More Half Mile Hauler 1963 Galaxie Episodes

Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Baer Brake Systems

Disc Brakes, Pro-Plus, Rear, Cross-Drilled/Slotted Rotors, 6-Piston Calipers, Ford, Kit

Dupli-Color

Paint, Engine, Enamel with Ceramic Resin, Gloss, Ford Red, 12 oz., Aerosol, Each

Eagle Specialty Products

Engine Rotating Assembly, Competition,(ESP)Forged Crank, Forged Mahle Pistons, H-Beam Rods, Ford, Small Block, Kit

EBC Brakes

Brake Rotors, Stage 3, Slotted and Dimpled Surface, Black Geomet Coated, Pads, Front,Kit

Jesel Inc.

Rocker System, Full Roller, 1.7 Ratio, Shims, for AFR 165-225cc Outlaw Cylinder Heads, Ford, Small Block, Kit

Summit Racing

Flaming River, Rack and Pinion Conversion, Power, Ford 1962-64, Galaxie, Kit

Baer Brake Systems

Baer Tracker Full Floater rear upgrade without ABS sensor provision

Currie Enterprises

CUSTOM, F9 Fabricated Housing With 3" Tubes and Large Bearing Ends, Yukon 3.70 ring and pinion, Eaton Truetrac

DSS Racing

Custom Forged Piston Set

Edelbrock

Chrysler Power Package Top End Kit, Hemi

Gunk

All purpose cleaner and degreaser

Lunati

Custom Ground Turbo Camshaft HYD. Roller

Matco Tools

Cylinder Leakage Tester - CLT2APB

The Industrial Depot

The Industrial Depot - Fasteners, Hardware, and Shop Supplies

Episode Transcript

(PAT)>> WELCOME TO AN ALL

NEW EDITION OF ENGINE POWER. TODAY WE'RE RETRIEVING

ANOTHER UNFINISHED PROJECT FROM THE WAITING ROOM. IT'S MY OWN PERSONAL RIDE, A

TIME CAPSULE 1963 FORD GALAXIE WE STARTED WORKING

ON LAST YEAR. JUST IN CASE YOU MISSED

IT, HERE'S THE STORY. WE BROUGHT IT IN AS A

COMPLETE RUNNING AND DRIVING STREET CRUISER. WE STRAPPED IT TO THE CHASSIS

DYNO AND MADE A FEW PULLS, DOING SOME TUNING

ALONG THE WAY. THE MILD 351 WINDSOR SPUN

THE ROLLER TO THE TUNE OF 328 HORSEPOWER AND 347

POUND FEET OF TORQUE. AFTER THAT WE STARTED THE

TEAR DOWN BY PULLING THE OLD DRIVESHAFT, REMOVING THE

STARTER, HACKING OFF MY CUSTOM EXHAUST, WHICH HURT MY

WALLET, AND FINALLY REMOVING THE TRANSMISSION. CLEAR, CLEAR BABY! THIS WAS ALL DONE SO WE

COULD REMOVE THE POWERPLANT BUT NOT TO STORE IT. WE STUCK IT ON THE SUPERFLOW

ENGINE DYNO FOR SCIENTIFIC PURPOSES AND COMPARED IT TO

THE CHASSIS DYNO NUMBERS. THAT TEST PRODUCED 386

HORSEPOWER AND 382 POUND FEET OF TORQUE, TELLING US THAT

THE DRIVELINE LOSS WHILE THE

ENGINE WAS IN THE CAR WAS 15 PERCENT.

(MIKE)>> THIS OLD PLANET CRUISER DEFINITELY BEAT THE

ODDS OF THE ELEMENTS. IT'S GOT A SUPER SOLID BODY AND IT'S GONNA STAY IN THE SAME EXACT CONDITION. PLUS THIS OLD PATINA PAINT IS JUST A SIGN OF ITS ORIGINALITY. NOW WHAT IS GOING TO CHANGE ARE ALL THE COMPONENTS TO MAKE THE VEHICLE FUNCTION, LIKE THIS CUSTOM BUILT REAR END. IT'S GONNA REPLACE THE NINE INCH THAT'S IN THE CAR NOW, AND THESE BEEFY BAER BRAKES WILL REPLACE DRUMS OUT BACK AND SKIMPY DISCS UP FRONT.

NOW THE NEW POWER PLANT IS DEFINITELY GONNA MAKE ALL THOSE COMPONENTS HAVE TO DO THEIR JOBS. HERE'S A LITTLE BIT ABOUT IT.

(PAT)>> IT ALL STARTED WITH A DART IRON EAGLE BLOCK FOR STRENGTH. ONCE THE BEARINGS WERE DROPPED IN AND LUBED, AN EAGLE 43-40 COMPETITION CRANKSHAFT WAS LAID IN THE SADDLES. NEXT A CUSTOM ORDERED LUNATI HYDRAULIC ROLLER CAM SHAFT WAS SLID INTO THE CAM BORE, AND THEIR TIMING SET MADE THE LINK FROM THE CAM TO THE CRANKSHAFT. EAGLE HBEAM RODS AND CUSTOM DSS PISTONS SPEC'ED FOR THIS BUILD WERE PLACED IN THE BORES. THEN THE OIL PUMP AND PICK UP WERE INSTALLED, AND DSS' BILLET MAIN GIRDLE WAS FINISHED OFF.

(MIKE)>> AFR RENEGADE COMPETITION CYLINDER HEADS WENT ON AND WERE TORQUED DOWN USING ARP STUDS. CHROMOLY PUSH RODS WERE DROPPED IN, AND JESEL SENT US A SHAFT ROCKER SETUP TO ELIMINATE ANY VALVETRAIN WORRIES. A SUPER VICTOR INTAKE MANIFOLD WAS TRANSFORMED INTO EFI

FORM AND SEALED UP THE VALLEY, AND 120 POUND AN HOUR INJECTORS WILL SUPPLY FUEL TO THIS POWER PLANT. NOW A 1,000 CFM HOLLEY THROTTLE BODY WENT ON AND ONCE IN THE DYNO ROOM WE INSTALLED A HELLION POWER SYSTEMS FOX BODY TURBO KIT STARTING WITH THE HOT SIDE. THE BOOST PRODUCER IS A 76 MILLIMETER PRECISION TURBO WITH A BILLET COVER. A JONES' RACING FRONT DRIVE GIVES THE ENGINE THE RACY LOOK IT DESERVES.

[ engine revving ]

(MIKE)>> IT MADE 806 HORSEPOWER AND 782 POUND FEET OF TORQUE DURING A BREAK IN DYNO SESSION. ONCE IN THE CAR, 1,000 AT THE TIRES IS THE GOAL.

(PAT)>> WE'RE GONNA START AT THE FRONT OF THE CAR BY REMOVING ALL OF THE FACTORY STEERING COMPONENTS, AND THAT WILL MAKE WAY FOR THIS FLAMING RIVER POWER RACK AND PINION CRADLE KIT. NOW THIS BEEFY CRADLE BOLTS TO THE FRAME RAILS TO SUPPORT THE RACK, AND IT EVEN COMES WITH THIS PAINTABLE COLUMN THAT HAS TILT. SO LET'S START BY GETTING THE COMPONENTS OUT OF THE CAR.

(MIKE)>> FIRST WE'LL REMOVE THE DRAG LINK FROM THE PITMAN ARM.

THEN REMOVE BOTH TIE RODS FROM THE SPINDLES. UNBOLT THE IDLER AND REMOVE EVERYTHING AS AN ASSEMBLY. NOW THE FACTORY MANUAL STEERING BOX CAN BE UNBOLTED, AND THESE CARS WERE KNOWN TO HAVE QUITE A BIT OF PLAY IN THE STEERING. WITH THE STEERING SHAFT BOLT ALREADY REMOVED, WE CAN WRESTLE THE BOX COMPLETELY OUT.

(PAT)>> GOODNESS, THERE WE GO.

