Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Matco Tools

MATCO Tools are the Official Tool Supplier to Engine Power

The Industrial Depot

Tools, Hardware, and Shop Supplies

Trend Performance

Push Rods 8.500 / .105

Episode Transcript

(Narrator)>> You've got the skills to pay the bills, and they've got the tools. Today on Engine Power we get a sneak peek at all the cool new items at the Matco Tool Expo. Plus our stroker Windsor gets a couple of upgrades that make big power. ♪ ♪

(Mike)>> Welcome to Engine Power. We don't like to brag at all but today we're going to. We're at the Matco Tool expo in the craziest city in the US, sin city, Las Vegas, Nevada. Now we're here to see all the new tools that Matco has to offer for this year, but more importantly talk to the distributors that bring all the tools out to you on the streets.

(Pat)>> Now Mike is an old pro at coming to this event but this is my first time at a tool expo and I am excited to hear about all the success stories people have from selling Matco Tools.

(Mike)>> This year Matco tools celebrates its 40th anniversary, and they are doing it in style at the Venetian in the heart of the Vegas strip. A lot of things can change in 40 years, but Matco relies on a proven time tested strategy.

(Tim)>> Service is how you win in this business. We all sell good products. We all sell them pretty much at the same price, but the way that you win in this business is service.

(Mike)>> We made our way over to the tool box section and this thing really caught our eye. David tell us about this box.

(David)>> This is a classic Six-S tool box. Two bay, 25 inch deep. Supercharged silver with black vein drawers. This is a really great box.

(Mike)>> Now something I really haven't see, the logo. It's color now?

(David)>> We introduced colored emblems. You can get colored emblems to match the trim of your box. Select your box color, select your trim, your colored emblems match. You can get them in blue, black, orange, green, red, and chrome.

(Mike)>> Awesome, something new, the light.

(David)>> The light is an LED light that is available from Matco Tools. A lot of them compliment the colors of our box. Really draws attention in that shop. Let them know that you've got a Matco Tools box.

(Pat)>> I'm here with Laura and she's gonna talk about something that's very important to a lot of the people who own boxes, graphics. Tell me about the graphics that you guys offer.

(Laura)>> Alright I'm gonna tell you about this Matco exclusive boxes. We've got a US flag, a Canadian flag, and two 40 anniversaries that they're being launched, and this vinyl here is made for your car. That's how durable it is. It's got a UV resistant overland that's going to be resistant to any type of chemical or fluid, and also to the sun if you dare put your beautiful boxes outside.

(Pat)>> Now I'll give you four bucks if you can sing the Canadian national anthem.

(Laura)>> I'll just get my purse.

(Pat)>> And filling these tool boxes are the highest quality sockets and hand tools.

(Lindley)>> We are launching a brand new 75 piece master bit socket set. It's going to include all your most common standard torques as well the long torques. Your full line of inverted torques, and then a full range of hex both in quarter, three eighths, and half inch drive as well as long hex in quarter and three-eighths drive. So in addition to the 75 piece master set we're gonna be launching nine smaller sets in star plus socket as well as tamper proof star plus, long triple square, some slotted and Philips drives, a real stubby star set, and then a couple of hex sets as well.

(Jody)>> I just want to show you some things we have recently introduced. We have brought out the half inch stubby impacts in December, and it's got that format that the technicians just love. At the show we're bringing out the three-eighths junior, and we're very proud of our brushless 12 volt three-eighths cordless impacts.

(Pat)>> Jason tell me a little bit about the brushless here.

(Jason)>> The brushless motor in this tool give the technician more use per charge. So he's able to remove 570 bolts versus 438 bolts on the previous tool.

(Jody)>> And also I do want to show you this beautiful 40th anniversary, Matco's 40th anniversary, gold plated ratchet.

(Pat)>> That's pretty sweet! There's a plethora of new items here. Let's take a look at some of the coolest. This is the easy solder clamp. This does the job of a bulky third hand tool and makes soldering a breeze, even in tight places.

(Mike)>> Knipex was founded in 1882 and they keep introducing handy new tools, like the Matco exclusive 22 inch Swedish pipe wrench with a quick adjustment button.

(Peter)>> This tool's perfect for tie rod adjustments. You're in a narrow area. You know what I'm talking about. You're trying to get in there. Push the button, lock it in place, you're ready to go.

