More In House Power Mouse Episodes

Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Air Flow Research

Intake Manifold, Titon, Street/Strip, Plastic, Black, Single Plane, Square-Bore Flange, SBC Chevy, Each

Comp Cams

Timing Chain and Gear Set, Ultimate Adjustable, Double Roller, Billet Steel Sprockets, Chevy, Small Block, Set

Design Engineering, Inc. (DEI)

Intercooler Sprayer kit, Includes 16 in. x 5 in. Spray Bar, Feed Line, Solenoid, Bottle and Mounts, Kit

Jesel Inc.

Rocker Arms, Shaft Mount, 1.6 Ratio, Aluminum, Full Roller, Chevy, Small Block, Victor Jr., E-Tec Heads, Kit

Lizard Skin LLC

Sound Control, Advanced Water-based Composition of a High-grade Acrylic, Spray-on, Black, 2 gallon, Each

MSD Ignition

Distributor Gear, Aluminum, Bronze, Race, .466 in. Diameter Shaft, Ford, 289, 302, Each

Summit Racing

Engine Block, Cast Iron, 4-Bolt Mains, 4.030 in. Bore, Clearanced, 1-Piece Rear Seal, Chevy, Small Block, Each

Summit Racing

Harmonic Balancer, SFI, Internal Balance, Steel, Clearcoated, Chevy, Small Block, Each

Summit Racing

Combo, Oil Pan, Black Zinc, Pickup, High-Volume Pump, Shaft, Tray, Scraper, Gaskets, Chevy, Small Block, Kit

Comp Cams

Custom Grind Billet Roller Camshaft

Eagle Specialty Products

Eagle Specialty Products 383 Chevrolet Rotating Assembly W/Mahle Pistons, Mahle Rings, King Bearings

EBC Brakes

Front Kit, Stage 5 Superstreet Brake Kit, Includes GD Series Rotors and Yellow Stuff Pads, Front Rotor Dia. 13.0 in.

Goodson Shop Supplies

Powered Ring Filer with Integral De-burring Wheel

The Industrial Depot

The Industrial Depot - Fasteners, Hardware, and Shop Supplies

Episode Transcript

(ANNOUNCER)>> TODAY ON

ENGINE POWER IT'S TIME FOR STAGE TWO ON OUR SMALL

BLOCK CHEVY POWER HOUSE

WITH A BUDGET BREAKING LIST OF INTERNALS. PLUS HOW TO CORRECTLY INSTALL YOUR DISTRIBUTOR.

(PAT)>> GLAD YOU COULD JOIN US FOR MORE ENGINE POWER. TODAY WE'RE CONTINUING ON WITH STAGE TWO OF A THREE STAGE BUILD UP OF OUR SMALL BLOCK CHEVY. LAST WEEK WE COMPLETED STAGE ONE. WE STARTED WITH A MACHINED STOCK BLOCK FROM SUMMIT RACING, ALONG WITH THEIR PRO PACK KITS, WHICH INCLUDED STOCK REPLACEMENT PISTONS, RODS, AND CRANK SHAFT. IT WAS TOPPED OFF WITH SUMMIT 170cc ALUMINUM HEADS, A WEIAND INTAKE, AND A 650 HOLLEY CARB. THEN A SHORT DYNO FLOG YIELDED IMPRESSIVE 357 HORSEPOWER AND 389 POUND FEET OF TORQUE. AND WE BUILT IT FOR LESS THAT $4,000 DOLLARS. THIS IS WHAT IT LOOKS LIKE TODAY. WE'RE REUSING THE BLOCK. THE REST GOES ON THE SHELF BECAUSE TODAY THE BUDGET GOES OUT THE WINDOW.

(JOE)>> THAT'S WHY I'M HERE. I HEARD THAT SMALL BLOCK ROARING THROUGH THE BUILDING LAST WEEK, AND WELL I DECIDED I HAD BE A PART OF THIS BUILD, ESPECIALLY SINCE WE'RE UPGRADING TO SOME BULLETPROOF PARTS THAT'LL RAISE THE CUBIC INCHES TO 383 AND THE HORSEPOWER TO MORE THAN 500. FOR EXAMPLE IN STAGE ONE WE USED THESE CAST PISTONS. NOW WE'RE UPGRADING TO THESE MOLY POWER PACK PISTONS THAT ARE FULLY MACHINED FORGINGS. NOW THEY HAVE A PHOSPHATE COATING THAT REDUCES PIN GALLING AND MICRO WELDING.

PLUS, ON THE SKIRTS, A GRAFAL COATING THAT REDUCES DRAG. THE CONNECTING RODS WE USED IN STAGE ONE WERE MORE THAN ADEQUATE FOR OUR COMBINATION THEN. NOW THOUGH WE'RE GONNA UPGRADE TO THESE MUCH BEEFIER HBEAM FORGED RODS WITH FLOATING PINS, AND THEY'LL BE ABLE TO HANDLE ALL THAT ABUSE. FOR A CAM SHAFT WE'RE GOING FROM THIS BASIC HYDRAULIC FLAT TAPPET TO THIS CUSTOM GRIND BILLET SOLID ROLLER FROM COMP. NOW THE BASE CIRCLE IS SMALLER ON THIS CAM THAN THE STAGE ONE, AND THAT'S SO IT'LL CLEAR THE CONNECTING RODS WITH OUR STROKER. NOW CHECK THE DIFFERENCE IN THE DURATION OF THESE LOBES. OVER HERE WE'VE GOT 218 INTAKE AND EXHAUST AT 50 THOUSANDTHS. OVER HERE 252 AND 260. THIS ULTIMATE ADJUSTABLE BILLET TIMING SET IS A BIG UPGRADE AS WELL, ESPECIALLY WITH ALL OF ITS ADJUSTABILITY.

UP TO SIX DEGREES ADVANCE OR RETARD TO MAKE DIALING IN THE CAM A SNAP. AND WE'LL GO FROM HYDRAULIC LIFTERS TO A SET OF SOLID ROLLERS. THOSE NEW LIFTERS, TIMING SET, AND CAM ALL CAME FROM COMP.

WHILE OUR PISTONS, RODS, AND CRANK SHAFT ARE PART OF EAGLE'S COMPETITION SERIES.

IT'S A 4340 FORGED CRANK SHAFT THAT'S GONNA BRING

OUR STROKE UP FROM THREEFOUR-80 TO THREESEVEN-50 WITH A FOURZERO-30 BORE.

(PAT)>> AND THAT'S WHERE WE PLANNED AHEAD. NOW NORMALLY WE WOULD HAVE TO GRIND ON THE BLOCK TO MAKE ROOM FOR THAT ADDITIONAL STROKE, BUT WE

ORDERED THE BLOCK WITH THE CLEARANCING ALREADY DONE. WITH THAT BEING SAID, THERE'S STILL MORE WORK TO DO. WITH THE BLOCK WASHED IT'S TIME TO FOCUS ON OIL FLOW. I'LL START IN THE OIL FILTER BOSS AREA, REMOVING ALL SHARP EDGES AND MAKING SMOOTH TRANSITIONS. THE SAME PROCESS FOR THE OIL PUMP MOUNT ON THE REAR MAIN CAP. NOW WITH THAT ADDITIONAL FLOW WE'RE GONNA PUT THAT OIL RIGHT WHERE IT NEEDS TO BE, THE MAINS. SOME PERFORMANCE ENGINES, LIKE OUR 572, HAVE GROOVE IN THE MAIN SADDLE TO PUT EXTRA OIL TO THE MAINS. SINCE OUR STOCK BLOCK DOESN'T HAVE THEM, I'LL SHOW YOU HOW TO PUT THEM IN YOURSELF. ALL IT TAKES IS A DISCARDED MAIN BEARING FOR A TEMPLATE. INSTALL IT IN THE SADDLE ALONG WITH A COUPLE OF BOLTS AND WASHERS TO KEEP IT IN PLACE. THEN USE A CUTOFF WHEEL TO GENTLY GRIND THROUGH THE BEARING INTO THE MAIN APPROXIMATELY 60 THOUSANDTHS, OR A 16TH OF AN INCH DEEP. TAKE YOUR TIME AND CHECK YOUR PROGRESS REGULARLY.

IT'S GOT TO GO A LITTLE FURTHER ON THIS SIDE, BUT THAT'S REALLY CLOSE.

