Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Edelbrock

AVS2 Carburetor

Matco Tools

MATCO Tools are the Official Tool Supplier to PowerNation

The Industrial Depot

Tools, Hardware, Shop Supplies

Episode Transcript

(Mike)>> The Carcass shop is working on a tow truck.

(Pat)>> We can't do anything about the way it looks but we can definitely change the way it runs. [ Music ]

(Mike)>> Hey everybody we're hanging out in the big ole staging area here at Powernation studios with Jeremy and Jimmy from Carcass. Now they want to talk about some plans on a project they have in the works. Now these guys throw all the rules out the door when they build their project vehicles and they put together some pretty cool rigs, but since Pat and I do supply a lot of the engines for the projects around here we have a little idea of what they want to talk about.

(Pat)>> Now the idea of having us build another engine for these guys is pretty obvious. Look what we have sitting in the studio, but we are going to listen to them because they always have some sort of crazy ideas they're throwing around. Tell us about this.

(Jeremy)>> So we were brain storming and this is what we came up with. You know when you see a tow truck you associate it with being slow, and they're always helping people. Why not take something that's extremely slow, make it go really fast, but still help people by bringing them enjoyment as it rips down a drag strip.

(Pat)>> I like it already.

(Jimmy)>> And even cooler than that the previous owner right before we bought it he went on a 200 mile round trip towing somebody. So this truck is still fully functional but we just want to amp it up a little bit, maybe involve some nitrous.

(Mike)>> This happen on the 200 mile trip, the hood, or what?

(Pat)>> They are flirting with disaster. I think there's a song about that, but tell me about the engine. Do you know anything about the engine or anything like that?

(Jeremy)>> I know nothing about it. I don't know what's under the hood. Small block but I don't know how big or what size.

(Mike)>> This thing's gonna make pretty decent power. If you leave everything like it is on this truck you may have some issues.

(Jeremy)>> We plan on doing some major drivetrain upgrades. We've got to do a little bit of frame repair. The truck's a '77. It's been around the block a little bit. So we're gonna do what we have to do. I'll tell you what. When you guys give us a number horsepower wise we'll figure it out from transmission back on what we have to make.

(Pat)>> Speaking of horsepower, or lack thereof, open the hood on this thing. I want to see the engine.

(Jeremy)>> Is it tricky? Yeah you know that's the GM hood flex there.

(Pat)>> Look at that rig.

(Jeremy)>> There's not a whole lot underneath there.

(Pat)>> Put that board in here.

(Mike)>> That's why it was there probably.

(Pat)>> So we have an iron headed small block with an old school intake manifold, an old school single plane.

(Mike)>> Edelbrock AVS-2.

(Pat)>> That's a newer carburetor. Now is just gonna be strictly drag race or are you gonna actually drive it? I mean it has blinkers and stuff. Can you actually drive it still, or do you want to drive it around?

(Jeremy)>> Sure!

(Jimmy)>> Yeah I think so. Making it a street drivable truck would be nice too.

(Pat)>> Okay so that means pump gas, which is fine cause you can make something run, and we can make some decent power. It's gonna take a big engine to go as fast as I think you want to go. It'll be big inch big block but still pump gas, and I think we have something in the archives we can dig out. You already know what I'm talking about.

(Mike)>> We think a lot alike on this kinda stuff.

(Pat)>> Alright well there you go.

(Mike)>> Let's go check this engine out.

(Jeremy)>> Let's go look at what you guys got.

(Pat)>> We've got to dig an engine out of the archives. Alright we do have a few laying around in inventory but I think this bad boy is gonna be your best bet here.

(Jeremy)>> Well it sure is big enough.

