More Project Nightrain Episodes

Truck Tech Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

B&M Racing

Fluid Cooler, Engine, Transmission, Plate-Type, Aluminum, Black, 11 in. x 11 in. x 1 1/2 in., Each

MBRP Performance Exhuast

Exhaust System, Installer Series, Down Pipe-Back, Steel, Aluminized, Single Side Exit, Chevy/GMC, Duramax, Kit

Optima

Red Top Optima Battery, Top and Side Terminals, 800 Cold Cranking Amps, 10 in. x 6.875 in. x 7.813 in., Each

PowerStop

Power Stop Z36 truck & tow Brake Kit with Power Stop Extreme Severe-Duty Pads with drilled & Slotted Rotors, Front and Rear kit

Summit Racing

BD DIESEL - Transmission Oil Cooler, Xtrude, Plate, Aluminum, Natural, 5/8 in. Male Threads Inlet/Outlet, Fan, Kit

Warn Industries

Winch, VR 10000, 12 V, Hawse Fairlead, Power In/Out, 3/8 in. x 100 ft. Synthetic Rope, 12 ft. Hand-Held Remote, Each

Advance Adapters

Yoke Removal Trail Tool - Yoke Puller

Advanced Plating

Black Nickel Plating and Motor Oil Powder Coating

BT DieselWorks

ECU Tune and Custom Engine Harness

Rev Wheels

REV Classic 100, Chrome, 20x8, 20x9.5

The Industrial Depot

Fasteners, Hardware, Shop Supplies

Episode Transcript

(ANNOUNCER)>> TODAY WE'LL

FIRE UP PROJECT NIGHTRAIN FOR THE FIRST TIME. WE'RE RUNNING NEW FUEL

LINES, ADDING A FUEL COOLER, AND

INSTALLING OUR TANK. THEN WE'RE BUILDING OUR

EXHAUST FROM A KIT BEFORE HEADING OVER TO ADVANCE

PLATING TO GET OUR WHEELS LOOKING RIGHT. AND FINALLY WE'LL

PUT THE FIRE TO OUR DURAMAX ENGINE. IT'S ALL TODAY

HERE ON TRUCK TECH.

(JEREMY)>> HEY GUYS, WELCOME TO TRUCK TECH. WE'RE BACK ON PROJECT NIGHTRAIN. NOW AS COOL AS THIS PROJECT IS IT HASN'T MADE A SOUND YET. SO WE'RE GONNA GET IT ALL WIRED UP, THROW SOME FUEL

AT IT, AND SEE IF WE CAN GET THIS ENGINE TO MAKE SOME NOISE.

(LT)>> THIS WHOLE PILE OF PARTS IS WHAT IT'S GONNA TAKE TO MAKE THAT HAPPEN. WE'RE GONNA START BY RUNNING A FEED AND RETURN FUEL LINE AS WELL AS INSTALLING ALL THE NECESSARY FITTINGS TO MAKE THE CONNECTIONS. IN THE RETURN SIDE OF THE FUEL LINE WE'RE GONNA BE INSTALLING THIS FUEL COOLER, AND WE'LL EXPLAIN

WHY WE'RE GONNA DO THAT IN JUST A LITTLE BIT. NOW THE KEY TO MAKING THIS ENGINE SWAP SUCCESSFUL IS THIS WIRING HARNESS FROM BT DIESEL WORKS. NOW WE SIMPLY SENT THEM OUR EXISTING WIRING HARNESS AND THEY MODIFIED IT BY TAKING OUT ALL THE THINGS THAT WE WOULDN'T NEED. THEY ALSO PROVIDED A TUNE IN THE ENGINE COMPUTER SO THAT IT COULD RUN IN STAND ALONE OPERATION. NOW BECAUSE THIS IS A DIESEL WE'RE GONNA NEED A LOT OF AMPERAGE TO GET THE THING STARTED UP. WE ORDERED A PAIR OF OPTIMA RED TOP BATTERIES

THAT'LL PROVIDE THE CRANK AND CURRENT TO GET THIS THING FIRED.

BUT UNTIL WE GET SOME FUEL TO THIS THING, IT'S NOT GOING ANYWHERE. BECAUSE WE'RE USING AN STYLE FITTINGS AND HOSES,

THE TIPS OF THE FACTORY HARD LINES NEED TO BE CUT OFF. [ saw cutting ]

(LT)>> NOW ANYTIME YOU CUT A STEEL OR

ALUMINUM HARD LINE IT'S VERY IMPORTANT THAT YOU DEBURR THE FRESH EDGE BOTH INSIDE AND OUT.

I'M USING A DASH EIGHT COMPRESSION UNION ON THE FEED SIDE. THE NUT IS FOLLOWED BY THE BRASS FERAL, AND

THEN THE FITTING IS SCREWED TOGETHER. NOW THESE COMPRESSION FITTINGS MAKE A GREAT SEAL ON THESE RELATIVELY LOW PRESSURE FEED AND RETURN LINES.

NOW IT'S A DASH SIX FITTING ON THE RETURN SIDE. NOW THE SEAL IS MADE WHEN THE RELATIVELY SOFT FERAL IS COMPRESSED INTO THE HARD LINE.

THIS ALSO MEANS THAT NO THREAD SEALANT IS REQUIRED.

WHEN ADDING THE ENDS ONTO OUR BRAIDED FUEL LINE,

START BY THREADING THE NUT ONTO THE HOSE.

WITH THAT DONE IT'S IMPORTANT TO SECURE THE NUT SO IT JUST DOESN'T SPIN ON THE END OF THE HOSE. YOU THEN THREAD THE REMAINING PART OF THE FITTING TOGETHER AND YOU'RE DONE. A GREAT TIP I'VE LEARNED OVER THE YEARS IS TO TAKE

A PIECE OF WELDING WIRE OR A ZIP TIE AND JAM IT INTO THE END OF THE HOSE. NOW THIS WILL LET YOU KNOW IF THE HOSE HAS COLLAPSED ON ITSELF. GOOD TO GO!

WHEN ROUTING ANY SORT OF FLUID LINE BE MINDFUL TO AVOID ANY HOT SURFACE OR SHARP EDGES THAT MIGHT DAMAGE YOUR HOSE DOWN THE ROAD. NOW YOU DON'T HAVE TO GET OUT THE BREAKER BAR WHEN YOU'RE TIGHTENING THESE FITTINGS, JUST SNUG THEM UP.

