Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Matco Tools

MATCO Tools are the Official Tool Supplier to Engine Power

The Industrial Depot

Tools, Hardware, Shop Supplies

Episode Transcript

(Pat)>> You're watching Powernation.

(Pat)>> The last time we ran this 305 everyone said why don't you put a dual plane manifold on it?

(Frankie)>> Today your wish will be granted. ♪ ♪

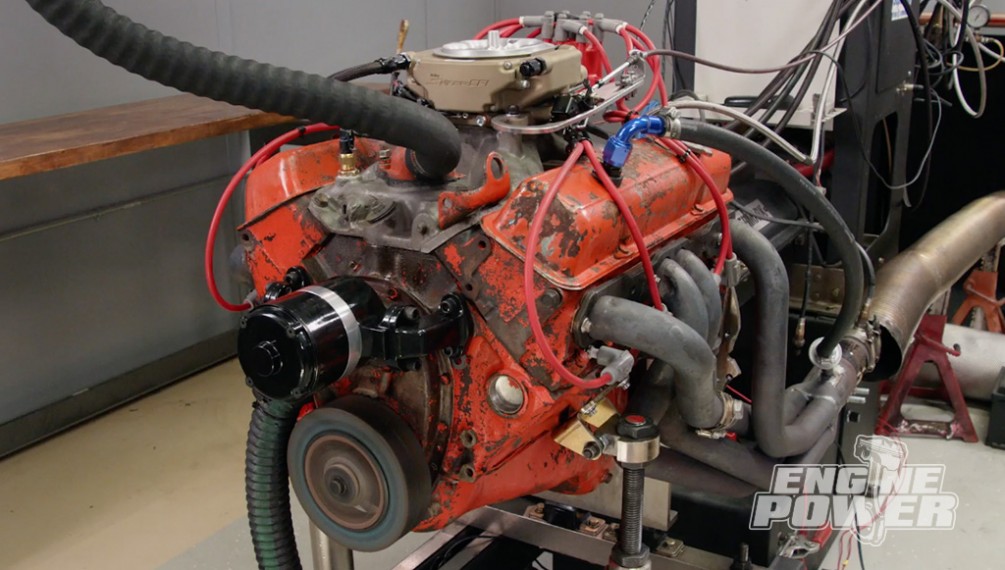

(Frankie)>> Hey everyone welcome to Engine Power! Not too long ago we started a segment called Back to Basics where we went over some simple engine tech on the dyno. We started out with our 305, and it was in pretty rough shape but we got some seriously cool results. If you haven't seen that check this out. The engine had baseline numbers of 177 horsepower and 249 pound feet of torque. We tested the 305 by making adjustments to timing, swapping carburetors, changing air cleaners, and trying several different weights of oil. By adjusting the timing for peak power we picked up 12 horsepower and 20 pound feet of torque.

(Pat)>> Carburetor selection made the biggest difference, going from a two barrel 500 c-f-m unit to a four barrel 950 c-f-m carb we gained 36 horsepower and 33 pound feet of torque.

(Frankie)>> Air cleaner selection made a smaller but still noticeable difference. The 14 inch high flow design was good for five additional horsepower and four more pound feet of torque compared to the o-e-m model.

(Pat)>> We thought that running thin 0-W-10 oil might give us a little more horsepower but on this particular engine it made almost no difference at all. By the end of the day the engine made 32 more horsepower and 34 more pound feet of torque than the baseline run. We received a ton of great comments from you viewers on what we've done so far. So we've decided to keep that tech going. One of the questions was why use a single plane intake on our testing, especially on a 305? Well quite honestly we took the engine off the shelf and that was what was on it when we started, but you will be happy to know we are going to fix that as well, but before we do anything we are going to take this out and give it a good bath to start with a clean engine.

(Frankie)>> A clean engine is a happy engine. ♪ ♪ [ pressurized water hissing ] ♪ ♪

(Pat)>> We have our banged up 305 ready to run on the dyno aside from how we want to mix the air and fuel, and this time we're gonna go a little more high tech than last time. We will be installing one of Holley's Sniper X-flow units. The X-flow has a contoured top just like a high end carburetor but it contains four 120 pound injectors that will support 800 horsepower naturally aspirated, but if you want to put a little bit of boost to it later it also has an internal two and a half bar MAP sensor. We will be using this instead of a carburetor to make easy tune-up changes without getting our hands all dirty. This engine is already hooked up with the wiring harness and it comes with a hand held to do its programming and an O-2 sensor. If you want to get into more extensive programming this can also be hooked to a laptop to get deeper into the tune-up. Right now we're just gonna get this on and fire this dude up. This unit will bolt to either a 41-50 carb flange or a spread bore flange, making it extremely versatile. ♪ ♪

(Frankie)>> So am I running this thing?