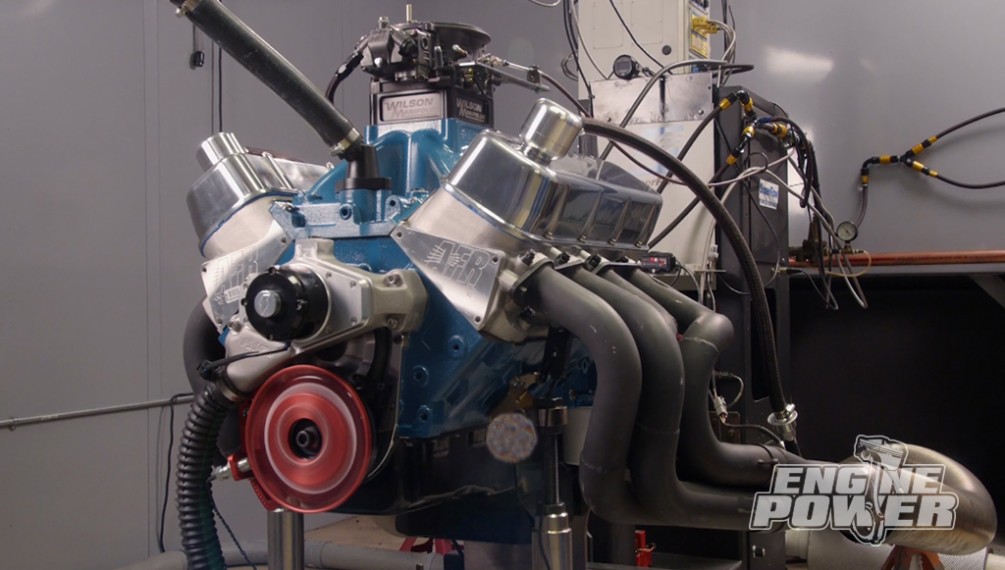

(Pat)>> Well 632 cubic inches of glorious big block Chevy.

(Jeremy)>> This had a life before. This was slotted for a project at one point right?

(Pat)>> It was slotted for a project but we stay pretty fluid around here, mostly because you guys change your mind all the time. I think this one's gonna be great for what you're gonna be doing. Definitely has a ton of power. Now this is not a pump gas engine by any stretch of the imagination right now. At some point you say we're gonna de-tune it, or de-fang it, or whatever. I don't consider it that. We're repurposing it for a specific application. We have the parts to do it as well. We have pistons, the camshaft. To reconfigure it's still gonna make a lot of power. It's just not gonna make it in a high r-p-m range with race gas. This engine made 1,020 and 830 pound feet of torque, and we turned it 7,500 before.

(Jimmy)>> The thing that I love about it too is that it's gonna drop right into our truck because it's a Chevy going into a Chevy.

(Pat)>> Yeah there's not gonna be a lot of fabrication other than the exhaust. I don't know if you can fit a two and three-eighths to a two and a half inch stepped exhaust, little tiny header on it like that, in the truck but you're gonna have to do something a little bit different there. As far as the pan, as far getting everything hooked up, no problem.

(Mike)>> With how heavy the truck is it's a hell of a lot of torque, and that's what you guys are really looking for to get that big ole thing moving.

(Pat)>> Changing the cam up we're gonna move the torque curve way down.

(Mike)>> You guys said you were gonna help out. You could come give us a tow. You saw how hard this thing is to pull out of the hole. If you guys want to roll it into our disassembly area we'll get started.

(Pat)>> Yeah go ahead and push it. A couple of strapping you lads.

(Jeremy)>> You grab a header, I'll grab a header.

(Pat)>> Help an old guy out.

(Jeremy)>> Holy cow! It's pretty but I don't know if it's too pretty to go in our truck.

(Pat)>> This way.

(Mike)>> I'm glad I didn't have to push it.

(Pat)>> You have to parallel park and back her in here.

(Jeremy)>> Thanks for the direction Mike.

(Mike)>> That thing is so big.

(Jeremy)>> It barely fits in here.

(Pat)>> It looks cool! That's an awesome engine right there.

(Mike)>> Coming up a new camshaft and pistons make this big block a perfect fit for the tow truck.

(Mike)>> How do you know if you need a high volume or high pressure oil pump? The answer is in today's tech tip.

(Tim)>> Most street engines, even high performance ones, don't require a high volume high pressure oil pump. A standard volume standard pressure oil pump can do the job. A high volume oil pump is necessary if you are using an external engine oil cooler or a remote mount oil filter. A high pressure oil pump is also recommended for racing engines to ensure adequate oil circulation at higher r-p-ms.