(MIKE)>> WE CAN ALSO REMOVE THE CLUTCH ROD AND ZBAR SINCE WE'RE GOING WITH A HYDRAULIC SETUP. FROM INSIDE THE CAR WE CAN REMOVE THE FACTORY COLUMN. IT'S A SAD TIME TO SEE THIS BREAK UP. IT'S BEEN WITH THE CAR FOR 53 YEARS.

THE NEW COLUMN WAS ORDERED PAINTABLE SO WE COULD MATCH IT TO THE GALAXIE'S INTERIOR. SO DUPLICOLOR TO THE RESCUE.

WE'RE USING ENGINE ENAMEL WITH CERAMIC. THIS IS RED AND IS THE CLOSEST TO THE ORIGINAL COLUMN COLOR WE COULD FIND.

TO PREVENT RUNS AND SAGS I'LL APPLY IT IN TWO LIGHT COATS. ONCE IT SETS UP, ANOTHER MEDIUM COAT TO GET GOOD COVERAGE. AFTER ABOUT 10 MINUTES OF WAIT TIME ONE LAST MEDIUM COAT WILL MAKE IT SHINE AND LOOK LIKE A PAINT SHOP'S QUALITY. WHILE IT'S DRYING WE'RE GOING TO TAKE A BREAK, WE'LL BE RIGHT BACK.

(MIKE)>> WE'RE BACK AND BEFORE WE INSTALL ANYTHING IT'S TIME TO DEGREASE THE UNDERSIDE OF THE CAR. GUNK ALL PURPOSE CLEANER AND DEGREASER WILL BREAK UP THE GREASE AND DIRT TO GIVE US A CLEAN SURFACE. IT'S BIODEGRADABLE AND NONTOXIC, MAKING IT REALLY SAFE TO USE. WE'LL SPRAY THE ENTIRE UNDERNEATH OF THE VEHICLE WITH A HEAVY COATING OF IT.

(PAT)>> LET HER SIT FOR A BIT.

(MIKE)>> FOR EXTRA CLEANING POWER WE'LL SUBMERGE THE SOAP PICK UP TUBE FROM THE PRESSURE WASHER IN THE GALLON JUG OF THE CLEANER AND LET THE GREASE AND DIRT REMOVAL BEGIN. THE GUNK STARTS WORKING RIGHT WAY. AFTER WE SPRAYED IT ON WE COULD SEE THE GREASE COMING OFF IN THE FORM OF DARK DROPLETS OF THE CLEANER.

(PAT)>> WELL FOR A 1963, ONCE YOU GET PAST ALL THE OIL IT'S

ACTUALLY IN REALLY GOOD SHAPE.

IT'S PROBABLY THE NICEST OLDER CAR I'VE RUN INTO IN A LONG TIME, AND THAT'S WHY I BOUGHT IT.

(MIKE)>> NOW THE PRESSURE WASHER ALLOWS THE HEAVY BUILD UP TO BLAST RIGHT OFF. AFTER 20 MINUTES THE BOTTOM OF THIS CAR IS WELL DEGREASED AND IT REVEALS HOW NICE THIS 53 YEAR OLD SHEET METAL REALLY IS. THE ENGINE BAY SHARES THE SAME CLEANLINESS. THE GUNK ALL PURPOSE CLEANER AND DEGREASER

REALLY DID ITS JOB. NOW THE FIRST NEW PART TO GO IN THE CAR IS OUR FRESHLY PAINTED STEERING COLUMN. THE ORIGINAL FLOOR BRACKET GOES ON THE LOWER PART OF THE COLUMN. ITS JOB IS TO SUPPORT IT AT THE FIREWALL. WITH THE COLUMN IN PLACE, WE CAN START THE FASTENERS TO SECURE THE FIREWALL BRACKET. NOW WE CAN POSITION THE COLUMN AND START THE NUTS ON THE SUPPORT BRACKET. MAKE SURE THE COLUMN IS STRAIGHT BEFORE THESE NUTS ARE TIGHTENED. WITH THE CAR BACK IN THE AIR, WE CAN POSITION THE POWER RACK AND PINION CRADLE ASSEMBLY BY ALIGNING IT WITH THE THREE HOLES WHERE THE STEERING BOX WAS MOUNTED. USING NEW SEVENSIXTEENTHS HARDWARE FROM THE KIT, WE CAN TIGHTEN THE CRADLE DOWN AND TORQUE THEM TO 60 POUND FEET.

[ torque wrench clicking ]

(MIKE)>> THIS HAS TO BE THE EASIEST RACK CONVERSION WE HAVE EVER INSTALLED. WELL ENGINEERED AND WILL DEFINITELY IMPROVE THE STEERING CHARACTERISTICS OF THIS GALAXIE. THE KIT ALSO INCLUDES ALL THE STEERING JOINTS AND DOUBLED SHAFT TO MAKE THE CONNECTION FROM THE STEERING COLUMN TO THE RACK. NOW THE JOINTS ARE FILLED WITH PRECISION NEEDLE BEARINGS FOR SUPER SMOOTH OPERATION. HERE'S A LITTLE TIP, DON'T USE THE DOUBLED SHAFT FOR MOCK UP. USE SOME THREE QUARTER INCH DOWEL ROD BECAUSE IT'S CHEAPER AND EASIER TO FIND IF YOU MAKE A CUT TOO SHORT.

(PAT)>> WE'LL START AT THE COLUMN BY INSTALLING THE FIRST UNIVERSAL JOINT. MAKE SURE THERE IS PLENTY OF ROOM FOR THE JOINT TO ROTATE WITHOUT BINDING ON THE STEERING COLUMN SHAFT AND TIGHTEN THE SET SCREW. THE JOINT THAT ATTACHES THE RACK IS POSITIONED AND THE THROUGH BOLT SLID INTO PLACE, AND THE SET SCREW IS SNUGGED DOWN. A PRECUT PIECE OF STEEL ROD IS PLACED BETWEEN THE JOINTS AND THE SET SCREWS ARE TIGHTENED TO HOLD IT. THIS ALLOWS US TO SEE IF THE HEIM SUPPORT WILL LINE UP. A SLIGHT ADJUSTMENT IS NEEDED. BY ROTATING THE RACK WE LOWER THE SHAFT LOCATION SO THE CRADLE BOLT CAN SECURE THE BRACKET FOR THE HEIM SUPPORT. NOW THE DOUBLED SHAFT CAN BE CUT TO LENGTH IN OUR BAND SAW. BACK AT THE CAR THE HEIM JOINT IS SLID ONTO THE SHAFT, THE SHAFT IS PLACED BETWEEN THE JOINTS, AND THE SET SCREWS ARE TIGHTENED DOWN. POSITIONING THE HEIM BRACKET AND SNUGGING IT UP WILL ALLOW

US TO TURN THE WHEEL AND VERIFY NO BINDING IS PRESENT IN THE STEERING. THE FINAL STEP IS A BIG SAFETY CONCERN. WHEN THE SET SCREWS WERE TIGHTENED THEY LEFT A MARK ON WHAT THEY TOUCHED. USING A DRILL BIT, DIMPLE THE SPOTS WHERE THE MARKS ARE. THIS MAKES SURE THAT THE SHAFT AND JOINTS CANNOT SLIP AND CAUSE A STEERING FAILURE. RED LOCTITE IS A MUST ON ALL THE SET SCREWS, AND I WOULDN'T STEER YOU WRONG. WE'LL BE RIGHT BACK.

(MIKE)>> THIS PIPING'S GONNA GET A LITTLE INTERESTING.

(PAT)>> THAT'S WHAT MOCK UP'S FOR.

(MIKE)>> HEY WE'RE BACK AND IT'S TIME TO

FINISH UP THE STEERING. NOW THE FIRST THING I'M GONNA DO IS THROW JAM NUTS ON BOTH ENDS OF THE RACK. NOW THE ADJUSTOR SLEEVES AND NEW MOOG OUTER TIE ROD ENDS CAN THREAD ON. WE'LL GET THE FRONT TIRES AS STRAIGHT AS WE CAN USING THE OLD EYEROMETER. NOW TIGHTEN THE CASTLE NUTS AND INSTALL THE COTTER PINS.

