More Overland Scout Episodes

XOR - Xtreme Off-Road Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

PSC Motorsports

Performance Steering Components PSC Hydraulic Steering Kit Replacement Cylinders

Centimark

A leading provider of polished concrete floor systems and epoxy floor systems to the industrial, commercial and retail markets. QuestMark serves our local flooring customers across North America with a commitment to professionalism. We remain at the forefront of modern flooring technologies. We provide a comprehensive Safety & Risk Program that ensures a safe work environment with on-going training, state-of-the-art and equipment.

Lincoln Electric

Official welding equipment of XOR

Swisstrax

Vinyltrax & Ribtrax Modular Flooring Tiles

The Industrial Depot

Tools, Shop Supplies, Hardware

Episode Transcript

(NARRATOR)>> TODAY JEREMY AND ELIZA ARE GETTING THEIR NEW AXLES UNDER THEIR OVERLAND SCOUT.

(ELIZA)>> YEP, WE'RE IN!

(NARRATOR)>> AND THEY'RE ADDING HYDRAULIC ASSISTED STEERING TO HELP POINT OUR 37 INCHES TIRES IN THE RIGHT DIRECTION. IT'S ALL HERE ON XOR.

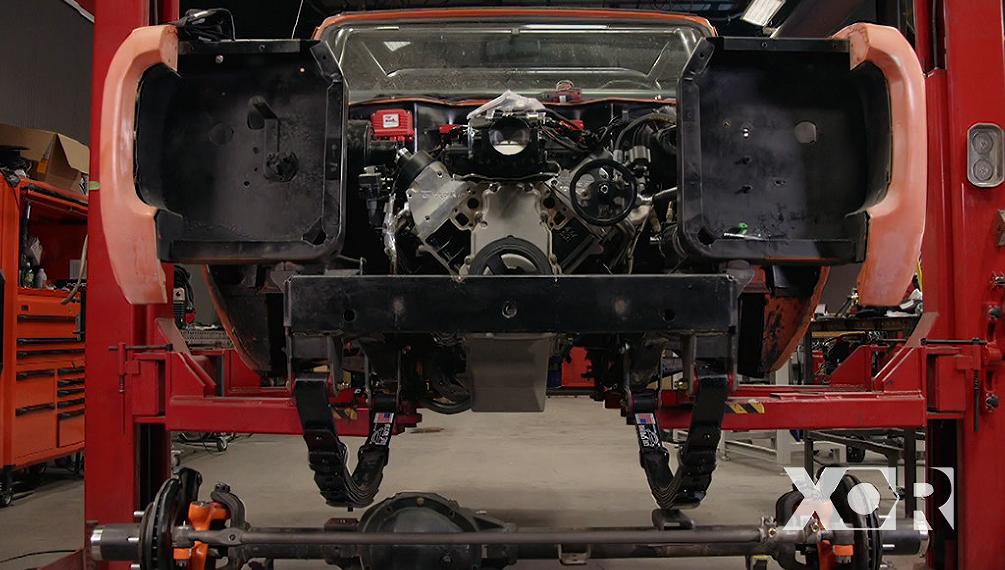

(JEREMY)>> HEY GUYS, WELCOME TO XOR. TODAY WE'RE BACK ON OUR "OVERLAND SCOUT", AND SINCE YOU SAW IT LAST WE WENT AHEAD AND SPRAYED A LINER ON THE INSIDE TO MAKE IT EASIER TO CLEAN OUT. WE ALSO INSTALLED OUR SUSPENSION TO CLEAR OUR 37'S. NOW WE KNOW OUR STOCK STEERING WON'T WORK WELL WITH OUR 37 INCH TALL TIRES. SO AN UPGRADED HYDRAULICALLY ASSISTED STEERING SETUP IS IN ORDER.

(ELIZA)>> AND THE OTHER HALF OF THAT IS GETTING OUR NEW STEERING SYSTEM CONNECTED TO OUR AXLES. NOW THAT WE'VE GOT OUR AXLES REGEARED AND LOCKED WE WANT TO MAKE SURE THAT WHEN OUR SUSPENSION SYSTEM FLEXES THAT OUR SCOUT STEERS EFFORTLESSLY WHEN WE'RE HITTING THE TRAILS.

(JEREMY)>> THIS IS OUR STOCK STEERING GEAR BOX OUT OF OUR SCOUT. WE SENT THIS IN TO PSC TO HAVE IT MODIFIED AND REBUILT WITH THE FITTINGS TO MAKE THIS WHOLE SYSTEM WORK. WE ALSO GOT THEIR PUMP THAT FITS THE LS, RESERVOIR AND CYLINDER, SOME HARDWARE, AND THE HOSES AND FITTINGS TO HOOK THIS ALL UP. SO THE FIRST THING WE'VE GOT TO DO IS PUT THIS BACK IN OUR SCOUT.

WHEN REINSTALLING THE GEAR BOX IT'S A GOOD IDEA TO USE ALL NEW FASTENERS. WE'RE GOING WITH GRADE EIGHT BOLTS BECAUSE LET'S FACE IT, STEERING IS ONE THING YOU DON'T WANT TO LOSE OUT ON THE TRAIL. [ drill spinning ]

(JEREMY)>> WHEN IT COMES TIME TO MOUNT THE PUMP, MAKE SURE YOU GET THE CORRECT BRACKET FOR YOUR SPECIFIC ENGINE. OURS HAPPENS TO MOUNT DIRECTLY TO THE CYLINDER HEAD.

MAKE SURE YOU MOUNT THE PUMP SO YOU HAVE EASY ACCESS TO BOTH THE FEED AND RETURN FITTINGS. WE'RE GONNA POSITION OURS ON THE SAME SIDE OF THE ENGINE BAY AS OUR GEARBOX. WITH THE PUMP INSTALLED WHAT WE'VE GOT TO DO NOW IS MOUNT OUR RESERVOIR AND HOOK UP OUR LINES. ABOUT TWO AND A QUARTER.