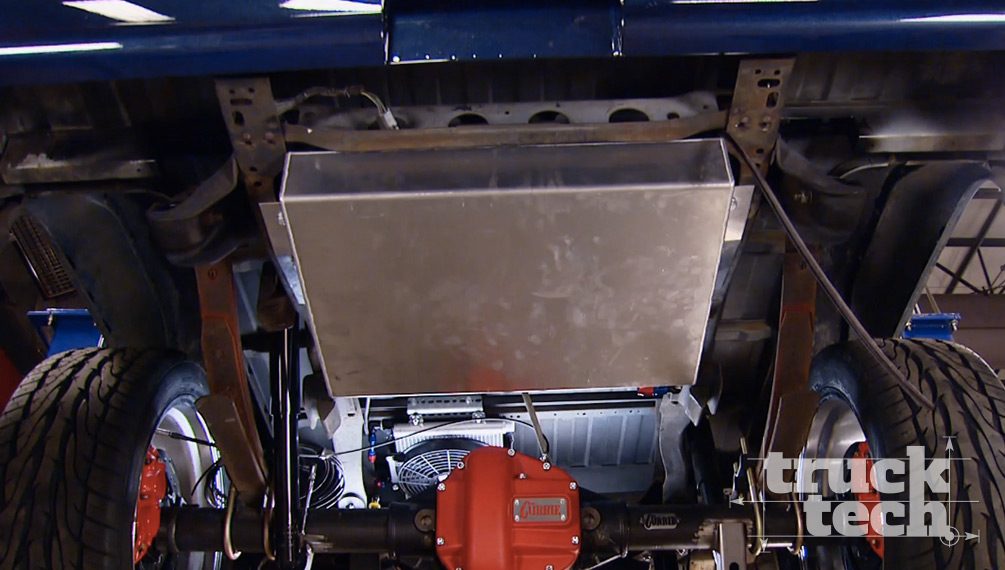

NOW THIS IS AN AUXILIARY TRANSMISSION COOLER WE PICKED UP FROM SUMMIT. NOW I'M GONNA MODIFY IT AND INSTALL THE FUEL COOLER ON TOP AND RELY ON THE FAN TO COOL THEM BOTH. NOW THE REASON WE NEEDED A FUEL COOLER IS BECAUSE OF THE EXTREME PRESSURES IN THE FUEL RAIL WILL HEAT UP THE FUEL. NOW IF WE DIDN'T INSTALL A FUEL COOLER THE ENTIRE CONTENTS OF THE TANK WOULD HEAT UP, WE'D GET A CHECK

ENGINE LIGHT, AND WE WOULD HAVE REDUCED PERFORMANCE.

I'M USING THESE INCH AND A QUARTER STAINLESS STEEL SPACERS TO PROVIDE A LITTLE BIT OF AIR GAP BETWEEN THE TWO COOLERS SO THEY DON'T RUB INTO EACH OTHER, POTENTIALLY CAUSING LEAKS.

NOW USING THE BRACKETS PROVIDED IN THE TRANSMISSION COOLER KIT, I'M GOING TO MOUNT THE WHOLE ASSEMBLY. NOW I DIDN'T MESS UP HERE. I OFFSET THE UPPER BRACKET ON PURPOSE TO ACCOMMODATE THE STEP IN THE FRAME AND ALLOW BOTH

COOLERS TO SIT LEVEL.

NOW THERE ARE MANY TYPES OF FITTINGS IN THE AUTOMOTIVE WORLD BUT IT'S VERY CRITICAL THAT YOU ONLY USE TEFLON TAPE OR THREAD SEALANT ON TAPERED PIPE THREAD, ALSO KNOWN AS NPT. NOW BECAUSE THIS STYLE OF FITTING WON'T SWIVEL AFTER IT'S INSTALLED, IT'S IMPORTANT THAT YOU

DETERMINE AHEAD OF TIME WHERE YOU NEED THEM CLOCKED. BACK UNDER THE TRUCK I'M GOING TO TEMPORARILY INSTALL THIS PIECE OF ANGLE IRON BRACKET IN

WHICH I'VE PREDRILLED HOLES TO MOUNT THE COOLER. NOW ONCE I'M HAPPY WITH THE FINAL POSITION I CAN PERMANENTLY INSTALL THE BRACKET TO THE FRAME AND THE COOLER TO THE BRACKET. IT'S IMPORTANT THAT I DIDN'T INSTALL THE COOLER DIRECTLY AGAINST THE FLOOR OF THE BED. I UTILIZED THIS GAP BETWEEN THE BED RAILS TO ALLOW FOR ADEQUATE AIR FLOW.

A WHILE BACK RYAN MOUNTED THE FUEL TANK FOR PROJECT NIGHTRAIN BETWEEN THE FRAME RAILS, BUT THERE'S ONE SMALL MODIFICATION THAT WE'VE HAD TO DO SINCE. NOW THIS FUEL TANK WAS INTENDED TO BE RUN IN A CARBURETED APPLICATION. NOW THAT JUST MEANS THERE WAS NO PROVISION FOR A FUEL RETURN LINE. TO SOLVE THAT WE SIMPLY DRILLED IN AND WELDED AN ALUMINUM DASH SIX AN FITTING. NOW SINCE THEN I'VE ALSO INSTALLED THE FUEL LEVEL SENDING UNIT AS WELL AS THE FUEL TANK VENT. NOW THE LAST PIECE OF THE PUZZLE IS TRIMMING THE FUEL FILLER NECK TO THE RIGHT LENGTH AND THAT'LL COMPLETE THE INSTALLATION FOR GOOD.

(ANNOUNCER)>> AFTER THE BREAK WE'LL RUN OUR FUEL LINES DOWN THE FRAME RAIL. AND LATER WE'LL GET OUR LBZ ENGINE FIRED UP FOR THE VERY FIRST TIME, STAY TUNED!

(LT)>> HEY GUYS WELCOME BACK TO TRUCK TECH AND THE FIRST TIME FIRE UP OF PROJECT NIGHTRAIN.

NOW THAT WE'VE GOT OUR FILLER NECK INSTALLED IN THE BED, IT'S TIME TO REINSTALL THE MODIFIED FUEL TANK. IT'S IMPORTANT TO MENTION THE HOSE WE'RE USING FOR THE FUEL FILLER NECK ISN'T A RADIATOR HOSE. IT'S A SPECIALLY FORMULATED RUBBER SPECIFICALLY FOR FUEL FILLER NECKS. [ drill spinning ]

(LT)>> BEFORE WE INSTALL OUR FUEL LINES ON THESE FRESHLY BOXED FRAME RAILS WE'RE GONNA TAKE A MOMENT AND CLEAN THEM UP SO WE CAN PROTECT THEM

FROM THE ELEMENTS.

WITH THE PAINT DRY, I LIKE TO USE THESE HANDY MAGNETIC ZIP TIE HOLDERS TO ALLOW ME TO TEMPORARILY ROUTE THE LINES. THIS ALLOWS ME TO DETERMINE THE CORRECT LENGTH TO MAKE THE FUEL LINES AS WELL AS FIND A SAFE PATH TO ROUTE THEM. THE GREAT THING ABOUT THESE MAGNETIC CLIPS IS THAT THEY'RE EASY TO REMOVE ONE AT A TIME AS

YOU REPLACE THEM WITH YOUR PERMANENT MOUNTING SOLUTION. THIS WILL KEEP THE FUEL LINE EXACTLY WHERE YOU WANT IT.