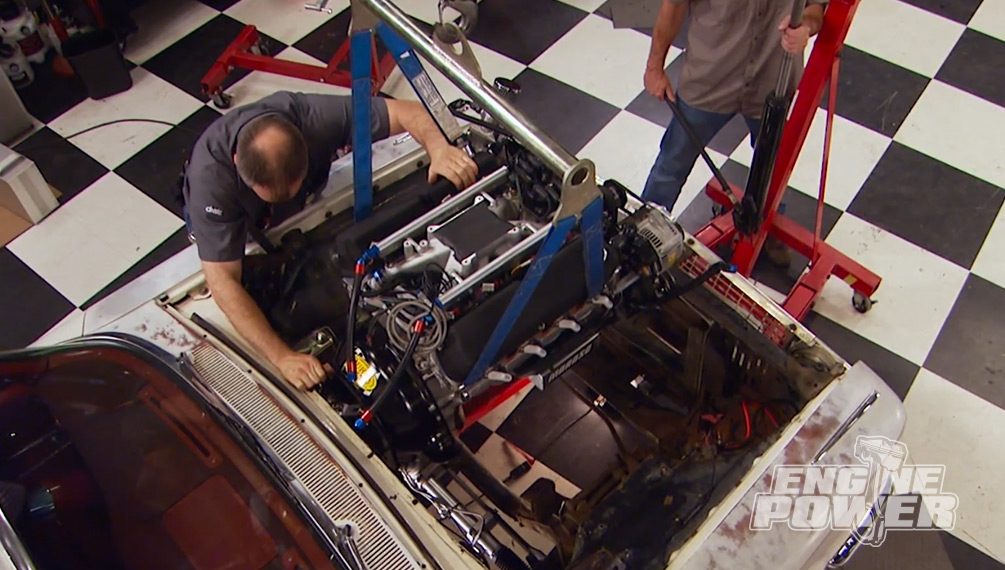

(PAT)>> AS YOU'RE PROBABLY AWARE, THE SINGLE TURBO OPTION WAS NOT AVAILABLE IN THE GALAXIE IN 1963, AND WE'RE NOT SURE IF EVERYTHING GOING IN IS GONNA CLEAR.

SO AT THIS TIME WE'RE GONNA MOCK THE ENGINE UP IN THE ENGINE BAY, AND TO MAKE THINGS EASIER WE'RE GONNA REMOVE A

FEW THINGS, LIKE THE EXHAUST FROM THE EXHAUST HOUSING, WHICH IS HELD ON WITH A VBAND CLAMP. THE 76 MILLIMETER PRECISION TURBO CAN GO NEXT, THE CROSS OVER PIPE TO THE HEADERS, AND FINALLY THE SHORTY HEADERS THEMSELVES. THE JONES RACING FRONT DRIVE WILL STAY WHERE IT'S AT. WITH THE FACTORY MOUNTS ATTACHED TO THE BLOCK FOR NOW...

(MIKE)>> ALRIGHT HERE WE GO.

(PAT)>> ...WE'LL USE OUR PIT PALL ENGINE SLING FROM SUMMIT RACING TO LOWER IT INTO THE BAY. IT'S GONNA GET ON THIS, STOP, GO UP, GO UP. IT'S ON THIS THROTTLE BRACKET. FIRST OBSTACLE SOLVED! SECOND CHALLENGE... YEP, IT'S IN ...NET. NOW COMES THE BIGGEST QUESTION, WILL THE EXHAUST SETUP WE USED ON THE DYNO FIT IN THIS ENGINE BAY?

(MIKE)>> IT'S NOT GONNA HAPPEN.

(PAT)>> IT HAS A LOT OF ROOM, JUST NOT FOR THIS.

(MIKE)>> IT'S A LITTLE PROBLEM, WE'LL SOLVE IT.

(PAT)>> IT'S A PROBLEM.

THERE'S CHALLENGES, NO SUCH THINGS AS PROBLEMS. THIS FULL CUSTOM. WITH A GAME PLAN IN PLACE IT'S TIME TO GET TO WORK. FIRST UP MIKE SQUARED UP THE HEADER OUTLET WHERE THE WASTE GATE AND CROSS OVER PIPE WAS HACKED OFF. NEXT I CUT OFF THE TFOUR FLANGE AND GROUND IT SMOOTH. WHILE IT WAS THERE I ALSO KNOCKED THE OLD WELDS OUT OF THE INSIDE AND PRETTIED IT UP. THE HEADER WAS PUT BACK IN PLACE AND A VBAND CLAMP FLANGE WAS WELDED ON.

(MIKE)>> THAT TURNED OUT REAL NICE. WE GOT CLEARANCE BETWEEN THE MAIN BRACKET THAT HOLDS THE CONTROL ARM ON. NOW WE CAN MAKE OUR BENDS AND START WORKING OUR WAY TO THAT TURBO.

(PAT)>> THEN A COUPLE OF BENDS WERE CUT, POSITIONED, AND WELDED UP TO GET THE LOCATION OF THE TURBO FLANGE WHERE WE WANTED IT. FINALLY THE TFOUR FLANGE WAS WELDED TO THE PIPE AND THE PRECISION TURBO WAS READY FOR TEST FIT. THAT WAS NICE. THAT IS A NICE JOB RIGHT THERE.

(MIKE)>> GETTING THE TURBO MOUNTED WAS AS FAR AS WE COULD GET TODAY BECAUSE OF TIME. NOW PAT HAD TO TAKE OFF TO A LITTLE EVENT THAT PROVES OUR CAR CULTURE IS STILL ALIVE. UP NEXT, JOIN HIM AT CARS AND COFFEE.

(PAT)>> WELL IT'S THE FIRST SATURDAY OF THE MONTH AND

WE'RE HERE JUST OUTSIDE OF NASHVILLE AT CARS AND COFFEE. NOW THESE HAPPEN EVERYWHERE AROUND THE US. THIS ONE GETS REALLY BIG THOUGH. WE GET EXOTICS, WE GET HOT RODS, AND WE GET IMPORTS.

SO A LITTLE BIT OF EVERYTHING WILL SHOW UP, AND IT'S A LOT OF PEOPLE IN A VERY SHORT AMOUNT OF TIME. SO LET'S GET STARTED LOOKING.

WELL I'VE PROCURED MY COFFEE. NOW IT'S TIME TO LOOK AT SOME CARS, AND BOY DO WE EVER GET CARS HERE AT CARS AND COFFEE. THIS IS A 1964 FORD THUNDERBOLT FACTORY RACE CAR. NOW THERE'S ONLY ABOUT 111 OF THESE EVER MADE, AND THIS ONE ALL FIBERGLASS FRONT END, PLEXIGLASS WINDOWS, BUT MORE IMPORTANTLY A 427 HIGH RISE. THIS CAR WAS ACTUALLY NUMBER 25 THAT WAS CAMPAIGNED OUT OF ALABAMA BACK IN THE DAY. SO HEY, THIS IS THE KIND OF THINGS YOU SEE HERE. OTHER PRIME EXAMPLES INCLUDE JOHN RIPPY'S 1968 PONTIAC FIREBIRD 400 CONVERTIBLE.

(JOHN)>> PUT IT TOGETHER IN THE GARAGE, TOOK IT UP TO THE TRANS AM NATIONALS FOR THE FIRST TIME AND WON NATIONAL CHAMPION. I WAS KIND OF PROUD OF THAT AND REAL SURPRISED. THAT'S ABOUT ALL I CAN TELL YOU.

I'VE ENJOYED THE HECK OUT OF IT.

(PAT)>> WHERE ELSE CAN YOU SEE A CAMARO FOLLOWED BY A MASERATI? WHOA, WHAT THE?

I HAVE TO SAY THIS IS THE NICEST CHRYSLER IMPERIAL

I'VE SEEN HERE TODAY. WHAT WE LOVE ABOUT THIS IS A VERY FAMILY FRIENDLY EVENT. ALL ARE WELCOME, KIDS, WIVES, A LOT OF PEOPLE ARE OUT HERE, AND INTERESTINGLY ENOUGH THERE ARE PLENTY OF CAR PEOPLE AS WELL AS NONCAR PEOPLE OUT HERE ENJOYING THE DAY.

