More Fauxtina '71 C10 Episodes

Truck Tech Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Yukon Gear & Axle

Dura Grip Positraction Carrier, Traction-Loc, GM 8.875 in., 30 Spline, 3.08 to 3.90 Ratio, Each

Yukon Gear & Axle

Ring and Pinion Gear Installation Kit, Master Overhaul Kit, 30 Spline, GM 8.875 in., Kit

American Powertrain Systems

Tremec T-56 Complete Manual Transmission Conversion Kit With Hydramax Hydraulic Slave Kit, White Lightning Shifter, And Quicktime Bell Housing

Baer Brake Systems

13" Front Track4 Brake System, 1960-1987 C-10, Front Systems, Vehicles with CPP 2" Drop Spindles 5 Lug

Baer Brake Systems

12" Rear SS4 Brake System with Park Brake, 1960-1987 C-10, Rear Systems, Stock 12 bolt 5 lug

Brothers Truck Parts

Pre-Bent Brake Line Kit, 1971 Shortbed - Rear Coil - Brake Lines - 1/2 Ton - Power Disc - Steel

Brothers Truck Parts

63-72 Gas Tank - Underbed - Aluminum

JBA Performance Exhaust Co.

Headers, GM, LT1, Full Length

JBA Performance Exhaust Co.

Headers, GM, LT1, Shorty

LMC Truck

Bed Floor Assembly

LMC Truck

Front Bed Panel - Steel Floor

LMC Truck

Inner Fender - Primed

LMC Truck

Grille - Radiator Support

LMC Truck

Front Cab Support

LMC Truck

Cab Corner

Pace Performance

Prototype Front Accessory Drive System For GM Lt1 Engine

Pace Performance

LT1 Wet-Sump 6.2L 460HP Crate Engine

PowerTrain Products

One of the nation s leading supplier of remanufactured, rebuilt and used engines, transmissions, differentials, transfer cases & cylinder heads. Providing you with an industry-leading, nationwide parts & labor warranty of up to 4 years

The Industrial Depot

The Industrial Depot - Fasteners, Hardware, and Shop Supplies

Episode Transcript

(ANNOUNCER)>> THE C-10 IS

BACK AND LT AND JEREMY HAVE A LOT ON THEIR SHIFT

LIST, INCLUDING MARRYING UP THEIR CORVETTE ENGINE TO

THIS BULLETPROOF SIX SPEED.

PLUS HOW TO FIT THIS MODERN PACKAGE INTO A 45 YEAR OLD CHASSIS. THAT'S ALL TODAY ON TRUCK TECH.

(JEREMY)>> WE'RE VERY EXCITED TODAY TO BRING YOU A FIRST HERE ON TRUCK TECH. WELL YOU KNOW THE SAYING, WHAT'S OLD IS NEW AGAIN. WELL TODAY WHAT'S OLD IS OUR '71 C-10 THAT WE TORE DOWN A FEW WEEKS AGO.

(LT)>> AND WHAT'S NEW IS THE POWER PLANT THAT'S HIDING UNDERNEATH THIS BLANKET. SOMETHING THAT'S SO CUTTING EDGE IT JUST RECENTLY BECAME AVAILABLE AS A CRATE ENGINE, AND SOMETHING GM PROBABLY NEVER IMAGINED WOULD BE BETWEEN THE FRAME RAILS OF A CLASSIC C-10.

(JEREMY)>> READY?

(LT)>> LET'S DO IT, BOOM!

(JEREMY)>> THIS IS THE LT ONE FROM PACE PERFORMANCE. IT'S THE MOST TECHNICALLY ADVANCED SMALL BLOCK VEIGHT THAT CHEVROLET HAS EVER DESIGNED, AND WHAT'S EQUALLY IMPRESSIVE IS WHERE THIS ENGINE CALLS HOME FROM THE FACTORY.

(LT)>> THE LT ONE IS THE CENTER PIECE OF TWO OF THE HOTTEST SPORT CARS AVAILABLE FROM GENERAL MOTORS TODAY, THE CAMARO SS AND THE CORVETTE STINGRAY. EVERYTHING ABOUT THESE HIGH PERFORMANCE MACHINES

IS AN ENGINEERING MARVEL, FROM THE HIGH TECH ELECTRONICS AND AERODYNAMICS OF THE

STINGRAY TO THE SPEED AND PIN POINT HANDLING OF THE SS. BUT THIS IS A TRUCKS SHOW RIGHT?

(JEREMY)>> ABSOLUTELY, AND FROM WHERE WE STAND THIS IS A LIGHT TRUCK ENGINE. SO WHETHER YOU WANT MORE POWER FOR YOUR LATE MODEL SPORT TRUCK OR YOU'RE JUST REVIVING A CLASSIC LIKE WE

ARE, HERE'S WHAT MAKES THE LT ONE SO ADVANCED.

(LT)>> THE GEN FIVE LT ONE USES A TRIO OF TECHNOLOGIES THAT DELIVERS HIGH PERFORMANCE WITH GREATER FUEL EFFICIENCY. DIRECT INJECTION USES HIGH PRESSURE INJECTORS TO PRECISELY DELIVER FUEL TO EACH CYLINDER FOR EFFICIENT COMBUSTION. THIS REDUCES FUEL CONSUMPTION AND EMISSIONS WHILE INCREASING POWER.

(JEREMY)>> ACTIVE FUEL MANAGEMENT REDUCES FUEL CONSUMPTION BY USING TWO STAGE HYDRAULIC VALVE LIFTERS, TO TEMPORARILY AND SEAMLESSLY DEACTIVATE HALF OF THE CYLINDERS UNDER LIGHT LOAD DRIVING CONDITIONS.

THE SYSTEM REACTIVATES THE CYLINDERS WHEN THE DRIVER NEEDS MORE POWER.

(LT)>> CONTINUOUSLY VARIABLE VALVE TIMING WORKS WITH ACTIVE FUEL MANAGEMENT TO GET AIR IN AND EXHAUST GASES OUT OF THE COMBUSTION CHAMBER. THIS IMPROVES FUEL ECONOMY AND DRIVABILITY WHILE REDUCING EMISSIONS.

(JEREMY)>> WHAT DOES THIS TRANSLATE TO? 460 HORSEPOWER OUT OF SIX POINT TWO LITERS, AND IN THE NEW CORVETTE STINGRAY ZERO TO 60 IN THREE POINT SEVEN SECONDS WITH A TOP SPEED OF 186 MILES PER HOUR.

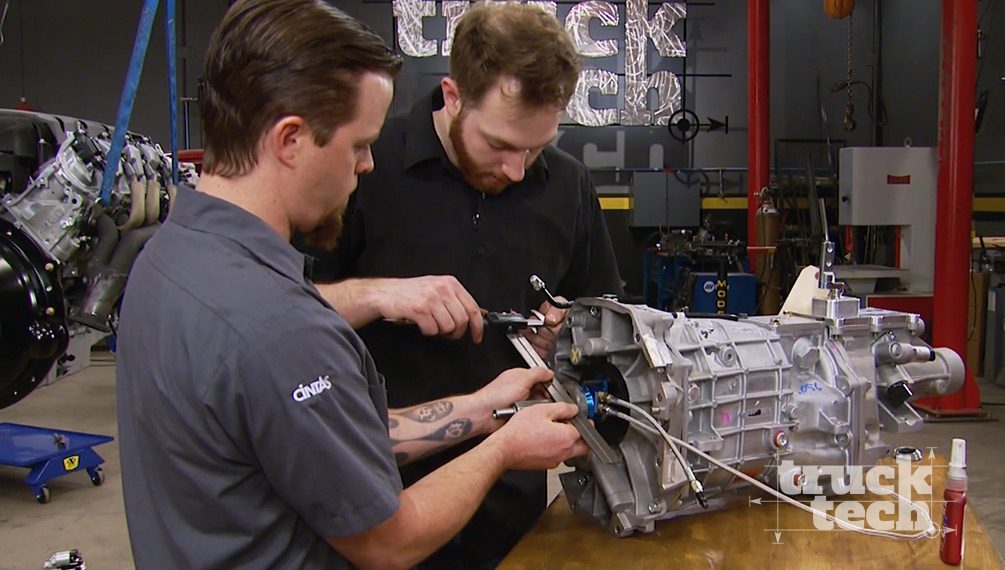

(LT)>> WE'RE GONNA GO AHEAD AND MATE UP OUR LT ONE TO THIS STATE OF THE ART T-56 SIX SPEED MANUAL TRANSMISSION WE PICKED UP FROM AMERICAN POWERTRAIN, BUT BEFORE WE DO THAT THERE'S A FEW PLUMBING

ISSUES WE HAVE TO FINISH UP BACK AT THE CHASSIS INVOLVING THE FUEL SYSTEM AND SOME BRAKE LINES.

