More Model A Episodes

Truck Tech Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Dana Incorporated

Sponsor

Matco Tools

Matco is the official tool supplier to Truck Tech

Sawblade.com

Metalworking Bandsaw

Episode Transcript

(NARRATOR)>> FROM STOCK TO SLAMMED, OUR MODELA STREET ROD RETURNS FOR ITS FRAME DROP. SEE HOW STRETCHING THIS CHASSIS WILL HELP GET HER DOWN TO THE GROUND WHERE SHE BELONGS. THAT AND MORE TODAY ON TRUCK TECH.

(JEREMY)>> IT'S REALLY NOT GONNA BE THAT BAD TO MAKE THIS HAPPEN.

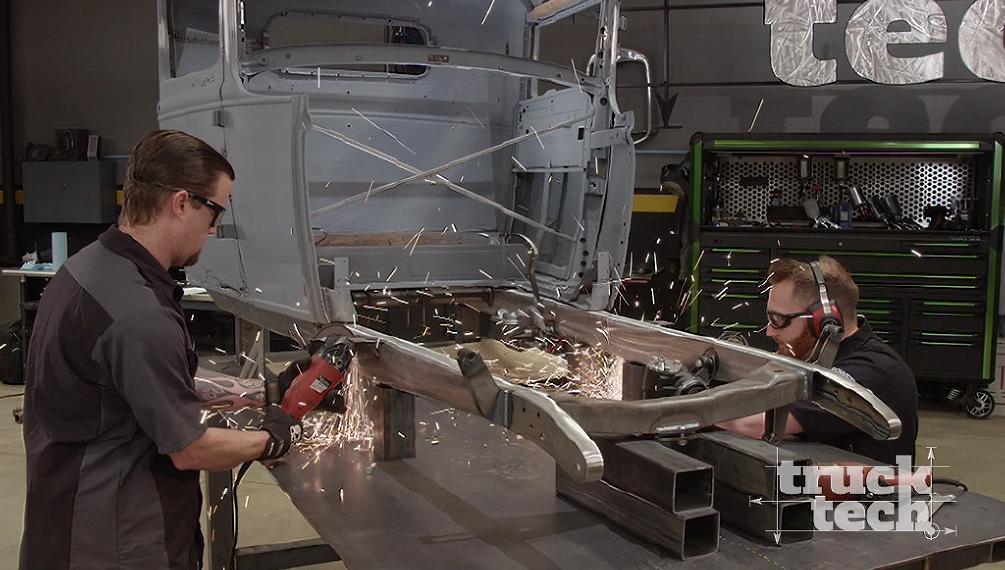

(LT)>> A LITTLE BIT OF CUTTING AND WELDING MAN AND WE'RE IN BUSINESS. WELCOME TO TRUCK TECH. TODAY WE'RE GONNA BE BACK WORKING ON OUR 1930 MODELA STREET ROD PICK UP TRUCK.

(JEREMY)>> NOW YOU NOTICE WE'VE GOT OUR TRUCK SITTING UP ON THE TABLE THAT WE BUILT NOT TOO LONG AGO FOR THE PURPOSE OF MODIFYING THIS FRAME, AND TODAY WE FINALLY GET TO CUT THIS THING UP AND MAKE THAT HAPPEN.

(LT)>> NOW ONE OF THE THINGS THAT MAKES A TRADITIONAL STREET ROD LOOK SO COOL IS HAVING IT SIT RIGHT ON THE GROUND, AND THIS TRUCK IS FAR FROM THAT. WE ALREADY CHOPPED THE TOP THREE INCHES, BUT THAT'S NOWHERE NEAR ENOUGH.

(JEREMY)>> YEAH, SO TO FIX THAT WE'RE GONNA DROP THE CENTER OF THE FRAME EIGHT INCHES. THEN WE'RE GONNA CHANNEL THE CAB ANOTHER FOUR FOR A TOTAL OF 12. SO I GUESS THE FIRST THING FOR US TO DO IS GET THIS CAB MOVED BACK AND START PREPPING FOR A FEW CUTS. LAST TIME WHEN WE MOUNTED THE FRAME TO OUR TABLE WE WENT AHEAD AND PULLED THE MEASUREMENTS WHERE WE WANTED TO MAKE OUR CUTS TO MAKE THIS FRAME TRANSITION HAPPEN.

(LT)>> CUT HER UP!

(JEREMY)>> WE NEEDED IT TO BE SLIGHTLY IN FRONT OF THE FIREWALL SO WE DIDN'T RUN INTO ANY CLEARANCE ISSUES THERE. SO WE TEMPORARILY MOUNTED THE CAB, MADE OUR MARKS, AND THAT'S WHERE WE'RE MAKING OUR CUTS. ALL RIGHT, WHEN DOING THIS TYPE OF WORK IT'S VERY IMPORTANT THAT YOU'RE PRECISE BECAUSE WE'RE DEALING WITH THE FRAME, AND WE'RE DEALING WITH SUSPENSION. SO WE WANT TO MAKE SURE IT'S ACCURATE. NOW WITH THE LINE THAT WE PUT DOWN IT'S ABOUT AN EIGHTH INCH THICK. SO IF WE CUT ON THE FRONT OR BACK SIDE OF THE LINE ON EITHER SIDE THAT COULD MAKE A HUGE DIFFERENCE. SO YOU WANT TO BE SURE THAT YOU CUT IN THE SAME SPOT ON BOTH SIDES OF THE FRAME.

[ saw cutting metal ]

(LT)>> WITH THE INSIDE EDGES OF THE FRAME CUT, ALL THAT'S LEFT IS THE TOP. WE HAVE THE FRONT CLIP SUPPORTED ON BLOCKS SO IT DOESN'T FALL TO THE TABLE WHEN IT SEPARATES. [ saw cutting metal ]

(JEREMY)>> WELL NO TURNING BACK NOW.

(LT)>> I WAS GONNA SAY THE SAME EXACT THING. COOL, LET'S SPACE THIS THING UP. WE'LL CLEAN UP THE FRESHLY CUT EDGES OF THE REAR PART OF THE FRAME, TAKING CARE TO ENSURE EVERYTHING IS STRAIGHT AND FREE OF ANY BURRS OR SHARP EDGES. A THIN CUTOFF WHEEL QUICKLY AND ACCURATELY GETS THE JOB DONE. NOW IT MIGHT BE JUST A LITTLE BIT INTIMIDATING TO GO AND SLICE UP A FRAME LIKE THIS, BUT WE HAVE A SOLID PLAN IN PLACE TO MAKE SURE ALL THE GEOMETRY THAT'S BEEN ENGINEERED INTO THE STEERING AND SUSPENSION ARE MAINTAINED CAUSE THAT'S THE MOST IMPORTANT THING ABOUT BUILDING A PROJECT LIKE THIS. YOU WANT IT TO DRIVE STRAIGHT DOWN THE ROAD. ESSENTIALLY ALL WE'RE DOING IS LOWERING THE CENTER SECTION EIGHT INCHES, BUT IT'S WELDED TO A TABLE. SO WE'RE GOING TO RAISE THE FRONT. THAT REALLY ACCOMPLISHES THE SAME THING. BEFORE WE DID ANY CUTTING I TOOK SOME MEASUREMENTS AND BUILT FOUR BLOCKS THAT ARE EXACTLY EIGHT INCHES TALLER THAN WHERE IT SET BEFORE. SO WE'LL GET THIS THING RAISED UP IN THE AIR. EACH BLOCK WE MADE WAS SPECIFICALLY DESIGNED FOR A PARTICULAR CORNER. ON THE FRONT WE MADE SOME REFERENCE LINES THAT MATCH UP WITH THE UPPER SHOCK BRACKET. IN ADDITION TO THE DROP WE'RE ALSO PLANNING TO STRETCH THE WHEEL BASE BY TWO INCHES. SO BY USING THIS CARPENTERS SQUARE WE CAN LINE UP THE FRONT PART EIGHT INCHES HIGHER AND TWO INCHES FORWARD, AND ONCE WE'RE HAPPY WITH THE POSITIONING BOTH FRONT TO BACK AND LEVEL... LOOKS PERFECT TO ME.