(Pat)>> Well you're gonna fire it up and you are doing the dyno on this.

(Frankie)>> Okay, that's what I was asking.

(Pat)>> Are you nervous?

(Frankie)>> A little bit but not about the dyno. Just doing it I guess.

(Pat)>> Only thing you can do is just don't mess it up.

(Frankie)>> As long as you hit start you're good.

(Pat)>> Just don't blow it up. You have obviously run some dyno stuff before.

(Frankie)>> I've ran a dyno just never here. Ready? It starts right up.

(Pat)>> I was waiting for you to pump it.

(Frankie)>> I don't need to. It just fires right up.

(Pat)>> My last birthday my wife made me this really nice cake. I'm getting up there in age right, but she made me a cake that was shaped like a clock, but I told her I couldn't eat it.

(Frankie)>> Why?

(Pat)>> Because it's too time consuming. [ engine revving ]

(Pat)>> Nothing like a smooth 305. Look at that, 214.9 and 277. We didn't make any fuel adjustments. We have the wide open at like 13-0.

(Frankie)>> Super rich but that's pretty close, and actually more power than we made before.

(Pat)>> Little bit more power than before. Dang, coming up our 305 gets a little bit cleaner and a little bit meaner.

(Pat)>> I'm hanging out with Team Summit's NHRA Funny Car driver Tim Wilkerson with a table full of parts in front of us. Now with so many go fast goodies that are available what do you think are the top five things that a person can do to their vehicle for the money?

(Tim)>> I guess Pat we'll just start at the top. The basics, exhaust. That's got to be the easiest thing you can do. Just add headers onto your vehicle. You can go to your local exhaust shop. They can put you some hot rod exhaust on there to make the engine breathe better.

(Pat)>> Speaking of breathing better on the opposite side of that induction. Tell me about modern cars versus our old school stuff.

(Tim)>> Well you know late model cars now, the fuel injection systems in them are so complex that they just work so well. You can see how efficient cars are with the fuel mileage they get and the power they make out of small motors, but your older vehicles we have this kind of thing. We have a four barrel intake manifold that you know is gonna make your vehicle a little bit faster, make it a little bit more efficient. The induction system, the carburetors, now you can get a late model fuel injection. You can adapt that to your late model, your '60's Chevrolet. Make it start and run better.

(Pat)>> Another thing you have to have is good spark. So ignition is a key for something to run better and more efficiently.

(Tim)>> And here you've got a late model ignition adapting system and can turn the points system into an electronic ignition system now. Spark plug wires, all that stuff is gonna make a huge difference.

(Pat)>> Valvetrain, that can really wake up an engine.

(Tim)>> Nothing neater than a new cam shaft right? Cam shafts, late model roller rockers now have reduced all the friction problems we used to see. Now we have late model rocker arms. That kind of stuff really makes a big difference in friction reduction. These coming kits, everybody pay attention when you do that. If you're not exactly sure what you're up to people at Summit, they have people you can talk to in the tech line.

(Pat)>> Now if the engine runs good I still think it has to look good. so how about some dress up stuff.

(Tim)>> We want to open the hood up. Neat air cleaner, neat valve covers, some wire looms, maybe some chrome on our radiator hoses. We've got all kinds of neat stuff. So really Pat based on your budget you go through these one at a time you'll get some great results.

(Pat)>> I don't think I've ever heard of someone who hasn't used Seafoam some time in their career if they're a mechanic, or a d-i-y'er, or you just like working on your own car. Seafoam has been around since the 1940's and you can either put it in your fuel or your oil to keep the inside of your engine clean. Now for our particular application we're gonna be using their high mileage formula. This is specially designed for engines with over 75,000 miles. Now I'm gonna go out on a limb but I think this engine will fall into that category. So what we're gonna do is run some Seafoam through it, drain the oil, put some fresh oil in it, put another round of Seafoam through it, and then we're gonna continue with our testing. I think that's gonna do the trick. The cool thing about Seafoam is that it contains no harsh chemicals or detergents. Just petroleum based cleaners and lubricants. It cannot harm the inside of your engine. Since this engine has seen a lot of hard miles we're gonna use half a can. Alright, get some temp in it and give it some r-p-m. Get it up around 2,000, 2,500 and put 20, 25 percent load on it. It's like we're taking a road trip. We'll run this thing typically for several hundred miles doing this. We can put miles on it just by running it. Let's run this thing for a half hour.