(JEREMY)>> WE PICKED UP THIS NEW FUEL TANK FROM BROTHERS TRUCK PARTS TO REPLACE THE ORIGINAL IN CAB TANK CAUSE LET'S FACE IT, THAT'S NOT THE SAFEST PLACE FOR 20 GALLONS OF GASOLINE. INSTALLATION IS PRETTY SIMPLE. WE'LL USE ONE EXISTING HOLE ALREADY IN THE FRAME. SO THE FIRST STEP IS TO LINE OUR MOUNTING BRACKET UP WITH THAT HOLE. AND SINCE IT'S EASIER TO GET A DRILL ON THE UNDERSIDE OF THE FRAME, I'LL LINE THE BRACKET UP ON THE BOTTOM AND THEN MARK AND DRILL TWO ADDITIONAL HOLES IN EACH FRAME RAIL. WITH THE FRAME RAILS COMPLETE, WE CAN TEMPORARILY SLIDE THE TANK UP INTO PLACE.

(LT)>> LOOKS GOOD.

(JEREMY)>> NOW LOOKING DOWN AT OUR TANK IT ACTUALLY LOOKS A LITTLE CROOKED IN THE FRAME BUT WHAT'S GOING ON HERE IS THIS CROSSMEMBER IS RUNNING AT AN ANGLE, IT'S NOT STRAIGHT. SO WE MEASURED OFF THE REAR CROSSMEMBER AND THE

FRAME RAILS BECAUSE WE KNOW THEY'RE STRAIGHT. THAT WAY WE KNOW OUR TANK IS GOOD AND CENTERED. WITH THE TANK HELD DOWN, I CAN GO BACK AND MARK ALL THE HOLES, AND THEN DRILL THE SIX HOLES AWAY FROM THE C-10 FRAME. DOING IT THIS WAY ENSURES PERFECT ALIGNMENT

WITHOUT GUESSING. NOW WE CAN MOUNT THE TANK IN BETWEEN THE FRAME RAILS FOR GOOD.

(LT)>> BROTHERS TRUCK PARTS SUPPLIED PREBENT AND PREFLARED LINES FOR THE PROJECT, AND IT'S A GOOD IDEA TO INSTALL THEM NOW BECAUSE SOME OF THEM RUN UNDERNEATH OUR SOON TO BE MOUNTED DRIVETRAIN.

(ANNOUNCER)>> COMING UP, THE LT ONE AND T-56 SAY I DO.

(LT)>> THERE ARE MANY DIFFERENT WAYS TO GET THE POWER FROM THE BACK OF YOUR ENGINE TO THE GROUND, AND WE KNEW EARLY ON WE WANTED A MANUAL TRANSMISSION IN OUR CLASSIC C-10 FOR THAT CLASSIC MUSCLE CAR FEEL. I MEAN YOU GUYS KNOW WHAT I'M TALKING ABOUT. BUT BECAUSE WE'RE CONVERTING FROM AN AUTOMATIC TRANSMISSION, WE JUST DIDN'T HAVE ANY OF THE PARTS THAT WE WOULD NEED TO GET STARTED.

(JEREMY)>> AMERICAN POWERTRAIN SPECIALIZES IN PRO FIT INSTALLATION KITS FOR FIVE AND SIX SPEED MANUAL TRANSMISSIONS, AND IT BEGINS WITH THE INDUSTRY STANDARD. TREMEC FIVE AND SIX SPEED GEAR BOXES ARE MANUFACTURED IN NORTH AMERICA, AND ARE KNOWN AS ONE OF THE SMOOTHEST SHIFTING, LONGEST LASTING POWERTRAINS MONEY CAN BUY.

AMERICAN POWERTRAIN IS THE WORLD'S LARGEST DISTRIBUTOR OF THESE BAD BOYS.

(LT)>> ONCE THEY ARRIVE IN THE COOKEVILLE, TENNESSEE, FACILITY, TECHNICIANS WORK WITH CUSTOMERS TO PUT TOGETHER A PACKAGE THAT WILL HELP GET THEIR TRANS INSTALLED IN THEIR PROJECT IN A WEEKEND.

NO GUESS WORK REQUIRED.

(JEREMY)>> WE PROVIDED THE INFORMATION ON OUR '71 C-10 AND THEY CAME UP WITH AN INSTALLATION PACKAGE, WHICH INCLUDES THIS T-56 TREMEC TRANSMISSION, A WHITE LIGHTNING ADJUSTABLE SHIFTER, A HYDRAMAX CLUTCH ACTUATOR KIT, ALONG WITH A NEW CLUTCH AND A QUICK

TIME BELL HOUSING.

(LT)>> TO PREVENT YOU FROM RUNNING BACK TO THE STORE CHASING PARTS AMERICAN POWERTRAIN INCLUDED ALL THE LITTLE THINGS YOU NEED TO COMPLETE SWAP, LIKE THIS ADJUSTABLE CROSS MEMBER, A SHIFT HANDLE FOR A BENCH SEAT, SOME SPACERS FOR THE THROW OUT BEARING,

ALL THE HARDWARE, AND A TRANSMISSION MOUNT.

(JEREMY)>> WITH THE FLYWHEEL TORQUED DOWN, WE NEED TO INSTALL THE CLUTCH DISC.

(LT)>> I'VE GOT TO GET ALL THE OILS OFF THE FLYWHEEL SO THE CLUTCH DOESN'T SLIP ON IT.

(JEREMY)>> USE THE ALIGNMENT TOOL TO HOLD THE CLUTCH IN PLACE WHILE THE PRESSURE PLATE IS BOLTED ON.

(LT)>> NOW THEY GIVE YOU THESE TOOLS HERE TO CENTER THE CLUTCH DISC ON THE FLYWHEEL, BUT THEY NEVER

GET IT EXACTLY CENTERED. SO WHILE YOU TIGHTEN IT UP I ALWAYS LIKE TO KINDA WIGGLE IT BACK AND FORTH AND UP AND DOWN JUST TO MAKE SURE IT'S AS CENTERED AS WE CAN GET IT. SO WHEN YOU INSTALL THE TRANSMISSION THE INPUT SHAFT SLIDES RIGHT INTO THE BEARING.

(JEREMY)>> INSTALL THE BELL HOUSING AND TORQUE TO SPEC. BEFORE WE GO ANY FURTHER WE NEED TO SET THE SPACING ON THE CLUTCH RELEASE BEARING.

(LT)>> SO WE'VE GOT TO HAVE BETWEEN 150 AND 200 THOUSANDTHS OF FREE TRAVEL BETWEEN THE FINGERS OF THE PRESSURE PLATE AND THE THROW OUT BEARING. LET'S SEE WHAT WE'VE GOT HERE. IT'S ABOUT TWOZEROSIXSIX, OKAY. LET'S SEE WHAT WE HAVE ON THIS SIDE.

(JEREMY)>> IF THE SPACING IS WRONG, THE CLUTCH WON'T ENTIRELY DISENGAGED, MAKING SHIFTING DIFFICULT, OR WOULDN'T ENTIRELY GRAB AND WILL SLIP. WE HAD TOO MUCH CLEARANCE. SO WE ADDED A SHIM TO ADJUST AND BRING IT INTO RANGE.

(LT)>> WITH THE CLUTCH RELEASE BEARING IN SPEC, WE CAN BEGIN LINING UP THE ENGINE TO THE TRANSMISSION, SLIDING THE INPUT SHAFT INTO THE CLUTCH.

(JEREMY)>> THE DOWEL PIN'S JUST NOT SLIDING IN THE HOLE. IT'S RIGHT THERE, IT'S JUST NOT.