NOW WE'RE NOT BUILDING A SHOW TRUCK HERE. SO INSTEAD OF SPENDING BIG BUCKS ON SOME FANCY BILLET

ALUMINUM OR MOLDED PLASTIC HOSE CLAMP WE'RE USING THESE SIMPLE CUSHION CLAMPS. THEY'RE INEXPENSIVE, EASY TO FIND, AND THEY'LL MOUNT THE HOSE SECURELY IN RUBBER. THEY INSTALL WITH A SIMPLE SHEET METAL SCREW. I'M FACING THE TWO CLAMPS TOWARDS EACH OTHER SO THEY SHARE A SINGLE MOUNTING POINT AND PROVIDE CONSISTENT SPACING FOR THE LINES. AND IT'S NOT A SHOW TRUCK BUT WE DO STILL CARE ABOUT HOW IT'S GONNA LOOK. [ whistling ]

(LT)>> THIS IS WHY CLOCKING THE FITTINGS ON THE FUEL COOLER EARLIER WAS SO IMPORTANT. THE RETURN LINE FROM THE ENGINE TO THE COOLER GOES INTO THE BACK PORT AND THE LINE FROM THE FUEL COOLER TO THE TANK GOES INTO THE FRONT PORT. THIS ALLOWS FOR CLEAN ROUTING OF THE HOSES WITHOUT ANY KINKING. MORE ZIP TIES HOLD EVERYTHING IN PLACE. THE RETURN LINE INSTALLS IN THE NEWLY ADDED PORT ON THE TOP OF THE TANK AND THE FEED LINE INSTALLS IN THE PREINSTALLED PORT ON THE BOTTOM.

ZIP TIES ARE A MECHANICS BEST FRIEND, JUST REMEMBER TO TRIM THE TAILS. AND THAT'S THE FUEL SYSTEM. ONE OF THE LAST IMPORTANT STEPS ON PROJECT NIGHTRAIN IS FINISHING THE EXHAUST. NOW OBVIOUSLY YOU CAN'T GO DOWN TO YOUR LOCAL PARTS STORE AND PICK UP A KIT THAT'LL FIT AN '87 CHEVY

WITH A DURAMAX IN IT. SO I DID THE NEXT BEST THING. I CALLED UP SUMMIT RACING AND THEY SENT ME THIS FOUR INCH EXHAUST FOR A 2007 DURAMAX POWERED SILVERADO. NOW OBVIOUSLY THERE'S A LOT OF MATERIAL HERE, PROBABLY MORE THAN WE'RE GOING TO USE, BUT WE'LL

GET A LITTLE BIT CREATIVE AND WE'LL REARRANGE THE PIECES, AND WE'LL MAKE IT WORK PERFECTLY.

WITH THE FRONT PIPE TRIMMED TO CLEAR THE CROSS MEMBER I USE A VBAND CLAMP TO ATTACH IT TO THE FACTORY DOWN PIPE.

FOR THE MIDDLE PIPE I HAVE TWO CHALLENGES. NUMBER ONE, I HAVE TO CLEAR THE CROSS MEMBER, AND NUMBER TWO, I HAVE TO RAISE THE PIPE UP TO FOLLOW THE TRANSITION OF THE FRAME RAIL AND MAINTAIN ADEQUATE GROUND CLEARANCE.

TO ACHIEVE THIS I'M CUTTING THE STRAIGHT SECTION OUT OF THIS BEND AND WELDING THE TWO CURVED PIECES TOGETHER. THIS WILL GIVE ME THE THREE INCHES OF HEIGHT THAT I'M AFTER. I'VE MOUNTED THE MUFFLER ON SOME STANDS AND PUT A STRAIGHT PIECE OF PIPE IN THE FRONT IT, WHICH MY BEND WILL CONNECT TO. I SIMPLY HAVE TO MARK IT AND TAKE IT TO THE WELDING TABLE AND TACK IT ALL TOGETHER.

HERE'S SOMETHING I LEARNED THE HARD WAY. THIS ALUMINIZED STEEL IS A VERY DIRTY MATERIAL. IF YOU DON'T TAKE THE TIME TO PROPERLY CLEAN AND PREPARE THE SURFACE THE COATING CAN BURN OFF AND CONTAMINATE THE WELD. THIS WILL MAKE IT DIFFICULT TO GET A QUALITY FINISHED PRODUCT. SINCE THE ALIGNMENT OF THESE TWO LARGE PIECES WILL BE DIFFICULT TO DUPLICATE ON THE WELDING TABLE, I'M USING A MIG TO TACK THEM INTO PLACE. AFTER I'M DONE MOCKING UP THE WHOLE SYSTEM I'LL REMOVE IT AND FINISH WELD IT WITH THE TIG. WHEN IT COMES TO MAKING CUSTOM EXHAUST HANGERS, SOMETIMES YOU HAVE TO GET A LITTLE BIT CREATIVE. A LITTLE BIT OF HEAT WILL HELP YOU BEND THESE HANGERS ANY WHICH WAY YOU'D LIKE.

TO MAKE A COMPOUND BEND BE SURE TO LET THE FIRST BEND

COOL THOROUGHLY BEFORE YOU HEAT AND BEND THE SECOND ONE. THIS WILL KEEP THE FIRST BEND EXACTLY WHERE YOU INTENDED IT.

THIS STYLE OF HANGER CAN BE WELDED

DIRECTLY TO THE MUFFLER. NOW A GOOD RULE OF THUMB TO FOLLOW IS ATTACH A HANGER ON EACH END OF THE MUFFLER BUT ON OPPOSITE SIDES OF THE PIPE. THIS WILL PREVENT ANY TWISTING IN THE EXHAUST SYSTEM. [ welder crackling ] [ grinder spinning ]

(LT)>> AND WITH A LITTLE BIT OF LUCK AND SOME PLANNING THIS UNMODIFIED TAIL PIPE FROM THE KIT ENDED UP FITTING PERFECTLY.

(ANNOUNCER)>> WHEN WE COME BACK WE'RE HEADING TO ADVANCED PLATING, STICK AROUND.

(JEREMY)>> HEY GUYS, WELCOME BACK TO TRUCK TECH. NOW YOU KNOW ON PROJECT NIGHTRAIN WE'VE BEEN TRYING TO BLACK EVERYTHING WE CAN.

NOW EVEN THOUGH WE LOVE OUR BRIGHT AND SHINY

WHEELS, WE THOUGHT WE'D COME DOWN TO OUR BUDDIES AT ADVANCE PLATING AND SEE WHAT THEY COULD DO FOR US.

NOW WE'VE BEEN COMING OVER TO OUR BUDDIES AT ADVANCED

PLATING FOR A LONG TIME, AND IN OUR OPINION THEY DO SOME OF THE BEST CHROME PLATING IN THE WORLD. AND IN ADDITION TO THEIR REGULAR CHROME, THEY HAVE A REALLY COOL PROCESS THEY CALL BLACK NICKEL. NOW IT STARTS WITH A REGULAR CHROME PIECE THAT GETS THOROUGHLY RINSED AND THEN DIPPED IN THE BLACK NICKEL TANK. AND THE PROCESS DOESN'T TAKE VERY LONG. OUR CHEVY VALVE COVER WILL SIT IN THE TANK FOR AROUND THREE MINUTES BEFORE IT COMES OUT WITH THIS NICE SMOKEY LOOK. NOW AS COOL AS THIS PROCESS IS, LET'S FACE IT, NIGHTRAIN IS A WORK TRUCK AND SHE'S PROBABLY GONNA GET ABUSED. SO THE GUYS AT ADVANCE PLATING HAD A SUGGESTION FOR A FINISH THAT WOULD BETTER SUIT OUR NEEDS.