(Frankie)>> Now we've just got to let it do its thing and just kinda sit here.

(Pat)>> Now we wait.

(Frankie)>> Need a pencil? ♪ ♪

(Pat)>> 13 down, what is a 10 letter word for awesome?

(Frankie)>> Incredible, is that right? Is that 10?

(Pat)>> Horsepower!

(Frankie)>> Oh! [ engine running ]

(Pat)>> Are we done?

(Frankie)>> Not yet.

(Pat)>> I think I have a chip problem.

(Frankie)>> I don't think it's the chip's problem.

(Pat)>> I need something to drink.

(Frankie)>> Here we go! Fastest hands in the west! I think this is the only time you should be happy about your oil being black. Put this in here before I spill it every where.

(Pat)>> Don't get that on your school pants!

(Frankie)>> The last time we ran this engine we used 0-W-10, and it's still in it. So that's why the oil looks so thin. We're replacing it with some higher viscosity oil along with another round of Seafoam. ♪ ♪ Alright let's do it again.

(Pat)>> It immediately has more oil pressure because it doesn't have lacquer thinner in it for oil.

(Frankie)>> Let's get this warmed up then.

(Pat)>> Let's do another half hour.

(Frankie)>> Did I ever tell you about my horse, Mayo?

(Pat)>> Your horse Mayo?

(Frankie)>> Yeah I called him Mayo.

(Pat)>> Why?

(Frankie)>> When I would go home Mayonnaise!

(Pat)>> What in the hell kind of joke is that?

(Frankie)>> That was good, no? Don't quit my day job huh?

(Pat)>> I think you better stick to dynoing there pal.

(Frankie)>> Yeah probably. ♪ ♪

(Pat)>> That looks actually nicer.

(Frankie)>> Way, way cleaner.

(Pat)>> Notice how it doesn't have a black tinge to it anymore.

(Frankie)>> Up next, setting the valvetrain to zero lash is supposed to give you more power but will it help our little 305? ♪ ♪

(Pat)>> We've pulled the valve covers for the first time on our 305 for a few different reasons. One we wanted to see how the Seafoam worked, and quite honestly it worked quite well. It's decently clean for how old this engine is. Two, this engine was a little valve floaty, meaning it had a few misses at the top of the r-p-m. we wanted to see what the valve spring pressure was. It's not gonna be that high I'm sure. And three, we were gonna show you some things on how to set lifter pre-load. There's a couple of different theories on what you want to do when you're setting lifter pre-load depending on what you are doing with the engine. Lifter pre-load is important for a couple of different reasons. It keeps the valvetrain quiet on an o-e-m engine. You don't want to hear that clatter. What it does is when you run the push rod down and run pre-load you actually depress the plunger and slight amount and that keeps tension between the valve, the rocker, and the push rod and the lifter, and that's what keeps everything from clacking. We are going to show you how to set lifter pre-load properly on this engine. Then we're gonna try something that you may or may not have heard of people doing at drag strip and circle tracks.

(Frankie)>> There's a common theory you'll hear at some tracks of setting the lifter pre-load at zero. So there's really no pre-load at all. This is supposed to increase power but since we have our engine on the dyno we figured we'd go ahead and test it. So what we're gonna do first is go through and set all the pre-loads at half a turn, and then we'll do a baseline run, come back, set all the pre-loads at zero, and see what happens.

(Pat)>> Setting lifter pre-load is just about the same on any engine you'll do that has push rods in it. So what we'll do is we'll turn the engine over in the direction of its rotation. I've seen people do it backwards and it screws them up. So we're gonna turn it turn this over until nothing happens and that means the engine is coming up on t-d-c on that cylinder, and what we'll do is turn over until the next thing moves will be when the exhaust valve will crack. When that happens that ensures that the intake is on the base circle of its cam load, and that's where we'll set our pre-load. So go ahead and turn me over there. [ ratchet clicking ]