WITH THE FIRST ONE DONE YOU'VE ALSO CREATED A PERFECT TEMPLATE FOR THE REST. MOVE THE BEARING TO THE NEXT SADDLE AND REPEAT THE PROCESS. FINISH IT OFF BY DEBURRING THE OIL HOLES, GORGEOUS! THAT LOOKS LIKE A MACHINE DID IT. WE'LL DRILL EXTRA HOLES IN THE NEW MAIN BEARINGS BEFORE THEY GO IN. THE PRESSED IN FRONT OIL GALLERY PLUGS CAN POP OUT UNDER HIGH PRESSURE. SO I TAPPED THEM FOR SCREW IN PIPE PLUGS, WHICH I'LL INSTALL ON FINAL ASSEMBLY.

(JOE)>> HEY THAT'S SOME NICE TECH ON THOSE MAINS, I LIKE THAT. NOW THAT INCREASED FLOW WITH ALSO INCREASE THE PRESSURE WHERE WE WANT, GIVEN THE OIL HAS THE SAME VISCOSITY.

NOW BOTTOM LINE IS THIS BLOCK'S GONNA STAND UP TO

THE RPM'S AND EXTRA HORSEPOWER WE THROW AT IT. NOW WE'RE GONNA GIVE IT A BATH AND WHEN WE COME BACK WE'LL START THROWING SOME PARTS AT IT.

(PAT)>> WE'RE BACK AND GONNA START THE BUILD OF OUR STAGE TWO SMALL BLOCK CHEVY. NOW LIKE WITH ANY HIGH PERFORMANCE ENGINE, YOU DON'T WANT TO LEAVE ANYTHING TO CHANCE, LIKE BEARING CLEARANCES. IF YOU REMEMBER IN STAGE ONE WE PLASTIGAUGED OUR CLEARANCES, WHICH WAS FINE FOR ITS POWER LEVEL AND APPLICATION.

(JOE)>> YEAH BUT FOR THIS STAGE WE'LL BE MORE PRECISE, AND THAT MEANS USING A SET OF QUALITY MICROMETERS AND A DIAL BORE GAUGE. THIS WAY WE CAN MEASURE DOWN TO 10 THOUSANDTHS OF AN INCH, AND WE'LL START WITH THE NUMBER ONE CRANK JOURNAL, AND TRANSFER THAT MEASUREMENT TO THE DIAL BORE GAUGE. TO AVOID SCRATCHING THE NEW BEARINGS WE'LL DO ONE JOURNAL AT A TIME, AND RECORD THE RESULTS TO A BUILD SHEET LIKE THIS ONE YOU CAN DOWNLOAD FROM OUR WEBSITE.

(PAT)>> THE MINIMUM VERTICAL OIL CLEARANCE FOR A HIGH PERFORMANCE ENGINE SHOULD BE ONE THOUSANDTHS PER INCH OF SHAFT DIAMETER. SO FOR OUR SMALL BLOCK CHEVY THE MINIMUM OIL CLEARANCE SHOULD BE 25 TEN THOUSANDTHS AND WE HAVE BETWEEN 30 AND 33 TEN THOUSANDTHS, SO WE'RE IN THE GOOD. WITH THE MAINS ALL SET UP WE CAN NOW DRILL THE EXTRA HOLES IN THE NEW BEARINGS.

WE'LL SPACE TWO OF THEM EVENLY ON EACH SIDE, 60 THOUSANDTHS IN DIAMETER. WE'LL MAKE SURE TO DEBURR THEM AFTERWARDS. WITH THAT HANDLED, APPLY A DAB OF HIGH PRESSURE LUBE TO THE REAR MAIN SEAL AND INSTALL IT. NOW WE CAN PLACE OUR MODIFIED BEARINGS IN OUR MODIFIED SADDLES. AND WITH SOME HIGH VISCOSITY LUBE ON THEM WE'RE READY TO CAREFULLY LAY THE CRANK IN FOR GOOD. OUR LUBE CAPS CAN GO ON NOW. WE'LL TORQUE THE CAPS IN A CIRCULAR PATTERN FROM THE INSIDE OUT, FIRST AT 40, THEN FINALLY TO 70 POUND FEET. AS ALWAYS WE'LL CHECK THE CRANK'S THRUST. IT'S AT A SWEET FIVE THOUSANDTHS. NEXT I'M GONNA DROP A COUPLE OF RINGLESS PISTON AND ROD ASSEMBLIES IN THE BLOCK. HERE'S WHY, WE WANT TO MAKE ABSOLUTELY SURE THE CLEARANCING THAT WAS DONE INSIDE THE BLOCK IS

COMPATIBLE WITH OUR PARTS COMBINATION. IF WE NEED TO DO ANY MORE GRINDING NOW IS THE TIME TO KNOW, NOT DURING FINAL ASSEMBLY. WE ARE GOOD TO GO! TIME TO PUT SOME PLUGS IN OUR NEWLY THREADED OIL GALLERIES. MAKE SURE TO PUT SOME HIGH PRESSURE LUBE ON THEM OR

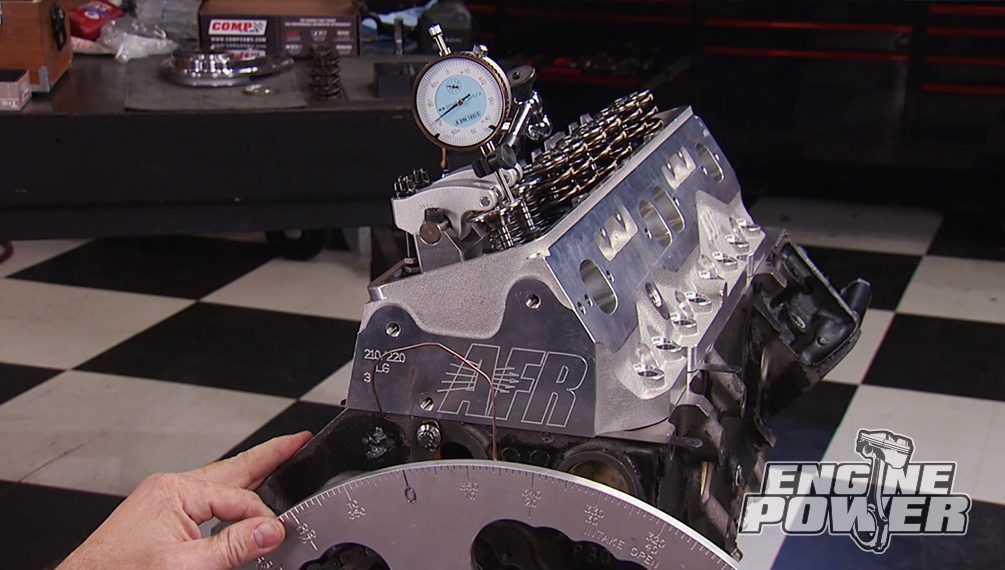

THEY CAN GALL GOING IN. SEALANT ISN'T REQUIRED ON THEM SINCE THEY'RE INSIDE THE ENGINE. NOW OUR COMP CUSTOM SOLID ROLLER GETS CAREFULLY SLID IN. THIS IS THE MOST AGGRESSIVE CAM PROFILE WE CAN PUT IN THIS ENGINE WITHOUT HAVE TO DO MAJOR CHANGES TO PARTS ELSEWHERE. KEEPING THE CAM IN PHASE EXACTLY WHERE WE WANT IT IS THIS COMP ULTIMATE ADJUSTABLE TIMING SET. WITH OUR BUTTON BACK IN PLACE, THE FASTENERS ARE TORQUED TO 28 POUND FEET. DEGREEING THE CAM IS THE NEXT STEP ON OUR LIST. I'M SETTING UP THE INTAKE CENTER LINE ON 108 DEGREES, WHICH IS TWO DEGREES ADVANCED. WHEN FINISHED, THE INNER BOLTS GET TORQUED TO 13 POUND FEET.

DEGREEING A CAM SHAFT IS A MUST FOR ANY HIGH PERFORMANCE ENGINE BECAUSE IT'S THE INTAKE CENTER

LINE'S POSITION RELATIVE TO ITS LOBE SEPARATION THAT DICTATES THE ENGINE'S POWER BAND. NOW I'LL EXPAND ON THAT LATER BECAUSE RIGHT NOW WE'RE GONNA CHECK FOR PISTON TO VALVE CLEARANCE, AND NO USING CLAY HERE. WE'RE GONNA USE OUR DEGREE WHEEL AND A DIAL INDICATOR TO GET AN EXACT MEASUREMENT. I'LL LEAVE THE NUMBER ONE PISTON AND ROD ASSEMBLY IN THE BORE. I TOOK OUR NEW CYLINDER HEAD AND PULLED THE SPRINGS OFF NUMBER CYLINDER AND REPLACED THEM WITH CHECKING SPRINGS. NOW I'LL PLACE SOME LONG FEELER GAUGES THAT ARE THE SAME COMPRESSED THICKNESS AS OUR NEW HEAD GASKET ON THE DECK. IN OUR CASE THAT'S 27 THOUSANDTHS. A SET OF ROCKERS IS NEXT TO GO ON AND GET MOCKED UP.

