Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterEpisode Transcript

(Frankie)>> You're

watching Powernation.

(Frankie)>> Last time we upped the safety and power of our 2008 Club Spec Mustang and today we are gonna continue on with some serious suspension and braking upgrades.

(Pat)>> Then when she's all said and done we take it to the track and test it out.

(Frankie)>> Don't wreck it before I get a chance to drive it. [ Music ] [ drill humming ]

(Frankie)>> Welcome to the Engine Power shop where as you can tell we have our 2008 Mustang GT back on the lift because we are gonna be continuing this build. We are building this car in conjunction with Summit Racing Equipment to be legal for the SCCA's new spec racing class. It's called Spec Mustang. A spec class is an even playing field entry level driver's class for people who want to get into racing in an easy and relatively affordable way. We've already done a bunch to this car in terms of performance and safety, but today we're gonna get underneath and do some more upgrades. While we get the rest of these wheels and tires off take a look at all the modifications we've already done to this car. After giving it a shakedown on the street we brought this pony car into the shop and immediately strapped it to our chassis dyno to see what the stock wheel horsepower numbers were. Unsure whether we were happy about that or not we got cracking on upgrading our Mustang in the safety department to give us some protection from our amateur driving. We removed most of the interior and fitted up a simple bolt in roll bar from Maximum Motorsports.

(Pat)>> This complimented a set of Summit Racing fixed seats with custom brackets and comfy foam inlays because this is still a street car. Our car was speedily wrapped right here in our shop to give it a racy look, and then we completed some bolt-on performance upgrades to back it up. These were quick, simple, and included a cold air intake, short throw shifter, catback exhaust, and a flash tuner. All of our upgrades added up to a healthy improvement to 289 horsepower and 306-pound feet at the wheels. All of that worked out great but now we're only halfway done. The next thing we have to do is get on the suspension side to make this car legal both on a regional and national level for the SCCA. That includes some rulebook specific parts. First off the shocks. The shocks have been sealed at Summit to prove they have not been tampered with. Also a specific spring rate on the front and back to make the cars legal. Also we have some optional items in there like an adjustable pan hard bar and a strut brace bar, and we'll also be putting on some adjustable caster/camber plates. This car has a spec wheel and tire size. So we'll get into that later, but all these parts are very easy to bolt on and make the legal. So let's get to it.

(Frankie)>> We'll start in the back of the car by removing the old parts that we won't be reusing. The factory anti-roll bar with its tiny links is removed, followed by the pan hard bar. Finally, after unbolting them inside the trunk and on the bottom the original shocks are removed. Now that the rear end is only held in by the three link setup we gently pull the rear end down and snake the stock coil spring out. These new spec springs will lower the car and have a shorter free length so they are a bit easier to slide back in.

(Pat)>> The new Koni shocks are spec'ed out by the SCCA rules, and to be legal at an event must have an untampered seal over the shock nut like these ones Summit Racing puts on. If you plan on building a Club Spec Mustang you can call the experts at Summit Racing Equipment and they can make sure that you get a sealed set. We'll set the newly installed shock absorbers to the middle of their adjustment for now and can always tune on them later. The next upgraded piece is the adjustable pan hard bar, and the rear suspension must be loaded to install it. It is set to a starting length and then we will check the rear end center alignment once the car's fully back on the ground. The last cool part to install is this Eibach anti-roll bar, which is a stiffer design and comes with stronger billet support links to stand up to the deflection under hard loading. It comes with new hardware and clamshells to connect it to the rear axle. And with that our rear suspension upgrades are complete.

(Frankie)>> Up next, we finish up giving our Mustang its lowered swagger and some new struts.

(Frankie)>> Now that we have the rear suspension done on our 2008 Mustang we're gonna move on to the front, and it's pretty similar in terms of upgrades. We're gonna be doing a spec strut, a spec spring, an anti-roll bar, and we also have a shock tower brace and camber/castor plates to go on top of the struts. But we do have to get all of the old stuff out first. So we'll get started and then we'll show you our upgrades.

(Pat)>> Our suspension upgrades on the front of the car are a bit more involved, but we can still start by removing all of the old parts that we aren't gonna be using. The front anti-roll bar comes first, and after disconnecting the links we can unbolt the chassis mounts and pull it out of the way. Next we can unbolt the strut from the knuckle, lower the car, and unbolt the four upper bearing mount nuts before sliding the entire strut assembly out of the wheel well.