...WE CAN LOCK IT IN PLACE WITH A FEW TACK WELDS. I'LL START BY ATTACHING THE BASE OF EACH LEG TO THE TABLE. THEN WELD THE FRAME TO THAT LEG. [ welder crackling ]

(LT)>> NOW ONE OF THE NICEST THINGS ABOUT HAVING A STEEL TABLE IS YOU CAN WELD STUFF DIRECTLY TO IT TO LOCK IT IN PLACE WHILE YOU'RE WORKING, AND WHEN YOU'RE DONE JUST GRIND OFF THE WELDS. I AM USING A FAIRLY BEEFY TACK WELD JUST TO BE SURE NOTHING MOVES AROUND. WITH ONE LAST DOUBLE CHECK FOR LEVEL... STILL PERFECT. ...I'LL FINISH WELDING THE PASSENGER SIDE SUPPORTS INTO PLACE. [ welder crackling ]

(NARRATOR)>> NEXT BUILDING YOUR OWN FRAME SECTION.

(JEREMY)>> UH, WHAT DO YOU THINK MAN?

(LT)>> I DON'T KNOW. IT'S A PRETTY STEEP CURVE BEING SO SHORT. I DON'T KNOW IF I LIKE IT.

(JEREMY)> YEAH IT IS. NOW THIS IS THE ORIGINAL TEMPLATE WE CAME UP WITH NOT TOO LONG AGO, AND YOU CAN SEE THE TRANSITION IS QUITE DRASTIC, BUT WE MADE THIS BEFORE WE KNEW WE WERE GONNA STRETCH OUR FRAME. SO SINCE WE'VE STRETCHED IT A COUPLE OF INCHES IT'S GONNA GIVE US A LITTLE MORE WIGGLE ROOM TO COME UP WITH ANOTHER DESIGN THAT'S A LITTLE MORE PLEASING TO THE EYE. SO WE'LL GET STARTED BY MAKING ANOTHER TEMPLATE.

(LT)>> NOW WE COULD START WAY UP HERE AND MAKE A CUT, AND THAT WOULD MAKE A REALLY GOOD SWEEPING TRANSITION AND IT WOULD LOOK GREAT, BUT REMEMBER. WE'RE TRYING TO WORK AROUND THE STEERING BOX SO WE DON'T DISTURB ITS POSITION. I MADE A MARK RIGHT HERE AND THAT'S AS FAR FORWARD AS CAN CUT. SO WE'LL START BY MAKING A TEMPLATE ON THE DRIVER'S SIDE AND THEN WE CAN MIRROR IT OVER HERE ON THE PASSENGER.

WE'RE USING A BIG PIECE OF 16TH INCH CHIP BOARD, WHICH YOU CAN GET FROM A HOBBY STORE OR OFFICE SUPPLY. ALL WE NEED IS TO MARK EACH END OF THE FRAME WHERE THE CUTS ARE. THERE YOU GO MAN.

(JEREMY)>> OKAY, NOW WE'RE READY TO MAKE OUR TRANSITION. NOW THIS IS THE REAR OF THE FRAME AND THAT'S THE FRONT. SO WE NEED TO DO SOMETHING RIGHT IN THERE. NOW WE COULD HAND SKETCH SOMETHING OUT, PULL A FEW MEASUREMENTS, AND PROBABLY GET SOMETHING PRETTY COOL, BUT YOU MAY HAVE SOMETHING LAYING AROUND YOUR SHOP THAT WILL WORK FOR YOU, LIKE THIS CUTOFF WHEEL. YOU CAN SEE YOU COULD MAKE A NICE CURVE OUT OF THAT BUT THAT'S A LITTLE TOO TIGHT. SO WE'RE GONNA USE THIS. NOW THIS WHEEL WILL MAKE A VERY NICE BUT LARGER CURVE. I'M LINING UP THE CENTER OF THE WHEEL WITH THE MARKS LT JUST MADE, AND THEN TRACING AROUND THE WHEEL ABOUT 10 INCHES, AND I'M DOING THIS AT ALL FOUR CORNERS. THEN TAKING A STRAIGHT EDGE, I'M MAKING A LINE BETWEEN THE TWO CURVES.

THEN I CAN CUT THE PIECE OUT.

ALL RIGHT, LET'S HAVE A LOOK AT OUR NEW TEMPLATE. YEAH, IT LOOKS A LOT BETTER. MUCH SMOOTHER TRANSITION. SO MAYBE WE CAN THROW THIS ONE IN THE GARBAGE. THE NEXT THING WE'RE GONNA DO IS WE'RE GONNA TAKE A COUPLE OF MORE LEGS AND WELD THEM IN RIGHT BEFORE WHERE WE'RE GONNA MAKE OUR CUT, AND THEN TAKE OUR TEMPLATE AND START FABBING UP SOME METAL. SINCE WE'LL BE REMOVING THE REAR BRACE, WE NEED TO PROVIDE A LITTLE EXTRA STABILITY IN ADDITION TO THE FRONT SQUARE BRACES WE ATTACHED EARLIER. SO WE'RE TACKING IN A FEW SHORT LINKS OF HALF INCH SQUARE BAR.

(LT)>> WE'VE MADE SOME MARKS ON EACH FRAME RAIL AT EXACTLY THE SAME SPOT, AND WE'LL USE OUR TRUSTY ANGLE GRINDERS TO MAKE THE CUT. ON THE DRIVER'S SIDE THE GRINDER COULDN'T QUITE GET ALL THE WAY THROUGH. SO WE HAD TO CALL IN SOME BACK UP. YOU KNOW SOME PEOPLE LIKE TO USE SAWZALLS. I DON'T REALLY LIKE TO DO IT ON A FRAME LIKE THIS WHERE YOU'VE GOT TO MAKE A NICE, STRAIGHT CUT, BUT REALLY IN THIS CORNER I DON'T THINK WE HAVE A CHOICE. SO HERE GOES NOTHING.

[ saw cutting metal ]

(LT)>> MAKE IT?

(JEREMY)>> YEP, YOU GOT IT.

(LT)>> ALL RIGHT, LET'S CUT THE LEGS OFF.

(JEREMY)>> WE'LL CUT THE TACK WELDS HOLDING THE CENTER SECTION TO THE TABLE.

TRASH! FINALLY WE'LL CLEAN UP THE EDGES.

(LT)>> SO ALL WE'RE REALLY TRYING TO ACCOMPLISH IS TO MAKE SURE THE END OF THE CUT IS PERFECTLY SQUARE TO THE SURFACE OF THE TABLE. WE ALREADY TRUED UP THE OTHER END. SO BY DOING THIS WE'LL MAKE SURE BOTH ENDS OF THE PATCH ARE EXACTLY PARALLEL TO ONE ANOTHER, MAKING THE PATCH JUST A LITTLE BIT EASIER TO PUT BACK TOGETHER.

A LITTLE MORE AND WE'RE GOOD. [ grinding metal ]

(LT)>> YEP, LOOKS GOOD TO ME.

(NARRATOR)>> NEXT, JUST AS STRONG AS STOCK.