(Pat)>> We're continuing our 632 big block Chevy, which is going from a high compression race engine to a streetable but powerful tow truck bullet. Before we pull out the valvetrain we'll check the spring pressure with this LSM pressure tester we picked up from Summit Racing Equipment. In addition to parts Summit offers high quality tools for engine builders. This particular build we'll reuse the majority of the parts already installed. So we're giving everything a careful inspection to make sure nothing looks damaged or compromised. Keeping everything in order will make reassembly much easier and ensure the engine runs its best. Parts develop a specific wear pattern over time, and putting everything back in the same place is crucial for reliability. The oil looks good, which indicates a well running engine. The foundation we will still be using for this build is a tall deck 632 cast in the USA block from Blueprint Engines. It gets cleaned in our jet washer for about one hour at 150 degrees. We wanted a color that would complement the paint job on the Chevy but still keep the General Motors theme. We chose GM blue. [ Music ] Now that the block has been cleaned and repainted we can start the assembly process, and as you can probably figure out we're reusing the majority of the parts but we are changing things because we are going from a race gas engine to a pump gas engine. So we have to change the compression ratio to start. We are changing the rod and piston assemblies back to what it came with originally. Now we are taking literally five points of compression out of the engine, from 15:1 down to around 10:1 for pump gas. Also that means we are changing the cam shaft as well. The operating range of the engine will be changing. So because we're not turning it a bunch more r-p-m we are gonna take some cam shaft out of it. That's not gonna mean that it makes a whole lot less power though. You'll see, but everything else is in very good shape and we're gonna use 90 percent of it. So let's get started. The previous application for this engine was high horsepower for a short amount of time on race gas. So we put some really really good parts in it. Jesel belt drive, Jesel valvetrain, Trent push rods, and Comp's solid roller lifters. Now these will all stay because those won't change the operation of the engine itself. We are just changing its range. I've also taken and cleaned up the bearings, and put them back in. The main bearings are perfect and we're gonna reuse them, and everything is in good shape. We will have to put new rod bearings in because we are changing the connecting rod. [ Music ] Permatex Ultra Slick Assembly Lube goes on both sides of the main bearings. [ Music ] With the caps snugged up they are torqued to 100 pound feet. [ torque wrench clicking ]

(Pat)>> Crankshaft end play measures at a comfortable six thousandths. With the crankshaft in for good it's time to focus on the camshaft. Now remember because we are changing the engine's operating range and its fuel we have to take some camshaft out of it, but because it is 632 cubic inches it's gonna sound like it's still a big cam but it's gonna be more suited for our application. The one coming out is 285 and 300 at 50 with over 800 lift. A little extreme for what we're doing. So we are switching up to a cam that we had in a different pump gas big inch project. This camshaft is 274 on the intake, 284 on a 114 and it has around 770 lift. Much more suited for our application. The Jesel hub adapter goes back on and the cam is ready for installation. It's a custom grind Comp cam that was previously made for a 572 inch pump gas build. This cam also has a 4-7 firing order swap. The billet timing cover with an O-ring seal slides back into place, and the belt drive is reinstalled. [ Music ] Finally the cam is degreed. It comes in at 110 degrees intake centerline, which is four degrees advanced. Coming up the big block decompresses a little.

(Pat)>> The biggest change we are making to this engine is the static compression ratio. Remember this was a race gas engine with 15.03:1 compression because it has a 42cc dome on top of the piston. We are gonna be reducing that by 5.46 points of a compression with a 14cc dish. Now that does a couple of things. One, we can run pump gas because we don't need all that octane to keep it away from detonation. Two, it widens a tuning window because I am sure these guys are gonna hammer that nitrous and we want a tuning window that will keep them out of trouble. So we're gonna put these in. The bearing clearance has already been set with new Clevite bearings at 25 to 27 ten thousandths. With the pins and skirts fully lubricated we'll drop the pistons into our ARP tapered piston ring compressor at 4-600 bore. Then tap them into the bores. They have been refinished with a 320 grit ball hone to promote good ring seal. We're using ARP 87-40 rod bolts, which are torqued to 90 pound feet to achieve the recommended stretch of 59 to 63 ten thousandths. We'll check this with our ARP rod bolt stretch gauge. Every bolt is checked, not just one or two. Using a feeler gauge we'll check the rod side clearance. It comes in at 20 thousandths. The Melling high volume oil pump drops in and the fastener is torqued to 60 pound feet. Permatex Right Stuff One Minute Gasket Maker secures the oil pan gasket, and the oil pan is bolted down. [ Music ] The ATI super damper is installed with our Matco balancer installer kit. Before the heads go on true t-d-c is set on the pointer using a piston stop. [ Music ] The Comp Cams heavy duty solid roller lifters go back in their respective lifter bores. The Fel Pro m-l-s gasket with a 53 thousandths compressed thickness drops on, followed by the AFR 385 Magnum competition series racing heads. The ARP stud installer makes quick work of tightening up the fasteners. They are torqued to 80 pound feet. The Trent 130 thousandths walled chro-moly pushrods slide in, followed by a set of Jesel Sportsman Series shaft rockers. The ratio is one point eight. The LSM valve lash tool lets you tighten and torque the rocker adjustor in one step. Cold lash is set to 14 thousandths on the intake and 16 thousandths on the exhaust. The Edelbrock Super Victor 2 intake manifold is designed for high flow 1,000 horsepower plus drag race applications. It features 5.38 square inches of runner area at the plenum. Comp Cam's Valvetrain Assembly Spray penetrates deep into the rockers and springs making sure they don't run dry on initial startup. The Summit cast aluminum polished valve covers seal up the engine nicely so the Moroso crankcase evac breathers can do their job. Finally the MSD crank trigger provides incredibly accurate timing, and with the Summit Pro Flow water pump in position we're off to the dyno cell. If you have a late model Chrysler power plant check this out. This is the new Holley Terminator-X Gen 3 Hemi kit. Designed for 2007 through 2013 plus engines, it ships pre-loaded with base maps for common gen-3 Hemi engine combinations to get your vehicle on the road or track fast. The 3.5 inch touch screen includes a calibration wizard as well as tuning and gauge display functions, plus data logging. Also a Bosch wide band O-2 sensor provides accurate readings and precise tuning control. Nitrous and boosted applications are fully supported. Plus there are four inputs for things like electric fans, progressive nitrous control, boost solenoids, and much more. This system has a ton of features. Go to Holley dot com to find out more. The Ford Coyote has become a very desirable engine for all types of swaps nowadays. Now if you want to do that for yourself or just replace a tired old engine in your daily driver look no further than Powertrain Products' 5 liter Coyote. The block and heads are both made out of aluminum, and the engine has been updated to improve performance over the factory design. Powertrain Products addresses known o-e-m problems and re-engineers the areas for better durability and performance. The engine comes with a full gasket set, and the oil pan and timing cover are pre-installed. Included in the price is Powertrain Products' five year promise warranty. Head over to Shop Engines dot com to find out more. Up next the 632 is truly the right tool for the job.