[ drill spinning ]

(JEREMY)>> AGAIN, WE'RE USING GRADE EIGHT HARDWARE FOR THE BOLTS THAT SECURE THE RESERVOIR FROM UNDERNEATH THROUGH THE WHEEL WELL. THIS KIT USES PUSH LOCK FITTINGS, WHICH MAKES CONNECTING HOSES AS SIMPLE AS THE NAME IMPLIES. JUST FULLY PUSH THE HOSES ON AND THEY'RE LOCKED IN PLACE.

NOW WITH ALL THE FITTINGS IN PLACE WE CAN GO AHEAD AND PUT OUR HOSES IN AND CUT THEM TO LENGTH. AFTER THAT WE'LL MOUNT THE CYLINDER ON THE AXLE, RUN THOSE HOSES TO, AND WE SHOULD BE ALL SET.

(ELIZA)>> WITH OUR FRONT AXLE REGEARED, LOCKED, AND STRIPPED DOWN, WE ARE NOW READY TO INSTALL STEERING KNUCKLES. SO WE FIRED UP THE OLD COMPUTER, WENT TO SUMMIT RACING DOT COM TO PICK UP A HIGH STEER KIT AND A HIGH STEER KNUCKLE ASSEMBLY. OUR HIGH STEER KNUCKLE ALREADY COMES EQUIPPED TO RECEIVE YOUR TIE ROD OVER THE KNUCKLE, WHERE AS YOUR STOCK APPLICATION WOULD HAVE YOU MOUNTING UNDER. THIS IS FOR CLEARANCE. OUR HIGH STEER MOVES OUR DRAG LINK UP AND OVER. THIS IS FOR BETTER CROSS STEERING. WHILE WE WERE THERE WE ALSO PICKED UP ALL THE BALL JOINTS AND HARDWARE NECESSARY FOR INSTALLATION. THE COOL THING ABOUT YOUR HIGH STEER KIT IS THAT IT COMES WITH CONE WASHERS FOR INSTALLATION ON THE OPPOSITE SIDE IF NECESSARY. SO WHEN YOU WANT TO KNOW WHAT BALL JOINT GOES WHERE, THE UPPER BALL JOINT IS ACTUALLY LONGER AND HAS A HOLE TO RECEIVE YOUR COTTER PIN WHEN YOU PUT ON YOUR CASTLE NUT. DON'T WORRY IF YOU DON'T HAVE A BALL JOINT PRESS. YOU CAN RENT ONE FROM JUST ABOUT ANY AUTO PARTS STORE. [ drill spinning ]

(ELIZA)>> DON'T FORGET TO INSTALL THE SNAP RING. IT HELPS KEEP THE BALL JOINT IN PLACE. GO, SNAP RING'S IN, PUT THE LITTLE BOOT ON.

THE SHAPE OF OUR KNUCKLES REQUIRES THE USE OF A TAPERED PRESS ADAPTER TO SEAT THE UPPER BALL JOINT CORRECTLY.

[ drill spinning ]

(ELIZA)>> PUT ON THE SNAP RING.

GET THE BOOT ON.

INSTALLING THE LOWER GREASE NUT.

SITS RIGHT ON IT, AND WE CAN GREASE IT. ONE HAND! OKAY, GET READY TO PUT THIS IN.

ONCE YOU GET THE KNUCKLE SEATED INTO THE INNERC OF THE AXLE HOUSING, THE TORQUE SPECS FOR THE UPPER CASTLE NUT IS 100 FOOT POUNDS, AND THE LOWER IS 70.

[ ratchet spinning ]

(ELIZA)>> AND AFTER TIGHTENING AND TORQUING DON'T FORGET TO INSTALL YOUR COTTER PIN.

OKAY!

(NARRATOR)>> UP NEXT WE'LL GET OUR AXLES ALL WRAPPED UP AND INSTALLED IN OUR SCOUT, STICK AROUND!

(JEREMY)>> HEY GUYS, WELCOME BACK TO XOR AND THE AXLE AND STEERING UPGRADE ON OUR "OVERLAND SCOUT". AFTER INSTALLING A UJOINT IN OUR NEW 30 SPLINED AXLE SHAFTS, IT'S AS EASY AS JUST SLIDING THEM INTO PLACE. COAT THE AXLE SHAFT WITH GREASE BEFORE INSTALLING THE SPINDLE.

[ hammer tapping metal ]

(JEREMY)>> WE'RE REUSING OUR STOCK CALIPER MOUNT AND DUST SHIELD. SINCE IT CAN BE INSTALLED IN ANY POSITION IT'S A GOOD IDEA TO NOTE THE CALIPER'S LOCATION BEFORE DISASSEMBLY. [ drill spinning ]

(JEREMY)>> NOT ONLY WILL WE APPLY GREASE INSIDE THE HUB, SINCE THE BEARINGS RIDE DIRECTLY ON THE SPINDLE, WE ALSO LIKE TO COAT THE SPINDLE ITSELF.

WE ALREADY INSTALLED THE INNER WHEEL BEARING AND SEAL IN THE HUB. SO UP NEXT IS THE OUTER BEARING.

THAT'S FOLLOWED BY THE INNER LOCKING NUT THAT GETS TIGHTENED WITH THE SPINDLE NUT SOCKET. DON'T WORRY, YOU CAN RENT THOSE TOO. NEXT IS THE LOCK WASHER...

...FOLLOWED BY THE OUTER LOCKING NUT.

BEFORE INSTALLING THE LOCKING HUB, PACK THE HUB WITH PLENTY OF GREASE TO HELP PROLONG THE LIFE OF THE BEARINGS.

THE LOCKING HUB BODY IS SECURED WITH TWO SNAP RINGS. ONE FOR THE AXLE SHAFT, AND THE OTHER FOR THE HUB.

(ELIZA)>> LAST PART OF GETTING OUR FRONT AXLE READY FOR INSTALL.

WE'RE DONE!