NOW BECAUSE OF THE INCREASED POWER LEVEL AND RPM WE'RE GONNA HAVE, WE OPTED TO INSTALL A SET OF JESEL SPORTSMAN SERIES SHAFT ROCKERS. THEY'RE BUILT OUT OF 2024 ALUMINUM THAT'S BEEN CNC'ED AND SHOT PEENED, AND THEY FEATURE CENTERLESS GROUND SHAFTS, NEEDLE BEARINGS

THROUGHOUT, AND EVEN HAVE TOOL STEEL ADJUSTERS.

WE ARE DANGEROUSLY CLOSE TO CHECKING OUR PISTON TO VALVE CLEARANCE, BUT BEFORE WE CAN GET STARTED WE HAVE TO FIND OUR PUSH ROD LENGTH. SO I'M GONNA TAKE A COUPLE OF ADJUSTABLE PUSH RODS AND DROP THEM INTO THE LIFTERS WHILE THE CAM IS ON ITS BASE CIRCLE. THE ROCKERS GET BOLTED DOWN AND THE PUSH RODS GET EXTENDED. THEN THE LASH IS SET WITH A FEELER GAUGE TO 20 THOUSANDTHS ON EACH ONE. THE LENGTH IS NOW SET AND THEY'LL STAY PUT FOR OUR PISTON TO VALVE CLEARANCE CHECK, BUT WHEN WE PULL THEM OUT WE'LL GET A LENGTH ON THEM TO ORDER OUR NEW ONES.

A MAGNETIC BASE DIAL INDICATOR GETS POSITIONED ON THE INTAKE VALVE SPRING RETAINER. NEXT I'LL ROTATE THE DEGREE WHEEL UNTIL IT GETS TO 10 DEGREES AFTER TDC ON SPLIT OVERLAP, MEANING THE EXHAUST VALVE IS ALMOST CLOSED AND THE INTAKE VALVE IS STARTING TO OPEN. THEN PRESS DOWN ON THE INTAKE ROCKER UNTIL YOU FEEL THE VALVE CONTACT THE TOP OF THE PISTON. THE AMOUNT OF TRAVEL ON THE DIAL INDICATOR IS THE EXACT AMOUNT OF CLEARANCE IT HAS. THE EXHAUST GETS THE SAME TREATMENT. THE ONLY DIFFERENCE IS THAT THE DEGREE WHEEL NEEDS TO BE AT 10 DEGREES BEFORE TDC ON SPLIT OVERLAP. THE MINIMUM CLEARANCES WE'RE LOOKING FOR ARE 60 THOUSANDTHS ON THE INTAKE AND 110 THOUSANDTHS ON THE EXHAUST TO KEEP THINGS SAFE. WE ACTUALLY HAVE 111 THOUSANDTHS ON THE INTAKE AND 116 THOUSANDTHS ON THE EXHAUST. SO WE'RE IN THE CLEAR.

THIS IS ABSOLUTELY NECESSARY TO CHECK ON CAM SHAFTS WITH A BIG DURATION AND BIG LIFT BECAUSE IF YOU DON'T HAVE ENOUGH CLEARANCE YOUR ENGINE IS GOING TO TURN INTO A ROMAN CANDLE WHEN YOU RUN IT. SO NOW THAT ALL OUR TIGHT CLEARANCES ARE CHECKED WE'RE

FINALLY READY TO START ASSEMBLY AND WE'LL GET TO THAT AFTER THE BREAK.

(JOE)>> HEY WE'RE BACK AND I'VE GOT TO SAY THAT WAS SOME COOL AND USEFUL TECH THAT PAT JUST SHARED WITH US. THE KIND OF STUFF THAT TAKES TIME BUT IT'S WELL WORTH IT FOR THE PEACE OF MIND. AND YOU KNOW WHAT, WE'VE GOT MORE BEFORE

WE START ASSEMBLY. IN FACT WE'VE GOT TO CHECK OUR ROD CLEARANCES LIKE WE DID OUR MAINS. WE'LL START ON THE FRONT JOURNAL THAT CARRIES THE NUMBER ONE AND TWO RODS, AND USE THE NUMBERS TO SET UP OUR DIAL BORE GAUGE.

(PAT)>> HEY, YOU GOT HER, YOU NAILED IT.

(JOE)>> THEN OF COURSE WE'LL FILL IN THESE BLANKS ON OUR BUILD SHEET. WE'LL USE THE ROD VICE TO TORQUE THE BOLTS TO

63 POUND FEET, JUST LIKE IN FINAL ASSEMBLY. THE READING ON THE DIAL IS OUR ACTUAL CLEARANCE. OF COURSE WE'LL MAKE SURE TO LOG IN THIS DATA ON OUR

BUILD SHEET AS WELL.

(PAT)>> WITH EVERYTHING IN THE GREEN ZONE WE'RE FINALLY READY TO MATE UP OUR RODS AND PISTONS. NOW WE HAVE FLOATING WRIST PIN ASSEMBLIES, WHICH ARE HIGHLY RECOMMENDED FOR HORSEPOWER LEVELS ABOVE 400. PLUS THEY'RE JUST EASIER TO ASSEMBLE THAN IF YOU HAVE TO HEAT UP A ROD FOR A PRESS FIT. THE WRIST PINS ARE RETAINED IN THE PISTONS WITH SIR CLIPS. THESE PISTONS, COMBINED WITH OUR HEADS AND OTHER PARTS, WILL GIVE US A CALCULATED COMPRESSION RATIO OF 11.00 TO ONE.

(JOE)>> WELL LIKE OUR PISTONS, WE'VE GOT MOLY RINGS IN OUR POWER PACK KIT.

THEY'RE DESIGNED FOR PRECISION LANDS, AND THE TOP RING AND SECOND RING ONLY MEASURE ONE AND A HALF MILLIMETERS.

THE OIL RING MEASURES THREE MILLIMETERS. NOW SMALLER RINGS MEAN LESS FRICTION. LESS FRICTION MEANS MORE HORSEPOWER. BUT AS WITH ANY PERFORMANCE BUILD WE FIRST HAVE TO FILE FIT THESE RINGS, AND FOR THAT WE'LL USE OUR GOODSON ELECTRIC FILER. WE START WITH THE SECOND RING, WHICH COMES OUT OF THE BOX WITH ALMOST NO GAP AT ALL. WE'LL FILE OFF ABOUT FIVE THOUSANDTHS, CHECK IT IN THE BORE WITH A FEELER GAUGE, YEP FIVE THOUSANDTHS, AND WE'LL CONTINUE SNEAKING UP ON IT. THERE'S 15 THOUSANDTHS, JUST A LITTLE MORE TO GO. FINALLY WE'RE AT 20 THOUSANDTHS, WHICH IS OUR TARGET. THE TOP RING GAP IS THE MOST CRITICAL AND NEEDS TO BE FOUR AND A HALF THOUSANDTHS PER INCH OF CYLINDER BORE. SINCE OUR BORE'S AT FOURZERO-30, THAT CALCULATES TO 18 THOUSANDTHS RING GAP.

(PAT)>> WITH ALL OF OUR RINGS GAPPED AND CLEANED WE CAN START INSTALLING THEM FROM THE OIL SCRAPER UP. THE SECOND RING IS NEXT, AND HERE'S SOMETHING IMPORTANT. THE TOPS OF THE SECOND AND TOP RINGS ARE MARKED AND NEED TO BE INSTALLED THAT WAY. SINCE THE RINGS ARE PRETTY DELICATE, YOU ALWAYS WANT TO TAKE YOUR TIME DOING THIS. I LIKE TO USE SPECIFIC BREAK IN OIL ON THE CYLINDERS AND ON THE PISTONS AND RINGS DURING ASSEMBLY. NOW BY THE TIME YOU GET BACK WE'LL HAVE THEM ALL STUFFED IN THE BLOCK. SO STAY WITH US.

(ANNOUNCER)>> COMING UP, THE QUICK AND CORRECT

TECHNIQUE FOR DISTRIBUTOR INSTALLATION.

(PAT)>> BEAUTIFUL!

