WE HAD TO WORK WITH SINCE THE TURBO KIT WAS DESIGNED FOR A FOX BODY MUSTANG. YEP IT'S IN.

HEADERS WERE A SMALL CHALLENGE WE OVERCAME IN A QUICK MANNER. WITH A LITTLE FAB WORK USING A BUILDER KIT FROM MAGNAFLOW WE POSITIONED THE TURBO EXACTLY WHERE WE WANTED IT.

(MIKE)>> FIRST ON THE LIST TODAY IS GETTING THE ENGINE AND TRANSMISSION MOUNTS AND SUPPORTS MADE. LIFTING THE ENGINE WILL ALLOW US TO REMOVE THE ORIGINAL MOUNTS. NOW THEY'RE NOT BEING SCRAPPED. WE HAVE A PLAN FOR PART OF THEM. NOW WE CAN MEASURE THE ENTIRE THICKNESS OF THE MOUNT, WHICH COMES IN TO ABOUT AN INCH-320. NOW THE ONLY PART OF THIS WE'RE GONNA REUSE IS THE ACTUAL METAL BRACKET. THE RUBBER PIECE IS GONNA TURN INTO A SOLID MOUNT. USING AN AIR HAMMER, THE RUBBER PORTIONS AND STUDS ARE FORCED OFF THE MOUNT'S MAIN BRACKETS. NOW USING A SANDING PAD, CLEAN THE ENTIRE AREA SINCE WE WILL

BE WELDING TO IT. NOW WE CAN WELD A BOLT THROUGH THE PLATE. THIS WILL ACT AS BOTH THE STUD AND ALIGNMENT GUIDE WHEN DROPPING THE ENGINE BACK DOWN. THIS HEAVY GAUGE SQUARE TUBE WILL BE THE NEW SOLID MOUNT.

IT IS WELDED TO THE FACTORY MOUNTING PLATE. NOW A NEW PLATE WE CUT GOES OVER THE BOLT AND IS WELDED TO THE SQUARE TUBE. THE FINAL WELDING IS DONE AROUND THE BOLT. NOW I'LL SPRAY THEM WITH SOME VHT SELF PRIMING, WEATHER RESISTANT EPOXY PAINT. THAT'S A SOLID ENGINE MOUNT. WE ALSO ADDED 125 THOUSANDTHS TO THE MOUNT TO COMPENSATE FOR THE FACTORY RUBBER SQUISHINESS. LOOK THAT UP DURING THE BREAK.

(MIKE)>> WE'RE BACK AND IT'S TIME TO GET THE REST OF THE

DRIVETRAIN MOUNTED. WE'RE UPGRADING THE CLUTCH SETUP IN THE GALAXIE IN A BIG WAY. NO MORE MANUAL LINKAGE. WE'RE GOING FULL HYDRAULIC WITH ONE OF AMERICAN POWERTRAIN'S HYDRAMAX SYSTEMS. NOW THIS SETUP FITS ANY CLASSIC FORD RUNNING A TREMEC

TRANSMISSION, OR EVEN THE FACTORY THREE OR FOUR SPEED. NOW IT INCLUDES A DUAL LINE SLAVE BEARING WITH DOUBLE

WIDTH SEALS INSIDE AND IT COMES PREBLED. THE MASTER CYLINDER HAS A THREE QUARTER INCH BORE AND IT'S VOLUME MATCHED TO THE SLAVE BEARING. NOW IT RESTS ON AN ADJUSTABLE HYDRAMAX FIREWALL MOUNT. NOW THE KIT ALSO INCLUDES THE PEDAL ROD AND HARDWARE, A RESERVOIR, AND ALL THE OTHER TRINKETS YOU NEED FOR A SUPER EASY INSTALL. AMERICAN POWERTRAIN ALSO OWNS THEIR OWN CLUTCH COMPANY. NOW THIS IS THEIR SCIENCE FRICTION ATOMIC TWIN DISC SETUP. NOW IT'S RATED TO HANDLE 950 POUND FEET OF TORQUE. NOW IT CAME WITH A CUSTOM LIGHTENED BILLET STEEL FLYWHEEL THAT IS NEUTRAL BALANCED.

THE CLUTCH COVER AND FLOATER PLATE ARE BOTH CRYOHARDENED, AND THE DISCS ARE CERAMIC WITH A 26 SPLINE.

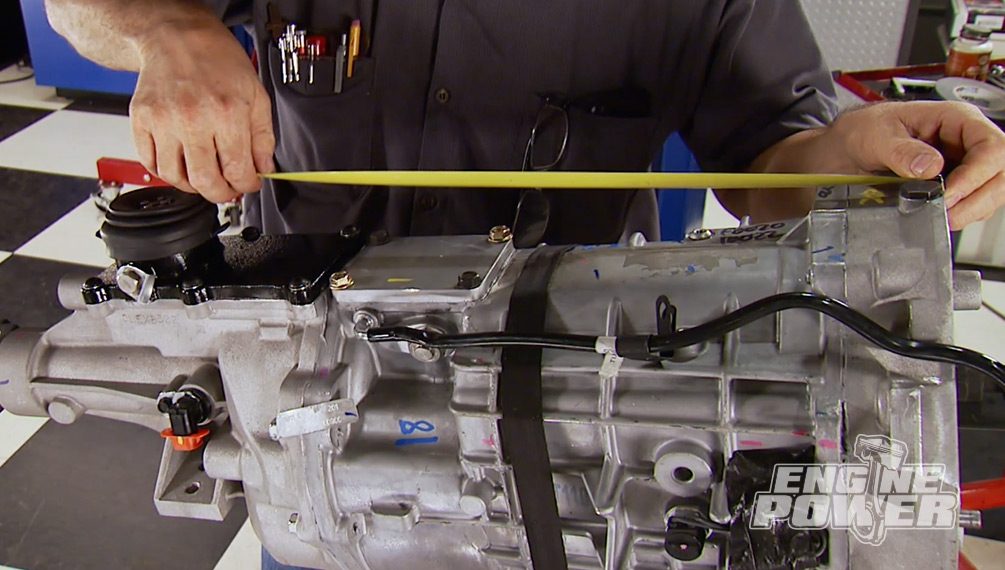

(PAT)>> IN MY HUMBLE OPINION A HOT ROD SHOULD HAVE THREE PEDALS, AND ALTHOUGH THE STOCK TOP LOADER THREE SPEED WAS OKAY FOR THE FACTORY RATED 164 HORSE OUT OF THE OLD 260 WE NEEDED A SERIOUS TRANSMISSION THAT WOULD HANDLE OVER SEVEN TIMES THAT AMOUNT. WELL AMERICAN POWERTRAIN HOOKED US UP WITH THE BADDEST OF THE BAD FOR THE APPLICATION.