(JOE)>> THE BEST PART ABOUT THIS IS THIS IS ACTUALLY MY SHIFT ASSIGNMENT.

SO I GET TO START EVERY SATURDAY MORNING COMING OUT HERE AND HANGING OUT WITH CAR GUYS, AND I GET PAID TO DO. SO IT'S A GREAT GIG.

(PAT)>> A NEWCOMER TO THIS EVENT WAS BOB BRANHOF AND WHAT'S LEFT OF HIS 1965 C-10 PICK UP.

(BOB)>> THE CONCEPT WAS ALL HERE WHEN I GOT IT. WE JUST HAD TO FINISH IT UP, BASICALLY. 12 INCHES CHOPPED OFF THE BOTTOM, THREE AND A HALF CHOPPED IN THE MIDDLE, AND A WORK IN PROGRESS.

(PAT)>> LOOKS LIKE HIS CREATURE COMFORTS COULD USE A LITTLE WORK AS WELL.

(BOB)>> I TRAILERED HALF WAY AT LEAST. I GET A WINDSHIELD NEXT SO I CAN DRIVE A LITTLE FURTHER.

(PAT)>> YOU NEVER KNOW WHAT OR WHO YOU'LL SEE DRIVING AROUND HERE AT CARS AND COFFEE. HEY KID, WHERE ARE THE REST OF THE BEAMERS PARKED? ( )>> THEY'RE OVER THERE PAT.

(PAT)>> OH THERE THEY ARE, NOT JUST BEAMERS BUT EVERYTHING FROM MERCEDES, TO LAMBOS, TO ITALIAN JOBS. ONE OF THE BEST REPRESENTED CLUBS IN ATTENDANCE WAS THE NASHVILLE BRITISH CAR CLUB.

(CHIP)>> PEOPLE LIKE OUR CARS BECAUSE THERE'S A LOT OF VARIETY.

THERE'S A LOT OF INTEREST IN YOU KNOW, MOST OF THESE CARS, MAYBE EXCEPT FOR THE JAGUARS, STOPPED BEING MADE AFTER 1980. NONE OF THESE CARS COST MORE THAN A FEW THOUSAND DOLLARS, AND YOU KNOW WE ENJOY WORKING ON THEM. JUST LIKE ALL THESE PEOPLE OUT HERE DO ENJOY FIDDLING WITH THEM AND HAVING SOMETHING TO DRIVE ON A SUNNY DAY. THAT'S MAINLY WHAT IT IS.

(PAT)>> FROM A HURST OLDS TO A ROLLS ROYCE, YOU GET A LITTLE BIT OF EVERYTHING. YOU'VE ALL PROBABLY BEEN TO A CAR EVENT WHERE THERE'S

AN ENTRY FEE TO PARK. THE BEST PART ABOUT CARS AND COFFEE IS THAT THEY ARE TOTALLY FREE TO BOTH PARTICIPANTS AND SPECTATORS. JUST MAKE SURE YOU BRING ENOUGH MONEY TO PICK UP A COFFEE ALONG THE WAY IF YOU DIDN'T BRING ONE OF YOUR OWN. HOT RODS, MUSCLE CARS, IMPORTS, EVEN LUXURY EXOTICS, THERE'S SOMETHING FOR EVERYONE AT CARS AND COFFEE. NOW KEEP IN MIND THESE ARE ALL OVER THE UNITED STATES. SO CHECK YOUR SEARCH ENGINES AND YOUR SOCIAL MEDIA FOR ONE THAT COMES TO YOUR AREA AND YOU WON'T BE SORRY YOU WENT TO ONE.

(MIKE)>> GOT A GEN TWO HEMI?

THEN EDELBROCK HAS A NEW HYDRAULIC ROLLER TOP END PACKAGE FOR YOU. NOW IT'S DESIGNED FOR ENGINES THAT MAKE 650 PLUS HORSEPOWER. THE CYLINDER HEADS ARE VICTOR JUNIORS THAT HAVE A 245cc INTAKE RUNNER A 170cc EXHAUST CHAMBER. THE VALVES MEASURE TWO-320 ON THE INTAKE, ONE-940 ON THE EXHAUST. NOW THE KIT ALSO INCLUDES A CAM SHAFT, TIMING SET, HEAD BOLTS, GASKETS, AND A DUAL QUAD INTAKE MANIFOLD. FOR PRICES LOG ON TO SUMMIT RACING DOT COM.

(PAT)>> IF YOU WANT A HIGH PERFORMANCE BRAKE UPGRADE FOR YOUR TRUCK, JEEP, OR SUV THEN THESE SEIGHT KITS FROM EBC BRAKES ARE WHAT YOU'VE BEEN LOOKING FOR. THEY'RE ENGINEERED TO STOP YOUR RIG BETTER WITH THESE SPECIALLY FORMULATED EXTRA DUTY PADS WITH ARAMID FIBER AND THEY HAVE THEIR PATENTED BREAK IN COATING ON THEM FOR QUICK SEATING. PLUS THESE GEOMET COATED DIMPLED AND SLOTTED ROTORS WILL RUN UP TO 200 DEGREES COOLER THAN YOUR OEM UNITS, AND YOU CAN SAVE 15 PERCENT FROM PURCHASING ALL THESE PARTS SEPARATELY BY PICKING UP ONE OF THESE EBC BRAKE KITS FROM YOUR FAVORITE AUTO PARTS RETAILER.

WE GET A BUNCH OF QUESTIONS IN OUR EMAILS FROM YOU VIEWERS ASKING FOR ADVICE ON WHAT TO LOOK FOR WHEN PURCHASING A USED ENGINE. WELL THE OVERALL CONDITION MAY OR MAY NOT TELL THE WHOLE STORY ABOUT WHAT YOU'RE TRYING TO BUY, AND SOME OF USE HAVE EVEN FALLEN FOR THE LOW MILE ENGINE WITH THE AEROSOL OVERHAUL THAT'S BEEN PRETTIED UP FOR THE SALE. WELL HERE'S A QUICK WAY TO AVOID THAT SITUATION. THE MOST STRAIGHT FORWARD OPERATION THAT CAN BE DONE TO AN ENGINE TO DETERMINE ITS CONDITION IS A LEAK DOWN TEST. WHAT IT MEASURES IS THE PERCENTAGE OF PRESSURE ESCAPING THE COMBUSTION AREA OF A GIVEN CYLINDER BEING TESTED.

IT'S A QUICK WAY TO HELP DIAGNOSE A PROBLEM IN AN ENGINE THAT'S NOT PERFORMING UP TO ITS POTENTIAL OR TO SEE

IF A USED BULLET IS A GOOD CANDIDATE TO BUY. TO DO THIS YOU NEED A QUALITY LEAK DOWN TESTER, AND WE USE THIS DUAL GAUGE SETUP FROM MATCO TOOLS, OR YOU CAN RENT ONE OF THESE AT YOUR LOCAL PARTS HOUSE. NOW HERE'S HOW IT WORKS. ON ONE SIDE IT'S HOOKED UP TO AN AIR COMPRESSOR AND THAT PRESSURE IS REGULATED TO 100 PSI, AND THE OTHER SIDE HAS A LINE ON IT THAT SCREWS INTO THE SPARK PLUG HOLE OF THE CYLINDER BEING TESTED. TO HAVE ACCURATE RESULTS THE ENGINE MUST BE ON TDC COMPRESSION STROKE OF THE CYLINDER BEING TESTED.

SO STARTING WITH THE NUMBER ONE CYLINDER, ROLL THE ENGINE OVER IN THE CORRECT ROTATION WITH A TEST HOSE IN THE PLUG HOLE. WHEN AIR FORCES PAST YOUR FINGER COVERING THE HOSE END, THE CYLINDER IS COMING UP ON TDC OF THE COMPRESSION STROKE.