(LT)>> WELL THEY'RE LOOKING GOOD TO ME. I GUESS I'LL START CUTTING OUT THE NEW PIECES.

(JEREMY)>> NOW WHILE HE DOES THAT WE'VE GOT ONE THING WE NEED TO DO OVER HERE BEFORE WE CAN WELD THOSE FRAME SECTIONS IN. WE NEED TO BUILD SOME REINFORCEMENT PLATES. NOW THESE PLATES FIT INSIDE OF THE FRAME RAIL, AND WHAT THEY'LL DO IS THEY'LL SPOT WELD TO THE OLD FRAME SECTION. THEN THE NEW FRAME SECTION BEFORE WE FULLY WELD EVERYTHING IN. NOW WE COULD CUT OUR FRAME SECTIONS AND JUST BUT WELD THEM IN, AND THAT WOULD WORK, OR WE COULD CUT THEM A LITTLE LONG AND OVERLAP OUR WELDS, AND HEY THAT'D BE REALLY STRONG TOO. I MEAN HECK THAT'S EVEN HOW SOME OF THE TRUCK FRAMES TODAY ARE PUT TOGETHER. KIND OF LIKE OUR DURAMAX WE SHORTENED 14 INCHES LAST SEASON. WHERE THE FRAME COMES TOGETHER THE METAL JUST OVERLAPS, AND THEN IS WELDED INTO PLACE AND IT'S REALLY STRONG, BUT THIS IS ANOTHER WAY TO DO IT WHERE IT'S JUST AS STRONG BUT IT'S A REALLY CLEAN LOOK, ESPECIALLY SINCE WE PLAN TO FINISH OUT THE FRAME LIKE THE EXTERIOR OF THE TRUCK. NOT ONLY THAT, YOU'LL PROBABLY NEVER EVEN BE ABLE TO TELL ANY WORK'S WENT ON. USING OUR TEMPLATE WE CAN TRACE IT OUT ON THE EIGHTH INCH PLATE. THEN I'LL GET SUITED UP AND FIRE UP THE PLASMA CUTTER. THEN WE CAN CUT OUT BOTH PIECES. NOW WE'LL LET THOSE SIT RIGHT THERE JUST FOR A SECOND TO COOL OFF. THEN WE CAN ALIGN THE TWO PIECES AND CLAMP THEM IN THE VICE TOGETHER. USING A GRINDER AND A 60 GRIT FLAT DISC, WE CAN CLEAN UP AND TRUE THE EDGES, MAKING BOTH PIECES MATCH PERFECTLY. WITH THE PIECES ALL FINISHED UP I'LL TEST FIT THEM IN THE FRAME. THEN I CAN MEASURE AND MARK WHERE I PLAN TO DRILL. USING A SEVENSIXTEENTHS BIT, I'M DRILLING FOUR HOLES, AND THESE WILL BE OUR SPOT WELDS. ONCE I HAVE BOTH SIDES DRILLED OUT WE CAN PUT THE PIECES IN AND TACK THEM INTO PLACE.

ALL RIGHT, THESE REINFORCEMENTS ARE NOT ONLY GONNA MAKE OUR FRAME A LOT STRONGER BUT THEY'RE ALSO GONNA ABSORB A LOT OF THE HEAT WHEN WE BURN THIS THING TOGETHER. IF THESE WEREN'T HERE THE FRAME WOULD SOAK MOST OF THAT UP, AND IF WE GOT IN TOO MUCH OF A HURRY THERE'S A GOOD CHANCE WE COULD WARP SOMETHING. SO AT LEAST WITH THESE IN HERE THEY'LL SOAK A LITTLE BIT OF THAT HEAT UP AND WE WON'T HAVE TO WORRY ABOUT THAT. THESE ARE ACTUALLY DOING A COUPLE OF JOBS FOR US, AND AS YOU CAN SEE, I'VE STILL GOT A FEW LEFT TO DO. [ saw cutting metal ]

(LT)>> WELL I HAVE THE TEMPLATE FINALIZED. IT'S MARKED OUT ON THE MATERIAL AND WE'RE READY TO MAKE OUR CUTS. AS YOU CAN SEE WE'RE USING A BAND SAW. YOU COULD USE A CUTOFF WHEEL OR EVEN A PLASMA CUTTER, BUT I LIKE TO USE A BAND SAW ON SOMETHING LIKE THIS BECAUSE YOU CAN SNEAK RIGHT UP ON THE LINE AND MAKE A VERY PRECISE CUT. IT IS SLOWER BUT THERE'S A LOT LESS CLEAN UP WORK TO HAVE TO DO LATER ON. NOW REMEMBER, WHEN YOU'RE USING A BAND SAW, TAKE IT SLOW AND LET THE MACHINE DO THE WORK. DON'T CRAM THE MATERIAL THROUGH THERE. IF YOU DO YOU COULD WIND UP BREAKING A BLADE. WE'LL GET EVERYTHING CUT OUT AND WHEN WE COME BACK WE'LL GET THE FRAME WELDED BACK TOGETHER.

(JEREMY)>> WE'RE BACK ON OUR MODELA PICK UP. WE'RE IN THE HOME STRETCH OF MODIFYING THE FRONT OF OUR FRAME WHERE WE'RE DROPPING THE CENTER SECTION EIGHT INCHES TO GET THIS DUDE ON THE GROUND. NOW WE'VE GOT THE FRAME CUT APART. WE'VE GOT OUR REINFORCEMENT PLATES TACKED INTO PLACE, AND WE'RE GOT THE CENTER SECTIONS CUT OUT AND ALL SHAPED UP, AND IT LOOKS REALLY GOOD. NOW WHEN YOU'RE MODIFYING A FRAME LIKE WE ARE AND YOU'RE USING REINFORCEMENT OR BACKING PLATES YOU WANT TO CUT THESE PIECES A LITTLE BIT SHORT. YOU WANT TO LEAVE YOURSELF ABOUT A 16TH TO EIGHTH INCH OF A GAP. NOW THIS IS GONNA ALLOW FOR REALLY GOOD PENETRATION THROUGH ALL THREE PIECES OF METAL. THAT'S WHAT'S GONNA MAKE IT REALLY STRONG AND SAFE, WHICH IS THE MOST IMPORTANT PART. SO NOW THAT WE'VE GOT EVERYTHING MOCKED UP WE'RE GONNA WORK ON GETTING THIS THING TACKED TOGETHER. [ welder crackling ]

(JEREMY)>> ALL RIGHT, I'M GONNA TAKE OUR TOP SECTION, MAKE A MARK RIGHT WHERE IT STARTS TO BEND. TAKE IT OVER TO THE TABLE SO WE CAN SHAPE IT UP.

LET'S SEE WHAT WE GOT. THAT'S NOT TOO BAD FOR THE FIRST ROUND. FITS PRETTY GOOD! A LITTLE MORE OF A BEND IN IT RIGHT IN THERE, AND THAT SHOULD DO THE TRICK.