(JOE)>> YES SIR, DID YOU EVER MEET AN ENGINE YOU DIDN'T LIKE?

(PAT)>> I HAVEN'T ACTUALLY.

(JOE)>> I DIDN'T THINK SO. WITH ALL OF OUR UPGRADED PISTONS AND RODS INSTALLED, AND THE ROD BOLTS TORQUED TO 63 POUND FEET, THIS GETS US CLOSE TO FINISHING UP OUR SHORT BLOCK.

(PAT)>> NEXT OUR CAST ALUMINUM TIMING COVER CAN GO BACK ON. NOW THE FACT THAT IT'S ONE PIECE AND DOES NOT GIVE US ACCESS TO THIS TRICK BILLET ADJUSTABLE TIMING GEAR IS OKAY FOR THIS STAGE BECAUSE IN STAGE THREE WE'LL USE A TWO PIECE COVER IN CASE WE WANT TO DO SOME CAM TWEAKING. NOW WE'LL REUSE THE SFI APPROVED BALANCER USED IN STAGE ONE, WHICH IS A MUST FOR THE INCREASE IN POWER AND RPM THAT WE'RE GONNA BE MAKING.

(JOE)>> WE WERE ALSO LOOKING AHEAD WHEN WE USED THIS SUMMIT PUMP AND PAN KIT IN STAGE ONE. BOTH WILL ENSURE THIS LITTLE BEAST IS WELL SUPPLIED WITH OIL, AND THAT IS OFFICIALLY IT FOR OUR SHORT BLOCK. WE SLOWED DOWN THIS TIME TO SHOW YOU MORE TECH THAN USUAL BUT YOU KNOW, KNOWLEDGE IS POWER, AND IN THIS CASE HORSEPOWER. WELL NEXT TIME WE'VE GOT SOME HARDCORE RACE PARTS FOR THE TOP END.

(PAT)>> CASE IN POINT, TO WORK WITH THOSE AFR ALUMINUM HEADS WE'RE GONNA BE USING ONE OF THEIR TITAN TXR RACE MANIFOLDS. NOW IT'S A TWO PIECE COMPOSITE DESIGN MADE OUT OF PLASTIC, WHICH WILL RUN UP TO 30 DEGREES COOLER THAN ALUMINUM. PLUS BE ABOUT 11 POUNDS LIGHTER. AFR SAYS THAT IT'S WORTH 15 HORSEPOWER AND 15 POUND FEET OVER THEIR COMPETITION, AND WE'RE GONNA SEE EXACTLY HOW MUCH POWER STAGE TWO MAKES IN THE DYNO ROOM BUT IT SHOULD BE WELL OVER 500 HORSEPOWER. OF COURSE THAT'S NOT THE FINALE. THE BEST AND BADDEST IS YET TO COME BECAUSE IN STAGE THREE WE'LL REUSE MOST OF THE TOP SHELF INTERNALS AND PUT THEM IN AN AFTERMARKET BLOCK THAT'S DESIGNED TO HANDLE ALL THAT ABUSE. THEN WE'RE GONNA PRESSURIZE IT ALL WITH A CENTRIFUGAL SUPERCHARGER AND IT'S GONNA MAKE POWER NUMBERS YOU'RE NOT GONNA WANNA MISS.

(JOE)>> YOU ALL KNOW THAT HEAT IS YOUR ENGINE'S ENEMY. WELL THIS COULD BE ITS NEW FRIEND. IT'S DEI'S CRYOTWO SYSTEM THAT'S ALL ABOUT REDUCING FUEL AND AIR TEMPERATURES TO MAKE MORE POWER. IT HARNESS THE PROPERTIES OF LIQUID CO TWO TO REDUCE INTAKE TEMPERATURES BY AS MUCH AS 50 DEGREES.

NOW THE FOUNDATION IS A FIVE OR 10 POUND BOTTLE LIKE THIS WITH ALL THE ACCESSORIES YOU NEED.

NOW IT'S MODULAR AND EXPANDABLE SO YOU CAN ADD THINGS LIKE THIS FUEL CHILLER. IT'S GOOD FOR TURBOCHARGED, SUPERCHARGED, AND OF COURSE NATURALLY ASPIRATED ENGINES. SINCE YOUR BRAKE PADS AND ROTORS HAVE TO WORK TOGETHER IT MAKES SENSE THAT THEY SHOULD COME TOGETHER AS A KIT, LIKE EBC'S STAGE FIVE KIT. NOW IT'S IDEAL FOR STREET AND OCCASIONAL TRACK USE.

IT COMES WITH A SET OF THEIR YELLOW STUFF BRAKE PADS FOR HIGH FRICTION BRAKING, AND THEIR GD SERIES DIMPLED AND SLOTTED ROTORS. NOW THESE SLOTS HELP THE BRAKE PADS AND ROTORS WEAR EVENLY, AND THE MATERIAL IN THE PADS CONTAINS NO HEAVY METAL. SO IT'S LESS ABRASIVE TO THE ROTORS. IT'S AN IDEAL COMBO FOR YOUR NEXT BRAKE UPGRADE.

(PAT)>> FOR ALL OF YOU CAR, TRUCK, AND STREET ROD BUILDERS LOOKING DAMPEN EXTERIOR NOISE AND OR ENHANCE YOUR STEREO SOUND, LIZARD SKIN SOUND CONTROL IS AN ENVIRONMENTALLY SAFE CLASS "A" FIRE RATED COATING THAT'S IN AN EASY SPRAY ON APPLICATION. IT ALSO DAMPENS VIBRATIONS AND SEALS OUT MOISTURE TO KEEP YOUR PRIZED PROJECT PROTECTED FOR YEARS TO COME. IT COMES IN A TWO GALLON PAIL THAT WILL EASILY COVER MOST INTERIORS, AND IT'S EASILY CLEANED UP WITH SOAP AND WATER. YOU CAN FIND YOURS AT SUMMIT RACING FOR AROUND $165 BUCKS.

(MIKE)>> INSTALLING A DISTRIBUTOR IS A POPULAR TOPIC IN OUR EMAIL BAG, AND MOST OF THEM ARE ASKING, HOW DO WE GET SO LUCKY DROPPING IN A DISTRIBUTOR AND GETTING AN IMMEDIATE FIRE UP EVERY TIME?

(PAT)>> WELL THERE'S NO LUCK INVOLVED. IT'S A SIMPLE UNDERSTANDING OF POSITIONING AND THE PROCESS WE'RE GONNA SHOW YOU HERE APPLIES TO ALL ENGINES THAT HAVE DISTRIBUTORS.

(MIKE)>> THE FIRST THING TO DO IS MAKE SURE THE NUMBER ONE CYLINDER IS COMING UP ON TOP DEAD CENTER ON THE COMPRESSION STROKE. THERE'S A COUPLE OF WAYS TO DO THAT. THE FIRST, AND GENERALLY EASIEST, IS TO HAVE THE NUMBER ONE CYLINDER SPARK PLUG REMOVED.

NOW PLACE YOUR FINGER OVER THE HOLE AND TURN

THE ENGINE OVER SLOWLY. WHEN THE PISTON COMES UP ON THE COMPRESSION STROKE IT WILL FORCE AIR OUT OF THE CYLINDER AND PUSH YOUR FINGER OFF ITS SEAL LIKE THIS.

(PAT)>> THE SECOND WAY IS MORE INVOLVED AND REQUIRES YOU TO PULL A VALVE COVER.

WHEN YOU'VE TURNED THE ENGINE OVER AND BOTH VALVES ARE CLOSED AND THE ROCKER'S NOT MOVING, YOU'RE COMING UP ON THE COMPRESSION STROKE. NOW SLOWLY TURN THE CRANK TO GET THE TIMING MARK, OR ZERO DEPENDING ON YOUR BALANCE, ABOUT 30 DEGREES BEFORE ON THE TIMING POINTER. TO PUT IT IN SIMPLE TERMS, THERE ARE 360 DEGREES IN A CIRCLE. SO THAT MEANS 30 DEGREES IS A LITTLE LESS THAN ONETENTH OF THAT, WHICH IS A VERY SMALL DISTANCE. NOW IT'S TIME TO DROP THE DISTRIBUTOR IN. THE IMPORTANT THING IS TO POSITION THE ROTOR WHERE YOU WANT IT, NOT WHERE IT FALLS. THIS IS IMPORTANT FOR YOUR WIRE ROUTING TO LOOK NEAT AND CLEAN. TO MAKE IT DROP ALL THE WAY DOWN ALL YOU HAVE TO DO IS ROTATE THE ENGINE AND THE DISTRIBUTOR WILL INDEX THE OIL PUMP DRIVE. THEN SIMPLE REVERSE THE ROTATION BACK TO 30 DEGREES BEFORE TDC. NOW THE CAP GOES ON, THE WIRES ARE ROUTED TO THE SPARK PLUGS, AND HERE'S THE RESULTS. [ ENGINE STARTS ]

(MIKE)>> SO ALL YOU NEED TO DO IS FOLLOW THAT SIMPLE

PROCEDURE AND YOU'LL NEVER SEE FLAMES COME OUT OF YOUR CARBURETOR AGAIN.