I NEED TO GO YOUR WAY JUST A LITTLE BIT. YEP, WE'RE IN!

(JEREMY)>> WHEN MOUNTING YOUR HYDRAULIC CYLINDER IT'S IMPORTANT TO KEEP IT AS PARALLEL TO THE TIE ROD AND BAR AS POSSIBLE, AND JUST TACK IT IN PLACE. THAT WAY YOU CAN CHECK FOR ANY CLEARANCE ISSUES. [ welder crackling ]

(JEREMY)>> WELL NOW I'VE JUST GOT TO MAKE SURE I CAN CYCLE THE STEERING ALL THE WAY OVER TO THIS SIDE. WE'VE GOT A LITTLE BIT OF PRESSURE. ACTUALLY IT'S MORE A VACUUM RIGHT NOW FIGHTING ME, ALL RIGHT, SO BRACKETS DON'T TOUCH, CLEAR THE PUMPKIN, CLEARANCE, CLEARANCE, CLEARANCE. WHEN IT ALL SITS IN THERE AND OUR TIRES ARE RUNNING TRUE STRAIGHT DOWN THE ROAD WE'VE GOT HYDRAULIC ASSIST. NOW BURN THEM IN! [ welder crackling ]

[ welder crackling ]

(JEREMY)>> THE CYLINDER FITTINGS IN THE KIT ARE ACTUALLY REUSABLE. THAT WAY IF YOU CUT OR BREAK A HOSE ON THE TRAIL ALL YOU HAVE TO DO IS REPLACE JUST THE HOSE.

(ELIZA)>> TO RIGHT ABOUT THERE. NEED TO GO YOUR WAY AND UP JUST A LITTLE BIT. THAT SHOULD BE FORWARD RIGHT THERE. OKAY, RIGHT THERE! ALL RIGHT, COME DOWN, WE'RE IN!

(JEREMY)>> PERFECT! [ welder crackling ]

(JEREMY)>> NOW WE KNEW OUR SHOP FLOOR WAS GONNA TAKE THE MOST ABUSE OUT OF PRETTY MUCH ANYTHING IN HERE, AND BEFORE WE BROUGHT ALL OF OUR EQUIPMENT BACK IN WE HAD THE OLD CONCRETE RECONDITIONED FOR MANY MORE YEARS OF ABUSE, AND HERE'S HOW IT HAPPENED. RESURFACING A CONCRETE FLOOR THE RIGHT WAY IS ACTUALLY A LOT OF WORK, AND THE GUYS FROM QUESTMARK ARE SOME OF THE VERY BEST IN THE BUSINESS. THEY STARTED BY CUTTING THE FLOOR JOINTS TO CLEAN THEM OUT AND EXPOSE FRESH CONCRETE.

THEN THE ENTIRE SURFACE WAS GROUND UP WITH A 480 VOLT ONE TON ELECTRIC GRINDER. THE CONCRETE DUST WAS NOT ONLY COLLECTED DIRECTLY OFF THE GRINDER, IT WAS SWEPT UP FOR REMOVAL AND VACUUMED OUT OF THE FLOOR JOINTS.

FROM THERE THEY WERE FILLED WITH A FLEXIBLE EPOXY TO GIVE US A COMPLETELY SMOOTH SURFACE ONCE THEY WERE DONE. NOW THIS SPECIAL FORMULA ALLOWS THE SLABS OF THE FLOOR TO MOVE INDEPENDENTLY, YET IT KEEPS THEM BONDED TOGETHER AND KEEPS DIRT, AND DUST, AND SMALL PARTS OUT OF THE JOINTS.

ONCE THE EPOXY WAS DRY THE FLOOR WAS THEN GROUND SMOOTH YET AGAIN AND VACUUMED CLEAN ONE MORE TIME.

(ELIZA)>> A LAYER OF GROUT COAT WAS SPREAD ON TOP OF THE CONCRETE TO HELP FILL IN ALL OF THE CHIPS, SCRATCHES, AND SMALL HOLES LEFT FROM YEARS OF ABUSE.

AND THEN ONE LAST TIME THE SURFACE WAS GROUND SMOOTH. AFTER ONE LAST THOROUGH CLEANING, A DARK CHARCOAL GRAY STAIN WAS APPLIED TO THE FLOOR SO IT WOULDN'T BE SO BRIGHT UNDER ALL OF OUR TV LIGHTS. THE LAST STEP WAS BURNISHING THE FLOOR. THAT HELPS PROTECT IT FROM ANY NEW STAINS. NOW WE THINK OUR NEW FLOOR LOOKS AWESOME, AND WE CERTAINLY KNOW IT IS READY FOR ANYTHING WE CAN THROW AT IT.

(JEREMY)>> NOW THERE'S A LOT OF BODY DAMAGE ON THIS DRIVER'S SIDE DOOR. THE COOL THING IS THE PASSENGER'S SIDE DOOR IS UNTOUCHED. SO WE'RE GONNA USE A PIECE OF CARDBOARD, MAKE A TEMPLATE, AND TRANSFER THAT OVER TO THE DRIVER'S SIDE DOOR.

BY MAKING A CARDBOARD TEMPLATE THIS WAY YOU GET TWO PATTERNS. AN OUTSIDE TEMPLATE TO CHECK ON THE OUTSIDE OF THE DOOR, AND AN INSIDE TEMPLATE TO CHECK ON THE INSIDE EDGE OF THE DOOR.