(Frankie)>> Now that we have our strut out of the car what we're gonna do is not really use any of this except for the rubber isolator at the top. We do have to pull it apart. We're gonna put it in our strut/spring compressor here. This is a fancy one that is honestly totally worth it to have. You could do this with a cheaper, less expensive one but if you're doing this more than once in your life it's worth it to get the nice one because it is much safer, much easier to use, and it's gonna make this job go way quicker. Once we have compressed the spring enough to remove the load from the upper strut mount we can take off the large shock nut and pull the bearing rubber isolator. If you are reusing the shock make sure you hold on to it after removing the nut, but since we're tossing it in scrap we're not too worried about it. Now we can put it back together. The reason we're only gonna be using these isolators and not these upper bearing mounts is because we're gonna be utilizing a set of Maximum Motorsports caster/camber plates on top of our new struts. Now these are spec'ed out and required by the class because the stock alignment settings really don't do that great on track. So this gives you some adjustability of castor and camber independently of each other in the car. That way we can set up the suspension just the way we like, and it comes with all the hardware you need to put it together. These are all the pieces and this is what it looks like when it's assembled. It even comes with a rubber band to kinda hold everything together while you get it up in the car. So we'll get our new isolator, new spring, new strut, and castor/camber plates together and in the car. The assembly process is the same but in reverse with all the new parts. Since this is a lower height spring it doesn't need to be compressed as much for installation. The important thing is to make sure the pigtails, or ends of the coil spring, are properly seated in the upper and lower notches when mating it with the strut. The new strut mount nut can be tightened down, and then the spring can be released and the whole assembly removed to be installed in the car. These castor/camber plates allow for full adjustment of both settings. So we'll just snug down the nuts for now so we can set our alignment once the vehicle is back on the ground. We will also wait until then to tighten all of the suspension fasteners.

(Pat)>> This is also a great time to bolt in this strut tower brace from UMI Performance to keep the shock towers from flexing during cornering. With the mounts bolted to the upper strut mounts the adjustable link can be bolted in with this beefy hardware. The final piece is our new anti-roll bar, which comes with new clamshell mounts and can go in with the original end links. With all that our new front suspension upgrades are wrapped up and ready for some action. Coming up, our braking power goes up to slow our Mustang down.

(Pat)>> The finish line is in sight on our SCCA Mustang project. So far we've made some great upgrades and now it's time for the final round. Not only is it important for a race car to accelerate on a race track. It is as important to have it do the brakes right. So we're gonna upgrade this car with some cool new parts.

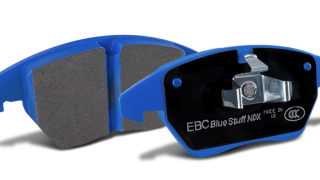

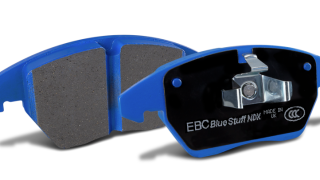

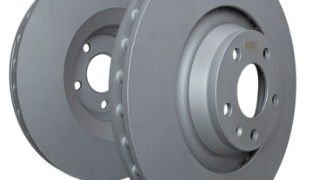

(Frankie)>> Our brakes on our car look fairly new because the car's low mile, but if we're going to the track we want all new stuff, mostly for safety. The rules are pretty specific on what you can do for brakes and what you can't. As far as rotors you can't have drilled or slotted. It's basically a stock replacement. So we do have a set of EBC stock replacement rotors. These are basically an o-e replacement but they do have a nice coating for rust prevention. When we get to the pads we're basically free reign. We can do whatever we want for compounds. So what that means is we can step up over an o-e compound. So we're gonna be using their BlueStuff pads. These are definitely a huge improvement over the OE pads, mostly in the compound department because they have a really stable temperature range that they work in. They have a really nice cold bite but when you start beating on this thing on the track and the temperatures get up they have a really even coefficient of friction. That's good because we want consistent braking. They also have a really nice V-groove in the center to remove dust particles when you're under heavy braking cause you don't want that getting in between the rotor face and the pad face cause that inhibits the braking effect. They also have a pre-engraved pad face so that they break in really quickly once you get them installed, and the body is powder coated so if you ever do have to change the pads later on in three or four years once they're worn out they come out nice and easy. They're not gonna be rusted in place. So we'll get these in but we do have to get all the stock stuff out of the way first. It doesn't get any more straight forward than this for a modern brake job. We'll remove the caliper on its own so we can clean and lube the slide pins. Then remove the caliper bracket so we can get to the old rotor. The bracket is cleaned and the slide pin bores and the pins themselves get a fresh application of high temp ceramic grease. Being careful not to touch the new rotor face with our dirty hands we can slide it on the anti-seize coated hub and use a lug nut to hold it in place. Then the bracket can be reinstalled and our new brake pads are slid into their grooves. The compressed caliper goes back on and the bolts can be tightened. Brake job done!