CONTINUE TURNING THE ENGINE UNTIL THE TIMING MARK ON THE BALANCER LINES UP WITH ZERO ON THE TIMING TAB. WITH THE HOSE PLUGGED INTO OUR TESTER, IT PRESSURIZES THE CYLINDER WITH 100 PSI OF AIR. ON THIS GAUGE IT SHOWS THE CYLINDER IS ONLY HOLDING 92 PSI, AND THAT SUBTRACTED FROM 100 IS EIGHT. SO THAT MEANS THE CYLINDER HAS EIGHT PERCENT LEAKAGE. YOU'RE LOOKING FOR A NUMBER BETWEEN FIVE AND 10 PERCENT. ANYTHING MORE THAN THAT INDICATES YOU MIGHT HAVE SOME ISSUES, BUT IT'S RELATIVELY EASY TO FIND THE LEAKAGE. FOR INSTANCE, IF YOU HEAR AIR COMING OUT THE INTAKE MANIFOLD YOUR INTAKE VALVES ARE NOT SEATED PROPERLY. IF YOU HEAR AIR COMING OUT THE EXHAUST MANIFOLDS CHANCES ARE THE EXHAUST VALVES OR VALVE SEATS ARE THE PROBLEM. BUT FOR THE MOST PART AIR WILL BE LEAKING PAST THE PISTON RINGS INTO THE CRANK CASE, AND THAT CAN BE HEARD, FELT, AND SEE THROUGH A VALVE COVER HOLE. HERE'S A QUICK TIP. WHILE YOU HAVE THE ENGINE AT TDC ON NUMBER ONE, GO AHEAD

AND MARK THE PULLEY EVERY 90 DEGREES. JUST USE A STRAIGHT EDGES AND A MARKER.

WHY DO THIS? A 90 DEGREE VEIGHT FIRES EVERY 90 DEGREES OF CRANK SHAFT ROTATION. SO TURNING THE ENGINE A QUARTER TURN, OR 90 DEGREES, PUTS THE NEXT CYLINDER IN THE FIRING ORDER AT TDC ON ITS COMPRESSION STROKE, AND THEN YOU SIMPLY SWITCH YOUR HOSE AND CONTINUE YOUR TEST, AND DO THIS UNTIL ALL THE CYLINDERS ARE CHECKED. NOW THIS IS A BIT TIME CONSUMING AND IT'S A PAIN WHEN IT'S IN THE CAR, BUT IT'S WELL WORTH THE TIME TO ELIMINATE ANY REGRETS.

(MIKE)>> THE NEXT TIME YOU SEE US WORKING ON THE GALAXIE IT'S GOING TO COME TOGETHER PRETTY QUICK. NOW THAT'S ALL THE TIME WE HAVE FOR THIS WEEK. MAKE SURE YOU JOIN US NEXT TIME FOR ANOTHER POWER PACKED EDITION OF ENGINE POWER.

Show Full Transcript

ENGINE WAS IN THE CAR WAS 15 PERCENT.

(MIKE)>> THIS OLD PLANET CRUISER DEFINITELY BEAT THE

ODDS OF THE ELEMENTS. IT'S GOT A SUPER SOLID BODY AND IT'S GONNA STAY IN THE SAME EXACT CONDITION. PLUS THIS OLD PATINA PAINT IS JUST A SIGN OF ITS ORIGINALITY. NOW WHAT IS GOING TO CHANGE ARE ALL THE COMPONENTS TO MAKE THE VEHICLE FUNCTION, LIKE THIS CUSTOM BUILT REAR END. IT'S GONNA REPLACE THE NINE INCH THAT'S IN THE CAR NOW, AND THESE BEEFY BAER BRAKES WILL REPLACE DRUMS OUT BACK AND SKIMPY DISCS UP FRONT.

NOW THE NEW POWER PLANT IS DEFINITELY GONNA MAKE ALL THOSE COMPONENTS HAVE TO DO THEIR JOBS. HERE'S A LITTLE BIT ABOUT IT.

(PAT)>> IT ALL STARTED WITH A DART IRON EAGLE BLOCK FOR STRENGTH. ONCE THE BEARINGS WERE DROPPED IN AND LUBED, AN EAGLE 43-40 COMPETITION CRANKSHAFT WAS LAID IN THE SADDLES. NEXT A CUSTOM ORDERED LUNATI HYDRAULIC ROLLER CAM SHAFT WAS SLID INTO THE CAM BORE, AND THEIR TIMING SET MADE THE LINK FROM THE CAM TO THE CRANKSHAFT. EAGLE HBEAM RODS AND CUSTOM DSS PISTONS SPEC'ED FOR THIS BUILD WERE PLACED IN THE BORES. THEN THE OIL PUMP AND PICK UP WERE INSTALLED, AND DSS' BILLET MAIN GIRDLE WAS FINISHED OFF.

(MIKE)>> AFR RENEGADE COMPETITION CYLINDER HEADS WENT ON AND WERE TORQUED DOWN USING ARP STUDS. CHROMOLY PUSH RODS WERE DROPPED IN, AND JESEL SENT US A SHAFT ROCKER SETUP TO ELIMINATE ANY VALVETRAIN WORRIES. A SUPER VICTOR INTAKE MANIFOLD WAS TRANSFORMED INTO EFI

FORM AND SEALED UP THE VALLEY, AND 120 POUND AN HOUR INJECTORS WILL SUPPLY FUEL TO THIS POWER PLANT. NOW A 1,000 CFM HOLLEY THROTTLE BODY WENT ON AND ONCE IN THE DYNO ROOM WE INSTALLED A HELLION POWER SYSTEMS FOX BODY TURBO KIT STARTING WITH THE HOT SIDE. THE BOOST PRODUCER IS A 76 MILLIMETER PRECISION TURBO WITH A BILLET COVER. A JONES' RACING FRONT DRIVE GIVES THE ENGINE THE RACY LOOK IT DESERVES.

[ engine revving ]

(MIKE)>> IT MADE 806 HORSEPOWER AND 782 POUND FEET OF TORQUE DURING A BREAK IN DYNO SESSION. ONCE IN THE CAR, 1,000 AT THE TIRES IS THE GOAL.

(PAT)>> WE'RE GONNA START AT THE FRONT OF THE CAR BY REMOVING ALL OF THE FACTORY STEERING COMPONENTS, AND THAT WILL MAKE WAY FOR THIS FLAMING RIVER POWER RACK AND PINION CRADLE KIT. NOW THIS BEEFY CRADLE BOLTS TO THE FRAME RAILS TO SUPPORT THE RACK, AND IT EVEN COMES WITH THIS PAINTABLE COLUMN THAT HAS TILT. SO LET'S START BY GETTING THE COMPONENTS OUT OF THE CAR.

(MIKE)>> FIRST WE'LL REMOVE THE DRAG LINK FROM THE PITMAN ARM.

THEN REMOVE BOTH TIE RODS FROM THE SPINDLES. UNBOLT THE IDLER AND REMOVE EVERYTHING AS AN ASSEMBLY. NOW THE FACTORY MANUAL STEERING BOX CAN BE UNBOLTED, AND THESE CARS WERE KNOWN TO HAVE QUITE A BIT OF PLAY IN THE STEERING. WITH THE STEERING SHAFT BOLT ALREADY REMOVED, WE CAN WRESTLE THE BOX COMPLETELY OUT.

(PAT)>> GOODNESS, THERE WE GO.

(MIKE)>> WE CAN ALSO REMOVE THE CLUTCH ROD AND ZBAR SINCE WE'RE GOING WITH A HYDRAULIC SETUP. FROM INSIDE THE CAR WE CAN REMOVE THE FACTORY COLUMN. IT'S A SAD TIME TO SEE THIS BREAK UP. IT'S BEEN WITH THE CAR FOR 53 YEARS.

THE NEW COLUMN WAS ORDERED PAINTABLE SO WE COULD MATCH IT TO THE GALAXIE'S INTERIOR. SO DUPLICOLOR TO THE RESCUE.

WE'RE USING ENGINE ENAMEL WITH CERAMIC. THIS IS RED AND IS THE CLOSEST TO THE ORIGINAL COLUMN COLOR WE COULD FIND.