(Pat)>> Alright our 632 is anchored to the dyno, and remember we have taken 5 points of compression out of this for pump gas, and because it's for Carcass we have someone from Carcass here.

(Jimmy)>> I'm so excited to run this thing man.

(Pat)>> Me too! I think you might be as excited as I am. Why are you all dirty?

(Jimmy)>> I've been sanding all morning and that's just how it goes.

(Pat)>> That body work stuff, that's not for us here. Let's see if we can light this thing. What do you think?

(Jimmy)>> Yeah let's do it man. [ engine idling ]

(Jimmy)>> Yeah that's what I like to hear.

(Pat)>> Alright so this engine's a little bit on the unique side and here's why. You guys wanted to use this for pump gas driving around drag strip and you said you're gonna spray it. So I intentionally knocked compression way down. Static compression ratio is 9.56:1, and I have a gigantic cam in it for that kind of compression ratio. This is a 274/284 on a 114. This is essentially if I was gonna build a nitrous race cam this is what it would be because if you want the engine to make a bunch of power you've got to cam up for that amount of power, but it's weird if you're doing it for nitrous. Just running around this is gonna be probably a little bit too big of a cam if you were gonna be naturally aspirated only. We're not there. We're gonna actually spray in the truck. So I'm at 30 degrees of timing right now. I'm gonna make the pulls from 4,000 to 6,500. First pull I'm gonna make it 600 per second just to make sure the engine keeps its guts. What do you think it's gonna make?

(Jimmy)>> 785!

(Pat)>> I like the way you think. [ engine revving ]

(Jimmy)>> That sounds dang good I'll tell you that. Oh wow!

(Pat)>> What'd you say it was gonna make?

(Jimmy)>> 830 geez man!

(Pat)>> 828 at 6,300, 731 pound feet of torque at 5,000. We have already achieved our goals and that is with 30 degrees of timing. We could put a way shorter cam in it. You could put a 250's at 50 cam in it and the torque would be way higher, but what happens on pump gas something this big with that kind of cylinder pressure when you load it for extended amounts of time this will become a detonation machine. If you wouldn't put good gas in it this would actually detonate and be detrimental to the running of the engine. I purposely put this big cam in it so it bleeds off cylinder pressure at lower r-p-ms. Now it's gonna have lower torque. At 4,000 r-p-m it's still making 638 pound feet of torque.

(Jimmy)>> Yeah that's not much at all.

(Pat)>> People always say big cams are doggy on the street. I guarantee you this is not gonna be doggy anywhere. Okay so before I make any changes what I'm gonna do is I'm gonna make a pull at 300 r-p-m per second because that does load it more like it's in the vehicle. So that's what we're gonna do.

(Jimmy)>> So is that loading it harder than 600?

(Pat)>> Yes, absolutely, it loads it harder. I was just hoping for 800.

(Jimmy)>> This is exciting!

(Pat)>> I kinda knew what it was gonna make. [ engine revving ]

(Pat)>> 826 for power, not bad, at 6,300, 734 pound feet of torque at 5,400.

(Jimmy)>> That's crazy man.

(Pat)>> That's pretty mean right there. You can tell a lot about how an engine is running by looking at the spark plugs. After a full pull at 300 r-p-m per second we see no damage and the plug looks clean, giving us the green light to increase ignition timing. That looks really nice. We'll advance the crank trigger two degrees for a total timing of 32 degrees. [ engine revving ]

(Pat)>> 839, 6,400, 735 pound feet of torque.