YEAH, I THINK WE CAN WORK WITH THAT. THAT LOOKS GOOD. THE ORIGINAL FRAME IS ACTUALLY DESIGNED OUT OF CCHANNEL WITH A PIECE OF FLAT PLATE WELDED ON THE INSIDE OF IT. NOW OBVIOUSLY WITH OUR SECTION WE CAN'T REALLY RECREATE THAT OUT OF ONE PIECE, WHICH IS WHY THERE'S SO MANY DIFFERENT LAYERS, BUT WE DO WANT TO KEEP THE SAME LOOK OF THE OLD PORTION OF THE FRAME RUNNING THROUGH NEW. SO YOU CAN'T REALLY TELL WE'VE EVER DONE ANYTHING. SO THERE'S ONE IMPORTANT THING YOU NEED TO KNOW. NOW IF WE WERE TO CUT THIS PIECE WHERE IT WAS FLUSH WITH OUR SIDE PIECES, ONCE WE WELDED IT UP AND WE GROUND AND SHAPED OUR METAL. WELL THEN YOU'RE PRETTY MUCH GRINDING AWAY ALL OF YOUR WELD AND THAT'S CERTAINLY NOT GOOD FOR STRENGTH. WHAT YOU WANT TO DO IS CUT THE PIECE A LITTLE BIT SHY. THAT WAY YOU'RE CREATING A BEVEL. THEN WE'RE ABLE TO WELD UP AND FILL THIS VOID. THEN WE'RE ABLE TO GRIND DOWN AND SHAPE OUR METAL BUT STILL KEEP ALL OF OUR WELD. THAT WAY THIS THING IS GONNA BE AS STRONG, IF NOT STRONGER, THAN IT WAS BEFORE, AND WE'RE ABLE TO KEEP A CONSISTENT LOOK THROUGHOUT. SO I'M GONNA WORK ON GETTING EVERYTHING CLAMPED INTO PLACE AND SEE IF WE CAN GET ALL THIS TACKED TOGETHER.

(LT)>> BEFORE WE FIRE UP THE WELDER WE NEED TO MAKE SURE THE NEW SECTION IS STRAIGHT. SO WE'LL LOCK OUT A PAIR OF CALIPERS AT EXACTLY TWO INCHES, THROW IN A CLAMP, AND SLOWLY TIGHTEN IT UP, AND WHEN IT'S A NICE, TIGHT FIT WE CAN PLACE TWO TACK WELDS IN TO HOLD IT IN PLACE. WE'LL CONTINUE THIS PROCESS DOWN THE FRAME RAIL UNTIL IT'S PERFECTLY EVEN, USING CLAMPS ON THE SIDE AND TOP AND BOTTOM. ONCE WE'RE AT THE END, WE'LL MARK AND CUT OFF THE EXCESS LENGTH. CLAMP IT INTO PLACE, AND WELD IT IN FOR GOOD.

(JEREMY)>> THERE IS NOTHING THAT SETS OFF YOUR PROJECT LIKE CUSTOM PAINT, AND HERE ON TRUCK TECH WE'VE BEEN ABLE TO DEMONSTRATE SOME COOL PAINTING TECHNIQUES. LIKE LAYING OUT FLAMES WITH TAPE AND USING AN AIR BRUSH TO CREATE A SHADOW EFFECT. WHAT WE ADDED TO THE PAINT SCHEME OF OUR EL CAMINO GOT A HUGE RESPONSE, WHEN WE HIT THE HOOD WITH WATER, AND THEN SPRAYED THE FRONT AND BACK SIDES OF THE DROPLETS FOR A PAINT EFFECT THAT MADE IT LOOK LIKE A WET SURFACE. IT'S ALL ABOUT ADDING A PERSONNEL TOUCH TO YOUR RIDE. YES, IT CAN BE TIME CONSUMING BUT ADDING THAT COOL FACTOR DOESN'T COME EASY. SO TODAY I'LL SHOW YOU A PAINT TRICK THAT LITERALLY ONLY TAKES A FEW MINUTES TO DO. THERE IS A VERY POPULAR THING GOING ON TODAY CALLED "HYDRO DIPPING". BASICALLY YOU TAKE A PART OFF YOUR CAR, YOU TAKE IT DOWN TO YOUR LOCAL HYDROGRAPHICS STORE OR MOST SIGN SHOPS. THEY PRINT OUT THE DESIGN YOU WANT, LAY IT OVER A BED OF WATER. THEN YOUR PART GOES IN AND THE GRAPHIC IS TRANSFERRED TO THE PART. GIVES IT A THREED EFFECT, BUT I'M GOING TO SHOW YOU A WAY TO DO THIS USING THESE ITEMS RIGHT HERE. A FEW CANS OF DUPLICOLOR ACRYLIC ENAMEL SPRAY PAINT IN A FEW DIFFERENT COLORS, A FIVE GALLON BUCKET, AND THE PART YOU PLAN TO DIP. THE FIRST THING WE WANT TO DO IS PREP THE PART WE PLAN TO DIP. SO I'M SANDING IT WITH A RED SCUFF PAD, AND I'M MASKING HALF OF THE PART SO I CAN SHOW YOU A BEFORE AND AFTER.

THEN THOROUGHLY CLEAN THE PART WITH A WAX AND GREASE REMOVER, AND LAY DOWN A COUPLE OF COATS OF DUPLICOLOR'S GRAY PRIMER.

ALL RIGHT, I'VE GOT OUR BUCKET FILLED ABOUT THREE QUARTERS OF THE WAY FULL WITH WATER. NOW WHAT I'M ABOUT TO DO IS PROBABLY GONNA SOUND A LITTLE CRAZY BECAUSE I AM NOT GOING TO SPRAY THE PART. I'M ACTUALLY GONNA SPRAY PAINT THE WATER, AND I'M GONNA START WITH DUPLICOLOR BLUE. I'LL START BY SPRAYING THE PAINT RIGHT INTO THE CENTER OF THE BUCKET. WE'LL FOLLOW THAT UP WITH WHITE, AND THEN RED, AND I'LL REPEAT THIS PROCESS UNTIL WE HAVE THE SURFACE OF THE WATER COMPLETELY COVERED. THEN I'LL SLOWLY STIR THE PAINT UP TO GET A PRETTY COOL EFFECT IN THE WATER. THEN AT A 45 DEGREE ANGLE I'LL SLOWLY DIP THE PART. THEN SHAKE THE PART IN THE WATER SO ANY EXCESS PAINT FALLS OFF. WELL THERE IT IS. IT JUST GOES TO SHOW WITH A FEW CANS OF SPRAY PAINT AND A BUCKET OF WATER YOU CAN MAKE SOMETHING REALLY COOL, AND YOU CAN DO THIS WITH ANY COLORS, AND YOU CAN DIP PRETTY MUCH ANYTHING, BUT I'M GONNA FINISH THIS UP. THROW ON A FEW COATS OF CLEAR.

(LT)>> EVERYBODY KNOWS THAT RUNNING A SYNTHETIC OIL HAS ITS BENEFITS, FROM IMPROVED POWER AND EFFICIENCY TO CLEANER RUNNING, AND ROYAL PURPLE HAS YOU COVERED. THEIR HPS, OR HIGH PERFORMANCE STREET OIL, HAS INCREASED LEVELS OF PHOSPHOROUS AND ZINC, AND IT'S GREAT FOR VEHICLES THAT SEE A LOT OF MILEAGE. XPR, OR XTREME PERFORMANCE RACING OIL, HAS ADDITIONAL ADDITIVES THAT MAXIMIZE POWER AND TORQUE, AND EACH OF THESE LINES ARE AVAILABLE IN A WIDE RANGE OF VISCOSITIES. ROYAL PURPLE ALSO HAS FLUIDS FOR EVERY OTHER SYSTEM IN YOUR VEHICLE FRONT TO BACK. SO BE SURE TO CHECK THEM OUT AT YOUR FAVORITE AUTOMOTIVE RETAILER.