(LT)>> THIS IS OBVIOUSLY AN IMPORTANT STEP, SO TAKE YOUR TIME.

ONCE THE TRANSMISSION MOUNT IS IN PLACE, WE CAN NOW LOWER THE WHOLE THING INTO THE FRAME.

WELL JEREMY IS IT GONNA FIT, WHAT DO YOU SAY?

(JEREMY)>> I THINK WE MAY GET LUCKY HERE LT.

(LT)>> WE'VE DONE OUR HOMEWORK, SO I HOPE IT DOES.

(JEREMY)>> EXCITING MOMENT I KNOW THAT. HOW ARE YOU LOOKING?

(LT)>> GOOD, SLIDE THAT CROSSEMEMBER ON. GOOD?

(JEREMY)>> OKAY, EASE IT ON DOWN. LOOKING GOOD BACK HERE.

(LT)>> BECAUSE THIS LT ONE ENGINE IS SO NEW, THERE REALLY ISN'T MUCH INFORMATION OUT THERE ABOUT SWAPPING IT INTO AN OLDER CHASSIS, BUT WITH A LITTLE BIT OF HOMEWORK THIS TURNED OUT TO BE A COMPLETELY BOLT IN SITUATION, NO CUTTING REQUIRED. FOR STARTERS ARE THE MOTOR MOUNTS. WE FOUND THESE ON AN ONLINE AUCTION OF ALL PLACES AND THEY'RE MADE OUT OF BILLET ALUMINUM, AND THEY ALLOW US TO BOLT UP OUR FACTORY 1971 350 RUBBER ISOLATORS.

(JEREMY)>> PACE PERFORMANCE HOOKED US UP WITH THIS PROTOTYPE SERPENTINE ACCESSORY DRIVE FROM STREET SHOP, WHICH INCLUDES THIS LS STYLE WATER PUMP AND A ONE WIRE ALTERNATOR, BUT WHAT'S REALLY COOL IS THEY WERE ABLE TO PROVIDE US WITH A POWER STEERING PUMP, WHICH THE LT ENGINE DID NOT COME EQUIPPED WITH FROM THE FACTORY. SO NOT ONLY WILL WE HAVE POWER STEERING, BUT WE'LL NOW BE ABLE TO RUN HYDRO BOOST BRAKES. NOW FOR HEADERS WE WENT TO JBA AND THEY SENT US TWO SETS TO CHOOSE FROM. A SET OF SHORTIES, WHICH WE ALREADY HAVE BOLTED ONTO THE ENGINE, AND A SET OF LONG TUBES, WHICH WE THINK WILL WORK A LITTLE BETTER FOR US IN THIS CHASSIS.

(LT)>> WE'RE GOING TO GET THE CAB BACK ON THE LIFT SO WE CAN MARRY THE TWO AND CHECK CLEARANCE FOR

THE TRANSMISSION AND SHIFTER LOCATION, AND AFTER A FEW MEASUREMENTS WE LEARNED WE'RE GONNA NEED TO DO A FEW ADDITIONAL MODIFICATIONS TO THE FLOOR. YOU CAN SEE WHERE I'VE MARKED THE FLOOR FOR THE SHIFTER OF THE T-56 TO PASS THROUGH, BUT UNFORTUNATELY WE'RE GONNA HAVE TO DO A LITTLE BIT MORE THAN JUST CUT A SMALL HOLE, AND THE REASON IS THE T-56 TRANSMISSION, WHILE IT'S NOT OVERLY LARGE, IT CARRIES A LOT OF MATERIAL ABOVE THE CENTER LINE. SO WE ARE GONNA HAVE TO DO SOME CUTTING TO GET IT TO

FIT UNDERNEATH OUR C-10.

(JEREMY)>> YEAH WE COULD GO AHEAD AND CUT THE FLOOR OUT, GO OUT TO THE METAL ROLLER OR THE ENGLISH WHEEL, AND FAB UP SOMETHING REALLY COOL, BUT AS YOU GUYS KNOW, THAT TAKES A LOT OF TIME. THE COOL THING ABOUT THIS ERA OF TRUCK, THE FOUR WHEEL DRIVES AND ONE TONS ACTUALLY COME WITH A BOLT IN TRANSMISSION TUNNEL THAT'S MUCH TALLER. YOU CAN SEE WHERE IT GOES. THAT'LL PROBABLY GIVE US ALL THE CLEARANCE WE NEED. SO IF WE CAN SOURCE ONE SOMEWHERE I THINK THAT'S THE ROUTE WE'RE GONNA TAKE.

(ANNOUNCER)>> NEXT A LITTLE TUNNEL VISION.

(JEREMY)>> AS YOU CAN SEE, WE'VE ALREADY CUT OUT OUR FLOOR TO MAKE ROOM FOR THIS TALLER TRANSMISSION TUNNEL THAT OUR BUDDY TOMMY BOSHERS SOURCED FOR US, BUT BEFORE WE WELD THIS THING IN THERE WE'VE GOT

A COUPLE OF ISSUES WE NEED TO ADDRESS. RUST LIKE THIS IS TYPICAL ON A TRUCK THAT SITS

OUTSIDE FOR YEARS AT A TIME. BASICALLY WHAT HAPPENS IS OXYGEN AND MOISTURE IN THE ATMOSPHERE ATTACK THE METAL, WHICH FIRST TURNS THE STEEL TO THIS KIND OF RED MUDDY COLOR, AND AFTER TIME DETERIORATION STARTS, WHICH IS LIKE WHAT WE HAVE HERE. NOW RUST IS A FORM OF OXIDATION AND THERE ARE MANY MATERIALS SUSCEPTIBLE TO THAT, LIKE ALUMINUM AND

PLASTIC FOR EXAMPLE BOTH CAN OXIDIZE. NOW WITH RUST LIKE THIS, DON'T LET IT SCARE YOU AWAY FROM STARTING OR PURCHASING A PROJECT. RUST IS EASILY REPAIRABLE, AND WITH THE AUTOMOTIVE AFTERMARKET THEY'VE MADE IT PRETTY EASY FOR US. REPLACEMENT SHEET METAL IS PLENTIFUL WHEN IT COMES TO

TRUCKS, ESPECIALLY POPULAR ONES LIKE OUR '71 C-10, AND LMC TRUCK HAS MOST EVERY PART AVAILABLE FOR OUR CHEVY, INCLUDING A BED FLOOR, BED HEADER PANEL, RADIATOR SUPPORT, FENDER WELLS, CAB CORNERS, BATTERY TRAY, WELL YOU NAME IT THEY'VE GOT JUST ABOUT EVERYTHING. NOW ALL THEIR PARTS ARE STAMPED TO OE SPECS AND ARE ECOATED FOR PROTECTION. NOW FOR OUR C-10 WE HAD THEM SEND US A CAB SUPPORT BECAUSE WELL, AS YOU JUST SAW, OURS WAS GONE.

THIS IS WHAT YOU CAN GET INTO WHEN DOING RUST REPAIR. GET BEHIND THE PANEL AND SOMETIMES THE RUST JUST KEEPS ON GOING, AND THE FLOOR'S PRETTY ROTTEN TOO. MAN THAT THING'S ROTTED OUT. ALSO SOMEONE'S BEEN UNDER HERE AND THEY'VE DONE A LITTLE PATCH WORK. NOW SOME PEOPLE DON'T HAVE THE MONEY TO PAY A PROFESSIONAL OR HAVE THE KNOWLEDGE TO DO A PROPER REPAIR.