(Jimmy)>> I can't wait to get this thing in the truck and see what it can do. It's gonna be a little scary I think.

(Pat)>> This is one of those things where we can get the tune on the razor's edge. That is what you don't want on a street engine. You want something that has a good average. If you're gonna miss you always miss on the rich side. If you miss on the lean side it's gonna cook something. If you miss on the rich side maybe it'll drop power, maybe it'll fowl some plugs. We'll add another two degrees of ignition timing for a total of 34. [ engine revving ]

(Pat)>> We did it! That's what I was looking for right there.

(Jimmy)>> 850, that's a good even number to hit.

(Pat)>> That's a nice good even number to stop. I'm gonna make sure everything's all cool, and pull this thing off, and the next time you'll see I'll be rolling into your studio.

(Jimmy)>> That's rad yeah! I can't wait.

(Pat)>> For more information on anything you've seen today visit Powernation t-v dot com.

Show Full Transcript

(Pat)>> We can't do anything about the way it looks but we can definitely change the way it runs. [ Music ]

(Mike)>> Hey everybody we're hanging out in the big ole staging area here at Powernation studios with Jeremy and Jimmy from Carcass. Now they want to talk about some plans on a project they have in the works. Now these guys throw all the rules out the door when they build their project vehicles and they put together some pretty cool rigs, but since Pat and I do supply a lot of the engines for the projects around here we have a little idea of what they want to talk about.

(Pat)>> Now the idea of having us build another engine for these guys is pretty obvious. Look what we have sitting in the studio, but we are going to listen to them because they always have some sort of crazy ideas they're throwing around. Tell us about this.

(Jeremy)>> So we were brain storming and this is what we came up with. You know when you see a tow truck you associate it with being slow, and they're always helping people. Why not take something that's extremely slow, make it go really fast, but still help people by bringing them enjoyment as it rips down a drag strip.

(Pat)>> I like it already.

(Jimmy)>> And even cooler than that the previous owner right before we bought it he went on a 200 mile round trip towing somebody. So this truck is still fully functional but we just want to amp it up a little bit, maybe involve some nitrous.

(Mike)>> This happen on the 200 mile trip, the hood, or what?

(Pat)>> They are flirting with disaster. I think there's a song about that, but tell me about the engine. Do you know anything about the engine or anything like that?

(Jeremy)>> I know nothing about it. I don't know what's under the hood. Small block but I don't know how big or what size.

(Mike)>> This thing's gonna make pretty decent power. If you leave everything like it is on this truck you may have some issues.

(Jeremy)>> We plan on doing some major drivetrain upgrades. We've got to do a little bit of frame repair. The truck's a '77. It's been around the block a little bit. So we're gonna do what we have to do. I'll tell you what. When you guys give us a number horsepower wise we'll figure it out from transmission back on what we have to make.

(Pat)>> Speaking of horsepower, or lack thereof, open the hood on this thing. I want to see the engine.

(Jeremy)>> Is it tricky? Yeah you know that's the GM hood flex there.

(Pat)>> Look at that rig.

(Jeremy)>> There's not a whole lot underneath there.

(Pat)>> Put that board in here.

(Mike)>> That's why it was there probably.

(Pat)>> So we have an iron headed small block with an old school intake manifold, an old school single plane.

(Mike)>> Edelbrock AVS-2.

(Pat)>> That's a newer carburetor. Now is just gonna be strictly drag race or are you gonna actually drive it? I mean it has blinkers and stuff. Can you actually drive it still, or do you want to drive it around?

(Jeremy)>> Sure!

(Jimmy)>> Yeah I think so. Making it a street drivable truck would be nice too.

(Pat)>> Okay so that means pump gas, which is fine cause you can make something run, and we can make some decent power. It's gonna take a big engine to go as fast as I think you want to go. It'll be big inch big block but still pump gas, and I think we have something in the archives we can dig out. You already know what I'm talking about.

(Mike)>> We think a lot alike on this kinda stuff.

(Pat)>> Alright well there you go.

(Mike)>> Let's go check this engine out.

(Jeremy)>> Let's go look at what you guys got.

(Pat)>> We've got to dig an engine out of the archives. Alright we do have a few laying around in inventory but I think this bad boy is gonna be your best bet here.

(Jeremy)>> Well it sure is big enough.

(Pat)>> Well 632 cubic inches of glorious big block Chevy.

(Jeremy)>> This had a life before. This was slotted for a project at one point right?