(LT)>> BELIEVE IT OR NOT THEY RECOMMENDED A NEW

POWDER COAT FINISH CALLED MOTOR OIL. THIS WILL GIVE US THE SAME LOOK AS THE BLACK NICKEL

BUT BE MUCH MORE DURABLE.

AFTER A THOROUGH CLEANING OF OUR ONE PIECE REV

WHEELS THEY ARE ROLLED INTO THE SPRAY BOOTH WHERE THE POWDER COAT IS APPLIED.

NOW OUR POWDER COAT IS DESIGNED TO GO DIRECTLY OVER A CHROME FINISH, AND WHEN IT'S FIRST APPLIED IT KINDA LOOKS LIKE PRIMER. BUT AFTER A COUPLE OF HOURS IN THE OVEN THAT WILL ALL CHANGE.

NOW THE RECIPE FOR OUR WHEELS CALLS FOR 350 DEGREES FOR FOUR HOURS.

WE DIDN'T HAVE TO LOOK TOO FAR TO GET AN IDEA OF WHAT OUR WHEELS WILL LOOK LIKE WHEN THEY'RE DONE. RIGHT OUTSIDE THE OVEN WAS JESSE GREENINGS XL 27 ROADSTER. THIS IS HIS DAILY DRIVER AND MUCH LIKE US HE WANTED A GOOD LOOKING FINISH THAT WAS ALSO DURABLE.

(JESSE)>> THE REACTION I HAD WHEN I FIRST SEEN THESE THINGS WERE JUST INCREDIBLE. I MEAN IT WAS LIKE, OKAY, THIS IS SOMETHING ORIGINAL, SOMETHING UNIQUE. IT'S BEEN A VERY DURABLE FINISH AND SUPER EASY TO CLEAN.

ACTUALLY I LIKE IT THE BEST BECAUSE ACTUALLY THOSE WHEELS ARE PROBABLY INCREDIBLY DIRTY RIGHT YOU JUST DON'T NOTICE IT. AND THAT'S PERFECT FOR ME BECAUSE I'M THE WORLD'S WORST AT KEEPING A CAR CLEAN.

(JEREMY)>> STEVE AND THE GUYS AT ADVANCED PLATING HAVE BEEN WORKING ON AN EVEN MORE DURABLE FINISH USING THE PROCESS OF VAPOR DEPOSITION.

THEY'RE EXPERIMENTING BY USING THIS PROCESS ON SMALLER GUITAR PARTS THAT TAKE A LOT OF ABUSE.

(STEVE)>> IN THE PAST BLACK CHROME AND GOLD, SATIN NICKEL, BRIGHT NICKEL HAVE BEEN VERY FRAGILE. WITH NEW TECHNOLOGY AND THE USE OF VAPOR

DEPOSITION, WHICH IS A CHAMBER UNDER EXTREME HEAT, VACUUM, AND ION EXCHANGE WE'RE ABLE TO PUT A TOP COAT ON THAT IS DURABLE AND OFFERS A LIFETIME WARRANTY. THIS VAPOR DEPOSITION DEPOSIT NEVER OXIDIZES. IT WILL STAY BRIGHT FROM THE TIME YOU PUT IT ON YOUR CAR, TO DRIVING DOWN THE ROAD IN THE RAIN, HAVING YOUR CAR IN STORAGE. THERE'S NO POLISHING OR WAXING.

(JEREMY)>> NOW THIS DREAM SCENARIO IS NOT THAT FAR AWAY. ADVANCE PLATING BELIEVES BY 2017 THEY'LL HAVE THIS

REFINED ENOUGH THAT THEY'LL BE APPLYING IT TO CAR PARTS. BUT FOR NOW WE'RE STOKED AT HOW OUR WHEELS TURNED OUT WITH THIS NEW MOTOR OIL POWDER COAT. AND IN OUR OPINION THEY LOOK JUST LIKE THE BLACK NICKEL.

(LT)>> HEY GUYS, WELCOME BACK TO TRUCK TECH AND THE FIRST TIME FIRE UP OF PROJECT NIGHTRAIN. WE'RE GONNA TEMPORARILY REINSTALL OUR BT DIESEL WORKS ENGINE CONTROL HARNESS ONTO THE ENGINE. THE GREAT THING ABOUT THIS HARNESS IS IT PLUGS DIRECTLY INTO THESE TWO LARGE FACTORY CONNECTORS. IT TAKES ALL THE GUESS WORK OUT. THE ENGINE PROBABLY WOULDN'T RUN VERY WELL WITHOUT AN ACCELERATOR PEDAL. SO WE'RE GONNA TEMPORARILY INSTALL IT ON TOP OF THE AIR CONDITIONING COMPRESSOR BRACKET. THE LAST INGREDIENT WE NEED TO FIRE THIS ENGINE IS FUEL. NOW BECAUSE THE ENTIRE FUEL SYSTEM IS BRAND NEW AND FILLED WITH AIR, WE NEED TO REPLACE THAT ALL WITH FUEL. SO UP ON THE FUEL FILTER HOUSING THERE'S A BLEEDER

SCREW AND A PRIMING PUMP. YOU SIMPLY HAVE TO LOOSEN THE BLEEDER SCREW AND PUMP UNTIL YOU SEE A STEADY STREAM OF FUEL COME OUT

WITH NO AIR BUBBLES IN IT.

THEN YOU SIMPLY HAVE TO CLEAN UP YOUR MESS AND YOU'RE READY TO SEE IF IT'LL START.

[ engine fires and revs ]

(LT)>> NOW THAT'S A MAJOR MILESTONE. NOW WE DO HAVE A LOT OF WORK LEFT TO DO TO GET THIS THING ROAD WORTHY INCLUDING ADDING A COOLING

SYSTEM, AND OF COURSE RELOCATING THIS ACCELERATOR PEDAL. IF YOU'VE EVER BEEN PULLING A TRAILER AND HAD SOMEBODY PULL OUT IN TRAFFIC IN FRONT OF YOU, THEN YOU DEFINITELY UNDERSTAND THE IMPORTANCE OF QUALITY BRAKING COMPONENTS. NOW THIS IS POWERSTOP'S EXTREME TRUCK AND TOW BRAKING PACKAGE. NOW THESE BRAKE PADS ARE CARBON FIBER INFUSED FOR OPTIMUM STOPPING PERFORMANCE AND HEAT REJECTION. NOW THEIR ROTORS ARE ZINC PLATE FOR A LIFETIME OF GOOD LOOKS AND THEY'RE ALSO DRILLED AND SLOTTED. SO THEY'LL RUN UP TO 180 DEGREES COOLER THAN YOUR STOCK PARTS. SO IF YOU'RE RIDING AROUND ON STOCK BRAKES IN YOUR TRUCK OR SUV, DEFINITELY CONSIDER AN UPGRADE

TO POWERSTOP BRAKES.