BEFORE WE USE OUR TEMPLATES WE'VE GOT SOME WORK TO DO. THIS DOOR EDGE WAS FOLDED IN DUE TO AN ACCIDENT IN OUR RANGER'S PREVIOUS LIFE. METAL HAS A MEMORY, AND KNOWS THE SHAPE IT WANTS TO GO BACK TO. USING A HAMMER AND DOLLY, WE'RE GONNA SLOWLY PUT THE ORIGINAL SHAPE BACK INTO THE METAL, AND BY SPEEDING UP THE VIDEO YOU CAN SEE THE EDGE OF THE DOOR IS TAKING ITS ORIGINAL SHAPE. WE'RE GONNA GO IN DEPTH WITH HAMMER AND DOLLY TECHNIQUES IN AN UPCOMING SHOW, BUT FOR NOW THE MOST IMPORTANT LESSON ABOUT RESHAPING METAL IS TO GO SLOW BECAUSE YOU DON'T WANT TO GO TOO FAR AND END UP HAVING TO RESHAPE THE METAL BACK THE OTHER BECAUSE THAT ACTUALLY WEAKENS IT. I LIKE TO MAKE THE CARDBOARD MORE PLIABLE BY RUNNING IT OVER A HARD EDGE BECAUSE THE AREA I'M WORKING ON ACTUALLY CURVES BACK TOWARDS THE REAR OF THE DOOR. THE BOTTOM HALF OF THE TEMPLATE SHOWS HOW CLOSE WE ARE ON THE DOOR'S INSIDE, AND THE TOP HALF SHOWS IF WE NEED TO SHAPE THE METAL FURTHER OUT, LIKE HERE. NOT ONLY CAN YOU SEE THIS HIGH SPOT, YOU CAN FEEL IT, AND BY USING THE STRAIGHT EDGE OF YOUR DOLLY IT SHOWS HOW FAR I NEED TO HAMMER THIS SPOT DOWN. AGAIN, GO SLOWLY AND UTILIZE NOT ONLY THE FACE OF YOUR HAMMER BUT ALSO THE CHISEL END TO FLATTEN THE RIDGE OUT. TOUCH AND YOUR DOLLY WILL TELL YOU WHEN YOU'RE DONE. THIS TYPE OF REPAIR WILL CHIP ANY PAINTED SURFACE. SO IT'S A GOOD IDEA TO USE COARSE SAND PAPER, LIKE 36 GRIT, TO QUICKLY REMOVE THE FINISH. THEN SHIFT TO A FINER PAPER, LIKE 180 GRIT, TO PREP THE SURFACE FOR A LAYER OF HIGH BUILD PRIMER. GREASE AND WAX REMOVER PREPS THE SURFACE FOR THREE TO FOUR LAYERS OF PRIMER. WE'RE NOT DOING ANY FILLER WORK ON THIS DOOR SINCE IT'S GOING BACK ON OUR PRERUNNER RANGER, AND IT WILL CERTAINLY SEE PLENTY MORE ABUSE OUT IN THE DESERT. SO THIS IS GOOD ENOUGH FOR OUR RACE READY PAINT JOB.

(ELIZA)>> EVEN WITH OUR NICE, NEW FLOORS SOMETIMES YOU NEED A BREAK FROM WORKING ON THE CONCRETE. SO FOR OUR TWO STALL GARAGE WE DECIDE TO GIVE IT A FACE LIFT AND A NICE, NEW DURABLE WORK SURFACE.

WE KNEW WE WANTED A DEDICATED SPACE TO BOTH STORE AND WORK ON OUR PROJECT VEHICLES, AND UNDERNEATH OUR UPSTAIRS STORAGE AREA TURNED OUT TO BE THE PERFECT PLACE. SO WE CALLED OUR FRIENDS AT SWISS TRACKS AND HAD THEM SEND US THEIR MODULAR GARAGE FLOOR TILE SYSTEM. THEIR RIBBED TRACKS ARE TILES THAT MEASURE ROUGHLY 16 BY 16 INCHES, AND ARE MADE OF A HIGH STRENGTH PLASTIC. THE TILES SNAP TOGETHER AND IT DOESN'T TAKE VERY MUCH TIME TO COVER A LARGE AREA. ONE OF THE GREAT ADVANTAGES OF THESE TILES IS THAT GAS, OIL, HYDRAULIC FLUID, ACIDS, AND SOLVENTS WON'T HURT THEM AT ALL.

OBVIOUSLY GARAGE FLOORS TAKE A BEATING. SO IF YOU FIND ANY CRACKING OR BROKEN TILES THERE'S A 15 YEAR NO QUESTIONS ASKED WARRANTY, AND THAT'S PRETTY GOOD. IF YOU DO HAVE TO REPLACE AS LITTLE AS JUST ONE TILE DON'T WORRY. EVEN THOUGH THE ENTIRE SYSTEM IS SNAPPED TOGETHER IT'S EASY TO POP OUT THE DAMAGED TILE BY ITSELF AND REPLACE IT WITH A NEW ONE. ALSO, SHOULD YOU MAKE A REALLY BIG MESS, YOU CAN TAKE OUT THE TILES AND CLEAN THEM. A SHOP VAC WORKS GREAT FOR WHAT'S UNDERNEATH, AND THE CHANNELS IN THE TILE LET COMPRESSED AIR BLOW ANY DIRT AND TRASH AWAY.

(JEREMY)>> YOU'RE PROBABLY WONDERING HOW STRONG IS RIBBED TRACKS? WELL THIS STUFF'S PRETTY COOL. IT CAN WITHSTAND UP TO 3,000 PSI, AND IT'S HEAT AND COOL RESISTANT DOWN TO 20 DEGREES BELOW ZERO AND UP TO ABOUT 240 DEGREES ABOVE ZERO. SO THIS STUFF'S PRETTY RIGID. THEY ALSO MAKE A PRODUCT CALLED VINYL TRACKS. THIS STUFF'S PRETTY COOL. WE'VE GOT A LITTLE PROJECT FOR THAT AND WE'LL SHOW YOU THAT IN A BIT.

(ELIZA)>> JUST FOR REFERENCE, 3,000 PSI EQUATES TO ABOUT 70,000 POUNDS OR SO. EVEN YOUR BIGGEST, BADDEST DUALLY AND FULLY LOADED RACE TRAILER WON'T HURT THEM AT ALL.

(JEREMY)>> SEE HOW EASY THAT STUFF WAS TO INSTALL, AND IT LOOKS AMAZING, AND REMEMBER THAT PIECE I SHOWED YOU BEFORE?