THIS IS THEIR TREMEC MAGNUM SIX SPEED WIDE RATIO TRANSMISSION.

IT'S THE AFTERMARKET VERSION OF THE SAME TRANS USED IN MODERN SUPER CARS LIKE THE ZR ONE VETTE AND THE ACR VIPER.

WITH DOUBLE OVERDRIVE, CRISP SHORT THROW SHIFTS, AND THE

ABILITY FOR MULTIPLE SHIFTER LOCATIONS, IT FITS THE BILL PERFECTLY.

NORMALLY IT RATED TO HANDLE 700 POUND FEET OF CONTINUOUS LOAD. THIS ONE HAS BEEN FULLY CRYO'ED AND PREPPED TO UP THAT RATING 1,100 POUND FEET. MATING IT TO THE ENGINE AND KEEPING MY LEGS SAFE IS THIS SFI APPROVED BELL HOUSING FROM QUICKTIME.

(MIKE)>> THE FIRST THING TO BE INSTALLED IS THE SUPPLIED PILOT BEARING. IT IS TAPPED IN AND HAS A LIP THAT WILL SEAT AGAINST THE CRANK TO LET YOU KNOW IT'S ALL THE WAY IN. FORDS USE AN ENGINE PLATE BETWEEN THE BLOCK AND BELL HOUSING. THIS LOCATES THE STARTER MOTOR.

NOW THE BILLET FLYWHEEL CAN BE POSITIONED AND THE HOLES ALIGNED WITH THE CRANK. ARP FLY WHEEL BOLTS WILL HOLD IT IN PLACE AND THEY'RE TORQUED TO 75 POUND FEET. THE DOWELS FOR THE CLUTCH GO IN NEXT, FOLLOWED BY THE ATOMIC TWIN DISC CLUTCH ASSEMBLY. JUST AN FYI, THIS IS DESIGNED FOR HIGH POWER STREET APPLICATIONS AND REQUIRES LITTLE PEDAL EFFORT. FINALLY THE QUICKTIME BELL HOUSING MAKES ITS

WAY TO THE BLOCK. IT ALIGNS ON DOWELS FOR A QUICK ALIGNMENT AND SECURED WITH MORE ARP FASTENERS.

(PAT)>> AFTER THE BREAK WE'LL SEE HOW WELL THE TRANSMISSION FITS.

(PAT)>> SO FAR TODAY WE HAVE TAKEN THE STOCK GALAXIE RUBBER ENGINE MOUNTS AND CONVERTED THEM TO HEAVY DUTY STEEL ONES, AND THAT ALLOWED US TO POSITION THE ENGINE EXACTLY WHERE WE WANTED IT.

THEN WE INSTALLED THE BELL HOUSING ENGINE PLATE, ATTACHED THE BILLET FLYWHEEL, AND FINALLY TORQUED UP THE SUPER TRICK TWIN DISC CLUTCH AND ENCASED IT IN AN SFI APPROVED BELL HOUSING. THAT BRINGS US TO CHECKING THE FIT OF THE NEW SIX SPEED TRANSMISSION IN THE CHASSIS, OR IN THIS CASE, LACK THERE OF. THE OLD EYEROMETER TOLD ME THAT SOME WORK WAS GONNA HAVE

TO BE DONE TO THE TUNNEL TO GET IT IN WHERE IT NEEDS TO BE, AND THE ONLY WAY TO GET AN ACCURATE PICTURE OF WHAT HAS TO BE MODIFIED WAS TO GET IN UP INTO POSITION AND EVALUATE THE SITUATION. THE TREMEC MAGNUM'S A PHYSICALLY LARGER TRANSMISSION THAN THE OLD TOP LOADER THAT WAS IN HERE, AND UNFORTUNATELY THE ONLY WAY WE'RE GONNA GET IT UP IN HERE IS TO DO SOME CUTTING, BUT THAT WAS PLANNED FOR AND IS TO BE EXPECTED

WHEN BUILDING A HOT ROD WITH AFTERMARKET PARTS. WHILE WE'RE DOWN HERE I'LL MEASURE WHERE THE SHIFTER WILL END UP IN ITS CURRENT POSITION.

IT'S ABOUT 21 INCHES FROM THE BELL HOUSING FACE. JUST IN CASE WE NEED IT WE'LL ALSO MEASURE FROM THE

MIDDLE SHIFTER POSITION. IT'S ABOUT 17 AND A HALF INCHES. WE'RE NOT GONNA DO ANY OF THE CUTTING TODAY HOWEVER BECAUSE THE WHOLE INTERIOR OF THE CAR HAS TO COME OUT FOR THAT TYPE

OF SURGICAL PROCEDURE, BUT WHILE THE CAR IS ON THE LIFT THERE ARE A FEW OTHER THINGS THAT CAN COME OFF TO MAKE WAY FOR THE TRICK SUSPENSION THAT'S GOING IN, LIKE REMOVING THE FUEL TANK. THE FACTORY ONE HOLDS 20 GALLONS AND THANKFULLY IT'S EMPTY, BUT THIS TANK HAS AN ACTUAL DRAIN PLUG IN IT TO MAKE IT EASY TO DO IF NECESSARY. WITH THE TANK SUPPORTED, I'LL UNHOOK THE SENDER AND CLIP THE FUEL LINE. THEN SPRAY THE TANK STRAP FASTENERS WITH A LITTLE WD 40 SPECIALIST RUST RELEASE PENETRANT SPRAY. THEN OUR MATCO IMPACT MAKES SHORT WORK OF THE REST. A NEW FUEL CELL WILL BE INSTALLED LATER, BUT THIS TANK IS GETTING PUT IN THE SAVE PILE BECAUSE IT'S RELATIVELY NEW AND DENT FREE. [ metal clanging ]

(PAT)>> WELL IT WAS DENT FREE THAT IS.