(Pat)>> Next thing that will happen, exhaust cracks. We'll loosen our rocker until it has clearance between the rocker and the push rod, and we'll slowly tighten our jam nut down until that goes away, which is considered zero lash, which is right there. Now we will take at zero lash and we will add an additional half turn, and that means I have a half turn of pre-load in that lifter. With the intake set we will now turn the engine over until the intake valve cycles through and is coming back up to seat that ensures that when we set the exhaust valve the exhaust is on the base circle of its cam lobe. [ ratchet clicking ] It's through full lift and on its way back up. Now we'll set the exhaust same way. A lot of people will say turn the push rod between your fingers until you feel resistance. Well the problem with that is sometimes if the lifters aren't pumped up you can actually depress the plunger all the way to the bottom and set your pre-load and it will actually open the valve instead of pre-load the lifter. So don't do that. We want to see that there's clearance in between it. We'll tighten our jam nut until there is no clearance between the rocker, push rod, valve tip, and lifter. We're not depressing the plunger yet. We are just at zero lash and that's where we'll leave it on the next one but for right now we're gonna go ahead and put that half turn of pre-load and lifter and we're done. You'll notice that it did open the valve slightly and that's because the lifter is fully pumped up. After it bleeds down it goes right back down on its seat. Just because we have to know before the valve cover goes back on I'm gonna check seat pressure on these springs. They seem a little low just by the way the engine was acting during the pull. So we're gonna take our valve spring checker and check seat pressure on them. There's about 60, 55, 60. Anything that's loose you can check. 60, as we suspected a little bit low. 65 to 75 on the seat. Normally a hydraulic flat tappet like this is setup at about 100 pounds stock. That's a little light and that's why the engine's acting a little weird around 5,000 r-p-m. No big deal cause we're not gonna change it and it won't effect our test the way we're doing it. So they are what they are. [ engine revving ]

(Frankie)>> A little bit yeah.

(Pat)>> It essentially made the same pull. Pretty much the same pull. Okay so now let's do the zero-zero to it.

(Frankie)>> Let's see what this does. This time we'll set everything at zero lash. This will have different results from engine to engine. It'll be interesting to see what it does on our little 305. [ engine revving ]

(Frankie)>> Oh?

(Pat)>> 210 for power, 270.

(Frankie)>> Down a little bit, that's kinda what I was thinking there.

(Pat)>> That's interesting.

(Frankie)>> It's down everywhere. So you can't really deny that. It's not like it's down in one spot and same in another. That's pretty undisputable.

(Pat)>> Kinda like all the tests we did to this one we're gonna have to make something like this the same type of run on something that makes a lot of power.

(Frankie)>> I'm not opposed to that. We could try this on everything.

(Pat)>> Up next, let's see what the 305 will do with a couple of different manifolds. Loaded up high! [ engine revving ]

(Pat)>> I don't think it was that bad.

(Frankie)>> We've gone ahead and pulled the intake manifold off our 305. Now this is a really small single plane and we got a lot of comments about why we used it the first time around. To be honest it was on the engine when it came in and there really wasn't a big point to pulling it. It ran pretty well but since we can never leave well enough alone we wanted to try a few others. First up we'll be trying a high rise dual plane manifold and then we'll be going to the other end of the spectrum with a pretty racy high rise single plane manifold that came off a great running stroker project. We love to try new things here. So we're gonna compare the numbers and see how these two stack up. ♪ ♪ [ engine revving ]

(Pat)>> That loads up okay.

(Frankie)>> Very smooth! [ engine revving ]

(Pat)>> That's okay, that's inconsequential. That's not bad right there.

(Frankie)>> 286.3 at 3,600 and 220.8 at 4,400. That's a mean stomping machine.

(Pat)>> That's a difference right. Pull up that last one, number three there. Yeah look at that. It's way fatter through the torque. And is it surprising, no. I don't even know if this thing's eight to one. On an eight to one compression 305 sure.

(Frankie)>> I'm gonna take a guess and say it's completely stock.

(Pat)>> Now torque wise they're making about the same until about 3,000, but after that past 3,500 that dual plane kinda kicks its butt a little bit. Now before we start sending hate mail we know that this manifold with a taller height, larger cross sectional area, and substantial port mismatch is not a good fit for this engine, but in the spirit of testing we just want to know what it will do. [ engine revving ]

(Pat)>> Wow, loaded up fine. [ engine revving ]

(Pat)>> That's a nice looking graph. 281 for torque and almost 220 horse, 218.9. I think it's basically in the same spot. Okay so overlay the last one to this one. This is gonna be straight single plane to dual plane.