(JEREMY)>> THIS IS WARN'S VR 10,000-S HEAVY DUTY LOW PROFILE WINCH. SO IT WILL FIT MOST TRUCKS AND SUV'S ON THE ROAD TODAY. IT COMES WITH THIS POLISHED ALUMINUM FAIRLEAD, A SEPARATE CONTROL BOX FOR VARIOUS MOUNTING LOCATIONS, THIS REMOTE CONTROL SWITCH

WITH 12 FEET OF LEAD. SO IF YOU GET IN A STICKY SITUATION YOU WON'T GET RUN OVER. AND LAST BUT NOT LEAST, WARN'S 100 FEET OF SYNTHETIC ROPE.

AND THIS THING'S RATED AT 10,000 POUNDS. SO FOR YOU GUYS THAT ARE SERIOUS ON THE TRAIL, CHECK OUT WARN.

(LT)>> YOU KNOW NEXT TIME YOU SEE PROJECT NIGHTRAIN WE'RE GONNA BE SWAPPING OUT THIS PINION YOKE FOR ONE THAT'S A LITTLE BIT STRONGER. NOW LET ME SHOW WHAT WE'RE GONNA USE TO GET THAT JOB DONE. THIS IS ADVANCE ADAPTERS' YOKE REMOVAL TRAIL TOOL. NOW THIS WILL WORK WITH ALMOST ANY PINION YOKE FROM A 1310 ALL THE WAY UP TO A 1480. NOW IT'S MADE FROM BILLET CNC CONSTRUCTION AND IT'S SUPER DURABLE. YOU ALSO WON'T RISK DAMAGING YOUR PINION YOKE BY HITTING IT WITH A HAMMER. NOW THESE THINGS ARE LIGHT AND INEXPENSIVE. YOU CAN KEEP IT IN YOUR TOOL BOX OR YOUR TRUCK AND THEY ONLY COST ABOUT $50 BUCKS. HEY GUYS, THANKS FOR WATCHING TRUCK TECH, WE'LL CATCH YOU NEXT TIME.

Show Full Transcript

(JEREMY)>> HEY GUYS, WELCOME TO TRUCK TECH. WE'RE BACK ON PROJECT NIGHTRAIN. NOW AS COOL AS THIS PROJECT IS IT HASN'T MADE A SOUND YET. SO WE'RE GONNA GET IT ALL WIRED UP, THROW SOME FUEL

AT IT, AND SEE IF WE CAN GET THIS ENGINE TO MAKE SOME NOISE.

(LT)>> THIS WHOLE PILE OF PARTS IS WHAT IT'S GONNA TAKE TO MAKE THAT HAPPEN. WE'RE GONNA START BY RUNNING A FEED AND RETURN FUEL LINE AS WELL AS INSTALLING ALL THE NECESSARY FITTINGS TO MAKE THE CONNECTIONS. IN THE RETURN SIDE OF THE FUEL LINE WE'RE GONNA BE INSTALLING THIS FUEL COOLER, AND WE'LL EXPLAIN

WHY WE'RE GONNA DO THAT IN JUST A LITTLE BIT. NOW THE KEY TO MAKING THIS ENGINE SWAP SUCCESSFUL IS THIS WIRING HARNESS FROM BT DIESEL WORKS. NOW WE SIMPLY SENT THEM OUR EXISTING WIRING HARNESS AND THEY MODIFIED IT BY TAKING OUT ALL THE THINGS THAT WE WOULDN'T NEED. THEY ALSO PROVIDED A TUNE IN THE ENGINE COMPUTER SO THAT IT COULD RUN IN STAND ALONE OPERATION. NOW BECAUSE THIS IS A DIESEL WE'RE GONNA NEED A LOT OF AMPERAGE TO GET THE THING STARTED UP. WE ORDERED A PAIR OF OPTIMA RED TOP BATTERIES

THAT'LL PROVIDE THE CRANK AND CURRENT TO GET THIS THING FIRED.

BUT UNTIL WE GET SOME FUEL TO THIS THING, IT'S NOT GOING ANYWHERE. BECAUSE WE'RE USING AN STYLE FITTINGS AND HOSES,

THE TIPS OF THE FACTORY HARD LINES NEED TO BE CUT OFF. [ saw cutting ]

(LT)>> NOW ANYTIME YOU CUT A STEEL OR

ALUMINUM HARD LINE IT'S VERY IMPORTANT THAT YOU DEBURR THE FRESH EDGE BOTH INSIDE AND OUT.

I'M USING A DASH EIGHT COMPRESSION UNION ON THE FEED SIDE. THE NUT IS FOLLOWED BY THE BRASS FERAL, AND

THEN THE FITTING IS SCREWED TOGETHER. NOW THESE COMPRESSION FITTINGS MAKE A GREAT SEAL ON THESE RELATIVELY LOW PRESSURE FEED AND RETURN LINES.

NOW IT'S A DASH SIX FITTING ON THE RETURN SIDE. NOW THE SEAL IS MADE WHEN THE RELATIVELY SOFT FERAL IS COMPRESSED INTO THE HARD LINE.

THIS ALSO MEANS THAT NO THREAD SEALANT IS REQUIRED.

WHEN ADDING THE ENDS ONTO OUR BRAIDED FUEL LINE,

START BY THREADING THE NUT ONTO THE HOSE.

WITH THAT DONE IT'S IMPORTANT TO SECURE THE NUT SO IT JUST DOESN'T SPIN ON THE END OF THE HOSE. YOU THEN THREAD THE REMAINING PART OF THE FITTING TOGETHER AND YOU'RE DONE. A GREAT TIP I'VE LEARNED OVER THE YEARS IS TO TAKE

A PIECE OF WELDING WIRE OR A ZIP TIE AND JAM IT INTO THE END OF THE HOSE. NOW THIS WILL LET YOU KNOW IF THE HOSE HAS COLLAPSED ON ITSELF. GOOD TO GO!

WHEN ROUTING ANY SORT OF FLUID LINE BE MINDFUL TO AVOID ANY HOT SURFACE OR SHARP EDGES THAT MIGHT DAMAGE YOUR HOSE DOWN THE ROAD. NOW YOU DON'T HAVE TO GET OUT THE BREAKER BAR WHEN YOU'RE TIGHTENING THESE FITTINGS, JUST SNUG THEM UP.

NOW THIS IS AN AUXILIARY TRANSMISSION COOLER WE PICKED UP FROM SUMMIT. NOW I'M GONNA MODIFY IT AND INSTALL THE FUEL COOLER ON TOP AND RELY ON THE FAN TO COOL THEM BOTH. NOW THE REASON WE NEEDED A FUEL COOLER IS BECAUSE OF THE EXTREME PRESSURES IN THE FUEL RAIL WILL HEAT UP THE FUEL. NOW IF WE DIDN'T INSTALL A FUEL COOLER THE ENTIRE CONTENTS OF THE TANK WOULD HEAT UP, WE'D GET A CHECK

ENGINE LIGHT, AND WE WOULD HAVE REDUCED PERFORMANCE.