ANYWAY, OUR PLANS FOR THIS RIDE MAKE IT NECESSARY TO DO A MAJOR CHANGE OUT BACK. SO THE ENTIRE REAR END ASSEMBLY AND LEAF SPRINGS ARE GOING AWAY TO MAKE ROOM FOR A NINE INCH FORD AND A TRICK TORQUE ARM STYLE REAR SUSPENSION SETUP SIMILAR TO THAT OF A CAMARO OR A FIREBIRD, AND WE STILL HAVE TO CUT THE TRANS TUNNEL OUT TO MAKE ROOM FOR THAT BEEFY MAGNUM SIX SPEED TRANSMISSION, NOT TO MENTION FINISHING THINGS UP ON THE ENGINE SIDE, INCLUDING DOING ALL THAT CRAZY TURBO PIPING. SO OBVIOUSLY THERE'S A BUNCH MORE THAT'S GOT TO BE DONE TO THIS OLD GIRL BEFORE SHE GETS BACK ON THE ROAD, BUT FOR NOW WE HAVE OTHER THINGS THAT WE NEED TO DO TODAY.

(MIKE)>> HERE WE GO WITH ANOTHER ENGINE POWER TECH TIP. THIS TIME IT'S ON A TOPIC WE GET ASKED ABOUT ON A REGULAR BASIS. IT IS ENGINE BEARINGS. NOW THESE ARE THE MOST CRITICAL ITEMS IN AN ENGINE PERIOD. THEY HAVE TO BE SIZED TO PERFECTION, NOT ONLY IN CLEARANCE BUT ALSO EXCENTRICITY. NOW IF YOU HAVE TOO MUCH CLEARANCE YOU RISK INADEQUATE OIL PRESSURE. TOO LITTLE BIT OF CLEARANCE AND YOU RISK BURNING A BEARING UP DUE TO EXCESSIVE HEAT.

(PAT)>> THERE ARE SEVERAL DIFFERENT TYPES OF BEARINGS DEPENDING ON YOUR APPLICATION, FROM STOCK AND MILD PERFORMANCE ALL THE WAY UP TO HIGH HORSEPOWER RACING ENGINES, AND THEY WILL VARY IN BOTH CONSTRUCTION AND MATERIALS, AND HAVE DIFFERENT COATINGS ON THE BEARING FACE, BUT LIKE ALL OTHER ENGINE PARTS, THERE IS A LOT OF COMPANIES THAT WILL OFFER YOU A QUALITY PRODUCT.

(MIKE)>> OUR OFFICIAL ENGINE BEARING SUPPLIER IS CLEVITE. THEY HAVE THE LARGEST SELECTION OF BEARINGS FOR ENGINES IN THE INDUSTRY. NOW WE'RE GOING TO COVER THE PERFORMANCE LINE THEY OFFER FOR US GEAR HEADS. THEY ARE CATEGORIZED IN SERIES TO HELP YOU CHOOSE THE RIGHT ONE FOR YOUR SETUP.

(PAT)>> THE FIRST ONES WE'RE GONNA COVER ARE THE "P" SERIES. NOW THERE ARE TWO DIFFERENT TYPES OF "P" SERIES AND HERE'S THE DIFFERENCE. THE OEM QUALITY "P" SERIES IS A TRIMILLED DESIGN WITH A STEEL BACKING, A COPPER LEAD ALLOY LAYER, AND A ONE THOUSANDTHS THICK ELECTROPLATED LEAD TIN OVERLAY. THESE ARE MADE FOR A STOCK REBUILD APPLICATION AND ARE OFFERED IN SEVERAL DIFFERENT UNDER SIZES TO ACCOMMODATE GROUND CRANK SHAFTS. THE PERFORMANCE "P" BEARINGS ARE MADE OUT OF THE SAME CONSTRUCTION BUT WITH SOME ADDITIONAL FEATURES, LIKE HAVING THE GREATEST AMOUNT OF EXCENTRICITY AND MOST MAIN SETS ARE FULLY GROOVED TO MAXIMIZE OIL FLOW. THEY HAVE A HIGHER CRUSH AND HARDENED STEEL BACKS WITH REDUCED THICKNESS OVERLAY TO REDUCE FATIGUE, AND THESE CAN FIND A HOME IN STREET AND STRIP ENGINES.

(MIKE)>> NEXT IN THE LINE UP ARE "H" SERIES BEARINGS. NOW THESE WERE DEVELOPED PRIMARILY FOR USE IN NASCAR BUT ARE SUITABLE FOR ALL TYPES OF RACING ENGINES. THESE HAVE A PRECISION WALL TOLERANCE, HIGH CRUSH FOR BETTER RETENTION, AN EXTRA THIN OVERLAY TO WITHSTAND HIGH BEARING LOADING. NOW THEY ARE ALSO OFFERED IN BOTH STANDARD AND NARROW WIDTHS TO CLEAR LARGE RADII ON THE JOURNALS.

(PAT)>> "K" SERIES BEARINGS ARE THE SAME AS "H" BUT HAVE A PROPRIETARY THREE TEN THOUSANDTHS THICK DRY FILM TREATMENT APPLIED TO THE BEARING SURFACE ONLY. IT GIVES PROTECTION ON START UP AND SERVES AS A HIGH PRESSURE, HIGH LOAD, DRY FILM ANTIWEAR AGENT.

IN LAYMAN'S TERMS THIS IS THEIR COATED BEARING, OR AS CLEVITE REFERS TO THEM AS THEIR TRIARMOR SERIES.

(MIKE)>> THIS WAS TO GIVE YOU A GENERAL IDEA ON THE BEARINGS OFFERED AS WELL AS WHAT THE SERIES MEANS. NOW WE'RE GONNA TOUCH BASE ON THIS SUBJECT AGAIN IN THE NEAR FUTURE, BUT IT'S GONNA BE A LITTLE MORE TECHNICAL. WE'RE GONNA SHOW YOU HOW TO CHECK BEARING TOLERANCES AS WELL AS SET THEM UP THE WAY YOU WANT BY MIXING

DIFFERENT BEARING SIZES. NOW DON'T BE INTIMIDATED, THIS IS EASIER THAN YOU THINK AND

WILL JUST ENSURE PROPER BEARING CLEARANCE.