(ELIZA)>> VINYL TRACKS, THIS STUFF IS COMING UPSTAIRS AND I'LL SHOW YOU WHY. THIS IS NOW OUR OFFICE AREA. SO WHEN WE'RE NOT DOWN THERE WORKING ON OUR PROJECT TRUCKS WE ARE UP HERE RESEARCHING FUTURE BUILDS. WE NEED SOMETHING JUST AS STRONG AND STURDY BUT WITH A LITTLE MORE FINISH. WELL THERE YOU. THIS STEP IS GONNA BE GREAT FOR OUR OFFICE. OBVIOUSLY YOU CAN INSTALL VINYL TRACKS IN YOUR GARAGE, BUT OTHER COOL APPLICATIONS FOR THIS STUFF WOULD BE A LAUNDRY ROOM, YOU MUD ROOM, AND IF YOU HAVE A CONCRETE PATIO OUT BACK THIS STUFF IS U/V RESISTANT. NOW LET'S GET BACK TO PUTTING TOGETHER OUR OFFICE. WELL THESE LOOK GREAT. IF YOU HAVE ANY QUESTIONS ABOUT WHAT YOU'VE SEEN ON TODAY'S SHOW VISIT US AT POWERNATION TV DOT COM AND WE'LL SEE YOU NEXT TIME!

Show Full Transcript

(ELIZA)>> YEP, WE'RE IN!

(NARRATOR)>> AND THEY'RE ADDING HYDRAULIC ASSISTED STEERING TO HELP POINT OUR 37 INCHES TIRES IN THE RIGHT DIRECTION. IT'S ALL HERE ON XOR.

(JEREMY)>> HEY GUYS, WELCOME TO XOR. TODAY WE'RE BACK ON OUR "OVERLAND SCOUT", AND SINCE YOU SAW IT LAST WE WENT AHEAD AND SPRAYED A LINER ON THE INSIDE TO MAKE IT EASIER TO CLEAN OUT. WE ALSO INSTALLED OUR SUSPENSION TO CLEAR OUR 37'S. NOW WE KNOW OUR STOCK STEERING WON'T WORK WELL WITH OUR 37 INCH TALL TIRES. SO AN UPGRADED HYDRAULICALLY ASSISTED STEERING SETUP IS IN ORDER.

(ELIZA)>> AND THE OTHER HALF OF THAT IS GETTING OUR NEW STEERING SYSTEM CONNECTED TO OUR AXLES. NOW THAT WE'VE GOT OUR AXLES REGEARED AND LOCKED WE WANT TO MAKE SURE THAT WHEN OUR SUSPENSION SYSTEM FLEXES THAT OUR SCOUT STEERS EFFORTLESSLY WHEN WE'RE HITTING THE TRAILS.

(JEREMY)>> THIS IS OUR STOCK STEERING GEAR BOX OUT OF OUR SCOUT. WE SENT THIS IN TO PSC TO HAVE IT MODIFIED AND REBUILT WITH THE FITTINGS TO MAKE THIS WHOLE SYSTEM WORK. WE ALSO GOT THEIR PUMP THAT FITS THE LS, RESERVOIR AND CYLINDER, SOME HARDWARE, AND THE HOSES AND FITTINGS TO HOOK THIS ALL UP. SO THE FIRST THING WE'VE GOT TO DO IS PUT THIS BACK IN OUR SCOUT.

WHEN REINSTALLING THE GEAR BOX IT'S A GOOD IDEA TO USE ALL NEW FASTENERS. WE'RE GOING WITH GRADE EIGHT BOLTS BECAUSE LET'S FACE IT, STEERING IS ONE THING YOU DON'T WANT TO LOSE OUT ON THE TRAIL. [ drill spinning ]

(JEREMY)>> WHEN IT COMES TIME TO MOUNT THE PUMP, MAKE SURE YOU GET THE CORRECT BRACKET FOR YOUR SPECIFIC ENGINE. OURS HAPPENS TO MOUNT DIRECTLY TO THE CYLINDER HEAD.

MAKE SURE YOU MOUNT THE PUMP SO YOU HAVE EASY ACCESS TO BOTH THE FEED AND RETURN FITTINGS. WE'RE GONNA POSITION OURS ON THE SAME SIDE OF THE ENGINE BAY AS OUR GEARBOX. WITH THE PUMP INSTALLED WHAT WE'VE GOT TO DO NOW IS MOUNT OUR RESERVOIR AND HOOK UP OUR LINES. ABOUT TWO AND A QUARTER.

[ drill spinning ]

(JEREMY)>> AGAIN, WE'RE USING GRADE EIGHT HARDWARE FOR THE BOLTS THAT SECURE THE RESERVOIR FROM UNDERNEATH THROUGH THE WHEEL WELL. THIS KIT USES PUSH LOCK FITTINGS, WHICH MAKES CONNECTING HOSES AS SIMPLE AS THE NAME IMPLIES. JUST FULLY PUSH THE HOSES ON AND THEY'RE LOCKED IN PLACE.

NOW WITH ALL THE FITTINGS IN PLACE WE CAN GO AHEAD AND PUT OUR HOSES IN AND CUT THEM TO LENGTH. AFTER THAT WE'LL MOUNT THE CYLINDER ON THE AXLE, RUN THOSE HOSES TO, AND WE SHOULD BE ALL SET.