I'M USING THESE INCH AND A QUARTER STAINLESS STEEL SPACERS TO PROVIDE A LITTLE BIT OF AIR GAP BETWEEN THE TWO COOLERS SO THEY DON'T RUB INTO EACH OTHER, POTENTIALLY CAUSING LEAKS.

NOW USING THE BRACKETS PROVIDED IN THE TRANSMISSION COOLER KIT, I'M GOING TO MOUNT THE WHOLE ASSEMBLY. NOW I DIDN'T MESS UP HERE. I OFFSET THE UPPER BRACKET ON PURPOSE TO ACCOMMODATE THE STEP IN THE FRAME AND ALLOW BOTH

COOLERS TO SIT LEVEL.

NOW THERE ARE MANY TYPES OF FITTINGS IN THE AUTOMOTIVE WORLD BUT IT'S VERY CRITICAL THAT YOU ONLY USE TEFLON TAPE OR THREAD SEALANT ON TAPERED PIPE THREAD, ALSO KNOWN AS NPT. NOW BECAUSE THIS STYLE OF FITTING WON'T SWIVEL AFTER IT'S INSTALLED, IT'S IMPORTANT THAT YOU

DETERMINE AHEAD OF TIME WHERE YOU NEED THEM CLOCKED. BACK UNDER THE TRUCK I'M GOING TO TEMPORARILY INSTALL THIS PIECE OF ANGLE IRON BRACKET IN

WHICH I'VE PREDRILLED HOLES TO MOUNT THE COOLER. NOW ONCE I'M HAPPY WITH THE FINAL POSITION I CAN PERMANENTLY INSTALL THE BRACKET TO THE FRAME AND THE COOLER TO THE BRACKET. IT'S IMPORTANT THAT I DIDN'T INSTALL THE COOLER DIRECTLY AGAINST THE FLOOR OF THE BED. I UTILIZED THIS GAP BETWEEN THE BED RAILS TO ALLOW FOR ADEQUATE AIR FLOW.

A WHILE BACK RYAN MOUNTED THE FUEL TANK FOR PROJECT NIGHTRAIN BETWEEN THE FRAME RAILS, BUT THERE'S ONE SMALL MODIFICATION THAT WE'VE HAD TO DO SINCE. NOW THIS FUEL TANK WAS INTENDED TO BE RUN IN A CARBURETED APPLICATION. NOW THAT JUST MEANS THERE WAS NO PROVISION FOR A FUEL RETURN LINE. TO SOLVE THAT WE SIMPLY DRILLED IN AND WELDED AN ALUMINUM DASH SIX AN FITTING. NOW SINCE THEN I'VE ALSO INSTALLED THE FUEL LEVEL SENDING UNIT AS WELL AS THE FUEL TANK VENT. NOW THE LAST PIECE OF THE PUZZLE IS TRIMMING THE FUEL FILLER NECK TO THE RIGHT LENGTH AND THAT'LL COMPLETE THE INSTALLATION FOR GOOD.

(ANNOUNCER)>> AFTER THE BREAK WE'LL RUN OUR FUEL LINES DOWN THE FRAME RAIL. AND LATER WE'LL GET OUR LBZ ENGINE FIRED UP FOR THE VERY FIRST TIME, STAY TUNED!

(LT)>> HEY GUYS WELCOME BACK TO TRUCK TECH AND THE FIRST TIME FIRE UP OF PROJECT NIGHTRAIN.

NOW THAT WE'VE GOT OUR FILLER NECK INSTALLED IN THE BED, IT'S TIME TO REINSTALL THE MODIFIED FUEL TANK. IT'S IMPORTANT TO MENTION THE HOSE WE'RE USING FOR THE FUEL FILLER NECK ISN'T A RADIATOR HOSE. IT'S A SPECIALLY FORMULATED RUBBER SPECIFICALLY FOR FUEL FILLER NECKS. [ drill spinning ]

(LT)>> BEFORE WE INSTALL OUR FUEL LINES ON THESE FRESHLY BOXED FRAME RAILS WE'RE GONNA TAKE A MOMENT AND CLEAN THEM UP SO WE CAN PROTECT THEM

FROM THE ELEMENTS.

WITH THE PAINT DRY, I LIKE TO USE THESE HANDY MAGNETIC ZIP TIE HOLDERS TO ALLOW ME TO TEMPORARILY ROUTE THE LINES. THIS ALLOWS ME TO DETERMINE THE CORRECT LENGTH TO MAKE THE FUEL LINES AS WELL AS FIND A SAFE PATH TO ROUTE THEM. THE GREAT THING ABOUT THESE MAGNETIC CLIPS IS THAT THEY'RE EASY TO REMOVE ONE AT A TIME AS

YOU REPLACE THEM WITH YOUR PERMANENT MOUNTING SOLUTION. THIS WILL KEEP THE FUEL LINE EXACTLY WHERE YOU WANT IT.

NOW WE'RE NOT BUILDING A SHOW TRUCK HERE. SO INSTEAD OF SPENDING BIG BUCKS ON SOME FANCY BILLET

ALUMINUM OR MOLDED PLASTIC HOSE CLAMP WE'RE USING THESE SIMPLE CUSHION CLAMPS. THEY'RE INEXPENSIVE, EASY TO FIND, AND THEY'LL MOUNT THE HOSE SECURELY IN RUBBER. THEY INSTALL WITH A SIMPLE SHEET METAL SCREW. I'M FACING THE TWO CLAMPS TOWARDS EACH OTHER SO THEY SHARE A SINGLE MOUNTING POINT AND PROVIDE CONSISTENT SPACING FOR THE LINES. AND IT'S NOT A SHOW TRUCK BUT WE DO STILL CARE ABOUT HOW IT'S GONNA LOOK. [ whistling ]

(LT)>> THIS IS WHY CLOCKING THE FITTINGS ON THE FUEL COOLER EARLIER WAS SO IMPORTANT. THE RETURN LINE FROM THE ENGINE TO THE COOLER GOES INTO THE BACK PORT AND THE LINE FROM THE FUEL COOLER TO THE TANK GOES INTO THE FRONT PORT. THIS ALLOWS FOR CLEAN ROUTING OF THE HOSES WITHOUT ANY KINKING. MORE ZIP TIES HOLD EVERYTHING IN PLACE. THE RETURN LINE INSTALLS IN THE NEWLY ADDED PORT ON THE TOP OF THE TANK AND THE FEED LINE INSTALLS IN THE PREINSTALLED PORT ON THE BOTTOM.

ZIP TIES ARE A MECHANICS BEST FRIEND, JUST REMEMBER TO TRIM THE TAILS. AND THAT'S THE FUEL SYSTEM. ONE OF THE LAST IMPORTANT STEPS ON PROJECT NIGHTRAIN IS FINISHING THE EXHAUST. NOW OBVIOUSLY YOU CAN'T GO DOWN TO YOUR LOCAL PARTS STORE AND PICK UP A KIT THAT'LL FIT AN '87 CHEVY

WITH A DURAMAX IN IT. SO I DID THE NEXT BEST THING. I CALLED UP SUMMIT RACING AND THEY SENT ME THIS FOUR INCH EXHAUST FOR A 2007 DURAMAX POWERED SILVERADO. NOW OBVIOUSLY THERE'S A LOT OF MATERIAL HERE, PROBABLY MORE THAN WE'RE GOING TO USE, BUT WE'LL

GET A LITTLE BIT CREATIVE AND WE'LL REARRANGE THE PIECES, AND WE'LL MAKE IT WORK PERFECTLY.