(Pat)>> I'm with a guy who has the name of my favorite Canadian band. Rush tell me a little bit about this tool here.

(Rush)>> We have a universal wind back tool. It's a left hand/right hand and a static push back tool. Typically traditionally you would have a break caliper tool that has a left hand, a right hand, and all these adapters. What we've been able to do is shrink all this kit down into this size kit. It saves a ton of room in the tool box. So the way it works is you have a specially built screw that has a screw inside of a screw. So that allows us to go left or right, and we have this handy adapter here that has pins that adjust to any different configuration you have. Huge time saver. It's a money making tool. It's a great tool.

(Narrator)>> Up next, new tools, new opportunities, and old friends.

(Antron)>> This guy is sharp in the engine department and we could use a little bit of that in the valve train.

(Pat)>> Thanks my brother.

(Antron)>> Any time!

(Pat)>> Welcome back to sunny Las Vegas and the Matco Tool expo. When Antron Brown takes the stage you can feel the energy from the crown. They love this three time NHRA Top Fuel champion, and the feeling is mutual.

(Antron)>> The race is won in the pits. Only thing you're doing when you go out to the track, you're showcasing the work that you have done in the pits, and for us we rebuild these engines in 35 minutes. You need the best tools to do the job, and that's where Matco has come in over all the years, and all the championships, and allof our national event wins.

(Mike)>> Each year the new item showcase is always a hit. From true timber welding helmets and the Synergic welder with l-c-d screen, to this very portable belt sander. There's a wide variety of tools and accessories to make work easier.

(Melissa)>> Being new and innovative is really important to us. So this is just a great place for our distributors to see what's new for the show.

(Pat)>> Let's be honest. We think removing ball joints can be a pain. Lots of people must agree with us based on the crowd gathered around the Matco exclusive VJP 18-100 ball joint press.

(Chad)>> This tool has a two to one leverage ratio. So at a lower input torque we get a much higher pressure on the actual ball joint. And that's kind of the name of the game with getting these things out. They just rusted in there and they're just not wanting to pop out anymore.

(Pat)>> At 50 pound feet a typical press creates two point five tons of pressure. The Matco version provides over seven tons of pressure at the same torque output. With a much lower tool height the press easily fits into tight spaces, saving you time and hassle.

(Chad)>> Wow, just like that.

(Pat)>> It doesn't get any easier than that. Another time saver is the Matco Hyper Step drill bit. This step bit lets you drill your pilot and final holes in one pass.

(Chris)>> What's nice about it is you could drill a hole without a pilot hole. You don't need to center punch the piece. You don't need to drill a pilot hole and then your final hole. We developed them for use on the hand drill specifically. They take a lot of beating from guys not being able to get the right angle.

(Pat)>> That's guys like me you know?

(Chris)>> Well I assume so. I assume that's why you're looking at them.

(Mike)>> RRR stands for recover, recycle, recharge, and the Matco AC 439 machine handles R-134A refrigerant with ease. It includes automatic air purge, fast charging action, and vacuum pump oil that lasts up to 1,000 hours. Free Wi-Fi updates are just one of its many high tech features.

(Chuck)>> You can do things on this unit that we could never do in the past with the Wi-Fi and Bluetooth connectivity. So I can screen mirror from my tech support group, come in, take control over the unit. It helps with service, trouble shooting, training.

(Mike)>> From driver assist technology to full autonomous vehicles computers play an increasing role in our cars, and Matco stands ready.

(Ben)>> Advanced driver assist systems are coming on very quickly, and that means extra sensors, which means calibration and it requires specialized tools to handle those. So we're spending a lot of time on research and development to make sure that we're always staying ahead of those curves.

(Pat)>> The Maximus 3.0 diagnostic scan tool gathers massive amounts of computer data and delivers it on a 10.1 inch touch screen display. It runs an open android system with full Bluetooth and Wi-Fi capability. Features include data sampling, which lets you compare a poorly running car with a good one. And Maximus fix, a comprehensive online database with crucial repair information.

(Eric)>> Technicians can't repair cars without information, and now with the biggest addition with Maximus Fix we've added the capability with our software to get to the information for repairs with t-s-b's, wiring diagrams, component locations. You know anything that you would need to repair and finish the job.