(Pat)>> We're outside the shop here in general population to get our wheels and tires mounted up. Keep in mind this is a spec wheel and tire as per the class rules for SCCA. So we picked up some ones from Summit Racing that were an affordable option. Our wheel is an 18 by 9.5 and it's plus 35 offset. They're gonna be fitted with a set of tires from Goodyear. This is a spec tire which is a 275/40 ZR-18 Eagle F-1 Supercar-3. Now there's a couple of great things about having a spec tire. One, we know it's gonna fit the car because that's what it's designed around and two, everyone is on a level playing field because it's the same tire. So everyone has the same footing. We're out here and we're gonna mount these in-house ourselves because we have the tools and Frankie has the talent. We've already installed these new valve stems with aftermarket t-p-m-s sensors so we can calibrate them on the vehicle later. After buttering up the wheel and tire with this slick tire soap we can verify which side of the tire is the outside and push the inner bead of the tire onto the wheel easily. The machine arms and duck bill will help us push the outer bead over the wheel without damaging it. Using a machined air chuck we can seat the tire beads, and then install the valve stem core and set the tire pressure to 30 p-s-i. Our balancing machine lets us use low profile sticky weights on the inner and outer planes to balance them all within one tenth of an ounce. [ Music ] Back in the shop the new setup can be mounted to the car with new matching lug nuts, and finally our race inspired look comes together. The last thing we need to do on this pony is give it an oil change. The oil isn't in bad shape, but we have no way to know when this oil change was last done. So better be safe than sorry. A new Motorcraft oil filter wraps up the bottom end and keeps the Ford purists at bay.

(Frankie)>> So we are going to be filling our Mustang with Schaeffer's Specialized Lubricants Supreme 9000 Series oil. Now this is a full synthetic oil they have formulated to meet and exceed the APISP certification, which is a certification for modern oils. What that means is it's gonna have great prevention against low speed preignition, it's gonna have great wear prevention for timing chain engines, which we have in this Mustang, and it has great prevention against buildup of oil residue and varnish inside the engine. Which our engine is basically new and we want to keep it that way. We're gonna put six quarts of this in there and then we'll be almost ready for the track. Schaeffers has been making high quality lubricants for over 175 years, and they have various lines of oils, greases, and shop lubricants for whatever you are working on. Slam the hood on this baby and let's get it to the track.

(Pat)>> To the track! Coming up, we take our Club Spec Mustang out on the track here at Mid-Ohio and see how our modifications are gonna perform, and we're gonna try to keep it out of the grass.

(Frankie)>> We all know what happened last time.

(Pat)>> It's time to test our 2008 Club Spec Mustang. So we left Tennessee and headed to Ohio to find a suitable track for ringing this car out.

(Frankie)>> We have finished up our Club Spec Mustang. We've brought it out here to the Mid-Ohio Sports Car Course in Lexington, Ohio. Summit Racing was a huge partner on this build and they have rented the track for the day. So we're gonna tag along, get some time on track, test and tune, and see how our upgrades perform with the car.

(Pat)>> I've been here a few times and this is Frankie's first. It's a fantastic facility and a lot of fun to drive on. We're gonna take our old car here and see what we can make happen with it, and we're gonna try to get it in before the rain because this is Ohio and you never know what the weather's gonna do next.

(Frankie)>> We do have wipers though. So if we do we're just gonna run it and see what happens.

(Pat)>> That's what a car's for.