(PAT)>> OPTIMA REVOLUTIONIZED THE AUTOMOTIVE BATTERY INDUSTRY MANY YEARS AGO BY BEING THE FIRST TO HAVE THEIR PATENTED SPIRAL CORE TECHNOLOGY IN A TRUE HIGH

PERFORMANCE AGM BATTERY. THAT'S WHAT GIVES IT ITS DISTINCTIVE OPTIMA SIX PACK SHAPE, BUT MORE IMPORTANTLY, ALLOWS IT TO RECHARGE FASTER, HAVE UP TO 15 TIMES THE VIBRATION RESISTANCE OF A NORMAL BATTERY, AND BE VIRTUALLY MAINTENANCE FREE AND SPILL PROOF. THIS RED TOP ALSO HAS THE STRONGEST FIVE SECOND STARTING BURST IN THE INDUSTRY AND WILL LAST UP TO THREE TIMES LONGER.

GO TO OPTIMA BATTERIES DOT COM TO FIND ONE THAT FITS YOUR PROJECT.

(MIKE)>> POWERTRAIN PRODUCTS IS A MAIN CONTENDER IN THE USED AND REMANUFACTURED AUTOMOTIVE PARTS INDUSTRY. NOW WHAT SETS THEM APART FROM THEIR COMPETITION IS THEIR ATTENTION TO DETAIL AND AWESOME WARRANTIES. NOW THIS IS ONE OF THEIR REMANUFACTURED ENGINES THEY REENGINEER AND ASSEMBLE USING OE QUALITY COMPONENTS. NOW WHEN PURCHASED YOU CAN ADD A COMPLETELY NO FAULT

WARRANTY FOR $349 DOLLARS.

NOW WHEN I SAY NO FAULT THAT MEANS NO MATTER WHAT THE REASON IS IT FAILS THEY'LL COVER A RENTAL, TOWING, AS WELL DIAGNOSTIC TESTING. NOW TO FIND A USED REMANUFACTURED ENGINE OR ANY OTHER VEHICLE PART LOG ON TO POWERTRAIN PRODUCTS DOT NET.

(PAT)>> NOW WE'RE ALL DONE, WE'LL SEE YOU NEXT TIME.

Show Full Transcript

THE JOB DONE AS HIS BUDGET ALLOWS.

UNDER THE HOOD IS AN IRON HEADED SMALL BLOCK CHEVY 350 WITH A NICE LITTLE CAM, INTAKE, AND CARB.

NOW AS PAT LIKES TO SAY, IT'S A MAN'S HOT ROD BECAUSE IT ALSO HAS A FOUR SPEED MANUAL TRANS. NOW THE OWNER SAYS THE CAR HAS A LITTLE HESITATION AND STUMBLED DURING ACCELERATION, BUT NO MATTER WHAT THE ISSUE IS WE'RE NOT MESSING WITH THE CARB. WE ACTUALLY HAVE A LITTLE SURPRISE FOR HIM, BUT FIRST WE'RE GONNA GO OUT, DRIVE IT AROUND, HAVE A LITTLE FUN, AND SEE WHAT HE'S TALKING ABOUT.

AT QUICK ACCELERATION THIS ENGINE IS STRONG. SO THAT'S NOT WHERE THE PROBLEM IS. YEAH, CRUISING EASY, FOURTH GEAR, ABOUT 2,400 RPM. I'LL JUST ROLL INTO THE THROTTLE REAL EASY.

(PAT)>> WHOA!

(MIKE)>> DOWN INTO THIRD. IT'S A LOT WORSE IN THE LOWER GEAR WHEN THE

LOAD ISN'T AS MUCH.

(PAT)>> BEFORE WE SHOW YOU OUR SOLUTION TO THE CARB ISSUES WE'RE GONNA GET A BASELINE ON THE DYNO JUST THE WAY IT IS. FOURTH GEAR IS ONE TO ONE, SO THE PULL WILL BE IN FOURTH GEAR TO 5,200 RPM. 235 AND 310 POUND FEET. YOU'VE GOTTA START SOMEWHERE.

(MIKE)>> THAT'S A GOOD ONE.

(PAT)>> GETTING RID OF OUR CARB PROBLEMS IS A SIMPLE SOLUTION AND IT WILL INCLUDE BETTER THROTTLE RESPONSE, FUEL MILEAGE, AND OVERALL DRIVABILITY. THIS IS FITECH EFI'S GO EFI FOUR. IT'S A SELF CONTAINED EFI SYSTEM THAT OFFERS THE FASTEST AND MOST ACCURATE SELF LEARNING AVAILABLE. IT HOUSE FOUR INJECTORS THAT WILL SUPPORT FROM 250 ALL THE WAY UP TO 600 HORSEPOWER, AND THE ECU IS MOUNTED

TO THE THROTTLE BODY. SO NO EXTERNAL BOXES OR HARNESSES WILL CLUTTER

YOUR ENGINE COMPARTMENT. IT HAS A BUILT IN FUEL PRESSURE REGULATOR AND TIMING CONTROL AS WELL AS THE AIR FUEL CAN BE CHANGED ON THE FLY WITH THIS HAND HELD MONITOR, AND AS WE INSTALL IT PAY ATTENTION. THERE ARE SEVERAL MORE OPTIONS WE'LL TELL YOU ABOUT.

(MIKE)>> WITH THE FUEL LINE, CHOKE CABLE, AND THROTTLE LINKAGE REMOVED, THE CARB IS THE FIRST THING TO GO. WE'LL REPLACE THE OLD FOUR HOLE CARBURETOR GASKET

WITH A NEW ONE. NOW THE CROWNING JEWEL IS LAID IN. THE THROTTLE BODY IS DIE CAST AND THE LINKAGE WILL WORK WITH MOST TRANSMISSIONS. THE SENSORS INCLUDE AN AIR IDLE BYPASS MOTOR ON THE BACK, A TWO AND A HALF BAR MAP SENSOR IN THIS VENTURI, AND A TPS SENSOR.

(PAT)>> WE NOTICED THE DISTRIBUTOR CAP WAS BADLY CRACKED. SO A NEW ROTOR AND CAP ARE GOING ON.