(Pat)>> It was slotted for a project but we stay pretty fluid around here, mostly because you guys change your mind all the time. I think this one's gonna be great for what you're gonna be doing. Definitely has a ton of power. Now this is not a pump gas engine by any stretch of the imagination right now. At some point you say we're gonna de-tune it, or de-fang it, or whatever. I don't consider it that. We're repurposing it for a specific application. We have the parts to do it as well. We have pistons, the camshaft. To reconfigure it's still gonna make a lot of power. It's just not gonna make it in a high r-p-m range with race gas. This engine made 1,020 and 830 pound feet of torque, and we turned it 7,500 before.

(Jimmy)>> The thing that I love about it too is that it's gonna drop right into our truck because it's a Chevy going into a Chevy.

(Pat)>> Yeah there's not gonna be a lot of fabrication other than the exhaust. I don't know if you can fit a two and three-eighths to a two and a half inch stepped exhaust, little tiny header on it like that, in the truck but you're gonna have to do something a little bit different there. As far as the pan, as far getting everything hooked up, no problem.

(Mike)>> With how heavy the truck is it's a hell of a lot of torque, and that's what you guys are really looking for to get that big ole thing moving.

(Pat)>> Changing the cam up we're gonna move the torque curve way down.

(Mike)>> You guys said you were gonna help out. You could come give us a tow. You saw how hard this thing is to pull out of the hole. If you guys want to roll it into our disassembly area we'll get started.

(Pat)>> Yeah go ahead and push it. A couple of strapping you lads.

(Jeremy)>> You grab a header, I'll grab a header.

(Pat)>> Help an old guy out.

(Jeremy)>> Holy cow! It's pretty but I don't know if it's too pretty to go in our truck.

(Pat)>> This way.

(Mike)>> I'm glad I didn't have to push it.

(Pat)>> You have to parallel park and back her in here.

(Jeremy)>> Thanks for the direction Mike.

(Mike)>> That thing is so big.

(Jeremy)>> It barely fits in here.

(Pat)>> It looks cool! That's an awesome engine right there.

(Mike)>> Coming up a new camshaft and pistons make this big block a perfect fit for the tow truck.

(Mike)>> How do you know if you need a high volume or high pressure oil pump? The answer is in today's tech tip.

(Tim)>> Most street engines, even high performance ones, don't require a high volume high pressure oil pump. A standard volume standard pressure oil pump can do the job. A high volume oil pump is necessary if you are using an external engine oil cooler or a remote mount oil filter. A high pressure oil pump is also recommended for racing engines to ensure adequate oil circulation at higher r-p-ms.

(Pat)>> We're continuing our 632 big block Chevy, which is going from a high compression race engine to a streetable but powerful tow truck bullet. Before we pull out the valvetrain we'll check the spring pressure with this LSM pressure tester we picked up from Summit Racing Equipment. In addition to parts Summit offers high quality tools for engine builders. This particular build we'll reuse the majority of the parts already installed. So we're giving everything a careful inspection to make sure nothing looks damaged or compromised. Keeping everything in order will make reassembly much easier and ensure the engine runs its best. Parts develop a specific wear pattern over time, and putting everything back in the same place is crucial for reliability. The oil looks good, which indicates a well running engine. The foundation we will still be using for this build is a tall deck 632 cast in the USA block from Blueprint Engines. It gets cleaned in our jet washer for about one hour at 150 degrees. We wanted a color that would complement the paint job on the Chevy but still keep the General Motors theme. We chose GM blue. [ Music ] Now that the block has been cleaned and repainted we can start the assembly process, and as you can probably figure out we're reusing the majority of the parts but we are changing things because we are going from a race gas engine to a pump gas engine. So we have to change the compression ratio to start. We are changing the rod and piston assemblies back to what it came with originally. Now we are taking literally five points of compression out of the engine, from 15:1 down to around 10:1 for pump gas. Also that means we are changing the cam shaft as well. The operating range of the engine will be changing. So because we're not turning it a bunch more r-p-m we are gonna take some cam shaft out of it. That's not gonna mean that it makes a whole lot less power though. You'll see, but everything else is in very good shape and we're gonna use 90 percent of it. So let's get started. The previous application for this engine was high horsepower for a short amount of time on race gas. So we put some really really good parts in it. Jesel belt drive, Jesel valvetrain, Trent push rods, and Comp's solid roller lifters. Now these will all stay because those won't change the operation of the engine itself. We are just changing its range. I've also taken and cleaned up the bearings, and put them back in. The main bearings are perfect and we're gonna reuse them, and everything is in good shape. We will have to put new rod bearings in because we are changing the connecting rod. [ Music ] Permatex Ultra Slick Assembly Lube goes on both sides of the main bearings. [ Music ] With the caps snugged up they are torqued to 100 pound feet. [ torque wrench clicking ]