(JEREMY)>> ALL RIGHT, WE'VE GOT OUR FRAME MODS ALMOST FINISHED UP. NOW WE'RE WORKING ON GETTING THIS THING FULLY WELDED BUT AS YOU CAN SEE, WE'VE STILL GOT QUITE A WAYS TO GO, BUT NEXT WE CAN WORK ON GETTING IT METAL FINISHED, AND I'VE GOT A PRETTY COOL FOUR STEP PROCESS TO DO THAT THAT I'LL SHOW YOU ANOTHER TIME. BUT ONCE I DO THAT THIS BABY WILL JUST FLOW RIGHT TOGETHER.

(LT)>> NOW WE'RE DEFINITELY MAKING HEAD WAY EVERY TIME WE WORK ON THIS MODELA. WE GOT THE FRAME DONE BUT THINK ABOUT THIS. WE HAVE THE BACK HALF OF THE FRAME YET TO DO, AND THERE'S EVERYBODY'S LEAST FAVORITE ACTIVITY, BODY WORK. SO WHAT DO WE GOT, ANOTHER COUPLE HUNDRED HOURS LEFT IN THIS THING?

(JEREMY)>> I'D SAY YOU'RE A LITTLE SHY. PROBABLY AROUND 1,000 HOURS.

(LT)>> I DON'T WANT TO THINK ABOUT IT.

(JEREMY)>> TO CHECK OUT MORE ON THIS AND OUR OTHER BUILDS GO TO POWERNATION TV DOT COM.

Show Full Transcript

(JEREMY)>> IT'S REALLY NOT GONNA BE THAT BAD TO MAKE THIS HAPPEN.

(LT)>> A LITTLE BIT OF CUTTING AND WELDING MAN AND WE'RE IN BUSINESS. WELCOME TO TRUCK TECH. TODAY WE'RE GONNA BE BACK WORKING ON OUR 1930 MODELA STREET ROD PICK UP TRUCK.

(JEREMY)>> NOW YOU NOTICE WE'VE GOT OUR TRUCK SITTING UP ON THE TABLE THAT WE BUILT NOT TOO LONG AGO FOR THE PURPOSE OF MODIFYING THIS FRAME, AND TODAY WE FINALLY GET TO CUT THIS THING UP AND MAKE THAT HAPPEN.

(LT)>> NOW ONE OF THE THINGS THAT MAKES A TRADITIONAL STREET ROD LOOK SO COOL IS HAVING IT SIT RIGHT ON THE GROUND, AND THIS TRUCK IS FAR FROM THAT. WE ALREADY CHOPPED THE TOP THREE INCHES, BUT THAT'S NOWHERE NEAR ENOUGH.

(JEREMY)>> YEAH, SO TO FIX THAT WE'RE GONNA DROP THE CENTER OF THE FRAME EIGHT INCHES. THEN WE'RE GONNA CHANNEL THE CAB ANOTHER FOUR FOR A TOTAL OF 12. SO I GUESS THE FIRST THING FOR US TO DO IS GET THIS CAB MOVED BACK AND START PREPPING FOR A FEW CUTS. LAST TIME WHEN WE MOUNTED THE FRAME TO OUR TABLE WE WENT AHEAD AND PULLED THE MEASUREMENTS WHERE WE WANTED TO MAKE OUR CUTS TO MAKE THIS FRAME TRANSITION HAPPEN.

(LT)>> CUT HER UP!

(JEREMY)>> WE NEEDED IT TO BE SLIGHTLY IN FRONT OF THE FIREWALL SO WE DIDN'T RUN INTO ANY CLEARANCE ISSUES THERE. SO WE TEMPORARILY MOUNTED THE CAB, MADE OUR MARKS, AND THAT'S WHERE WE'RE MAKING OUR CUTS. ALL RIGHT, WHEN DOING THIS TYPE OF WORK IT'S VERY IMPORTANT THAT YOU'RE PRECISE BECAUSE WE'RE DEALING WITH THE FRAME, AND WE'RE DEALING WITH SUSPENSION. SO WE WANT TO MAKE SURE IT'S ACCURATE. NOW WITH THE LINE THAT WE PUT DOWN IT'S ABOUT AN EIGHTH INCH THICK. SO IF WE CUT ON THE FRONT OR BACK SIDE OF THE LINE ON EITHER SIDE THAT COULD MAKE A HUGE DIFFERENCE. SO YOU WANT TO BE SURE THAT YOU CUT IN THE SAME SPOT ON BOTH SIDES OF THE FRAME.

[ saw cutting metal ]

(LT)>> WITH THE INSIDE EDGES OF THE FRAME CUT, ALL THAT'S LEFT IS THE TOP. WE HAVE THE FRONT CLIP SUPPORTED ON BLOCKS SO IT DOESN'T FALL TO THE TABLE WHEN IT SEPARATES. [ saw cutting metal ]

(JEREMY)>> WELL NO TURNING BACK NOW.

(LT)>> I WAS GONNA SAY THE SAME EXACT THING. COOL, LET'S SPACE THIS THING UP. WE'LL CLEAN UP THE FRESHLY CUT EDGES OF THE REAR PART OF THE FRAME, TAKING CARE TO ENSURE EVERYTHING IS STRAIGHT AND FREE OF ANY BURRS OR SHARP EDGES. A THIN CUTOFF WHEEL QUICKLY AND ACCURATELY GETS THE JOB DONE. NOW IT MIGHT BE JUST A LITTLE BIT INTIMIDATING TO GO AND SLICE UP A FRAME LIKE THIS, BUT WE HAVE A SOLID PLAN IN PLACE TO MAKE SURE ALL THE GEOMETRY THAT'S BEEN ENGINEERED INTO THE STEERING AND SUSPENSION ARE MAINTAINED CAUSE THAT'S THE MOST IMPORTANT THING ABOUT BUILDING A PROJECT LIKE THIS. YOU WANT IT TO DRIVE STRAIGHT DOWN THE ROAD. ESSENTIALLY ALL WE'RE DOING IS LOWERING THE CENTER SECTION EIGHT INCHES, BUT IT'S WELDED TO A TABLE. SO WE'RE GOING TO RAISE THE FRONT. THAT REALLY ACCOMPLISHES THE SAME THING. BEFORE WE DID ANY CUTTING I TOOK SOME MEASUREMENTS AND BUILT FOUR BLOCKS THAT ARE EXACTLY EIGHT INCHES TALLER THAN WHERE IT SET BEFORE. SO WE'LL GET THIS THING RAISED UP IN THE AIR. EACH BLOCK WE MADE WAS SPECIFICALLY DESIGNED FOR A PARTICULAR CORNER. ON THE FRONT WE MADE SOME REFERENCE LINES THAT MATCH UP WITH THE UPPER SHOCK BRACKET. IN ADDITION TO THE DROP WE'RE ALSO PLANNING TO STRETCH THE WHEEL BASE BY TWO INCHES. SO BY USING THIS CARPENTERS SQUARE WE CAN LINE UP THE FRONT PART EIGHT INCHES HIGHER AND TWO INCHES FORWARD, AND ONCE WE'RE HAPPY WITH THE POSITIONING BOTH FRONT TO BACK AND LEVEL... LOOKS PERFECT TO ME.

...WE CAN LOCK IT IN PLACE WITH A FEW TACK WELDS. I'LL START BY ATTACHING THE BASE OF EACH LEG TO THE TABLE. THEN WELD THE FRAME TO THAT LEG. [ welder crackling ]

(LT)>> NOW ONE OF THE NICEST THINGS ABOUT HAVING A STEEL TABLE IS YOU CAN WELD STUFF DIRECTLY TO IT TO LOCK IT IN PLACE WHILE YOU'RE WORKING, AND WHEN YOU'RE DONE JUST GRIND OFF THE WELDS. I AM USING A FAIRLY BEEFY TACK WELD JUST TO BE SURE NOTHING MOVES AROUND. WITH ONE LAST DOUBLE CHECK FOR LEVEL... STILL PERFECT. ...I'LL FINISH WELDING THE PASSENGER SIDE SUPPORTS INTO PLACE. [ welder crackling ]

(NARRATOR)>> NEXT BUILDING YOUR OWN FRAME SECTION.