(Tim)>> You know I think the interesting thing for Matco Tools in the future as we read all the papers is things are going to change from a technology standpoint to electric vehicles, autonomous vehicles, and I think it's going to present a great deal of opportunity for the tool business.

(Mike)>> For 40 years now Matco distributors have delivered the finest in tools and customer service. This is a family and the Matco Tool expo is their reunion. If you want to take charge of your future and do work you truly love consider becoming a Matco Tools distributor. Matco provides all the training and support you need.

(John)>> You know a line in our mission statement really drives home why we're here, and that's to give everyone an opportunity to own a franchise and be a successful business owner, and that's what we do.

(Alaina)>> If you're looking for the freedom to work for yourself and have the time to do what you want in life aside from work, it's the best decision that we've ever made.

(Narrator)>> For our stroker Windsor the math is simple. More air equals more power.

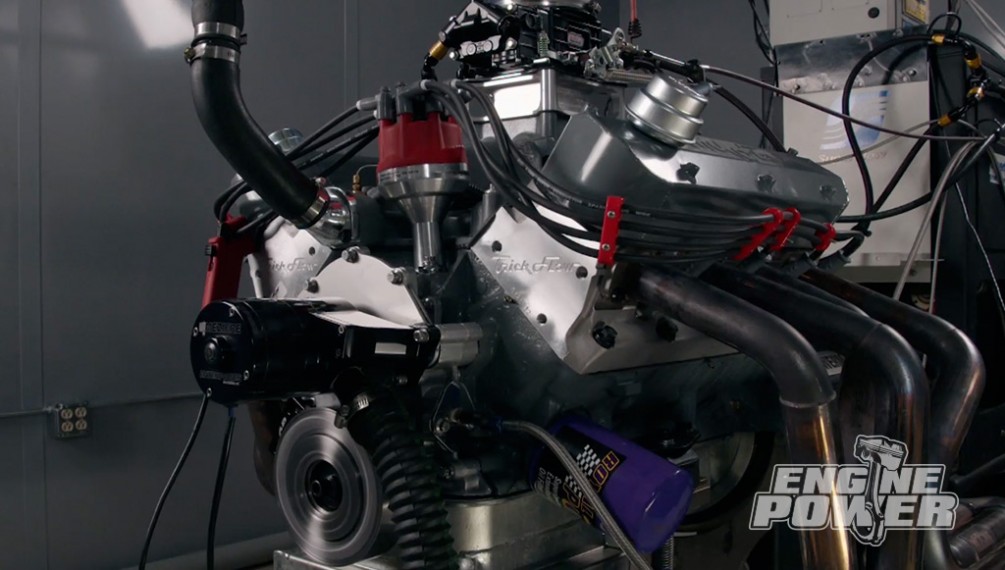

(Pat)>> Hey we're back at the shop and ready to put our Matco tools to use on our "Old Gray Mare" project. Now if you remember this engine started out as a stock cubic inch Windsor, and we put a top end kit on it from Trick Flow. And we ran it against a six liter LS that had comparable parts.

(Mike)>> Now recently we increased the cubic inches by adding an Eagle rotating assembly while keeping the cylinder heads, cam shaft, intake, and carburetor the same. This allowed us to show you what gains to expect by just increasing the cubic inches, and the results were impressive. In the 351 cubic inch version this engine pumped out 448 horsepower and 423 pound feet of torque. With the increased stroke, a nice hone job, and a gain of 57 cubic inches our new version we dubbed "Old Gray Mare" increased the power and torque numbers to 522 on the horsepower side, and 530 pound feet of torque.

(Pat)>> Now currently we are running a dual plane intake manifold, and with this air stack on that has an air turbine that measures air flow, and this line in the back that measures manifold vacuum, we can tell by our dyno data that we have some sort of air restriction. Now we know this because the carburetor will flow up to 950 c-f-m but the air turbine is telling us only about 680 c-f-m is going by it. Now couple that with the one point seven inches of manifold vacuum. In this case it looks like our intake is the air restriction.

(Mike)>> With that being said this engine has more potential and we have the parts to show it. Now we will be swapping the hydraulic roller cam shaft out for a solid roller with the more aggressive profile, but first let's see what potential this engine has by increasing the air flow with a single plane manifold.