TO PREVENT RUNS AND SAGS I'LL APPLY IT IN TWO LIGHT COATS. ONCE IT SETS UP, ANOTHER MEDIUM COAT TO GET GOOD COVERAGE. AFTER ABOUT 10 MINUTES OF WAIT TIME ONE LAST MEDIUM COAT WILL MAKE IT SHINE AND LOOK LIKE A PAINT SHOP'S QUALITY. WHILE IT'S DRYING WE'RE GOING TO TAKE A BREAK, WE'LL BE RIGHT BACK.

(MIKE)>> WE'RE BACK AND BEFORE WE INSTALL ANYTHING IT'S TIME TO DEGREASE THE UNDERSIDE OF THE CAR. GUNK ALL PURPOSE CLEANER AND DEGREASER WILL BREAK UP THE GREASE AND DIRT TO GIVE US A CLEAN SURFACE. IT'S BIODEGRADABLE AND NONTOXIC, MAKING IT REALLY SAFE TO USE. WE'LL SPRAY THE ENTIRE UNDERNEATH OF THE VEHICLE WITH A HEAVY COATING OF IT.

(PAT)>> LET HER SIT FOR A BIT.

(MIKE)>> FOR EXTRA CLEANING POWER WE'LL SUBMERGE THE SOAP PICK UP TUBE FROM THE PRESSURE WASHER IN THE GALLON JUG OF THE CLEANER AND LET THE GREASE AND DIRT REMOVAL BEGIN. THE GUNK STARTS WORKING RIGHT WAY. AFTER WE SPRAYED IT ON WE COULD SEE THE GREASE COMING OFF IN THE FORM OF DARK DROPLETS OF THE CLEANER.

(PAT)>> WELL FOR A 1963, ONCE YOU GET PAST ALL THE OIL IT'S

ACTUALLY IN REALLY GOOD SHAPE.

IT'S PROBABLY THE NICEST OLDER CAR I'VE RUN INTO IN A LONG TIME, AND THAT'S WHY I BOUGHT IT.

(MIKE)>> NOW THE PRESSURE WASHER ALLOWS THE HEAVY BUILD UP TO BLAST RIGHT OFF. AFTER 20 MINUTES THE BOTTOM OF THIS CAR IS WELL DEGREASED AND IT REVEALS HOW NICE THIS 53 YEAR OLD SHEET METAL REALLY IS. THE ENGINE BAY SHARES THE SAME CLEANLINESS. THE GUNK ALL PURPOSE CLEANER AND DEGREASER

REALLY DID ITS JOB. NOW THE FIRST NEW PART TO GO IN THE CAR IS OUR FRESHLY PAINTED STEERING COLUMN. THE ORIGINAL FLOOR BRACKET GOES ON THE LOWER PART OF THE COLUMN. ITS JOB IS TO SUPPORT IT AT THE FIREWALL. WITH THE COLUMN IN PLACE, WE CAN START THE FASTENERS TO SECURE THE FIREWALL BRACKET. NOW WE CAN POSITION THE COLUMN AND START THE NUTS ON THE SUPPORT BRACKET. MAKE SURE THE COLUMN IS STRAIGHT BEFORE THESE NUTS ARE TIGHTENED. WITH THE CAR BACK IN THE AIR, WE CAN POSITION THE POWER RACK AND PINION CRADLE ASSEMBLY BY ALIGNING IT WITH THE THREE HOLES WHERE THE STEERING BOX WAS MOUNTED. USING NEW SEVENSIXTEENTHS HARDWARE FROM THE KIT, WE CAN TIGHTEN THE CRADLE DOWN AND TORQUE THEM TO 60 POUND FEET.

[ torque wrench clicking ]

(MIKE)>> THIS HAS TO BE THE EASIEST RACK CONVERSION WE HAVE EVER INSTALLED. WELL ENGINEERED AND WILL DEFINITELY IMPROVE THE STEERING CHARACTERISTICS OF THIS GALAXIE. THE KIT ALSO INCLUDES ALL THE STEERING JOINTS AND DOUBLED SHAFT TO MAKE THE CONNECTION FROM THE STEERING COLUMN TO THE RACK. NOW THE JOINTS ARE FILLED WITH PRECISION NEEDLE BEARINGS FOR SUPER SMOOTH OPERATION. HERE'S A LITTLE TIP, DON'T USE THE DOUBLED SHAFT FOR MOCK UP. USE SOME THREE QUARTER INCH DOWEL ROD BECAUSE IT'S CHEAPER AND EASIER TO FIND IF YOU MAKE A CUT TOO SHORT.

(PAT)>> WE'LL START AT THE COLUMN BY INSTALLING THE FIRST UNIVERSAL JOINT. MAKE SURE THERE IS PLENTY OF ROOM FOR THE JOINT TO ROTATE WITHOUT BINDING ON THE STEERING COLUMN SHAFT AND TIGHTEN THE SET SCREW. THE JOINT THAT ATTACHES THE RACK IS POSITIONED AND THE THROUGH BOLT SLID INTO PLACE, AND THE SET SCREW IS SNUGGED DOWN. A PRECUT PIECE OF STEEL ROD IS PLACED BETWEEN THE JOINTS AND THE SET SCREWS ARE TIGHTENED TO HOLD IT. THIS ALLOWS US TO SEE IF THE HEIM SUPPORT WILL LINE UP. A SLIGHT ADJUSTMENT IS NEEDED. BY ROTATING THE RACK WE LOWER THE SHAFT LOCATION SO THE CRADLE BOLT CAN SECURE THE BRACKET FOR THE HEIM SUPPORT. NOW THE DOUBLED SHAFT CAN BE CUT TO LENGTH IN OUR BAND SAW. BACK AT THE CAR THE HEIM JOINT IS SLID ONTO THE SHAFT, THE SHAFT IS PLACED BETWEEN THE JOINTS, AND THE SET SCREWS ARE TIGHTENED DOWN. POSITIONING THE HEIM BRACKET AND SNUGGING IT UP WILL ALLOW

US TO TURN THE WHEEL AND VERIFY NO BINDING IS PRESENT IN THE STEERING. THE FINAL STEP IS A BIG SAFETY CONCERN. WHEN THE SET SCREWS WERE TIGHTENED THEY LEFT A MARK ON WHAT THEY TOUCHED. USING A DRILL BIT, DIMPLE THE SPOTS WHERE THE MARKS ARE. THIS MAKES SURE THAT THE SHAFT AND JOINTS CANNOT SLIP AND CAUSE A STEERING FAILURE. RED LOCTITE IS A MUST ON ALL THE SET SCREWS, AND I WOULDN'T STEER YOU WRONG. WE'LL BE RIGHT BACK.

(MIKE)>> THIS PIPING'S GONNA GET A LITTLE INTERESTING.

(PAT)>> THAT'S WHAT MOCK UP'S FOR.

(MIKE)>> HEY WE'RE BACK AND IT'S TIME TO

FINISH UP THE STEERING. NOW THE FIRST THING I'M GONNA DO IS THROW JAM NUTS ON BOTH ENDS OF THE RACK. NOW THE ADJUSTOR SLEEVES AND NEW MOOG OUTER TIE ROD ENDS CAN THREAD ON. WE'LL GET THE FRONT TIRES AS STRAIGHT AS WE CAN USING THE OLD EYEROMETER. NOW TIGHTEN THE CASTLE NUTS AND INSTALL THE COTTER PINS.

(PAT)>> AS YOU'RE PROBABLY AWARE, THE SINGLE TURBO OPTION WAS NOT AVAILABLE IN THE GALAXIE IN 1963, AND WE'RE NOT SURE IF EVERYTHING GOING IN IS GONNA CLEAR.

SO AT THIS TIME WE'RE GONNA MOCK THE ENGINE UP IN THE ENGINE BAY, AND TO MAKE THINGS EASIER WE'RE GONNA REMOVE A

FEW THINGS, LIKE THE EXHAUST FROM THE EXHAUST HOUSING, WHICH IS HELD ON WITH A VBAND CLAMP. THE 76 MILLIMETER PRECISION TURBO CAN GO NEXT, THE CROSS OVER PIPE TO THE HEADERS, AND FINALLY THE SHORTY HEADERS THEMSELVES. THE JONES RACING FRONT DRIVE WILL STAY WHERE IT'S AT. WITH THE FACTORY MOUNTS ATTACHED TO THE BLOCK FOR NOW...