(Frankie)>> There's the difference right there.

(Pat)>> The dual plane's still a little bit better through the middle.

(Frankie)>> And then you can see right where they crossover right here around 4,600 and they switch.

(Pat)>> Alright so what did we learn right here? Well the actual small torquer single plane isn't that bad.

(Frankie)>> And I think because this engine's mostly stock everything is kinda relative because this is a mild slash stock engine. So you might see more of a difference if we go up in horsepower, which maybe we'll have to test this again later like everything else.

(Pat)>> If you had to wrap this up and tie a bow on it and say intakes matter but don't matter that much on something with this much power. That injection system is absolutely stellar, and no matter what you put it on it'll maintain the same air/fuel ratio and it'll be optimally tuned. It'll be tuned up enough to where you don't have to mess with it for cold start, or a partial throttle, or a full throttle. It's basically done all the hard work for you. So hat's off to Holley. They really have a good, that Sniper's very, very good.

(Frankie)>> Another successful dyno day. For more information on anything you've seen today check out Powernation TV dot com.

Show Full Transcript

(Pat)>> The last time we ran this 305 everyone said why don't you put a dual plane manifold on it?

(Frankie)>> Today your wish will be granted. ♪ ♪

(Frankie)>> Hey everyone welcome to Engine Power! Not too long ago we started a segment called Back to Basics where we went over some simple engine tech on the dyno. We started out with our 305, and it was in pretty rough shape but we got some seriously cool results. If you haven't seen that check this out. The engine had baseline numbers of 177 horsepower and 249 pound feet of torque. We tested the 305 by making adjustments to timing, swapping carburetors, changing air cleaners, and trying several different weights of oil. By adjusting the timing for peak power we picked up 12 horsepower and 20 pound feet of torque.

(Pat)>> Carburetor selection made the biggest difference, going from a two barrel 500 c-f-m unit to a four barrel 950 c-f-m carb we gained 36 horsepower and 33 pound feet of torque.

(Frankie)>> Air cleaner selection made a smaller but still noticeable difference. The 14 inch high flow design was good for five additional horsepower and four more pound feet of torque compared to the o-e-m model.

(Pat)>> We thought that running thin 0-W-10 oil might give us a little more horsepower but on this particular engine it made almost no difference at all. By the end of the day the engine made 32 more horsepower and 34 more pound feet of torque than the baseline run. We received a ton of great comments from you viewers on what we've done so far. So we've decided to keep that tech going. One of the questions was why use a single plane intake on our testing, especially on a 305? Well quite honestly we took the engine off the shelf and that was what was on it when we started, but you will be happy to know we are going to fix that as well, but before we do anything we are going to take this out and give it a good bath to start with a clean engine.

(Frankie)>> A clean engine is a happy engine. ♪ ♪ [ pressurized water hissing ] ♪ ♪

(Pat)>> We have our banged up 305 ready to run on the dyno aside from how we want to mix the air and fuel, and this time we're gonna go a little more high tech than last time. We will be installing one of Holley's Sniper X-flow units. The X-flow has a contoured top just like a high end carburetor but it contains four 120 pound injectors that will support 800 horsepower naturally aspirated, but if you want to put a little bit of boost to it later it also has an internal two and a half bar MAP sensor. We will be using this instead of a carburetor to make easy tune-up changes without getting our hands all dirty. This engine is already hooked up with the wiring harness and it comes with a hand held to do its programming and an O-2 sensor. If you want to get into more extensive programming this can also be hooked to a laptop to get deeper into the tune-up. Right now we're just gonna get this on and fire this dude up. This unit will bolt to either a 41-50 carb flange or a spread bore flange, making it extremely versatile. ♪ ♪

(Frankie)>> So am I running this thing?

(Pat)>> Well you're gonna fire it up and you are doing the dyno on this.

(Frankie)>> Okay, that's what I was asking.

(Pat)>> Are you nervous?

(Frankie)>> A little bit but not about the dyno. Just doing it I guess.

(Pat)>> Only thing you can do is just don't mess it up.

(Frankie)>> As long as you hit start you're good.

(Pat)>> Just don't blow it up. You have obviously run some dyno stuff before.

(Frankie)>> I've ran a dyno just never here. Ready? It starts right up.

(Pat)>> I was waiting for you to pump it.

(Frankie)>> I don't need to. It just fires right up.