PLUS IT'LL JUST MAKE YOUR LIFE SIMPLER.

(PAT)>> ONE MORE THING ABOUT DISTRIBUTORS, YOU CAN'T RUN AN IRON GEAR ON A STEEL CAM. IN THIS CASE THE MATERIALS HATE EACH OTHER AND YOU'LL GET ALMOST IMMEDIATE FAILURE ON YOUR DISTRIBUTOR GEAR. A COMPOSITE, OR BRONZE, GEAR LIKE THIS ONE FROM MSD WILL SOLVE THE PROBLEM. THE BRONZE MATERIAL IS SOFTER THAN THE CAM SHAFT GEAR, ALLOWING FOR A FRIENDLY MESH BETWEEN THE TWO. THE GEAR ISN'T HARD TO CHANGE, BUT IT'S POSITION ON THE DISTRIBUTOR SHAFT IS CRUCIAL.

LUCKILY MSD PROVIDES THE CORRECT DIMENSIONS FOR ITS PLACEMENT ON THIS SHEET.

SIMPLY REMOVE THE PIN AND PRESS IT OFF AND THE NEW ONE ON. MAKING SURE IT'S AT FACTORY SPEC, DRILL A NEW HOLE FOR THE NEW PIN AND YOU'RE GOOD TO GO FOR THE LONG HAUL.

(JOE)>> WELL LIKE THE OLD MAID SAID TO THE PEEPING TOM, THANKS FOR LOOKING IN. WE'LL SEE YOU NEXT TIME.

Show Full Transcript

WITH A BUDGET BREAKING LIST OF INTERNALS. PLUS HOW TO CORRECTLY INSTALL YOUR DISTRIBUTOR.

(PAT)>> GLAD YOU COULD JOIN US FOR MORE ENGINE POWER. TODAY WE'RE CONTINUING ON WITH STAGE TWO OF A THREE STAGE BUILD UP OF OUR SMALL BLOCK CHEVY. LAST WEEK WE COMPLETED STAGE ONE. WE STARTED WITH A MACHINED STOCK BLOCK FROM SUMMIT RACING, ALONG WITH THEIR PRO PACK KITS, WHICH INCLUDED STOCK REPLACEMENT PISTONS, RODS, AND CRANK SHAFT. IT WAS TOPPED OFF WITH SUMMIT 170cc ALUMINUM HEADS, A WEIAND INTAKE, AND A 650 HOLLEY CARB. THEN A SHORT DYNO FLOG YIELDED IMPRESSIVE 357 HORSEPOWER AND 389 POUND FEET OF TORQUE. AND WE BUILT IT FOR LESS THAT $4,000 DOLLARS. THIS IS WHAT IT LOOKS LIKE TODAY. WE'RE REUSING THE BLOCK. THE REST GOES ON THE SHELF BECAUSE TODAY THE BUDGET GOES OUT THE WINDOW.

(JOE)>> THAT'S WHY I'M HERE. I HEARD THAT SMALL BLOCK ROARING THROUGH THE BUILDING LAST WEEK, AND WELL I DECIDED I HAD BE A PART OF THIS BUILD, ESPECIALLY SINCE WE'RE UPGRADING TO SOME BULLETPROOF PARTS THAT'LL RAISE THE CUBIC INCHES TO 383 AND THE HORSEPOWER TO MORE THAN 500. FOR EXAMPLE IN STAGE ONE WE USED THESE CAST PISTONS. NOW WE'RE UPGRADING TO THESE MOLY POWER PACK PISTONS THAT ARE FULLY MACHINED FORGINGS. NOW THEY HAVE A PHOSPHATE COATING THAT REDUCES PIN GALLING AND MICRO WELDING.

PLUS, ON THE SKIRTS, A GRAFAL COATING THAT REDUCES DRAG. THE CONNECTING RODS WE USED IN STAGE ONE WERE MORE THAN ADEQUATE FOR OUR COMBINATION THEN. NOW THOUGH WE'RE GONNA UPGRADE TO THESE MUCH BEEFIER HBEAM FORGED RODS WITH FLOATING PINS, AND THEY'LL BE ABLE TO HANDLE ALL THAT ABUSE. FOR A CAM SHAFT WE'RE GOING FROM THIS BASIC HYDRAULIC FLAT TAPPET TO THIS CUSTOM GRIND BILLET SOLID ROLLER FROM COMP. NOW THE BASE CIRCLE IS SMALLER ON THIS CAM THAN THE STAGE ONE, AND THAT'S SO IT'LL CLEAR THE CONNECTING RODS WITH OUR STROKER. NOW CHECK THE DIFFERENCE IN THE DURATION OF THESE LOBES. OVER HERE WE'VE GOT 218 INTAKE AND EXHAUST AT 50 THOUSANDTHS. OVER HERE 252 AND 260. THIS ULTIMATE ADJUSTABLE BILLET TIMING SET IS A BIG UPGRADE AS WELL, ESPECIALLY WITH ALL OF ITS ADJUSTABILITY.

UP TO SIX DEGREES ADVANCE OR RETARD TO MAKE DIALING IN THE CAM A SNAP. AND WE'LL GO FROM HYDRAULIC LIFTERS TO A SET OF SOLID ROLLERS. THOSE NEW LIFTERS, TIMING SET, AND CAM ALL CAME FROM COMP.

WHILE OUR PISTONS, RODS, AND CRANK SHAFT ARE PART OF EAGLE'S COMPETITION SERIES.

IT'S A 4340 FORGED CRANK SHAFT THAT'S GONNA BRING

OUR STROKE UP FROM THREEFOUR-80 TO THREESEVEN-50 WITH A FOURZERO-30 BORE.

(PAT)>> AND THAT'S WHERE WE PLANNED AHEAD. NOW NORMALLY WE WOULD HAVE TO GRIND ON THE BLOCK TO MAKE ROOM FOR THAT ADDITIONAL STROKE, BUT WE

ORDERED THE BLOCK WITH THE CLEARANCING ALREADY DONE. WITH THAT BEING SAID, THERE'S STILL MORE WORK TO DO. WITH THE BLOCK WASHED IT'S TIME TO FOCUS ON OIL FLOW. I'LL START IN THE OIL FILTER BOSS AREA, REMOVING ALL SHARP EDGES AND MAKING SMOOTH TRANSITIONS. THE SAME PROCESS FOR THE OIL PUMP MOUNT ON THE REAR MAIN CAP. NOW WITH THAT ADDITIONAL FLOW WE'RE GONNA PUT THAT OIL RIGHT WHERE IT NEEDS TO BE, THE MAINS. SOME PERFORMANCE ENGINES, LIKE OUR 572, HAVE GROOVE IN THE MAIN SADDLE TO PUT EXTRA OIL TO THE MAINS. SINCE OUR STOCK BLOCK DOESN'T HAVE THEM, I'LL SHOW YOU HOW TO PUT THEM IN YOURSELF. ALL IT TAKES IS A DISCARDED MAIN BEARING FOR A TEMPLATE. INSTALL IT IN THE SADDLE ALONG WITH A COUPLE OF BOLTS AND WASHERS TO KEEP IT IN PLACE. THEN USE A CUTOFF WHEEL TO GENTLY GRIND THROUGH THE BEARING INTO THE MAIN APPROXIMATELY 60 THOUSANDTHS, OR A 16TH OF AN INCH DEEP. TAKE YOUR TIME AND CHECK YOUR PROGRESS REGULARLY.

IT'S GOT TO GO A LITTLE FURTHER ON THIS SIDE, BUT THAT'S REALLY CLOSE.

WITH THE FIRST ONE DONE YOU'VE ALSO CREATED A PERFECT TEMPLATE FOR THE REST. MOVE THE BEARING TO THE NEXT SADDLE AND REPEAT THE PROCESS. FINISH IT OFF BY DEBURRING THE OIL HOLES, GORGEOUS! THAT LOOKS LIKE A MACHINE DID IT. WE'LL DRILL EXTRA HOLES IN THE NEW MAIN BEARINGS BEFORE THEY GO IN. THE PRESSED IN FRONT OIL GALLERY PLUGS CAN POP OUT UNDER HIGH PRESSURE. SO I TAPPED THEM FOR SCREW IN PIPE PLUGS, WHICH I'LL INSTALL ON FINAL ASSEMBLY.