(MIKE)>> ALRIGHT HERE WE GO.

(PAT)>> ...WE'LL USE OUR PIT PALL ENGINE SLING FROM SUMMIT RACING TO LOWER IT INTO THE BAY. IT'S GONNA GET ON THIS, STOP, GO UP, GO UP. IT'S ON THIS THROTTLE BRACKET. FIRST OBSTACLE SOLVED! SECOND CHALLENGE... YEP, IT'S IN ...NET. NOW COMES THE BIGGEST QUESTION, WILL THE EXHAUST SETUP WE USED ON THE DYNO FIT IN THIS ENGINE BAY?

(MIKE)>> IT'S NOT GONNA HAPPEN.

(PAT)>> IT HAS A LOT OF ROOM, JUST NOT FOR THIS.

(MIKE)>> IT'S A LITTLE PROBLEM, WE'LL SOLVE IT.

(PAT)>> IT'S A PROBLEM.

THERE'S CHALLENGES, NO SUCH THINGS AS PROBLEMS. THIS FULL CUSTOM. WITH A GAME PLAN IN PLACE IT'S TIME TO GET TO WORK. FIRST UP MIKE SQUARED UP THE HEADER OUTLET WHERE THE WASTE GATE AND CROSS OVER PIPE WAS HACKED OFF. NEXT I CUT OFF THE TFOUR FLANGE AND GROUND IT SMOOTH. WHILE IT WAS THERE I ALSO KNOCKED THE OLD WELDS OUT OF THE INSIDE AND PRETTIED IT UP. THE HEADER WAS PUT BACK IN PLACE AND A VBAND CLAMP FLANGE WAS WELDED ON.

(MIKE)>> THAT TURNED OUT REAL NICE. WE GOT CLEARANCE BETWEEN THE MAIN BRACKET THAT HOLDS THE CONTROL ARM ON. NOW WE CAN MAKE OUR BENDS AND START WORKING OUR WAY TO THAT TURBO.

(PAT)>> THEN A COUPLE OF BENDS WERE CUT, POSITIONED, AND WELDED UP TO GET THE LOCATION OF THE TURBO FLANGE WHERE WE WANTED IT. FINALLY THE TFOUR FLANGE WAS WELDED TO THE PIPE AND THE PRECISION TURBO WAS READY FOR TEST FIT. THAT WAS NICE. THAT IS A NICE JOB RIGHT THERE.

(MIKE)>> GETTING THE TURBO MOUNTED WAS AS FAR AS WE COULD GET TODAY BECAUSE OF TIME. NOW PAT HAD TO TAKE OFF TO A LITTLE EVENT THAT PROVES OUR CAR CULTURE IS STILL ALIVE. UP NEXT, JOIN HIM AT CARS AND COFFEE.

(PAT)>> WELL IT'S THE FIRST SATURDAY OF THE MONTH AND

WE'RE HERE JUST OUTSIDE OF NASHVILLE AT CARS AND COFFEE. NOW THESE HAPPEN EVERYWHERE AROUND THE US. THIS ONE GETS REALLY BIG THOUGH. WE GET EXOTICS, WE GET HOT RODS, AND WE GET IMPORTS.

SO A LITTLE BIT OF EVERYTHING WILL SHOW UP, AND IT'S A LOT OF PEOPLE IN A VERY SHORT AMOUNT OF TIME. SO LET'S GET STARTED LOOKING.

WELL I'VE PROCURED MY COFFEE. NOW IT'S TIME TO LOOK AT SOME CARS, AND BOY DO WE EVER GET CARS HERE AT CARS AND COFFEE. THIS IS A 1964 FORD THUNDERBOLT FACTORY RACE CAR. NOW THERE'S ONLY ABOUT 111 OF THESE EVER MADE, AND THIS ONE ALL FIBERGLASS FRONT END, PLEXIGLASS WINDOWS, BUT MORE IMPORTANTLY A 427 HIGH RISE. THIS CAR WAS ACTUALLY NUMBER 25 THAT WAS CAMPAIGNED OUT OF ALABAMA BACK IN THE DAY. SO HEY, THIS IS THE KIND OF THINGS YOU SEE HERE. OTHER PRIME EXAMPLES INCLUDE JOHN RIPPY'S 1968 PONTIAC FIREBIRD 400 CONVERTIBLE.

(JOHN)>> PUT IT TOGETHER IN THE GARAGE, TOOK IT UP TO THE TRANS AM NATIONALS FOR THE FIRST TIME AND WON NATIONAL CHAMPION. I WAS KIND OF PROUD OF THAT AND REAL SURPRISED. THAT'S ABOUT ALL I CAN TELL YOU.

I'VE ENJOYED THE HECK OUT OF IT.

(PAT)>> WHERE ELSE CAN YOU SEE A CAMARO FOLLOWED BY A MASERATI? WHOA, WHAT THE?

I HAVE TO SAY THIS IS THE NICEST CHRYSLER IMPERIAL

I'VE SEEN HERE TODAY. WHAT WE LOVE ABOUT THIS IS A VERY FAMILY FRIENDLY EVENT. ALL ARE WELCOME, KIDS, WIVES, A LOT OF PEOPLE ARE OUT HERE, AND INTERESTINGLY ENOUGH THERE ARE PLENTY OF CAR PEOPLE AS WELL AS NONCAR PEOPLE OUT HERE ENJOYING THE DAY.

(JOE)>> THE BEST PART ABOUT THIS IS THIS IS ACTUALLY MY SHIFT ASSIGNMENT.

SO I GET TO START EVERY SATURDAY MORNING COMING OUT HERE AND HANGING OUT WITH CAR GUYS, AND I GET PAID TO DO. SO IT'S A GREAT GIG.

(PAT)>> A NEWCOMER TO THIS EVENT WAS BOB BRANHOF AND WHAT'S LEFT OF HIS 1965 C-10 PICK UP.

(BOB)>> THE CONCEPT WAS ALL HERE WHEN I GOT IT. WE JUST HAD TO FINISH IT UP, BASICALLY. 12 INCHES CHOPPED OFF THE BOTTOM, THREE AND A HALF CHOPPED IN THE MIDDLE, AND A WORK IN PROGRESS.

(PAT)>> LOOKS LIKE HIS CREATURE COMFORTS COULD USE A LITTLE WORK AS WELL.

(BOB)>> I TRAILERED HALF WAY AT LEAST. I GET A WINDSHIELD NEXT SO I CAN DRIVE A LITTLE FURTHER.

(PAT)>> YOU NEVER KNOW WHAT OR WHO YOU'LL SEE DRIVING AROUND HERE AT CARS AND COFFEE. HEY KID, WHERE ARE THE REST OF THE BEAMERS PARKED? ( )>> THEY'RE OVER THERE PAT.

(PAT)>> OH THERE THEY ARE, NOT JUST BEAMERS BUT EVERYTHING FROM MERCEDES, TO LAMBOS, TO ITALIAN JOBS. ONE OF THE BEST REPRESENTED CLUBS IN ATTENDANCE WAS THE NASHVILLE BRITISH CAR CLUB.

(CHIP)>> PEOPLE LIKE OUR CARS BECAUSE THERE'S A LOT OF VARIETY.

THERE'S A LOT OF INTEREST IN YOU KNOW, MOST OF THESE CARS, MAYBE EXCEPT FOR THE JAGUARS, STOPPED BEING MADE AFTER 1980. NONE OF THESE CARS COST MORE THAN A FEW THOUSAND DOLLARS, AND YOU KNOW WE ENJOY WORKING ON THEM. JUST LIKE ALL THESE PEOPLE OUT HERE DO ENJOY FIDDLING WITH THEM AND HAVING SOMETHING TO DRIVE ON A SUNNY DAY. THAT'S MAINLY WHAT IT IS.