NOW THIS I WOULD NOT CONSIDER A LIFETIME REPAIR BECAUSE IT LOOKS LIKE THEY JUST LAID THE METAL RIGHT OVER THE TOP OF THE RUST. AND PLUS YOU CAN SEE RIGHT HERE WHERE THEY BURNED IN A WELD AND WELL, THAT'S NOT VERY SAFE WHEN YOUR WELDS JUST POP OFF LIKE THAT. SO WE'LL GO AHEAD AND CALL LMC, GET THEM TO SEND US AN INNER ROCKER AND THE FRONT SECTION OF A FLOOR PAN. THAT'LL PROBABLY TAKE A COUPLE OF DAYS TO GET HERE. SO WHILE WE WAIT ON THAT WE'LL GO AHEAD AND START WORKING ON OUR TRANSMISSION TUNNEL,

SEE IF WE CAN GET IT IN THE CAB. '67 THROUGH '72 THREE QUARTER, ONE TON, AND FOUR WHEEL DRIVE TRUCKS CAME WITH A RAISED TUNNEL SECTION THAT PROVIDED PLENTY OF ROOM FOR THE DRIVETRAIN. WE SOURCED THIS ONE FROM A JUNKYARD AND IT WILL BOLT IN NICELY. WITH IT SAND BLASTED, THE FIRST STEP IS TO CLOSE THIS PREVIOUSLY CUT HOLE. [ SAW CUTTING ]

(JEREMY)>> I'LL TEST FIT THE NEW PIECE, AND THEN USING THE EDGE OF MY TABLE, MAKE A SMALL BEND TO MATCH THE TUNNEL. THE NEXT STEP IS TO BURN IT IN. [ WELDER CRACKLING ]

(JEREMY)>> I WANT TO LEAVE A ONE INCH LIP FOR THE TUNNEL, SO I'LL PULL A COUPLE OF MEASUREMENTS AND MAKE A FEW CLEAN CUTS. THAT LOOKS GOOD! OKAY, IF WE WERE BUILDING A SHOW TRUCK, WE WOULD GO AHEAD AND BUTT WELD THIS THING IN. THAT WAY YOU WOULDN'T KNOW WE PUT A TRANSMISSION TUNNEL IN IT UP TOP OR UNDERNEATH, BUT SINCE WE WANT EVERYTHING TO BE AS ACCESSIBLE AS POSSIBLE BECAUSE WE PLAN ON DRIVING THIS TRUCK A LOT, WE'RE GONNA GO AHEAD AND BOLT THE TUNNEL IN.

PLUS THIS IS HOW THEY DID IT AT THE FACTORY. SO IF IT WORKED FOR THEM IT'LL WORK GOOD FOR US. ONCE I'VE GOT ALL THE HOLES DRILLED, I'M USING CLIP NUTS AND BODY BOLTS TO SECURE THE TUNNEL. NOW WE CAN MAKE OUR CUT FOR THE NEW SHIFTER TO FIT THROUGH, AND WE'VE MADE A VERY EASY TRANSMISSION TUNNEL UPGRADE, PERFECT!

(ANNOUNCER)>> NEXT, THIS DIFFERENTIAL UPGRADE IS POSITIVELY COOL!

(LT)>> THE LAST PLACE YOUR HORSEPOWER GOES BEFORE IT REACHES THE GROUND IS THE REAR DIFFERENTIAL, AND WE'RE PRETTY SURE THIS STOCK 12 BOLT HAS AN OPEN

CARRIER IN IT, AND THAT JUST ISN'T GONNA CUT IT WITH OUR 460 HORSEPOWER LT ONE. WE JUST CAN'T HAVE ANY OF THAT ONE TIRE FIRE.

SO WE'RE GONNA SHOW YOU HOW TO REPLACE THE OPEN CARRIER WITH A POSI SO YOU GET THE SAME AMOUNT OF TRACTION TO EACH WHEEL AND GET MAXIMUM ACCELERATION. YEP, JUST AS WE SUSPECTED, OPEN CARRIER. WITH THE FLUID DRAINED FROM THE DIFFERENTIAL, THE TEARDOWN BEGINS BY REMOVING THE CENTER PIN FROM THE CARRIER. THE BRAKE DRUMS NEED A LITTLE CONVINCING TO COME OFF. THEN WE CAN PUSH THE AXLES IN TO ACCESS THE CCLIPS AND REMOVE THEM. BEFORE WE GO ANY FARTHER, WE NEED TO MEASURE THE RING GEAR BACKLASH SO WE CAN DUPLICATE IT WITH THE NEW CARRIER. I'LL MARK THE BEARING CAPS TO MAKE SURE THEY GO BACK IN WHERE THEY CAME FROM. [ DRILL SPINNING ]

(LT)>> TO MAKE SURE WE GET BOTH WHEELS SPINNING WHEN WE'RE ON THE GAS OF OUR C-10 WE WENT AHEAD AND PICKED UP A YUKON DURAGRIP CLUTCH STYLE POSITRACTION. IT'S A FOUR SPRING DESIGN THAT USES RAYBESTOS CLUTCH

DISCS FOR AGGRESSIVE OPERATION THAT'LL STILL DRIVE SMOOTHLY WHEN WE'RE ON THE STREET. I PICKED UP A SHIM KIT SO WE CAN GET THE BACKLASH WHERE IT NEEDS TO BE, AND I ALREADY WENT AHEAD AND PRESSED ON THE CARRIER BEARING. SO THE NEXT STEP FOR US IS TO SWAP OVER THE RING GEAR. WE'RE KEEPING THE 3.73 GEARS IN THIS TRUCK. THEY'RE A GOOD RATIO FOR QUICK ACCELERATION AND LOW RPM WHEN CRUISING DOWN THE HIGHWAY. I ALWAYS USE LOCTITE 243 TO MAKE SURE THE BOLTS DON'T BACK OUT, AND ONCE THE RING GEAR IS MATED WE CAN INSTALL THE CARRIER. [ DRILL SPINNING ]

(LT)>> THE BACKLASH MEASURES A LITTLE LOOSE, SO MOVING SOME SHIMS WILL GET THE CARRIER CLOSER TO THE PINION GEAR. WE'RE SHOOTING FOR SIX THOUSANDTHS BACKLASH BECAUSE THAT'S WHAT WE HAD BEFORE.

BEFORE WE SLIDE THOSE AXLE SHAFTS INTO PLACE, WE'RE GONNA TAKE CARE OF THE STOPPING POWER WITH A LITTLE BIT OF HELP FROM BAER BRAKES, AND ON THE

FRONT WE'RE USING THEIR TRACK FOUR SYSTEM, WHICH COMES WITH THESE 13 INCH DRILLED AND SLOTTED ROTORS AND THESE BEEFY FOUR PISTON CALIPERS. WE GOT THEM POWDER COATED SILVER BUT YOU CAN CHOOSE ALMOST ANY COLOR UNDER THE SUN. THEY COME WITH THE BRACKETS TO MOUNT UP TO OUR CPP TWO INCH DROP SPINDLES AND UTILIZE A BANJO STYLE FITTING UNLIKE A LOT OF OTHER AFTERMARKET CALIPERS, WHICH USE PIPE THREAD. WHEN YOU SET THEM DOWN WITH OUR STOCK SINGLE PISTON CALIPERS YOU CAN DEFINITELY TELL THE DIFFERENCE. THE KIT ALSO COMES WITH A NEW WHEEL HUB THAT COMES PREASSEMBLED WITH SEALS, BEARINGS, AND EVEN NEW STUDS. FOR THE REAR WE'RE USING THE SS FOUR KIT, WHICH HAS 12 INCH DRILLED AND SLOTTED ROTORS, SLIGHTLY

SMALLER FOUR PISTON CALIPERS, AND A FACTORY STYLE PARKING BRAKE, AND WE'RE GONNA GET STARTED BY TEARING OFF THE OLD BACKING PLATES. THE NEW PARKING BRAKE BOLTS UP USING THE FACTORY HOLES. WITH THE CENTER PIN REMOVED, THE AXLES CAN SLIDE INTO PLACE WITH CCLIPS JUST LIKE BEFORE. REINSTALL THE CENTER PIN, AND INSTALL THE COVER WITH RTV SILICONE. FOR THE NEW BAER BRAKES THE ROTOR SLIDES ON, FOLLOWED BY THE CALIPER. FOR THE FRONT A COTTER PIN AND NUT HOLD ON THE OLD HUB. WITH THE SPINDLE CLEANED UP, THE NEW PARTS FALL INTO PLACE.

(JEREMY)>> KNOWING WHAT'S GOING ON INSIDE YOUR LATE MODEL CAR OR TRUCK IS KEY TO DIAGNOSING PROBLEMS. HP TUNERS' VCM SCANNER LET'S YOU RECORD AND PLAY BACK REAL TIME DATA FROM ALL FACTORY SENSORS AND

AFTER MARKET SENSORS YOU ADD YOURSELF. YOU CAN MONITOR ENGINE AND TRANSMISSION FUNCTIONS, CLEAR DIAGNOSTIC TROUBLE CODES, AND IT INTEGRATES SEAMLESSLY WITH THEIR EDITOR FOR TUNING PURPOSES. THIS VCM SCANNER IS AVAILABLE FOR 349 AT HP TUNERS DOT COM.