WITH THE FRONT PIPE TRIMMED TO CLEAR THE CROSS MEMBER I USE A VBAND CLAMP TO ATTACH IT TO THE FACTORY DOWN PIPE.

FOR THE MIDDLE PIPE I HAVE TWO CHALLENGES. NUMBER ONE, I HAVE TO CLEAR THE CROSS MEMBER, AND NUMBER TWO, I HAVE TO RAISE THE PIPE UP TO FOLLOW THE TRANSITION OF THE FRAME RAIL AND MAINTAIN ADEQUATE GROUND CLEARANCE.

TO ACHIEVE THIS I'M CUTTING THE STRAIGHT SECTION OUT OF THIS BEND AND WELDING THE TWO CURVED PIECES TOGETHER. THIS WILL GIVE ME THE THREE INCHES OF HEIGHT THAT I'M AFTER. I'VE MOUNTED THE MUFFLER ON SOME STANDS AND PUT A STRAIGHT PIECE OF PIPE IN THE FRONT IT, WHICH MY BEND WILL CONNECT TO. I SIMPLY HAVE TO MARK IT AND TAKE IT TO THE WELDING TABLE AND TACK IT ALL TOGETHER.

HERE'S SOMETHING I LEARNED THE HARD WAY. THIS ALUMINIZED STEEL IS A VERY DIRTY MATERIAL. IF YOU DON'T TAKE THE TIME TO PROPERLY CLEAN AND PREPARE THE SURFACE THE COATING CAN BURN OFF AND CONTAMINATE THE WELD. THIS WILL MAKE IT DIFFICULT TO GET A QUALITY FINISHED PRODUCT. SINCE THE ALIGNMENT OF THESE TWO LARGE PIECES WILL BE DIFFICULT TO DUPLICATE ON THE WELDING TABLE, I'M USING A MIG TO TACK THEM INTO PLACE. AFTER I'M DONE MOCKING UP THE WHOLE SYSTEM I'LL REMOVE IT AND FINISH WELD IT WITH THE TIG. WHEN IT COMES TO MAKING CUSTOM EXHAUST HANGERS, SOMETIMES YOU HAVE TO GET A LITTLE BIT CREATIVE. A LITTLE BIT OF HEAT WILL HELP YOU BEND THESE HANGERS ANY WHICH WAY YOU'D LIKE.

TO MAKE A COMPOUND BEND BE SURE TO LET THE FIRST BEND

COOL THOROUGHLY BEFORE YOU HEAT AND BEND THE SECOND ONE. THIS WILL KEEP THE FIRST BEND EXACTLY WHERE YOU INTENDED IT.

THIS STYLE OF HANGER CAN BE WELDED

DIRECTLY TO THE MUFFLER. NOW A GOOD RULE OF THUMB TO FOLLOW IS ATTACH A HANGER ON EACH END OF THE MUFFLER BUT ON OPPOSITE SIDES OF THE PIPE. THIS WILL PREVENT ANY TWISTING IN THE EXHAUST SYSTEM. [ welder crackling ] [ grinder spinning ]

(LT)>> AND WITH A LITTLE BIT OF LUCK AND SOME PLANNING THIS UNMODIFIED TAIL PIPE FROM THE KIT ENDED UP FITTING PERFECTLY.

(ANNOUNCER)>> WHEN WE COME BACK WE'RE HEADING TO ADVANCED PLATING, STICK AROUND.

(JEREMY)>> HEY GUYS, WELCOME BACK TO TRUCK TECH. NOW YOU KNOW ON PROJECT NIGHTRAIN WE'VE BEEN TRYING TO BLACK EVERYTHING WE CAN.

NOW EVEN THOUGH WE LOVE OUR BRIGHT AND SHINY

WHEELS, WE THOUGHT WE'D COME DOWN TO OUR BUDDIES AT ADVANCE PLATING AND SEE WHAT THEY COULD DO FOR US.

NOW WE'VE BEEN COMING OVER TO OUR BUDDIES AT ADVANCED

PLATING FOR A LONG TIME, AND IN OUR OPINION THEY DO SOME OF THE BEST CHROME PLATING IN THE WORLD. AND IN ADDITION TO THEIR REGULAR CHROME, THEY HAVE A REALLY COOL PROCESS THEY CALL BLACK NICKEL. NOW IT STARTS WITH A REGULAR CHROME PIECE THAT GETS THOROUGHLY RINSED AND THEN DIPPED IN THE BLACK NICKEL TANK. AND THE PROCESS DOESN'T TAKE VERY LONG. OUR CHEVY VALVE COVER WILL SIT IN THE TANK FOR AROUND THREE MINUTES BEFORE IT COMES OUT WITH THIS NICE SMOKEY LOOK. NOW AS COOL AS THIS PROCESS IS, LET'S FACE IT, NIGHTRAIN IS A WORK TRUCK AND SHE'S PROBABLY GONNA GET ABUSED. SO THE GUYS AT ADVANCE PLATING HAD A SUGGESTION FOR A FINISH THAT WOULD BETTER SUIT OUR NEEDS.

(LT)>> BELIEVE IT OR NOT THEY RECOMMENDED A NEW

POWDER COAT FINISH CALLED MOTOR OIL. THIS WILL GIVE US THE SAME LOOK AS THE BLACK NICKEL

BUT BE MUCH MORE DURABLE.

AFTER A THOROUGH CLEANING OF OUR ONE PIECE REV

WHEELS THEY ARE ROLLED INTO THE SPRAY BOOTH WHERE THE POWDER COAT IS APPLIED.

NOW OUR POWDER COAT IS DESIGNED TO GO DIRECTLY OVER A CHROME FINISH, AND WHEN IT'S FIRST APPLIED IT KINDA LOOKS LIKE PRIMER. BUT AFTER A COUPLE OF HOURS IN THE OVEN THAT WILL ALL CHANGE.

NOW THE RECIPE FOR OUR WHEELS CALLS FOR 350 DEGREES FOR FOUR HOURS.

WE DIDN'T HAVE TO LOOK TOO FAR TO GET AN IDEA OF WHAT OUR WHEELS WILL LOOK LIKE WHEN THEY'RE DONE. RIGHT OUTSIDE THE OVEN WAS JESSE GREENINGS XL 27 ROADSTER. THIS IS HIS DAILY DRIVER AND MUCH LIKE US HE WANTED A GOOD LOOKING FINISH THAT WAS ALSO DURABLE.

(JESSE)>> THE REACTION I HAD WHEN I FIRST SEEN THESE THINGS WERE JUST INCREDIBLE. I MEAN IT WAS LIKE, OKAY, THIS IS SOMETHING ORIGINAL, SOMETHING UNIQUE. IT'S BEEN A VERY DURABLE FINISH AND SUPER EASY TO CLEAN.