(JEREMY)>> UH, WHAT DO YOU THINK MAN?

(LT)>> I DON'T KNOW. IT'S A PRETTY STEEP CURVE BEING SO SHORT. I DON'T KNOW IF I LIKE IT.

(JEREMY)> YEAH IT IS. NOW THIS IS THE ORIGINAL TEMPLATE WE CAME UP WITH NOT TOO LONG AGO, AND YOU CAN SEE THE TRANSITION IS QUITE DRASTIC, BUT WE MADE THIS BEFORE WE KNEW WE WERE GONNA STRETCH OUR FRAME. SO SINCE WE'VE STRETCHED IT A COUPLE OF INCHES IT'S GONNA GIVE US A LITTLE MORE WIGGLE ROOM TO COME UP WITH ANOTHER DESIGN THAT'S A LITTLE MORE PLEASING TO THE EYE. SO WE'LL GET STARTED BY MAKING ANOTHER TEMPLATE.

(LT)>> NOW WE COULD START WAY UP HERE AND MAKE A CUT, AND THAT WOULD MAKE A REALLY GOOD SWEEPING TRANSITION AND IT WOULD LOOK GREAT, BUT REMEMBER. WE'RE TRYING TO WORK AROUND THE STEERING BOX SO WE DON'T DISTURB ITS POSITION. I MADE A MARK RIGHT HERE AND THAT'S AS FAR FORWARD AS CAN CUT. SO WE'LL START BY MAKING A TEMPLATE ON THE DRIVER'S SIDE AND THEN WE CAN MIRROR IT OVER HERE ON THE PASSENGER.

WE'RE USING A BIG PIECE OF 16TH INCH CHIP BOARD, WHICH YOU CAN GET FROM A HOBBY STORE OR OFFICE SUPPLY. ALL WE NEED IS TO MARK EACH END OF THE FRAME WHERE THE CUTS ARE. THERE YOU GO MAN.

(JEREMY)>> OKAY, NOW WE'RE READY TO MAKE OUR TRANSITION. NOW THIS IS THE REAR OF THE FRAME AND THAT'S THE FRONT. SO WE NEED TO DO SOMETHING RIGHT IN THERE. NOW WE COULD HAND SKETCH SOMETHING OUT, PULL A FEW MEASUREMENTS, AND PROBABLY GET SOMETHING PRETTY COOL, BUT YOU MAY HAVE SOMETHING LAYING AROUND YOUR SHOP THAT WILL WORK FOR YOU, LIKE THIS CUTOFF WHEEL. YOU CAN SEE YOU COULD MAKE A NICE CURVE OUT OF THAT BUT THAT'S A LITTLE TOO TIGHT. SO WE'RE GONNA USE THIS. NOW THIS WHEEL WILL MAKE A VERY NICE BUT LARGER CURVE. I'M LINING UP THE CENTER OF THE WHEEL WITH THE MARKS LT JUST MADE, AND THEN TRACING AROUND THE WHEEL ABOUT 10 INCHES, AND I'M DOING THIS AT ALL FOUR CORNERS. THEN TAKING A STRAIGHT EDGE, I'M MAKING A LINE BETWEEN THE TWO CURVES.

THEN I CAN CUT THE PIECE OUT.

ALL RIGHT, LET'S HAVE A LOOK AT OUR NEW TEMPLATE. YEAH, IT LOOKS A LOT BETTER. MUCH SMOOTHER TRANSITION. SO MAYBE WE CAN THROW THIS ONE IN THE GARBAGE. THE NEXT THING WE'RE GONNA DO IS WE'RE GONNA TAKE A COUPLE OF MORE LEGS AND WELD THEM IN RIGHT BEFORE WHERE WE'RE GONNA MAKE OUR CUT, AND THEN TAKE OUR TEMPLATE AND START FABBING UP SOME METAL. SINCE WE'LL BE REMOVING THE REAR BRACE, WE NEED TO PROVIDE A LITTLE EXTRA STABILITY IN ADDITION TO THE FRONT SQUARE BRACES WE ATTACHED EARLIER. SO WE'RE TACKING IN A FEW SHORT LINKS OF HALF INCH SQUARE BAR.

(LT)>> WE'VE MADE SOME MARKS ON EACH FRAME RAIL AT EXACTLY THE SAME SPOT, AND WE'LL USE OUR TRUSTY ANGLE GRINDERS TO MAKE THE CUT. ON THE DRIVER'S SIDE THE GRINDER COULDN'T QUITE GET ALL THE WAY THROUGH. SO WE HAD TO CALL IN SOME BACK UP. YOU KNOW SOME PEOPLE LIKE TO USE SAWZALLS. I DON'T REALLY LIKE TO DO IT ON A FRAME LIKE THIS WHERE YOU'VE GOT TO MAKE A NICE, STRAIGHT CUT, BUT REALLY IN THIS CORNER I DON'T THINK WE HAVE A CHOICE. SO HERE GOES NOTHING.

[ saw cutting metal ]

(LT)>> MAKE IT?

(JEREMY)>> YEP, YOU GOT IT.

(LT)>> ALL RIGHT, LET'S CUT THE LEGS OFF.

(JEREMY)>> WE'LL CUT THE TACK WELDS HOLDING THE CENTER SECTION TO THE TABLE.

TRASH! FINALLY WE'LL CLEAN UP THE EDGES.

(LT)>> SO ALL WE'RE REALLY TRYING TO ACCOMPLISH IS TO MAKE SURE THE END OF THE CUT IS PERFECTLY SQUARE TO THE SURFACE OF THE TABLE. WE ALREADY TRUED UP THE OTHER END. SO BY DOING THIS WE'LL MAKE SURE BOTH ENDS OF THE PATCH ARE EXACTLY PARALLEL TO ONE ANOTHER, MAKING THE PATCH JUST A LITTLE BIT EASIER TO PUT BACK TOGETHER.

A LITTLE MORE AND WE'RE GOOD. [ grinding metal ]

(LT)>> YEP, LOOKS GOOD TO ME.

(NARRATOR)>> NEXT, JUST AS STRONG AS STOCK.

(LT)>> WELL THEY'RE LOOKING GOOD TO ME. I GUESS I'LL START CUTTING OUT THE NEW PIECES.