(Pat)>> To pull the dual plane manifold we have to remove the air stack, carburetor, drain the water level of the block, remove the temp sensor adapter, the thermostat housing, and pull the distributor cap for a little extra room.

(Mike)>> Finally the manifold bolts are loosened and Pat gets a little workout to get the manifold separated.

(Pat)>> A little cleanup work is necessary to remove the gasket material from the heads and the silicone from the China rails. Do yourself a favor and always lay a few paper towels down to catch as much debris as possible.

(Mike)>> With the clean surfaces new Fel-Pro gaskets from Summit can go on, followed by a fancy bead of Permatex Right Stuff silicone. The manifold going on is a Trick Flow "R" series single plane we picked up from Summit Racing. This manifold has a larger volume and larger cross sectional areas in the runners. A straighter path for the air/fuel mix to enter the cylinders creates a high velocity for more efficient cylinder filling at all r-p-m's.

(Pat)>> What do you think?

(Mike)>> Let her rip tater chip.

(Pat)>> Just make a bang on it? [ engine revving ]

(Mike)>> Whoa, whoa!

(Pat)>> That was pretty mean right there.

(Mike)>> That was really mean. A 66, a 66 and a 31 on torque.

(Pat)>> That is nice, nice, nice. We've got to run it higher because now we're not even shutting down at peak power yet. At 6,500 it's going up. It's probably leveling off right there.

(Mike)>> Add another 300 to it.

(Pat)>> Yeah let's add a little r-p-m to it. No I'm gonna add 500 to it.

(Mike)>> Alright, remember we still have to do a cam swap in this thing.

(Pat)>> I know.

(Mike)>> Mister beat it until it's dead. And you know what it's kinda funny because it is an old gray mare. You're gonna beat the horse until it's dead.

(Pat)>> She ain't what she used to be. [ engine revving ]

(Mike)>> I saw it.

(Pat)>> It carries power well.

(Mike)>> It carries it real well. A 71, yes, yes, yes!

(Pat)>> 530 for torque.

(Mike)>> In that 500 additional r-p-m it fell off to 496.

(Pat)>> You know what that's a function of? I can already tell you. That's a function of cam shaft.

(Narrator)>> And if the man wants a cam shaft give him a camshaft.

(Pat)>> Back in the dyno room the hydraulic roller cam shaft is ready to come out. It is being replaced with a solid roller. That requires new lifters and push rods, which you'll see after we tell you about the new cam, which is a Comp Cam from Summit Racing. Duration at 50 thousandths lift is 254 degrees on the intake and 260 degrees on the exhaust. That's a gain of 18 degrees on the intake and 12 degrees on the exhaust. Lobe separation angle is 110 degrees and the lift at the valve with our one point seven-two rocker ratio is 669 on the intake and 676 on the exhaust. That's a difference of 52 thousandths more on the intake and 34 more thousandths on the exhaust.

(Mike)>> This cam shaft is going to make power higher in the r-p-m range. It's also going to increase our peak numbers. Now the operating range of this engine is going to drastically change. More towards drag racing and wide open throttle operation. Now between the intake swap and the cam shaft change we're going to see and engine with a totally different attitude, and the dyno is going to prove it. What you got?

(Pat)>> It's in at 107 like the other one.

(Mike)>> We also had to change the valve springs for a solid roller application. With an inch 900 installed height these springs are 260 pounds on the seat with a 460 pound per inch rate. That means at full lift we will have almost 600 pounds of open pressure. Summit also sent us Comp solid roller lifters with a tie bar design. They are eight-75 in diameter, and because of the different push rod cup location new Trent push rods had to be ordered. These new push rods are chro-moly and have 105 thousandths wall thickness. They're five-sixteenths out diameter and are eight-500 long, with five-sixteenths ball ends.

(Pat)>> Once we get this bullet back together it's time for some dyno runs. On the first run we made and impressive 613 horsepower and 534 pound feet of torque, but we wanted to see what she'd make with a second inch of spacer under the carb. [ engine revving ]

(Mike)>> A 17 and a 37.

(Pat)>> That's a little more.

(Mike)>> And vacuum did drop a hair at the top end. About two tenths.