(Jim)>> As part of our partnership with the track we get to bring employees out and they get to run through their advanced schooling. On day one they get to go through some drills and some autocross and then get to play on the big track. Once they complete that they get to come back to following year and we can spend the day on the big track.

(Frankie)>> This is the first time Jim has seen our car, and he's an experienced racer. So we had to get his opinion on it.

(Jim)>> Awesome car! It's fun to see what you guys have done with it. Obviously you started with a stock car, you found a nice start, and then you dressed it up and made it look great. New wheels, and the stripes, and everything else, and we're excited to see it on the track.

(Pat)>> This is a lot different than the Test Sled.

(Frankie)>> Going from something that weighs 2,200 pounds with almost 500 wheel to something that weighs 34-ish with 290. It's definitely a lot more car to throw around. That's a huge part of this is it's a rear wheel drive car, manual, V-8. It's got a lot of fun aspect to it. It's not too much power where you can't get yourself in trouble.

(Pat)>> Remember who you're driving with here.

(Frankie)>> I'm not worried about it. Just don't wreck it before I get a chance to drive it.

(Pat)>> I'm just gonna take it easy here and get the feel for the track.

(Frankie)>> Get some heat in the tires. This is a nice track though.

(Pat)>> It's a beautiful track.

(Frankie)>> I've never been here. I've only seen clips of races and stuff like that. It always looks super fun. This first little bit here seems really, really fun to drive. [ Music ]

(Pat)>> The brakes are unbelievably good. The thing about this car, the key word is predictability. That's on the floor right there. [ engine revving ]

(Frankie)>> It seems like a fun, fun car to drive.

(Pat)>> Well you're gonna be driving here in a little bit.

(Frankie)>> I'm excited. The Test Sled, that was a totally different animal. [ tires squealing ]

(Frankie)>> And a lot of fun, but I'm super excited to drive this thing.

(Pat)>> I've been here a few times and I think they've done some improvements on the track itself for the surface. Not bad!

(Frankie)>> That seemed super fun. Get out and do some switcher-roo! [ Music ] Only bad part about having totally different height drivers is that we have to move the racing seat so I can drive. We drilled two different holes in the seat bracket. So there's one that is about right for a six foot person or just over six foot, and then there's a whole other set that's about three and a half inches forward. We'll just take this whole seat and slide it back a little bit like that. Seat is changed. Now it's my turn. [ engine revving ] [ Music ]

(Pat)>> Nice, big back straightaway.

(Frankie)>> Look at that.

(Pat)>> I can't believe you can bolt parts on and have it run this well.

(Frankie)>> That's what I was saying earlier. It's totally changed the feel of the car.

(Pat)>> Alright, let's see what you can do here. Remember, should be on the gas at that. Let her fade out.

(Frankie)>> Kinda push out.

(Pat)>> Nice! I'm surely not the one to be giving driving tips that's for sure.

(Frankie)>> Well you definitely have more experience at this track than I do. I am all ears.

(Pat)>> On this you can usually get about 120, 130.

(Frankie)>> There's 120.

(Pat)>> Start braking. Remember, you should be in third already. This is your turn in. You should be able to almost run that cone over. A little hot coming in there. Now this is a weird blind corner. We're gonna be down on the other end here. Same thing. By the time you hit the peg of that corner you should be on the gas. This one's a little bit freaky right here. Very nice! They say that the track has a lot of forgiving corners.

(Frankie)>> The friendly curbs are really nice cause you can just run right up over them.

(Pat)>> Stay more to the middle of the track. Get close to this cone. Stay more to the middle. Too far, too far.

(Frankie)>> Little too hot there.

(Pat)>> On the gas now. There you go! Revv limiter, almost.

(Frankie)>> This thing is so much fun.

(Pat)>> Is that something or what?

(Frankie)>> Think about that. This is basically a mildly upgraded stock car and it's so much fun on the track. This is a great track too. Never being here and driving it for the first time so cool. That was an awesome drive!

(Pat)>> Very, very fun.

(Frankie)>> That was a lot of fun, and this thing kinda surprised me with how well it drove.

(Pat)>> It's pretty impressive that you can take and bolt a bunch of parts on a stock car and go out here and thrash it and handled great, and drive well, and be fast, and it makes us look better than we actually are.