(ELIZA)>> WITH OUR FRONT AXLE REGEARED, LOCKED, AND STRIPPED DOWN, WE ARE NOW READY TO INSTALL STEERING KNUCKLES. SO WE FIRED UP THE OLD COMPUTER, WENT TO SUMMIT RACING DOT COM TO PICK UP A HIGH STEER KIT AND A HIGH STEER KNUCKLE ASSEMBLY. OUR HIGH STEER KNUCKLE ALREADY COMES EQUIPPED TO RECEIVE YOUR TIE ROD OVER THE KNUCKLE, WHERE AS YOUR STOCK APPLICATION WOULD HAVE YOU MOUNTING UNDER. THIS IS FOR CLEARANCE. OUR HIGH STEER MOVES OUR DRAG LINK UP AND OVER. THIS IS FOR BETTER CROSS STEERING. WHILE WE WERE THERE WE ALSO PICKED UP ALL THE BALL JOINTS AND HARDWARE NECESSARY FOR INSTALLATION. THE COOL THING ABOUT YOUR HIGH STEER KIT IS THAT IT COMES WITH CONE WASHERS FOR INSTALLATION ON THE OPPOSITE SIDE IF NECESSARY. SO WHEN YOU WANT TO KNOW WHAT BALL JOINT GOES WHERE, THE UPPER BALL JOINT IS ACTUALLY LONGER AND HAS A HOLE TO RECEIVE YOUR COTTER PIN WHEN YOU PUT ON YOUR CASTLE NUT. DON'T WORRY IF YOU DON'T HAVE A BALL JOINT PRESS. YOU CAN RENT ONE FROM JUST ABOUT ANY AUTO PARTS STORE. [ drill spinning ]

(ELIZA)>> DON'T FORGET TO INSTALL THE SNAP RING. IT HELPS KEEP THE BALL JOINT IN PLACE. GO, SNAP RING'S IN, PUT THE LITTLE BOOT ON.

THE SHAPE OF OUR KNUCKLES REQUIRES THE USE OF A TAPERED PRESS ADAPTER TO SEAT THE UPPER BALL JOINT CORRECTLY.

[ drill spinning ]

(ELIZA)>> PUT ON THE SNAP RING.

GET THE BOOT ON.

INSTALLING THE LOWER GREASE NUT.

SITS RIGHT ON IT, AND WE CAN GREASE IT. ONE HAND! OKAY, GET READY TO PUT THIS IN.

ONCE YOU GET THE KNUCKLE SEATED INTO THE INNERC OF THE AXLE HOUSING, THE TORQUE SPECS FOR THE UPPER CASTLE NUT IS 100 FOOT POUNDS, AND THE LOWER IS 70.

[ ratchet spinning ]

(ELIZA)>> AND AFTER TIGHTENING AND TORQUING DON'T FORGET TO INSTALL YOUR COTTER PIN.

OKAY!

(NARRATOR)>> UP NEXT WE'LL GET OUR AXLES ALL WRAPPED UP AND INSTALLED IN OUR SCOUT, STICK AROUND!

(JEREMY)>> HEY GUYS, WELCOME BACK TO XOR AND THE AXLE AND STEERING UPGRADE ON OUR "OVERLAND SCOUT". AFTER INSTALLING A UJOINT IN OUR NEW 30 SPLINED AXLE SHAFTS, IT'S AS EASY AS JUST SLIDING THEM INTO PLACE. COAT THE AXLE SHAFT WITH GREASE BEFORE INSTALLING THE SPINDLE.

[ hammer tapping metal ]

(JEREMY)>> WE'RE REUSING OUR STOCK CALIPER MOUNT AND DUST SHIELD. SINCE IT CAN BE INSTALLED IN ANY POSITION IT'S A GOOD IDEA TO NOTE THE CALIPER'S LOCATION BEFORE DISASSEMBLY. [ drill spinning ]

(JEREMY)>> NOT ONLY WILL WE APPLY GREASE INSIDE THE HUB, SINCE THE BEARINGS RIDE DIRECTLY ON THE SPINDLE, WE ALSO LIKE TO COAT THE SPINDLE ITSELF.

WE ALREADY INSTALLED THE INNER WHEEL BEARING AND SEAL IN THE HUB. SO UP NEXT IS THE OUTER BEARING.

THAT'S FOLLOWED BY THE INNER LOCKING NUT THAT GETS TIGHTENED WITH THE SPINDLE NUT SOCKET. DON'T WORRY, YOU CAN RENT THOSE TOO. NEXT IS THE LOCK WASHER...

...FOLLOWED BY THE OUTER LOCKING NUT.

BEFORE INSTALLING THE LOCKING HUB, PACK THE HUB WITH PLENTY OF GREASE TO HELP PROLONG THE LIFE OF THE BEARINGS.

THE LOCKING HUB BODY IS SECURED WITH TWO SNAP RINGS. ONE FOR THE AXLE SHAFT, AND THE OTHER FOR THE HUB.

(ELIZA)>> LAST PART OF GETTING OUR FRONT AXLE READY FOR INSTALL.

WE'RE DONE!

I NEED TO GO YOUR WAY JUST A LITTLE BIT. YEP, WE'RE IN!

(JEREMY)>> WHEN MOUNTING YOUR HYDRAULIC CYLINDER IT'S IMPORTANT TO KEEP IT AS PARALLEL TO THE TIE ROD AND BAR AS POSSIBLE, AND JUST TACK IT IN PLACE. THAT WAY YOU CAN CHECK FOR ANY CLEARANCE ISSUES. [ welder crackling ]

(JEREMY)>> WELL NOW I'VE JUST GOT TO MAKE SURE I CAN CYCLE THE STEERING ALL THE WAY OVER TO THIS SIDE. WE'VE GOT A LITTLE BIT OF PRESSURE. ACTUALLY IT'S MORE A VACUUM RIGHT NOW FIGHTING ME, ALL RIGHT, SO BRACKETS DON'T TOUCH, CLEAR THE PUMPKIN, CLEARANCE, CLEARANCE, CLEARANCE. WHEN IT ALL SITS IN THERE AND OUR TIRES ARE RUNNING TRUE STRAIGHT DOWN THE ROAD WE'VE GOT HYDRAULIC ASSIST. NOW BURN THEM IN! [ welder crackling ]

[ welder crackling ]

(JEREMY)>> THE CYLINDER FITTINGS IN THE KIT ARE ACTUALLY REUSABLE. THAT WAY IF YOU CUT OR BREAK A HOSE ON THE TRAIL ALL YOU HAVE TO DO IS REPLACE JUST THE HOSE.