ACTUALLY I LIKE IT THE BEST BECAUSE ACTUALLY THOSE WHEELS ARE PROBABLY INCREDIBLY DIRTY RIGHT YOU JUST DON'T NOTICE IT. AND THAT'S PERFECT FOR ME BECAUSE I'M THE WORLD'S WORST AT KEEPING A CAR CLEAN.

(JEREMY)>> STEVE AND THE GUYS AT ADVANCED PLATING HAVE BEEN WORKING ON AN EVEN MORE DURABLE FINISH USING THE PROCESS OF VAPOR DEPOSITION.

THEY'RE EXPERIMENTING BY USING THIS PROCESS ON SMALLER GUITAR PARTS THAT TAKE A LOT OF ABUSE.

(STEVE)>> IN THE PAST BLACK CHROME AND GOLD, SATIN NICKEL, BRIGHT NICKEL HAVE BEEN VERY FRAGILE. WITH NEW TECHNOLOGY AND THE USE OF VAPOR

DEPOSITION, WHICH IS A CHAMBER UNDER EXTREME HEAT, VACUUM, AND ION EXCHANGE WE'RE ABLE TO PUT A TOP COAT ON THAT IS DURABLE AND OFFERS A LIFETIME WARRANTY. THIS VAPOR DEPOSITION DEPOSIT NEVER OXIDIZES. IT WILL STAY BRIGHT FROM THE TIME YOU PUT IT ON YOUR CAR, TO DRIVING DOWN THE ROAD IN THE RAIN, HAVING YOUR CAR IN STORAGE. THERE'S NO POLISHING OR WAXING.

(JEREMY)>> NOW THIS DREAM SCENARIO IS NOT THAT FAR AWAY. ADVANCE PLATING BELIEVES BY 2017 THEY'LL HAVE THIS

REFINED ENOUGH THAT THEY'LL BE APPLYING IT TO CAR PARTS. BUT FOR NOW WE'RE STOKED AT HOW OUR WHEELS TURNED OUT WITH THIS NEW MOTOR OIL POWDER COAT. AND IN OUR OPINION THEY LOOK JUST LIKE THE BLACK NICKEL.

(LT)>> HEY GUYS, WELCOME BACK TO TRUCK TECH AND THE FIRST TIME FIRE UP OF PROJECT NIGHTRAIN. WE'RE GONNA TEMPORARILY REINSTALL OUR BT DIESEL WORKS ENGINE CONTROL HARNESS ONTO THE ENGINE. THE GREAT THING ABOUT THIS HARNESS IS IT PLUGS DIRECTLY INTO THESE TWO LARGE FACTORY CONNECTORS. IT TAKES ALL THE GUESS WORK OUT. THE ENGINE PROBABLY WOULDN'T RUN VERY WELL WITHOUT AN ACCELERATOR PEDAL. SO WE'RE GONNA TEMPORARILY INSTALL IT ON TOP OF THE AIR CONDITIONING COMPRESSOR BRACKET. THE LAST INGREDIENT WE NEED TO FIRE THIS ENGINE IS FUEL. NOW BECAUSE THE ENTIRE FUEL SYSTEM IS BRAND NEW AND FILLED WITH AIR, WE NEED TO REPLACE THAT ALL WITH FUEL. SO UP ON THE FUEL FILTER HOUSING THERE'S A BLEEDER

SCREW AND A PRIMING PUMP. YOU SIMPLY HAVE TO LOOSEN THE BLEEDER SCREW AND PUMP UNTIL YOU SEE A STEADY STREAM OF FUEL COME OUT

WITH NO AIR BUBBLES IN IT.

THEN YOU SIMPLY HAVE TO CLEAN UP YOUR MESS AND YOU'RE READY TO SEE IF IT'LL START.

[ engine fires and revs ]

(LT)>> NOW THAT'S A MAJOR MILESTONE. NOW WE DO HAVE A LOT OF WORK LEFT TO DO TO GET THIS THING ROAD WORTHY INCLUDING ADDING A COOLING

SYSTEM, AND OF COURSE RELOCATING THIS ACCELERATOR PEDAL. IF YOU'VE EVER BEEN PULLING A TRAILER AND HAD SOMEBODY PULL OUT IN TRAFFIC IN FRONT OF YOU, THEN YOU DEFINITELY UNDERSTAND THE IMPORTANCE OF QUALITY BRAKING COMPONENTS. NOW THIS IS POWERSTOP'S EXTREME TRUCK AND TOW BRAKING PACKAGE. NOW THESE BRAKE PADS ARE CARBON FIBER INFUSED FOR OPTIMUM STOPPING PERFORMANCE AND HEAT REJECTION. NOW THEIR ROTORS ARE ZINC PLATE FOR A LIFETIME OF GOOD LOOKS AND THEY'RE ALSO DRILLED AND SLOTTED. SO THEY'LL RUN UP TO 180 DEGREES COOLER THAN YOUR STOCK PARTS. SO IF YOU'RE RIDING AROUND ON STOCK BRAKES IN YOUR TRUCK OR SUV, DEFINITELY CONSIDER AN UPGRADE

TO POWERSTOP BRAKES.

(JEREMY)>> THIS IS WARN'S VR 10,000-S HEAVY DUTY LOW PROFILE WINCH. SO IT WILL FIT MOST TRUCKS AND SUV'S ON THE ROAD TODAY. IT COMES WITH THIS POLISHED ALUMINUM FAIRLEAD, A SEPARATE CONTROL BOX FOR VARIOUS MOUNTING LOCATIONS, THIS REMOTE CONTROL SWITCH

WITH 12 FEET OF LEAD. SO IF YOU GET IN A STICKY SITUATION YOU WON'T GET RUN OVER. AND LAST BUT NOT LEAST, WARN'S 100 FEET OF SYNTHETIC ROPE.

AND THIS THING'S RATED AT 10,000 POUNDS. SO FOR YOU GUYS THAT ARE SERIOUS ON THE TRAIL, CHECK OUT WARN.

(LT)>> YOU KNOW NEXT TIME YOU SEE PROJECT NIGHTRAIN WE'RE GONNA BE SWAPPING OUT THIS PINION YOKE FOR ONE THAT'S A LITTLE BIT STRONGER. NOW LET ME SHOW WHAT WE'RE GONNA USE TO GET THAT JOB DONE. THIS IS ADVANCE ADAPTERS' YOKE REMOVAL TRAIL TOOL. NOW THIS WILL WORK WITH ALMOST ANY PINION YOKE FROM A 1310 ALL THE WAY UP TO A 1480. NOW IT'S MADE FROM BILLET CNC CONSTRUCTION AND IT'S SUPER DURABLE. YOU ALSO WON'T RISK DAMAGING YOUR PINION YOKE BY HITTING IT WITH A HAMMER. NOW THESE THINGS ARE LIGHT AND INEXPENSIVE. YOU CAN KEEP IT IN YOUR TOOL BOX OR YOUR TRUCK AND THEY ONLY COST ABOUT $50 BUCKS. HEY GUYS, THANKS FOR WATCHING TRUCK TECH, WE'LL CATCH YOU NEXT TIME.