(Frankie)>> The upgrades, really easy to do. Probably could do it in a weekend. The car, like you said, extremely fun to drive. We've got to thank Summit Racing for partnering with us on this build. It was a ton of fun to do and thank you to Mid-Ohio Sports Car for letting us come out here and thrash on this car around the road course and giving us part of their day. They still have cars running but I think we're gonna call it because we know our place is not on the podium.

(Pat)>> Our driving existence is a round number, zero. Time to get something to eat.

Show Full Transcript

(Frankie)>> Last time we upped the safety and power of our 2008 Club Spec Mustang and today we are gonna continue on with some serious suspension and braking upgrades.

(Pat)>> Then when she's all said and done we take it to the track and test it out.

(Frankie)>> Don't wreck it before I get a chance to drive it. [ Music ] [ drill humming ]

(Frankie)>> Welcome to the Engine Power shop where as you can tell we have our 2008 Mustang GT back on the lift because we are gonna be continuing this build. We are building this car in conjunction with Summit Racing Equipment to be legal for the SCCA's new spec racing class. It's called Spec Mustang. A spec class is an even playing field entry level driver's class for people who want to get into racing in an easy and relatively affordable way. We've already done a bunch to this car in terms of performance and safety, but today we're gonna get underneath and do some more upgrades. While we get the rest of these wheels and tires off take a look at all the modifications we've already done to this car. After giving it a shakedown on the street we brought this pony car into the shop and immediately strapped it to our chassis dyno to see what the stock wheel horsepower numbers were. Unsure whether we were happy about that or not we got cracking on upgrading our Mustang in the safety department to give us some protection from our amateur driving. We removed most of the interior and fitted up a simple bolt in roll bar from Maximum Motorsports.

(Pat)>> This complimented a set of Summit Racing fixed seats with custom brackets and comfy foam inlays because this is still a street car. Our car was speedily wrapped right here in our shop to give it a racy look, and then we completed some bolt-on performance upgrades to back it up. These were quick, simple, and included a cold air intake, short throw shifter, catback exhaust, and a flash tuner. All of our upgrades added up to a healthy improvement to 289 horsepower and 306-pound feet at the wheels. All of that worked out great but now we're only halfway done. The next thing we have to do is get on the suspension side to make this car legal both on a regional and national level for the SCCA. That includes some rulebook specific parts. First off the shocks. The shocks have been sealed at Summit to prove they have not been tampered with. Also a specific spring rate on the front and back to make the cars legal. Also we have some optional items in there like an adjustable pan hard bar and a strut brace bar, and we'll also be putting on some adjustable caster/camber plates. This car has a spec wheel and tire size. So we'll get into that later, but all these parts are very easy to bolt on and make the legal. So let's get to it.

(Frankie)>> We'll start in the back of the car by removing the old parts that we won't be reusing. The factory anti-roll bar with its tiny links is removed, followed by the pan hard bar. Finally, after unbolting them inside the trunk and on the bottom the original shocks are removed. Now that the rear end is only held in by the three link setup we gently pull the rear end down and snake the stock coil spring out. These new spec springs will lower the car and have a shorter free length so they are a bit easier to slide back in.

(Pat)>> The new Koni shocks are spec'ed out by the SCCA rules, and to be legal at an event must have an untampered seal over the shock nut like these ones Summit Racing puts on. If you plan on building a Club Spec Mustang you can call the experts at Summit Racing Equipment and they can make sure that you get a sealed set. We'll set the newly installed shock absorbers to the middle of their adjustment for now and can always tune on them later. The next upgraded piece is the adjustable pan hard bar, and the rear suspension must be loaded to install it. It is set to a starting length and then we will check the rear end center alignment once the car's fully back on the ground. The last cool part to install is this Eibach anti-roll bar, which is a stiffer design and comes with stronger billet support links to stand up to the deflection under hard loading. It comes with new hardware and clamshells to connect it to the rear axle. And with that our rear suspension upgrades are complete.

(Frankie)>> Up next, we finish up giving our Mustang its lowered swagger and some new struts.

(Frankie)>> Now that we have the rear suspension done on our 2008 Mustang we're gonna move on to the front, and it's pretty similar in terms of upgrades. We're gonna be doing a spec strut, a spec spring, an anti-roll bar, and we also have a shock tower brace and camber/castor plates to go on top of the struts. But we do have to get all of the old stuff out first. So we'll get started and then we'll show you our upgrades.