(LT)>> LET'S FACE IT, ANY TIME YOU PURCHASE A USED OR REMANUFACTURED ENGINE OR TRANSMISSION, THERE'S ALWAYS TREPIDATION. WILL IT EVEN RUN RIGHT, AND WHAT HAPPENS IF IT BLOWS UP PAST 30 DAYS?

WELL POWERTRAIN PRODUCTS OFFERS A NO FAULT WARRANTY THAT'LL RELIEVE SOME OF THAT STRESS. FOR $349 DOLLARS YOU GET ADDED COVERAGE AGAINST DETONATION, OVERHEATING, EVEN RUNNING LOW ON OIL FOR AN ADDITIONAL THREE TO FIVE YEARS. PLUS IT COVERS EXPENSES LIKE CAR RENTAL, TOWING, AND EVEN DIAGNOSTICS. POWERTRAIN PRODUCTS ARE AVAILABLE AT SHOP ENGINES DOT COM. WELL WE'VE MADE SOME GREAT PROGRESS ON OUR '71 C-10 TODAY. WE'VE GOT THE CHASSIS PLUMBED OUT, THE ENGINE AND TRANS ARE BACK IN THE FRAME, AND WE GOT A REAL NICE SET OF BRAKES AND A POSI.

(JEREMY)>> YEAH WE'VE GOT SOME SHEET METAL PARTS ON THE WAY. SO THE NEXT TIME YOU GUYS SEE THIS TRUCK WE'RE GONNA FINISH UP THAT RUST REPAIR, PERMANENTLY MOUNT THE CAB, AND MAYBE EVEN SHOW YOU A NEW SET OF WHEELS AND TIRES.

(LT)>> ALRIGHT, WELL LET'S GET THIS THING

OUT OF HERE THEN.

(JEREMY)>> LET'S DO IT.

Show Full Transcript

PLUS HOW TO FIT THIS MODERN PACKAGE INTO A 45 YEAR OLD CHASSIS. THAT'S ALL TODAY ON TRUCK TECH.

(JEREMY)>> WE'RE VERY EXCITED TODAY TO BRING YOU A FIRST HERE ON TRUCK TECH. WELL YOU KNOW THE SAYING, WHAT'S OLD IS NEW AGAIN. WELL TODAY WHAT'S OLD IS OUR '71 C-10 THAT WE TORE DOWN A FEW WEEKS AGO.

(LT)>> AND WHAT'S NEW IS THE POWER PLANT THAT'S HIDING UNDERNEATH THIS BLANKET. SOMETHING THAT'S SO CUTTING EDGE IT JUST RECENTLY BECAME AVAILABLE AS A CRATE ENGINE, AND SOMETHING GM PROBABLY NEVER IMAGINED WOULD BE BETWEEN THE FRAME RAILS OF A CLASSIC C-10.

(JEREMY)>> READY?

(LT)>> LET'S DO IT, BOOM!

(JEREMY)>> THIS IS THE LT ONE FROM PACE PERFORMANCE. IT'S THE MOST TECHNICALLY ADVANCED SMALL BLOCK VEIGHT THAT CHEVROLET HAS EVER DESIGNED, AND WHAT'S EQUALLY IMPRESSIVE IS WHERE THIS ENGINE CALLS HOME FROM THE FACTORY.

(LT)>> THE LT ONE IS THE CENTER PIECE OF TWO OF THE HOTTEST SPORT CARS AVAILABLE FROM GENERAL MOTORS TODAY, THE CAMARO SS AND THE CORVETTE STINGRAY. EVERYTHING ABOUT THESE HIGH PERFORMANCE MACHINES

IS AN ENGINEERING MARVEL, FROM THE HIGH TECH ELECTRONICS AND AERODYNAMICS OF THE

STINGRAY TO THE SPEED AND PIN POINT HANDLING OF THE SS. BUT THIS IS A TRUCKS SHOW RIGHT?

(JEREMY)>> ABSOLUTELY, AND FROM WHERE WE STAND THIS IS A LIGHT TRUCK ENGINE. SO WHETHER YOU WANT MORE POWER FOR YOUR LATE MODEL SPORT TRUCK OR YOU'RE JUST REVIVING A CLASSIC LIKE WE

ARE, HERE'S WHAT MAKES THE LT ONE SO ADVANCED.

(LT)>> THE GEN FIVE LT ONE USES A TRIO OF TECHNOLOGIES THAT DELIVERS HIGH PERFORMANCE WITH GREATER FUEL EFFICIENCY. DIRECT INJECTION USES HIGH PRESSURE INJECTORS TO PRECISELY DELIVER FUEL TO EACH CYLINDER FOR EFFICIENT COMBUSTION. THIS REDUCES FUEL CONSUMPTION AND EMISSIONS WHILE INCREASING POWER.

(JEREMY)>> ACTIVE FUEL MANAGEMENT REDUCES FUEL CONSUMPTION BY USING TWO STAGE HYDRAULIC VALVE LIFTERS, TO TEMPORARILY AND SEAMLESSLY DEACTIVATE HALF OF THE CYLINDERS UNDER LIGHT LOAD DRIVING CONDITIONS.

THE SYSTEM REACTIVATES THE CYLINDERS WHEN THE DRIVER NEEDS MORE POWER.

(LT)>> CONTINUOUSLY VARIABLE VALVE TIMING WORKS WITH ACTIVE FUEL MANAGEMENT TO GET AIR IN AND EXHAUST GASES OUT OF THE COMBUSTION CHAMBER. THIS IMPROVES FUEL ECONOMY AND DRIVABILITY WHILE REDUCING EMISSIONS.

(JEREMY)>> WHAT DOES THIS TRANSLATE TO? 460 HORSEPOWER OUT OF SIX POINT TWO LITERS, AND IN THE NEW CORVETTE STINGRAY ZERO TO 60 IN THREE POINT SEVEN SECONDS WITH A TOP SPEED OF 186 MILES PER HOUR.

(LT)>> WE'RE GONNA GO AHEAD AND MATE UP OUR LT ONE TO THIS STATE OF THE ART T-56 SIX SPEED MANUAL TRANSMISSION WE PICKED UP FROM AMERICAN POWERTRAIN, BUT BEFORE WE DO THAT THERE'S A FEW PLUMBING

ISSUES WE HAVE TO FINISH UP BACK AT THE CHASSIS INVOLVING THE FUEL SYSTEM AND SOME BRAKE LINES.

(JEREMY)>> WE PICKED UP THIS NEW FUEL TANK FROM BROTHERS TRUCK PARTS TO REPLACE THE ORIGINAL IN CAB TANK CAUSE LET'S FACE IT, THAT'S NOT THE SAFEST PLACE FOR 20 GALLONS OF GASOLINE. INSTALLATION IS PRETTY SIMPLE. WE'LL USE ONE EXISTING HOLE ALREADY IN THE FRAME. SO THE FIRST STEP IS TO LINE OUR MOUNTING BRACKET UP WITH THAT HOLE. AND SINCE IT'S EASIER TO GET A DRILL ON THE UNDERSIDE OF THE FRAME, I'LL LINE THE BRACKET UP ON THE BOTTOM AND THEN MARK AND DRILL TWO ADDITIONAL HOLES IN EACH FRAME RAIL. WITH THE FRAME RAILS COMPLETE, WE CAN TEMPORARILY SLIDE THE TANK UP INTO PLACE.

(LT)>> LOOKS GOOD.

(JEREMY)>> NOW LOOKING DOWN AT OUR TANK IT ACTUALLY LOOKS A LITTLE CROOKED IN THE FRAME BUT WHAT'S GOING ON HERE IS THIS CROSSMEMBER IS RUNNING AT AN ANGLE, IT'S NOT STRAIGHT. SO WE MEASURED OFF THE REAR CROSSMEMBER AND THE

FRAME RAILS BECAUSE WE KNOW THEY'RE STRAIGHT. THAT WAY WE KNOW OUR TANK IS GOOD AND CENTERED. WITH THE TANK HELD DOWN, I CAN GO BACK AND MARK ALL THE HOLES, AND THEN DRILL THE SIX HOLES AWAY FROM THE C-10 FRAME. DOING IT THIS WAY ENSURES PERFECT ALIGNMENT

WITHOUT GUESSING. NOW WE CAN MOUNT THE TANK IN BETWEEN THE FRAME RAILS FOR GOOD.