(MIKE)>> THE SMALL HARNESS REQUIRES FOUR LOOSE WIRES TO BE HOOKED UP, A HEAVY RED DIRECTLY TO THE BATTERY. THE BLUE WIRE GOES TO THE TACH OUTPUT ON THE HEI DISTRIBUTOR, THE WHITE WIRE GOES TO A SWITCHED 12 VOLT SOURCE. SINCE WE'RE NOT RUNNING A CDI IGNITION BOX IT'LL GO TO THE POSITIVE COIL WIRE. NOW WE CAN INSTALL THE SUPPLIED COOLANT TEMP SENSOR AND MAKE THE CONNECTION. NOW HOOK UP THE HAND HELD CONTROLLER HARNESS AND THE HAND HELD INSIDE THE CAR. FUEL INJECTION REQUIRES HIGHER FUEL PRESSURE

THAN A CARBURETOR DOES. SO FITECH GIVES YOU A COUPLE OF ADD ON OPTIONS. NOW FIRST IS THIS INLINE PUMP THAT REQUIRES A RETURN STYLE REGULATOR AND RETURN LINE BACK TO THE TANK. SECOND IS THEIR AWESOME FUEL COMMAND CENTER. NOW THIS THING ACTS AS A SUMP AND HAS A 340 LITER PER HOUR PUMP INSIDE OF IT. THE FACTORY CARBURETED PUMP FILLS THE SUMP, AND A FLOAT SHUTS THE FUEL FLOW OFF ONCE THE CORRECT LEVEL IS REACHED.

NOW THIS THING SUPPLIES 58 PSI TO THE FITECH UNIT. IT ALSO HAS A LOW PRESSURE GAUGE TO SHOW YOU THE INCOMING PRESSURE FROM THE STOCK PUMP. LET'S GET IT INSTALLED. NOW A LINE IS RAN FROM THE ORIGINAL CARB FEED LINE TO THE INLET OF THE COMMAND CENTER. ANOTHER LINE GOES FROM THE HIGH PRESSURE SIDE THROUGH A FILTER AND TO THE THROTTLE BODY.

NOW WE'LL RUN A VENT LINE TO OPEN ATMOSPHERE. UNDERNEATH WE CAN INSTALL THE OTWO SENSOR. IT USES A FLANGE AND GASKET SUPPLIED BY FITECH FOR AN EASY INSTALL. FINALLY MAKE THE CONNECTION. WITH THE COMMAND CENTER PRIMED WE CAN SET THE HAND HELD CONTROLLER TO RUN THE ENGINE. BASIC INPUTS ABOUT YOUR ENGINE ARE SELECTED. THIS IS JUST AS EASY AS MAKING A CALL ON A CELL PHONE.

(PAT)>> LOOK AT THAT, FIRST TRY, I LIKE IT.

(MIKE)>> THESE PULLS WILL MIMIC THE ONES WE DID WITH THE CARB. THE SAME EXACT TIMING AND RPM RANGE.

(PAT)>> FIRST PULL RIGHT OFF THE BAT, 250 HORSE, 325 POUND FEET OF TORQUE.

(MIKE)>> THAT'S 15 HORSE UP FROM THAT OLD CARBURETOR.

(PAT)>> YEAH, SOUNDED GREAT, EVERYTHING LOOKED GREAT.

(MIKE)>> THIS THING COMES RIGHT BACK DOWN TO IDLE. THERE WASN'T A HICK UP, A STUMBLE, NOTHING IN IT, WONDERFUL.

(PAT)>> THAT IS AWESOME RIGHT THERE. IT WAS UP 15 HORSEPOWER FROM 235 TO 250 AND UP 15 POUND FEET FROM 310 TO 325.

(MIKE)>> BUT THE PROOF IS ON THE ASPHALT.

YEAH, NIGHT AND DAY DIFFERENCE, NIGHT AND DAY! FITECH OFFERS KITS TO SUPPORT UP TO 1,200 HORSEPOWER, EVEN FOR BOOSTED APPLICATIONS. NOW DIFFERENT FINISHES ARE ALSO AVAILABLE. SIMPLY PUT WE'RE HUGE FANS.

(MIKE)>> WE'RE BACK AND CONTINUING ON PAT'S '63 GALAXIE. NOW THIS CAR IS A TRUE TIME CAPSULE. IT EVEN WEARS THE ORIGINAL PAINT FROM DAY ONE. NOW WHAT IT DOESN'T SPORT ANY MORE IS THE ORIGINAL THREE ON

THE TREE AND 260 CUBIC INCH WEEZER. NOW IF YOU HAVEN'T CAUGHT ANY OF THE SHOWS THAT GOT US TO THIS POINT, HERE'S A QUICK LOOK AT THE PROGRESS.

(PAT)>> THE POWER PLANT IS A SMALL BLOCK FORD WE BUILT TO HANDLE BOOST. ALL THE COMPONENTS REST IN A DART IRON EAGLE BLOCK, AND EAGLE SPECIALTIES COMPETITION ROTATING ASSEMBLY FILLED IT UP AND DSS RACING BUILT US A SET OF CUSTOM PISTONS. AFR COMPETITION CYLINDER HEADS COVERED THEM UP AND JESEL SHAFT ROCKERS WERE BOLTED ON. THE INTAKE MANIFOLD IS AN EDELBROCK SUPER VICTOR CONVERTED TO EFI. JONES RACING SUPPLIED A KILLER FRONT DRIVE, AND A HELLION SINGLE TURBO SYSTEM WAS BOLTED ON. THIS COMBO WAS DYNOED FOR BREAK IN PURPOSES AND MADE 806 HORSEPOWER ON LOW BOOST. THEN IT WAS TIME TO WORK ON THE CAR BY REMOVING ALL OF THE COMPONENTS WE WERE NOT GOING TO USE, LIKE THE ENGINE AND TRANSMISSION. WE NEEDED TO KEEP IT A ROLLER TO MOVE IT AROUND,

SO THE SUSPENSION STAYED. WE HAD A DATE WITH THE PRESSURE WASHER TO CLEAN THE ENGINE BAY AND ENTIRE UNDERNEATH OF THE CAR. IT WAS ROLLED BACK IN THE SHOP AND WORK BEGAN, STARTING WITH A TRICK RACK AND PINION CONVERSION KIT FROM FLAMING RIVER. IT USES A STURDY CRADLE THAT SUPPORTS THE POWER RACK. IT WAS A TRUE BOLT IN INSTALL ANYONE CAN HANDLE. THE KIT EVEN CAME WITH A NEW STEERING COLUMN. WE ORDERED IT BARE TO COLOR MATCH IT TO THE GALAXIE'S INTERIOR. FINALLY WE MADE THE LINK FROM THE COLUMN TO THE RACK WITH THE SUPPLIED DOUBLED SHAFTS AND UJOINTS. NEXT UP WAS LOWERING THE ENGINE IN SO WE COULD GET AN IDEA OF WHAT WE HAD TO WORK WITH SINCE THE TURBO KIT WAS DESIGNED FOR A FOX BODY MUSTANG. YEP IT'S IN.