(Pat)>> Our suspension upgrades on the front of the car are a bit more involved, but we can still start by removing all of the old parts that we aren't gonna be using. The front anti-roll bar comes first, and after disconnecting the links we can unbolt the chassis mounts and pull it out of the way. Next we can unbolt the strut from the knuckle, lower the car, and unbolt the four upper bearing mount nuts before sliding the entire strut assembly out of the wheel well.

(Frankie)>> Now that we have our strut out of the car what we're gonna do is not really use any of this except for the rubber isolator at the top. We do have to pull it apart. We're gonna put it in our strut/spring compressor here. This is a fancy one that is honestly totally worth it to have. You could do this with a cheaper, less expensive one but if you're doing this more than once in your life it's worth it to get the nice one because it is much safer, much easier to use, and it's gonna make this job go way quicker. Once we have compressed the spring enough to remove the load from the upper strut mount we can take off the large shock nut and pull the bearing rubber isolator. If you are reusing the shock make sure you hold on to it after removing the nut, but since we're tossing it in scrap we're not too worried about it. Now we can put it back together. The reason we're only gonna be using these isolators and not these upper bearing mounts is because we're gonna be utilizing a set of Maximum Motorsports caster/camber plates on top of our new struts. Now these are spec'ed out and required by the class because the stock alignment settings really don't do that great on track. So this gives you some adjustability of castor and camber independently of each other in the car. That way we can set up the suspension just the way we like, and it comes with all the hardware you need to put it together. These are all the pieces and this is what it looks like when it's assembled. It even comes with a rubber band to kinda hold everything together while you get it up in the car. So we'll get our new isolator, new spring, new strut, and castor/camber plates together and in the car. The assembly process is the same but in reverse with all the new parts. Since this is a lower height spring it doesn't need to be compressed as much for installation. The important thing is to make sure the pigtails, or ends of the coil spring, are properly seated in the upper and lower notches when mating it with the strut. The new strut mount nut can be tightened down, and then the spring can be released and the whole assembly removed to be installed in the car. These castor/camber plates allow for full adjustment of both settings. So we'll just snug down the nuts for now so we can set our alignment once the vehicle is back on the ground. We will also wait until then to tighten all of the suspension fasteners.

(Pat)>> This is also a great time to bolt in this strut tower brace from UMI Performance to keep the shock towers from flexing during cornering. With the mounts bolted to the upper strut mounts the adjustable link can be bolted in with this beefy hardware. The final piece is our new anti-roll bar, which comes with new clamshell mounts and can go in with the original end links. With all that our new front suspension upgrades are wrapped up and ready for some action. Coming up, our braking power goes up to slow our Mustang down.

(Pat)>> The finish line is in sight on our SCCA Mustang project. So far we've made some great upgrades and now it's time for the final round. Not only is it important for a race car to accelerate on a race track. It is as important to have it do the brakes right. So we're gonna upgrade this car with some cool new parts.

(Frankie)>> Our brakes on our car look fairly new because the car's low mile, but if we're going to the track we want all new stuff, mostly for safety. The rules are pretty specific on what you can do for brakes and what you can't. As far as rotors you can't have drilled or slotted. It's basically a stock replacement. So we do have a set of EBC stock replacement rotors. These are basically an o-e replacement but they do have a nice coating for rust prevention. When we get to the pads we're basically free reign. We can do whatever we want for compounds. So what that means is we can step up over an o-e compound. So we're gonna be using their BlueStuff pads. These are definitely a huge improvement over the OE pads, mostly in the compound department because they have a really stable temperature range that they work in. They have a really nice cold bite but when you start beating on this thing on the track and the temperatures get up they have a really even coefficient of friction. That's good because we want consistent braking. They also have a really nice V-groove in the center to remove dust particles when you're under heavy braking cause you don't want that getting in between the rotor face and the pad face cause that inhibits the braking effect. They also have a pre-engraved pad face so that they break in really quickly once you get them installed, and the body is powder coated so if you ever do have to change the pads later on in three or four years once they're worn out they come out nice and easy. They're not gonna be rusted in place. So we'll get these in but we do have to get all the stock stuff out of the way first. It doesn't get any more straight forward than this for a modern brake job. We'll remove the caliper on its own so we can clean and lube the slide pins. Then remove the caliper bracket so we can get to the old rotor. The bracket is cleaned and the slide pin bores and the pins themselves get a fresh application of high temp ceramic grease. Being careful not to touch the new rotor face with our dirty hands we can slide it on the anti-seize coated hub and use a lug nut to hold it in place. Then the bracket can be reinstalled and our new brake pads are slid into their grooves. The compressed caliper goes back on and the bolts can be tightened. Brake job done!