(LT)>> BROTHERS TRUCK PARTS SUPPLIED PREBENT AND PREFLARED LINES FOR THE PROJECT, AND IT'S A GOOD IDEA TO INSTALL THEM NOW BECAUSE SOME OF THEM RUN UNDERNEATH OUR SOON TO BE MOUNTED DRIVETRAIN.

(ANNOUNCER)>> COMING UP, THE LT ONE AND T-56 SAY I DO.

(LT)>> THERE ARE MANY DIFFERENT WAYS TO GET THE POWER FROM THE BACK OF YOUR ENGINE TO THE GROUND, AND WE KNEW EARLY ON WE WANTED A MANUAL TRANSMISSION IN OUR CLASSIC C-10 FOR THAT CLASSIC MUSCLE CAR FEEL. I MEAN YOU GUYS KNOW WHAT I'M TALKING ABOUT. BUT BECAUSE WE'RE CONVERTING FROM AN AUTOMATIC TRANSMISSION, WE JUST DIDN'T HAVE ANY OF THE PARTS THAT WE WOULD NEED TO GET STARTED.

(JEREMY)>> AMERICAN POWERTRAIN SPECIALIZES IN PRO FIT INSTALLATION KITS FOR FIVE AND SIX SPEED MANUAL TRANSMISSIONS, AND IT BEGINS WITH THE INDUSTRY STANDARD. TREMEC FIVE AND SIX SPEED GEAR BOXES ARE MANUFACTURED IN NORTH AMERICA, AND ARE KNOWN AS ONE OF THE SMOOTHEST SHIFTING, LONGEST LASTING POWERTRAINS MONEY CAN BUY.

AMERICAN POWERTRAIN IS THE WORLD'S LARGEST DISTRIBUTOR OF THESE BAD BOYS.

(LT)>> ONCE THEY ARRIVE IN THE COOKEVILLE, TENNESSEE, FACILITY, TECHNICIANS WORK WITH CUSTOMERS TO PUT TOGETHER A PACKAGE THAT WILL HELP GET THEIR TRANS INSTALLED IN THEIR PROJECT IN A WEEKEND.

NO GUESS WORK REQUIRED.

(JEREMY)>> WE PROVIDED THE INFORMATION ON OUR '71 C-10 AND THEY CAME UP WITH AN INSTALLATION PACKAGE, WHICH INCLUDES THIS T-56 TREMEC TRANSMISSION, A WHITE LIGHTNING ADJUSTABLE SHIFTER, A HYDRAMAX CLUTCH ACTUATOR KIT, ALONG WITH A NEW CLUTCH AND A QUICK

TIME BELL HOUSING.

(LT)>> TO PREVENT YOU FROM RUNNING BACK TO THE STORE CHASING PARTS AMERICAN POWERTRAIN INCLUDED ALL THE LITTLE THINGS YOU NEED TO COMPLETE SWAP, LIKE THIS ADJUSTABLE CROSS MEMBER, A SHIFT HANDLE FOR A BENCH SEAT, SOME SPACERS FOR THE THROW OUT BEARING,

ALL THE HARDWARE, AND A TRANSMISSION MOUNT.

(JEREMY)>> WITH THE FLYWHEEL TORQUED DOWN, WE NEED TO INSTALL THE CLUTCH DISC.

(LT)>> I'VE GOT TO GET ALL THE OILS OFF THE FLYWHEEL SO THE CLUTCH DOESN'T SLIP ON IT.

(JEREMY)>> USE THE ALIGNMENT TOOL TO HOLD THE CLUTCH IN PLACE WHILE THE PRESSURE PLATE IS BOLTED ON.

(LT)>> NOW THEY GIVE YOU THESE TOOLS HERE TO CENTER THE CLUTCH DISC ON THE FLYWHEEL, BUT THEY NEVER

GET IT EXACTLY CENTERED. SO WHILE YOU TIGHTEN IT UP I ALWAYS LIKE TO KINDA WIGGLE IT BACK AND FORTH AND UP AND DOWN JUST TO MAKE SURE IT'S AS CENTERED AS WE CAN GET IT. SO WHEN YOU INSTALL THE TRANSMISSION THE INPUT SHAFT SLIDES RIGHT INTO THE BEARING.

(JEREMY)>> INSTALL THE BELL HOUSING AND TORQUE TO SPEC. BEFORE WE GO ANY FURTHER WE NEED TO SET THE SPACING ON THE CLUTCH RELEASE BEARING.

(LT)>> SO WE'VE GOT TO HAVE BETWEEN 150 AND 200 THOUSANDTHS OF FREE TRAVEL BETWEEN THE FINGERS OF THE PRESSURE PLATE AND THE THROW OUT BEARING. LET'S SEE WHAT WE'VE GOT HERE. IT'S ABOUT TWOZEROSIXSIX, OKAY. LET'S SEE WHAT WE HAVE ON THIS SIDE.

(JEREMY)>> IF THE SPACING IS WRONG, THE CLUTCH WON'T ENTIRELY DISENGAGED, MAKING SHIFTING DIFFICULT, OR WOULDN'T ENTIRELY GRAB AND WILL SLIP. WE HAD TOO MUCH CLEARANCE. SO WE ADDED A SHIM TO ADJUST AND BRING IT INTO RANGE.

(LT)>> WITH THE CLUTCH RELEASE BEARING IN SPEC, WE CAN BEGIN LINING UP THE ENGINE TO THE TRANSMISSION, SLIDING THE INPUT SHAFT INTO THE CLUTCH.

(JEREMY)>> THE DOWEL PIN'S JUST NOT SLIDING IN THE HOLE. IT'S RIGHT THERE, IT'S JUST NOT.

(LT)>> THIS IS OBVIOUSLY AN IMPORTANT STEP, SO TAKE YOUR TIME.

ONCE THE TRANSMISSION MOUNT IS IN PLACE, WE CAN NOW LOWER THE WHOLE THING INTO THE FRAME.

WELL JEREMY IS IT GONNA FIT, WHAT DO YOU SAY?

(JEREMY)>> I THINK WE MAY GET LUCKY HERE LT.

(LT)>> WE'VE DONE OUR HOMEWORK, SO I HOPE IT DOES.

(JEREMY)>> EXCITING MOMENT I KNOW THAT. HOW ARE YOU LOOKING?

(LT)>> GOOD, SLIDE THAT CROSSEMEMBER ON. GOOD?

(JEREMY)>> OKAY, EASE IT ON DOWN. LOOKING GOOD BACK HERE.

(LT)>> BECAUSE THIS LT ONE ENGINE IS SO NEW, THERE REALLY ISN'T MUCH INFORMATION OUT THERE ABOUT SWAPPING IT INTO AN OLDER CHASSIS, BUT WITH A LITTLE BIT OF HOMEWORK THIS TURNED OUT TO BE A COMPLETELY BOLT IN SITUATION, NO CUTTING REQUIRED. FOR STARTERS ARE THE MOTOR MOUNTS. WE FOUND THESE ON AN ONLINE AUCTION OF ALL PLACES AND THEY'RE MADE OUT OF BILLET ALUMINUM, AND THEY ALLOW US TO BOLT UP OUR FACTORY 1971 350 RUBBER ISOLATORS.

(JEREMY)>> PACE PERFORMANCE HOOKED US UP WITH THIS PROTOTYPE SERPENTINE ACCESSORY DRIVE FROM STREET SHOP, WHICH INCLUDES THIS LS STYLE WATER PUMP AND A ONE WIRE ALTERNATOR, BUT WHAT'S REALLY COOL IS THEY WERE ABLE TO PROVIDE US WITH A POWER STEERING PUMP, WHICH THE LT ENGINE DID NOT COME EQUIPPED WITH FROM THE FACTORY. SO NOT ONLY WILL WE HAVE POWER STEERING, BUT WE'LL NOW BE ABLE TO RUN HYDRO BOOST BRAKES. NOW FOR HEADERS WE WENT TO JBA AND THEY SENT US TWO SETS TO CHOOSE FROM. A SET OF SHORTIES, WHICH WE ALREADY HAVE BOLTED ONTO THE ENGINE, AND A SET OF LONG TUBES, WHICH WE THINK WILL WORK A LITTLE BETTER FOR US IN THIS CHASSIS.