(JEREMY)>> NOW WHILE HE DOES THAT WE'VE GOT ONE THING WE NEED TO DO OVER HERE BEFORE WE CAN WELD THOSE FRAME SECTIONS IN. WE NEED TO BUILD SOME REINFORCEMENT PLATES. NOW THESE PLATES FIT INSIDE OF THE FRAME RAIL, AND WHAT THEY'LL DO IS THEY'LL SPOT WELD TO THE OLD FRAME SECTION. THEN THE NEW FRAME SECTION BEFORE WE FULLY WELD EVERYTHING IN. NOW WE COULD CUT OUR FRAME SECTIONS AND JUST BUT WELD THEM IN, AND THAT WOULD WORK, OR WE COULD CUT THEM A LITTLE LONG AND OVERLAP OUR WELDS, AND HEY THAT'D BE REALLY STRONG TOO. I MEAN HECK THAT'S EVEN HOW SOME OF THE TRUCK FRAMES TODAY ARE PUT TOGETHER. KIND OF LIKE OUR DURAMAX WE SHORTENED 14 INCHES LAST SEASON. WHERE THE FRAME COMES TOGETHER THE METAL JUST OVERLAPS, AND THEN IS WELDED INTO PLACE AND IT'S REALLY STRONG, BUT THIS IS ANOTHER WAY TO DO IT WHERE IT'S JUST AS STRONG BUT IT'S A REALLY CLEAN LOOK, ESPECIALLY SINCE WE PLAN TO FINISH OUT THE FRAME LIKE THE EXTERIOR OF THE TRUCK. NOT ONLY THAT, YOU'LL PROBABLY NEVER EVEN BE ABLE TO TELL ANY WORK'S WENT ON. USING OUR TEMPLATE WE CAN TRACE IT OUT ON THE EIGHTH INCH PLATE. THEN I'LL GET SUITED UP AND FIRE UP THE PLASMA CUTTER. THEN WE CAN CUT OUT BOTH PIECES. NOW WE'LL LET THOSE SIT RIGHT THERE JUST FOR A SECOND TO COOL OFF. THEN WE CAN ALIGN THE TWO PIECES AND CLAMP THEM IN THE VICE TOGETHER. USING A GRINDER AND A 60 GRIT FLAT DISC, WE CAN CLEAN UP AND TRUE THE EDGES, MAKING BOTH PIECES MATCH PERFECTLY. WITH THE PIECES ALL FINISHED UP I'LL TEST FIT THEM IN THE FRAME. THEN I CAN MEASURE AND MARK WHERE I PLAN TO DRILL. USING A SEVENSIXTEENTHS BIT, I'M DRILLING FOUR HOLES, AND THESE WILL BE OUR SPOT WELDS. ONCE I HAVE BOTH SIDES DRILLED OUT WE CAN PUT THE PIECES IN AND TACK THEM INTO PLACE.

ALL RIGHT, THESE REINFORCEMENTS ARE NOT ONLY GONNA MAKE OUR FRAME A LOT STRONGER BUT THEY'RE ALSO GONNA ABSORB A LOT OF THE HEAT WHEN WE BURN THIS THING TOGETHER. IF THESE WEREN'T HERE THE FRAME WOULD SOAK MOST OF THAT UP, AND IF WE GOT IN TOO MUCH OF A HURRY THERE'S A GOOD CHANCE WE COULD WARP SOMETHING. SO AT LEAST WITH THESE IN HERE THEY'LL SOAK A LITTLE BIT OF THAT HEAT UP AND WE WON'T HAVE TO WORRY ABOUT THAT. THESE ARE ACTUALLY DOING A COUPLE OF JOBS FOR US, AND AS YOU CAN SEE, I'VE STILL GOT A FEW LEFT TO DO. [ saw cutting metal ]

(LT)>> WELL I HAVE THE TEMPLATE FINALIZED. IT'S MARKED OUT ON THE MATERIAL AND WE'RE READY TO MAKE OUR CUTS. AS YOU CAN SEE WE'RE USING A BAND SAW. YOU COULD USE A CUTOFF WHEEL OR EVEN A PLASMA CUTTER, BUT I LIKE TO USE A BAND SAW ON SOMETHING LIKE THIS BECAUSE YOU CAN SNEAK RIGHT UP ON THE LINE AND MAKE A VERY PRECISE CUT. IT IS SLOWER BUT THERE'S A LOT LESS CLEAN UP WORK TO HAVE TO DO LATER ON. NOW REMEMBER, WHEN YOU'RE USING A BAND SAW, TAKE IT SLOW AND LET THE MACHINE DO THE WORK. DON'T CRAM THE MATERIAL THROUGH THERE. IF YOU DO YOU COULD WIND UP BREAKING A BLADE. WE'LL GET EVERYTHING CUT OUT AND WHEN WE COME BACK WE'LL GET THE FRAME WELDED BACK TOGETHER.

(JEREMY)>> WE'RE BACK ON OUR MODELA PICK UP. WE'RE IN THE HOME STRETCH OF MODIFYING THE FRONT OF OUR FRAME WHERE WE'RE DROPPING THE CENTER SECTION EIGHT INCHES TO GET THIS DUDE ON THE GROUND. NOW WE'VE GOT THE FRAME CUT APART. WE'VE GOT OUR REINFORCEMENT PLATES TACKED INTO PLACE, AND WE'RE GOT THE CENTER SECTIONS CUT OUT AND ALL SHAPED UP, AND IT LOOKS REALLY GOOD. NOW WHEN YOU'RE MODIFYING A FRAME LIKE WE ARE AND YOU'RE USING REINFORCEMENT OR BACKING PLATES YOU WANT TO CUT THESE PIECES A LITTLE BIT SHORT. YOU WANT TO LEAVE YOURSELF ABOUT A 16TH TO EIGHTH INCH OF A GAP. NOW THIS IS GONNA ALLOW FOR REALLY GOOD PENETRATION THROUGH ALL THREE PIECES OF METAL. THAT'S WHAT'S GONNA MAKE IT REALLY STRONG AND SAFE, WHICH IS THE MOST IMPORTANT PART. SO NOW THAT WE'VE GOT EVERYTHING MOCKED UP WE'RE GONNA WORK ON GETTING THIS THING TACKED TOGETHER. [ welder crackling ]

(JEREMY)>> ALL RIGHT, I'M GONNA TAKE OUR TOP SECTION, MAKE A MARK RIGHT WHERE IT STARTS TO BEND. TAKE IT OVER TO THE TABLE SO WE CAN SHAPE IT UP.

LET'S SEE WHAT WE GOT. THAT'S NOT TOO BAD FOR THE FIRST ROUND. FITS PRETTY GOOD! A LITTLE MORE OF A BEND IN IT RIGHT IN THERE, AND THAT SHOULD DO THE TRICK.

YEAH, I THINK WE CAN WORK WITH THAT. THAT LOOKS GOOD. THE ORIGINAL FRAME IS ACTUALLY DESIGNED OUT OF CCHANNEL WITH A PIECE OF FLAT PLATE WELDED ON THE INSIDE OF IT. NOW OBVIOUSLY WITH OUR SECTION WE CAN'T REALLY RECREATE THAT OUT OF ONE PIECE, WHICH IS WHY THERE'S SO MANY DIFFERENT LAYERS, BUT WE DO WANT TO KEEP THE SAME LOOK OF THE OLD PORTION OF THE FRAME RUNNING THROUGH NEW. SO YOU CAN'T REALLY TELL WE'VE EVER DONE ANYTHING. SO THERE'S ONE IMPORTANT THING YOU NEED TO KNOW. NOW IF WE WERE TO CUT THIS PIECE WHERE IT WAS FLUSH WITH OUR SIDE PIECES, ONCE WE WELDED IT UP AND WE GROUND AND SHAPED OUR METAL. WELL THEN YOU'RE PRETTY MUCH GRINDING AWAY ALL OF YOUR WELD AND THAT'S CERTAINLY NOT GOOD FOR STRENGTH. WHAT YOU WANT TO DO IS CUT THE PIECE A LITTLE BIT SHY. THAT WAY YOU'RE CREATING A BEVEL. THEN WE'RE ABLE TO WELD UP AND FILL THIS VOID. THEN WE'RE ABLE TO GRIND DOWN AND SHAPE OUR METAL BUT STILL KEEP ALL OF OUR WELD. THAT WAY THIS THING IS GONNA BE AS STRONG, IF NOT STRONGER, THAN IT WAS BEFORE, AND WE'RE ABLE TO KEEP A CONSISTENT LOOK THROUGHOUT. SO I'M GONNA WORK ON GETTING EVERYTHING CLAMPED INTO PLACE AND SEE IF WE CAN GET ALL THIS TACKED TOGETHER.