(Pat)>> We're outside the shop here in general population to get our wheels and tires mounted up. Keep in mind this is a spec wheel and tire as per the class rules for SCCA. So we picked up some ones from Summit Racing that were an affordable option. Our wheel is an 18 by 9.5 and it's plus 35 offset. They're gonna be fitted with a set of tires from Goodyear. This is a spec tire which is a 275/40 ZR-18 Eagle F-1 Supercar-3. Now there's a couple of great things about having a spec tire. One, we know it's gonna fit the car because that's what it's designed around and two, everyone is on a level playing field because it's the same tire. So everyone has the same footing. We're out here and we're gonna mount these in-house ourselves because we have the tools and Frankie has the talent. We've already installed these new valve stems with aftermarket t-p-m-s sensors so we can calibrate them on the vehicle later. After buttering up the wheel and tire with this slick tire soap we can verify which side of the tire is the outside and push the inner bead of the tire onto the wheel easily. The machine arms and duck bill will help us push the outer bead over the wheel without damaging it. Using a machined air chuck we can seat the tire beads, and then install the valve stem core and set the tire pressure to 30 p-s-i. Our balancing machine lets us use low profile sticky weights on the inner and outer planes to balance them all within one tenth of an ounce. [ Music ] Back in the shop the new setup can be mounted to the car with new matching lug nuts, and finally our race inspired look comes together. The last thing we need to do on this pony is give it an oil change. The oil isn't in bad shape, but we have no way to know when this oil change was last done. So better be safe than sorry. A new Motorcraft oil filter wraps up the bottom end and keeps the Ford purists at bay.

(Frankie)>> So we are going to be filling our Mustang with Schaeffer's Specialized Lubricants Supreme 9000 Series oil. Now this is a full synthetic oil they have formulated to meet and exceed the APISP certification, which is a certification for modern oils. What that means is it's gonna have great prevention against low speed preignition, it's gonna have great wear prevention for timing chain engines, which we have in this Mustang, and it has great prevention against buildup of oil residue and varnish inside the engine. Which our engine is basically new and we want to keep it that way. We're gonna put six quarts of this in there and then we'll be almost ready for the track. Schaeffers has been making high quality lubricants for over 175 years, and they have various lines of oils, greases, and shop lubricants for whatever you are working on. Slam the hood on this baby and let's get it to the track.

(Pat)>> To the track! Coming up, we take our Club Spec Mustang out on the track here at Mid-Ohio and see how our modifications are gonna perform, and we're gonna try to keep it out of the grass.

(Frankie)>> We all know what happened last time.

(Pat)>> It's time to test our 2008 Club Spec Mustang. So we left Tennessee and headed to Ohio to find a suitable track for ringing this car out.

(Frankie)>> We have finished up our Club Spec Mustang. We've brought it out here to the Mid-Ohio Sports Car Course in Lexington, Ohio. Summit Racing was a huge partner on this build and they have rented the track for the day. So we're gonna tag along, get some time on track, test and tune, and see how our upgrades perform with the car.

(Pat)>> I've been here a few times and this is Frankie's first. It's a fantastic facility and a lot of fun to drive on. We're gonna take our old car here and see what we can make happen with it, and we're gonna try to get it in before the rain because this is Ohio and you never know what the weather's gonna do next.

(Frankie)>> We do have wipers though. So if we do we're just gonna run it and see what happens.

(Pat)>> That's what a car's for.

(Jim)>> As part of our partnership with the track we get to bring employees out and they get to run through their advanced schooling. On day one they get to go through some drills and some autocross and then get to play on the big track. Once they complete that they get to come back to following year and we can spend the day on the big track.

(Frankie)>> This is the first time Jim has seen our car, and he's an experienced racer. So we had to get his opinion on it.