(ELIZA)>> TO RIGHT ABOUT THERE. NEED TO GO YOUR WAY AND UP JUST A LITTLE BIT. THAT SHOULD BE FORWARD RIGHT THERE. OKAY, RIGHT THERE! ALL RIGHT, COME DOWN, WE'RE IN!

(JEREMY)>> PERFECT! [ welder crackling ]

(JEREMY)>> NOW WE KNEW OUR SHOP FLOOR WAS GONNA TAKE THE MOST ABUSE OUT OF PRETTY MUCH ANYTHING IN HERE, AND BEFORE WE BROUGHT ALL OF OUR EQUIPMENT BACK IN WE HAD THE OLD CONCRETE RECONDITIONED FOR MANY MORE YEARS OF ABUSE, AND HERE'S HOW IT HAPPENED. RESURFACING A CONCRETE FLOOR THE RIGHT WAY IS ACTUALLY A LOT OF WORK, AND THE GUYS FROM QUESTMARK ARE SOME OF THE VERY BEST IN THE BUSINESS. THEY STARTED BY CUTTING THE FLOOR JOINTS TO CLEAN THEM OUT AND EXPOSE FRESH CONCRETE.

THEN THE ENTIRE SURFACE WAS GROUND UP WITH A 480 VOLT ONE TON ELECTRIC GRINDER. THE CONCRETE DUST WAS NOT ONLY COLLECTED DIRECTLY OFF THE GRINDER, IT WAS SWEPT UP FOR REMOVAL AND VACUUMED OUT OF THE FLOOR JOINTS.

FROM THERE THEY WERE FILLED WITH A FLEXIBLE EPOXY TO GIVE US A COMPLETELY SMOOTH SURFACE ONCE THEY WERE DONE. NOW THIS SPECIAL FORMULA ALLOWS THE SLABS OF THE FLOOR TO MOVE INDEPENDENTLY, YET IT KEEPS THEM BONDED TOGETHER AND KEEPS DIRT, AND DUST, AND SMALL PARTS OUT OF THE JOINTS.

ONCE THE EPOXY WAS DRY THE FLOOR WAS THEN GROUND SMOOTH YET AGAIN AND VACUUMED CLEAN ONE MORE TIME.

(ELIZA)>> A LAYER OF GROUT COAT WAS SPREAD ON TOP OF THE CONCRETE TO HELP FILL IN ALL OF THE CHIPS, SCRATCHES, AND SMALL HOLES LEFT FROM YEARS OF ABUSE.

AND THEN ONE LAST TIME THE SURFACE WAS GROUND SMOOTH. AFTER ONE LAST THOROUGH CLEANING, A DARK CHARCOAL GRAY STAIN WAS APPLIED TO THE FLOOR SO IT WOULDN'T BE SO BRIGHT UNDER ALL OF OUR TV LIGHTS. THE LAST STEP WAS BURNISHING THE FLOOR. THAT HELPS PROTECT IT FROM ANY NEW STAINS. NOW WE THINK OUR NEW FLOOR LOOKS AWESOME, AND WE CERTAINLY KNOW IT IS READY FOR ANYTHING WE CAN THROW AT IT.

(JEREMY)>> NOW THERE'S A LOT OF BODY DAMAGE ON THIS DRIVER'S SIDE DOOR. THE COOL THING IS THE PASSENGER'S SIDE DOOR IS UNTOUCHED. SO WE'RE GONNA USE A PIECE OF CARDBOARD, MAKE A TEMPLATE, AND TRANSFER THAT OVER TO THE DRIVER'S SIDE DOOR.

BY MAKING A CARDBOARD TEMPLATE THIS WAY YOU GET TWO PATTERNS. AN OUTSIDE TEMPLATE TO CHECK ON THE OUTSIDE OF THE DOOR, AND AN INSIDE TEMPLATE TO CHECK ON THE INSIDE EDGE OF THE DOOR.

BEFORE WE USE OUR TEMPLATES WE'VE GOT SOME WORK TO DO. THIS DOOR EDGE WAS FOLDED IN DUE TO AN ACCIDENT IN OUR RANGER'S PREVIOUS LIFE. METAL HAS A MEMORY, AND KNOWS THE SHAPE IT WANTS TO GO BACK TO. USING A HAMMER AND DOLLY, WE'RE GONNA SLOWLY PUT THE ORIGINAL SHAPE BACK INTO THE METAL, AND BY SPEEDING UP THE VIDEO YOU CAN SEE THE EDGE OF THE DOOR IS TAKING ITS ORIGINAL SHAPE. WE'RE GONNA GO IN DEPTH WITH HAMMER AND DOLLY TECHNIQUES IN AN UPCOMING SHOW, BUT FOR NOW THE MOST IMPORTANT LESSON ABOUT RESHAPING METAL IS TO GO SLOW BECAUSE YOU DON'T WANT TO GO TOO FAR AND END UP HAVING TO RESHAPE THE METAL BACK THE OTHER BECAUSE THAT ACTUALLY WEAKENS IT. I LIKE TO MAKE THE CARDBOARD MORE PLIABLE BY RUNNING IT OVER A HARD EDGE BECAUSE THE AREA I'M WORKING ON ACTUALLY CURVES BACK TOWARDS THE REAR OF THE DOOR. THE BOTTOM HALF OF THE TEMPLATE SHOWS HOW CLOSE WE ARE ON THE DOOR'S INSIDE, AND THE TOP HALF SHOWS IF WE NEED TO SHAPE THE METAL FURTHER OUT, LIKE HERE. NOT ONLY CAN YOU SEE THIS HIGH SPOT, YOU CAN FEEL IT, AND BY USING THE STRAIGHT EDGE OF YOUR DOLLY IT SHOWS HOW FAR I NEED TO HAMMER THIS SPOT DOWN. AGAIN, GO SLOWLY AND UTILIZE NOT ONLY THE FACE OF YOUR HAMMER BUT ALSO THE CHISEL END TO FLATTEN THE RIDGE OUT. TOUCH AND YOUR DOLLY WILL TELL YOU WHEN YOU'RE DONE. THIS TYPE OF REPAIR WILL CHIP ANY PAINTED SURFACE. SO IT'S A GOOD IDEA TO USE COARSE SAND PAPER, LIKE 36 GRIT, TO QUICKLY REMOVE THE FINISH. THEN SHIFT TO A FINER PAPER, LIKE 180 GRIT, TO PREP THE SURFACE FOR A LAYER OF HIGH BUILD PRIMER. GREASE AND WAX REMOVER PREPS THE SURFACE FOR THREE TO FOUR LAYERS OF PRIMER. WE'RE NOT DOING ANY FILLER WORK ON THIS DOOR SINCE IT'S GOING BACK ON OUR PRERUNNER RANGER, AND IT WILL CERTAINLY SEE PLENTY MORE ABUSE OUT IN THE DESERT. SO THIS IS GOOD ENOUGH FOR OUR RACE READY PAINT JOB.