HEADERS WERE A SMALL CHALLENGE WE OVERCAME IN A QUICK MANNER. WITH A LITTLE FAB WORK USING A BUILDER KIT FROM MAGNAFLOW WE POSITIONED THE TURBO EXACTLY WHERE WE WANTED IT.

(MIKE)>> FIRST ON THE LIST TODAY IS GETTING THE ENGINE AND TRANSMISSION MOUNTS AND SUPPORTS MADE. LIFTING THE ENGINE WILL ALLOW US TO REMOVE THE ORIGINAL MOUNTS. NOW THEY'RE NOT BEING SCRAPPED. WE HAVE A PLAN FOR PART OF THEM. NOW WE CAN MEASURE THE ENTIRE THICKNESS OF THE MOUNT, WHICH COMES IN TO ABOUT AN INCH-320. NOW THE ONLY PART OF THIS WE'RE GONNA REUSE IS THE ACTUAL METAL BRACKET. THE RUBBER PIECE IS GONNA TURN INTO A SOLID MOUNT. USING AN AIR HAMMER, THE RUBBER PORTIONS AND STUDS ARE FORCED OFF THE MOUNT'S MAIN BRACKETS. NOW USING A SANDING PAD, CLEAN THE ENTIRE AREA SINCE WE WILL

BE WELDING TO IT. NOW WE CAN WELD A BOLT THROUGH THE PLATE. THIS WILL ACT AS BOTH THE STUD AND ALIGNMENT GUIDE WHEN DROPPING THE ENGINE BACK DOWN. THIS HEAVY GAUGE SQUARE TUBE WILL BE THE NEW SOLID MOUNT.

IT IS WELDED TO THE FACTORY MOUNTING PLATE. NOW A NEW PLATE WE CUT GOES OVER THE BOLT AND IS WELDED TO THE SQUARE TUBE. THE FINAL WELDING IS DONE AROUND THE BOLT. NOW I'LL SPRAY THEM WITH SOME VHT SELF PRIMING, WEATHER RESISTANT EPOXY PAINT. THAT'S A SOLID ENGINE MOUNT. WE ALSO ADDED 125 THOUSANDTHS TO THE MOUNT TO COMPENSATE FOR THE FACTORY RUBBER SQUISHINESS. LOOK THAT UP DURING THE BREAK.

(MIKE)>> WE'RE BACK AND IT'S TIME TO GET THE REST OF THE

DRIVETRAIN MOUNTED. WE'RE UPGRADING THE CLUTCH SETUP IN THE GALAXIE IN A BIG WAY. NO MORE MANUAL LINKAGE. WE'RE GOING FULL HYDRAULIC WITH ONE OF AMERICAN POWERTRAIN'S HYDRAMAX SYSTEMS. NOW THIS SETUP FITS ANY CLASSIC FORD RUNNING A TREMEC

TRANSMISSION, OR EVEN THE FACTORY THREE OR FOUR SPEED. NOW IT INCLUDES A DUAL LINE SLAVE BEARING WITH DOUBLE

WIDTH SEALS INSIDE AND IT COMES PREBLED. THE MASTER CYLINDER HAS A THREE QUARTER INCH BORE AND IT'S VOLUME MATCHED TO THE SLAVE BEARING. NOW IT RESTS ON AN ADJUSTABLE HYDRAMAX FIREWALL MOUNT. NOW THE KIT ALSO INCLUDES THE PEDAL ROD AND HARDWARE, A RESERVOIR, AND ALL THE OTHER TRINKETS YOU NEED FOR A SUPER EASY INSTALL. AMERICAN POWERTRAIN ALSO OWNS THEIR OWN CLUTCH COMPANY. NOW THIS IS THEIR SCIENCE FRICTION ATOMIC TWIN DISC SETUP. NOW IT'S RATED TO HANDLE 950 POUND FEET OF TORQUE. NOW IT CAME WITH A CUSTOM LIGHTENED BILLET STEEL FLYWHEEL THAT IS NEUTRAL BALANCED.

THE CLUTCH COVER AND FLOATER PLATE ARE BOTH CRYOHARDENED, AND THE DISCS ARE CERAMIC WITH A 26 SPLINE.

(PAT)>> IN MY HUMBLE OPINION A HOT ROD SHOULD HAVE THREE PEDALS, AND ALTHOUGH THE STOCK TOP LOADER THREE SPEED WAS OKAY FOR THE FACTORY RATED 164 HORSE OUT OF THE OLD 260 WE NEEDED A SERIOUS TRANSMISSION THAT WOULD HANDLE OVER SEVEN TIMES THAT AMOUNT. WELL AMERICAN POWERTRAIN HOOKED US UP WITH THE BADDEST OF THE BAD FOR THE APPLICATION.

THIS IS THEIR TREMEC MAGNUM SIX SPEED WIDE RATIO TRANSMISSION.

IT'S THE AFTERMARKET VERSION OF THE SAME TRANS USED IN MODERN SUPER CARS LIKE THE ZR ONE VETTE AND THE ACR VIPER.

WITH DOUBLE OVERDRIVE, CRISP SHORT THROW SHIFTS, AND THE

ABILITY FOR MULTIPLE SHIFTER LOCATIONS, IT FITS THE BILL PERFECTLY.

NORMALLY IT RATED TO HANDLE 700 POUND FEET OF CONTINUOUS LOAD. THIS ONE HAS BEEN FULLY CRYO'ED AND PREPPED TO UP THAT RATING 1,100 POUND FEET. MATING IT TO THE ENGINE AND KEEPING MY LEGS SAFE IS THIS SFI APPROVED BELL HOUSING FROM QUICKTIME.

(MIKE)>> THE FIRST THING TO BE INSTALLED IS THE SUPPLIED PILOT BEARING. IT IS TAPPED IN AND HAS A LIP THAT WILL SEAT AGAINST THE CRANK TO LET YOU KNOW IT'S ALL THE WAY IN. FORDS USE AN ENGINE PLATE BETWEEN THE BLOCK AND BELL HOUSING. THIS LOCATES THE STARTER MOTOR.