(Jim)>> Awesome car! It's fun to see what you guys have done with it. Obviously you started with a stock car, you found a nice start, and then you dressed it up and made it look great. New wheels, and the stripes, and everything else, and we're excited to see it on the track.

(Pat)>> This is a lot different than the Test Sled.

(Frankie)>> Going from something that weighs 2,200 pounds with almost 500 wheel to something that weighs 34-ish with 290. It's definitely a lot more car to throw around. That's a huge part of this is it's a rear wheel drive car, manual, V-8. It's got a lot of fun aspect to it. It's not too much power where you can't get yourself in trouble.

(Pat)>> Remember who you're driving with here.

(Frankie)>> I'm not worried about it. Just don't wreck it before I get a chance to drive it.

(Pat)>> I'm just gonna take it easy here and get the feel for the track.

(Frankie)>> Get some heat in the tires. This is a nice track though.

(Pat)>> It's a beautiful track.

(Frankie)>> I've never been here. I've only seen clips of races and stuff like that. It always looks super fun. This first little bit here seems really, really fun to drive. [ Music ]

(Pat)>> The brakes are unbelievably good. The thing about this car, the key word is predictability. That's on the floor right there. [ engine revving ]

(Frankie)>> It seems like a fun, fun car to drive.

(Pat)>> Well you're gonna be driving here in a little bit.

(Frankie)>> I'm excited. The Test Sled, that was a totally different animal. [ tires squealing ]

(Frankie)>> And a lot of fun, but I'm super excited to drive this thing.

(Pat)>> I've been here a few times and I think they've done some improvements on the track itself for the surface. Not bad!

(Frankie)>> That seemed super fun. Get out and do some switcher-roo! [ Music ] Only bad part about having totally different height drivers is that we have to move the racing seat so I can drive. We drilled two different holes in the seat bracket. So there's one that is about right for a six foot person or just over six foot, and then there's a whole other set that's about three and a half inches forward. We'll just take this whole seat and slide it back a little bit like that. Seat is changed. Now it's my turn. [ engine revving ] [ Music ]

(Pat)>> Nice, big back straightaway.

(Frankie)>> Look at that.

(Pat)>> I can't believe you can bolt parts on and have it run this well.

(Frankie)>> That's what I was saying earlier. It's totally changed the feel of the car.

(Pat)>> Alright, let's see what you can do here. Remember, should be on the gas at that. Let her fade out.

(Frankie)>> Kinda push out.

(Pat)>> Nice! I'm surely not the one to be giving driving tips that's for sure.

(Frankie)>> Well you definitely have more experience at this track than I do. I am all ears.

(Pat)>> On this you can usually get about 120, 130.

(Frankie)>> There's 120.

(Pat)>> Start braking. Remember, you should be in third already. This is your turn in. You should be able to almost run that cone over. A little hot coming in there. Now this is a weird blind corner. We're gonna be down on the other end here. Same thing. By the time you hit the peg of that corner you should be on the gas. This one's a little bit freaky right here. Very nice! They say that the track has a lot of forgiving corners.

(Frankie)>> The friendly curbs are really nice cause you can just run right up over them.

(Pat)>> Stay more to the middle of the track. Get close to this cone. Stay more to the middle. Too far, too far.

(Frankie)>> Little too hot there.

(Pat)>> On the gas now. There you go! Revv limiter, almost.

(Frankie)>> This thing is so much fun.

(Pat)>> Is that something or what?

(Frankie)>> Think about that. This is basically a mildly upgraded stock car and it's so much fun on the track. This is a great track too. Never being here and driving it for the first time so cool. That was an awesome drive!

(Pat)>> Very, very fun.

(Frankie)>> That was a lot of fun, and this thing kinda surprised me with how well it drove.

(Pat)>> It's pretty impressive that you can take and bolt a bunch of parts on a stock car and go out here and thrash it and handled great, and drive well, and be fast, and it makes us look better than we actually are.

(Frankie)>> The upgrades, really easy to do. Probably could do it in a weekend. The car, like you said, extremely fun to drive. We've got to thank Summit Racing for partnering with us on this build. It was a ton of fun to do and thank you to Mid-Ohio Sports Car for letting us come out here and thrash on this car around the road course and giving us part of their day. They still have cars running but I think we're gonna call it because we know our place is not on the podium.

(Pat)>> Our driving existence is a round number, zero. Time to get something to eat.