(PAT)>> FROM A HURST OLDS TO A ROLLS ROYCE, YOU GET A LITTLE BIT OF EVERYTHING. YOU'VE ALL PROBABLY BEEN TO A CAR EVENT WHERE THERE'S

AN ENTRY FEE TO PARK. THE BEST PART ABOUT CARS AND COFFEE IS THAT THEY ARE TOTALLY FREE TO BOTH PARTICIPANTS AND SPECTATORS. JUST MAKE SURE YOU BRING ENOUGH MONEY TO PICK UP A COFFEE ALONG THE WAY IF YOU DIDN'T BRING ONE OF YOUR OWN. HOT RODS, MUSCLE CARS, IMPORTS, EVEN LUXURY EXOTICS, THERE'S SOMETHING FOR EVERYONE AT CARS AND COFFEE. NOW KEEP IN MIND THESE ARE ALL OVER THE UNITED STATES. SO CHECK YOUR SEARCH ENGINES AND YOUR SOCIAL MEDIA FOR ONE THAT COMES TO YOUR AREA AND YOU WON'T BE SORRY YOU WENT TO ONE.

(MIKE)>> GOT A GEN TWO HEMI?

THEN EDELBROCK HAS A NEW HYDRAULIC ROLLER TOP END PACKAGE FOR YOU. NOW IT'S DESIGNED FOR ENGINES THAT MAKE 650 PLUS HORSEPOWER. THE CYLINDER HEADS ARE VICTOR JUNIORS THAT HAVE A 245cc INTAKE RUNNER A 170cc EXHAUST CHAMBER. THE VALVES MEASURE TWO-320 ON THE INTAKE, ONE-940 ON THE EXHAUST. NOW THE KIT ALSO INCLUDES A CAM SHAFT, TIMING SET, HEAD BOLTS, GASKETS, AND A DUAL QUAD INTAKE MANIFOLD. FOR PRICES LOG ON TO SUMMIT RACING DOT COM.

(PAT)>> IF YOU WANT A HIGH PERFORMANCE BRAKE UPGRADE FOR YOUR TRUCK, JEEP, OR SUV THEN THESE SEIGHT KITS FROM EBC BRAKES ARE WHAT YOU'VE BEEN LOOKING FOR. THEY'RE ENGINEERED TO STOP YOUR RIG BETTER WITH THESE SPECIALLY FORMULATED EXTRA DUTY PADS WITH ARAMID FIBER AND THEY HAVE THEIR PATENTED BREAK IN COATING ON THEM FOR QUICK SEATING. PLUS THESE GEOMET COATED DIMPLED AND SLOTTED ROTORS WILL RUN UP TO 200 DEGREES COOLER THAN YOUR OEM UNITS, AND YOU CAN SAVE 15 PERCENT FROM PURCHASING ALL THESE PARTS SEPARATELY BY PICKING UP ONE OF THESE EBC BRAKE KITS FROM YOUR FAVORITE AUTO PARTS RETAILER.

WE GET A BUNCH OF QUESTIONS IN OUR EMAILS FROM YOU VIEWERS ASKING FOR ADVICE ON WHAT TO LOOK FOR WHEN PURCHASING A USED ENGINE. WELL THE OVERALL CONDITION MAY OR MAY NOT TELL THE WHOLE STORY ABOUT WHAT YOU'RE TRYING TO BUY, AND SOME OF USE HAVE EVEN FALLEN FOR THE LOW MILE ENGINE WITH THE AEROSOL OVERHAUL THAT'S BEEN PRETTIED UP FOR THE SALE. WELL HERE'S A QUICK WAY TO AVOID THAT SITUATION. THE MOST STRAIGHT FORWARD OPERATION THAT CAN BE DONE TO AN ENGINE TO DETERMINE ITS CONDITION IS A LEAK DOWN TEST. WHAT IT MEASURES IS THE PERCENTAGE OF PRESSURE ESCAPING THE COMBUSTION AREA OF A GIVEN CYLINDER BEING TESTED.

IT'S A QUICK WAY TO HELP DIAGNOSE A PROBLEM IN AN ENGINE THAT'S NOT PERFORMING UP TO ITS POTENTIAL OR TO SEE

IF A USED BULLET IS A GOOD CANDIDATE TO BUY. TO DO THIS YOU NEED A QUALITY LEAK DOWN TESTER, AND WE USE THIS DUAL GAUGE SETUP FROM MATCO TOOLS, OR YOU CAN RENT ONE OF THESE AT YOUR LOCAL PARTS HOUSE. NOW HERE'S HOW IT WORKS. ON ONE SIDE IT'S HOOKED UP TO AN AIR COMPRESSOR AND THAT PRESSURE IS REGULATED TO 100 PSI, AND THE OTHER SIDE HAS A LINE ON IT THAT SCREWS INTO THE SPARK PLUG HOLE OF THE CYLINDER BEING TESTED. TO HAVE ACCURATE RESULTS THE ENGINE MUST BE ON TDC COMPRESSION STROKE OF THE CYLINDER BEING TESTED.

SO STARTING WITH THE NUMBER ONE CYLINDER, ROLL THE ENGINE OVER IN THE CORRECT ROTATION WITH A TEST HOSE IN THE PLUG HOLE. WHEN AIR FORCES PAST YOUR FINGER COVERING THE HOSE END, THE CYLINDER IS COMING UP ON TDC OF THE COMPRESSION STROKE.

CONTINUE TURNING THE ENGINE UNTIL THE TIMING MARK ON THE BALANCER LINES UP WITH ZERO ON THE TIMING TAB. WITH THE HOSE PLUGGED INTO OUR TESTER, IT PRESSURIZES THE CYLINDER WITH 100 PSI OF AIR. ON THIS GAUGE IT SHOWS THE CYLINDER IS ONLY HOLDING 92 PSI, AND THAT SUBTRACTED FROM 100 IS EIGHT. SO THAT MEANS THE CYLINDER HAS EIGHT PERCENT LEAKAGE. YOU'RE LOOKING FOR A NUMBER BETWEEN FIVE AND 10 PERCENT. ANYTHING MORE THAN THAT INDICATES YOU MIGHT HAVE SOME ISSUES, BUT IT'S RELATIVELY EASY TO FIND THE LEAKAGE. FOR INSTANCE, IF YOU HEAR AIR COMING OUT THE INTAKE MANIFOLD YOUR INTAKE VALVES ARE NOT SEATED PROPERLY. IF YOU HEAR AIR COMING OUT THE EXHAUST MANIFOLDS CHANCES ARE THE EXHAUST VALVES OR VALVE SEATS ARE THE PROBLEM. BUT FOR THE MOST PART AIR WILL BE LEAKING PAST THE PISTON RINGS INTO THE CRANK CASE, AND THAT CAN BE HEARD, FELT, AND SEE THROUGH A VALVE COVER HOLE. HERE'S A QUICK TIP. WHILE YOU HAVE THE ENGINE AT TDC ON NUMBER ONE, GO AHEAD

AND MARK THE PULLEY EVERY 90 DEGREES. JUST USE A STRAIGHT EDGES AND A MARKER.

WHY DO THIS? A 90 DEGREE VEIGHT FIRES EVERY 90 DEGREES OF CRANK SHAFT ROTATION. SO TURNING THE ENGINE A QUARTER TURN, OR 90 DEGREES, PUTS THE NEXT CYLINDER IN THE FIRING ORDER AT TDC ON ITS COMPRESSION STROKE, AND THEN YOU SIMPLY SWITCH YOUR HOSE AND CONTINUE YOUR TEST, AND DO THIS UNTIL ALL THE CYLINDERS ARE CHECKED. NOW THIS IS A BIT TIME CONSUMING AND IT'S A PAIN WHEN IT'S IN THE CAR, BUT IT'S WELL WORTH THE TIME TO ELIMINATE ANY REGRETS.

(MIKE)>> THE NEXT TIME YOU SEE US WORKING ON THE GALAXIE IT'S GOING TO COME TOGETHER PRETTY QUICK. NOW THAT'S ALL THE TIME WE HAVE FOR THIS WEEK. MAKE SURE YOU JOIN US NEXT TIME FOR ANOTHER POWER PACKED EDITION OF ENGINE POWER.