NOW THE BILLET FLYWHEEL CAN BE POSITIONED AND THE HOLES ALIGNED WITH THE CRANK. ARP FLY WHEEL BOLTS WILL HOLD IT IN PLACE AND THEY'RE TORQUED TO 75 POUND FEET. THE DOWELS FOR THE CLUTCH GO IN NEXT, FOLLOWED BY THE ATOMIC TWIN DISC CLUTCH ASSEMBLY. JUST AN FYI, THIS IS DESIGNED FOR HIGH POWER STREET APPLICATIONS AND REQUIRES LITTLE PEDAL EFFORT. FINALLY THE QUICKTIME BELL HOUSING MAKES ITS

WAY TO THE BLOCK. IT ALIGNS ON DOWELS FOR A QUICK ALIGNMENT AND SECURED WITH MORE ARP FASTENERS.

(PAT)>> AFTER THE BREAK WE'LL SEE HOW WELL THE TRANSMISSION FITS.

(PAT)>> SO FAR TODAY WE HAVE TAKEN THE STOCK GALAXIE RUBBER ENGINE MOUNTS AND CONVERTED THEM TO HEAVY DUTY STEEL ONES, AND THAT ALLOWED US TO POSITION THE ENGINE EXACTLY WHERE WE WANTED IT.

THEN WE INSTALLED THE BELL HOUSING ENGINE PLATE, ATTACHED THE BILLET FLYWHEEL, AND FINALLY TORQUED UP THE SUPER TRICK TWIN DISC CLUTCH AND ENCASED IT IN AN SFI APPROVED BELL HOUSING. THAT BRINGS US TO CHECKING THE FIT OF THE NEW SIX SPEED TRANSMISSION IN THE CHASSIS, OR IN THIS CASE, LACK THERE OF. THE OLD EYEROMETER TOLD ME THAT SOME WORK WAS GONNA HAVE

TO BE DONE TO THE TUNNEL TO GET IT IN WHERE IT NEEDS TO BE, AND THE ONLY WAY TO GET AN ACCURATE PICTURE OF WHAT HAS TO BE MODIFIED WAS TO GET IN UP INTO POSITION AND EVALUATE THE SITUATION. THE TREMEC MAGNUM'S A PHYSICALLY LARGER TRANSMISSION THAN THE OLD TOP LOADER THAT WAS IN HERE, AND UNFORTUNATELY THE ONLY WAY WE'RE GONNA GET IT UP IN HERE IS TO DO SOME CUTTING, BUT THAT WAS PLANNED FOR AND IS TO BE EXPECTED

WHEN BUILDING A HOT ROD WITH AFTERMARKET PARTS. WHILE WE'RE DOWN HERE I'LL MEASURE WHERE THE SHIFTER WILL END UP IN ITS CURRENT POSITION.

IT'S ABOUT 21 INCHES FROM THE BELL HOUSING FACE. JUST IN CASE WE NEED IT WE'LL ALSO MEASURE FROM THE

MIDDLE SHIFTER POSITION. IT'S ABOUT 17 AND A HALF INCHES. WE'RE NOT GONNA DO ANY OF THE CUTTING TODAY HOWEVER BECAUSE THE WHOLE INTERIOR OF THE CAR HAS TO COME OUT FOR THAT TYPE

OF SURGICAL PROCEDURE, BUT WHILE THE CAR IS ON THE LIFT THERE ARE A FEW OTHER THINGS THAT CAN COME OFF TO MAKE WAY FOR THE TRICK SUSPENSION THAT'S GOING IN, LIKE REMOVING THE FUEL TANK. THE FACTORY ONE HOLDS 20 GALLONS AND THANKFULLY IT'S EMPTY, BUT THIS TANK HAS AN ACTUAL DRAIN PLUG IN IT TO MAKE IT EASY TO DO IF NECESSARY. WITH THE TANK SUPPORTED, I'LL UNHOOK THE SENDER AND CLIP THE FUEL LINE. THEN SPRAY THE TANK STRAP FASTENERS WITH A LITTLE WD 40 SPECIALIST RUST RELEASE PENETRANT SPRAY. THEN OUR MATCO IMPACT MAKES SHORT WORK OF THE REST. A NEW FUEL CELL WILL BE INSTALLED LATER, BUT THIS TANK IS GETTING PUT IN THE SAVE PILE BECAUSE IT'S RELATIVELY NEW AND DENT FREE. [ metal clanging ]

(PAT)>> WELL IT WAS DENT FREE THAT IS.

ANYWAY, OUR PLANS FOR THIS RIDE MAKE IT NECESSARY TO DO A MAJOR CHANGE OUT BACK. SO THE ENTIRE REAR END ASSEMBLY AND LEAF SPRINGS ARE GOING AWAY TO MAKE ROOM FOR A NINE INCH FORD AND A TRICK TORQUE ARM STYLE REAR SUSPENSION SETUP SIMILAR TO THAT OF A CAMARO OR A FIREBIRD, AND WE STILL HAVE TO CUT THE TRANS TUNNEL OUT TO MAKE ROOM FOR THAT BEEFY MAGNUM SIX SPEED TRANSMISSION, NOT TO MENTION FINISHING THINGS UP ON THE ENGINE SIDE, INCLUDING DOING ALL THAT CRAZY TURBO PIPING. SO OBVIOUSLY THERE'S A BUNCH MORE THAT'S GOT TO BE DONE TO THIS OLD GIRL BEFORE SHE GETS BACK ON THE ROAD, BUT FOR NOW WE HAVE OTHER THINGS THAT WE NEED TO DO TODAY.

(MIKE)>> HERE WE GO WITH ANOTHER ENGINE POWER TECH TIP. THIS TIME IT'S ON A TOPIC WE GET ASKED ABOUT ON A REGULAR BASIS. IT IS ENGINE BEARINGS. NOW THESE ARE THE MOST CRITICAL ITEMS IN AN ENGINE PERIOD. THEY HAVE TO BE SIZED TO PERFECTION, NOT ONLY IN CLEARANCE BUT ALSO EXCENTRICITY. NOW IF YOU HAVE TOO MUCH CLEARANCE YOU RISK INADEQUATE OIL PRESSURE. TOO LITTLE BIT OF CLEARANCE AND YOU RISK BURNING A BEARING UP DUE TO EXCESSIVE HEAT.