(JOE)>> HEY THAT'S SOME NICE TECH ON THOSE MAINS, I LIKE THAT. NOW THAT INCREASED FLOW WITH ALSO INCREASE THE PRESSURE WHERE WE WANT, GIVEN THE OIL HAS THE SAME VISCOSITY.

NOW BOTTOM LINE IS THIS BLOCK'S GONNA STAND UP TO

THE RPM'S AND EXTRA HORSEPOWER WE THROW AT IT. NOW WE'RE GONNA GIVE IT A BATH AND WHEN WE COME BACK WE'LL START THROWING SOME PARTS AT IT.

(PAT)>> WE'RE BACK AND GONNA START THE BUILD OF OUR STAGE TWO SMALL BLOCK CHEVY. NOW LIKE WITH ANY HIGH PERFORMANCE ENGINE, YOU DON'T WANT TO LEAVE ANYTHING TO CHANCE, LIKE BEARING CLEARANCES. IF YOU REMEMBER IN STAGE ONE WE PLASTIGAUGED OUR CLEARANCES, WHICH WAS FINE FOR ITS POWER LEVEL AND APPLICATION.

(JOE)>> YEAH BUT FOR THIS STAGE WE'LL BE MORE PRECISE, AND THAT MEANS USING A SET OF QUALITY MICROMETERS AND A DIAL BORE GAUGE. THIS WAY WE CAN MEASURE DOWN TO 10 THOUSANDTHS OF AN INCH, AND WE'LL START WITH THE NUMBER ONE CRANK JOURNAL, AND TRANSFER THAT MEASUREMENT TO THE DIAL BORE GAUGE. TO AVOID SCRATCHING THE NEW BEARINGS WE'LL DO ONE JOURNAL AT A TIME, AND RECORD THE RESULTS TO A BUILD SHEET LIKE THIS ONE YOU CAN DOWNLOAD FROM OUR WEBSITE.

(PAT)>> THE MINIMUM VERTICAL OIL CLEARANCE FOR A HIGH PERFORMANCE ENGINE SHOULD BE ONE THOUSANDTHS PER INCH OF SHAFT DIAMETER. SO FOR OUR SMALL BLOCK CHEVY THE MINIMUM OIL CLEARANCE SHOULD BE 25 TEN THOUSANDTHS AND WE HAVE BETWEEN 30 AND 33 TEN THOUSANDTHS, SO WE'RE IN THE GOOD. WITH THE MAINS ALL SET UP WE CAN NOW DRILL THE EXTRA HOLES IN THE NEW BEARINGS.

WE'LL SPACE TWO OF THEM EVENLY ON EACH SIDE, 60 THOUSANDTHS IN DIAMETER. WE'LL MAKE SURE TO DEBURR THEM AFTERWARDS. WITH THAT HANDLED, APPLY A DAB OF HIGH PRESSURE LUBE TO THE REAR MAIN SEAL AND INSTALL IT. NOW WE CAN PLACE OUR MODIFIED BEARINGS IN OUR MODIFIED SADDLES. AND WITH SOME HIGH VISCOSITY LUBE ON THEM WE'RE READY TO CAREFULLY LAY THE CRANK IN FOR GOOD. OUR LUBE CAPS CAN GO ON NOW. WE'LL TORQUE THE CAPS IN A CIRCULAR PATTERN FROM THE INSIDE OUT, FIRST AT 40, THEN FINALLY TO 70 POUND FEET. AS ALWAYS WE'LL CHECK THE CRANK'S THRUST. IT'S AT A SWEET FIVE THOUSANDTHS. NEXT I'M GONNA DROP A COUPLE OF RINGLESS PISTON AND ROD ASSEMBLIES IN THE BLOCK. HERE'S WHY, WE WANT TO MAKE ABSOLUTELY SURE THE CLEARANCING THAT WAS DONE INSIDE THE BLOCK IS

COMPATIBLE WITH OUR PARTS COMBINATION. IF WE NEED TO DO ANY MORE GRINDING NOW IS THE TIME TO KNOW, NOT DURING FINAL ASSEMBLY. WE ARE GOOD TO GO! TIME TO PUT SOME PLUGS IN OUR NEWLY THREADED OIL GALLERIES. MAKE SURE TO PUT SOME HIGH PRESSURE LUBE ON THEM OR

THEY CAN GALL GOING IN. SEALANT ISN'T REQUIRED ON THEM SINCE THEY'RE INSIDE THE ENGINE. NOW OUR COMP CUSTOM SOLID ROLLER GETS CAREFULLY SLID IN. THIS IS THE MOST AGGRESSIVE CAM PROFILE WE CAN PUT IN THIS ENGINE WITHOUT HAVE TO DO MAJOR CHANGES TO PARTS ELSEWHERE. KEEPING THE CAM IN PHASE EXACTLY WHERE WE WANT IT IS THIS COMP ULTIMATE ADJUSTABLE TIMING SET. WITH OUR BUTTON BACK IN PLACE, THE FASTENERS ARE TORQUED TO 28 POUND FEET. DEGREEING THE CAM IS THE NEXT STEP ON OUR LIST. I'M SETTING UP THE INTAKE CENTER LINE ON 108 DEGREES, WHICH IS TWO DEGREES ADVANCED. WHEN FINISHED, THE INNER BOLTS GET TORQUED TO 13 POUND FEET.

DEGREEING A CAM SHAFT IS A MUST FOR ANY HIGH PERFORMANCE ENGINE BECAUSE IT'S THE INTAKE CENTER

LINE'S POSITION RELATIVE TO ITS LOBE SEPARATION THAT DICTATES THE ENGINE'S POWER BAND. NOW I'LL EXPAND ON THAT LATER BECAUSE RIGHT NOW WE'RE GONNA CHECK FOR PISTON TO VALVE CLEARANCE, AND NO USING CLAY HERE. WE'RE GONNA USE OUR DEGREE WHEEL AND A DIAL INDICATOR TO GET AN EXACT MEASUREMENT. I'LL LEAVE THE NUMBER ONE PISTON AND ROD ASSEMBLY IN THE BORE. I TOOK OUR NEW CYLINDER HEAD AND PULLED THE SPRINGS OFF NUMBER CYLINDER AND REPLACED THEM WITH CHECKING SPRINGS. NOW I'LL PLACE SOME LONG FEELER GAUGES THAT ARE THE SAME COMPRESSED THICKNESS AS OUR NEW HEAD GASKET ON THE DECK. IN OUR CASE THAT'S 27 THOUSANDTHS. A SET OF ROCKERS IS NEXT TO GO ON AND GET MOCKED UP.

NOW BECAUSE OF THE INCREASED POWER LEVEL AND RPM WE'RE GONNA HAVE, WE OPTED TO INSTALL A SET OF JESEL SPORTSMAN SERIES SHAFT ROCKERS. THEY'RE BUILT OUT OF 2024 ALUMINUM THAT'S BEEN CNC'ED AND SHOT PEENED, AND THEY FEATURE CENTERLESS GROUND SHAFTS, NEEDLE BEARINGS

THROUGHOUT, AND EVEN HAVE TOOL STEEL ADJUSTERS.

WE ARE DANGEROUSLY CLOSE TO CHECKING OUR PISTON TO VALVE CLEARANCE, BUT BEFORE WE CAN GET STARTED WE HAVE TO FIND OUR PUSH ROD LENGTH. SO I'M GONNA TAKE A COUPLE OF ADJUSTABLE PUSH RODS AND DROP THEM INTO THE LIFTERS WHILE THE CAM IS ON ITS BASE CIRCLE. THE ROCKERS GET BOLTED DOWN AND THE PUSH RODS GET EXTENDED. THEN THE LASH IS SET WITH A FEELER GAUGE TO 20 THOUSANDTHS ON EACH ONE. THE LENGTH IS NOW SET AND THEY'LL STAY PUT FOR OUR PISTON TO VALVE CLEARANCE CHECK, BUT WHEN WE PULL THEM OUT WE'LL GET A LENGTH ON THEM TO ORDER OUR NEW ONES.