(Pat)>> Crankshaft end play measures at a comfortable six thousandths. With the crankshaft in for good it's time to focus on the camshaft. Now remember because we are changing the engine's operating range and its fuel we have to take some camshaft out of it, but because it is 632 cubic inches it's gonna sound like it's still a big cam but it's gonna be more suited for our application. The one coming out is 285 and 300 at 50 with over 800 lift. A little extreme for what we're doing. So we are switching up to a cam that we had in a different pump gas big inch project. This camshaft is 274 on the intake, 284 on a 114 and it has around 770 lift. Much more suited for our application. The Jesel hub adapter goes back on and the cam is ready for installation. It's a custom grind Comp cam that was previously made for a 572 inch pump gas build. This cam also has a 4-7 firing order swap. The billet timing cover with an O-ring seal slides back into place, and the belt drive is reinstalled. [ Music ] Finally the cam is degreed. It comes in at 110 degrees intake centerline, which is four degrees advanced. Coming up the big block decompresses a little.

(Pat)>> The biggest change we are making to this engine is the static compression ratio. Remember this was a race gas engine with 15.03:1 compression because it has a 42cc dome on top of the piston. We are gonna be reducing that by 5.46 points of a compression with a 14cc dish. Now that does a couple of things. One, we can run pump gas because we don't need all that octane to keep it away from detonation. Two, it widens a tuning window because I am sure these guys are gonna hammer that nitrous and we want a tuning window that will keep them out of trouble. So we're gonna put these in. The bearing clearance has already been set with new Clevite bearings at 25 to 27 ten thousandths. With the pins and skirts fully lubricated we'll drop the pistons into our ARP tapered piston ring compressor at 4-600 bore. Then tap them into the bores. They have been refinished with a 320 grit ball hone to promote good ring seal. We're using ARP 87-40 rod bolts, which are torqued to 90 pound feet to achieve the recommended stretch of 59 to 63 ten thousandths. We'll check this with our ARP rod bolt stretch gauge. Every bolt is checked, not just one or two. Using a feeler gauge we'll check the rod side clearance. It comes in at 20 thousandths. The Melling high volume oil pump drops in and the fastener is torqued to 60 pound feet. Permatex Right Stuff One Minute Gasket Maker secures the oil pan gasket, and the oil pan is bolted down. [ Music ] The ATI super damper is installed with our Matco balancer installer kit. Before the heads go on true t-d-c is set on the pointer using a piston stop. [ Music ] The Comp Cams heavy duty solid roller lifters go back in their respective lifter bores. The Fel Pro m-l-s gasket with a 53 thousandths compressed thickness drops on, followed by the AFR 385 Magnum competition series racing heads. The ARP stud installer makes quick work of tightening up the fasteners. They are torqued to 80 pound feet. The Trent 130 thousandths walled chro-moly pushrods slide in, followed by a set of Jesel Sportsman Series shaft rockers. The ratio is one point eight. The LSM valve lash tool lets you tighten and torque the rocker adjustor in one step. Cold lash is set to 14 thousandths on the intake and 16 thousandths on the exhaust. The Edelbrock Super Victor 2 intake manifold is designed for high flow 1,000 horsepower plus drag race applications. It features 5.38 square inches of runner area at the plenum. Comp Cam's Valvetrain Assembly Spray penetrates deep into the rockers and springs making sure they don't run dry on initial startup. The Summit cast aluminum polished valve covers seal up the engine nicely so the Moroso crankcase evac breathers can do their job. Finally the MSD crank trigger provides incredibly accurate timing, and with the Summit Pro Flow water pump in position we're off to the dyno cell. If you have a late model Chrysler power plant check this out. This is the new Holley Terminator-X Gen 3 Hemi kit. Designed for 2007 through 2013 plus engines, it ships pre-loaded with base maps for common gen-3 Hemi engine combinations to get your vehicle on the road or track fast. The 3.5 inch touch screen includes a calibration wizard as well as tuning and gauge display functions, plus data logging. Also a Bosch wide band O-2 sensor provides accurate readings and precise tuning control. Nitrous and boosted applications are fully supported. Plus there are four inputs for things like electric fans, progressive nitrous control, boost solenoids, and much more. This system has a ton of features. Go to Holley dot com to find out more. The Ford Coyote has become a very desirable engine for all types of swaps nowadays. Now if you want to do that for yourself or just replace a tired old engine in your daily driver look no further than Powertrain Products' 5 liter Coyote. The block and heads are both made out of aluminum, and the engine has been updated to improve performance over the factory design. Powertrain Products addresses known o-e-m problems and re-engineers the areas for better durability and performance. The engine comes with a full gasket set, and the oil pan and timing cover are pre-installed. Included in the price is Powertrain Products' five year promise warranty. Head over to Shop Engines dot com to find out more. Up next the 632 is truly the right tool for the job.