(PAT)>> THERE ARE SEVERAL DIFFERENT TYPES OF BEARINGS DEPENDING ON YOUR APPLICATION, FROM STOCK AND MILD PERFORMANCE ALL THE WAY UP TO HIGH HORSEPOWER RACING ENGINES, AND THEY WILL VARY IN BOTH CONSTRUCTION AND MATERIALS, AND HAVE DIFFERENT COATINGS ON THE BEARING FACE, BUT LIKE ALL OTHER ENGINE PARTS, THERE IS A LOT OF COMPANIES THAT WILL OFFER YOU A QUALITY PRODUCT.

(MIKE)>> OUR OFFICIAL ENGINE BEARING SUPPLIER IS CLEVITE. THEY HAVE THE LARGEST SELECTION OF BEARINGS FOR ENGINES IN THE INDUSTRY. NOW WE'RE GOING TO COVER THE PERFORMANCE LINE THEY OFFER FOR US GEAR HEADS. THEY ARE CATEGORIZED IN SERIES TO HELP YOU CHOOSE THE RIGHT ONE FOR YOUR SETUP.

(PAT)>> THE FIRST ONES WE'RE GONNA COVER ARE THE "P" SERIES. NOW THERE ARE TWO DIFFERENT TYPES OF "P" SERIES AND HERE'S THE DIFFERENCE. THE OEM QUALITY "P" SERIES IS A TRIMILLED DESIGN WITH A STEEL BACKING, A COPPER LEAD ALLOY LAYER, AND A ONE THOUSANDTHS THICK ELECTROPLATED LEAD TIN OVERLAY. THESE ARE MADE FOR A STOCK REBUILD APPLICATION AND ARE OFFERED IN SEVERAL DIFFERENT UNDER SIZES TO ACCOMMODATE GROUND CRANK SHAFTS. THE PERFORMANCE "P" BEARINGS ARE MADE OUT OF THE SAME CONSTRUCTION BUT WITH SOME ADDITIONAL FEATURES, LIKE HAVING THE GREATEST AMOUNT OF EXCENTRICITY AND MOST MAIN SETS ARE FULLY GROOVED TO MAXIMIZE OIL FLOW. THEY HAVE A HIGHER CRUSH AND HARDENED STEEL BACKS WITH REDUCED THICKNESS OVERLAY TO REDUCE FATIGUE, AND THESE CAN FIND A HOME IN STREET AND STRIP ENGINES.

(MIKE)>> NEXT IN THE LINE UP ARE "H" SERIES BEARINGS. NOW THESE WERE DEVELOPED PRIMARILY FOR USE IN NASCAR BUT ARE SUITABLE FOR ALL TYPES OF RACING ENGINES. THESE HAVE A PRECISION WALL TOLERANCE, HIGH CRUSH FOR BETTER RETENTION, AN EXTRA THIN OVERLAY TO WITHSTAND HIGH BEARING LOADING. NOW THEY ARE ALSO OFFERED IN BOTH STANDARD AND NARROW WIDTHS TO CLEAR LARGE RADII ON THE JOURNALS.

(PAT)>> "K" SERIES BEARINGS ARE THE SAME AS "H" BUT HAVE A PROPRIETARY THREE TEN THOUSANDTHS THICK DRY FILM TREATMENT APPLIED TO THE BEARING SURFACE ONLY. IT GIVES PROTECTION ON START UP AND SERVES AS A HIGH PRESSURE, HIGH LOAD, DRY FILM ANTIWEAR AGENT.

IN LAYMAN'S TERMS THIS IS THEIR COATED BEARING, OR AS CLEVITE REFERS TO THEM AS THEIR TRIARMOR SERIES.

(MIKE)>> THIS WAS TO GIVE YOU A GENERAL IDEA ON THE BEARINGS OFFERED AS WELL AS WHAT THE SERIES MEANS. NOW WE'RE GONNA TOUCH BASE ON THIS SUBJECT AGAIN IN THE NEAR FUTURE, BUT IT'S GONNA BE A LITTLE MORE TECHNICAL. WE'RE GONNA SHOW YOU HOW TO CHECK BEARING TOLERANCES AS WELL AS SET THEM UP THE WAY YOU WANT BY MIXING

DIFFERENT BEARING SIZES. NOW DON'T BE INTIMIDATED, THIS IS EASIER THAN YOU THINK AND

WILL JUST ENSURE PROPER BEARING CLEARANCE.

(PAT)>> OPTIMA REVOLUTIONIZED THE AUTOMOTIVE BATTERY INDUSTRY MANY YEARS AGO BY BEING THE FIRST TO HAVE THEIR PATENTED SPIRAL CORE TECHNOLOGY IN A TRUE HIGH

PERFORMANCE AGM BATTERY. THAT'S WHAT GIVES IT ITS DISTINCTIVE OPTIMA SIX PACK SHAPE, BUT MORE IMPORTANTLY, ALLOWS IT TO RECHARGE FASTER, HAVE UP TO 15 TIMES THE VIBRATION RESISTANCE OF A NORMAL BATTERY, AND BE VIRTUALLY MAINTENANCE FREE AND SPILL PROOF. THIS RED TOP ALSO HAS THE STRONGEST FIVE SECOND STARTING BURST IN THE INDUSTRY AND WILL LAST UP TO THREE TIMES LONGER.

GO TO OPTIMA BATTERIES DOT COM TO FIND ONE THAT FITS YOUR PROJECT.

(MIKE)>> POWERTRAIN PRODUCTS IS A MAIN CONTENDER IN THE USED AND REMANUFACTURED AUTOMOTIVE PARTS INDUSTRY. NOW WHAT SETS THEM APART FROM THEIR COMPETITION IS THEIR ATTENTION TO DETAIL AND AWESOME WARRANTIES. NOW THIS IS ONE OF THEIR REMANUFACTURED ENGINES THEY REENGINEER AND ASSEMBLE USING OE QUALITY COMPONENTS. NOW WHEN PURCHASED YOU CAN ADD A COMPLETELY NO FAULT

WARRANTY FOR $349 DOLLARS.

NOW WHEN I SAY NO FAULT THAT MEANS NO MATTER WHAT THE REASON IS IT FAILS THEY'LL COVER A RENTAL, TOWING, AS WELL DIAGNOSTIC TESTING. NOW TO FIND A USED REMANUFACTURED ENGINE OR ANY OTHER VEHICLE PART LOG ON TO POWERTRAIN PRODUCTS DOT NET.

(PAT)>> NOW WE'RE ALL DONE, WE'LL SEE YOU NEXT TIME.