(LT)>> BEFORE WE FIRE UP THE WELDER WE NEED TO MAKE SURE THE NEW SECTION IS STRAIGHT. SO WE'LL LOCK OUT A PAIR OF CALIPERS AT EXACTLY TWO INCHES, THROW IN A CLAMP, AND SLOWLY TIGHTEN IT UP, AND WHEN IT'S A NICE, TIGHT FIT WE CAN PLACE TWO TACK WELDS IN TO HOLD IT IN PLACE. WE'LL CONTINUE THIS PROCESS DOWN THE FRAME RAIL UNTIL IT'S PERFECTLY EVEN, USING CLAMPS ON THE SIDE AND TOP AND BOTTOM. ONCE WE'RE AT THE END, WE'LL MARK AND CUT OFF THE EXCESS LENGTH. CLAMP IT INTO PLACE, AND WELD IT IN FOR GOOD.

(JEREMY)>> THERE IS NOTHING THAT SETS OFF YOUR PROJECT LIKE CUSTOM PAINT, AND HERE ON TRUCK TECH WE'VE BEEN ABLE TO DEMONSTRATE SOME COOL PAINTING TECHNIQUES. LIKE LAYING OUT FLAMES WITH TAPE AND USING AN AIR BRUSH TO CREATE A SHADOW EFFECT. WHAT WE ADDED TO THE PAINT SCHEME OF OUR EL CAMINO GOT A HUGE RESPONSE, WHEN WE HIT THE HOOD WITH WATER, AND THEN SPRAYED THE FRONT AND BACK SIDES OF THE DROPLETS FOR A PAINT EFFECT THAT MADE IT LOOK LIKE A WET SURFACE. IT'S ALL ABOUT ADDING A PERSONNEL TOUCH TO YOUR RIDE. YES, IT CAN BE TIME CONSUMING BUT ADDING THAT COOL FACTOR DOESN'T COME EASY. SO TODAY I'LL SHOW YOU A PAINT TRICK THAT LITERALLY ONLY TAKES A FEW MINUTES TO DO. THERE IS A VERY POPULAR THING GOING ON TODAY CALLED "HYDRO DIPPING". BASICALLY YOU TAKE A PART OFF YOUR CAR, YOU TAKE IT DOWN TO YOUR LOCAL HYDROGRAPHICS STORE OR MOST SIGN SHOPS. THEY PRINT OUT THE DESIGN YOU WANT, LAY IT OVER A BED OF WATER. THEN YOUR PART GOES IN AND THE GRAPHIC IS TRANSFERRED TO THE PART. GIVES IT A THREED EFFECT, BUT I'M GOING TO SHOW YOU A WAY TO DO THIS USING THESE ITEMS RIGHT HERE. A FEW CANS OF DUPLICOLOR ACRYLIC ENAMEL SPRAY PAINT IN A FEW DIFFERENT COLORS, A FIVE GALLON BUCKET, AND THE PART YOU PLAN TO DIP. THE FIRST THING WE WANT TO DO IS PREP THE PART WE PLAN TO DIP. SO I'M SANDING IT WITH A RED SCUFF PAD, AND I'M MASKING HALF OF THE PART SO I CAN SHOW YOU A BEFORE AND AFTER.

THEN THOROUGHLY CLEAN THE PART WITH A WAX AND GREASE REMOVER, AND LAY DOWN A COUPLE OF COATS OF DUPLICOLOR'S GRAY PRIMER.

ALL RIGHT, I'VE GOT OUR BUCKET FILLED ABOUT THREE QUARTERS OF THE WAY FULL WITH WATER. NOW WHAT I'M ABOUT TO DO IS PROBABLY GONNA SOUND A LITTLE CRAZY BECAUSE I AM NOT GOING TO SPRAY THE PART. I'M ACTUALLY GONNA SPRAY PAINT THE WATER, AND I'M GONNA START WITH DUPLICOLOR BLUE. I'LL START BY SPRAYING THE PAINT RIGHT INTO THE CENTER OF THE BUCKET. WE'LL FOLLOW THAT UP WITH WHITE, AND THEN RED, AND I'LL REPEAT THIS PROCESS UNTIL WE HAVE THE SURFACE OF THE WATER COMPLETELY COVERED. THEN I'LL SLOWLY STIR THE PAINT UP TO GET A PRETTY COOL EFFECT IN THE WATER. THEN AT A 45 DEGREE ANGLE I'LL SLOWLY DIP THE PART. THEN SHAKE THE PART IN THE WATER SO ANY EXCESS PAINT FALLS OFF. WELL THERE IT IS. IT JUST GOES TO SHOW WITH A FEW CANS OF SPRAY PAINT AND A BUCKET OF WATER YOU CAN MAKE SOMETHING REALLY COOL, AND YOU CAN DO THIS WITH ANY COLORS, AND YOU CAN DIP PRETTY MUCH ANYTHING, BUT I'M GONNA FINISH THIS UP. THROW ON A FEW COATS OF CLEAR.

(LT)>> EVERYBODY KNOWS THAT RUNNING A SYNTHETIC OIL HAS ITS BENEFITS, FROM IMPROVED POWER AND EFFICIENCY TO CLEANER RUNNING, AND ROYAL PURPLE HAS YOU COVERED. THEIR HPS, OR HIGH PERFORMANCE STREET OIL, HAS INCREASED LEVELS OF PHOSPHOROUS AND ZINC, AND IT'S GREAT FOR VEHICLES THAT SEE A LOT OF MILEAGE. XPR, OR XTREME PERFORMANCE RACING OIL, HAS ADDITIONAL ADDITIVES THAT MAXIMIZE POWER AND TORQUE, AND EACH OF THESE LINES ARE AVAILABLE IN A WIDE RANGE OF VISCOSITIES. ROYAL PURPLE ALSO HAS FLUIDS FOR EVERY OTHER SYSTEM IN YOUR VEHICLE FRONT TO BACK. SO BE SURE TO CHECK THEM OUT AT YOUR FAVORITE AUTOMOTIVE RETAILER.

(JEREMY)>> ALL RIGHT, WE'VE GOT OUR FRAME MODS ALMOST FINISHED UP. NOW WE'RE WORKING ON GETTING THIS THING FULLY WELDED BUT AS YOU CAN SEE, WE'VE STILL GOT QUITE A WAYS TO GO, BUT NEXT WE CAN WORK ON GETTING IT METAL FINISHED, AND I'VE GOT A PRETTY COOL FOUR STEP PROCESS TO DO THAT THAT I'LL SHOW YOU ANOTHER TIME. BUT ONCE I DO THAT THIS BABY WILL JUST FLOW RIGHT TOGETHER.

(LT)>> NOW WE'RE DEFINITELY MAKING HEAD WAY EVERY TIME WE WORK ON THIS MODELA. WE GOT THE FRAME DONE BUT THINK ABOUT THIS. WE HAVE THE BACK HALF OF THE FRAME YET TO DO, AND THERE'S EVERYBODY'S LEAST FAVORITE ACTIVITY, BODY WORK. SO WHAT DO WE GOT, ANOTHER COUPLE HUNDRED HOURS LEFT IN THIS THING?

(JEREMY)>> I'D SAY YOU'RE A LITTLE SHY. PROBABLY AROUND 1,000 HOURS.

(LT)>> I DON'T WANT TO THINK ABOUT IT.

(JEREMY)>> TO CHECK OUT MORE ON THIS AND OUR OTHER BUILDS GO TO POWERNATION TV DOT COM.