(Pat)>> Yeah and that's a little bit of a function of just sheer plenum volume.

(Mike)>> So the engine's up to its potential. We're making killer power. It shows a good difference between a hydraulic roller a solid roller as far as carrying the power through the r-p-m.

(Pat)>> And this applies to all engines. It doesn't, Ford, Chevy, Dodge, Mitsubishi, it really doesn't matter. When you increase air flow, you increase cylinder pressure, you will increase power.

(Mike)>> Briggs and Stratton?

(Pat)>> Absolutely, absolutely. Alright, nice job.

(Mike)>> Hey good one. Another one bites the dust. For more information on anything you've seen today check out Powernation TV dot com. ♪ ♪

(Pat)>> Jason Line is with us today to talk go fast parts and the performance industry. Now he really needs no introduction but for those of you living under a rock he is the three time NHRA Pro Stock champion and he's sponsored by our favorite parts source, Summit Racing.

(Mike)>> We're going to discuss a few different things today, from pistons and cylinder heads, to high end lubes, and how the industry standards have been reset thanks to racing innovation and development over the last few years.

(Pat)>> So the first thing I want to talk about is pistons and how pistons have evolved over the last 20 years or so.

(Jason)>> Piston technology has changed drastically and probably more so from the manufacturing side because we have much better machining equipment, which allows the piston manufacturer to make the ring land, the finish much better, and the parallel of the ring land to the pin boss, which ultimately results in more power for not only race engines but again is transferred to the street cars.

(Pat)>> What about the design of the piston from the old coffee can style to the new style?

(Jason)>> You know over the years we just didn't know. So through trial and error, and obviously now better methods using science, we have much better programs to tell us where the piston needs to be strong and where it doesn't need to be strong. So the weight's moved to the place it needs to be and away from the places it doesn't.

(Pat)>> Now what about the total shape of the piston itself?

(Jason)>> The shape is definitely, you know there's certainly some magic there as far as making power goes, and obviously through a lot of trial and error testing. You're working on one specific engine, like a Pro Stock engine, we've figured out where it needs more material and where it needs less.

(Pat)>> And along with that the ring, physical size has changed.

(Jason)>> Yeah it's changed a lot over the years. You know back in the day a 1970 Buick had a five-sixty-fourths ring in it, which is a real big, heavy ring. It applied a lot of friction to the cylinder wall, and now that technology has changed a lot and everything is nice light weight, low tension ring packages that still seal much better.

(Mike)>> Moving on to the cylinder head we heard through the grape vine KB Racing and Trick Flow are going to be working together.

(Jason)>> We are actually. We've got some cool projects coming up, some LS stuff, and some small block Chevy stuff. So we're trying to apply a little racing technology into some other types of cylinder heads.

(Mike)>> I know this stuff is pretty good out of the box. So it's gonna be really neat to see what you guys come up with.

(Jason)>> It is, gonna be kinda fun.

(Pat)>> And last but certainly not least, oil technology.

(Jason)>> Yeah there's a lot of good oils on the market today with a lot of different oil additive packages. So the best thing to do is test them in your engine and see what flavor it likes, and they're all available at Summit.

(Pat)>> And they have a variety of weights and viscosities, like the zero-eight both for racing and some o-e-m applications, all the way up to 50 weight and everything in between.

(Jason)>> Exactly!

(Mike)>> Jason thanks a lot for coming in today and sharing your expertise. We really appreciate it.

(Jason)>> You bet, thanks for having me here.

(Pat)>> And I hope to see you out at a race very soon.

(Jason)>> Absolutely, thanks!

Show Full Transcript

(Mike)>> Welcome to Engine Power. We don't like to brag at all but today we're going to. We're at the Matco Tool expo in the craziest city in the US, sin city, Las Vegas, Nevada. Now we're here to see all the new tools that Matco has to offer for this year, but more importantly talk to the distributors that bring all the tools out to you on the streets.

(Pat)>> Now Mike is an old pro at coming to this event but this is my first time at a tool expo and I am excited to hear about all the success stories people have from selling Matco Tools.

(Mike)>> This year Matco tools celebrates its 40th anniversary, and they are doing it in style at the Venetian in the heart of the Vegas strip. A lot of things can change in 40 years, but Matco relies on a proven time tested strategy.