A MAGNETIC BASE DIAL INDICATOR GETS POSITIONED ON THE INTAKE VALVE SPRING RETAINER. NEXT I'LL ROTATE THE DEGREE WHEEL UNTIL IT GETS TO 10 DEGREES AFTER TDC ON SPLIT OVERLAP, MEANING THE EXHAUST VALVE IS ALMOST CLOSED AND THE INTAKE VALVE IS STARTING TO OPEN. THEN PRESS DOWN ON THE INTAKE ROCKER UNTIL YOU FEEL THE VALVE CONTACT THE TOP OF THE PISTON. THE AMOUNT OF TRAVEL ON THE DIAL INDICATOR IS THE EXACT AMOUNT OF CLEARANCE IT HAS. THE EXHAUST GETS THE SAME TREATMENT. THE ONLY DIFFERENCE IS THAT THE DEGREE WHEEL NEEDS TO BE AT 10 DEGREES BEFORE TDC ON SPLIT OVERLAP. THE MINIMUM CLEARANCES WE'RE LOOKING FOR ARE 60 THOUSANDTHS ON THE INTAKE AND 110 THOUSANDTHS ON THE EXHAUST TO KEEP THINGS SAFE. WE ACTUALLY HAVE 111 THOUSANDTHS ON THE INTAKE AND 116 THOUSANDTHS ON THE EXHAUST. SO WE'RE IN THE CLEAR.

THIS IS ABSOLUTELY NECESSARY TO CHECK ON CAM SHAFTS WITH A BIG DURATION AND BIG LIFT BECAUSE IF YOU DON'T HAVE ENOUGH CLEARANCE YOUR ENGINE IS GOING TO TURN INTO A ROMAN CANDLE WHEN YOU RUN IT. SO NOW THAT ALL OUR TIGHT CLEARANCES ARE CHECKED WE'RE

FINALLY READY TO START ASSEMBLY AND WE'LL GET TO THAT AFTER THE BREAK.

(JOE)>> HEY WE'RE BACK AND I'VE GOT TO SAY THAT WAS SOME COOL AND USEFUL TECH THAT PAT JUST SHARED WITH US. THE KIND OF STUFF THAT TAKES TIME BUT IT'S WELL WORTH IT FOR THE PEACE OF MIND. AND YOU KNOW WHAT, WE'VE GOT MORE BEFORE

WE START ASSEMBLY. IN FACT WE'VE GOT TO CHECK OUR ROD CLEARANCES LIKE WE DID OUR MAINS. WE'LL START ON THE FRONT JOURNAL THAT CARRIES THE NUMBER ONE AND TWO RODS, AND USE THE NUMBERS TO SET UP OUR DIAL BORE GAUGE.

(PAT)>> HEY, YOU GOT HER, YOU NAILED IT.

(JOE)>> THEN OF COURSE WE'LL FILL IN THESE BLANKS ON OUR BUILD SHEET. WE'LL USE THE ROD VICE TO TORQUE THE BOLTS TO

63 POUND FEET, JUST LIKE IN FINAL ASSEMBLY. THE READING ON THE DIAL IS OUR ACTUAL CLEARANCE. OF COURSE WE'LL MAKE SURE TO LOG IN THIS DATA ON OUR

BUILD SHEET AS WELL.

(PAT)>> WITH EVERYTHING IN THE GREEN ZONE WE'RE FINALLY READY TO MATE UP OUR RODS AND PISTONS. NOW WE HAVE FLOATING WRIST PIN ASSEMBLIES, WHICH ARE HIGHLY RECOMMENDED FOR HORSEPOWER LEVELS ABOVE 400. PLUS THEY'RE JUST EASIER TO ASSEMBLE THAN IF YOU HAVE TO HEAT UP A ROD FOR A PRESS FIT. THE WRIST PINS ARE RETAINED IN THE PISTONS WITH SIR CLIPS. THESE PISTONS, COMBINED WITH OUR HEADS AND OTHER PARTS, WILL GIVE US A CALCULATED COMPRESSION RATIO OF 11.00 TO ONE.

(JOE)>> WELL LIKE OUR PISTONS, WE'VE GOT MOLY RINGS IN OUR POWER PACK KIT.

THEY'RE DESIGNED FOR PRECISION LANDS, AND THE TOP RING AND SECOND RING ONLY MEASURE ONE AND A HALF MILLIMETERS.

THE OIL RING MEASURES THREE MILLIMETERS. NOW SMALLER RINGS MEAN LESS FRICTION. LESS FRICTION MEANS MORE HORSEPOWER. BUT AS WITH ANY PERFORMANCE BUILD WE FIRST HAVE TO FILE FIT THESE RINGS, AND FOR THAT WE'LL USE OUR GOODSON ELECTRIC FILER. WE START WITH THE SECOND RING, WHICH COMES OUT OF THE BOX WITH ALMOST NO GAP AT ALL. WE'LL FILE OFF ABOUT FIVE THOUSANDTHS, CHECK IT IN THE BORE WITH A FEELER GAUGE, YEP FIVE THOUSANDTHS, AND WE'LL CONTINUE SNEAKING UP ON IT. THERE'S 15 THOUSANDTHS, JUST A LITTLE MORE TO GO. FINALLY WE'RE AT 20 THOUSANDTHS, WHICH IS OUR TARGET. THE TOP RING GAP IS THE MOST CRITICAL AND NEEDS TO BE FOUR AND A HALF THOUSANDTHS PER INCH OF CYLINDER BORE. SINCE OUR BORE'S AT FOURZERO-30, THAT CALCULATES TO 18 THOUSANDTHS RING GAP.

(PAT)>> WITH ALL OF OUR RINGS GAPPED AND CLEANED WE CAN START INSTALLING THEM FROM THE OIL SCRAPER UP. THE SECOND RING IS NEXT, AND HERE'S SOMETHING IMPORTANT. THE TOPS OF THE SECOND AND TOP RINGS ARE MARKED AND NEED TO BE INSTALLED THAT WAY. SINCE THE RINGS ARE PRETTY DELICATE, YOU ALWAYS WANT TO TAKE YOUR TIME DOING THIS. I LIKE TO USE SPECIFIC BREAK IN OIL ON THE CYLINDERS AND ON THE PISTONS AND RINGS DURING ASSEMBLY. NOW BY THE TIME YOU GET BACK WE'LL HAVE THEM ALL STUFFED IN THE BLOCK. SO STAY WITH US.

(ANNOUNCER)>> COMING UP, THE QUICK AND CORRECT

TECHNIQUE FOR DISTRIBUTOR INSTALLATION.

(PAT)>> BEAUTIFUL!

(JOE)>> YES SIR, DID YOU EVER MEET AN ENGINE YOU DIDN'T LIKE?

(PAT)>> I HAVEN'T ACTUALLY.

(JOE)>> I DIDN'T THINK SO. WITH ALL OF OUR UPGRADED PISTONS AND RODS INSTALLED, AND THE ROD BOLTS TORQUED TO 63 POUND FEET, THIS GETS US CLOSE TO FINISHING UP OUR SHORT BLOCK.

(PAT)>> NEXT OUR CAST ALUMINUM TIMING COVER CAN GO BACK ON. NOW THE FACT THAT IT'S ONE PIECE AND DOES NOT GIVE US ACCESS TO THIS TRICK BILLET ADJUSTABLE TIMING GEAR IS OKAY FOR THIS STAGE BECAUSE IN STAGE THREE WE'LL USE A TWO PIECE COVER IN CASE WE WANT TO DO SOME CAM TWEAKING. NOW WE'LL REUSE THE SFI APPROVED BALANCER USED IN STAGE ONE, WHICH IS A MUST FOR THE INCREASE IN POWER AND RPM THAT WE'RE GONNA BE MAKING.

(JOE)>> WE WERE ALSO LOOKING AHEAD WHEN WE USED THIS SUMMIT PUMP AND PAN KIT IN STAGE ONE. BOTH WILL ENSURE THIS LITTLE BEAST IS WELL SUPPLIED WITH OIL, AND THAT IS OFFICIALLY IT FOR OUR SHORT BLOCK. WE SLOWED DOWN THIS TIME TO SHOW YOU MORE TECH THAN USUAL BUT YOU KNOW, KNOWLEDGE IS POWER, AND IN THIS CASE HORSEPOWER. WELL NEXT TIME WE'VE GOT SOME HARDCORE RACE PARTS FOR THE TOP END.