(Pat)>> My last birthday my wife made me this really nice cake. I'm getting up there in age right, but she made me a cake that was shaped like a clock, but I told her I couldn't eat it.

(Frankie)>> Why?

(Pat)>> Because it's too time consuming. [ engine revving ]

(Pat)>> Nothing like a smooth 305. Look at that, 214.9 and 277. We didn't make any fuel adjustments. We have the wide open at like 13-0.

(Frankie)>> Super rich but that's pretty close, and actually more power than we made before.

(Pat)>> Little bit more power than before. Dang, coming up our 305 gets a little bit cleaner and a little bit meaner.

(Pat)>> I'm hanging out with Team Summit's NHRA Funny Car driver Tim Wilkerson with a table full of parts in front of us. Now with so many go fast goodies that are available what do you think are the top five things that a person can do to their vehicle for the money?

(Tim)>> I guess Pat we'll just start at the top. The basics, exhaust. That's got to be the easiest thing you can do. Just add headers onto your vehicle. You can go to your local exhaust shop. They can put you some hot rod exhaust on there to make the engine breathe better.

(Pat)>> Speaking of breathing better on the opposite side of that induction. Tell me about modern cars versus our old school stuff.

(Tim)>> Well you know late model cars now, the fuel injection systems in them are so complex that they just work so well. You can see how efficient cars are with the fuel mileage they get and the power they make out of small motors, but your older vehicles we have this kind of thing. We have a four barrel intake manifold that you know is gonna make your vehicle a little bit faster, make it a little bit more efficient. The induction system, the carburetors, now you can get a late model fuel injection. You can adapt that to your late model, your '60's Chevrolet. Make it start and run better.

(Pat)>> Another thing you have to have is good spark. So ignition is a key for something to run better and more efficiently.

(Tim)>> And here you've got a late model ignition adapting system and can turn the points system into an electronic ignition system now. Spark plug wires, all that stuff is gonna make a huge difference.

(Pat)>> Valvetrain, that can really wake up an engine.

(Tim)>> Nothing neater than a new cam shaft right? Cam shafts, late model roller rockers now have reduced all the friction problems we used to see. Now we have late model rocker arms. That kind of stuff really makes a big difference in friction reduction. These coming kits, everybody pay attention when you do that. If you're not exactly sure what you're up to people at Summit, they have people you can talk to in the tech line.

(Pat)>> Now if the engine runs good I still think it has to look good. so how about some dress up stuff.

(Tim)>> We want to open the hood up. Neat air cleaner, neat valve covers, some wire looms, maybe some chrome on our radiator hoses. We've got all kinds of neat stuff. So really Pat based on your budget you go through these one at a time you'll get some great results.

(Pat)>> I don't think I've ever heard of someone who hasn't used Seafoam some time in their career if they're a mechanic, or a d-i-y'er, or you just like working on your own car. Seafoam has been around since the 1940's and you can either put it in your fuel or your oil to keep the inside of your engine clean. Now for our particular application we're gonna be using their high mileage formula. This is specially designed for engines with over 75,000 miles. Now I'm gonna go out on a limb but I think this engine will fall into that category. So what we're gonna do is run some Seafoam through it, drain the oil, put some fresh oil in it, put another round of Seafoam through it, and then we're gonna continue with our testing. I think that's gonna do the trick. The cool thing about Seafoam is that it contains no harsh chemicals or detergents. Just petroleum based cleaners and lubricants. It cannot harm the inside of your engine. Since this engine has seen a lot of hard miles we're gonna use half a can. Alright, get some temp in it and give it some r-p-m. Get it up around 2,000, 2,500 and put 20, 25 percent load on it. It's like we're taking a road trip. We'll run this thing typically for several hundred miles doing this. We can put miles on it just by running it. Let's run this thing for a half hour.

(Frankie)>> Now we've just got to let it do its thing and just kinda sit here.

(Pat)>> Now we wait.

(Frankie)>> Need a pencil? ♪ ♪

(Pat)>> 13 down, what is a 10 letter word for awesome?

(Frankie)>> Incredible, is that right? Is that 10?

(Pat)>> Horsepower!

(Frankie)>> Oh! [ engine running ]

(Pat)>> Are we done?

(Frankie)>> Not yet.

(Pat)>> I think I have a chip problem.

(Frankie)>> I don't think it's the chip's problem.

(Pat)>> I need something to drink.

(Frankie)>> Here we go! Fastest hands in the west! I think this is the only time you should be happy about your oil being black. Put this in here before I spill it every where.