(LT)>> WE'RE GOING TO GET THE CAB BACK ON THE LIFT SO WE CAN MARRY THE TWO AND CHECK CLEARANCE FOR

THE TRANSMISSION AND SHIFTER LOCATION, AND AFTER A FEW MEASUREMENTS WE LEARNED WE'RE GONNA NEED TO DO A FEW ADDITIONAL MODIFICATIONS TO THE FLOOR. YOU CAN SEE WHERE I'VE MARKED THE FLOOR FOR THE SHIFTER OF THE T-56 TO PASS THROUGH, BUT UNFORTUNATELY WE'RE GONNA HAVE TO DO A LITTLE BIT MORE THAN JUST CUT A SMALL HOLE, AND THE REASON IS THE T-56 TRANSMISSION, WHILE IT'S NOT OVERLY LARGE, IT CARRIES A LOT OF MATERIAL ABOVE THE CENTER LINE. SO WE ARE GONNA HAVE TO DO SOME CUTTING TO GET IT TO

FIT UNDERNEATH OUR C-10.

(JEREMY)>> YEAH WE COULD GO AHEAD AND CUT THE FLOOR OUT, GO OUT TO THE METAL ROLLER OR THE ENGLISH WHEEL, AND FAB UP SOMETHING REALLY COOL, BUT AS YOU GUYS KNOW, THAT TAKES A LOT OF TIME. THE COOL THING ABOUT THIS ERA OF TRUCK, THE FOUR WHEEL DRIVES AND ONE TONS ACTUALLY COME WITH A BOLT IN TRANSMISSION TUNNEL THAT'S MUCH TALLER. YOU CAN SEE WHERE IT GOES. THAT'LL PROBABLY GIVE US ALL THE CLEARANCE WE NEED. SO IF WE CAN SOURCE ONE SOMEWHERE I THINK THAT'S THE ROUTE WE'RE GONNA TAKE.

(ANNOUNCER)>> NEXT A LITTLE TUNNEL VISION.

(JEREMY)>> AS YOU CAN SEE, WE'VE ALREADY CUT OUT OUR FLOOR TO MAKE ROOM FOR THIS TALLER TRANSMISSION TUNNEL THAT OUR BUDDY TOMMY BOSHERS SOURCED FOR US, BUT BEFORE WE WELD THIS THING IN THERE WE'VE GOT

A COUPLE OF ISSUES WE NEED TO ADDRESS. RUST LIKE THIS IS TYPICAL ON A TRUCK THAT SITS

OUTSIDE FOR YEARS AT A TIME. BASICALLY WHAT HAPPENS IS OXYGEN AND MOISTURE IN THE ATMOSPHERE ATTACK THE METAL, WHICH FIRST TURNS THE STEEL TO THIS KIND OF RED MUDDY COLOR, AND AFTER TIME DETERIORATION STARTS, WHICH IS LIKE WHAT WE HAVE HERE. NOW RUST IS A FORM OF OXIDATION AND THERE ARE MANY MATERIALS SUSCEPTIBLE TO THAT, LIKE ALUMINUM AND

PLASTIC FOR EXAMPLE BOTH CAN OXIDIZE. NOW WITH RUST LIKE THIS, DON'T LET IT SCARE YOU AWAY FROM STARTING OR PURCHASING A PROJECT. RUST IS EASILY REPAIRABLE, AND WITH THE AUTOMOTIVE AFTERMARKET THEY'VE MADE IT PRETTY EASY FOR US. REPLACEMENT SHEET METAL IS PLENTIFUL WHEN IT COMES TO

TRUCKS, ESPECIALLY POPULAR ONES LIKE OUR '71 C-10, AND LMC TRUCK HAS MOST EVERY PART AVAILABLE FOR OUR CHEVY, INCLUDING A BED FLOOR, BED HEADER PANEL, RADIATOR SUPPORT, FENDER WELLS, CAB CORNERS, BATTERY TRAY, WELL YOU NAME IT THEY'VE GOT JUST ABOUT EVERYTHING. NOW ALL THEIR PARTS ARE STAMPED TO OE SPECS AND ARE ECOATED FOR PROTECTION. NOW FOR OUR C-10 WE HAD THEM SEND US A CAB SUPPORT BECAUSE WELL, AS YOU JUST SAW, OURS WAS GONE.

THIS IS WHAT YOU CAN GET INTO WHEN DOING RUST REPAIR. GET BEHIND THE PANEL AND SOMETIMES THE RUST JUST KEEPS ON GOING, AND THE FLOOR'S PRETTY ROTTEN TOO. MAN THAT THING'S ROTTED OUT. ALSO SOMEONE'S BEEN UNDER HERE AND THEY'VE DONE A LITTLE PATCH WORK. NOW SOME PEOPLE DON'T HAVE THE MONEY TO PAY A PROFESSIONAL OR HAVE THE KNOWLEDGE TO DO A PROPER REPAIR.

NOW THIS I WOULD NOT CONSIDER A LIFETIME REPAIR BECAUSE IT LOOKS LIKE THEY JUST LAID THE METAL RIGHT OVER THE TOP OF THE RUST. AND PLUS YOU CAN SEE RIGHT HERE WHERE THEY BURNED IN A WELD AND WELL, THAT'S NOT VERY SAFE WHEN YOUR WELDS JUST POP OFF LIKE THAT. SO WE'LL GO AHEAD AND CALL LMC, GET THEM TO SEND US AN INNER ROCKER AND THE FRONT SECTION OF A FLOOR PAN. THAT'LL PROBABLY TAKE A COUPLE OF DAYS TO GET HERE. SO WHILE WE WAIT ON THAT WE'LL GO AHEAD AND START WORKING ON OUR TRANSMISSION TUNNEL,

SEE IF WE CAN GET IT IN THE CAB. '67 THROUGH '72 THREE QUARTER, ONE TON, AND FOUR WHEEL DRIVE TRUCKS CAME WITH A RAISED TUNNEL SECTION THAT PROVIDED PLENTY OF ROOM FOR THE DRIVETRAIN. WE SOURCED THIS ONE FROM A JUNKYARD AND IT WILL BOLT IN NICELY. WITH IT SAND BLASTED, THE FIRST STEP IS TO CLOSE THIS PREVIOUSLY CUT HOLE. [ SAW CUTTING ]

(JEREMY)>> I'LL TEST FIT THE NEW PIECE, AND THEN USING THE EDGE OF MY TABLE, MAKE A SMALL BEND TO MATCH THE TUNNEL. THE NEXT STEP IS TO BURN IT IN. [ WELDER CRACKLING ]

(JEREMY)>> I WANT TO LEAVE A ONE INCH LIP FOR THE TUNNEL, SO I'LL PULL A COUPLE OF MEASUREMENTS AND MAKE A FEW CLEAN CUTS. THAT LOOKS GOOD! OKAY, IF WE WERE BUILDING A SHOW TRUCK, WE WOULD GO AHEAD AND BUTT WELD THIS THING IN. THAT WAY YOU WOULDN'T KNOW WE PUT A TRANSMISSION TUNNEL IN IT UP TOP OR UNDERNEATH, BUT SINCE WE WANT EVERYTHING TO BE AS ACCESSIBLE AS POSSIBLE BECAUSE WE PLAN ON DRIVING THIS TRUCK A LOT, WE'RE GONNA GO AHEAD AND BOLT THE TUNNEL IN.

PLUS THIS IS HOW THEY DID IT AT THE FACTORY. SO IF IT WORKED FOR THEM IT'LL WORK GOOD FOR US. ONCE I'VE GOT ALL THE HOLES DRILLED, I'M USING CLIP NUTS AND BODY BOLTS TO SECURE THE TUNNEL. NOW WE CAN MAKE OUR CUT FOR THE NEW SHIFTER TO FIT THROUGH, AND WE'VE MADE A VERY EASY TRANSMISSION TUNNEL UPGRADE, PERFECT!