(Pat)>> Alright our 632 is anchored to the dyno, and remember we have taken 5 points of compression out of this for pump gas, and because it's for Carcass we have someone from Carcass here.

(Jimmy)>> I'm so excited to run this thing man.

(Pat)>> Me too! I think you might be as excited as I am. Why are you all dirty?

(Jimmy)>> I've been sanding all morning and that's just how it goes.

(Pat)>> That body work stuff, that's not for us here. Let's see if we can light this thing. What do you think?

(Jimmy)>> Yeah let's do it man. [ engine idling ]

(Jimmy)>> Yeah that's what I like to hear.

(Pat)>> Alright so this engine's a little bit on the unique side and here's why. You guys wanted to use this for pump gas driving around drag strip and you said you're gonna spray it. So I intentionally knocked compression way down. Static compression ratio is 9.56:1, and I have a gigantic cam in it for that kind of compression ratio. This is a 274/284 on a 114. This is essentially if I was gonna build a nitrous race cam this is what it would be because if you want the engine to make a bunch of power you've got to cam up for that amount of power, but it's weird if you're doing it for nitrous. Just running around this is gonna be probably a little bit too big of a cam if you were gonna be naturally aspirated only. We're not there. We're gonna actually spray in the truck. So I'm at 30 degrees of timing right now. I'm gonna make the pulls from 4,000 to 6,500. First pull I'm gonna make it 600 per second just to make sure the engine keeps its guts. What do you think it's gonna make?

(Jimmy)>> 785!

(Pat)>> I like the way you think. [ engine revving ]

(Jimmy)>> That sounds dang good I'll tell you that. Oh wow!

(Pat)>> What'd you say it was gonna make?

(Jimmy)>> 830 geez man!

(Pat)>> 828 at 6,300, 731 pound feet of torque at 5,000. We have already achieved our goals and that is with 30 degrees of timing. We could put a way shorter cam in it. You could put a 250's at 50 cam in it and the torque would be way higher, but what happens on pump gas something this big with that kind of cylinder pressure when you load it for extended amounts of time this will become a detonation machine. If you wouldn't put good gas in it this would actually detonate and be detrimental to the running of the engine. I purposely put this big cam in it so it bleeds off cylinder pressure at lower r-p-ms. Now it's gonna have lower torque. At 4,000 r-p-m it's still making 638 pound feet of torque.

(Jimmy)>> Yeah that's not much at all.

(Pat)>> People always say big cams are doggy on the street. I guarantee you this is not gonna be doggy anywhere. Okay so before I make any changes what I'm gonna do is I'm gonna make a pull at 300 r-p-m per second because that does load it more like it's in the vehicle. So that's what we're gonna do.

(Jimmy)>> So is that loading it harder than 600?

(Pat)>> Yes, absolutely, it loads it harder. I was just hoping for 800.

(Jimmy)>> This is exciting!

(Pat)>> I kinda knew what it was gonna make. [ engine revving ]

(Pat)>> 826 for power, not bad, at 6,300, 734 pound feet of torque at 5,400.

(Jimmy)>> That's crazy man.

(Pat)>> That's pretty mean right there. You can tell a lot about how an engine is running by looking at the spark plugs. After a full pull at 300 r-p-m per second we see no damage and the plug looks clean, giving us the green light to increase ignition timing. That looks really nice. We'll advance the crank trigger two degrees for a total timing of 32 degrees. [ engine revving ]

(Pat)>> 839, 6,400, 735 pound feet of torque.

(Jimmy)>> I can't wait to get this thing in the truck and see what it can do. It's gonna be a little scary I think.

(Pat)>> This is one of those things where we can get the tune on the razor's edge. That is what you don't want on a street engine. You want something that has a good average. If you're gonna miss you always miss on the rich side. If you miss on the lean side it's gonna cook something. If you miss on the rich side maybe it'll drop power, maybe it'll fowl some plugs. We'll add another two degrees of ignition timing for a total of 34. [ engine revving ]

(Pat)>> We did it! That's what I was looking for right there.

(Jimmy)>> 850, that's a good even number to hit.

(Pat)>> That's a nice good even number to stop. I'm gonna make sure everything's all cool, and pull this thing off, and the next time you'll see I'll be rolling into your studio.

(Jimmy)>> That's rad yeah! I can't wait.

(Pat)>> For more information on anything you've seen today visit Powernation t-v dot com.