(Pat)>> Don't get that on your school pants!

(Frankie)>> The last time we ran this engine we used 0-W-10, and it's still in it. So that's why the oil looks so thin. We're replacing it with some higher viscosity oil along with another round of Seafoam. ♪ ♪ Alright let's do it again.

(Pat)>> It immediately has more oil pressure because it doesn't have lacquer thinner in it for oil.

(Frankie)>> Let's get this warmed up then.

(Pat)>> Let's do another half hour.

(Frankie)>> Did I ever tell you about my horse, Mayo?

(Pat)>> Your horse Mayo?

(Frankie)>> Yeah I called him Mayo.

(Pat)>> Why?

(Frankie)>> When I would go home Mayonnaise!

(Pat)>> What in the hell kind of joke is that?

(Frankie)>> That was good, no? Don't quit my day job huh?

(Pat)>> I think you better stick to dynoing there pal.

(Frankie)>> Yeah probably. ♪ ♪

(Pat)>> That looks actually nicer.

(Frankie)>> Way, way cleaner.

(Pat)>> Notice how it doesn't have a black tinge to it anymore.

(Frankie)>> Up next, setting the valvetrain to zero lash is supposed to give you more power but will it help our little 305? ♪ ♪

(Pat)>> We've pulled the valve covers for the first time on our 305 for a few different reasons. One we wanted to see how the Seafoam worked, and quite honestly it worked quite well. It's decently clean for how old this engine is. Two, this engine was a little valve floaty, meaning it had a few misses at the top of the r-p-m. we wanted to see what the valve spring pressure was. It's not gonna be that high I'm sure. And three, we were gonna show you some things on how to set lifter pre-load. There's a couple of different theories on what you want to do when you're setting lifter pre-load depending on what you are doing with the engine. Lifter pre-load is important for a couple of different reasons. It keeps the valvetrain quiet on an o-e-m engine. You don't want to hear that clatter. What it does is when you run the push rod down and run pre-load you actually depress the plunger and slight amount and that keeps tension between the valve, the rocker, and the push rod and the lifter, and that's what keeps everything from clacking. We are going to show you how to set lifter pre-load properly on this engine. Then we're gonna try something that you may or may not have heard of people doing at drag strip and circle tracks.

(Frankie)>> There's a common theory you'll hear at some tracks of setting the lifter pre-load at zero. So there's really no pre-load at all. This is supposed to increase power but since we have our engine on the dyno we figured we'd go ahead and test it. So what we're gonna do first is go through and set all the pre-loads at half a turn, and then we'll do a baseline run, come back, set all the pre-loads at zero, and see what happens.

(Pat)>> Setting lifter pre-load is just about the same on any engine you'll do that has push rods in it. So what we'll do is we'll turn the engine over in the direction of its rotation. I've seen people do it backwards and it screws them up. So we're gonna turn it turn this over until nothing happens and that means the engine is coming up on t-d-c on that cylinder, and what we'll do is turn over until the next thing moves will be when the exhaust valve will crack. When that happens that ensures that the intake is on the base circle of its cam load, and that's where we'll set our pre-load. So go ahead and turn me over there. [ ratchet clicking ]

(Pat)>> Next thing that will happen, exhaust cracks. We'll loosen our rocker until it has clearance between the rocker and the push rod, and we'll slowly tighten our jam nut down until that goes away, which is considered zero lash, which is right there. Now we will take at zero lash and we will add an additional half turn, and that means I have a half turn of pre-load in that lifter. With the intake set we will now turn the engine over until the intake valve cycles through and is coming back up to seat that ensures that when we set the exhaust valve the exhaust is on the base circle of its cam lobe. [ ratchet clicking ] It's through full lift and on its way back up. Now we'll set the exhaust same way. A lot of people will say turn the push rod between your fingers until you feel resistance. Well the problem with that is sometimes if the lifters aren't pumped up you can actually depress the plunger all the way to the bottom and set your pre-load and it will actually open the valve instead of pre-load the lifter. So don't do that. We want to see that there's clearance in between it. We'll tighten our jam nut until there is no clearance between the rocker, push rod, valve tip, and lifter. We're not depressing the plunger yet. We are just at zero lash and that's where we'll leave it on the next one but for right now we're gonna go ahead and put that half turn of pre-load and lifter and we're done. You'll notice that it did open the valve slightly and that's because the lifter is fully pumped up. After it bleeds down it goes right back down on its seat. Just because we have to know before the valve cover goes back on I'm gonna check seat pressure on these springs. They seem a little low just by the way the engine was acting during the pull. So we're gonna take our valve spring checker and check seat pressure on them. There's about 60, 55, 60. Anything that's loose you can check. 60, as we suspected a little bit low. 65 to 75 on the seat. Normally a hydraulic flat tappet like this is setup at about 100 pounds stock. That's a little light and that's why the engine's acting a little weird around 5,000 r-p-m. No big deal cause we're not gonna change it and it won't effect our test the way we're doing it. So they are what they are. [ engine revving ]