(ANNOUNCER)>> NEXT, THIS DIFFERENTIAL UPGRADE IS POSITIVELY COOL!

(LT)>> THE LAST PLACE YOUR HORSEPOWER GOES BEFORE IT REACHES THE GROUND IS THE REAR DIFFERENTIAL, AND WE'RE PRETTY SURE THIS STOCK 12 BOLT HAS AN OPEN

CARRIER IN IT, AND THAT JUST ISN'T GONNA CUT IT WITH OUR 460 HORSEPOWER LT ONE. WE JUST CAN'T HAVE ANY OF THAT ONE TIRE FIRE.

SO WE'RE GONNA SHOW YOU HOW TO REPLACE THE OPEN CARRIER WITH A POSI SO YOU GET THE SAME AMOUNT OF TRACTION TO EACH WHEEL AND GET MAXIMUM ACCELERATION. YEP, JUST AS WE SUSPECTED, OPEN CARRIER. WITH THE FLUID DRAINED FROM THE DIFFERENTIAL, THE TEARDOWN BEGINS BY REMOVING THE CENTER PIN FROM THE CARRIER. THE BRAKE DRUMS NEED A LITTLE CONVINCING TO COME OFF. THEN WE CAN PUSH THE AXLES IN TO ACCESS THE CCLIPS AND REMOVE THEM. BEFORE WE GO ANY FARTHER, WE NEED TO MEASURE THE RING GEAR BACKLASH SO WE CAN DUPLICATE IT WITH THE NEW CARRIER. I'LL MARK THE BEARING CAPS TO MAKE SURE THEY GO BACK IN WHERE THEY CAME FROM. [ DRILL SPINNING ]

(LT)>> TO MAKE SURE WE GET BOTH WHEELS SPINNING WHEN WE'RE ON THE GAS OF OUR C-10 WE WENT AHEAD AND PICKED UP A YUKON DURAGRIP CLUTCH STYLE POSITRACTION. IT'S A FOUR SPRING DESIGN THAT USES RAYBESTOS CLUTCH

DISCS FOR AGGRESSIVE OPERATION THAT'LL STILL DRIVE SMOOTHLY WHEN WE'RE ON THE STREET. I PICKED UP A SHIM KIT SO WE CAN GET THE BACKLASH WHERE IT NEEDS TO BE, AND I ALREADY WENT AHEAD AND PRESSED ON THE CARRIER BEARING. SO THE NEXT STEP FOR US IS TO SWAP OVER THE RING GEAR. WE'RE KEEPING THE 3.73 GEARS IN THIS TRUCK. THEY'RE A GOOD RATIO FOR QUICK ACCELERATION AND LOW RPM WHEN CRUISING DOWN THE HIGHWAY. I ALWAYS USE LOCTITE 243 TO MAKE SURE THE BOLTS DON'T BACK OUT, AND ONCE THE RING GEAR IS MATED WE CAN INSTALL THE CARRIER. [ DRILL SPINNING ]

(LT)>> THE BACKLASH MEASURES A LITTLE LOOSE, SO MOVING SOME SHIMS WILL GET THE CARRIER CLOSER TO THE PINION GEAR. WE'RE SHOOTING FOR SIX THOUSANDTHS BACKLASH BECAUSE THAT'S WHAT WE HAD BEFORE.

BEFORE WE SLIDE THOSE AXLE SHAFTS INTO PLACE, WE'RE GONNA TAKE CARE OF THE STOPPING POWER WITH A LITTLE BIT OF HELP FROM BAER BRAKES, AND ON THE

FRONT WE'RE USING THEIR TRACK FOUR SYSTEM, WHICH COMES WITH THESE 13 INCH DRILLED AND SLOTTED ROTORS AND THESE BEEFY FOUR PISTON CALIPERS. WE GOT THEM POWDER COATED SILVER BUT YOU CAN CHOOSE ALMOST ANY COLOR UNDER THE SUN. THEY COME WITH THE BRACKETS TO MOUNT UP TO OUR CPP TWO INCH DROP SPINDLES AND UTILIZE A BANJO STYLE FITTING UNLIKE A LOT OF OTHER AFTERMARKET CALIPERS, WHICH USE PIPE THREAD. WHEN YOU SET THEM DOWN WITH OUR STOCK SINGLE PISTON CALIPERS YOU CAN DEFINITELY TELL THE DIFFERENCE. THE KIT ALSO COMES WITH A NEW WHEEL HUB THAT COMES PREASSEMBLED WITH SEALS, BEARINGS, AND EVEN NEW STUDS. FOR THE REAR WE'RE USING THE SS FOUR KIT, WHICH HAS 12 INCH DRILLED AND SLOTTED ROTORS, SLIGHTLY

SMALLER FOUR PISTON CALIPERS, AND A FACTORY STYLE PARKING BRAKE, AND WE'RE GONNA GET STARTED BY TEARING OFF THE OLD BACKING PLATES. THE NEW PARKING BRAKE BOLTS UP USING THE FACTORY HOLES. WITH THE CENTER PIN REMOVED, THE AXLES CAN SLIDE INTO PLACE WITH CCLIPS JUST LIKE BEFORE. REINSTALL THE CENTER PIN, AND INSTALL THE COVER WITH RTV SILICONE. FOR THE NEW BAER BRAKES THE ROTOR SLIDES ON, FOLLOWED BY THE CALIPER. FOR THE FRONT A COTTER PIN AND NUT HOLD ON THE OLD HUB. WITH THE SPINDLE CLEANED UP, THE NEW PARTS FALL INTO PLACE.

(JEREMY)>> KNOWING WHAT'S GOING ON INSIDE YOUR LATE MODEL CAR OR TRUCK IS KEY TO DIAGNOSING PROBLEMS. HP TUNERS' VCM SCANNER LET'S YOU RECORD AND PLAY BACK REAL TIME DATA FROM ALL FACTORY SENSORS AND

AFTER MARKET SENSORS YOU ADD YOURSELF. YOU CAN MONITOR ENGINE AND TRANSMISSION FUNCTIONS, CLEAR DIAGNOSTIC TROUBLE CODES, AND IT INTEGRATES SEAMLESSLY WITH THEIR EDITOR FOR TUNING PURPOSES. THIS VCM SCANNER IS AVAILABLE FOR 349 AT HP TUNERS DOT COM.

(LT)>> LET'S FACE IT, ANY TIME YOU PURCHASE A USED OR REMANUFACTURED ENGINE OR TRANSMISSION, THERE'S ALWAYS TREPIDATION. WILL IT EVEN RUN RIGHT, AND WHAT HAPPENS IF IT BLOWS UP PAST 30 DAYS?

WELL POWERTRAIN PRODUCTS OFFERS A NO FAULT WARRANTY THAT'LL RELIEVE SOME OF THAT STRESS. FOR $349 DOLLARS YOU GET ADDED COVERAGE AGAINST DETONATION, OVERHEATING, EVEN RUNNING LOW ON OIL FOR AN ADDITIONAL THREE TO FIVE YEARS. PLUS IT COVERS EXPENSES LIKE CAR RENTAL, TOWING, AND EVEN DIAGNOSTICS. POWERTRAIN PRODUCTS ARE AVAILABLE AT SHOP ENGINES DOT COM. WELL WE'VE MADE SOME GREAT PROGRESS ON OUR '71 C-10 TODAY. WE'VE GOT THE CHASSIS PLUMBED OUT, THE ENGINE AND TRANS ARE BACK IN THE FRAME, AND WE GOT A REAL NICE SET OF BRAKES AND A POSI.

(JEREMY)>> YEAH WE'VE GOT SOME SHEET METAL PARTS ON THE WAY. SO THE NEXT TIME YOU GUYS SEE THIS TRUCK WE'RE GONNA FINISH UP THAT RUST REPAIR, PERMANENTLY MOUNT THE CAB, AND MAYBE EVEN SHOW YOU A NEW SET OF WHEELS AND TIRES.

(LT)>> ALRIGHT, WELL LET'S GET THIS THING

OUT OF HERE THEN.

(JEREMY)>> LET'S DO IT.