(PAT)>> CASE IN POINT, TO WORK WITH THOSE AFR ALUMINUM HEADS WE'RE GONNA BE USING ONE OF THEIR TITAN TXR RACE MANIFOLDS. NOW IT'S A TWO PIECE COMPOSITE DESIGN MADE OUT OF PLASTIC, WHICH WILL RUN UP TO 30 DEGREES COOLER THAN ALUMINUM. PLUS BE ABOUT 11 POUNDS LIGHTER. AFR SAYS THAT IT'S WORTH 15 HORSEPOWER AND 15 POUND FEET OVER THEIR COMPETITION, AND WE'RE GONNA SEE EXACTLY HOW MUCH POWER STAGE TWO MAKES IN THE DYNO ROOM BUT IT SHOULD BE WELL OVER 500 HORSEPOWER. OF COURSE THAT'S NOT THE FINALE. THE BEST AND BADDEST IS YET TO COME BECAUSE IN STAGE THREE WE'LL REUSE MOST OF THE TOP SHELF INTERNALS AND PUT THEM IN AN AFTERMARKET BLOCK THAT'S DESIGNED TO HANDLE ALL THAT ABUSE. THEN WE'RE GONNA PRESSURIZE IT ALL WITH A CENTRIFUGAL SUPERCHARGER AND IT'S GONNA MAKE POWER NUMBERS YOU'RE NOT GONNA WANNA MISS.

(JOE)>> YOU ALL KNOW THAT HEAT IS YOUR ENGINE'S ENEMY. WELL THIS COULD BE ITS NEW FRIEND. IT'S DEI'S CRYOTWO SYSTEM THAT'S ALL ABOUT REDUCING FUEL AND AIR TEMPERATURES TO MAKE MORE POWER. IT HARNESS THE PROPERTIES OF LIQUID CO TWO TO REDUCE INTAKE TEMPERATURES BY AS MUCH AS 50 DEGREES.

NOW THE FOUNDATION IS A FIVE OR 10 POUND BOTTLE LIKE THIS WITH ALL THE ACCESSORIES YOU NEED.

NOW IT'S MODULAR AND EXPANDABLE SO YOU CAN ADD THINGS LIKE THIS FUEL CHILLER. IT'S GOOD FOR TURBOCHARGED, SUPERCHARGED, AND OF COURSE NATURALLY ASPIRATED ENGINES. SINCE YOUR BRAKE PADS AND ROTORS HAVE TO WORK TOGETHER IT MAKES SENSE THAT THEY SHOULD COME TOGETHER AS A KIT, LIKE EBC'S STAGE FIVE KIT. NOW IT'S IDEAL FOR STREET AND OCCASIONAL TRACK USE.

IT COMES WITH A SET OF THEIR YELLOW STUFF BRAKE PADS FOR HIGH FRICTION BRAKING, AND THEIR GD SERIES DIMPLED AND SLOTTED ROTORS. NOW THESE SLOTS HELP THE BRAKE PADS AND ROTORS WEAR EVENLY, AND THE MATERIAL IN THE PADS CONTAINS NO HEAVY METAL. SO IT'S LESS ABRASIVE TO THE ROTORS. IT'S AN IDEAL COMBO FOR YOUR NEXT BRAKE UPGRADE.

(PAT)>> FOR ALL OF YOU CAR, TRUCK, AND STREET ROD BUILDERS LOOKING DAMPEN EXTERIOR NOISE AND OR ENHANCE YOUR STEREO SOUND, LIZARD SKIN SOUND CONTROL IS AN ENVIRONMENTALLY SAFE CLASS "A" FIRE RATED COATING THAT'S IN AN EASY SPRAY ON APPLICATION. IT ALSO DAMPENS VIBRATIONS AND SEALS OUT MOISTURE TO KEEP YOUR PRIZED PROJECT PROTECTED FOR YEARS TO COME. IT COMES IN A TWO GALLON PAIL THAT WILL EASILY COVER MOST INTERIORS, AND IT'S EASILY CLEANED UP WITH SOAP AND WATER. YOU CAN FIND YOURS AT SUMMIT RACING FOR AROUND $165 BUCKS.

(MIKE)>> INSTALLING A DISTRIBUTOR IS A POPULAR TOPIC IN OUR EMAIL BAG, AND MOST OF THEM ARE ASKING, HOW DO WE GET SO LUCKY DROPPING IN A DISTRIBUTOR AND GETTING AN IMMEDIATE FIRE UP EVERY TIME?

(PAT)>> WELL THERE'S NO LUCK INVOLVED. IT'S A SIMPLE UNDERSTANDING OF POSITIONING AND THE PROCESS WE'RE GONNA SHOW YOU HERE APPLIES TO ALL ENGINES THAT HAVE DISTRIBUTORS.

(MIKE)>> THE FIRST THING TO DO IS MAKE SURE THE NUMBER ONE CYLINDER IS COMING UP ON TOP DEAD CENTER ON THE COMPRESSION STROKE. THERE'S A COUPLE OF WAYS TO DO THAT. THE FIRST, AND GENERALLY EASIEST, IS TO HAVE THE NUMBER ONE CYLINDER SPARK PLUG REMOVED.

NOW PLACE YOUR FINGER OVER THE HOLE AND TURN

THE ENGINE OVER SLOWLY. WHEN THE PISTON COMES UP ON THE COMPRESSION STROKE IT WILL FORCE AIR OUT OF THE CYLINDER AND PUSH YOUR FINGER OFF ITS SEAL LIKE THIS.

(PAT)>> THE SECOND WAY IS MORE INVOLVED AND REQUIRES YOU TO PULL A VALVE COVER.

WHEN YOU'VE TURNED THE ENGINE OVER AND BOTH VALVES ARE CLOSED AND THE ROCKER'S NOT MOVING, YOU'RE COMING UP ON THE COMPRESSION STROKE. NOW SLOWLY TURN THE CRANK TO GET THE TIMING MARK, OR ZERO DEPENDING ON YOUR BALANCE, ABOUT 30 DEGREES BEFORE ON THE TIMING POINTER. TO PUT IT IN SIMPLE TERMS, THERE ARE 360 DEGREES IN A CIRCLE. SO THAT MEANS 30 DEGREES IS A LITTLE LESS THAN ONETENTH OF THAT, WHICH IS A VERY SMALL DISTANCE. NOW IT'S TIME TO DROP THE DISTRIBUTOR IN. THE IMPORTANT THING IS TO POSITION THE ROTOR WHERE YOU WANT IT, NOT WHERE IT FALLS. THIS IS IMPORTANT FOR YOUR WIRE ROUTING TO LOOK NEAT AND CLEAN. TO MAKE IT DROP ALL THE WAY DOWN ALL YOU HAVE TO DO IS ROTATE THE ENGINE AND THE DISTRIBUTOR WILL INDEX THE OIL PUMP DRIVE. THEN SIMPLE REVERSE THE ROTATION BACK TO 30 DEGREES BEFORE TDC. NOW THE CAP GOES ON, THE WIRES ARE ROUTED TO THE SPARK PLUGS, AND HERE'S THE RESULTS. [ ENGINE STARTS ]

(MIKE)>> SO ALL YOU NEED TO DO IS FOLLOW THAT SIMPLE

PROCEDURE AND YOU'LL NEVER SEE FLAMES COME OUT OF YOUR CARBURETOR AGAIN.

PLUS IT'LL JUST MAKE YOUR LIFE SIMPLER.

(PAT)>> ONE MORE THING ABOUT DISTRIBUTORS, YOU CAN'T RUN AN IRON GEAR ON A STEEL CAM. IN THIS CASE THE MATERIALS HATE EACH OTHER AND YOU'LL GET ALMOST IMMEDIATE FAILURE ON YOUR DISTRIBUTOR GEAR. A COMPOSITE, OR BRONZE, GEAR LIKE THIS ONE FROM MSD WILL SOLVE THE PROBLEM. THE BRONZE MATERIAL IS SOFTER THAN THE CAM SHAFT GEAR, ALLOWING FOR A FRIENDLY MESH BETWEEN THE TWO. THE GEAR ISN'T HARD TO CHANGE, BUT IT'S POSITION ON THE DISTRIBUTOR SHAFT IS CRUCIAL.

LUCKILY MSD PROVIDES THE CORRECT DIMENSIONS FOR ITS PLACEMENT ON THIS SHEET.

SIMPLY REMOVE THE PIN AND PRESS IT OFF AND THE NEW ONE ON. MAKING SURE IT'S AT FACTORY SPEC, DRILL A NEW HOLE FOR THE NEW PIN AND YOU'RE GOOD TO GO FOR THE LONG HAUL.

(JOE)>> WELL LIKE THE OLD MAID SAID TO THE PEEPING TOM, THANKS FOR LOOKING IN. WE'LL SEE YOU NEXT TIME.