(Frankie)>> A little bit yeah.

(Pat)>> It essentially made the same pull. Pretty much the same pull. Okay so now let's do the zero-zero to it.

(Frankie)>> Let's see what this does. This time we'll set everything at zero lash. This will have different results from engine to engine. It'll be interesting to see what it does on our little 305. [ engine revving ]

(Frankie)>> Oh?

(Pat)>> 210 for power, 270.

(Frankie)>> Down a little bit, that's kinda what I was thinking there.

(Pat)>> That's interesting.

(Frankie)>> It's down everywhere. So you can't really deny that. It's not like it's down in one spot and same in another. That's pretty undisputable.

(Pat)>> Kinda like all the tests we did to this one we're gonna have to make something like this the same type of run on something that makes a lot of power.

(Frankie)>> I'm not opposed to that. We could try this on everything.

(Pat)>> Up next, let's see what the 305 will do with a couple of different manifolds. Loaded up high! [ engine revving ]

(Pat)>> I don't think it was that bad.

(Frankie)>> We've gone ahead and pulled the intake manifold off our 305. Now this is a really small single plane and we got a lot of comments about why we used it the first time around. To be honest it was on the engine when it came in and there really wasn't a big point to pulling it. It ran pretty well but since we can never leave well enough alone we wanted to try a few others. First up we'll be trying a high rise dual plane manifold and then we'll be going to the other end of the spectrum with a pretty racy high rise single plane manifold that came off a great running stroker project. We love to try new things here. So we're gonna compare the numbers and see how these two stack up. ♪ ♪ [ engine revving ]

(Pat)>> That loads up okay.

(Frankie)>> Very smooth! [ engine revving ]

(Pat)>> That's okay, that's inconsequential. That's not bad right there.

(Frankie)>> 286.3 at 3,600 and 220.8 at 4,400. That's a mean stomping machine.

(Pat)>> That's a difference right. Pull up that last one, number three there. Yeah look at that. It's way fatter through the torque. And is it surprising, no. I don't even know if this thing's eight to one. On an eight to one compression 305 sure.

(Frankie)>> I'm gonna take a guess and say it's completely stock.

(Pat)>> Now torque wise they're making about the same until about 3,000, but after that past 3,500 that dual plane kinda kicks its butt a little bit. Now before we start sending hate mail we know that this manifold with a taller height, larger cross sectional area, and substantial port mismatch is not a good fit for this engine, but in the spirit of testing we just want to know what it will do. [ engine revving ]

(Pat)>> Wow, loaded up fine. [ engine revving ]

(Pat)>> That's a nice looking graph. 281 for torque and almost 220 horse, 218.9. I think it's basically in the same spot. Okay so overlay the last one to this one. This is gonna be straight single plane to dual plane.

(Frankie)>> There's the difference right there.

(Pat)>> The dual plane's still a little bit better through the middle.

(Frankie)>> And then you can see right where they crossover right here around 4,600 and they switch.

(Pat)>> Alright so what did we learn right here? Well the actual small torquer single plane isn't that bad.

(Frankie)>> And I think because this engine's mostly stock everything is kinda relative because this is a mild slash stock engine. So you might see more of a difference if we go up in horsepower, which maybe we'll have to test this again later like everything else.

(Pat)>> If you had to wrap this up and tie a bow on it and say intakes matter but don't matter that much on something with this much power. That injection system is absolutely stellar, and no matter what you put it on it'll maintain the same air/fuel ratio and it'll be optimally tuned. It'll be tuned up enough to where you don't have to mess with it for cold start, or a partial throttle, or a full throttle. It's basically done all the hard work for you. So hat's off to Holley. They really have a good, that Sniper's very, very good.

(Frankie)>> Another successful dyno day. For more information on anything you've seen today check out Powernation TV dot com.