(ELIZA)>> EVEN WITH OUR NICE, NEW FLOORS SOMETIMES YOU NEED A BREAK FROM WORKING ON THE CONCRETE. SO FOR OUR TWO STALL GARAGE WE DECIDE TO GIVE IT A FACE LIFT AND A NICE, NEW DURABLE WORK SURFACE.

WE KNEW WE WANTED A DEDICATED SPACE TO BOTH STORE AND WORK ON OUR PROJECT VEHICLES, AND UNDERNEATH OUR UPSTAIRS STORAGE AREA TURNED OUT TO BE THE PERFECT PLACE. SO WE CALLED OUR FRIENDS AT SWISS TRACKS AND HAD THEM SEND US THEIR MODULAR GARAGE FLOOR TILE SYSTEM. THEIR RIBBED TRACKS ARE TILES THAT MEASURE ROUGHLY 16 BY 16 INCHES, AND ARE MADE OF A HIGH STRENGTH PLASTIC. THE TILES SNAP TOGETHER AND IT DOESN'T TAKE VERY MUCH TIME TO COVER A LARGE AREA. ONE OF THE GREAT ADVANTAGES OF THESE TILES IS THAT GAS, OIL, HYDRAULIC FLUID, ACIDS, AND SOLVENTS WON'T HURT THEM AT ALL.

OBVIOUSLY GARAGE FLOORS TAKE A BEATING. SO IF YOU FIND ANY CRACKING OR BROKEN TILES THERE'S A 15 YEAR NO QUESTIONS ASKED WARRANTY, AND THAT'S PRETTY GOOD. IF YOU DO HAVE TO REPLACE AS LITTLE AS JUST ONE TILE DON'T WORRY. EVEN THOUGH THE ENTIRE SYSTEM IS SNAPPED TOGETHER IT'S EASY TO POP OUT THE DAMAGED TILE BY ITSELF AND REPLACE IT WITH A NEW ONE. ALSO, SHOULD YOU MAKE A REALLY BIG MESS, YOU CAN TAKE OUT THE TILES AND CLEAN THEM. A SHOP VAC WORKS GREAT FOR WHAT'S UNDERNEATH, AND THE CHANNELS IN THE TILE LET COMPRESSED AIR BLOW ANY DIRT AND TRASH AWAY.

(JEREMY)>> YOU'RE PROBABLY WONDERING HOW STRONG IS RIBBED TRACKS? WELL THIS STUFF'S PRETTY COOL. IT CAN WITHSTAND UP TO 3,000 PSI, AND IT'S HEAT AND COOL RESISTANT DOWN TO 20 DEGREES BELOW ZERO AND UP TO ABOUT 240 DEGREES ABOVE ZERO. SO THIS STUFF'S PRETTY RIGID. THEY ALSO MAKE A PRODUCT CALLED VINYL TRACKS. THIS STUFF'S PRETTY COOL. WE'VE GOT A LITTLE PROJECT FOR THAT AND WE'LL SHOW YOU THAT IN A BIT.

(ELIZA)>> JUST FOR REFERENCE, 3,000 PSI EQUATES TO ABOUT 70,000 POUNDS OR SO. EVEN YOUR BIGGEST, BADDEST DUALLY AND FULLY LOADED RACE TRAILER WON'T HURT THEM AT ALL.

(JEREMY)>> SEE HOW EASY THAT STUFF WAS TO INSTALL, AND IT LOOKS AMAZING, AND REMEMBER THAT PIECE I SHOWED YOU BEFORE?

(ELIZA)>> VINYL TRACKS, THIS STUFF IS COMING UPSTAIRS AND I'LL SHOW YOU WHY. THIS IS NOW OUR OFFICE AREA. SO WHEN WE'RE NOT DOWN THERE WORKING ON OUR PROJECT TRUCKS WE ARE UP HERE RESEARCHING FUTURE BUILDS. WE NEED SOMETHING JUST AS STRONG AND STURDY BUT WITH A LITTLE MORE FINISH. WELL THERE YOU. THIS STEP IS GONNA BE GREAT FOR OUR OFFICE. OBVIOUSLY YOU CAN INSTALL VINYL TRACKS IN YOUR GARAGE, BUT OTHER COOL APPLICATIONS FOR THIS STUFF WOULD BE A LAUNDRY ROOM, YOU MUD ROOM, AND IF YOU HAVE A CONCRETE PATIO OUT BACK THIS STUFF IS U/V RESISTANT. NOW LET'S GET BACK TO PUTTING TOGETHER OUR OFFICE. WELL THESE LOOK GREAT. IF YOU HAVE ANY QUESTIONS ABOUT WHAT YOU'VE SEEN ON TODAY'S SHOW VISIT US AT POWERNATION TV DOT COM AND WE'LL SEE YOU NEXT TIME!