(Tim)>> Service is how you win in this business. We all sell good products. We all sell them pretty much at the same price, but the way that you win in this business is service.

(Mike)>> We made our way over to the tool box section and this thing really caught our eye. David tell us about this box.

(David)>> This is a classic Six-S tool box. Two bay, 25 inch deep. Supercharged silver with black vein drawers. This is a really great box.

(Mike)>> Now something I really haven't see, the logo. It's color now?

(David)>> We introduced colored emblems. You can get colored emblems to match the trim of your box. Select your box color, select your trim, your colored emblems match. You can get them in blue, black, orange, green, red, and chrome.

(Mike)>> Awesome, something new, the light.

(David)>> The light is an LED light that is available from Matco Tools. A lot of them compliment the colors of our box. Really draws attention in that shop. Let them know that you've got a Matco Tools box.

(Pat)>> I'm here with Laura and she's gonna talk about something that's very important to a lot of the people who own boxes, graphics. Tell me about the graphics that you guys offer.

(Laura)>> Alright I'm gonna tell you about this Matco exclusive boxes. We've got a US flag, a Canadian flag, and two 40 anniversaries that they're being launched, and this vinyl here is made for your car. That's how durable it is. It's got a UV resistant overland that's going to be resistant to any type of chemical or fluid, and also to the sun if you dare put your beautiful boxes outside.

(Pat)>> Now I'll give you four bucks if you can sing the Canadian national anthem.

(Laura)>> I'll just get my purse.

(Pat)>> And filling these tool boxes are the highest quality sockets and hand tools.

(Lindley)>> We are launching a brand new 75 piece master bit socket set. It's going to include all your most common standard torques as well the long torques. Your full line of inverted torques, and then a full range of hex both in quarter, three eighths, and half inch drive as well as long hex in quarter and three-eighths drive. So in addition to the 75 piece master set we're gonna be launching nine smaller sets in star plus socket as well as tamper proof star plus, long triple square, some slotted and Philips drives, a real stubby star set, and then a couple of hex sets as well.

(Jody)>> I just want to show you some things we have recently introduced. We have brought out the half inch stubby impacts in December, and it's got that format that the technicians just love. At the show we're bringing out the three-eighths junior, and we're very proud of our brushless 12 volt three-eighths cordless impacts.

(Pat)>> Jason tell me a little bit about the brushless here.

(Jason)>> The brushless motor in this tool give the technician more use per charge. So he's able to remove 570 bolts versus 438 bolts on the previous tool.

(Jody)>> And also I do want to show you this beautiful 40th anniversary, Matco's 40th anniversary, gold plated ratchet.

(Pat)>> That's pretty sweet! There's a plethora of new items here. Let's take a look at some of the coolest. This is the easy solder clamp. This does the job of a bulky third hand tool and makes soldering a breeze, even in tight places.

(Mike)>> Knipex was founded in 1882 and they keep introducing handy new tools, like the Matco exclusive 22 inch Swedish pipe wrench with a quick adjustment button.

(Peter)>> This tool's perfect for tie rod adjustments. You're in a narrow area. You know what I'm talking about. You're trying to get in there. Push the button, lock it in place, you're ready to go.

(Pat)>> I'm with a guy who has the name of my favorite Canadian band. Rush tell me a little bit about this tool here.

(Rush)>> We have a universal wind back tool. It's a left hand/right hand and a static push back tool. Typically traditionally you would have a break caliper tool that has a left hand, a right hand, and all these adapters. What we've been able to do is shrink all this kit down into this size kit. It saves a ton of room in the tool box. So the way it works is you have a specially built screw that has a screw inside of a screw. So that allows us to go left or right, and we have this handy adapter here that has pins that adjust to any different configuration you have. Huge time saver. It's a money making tool. It's a great tool.

(Narrator)>> Up next, new tools, new opportunities, and old friends.

(Antron)>> This guy is sharp in the engine department and we could use a little bit of that in the valve train.

(Pat)>> Thanks my brother.

(Antron)>> Any time!

(Pat)>> Welcome back to sunny Las Vegas and the Matco Tool expo. When Antron Brown takes the stage you can feel the energy from the crown. They love this three time NHRA Top Fuel champion, and the feeling is mutual.

(Antron)>> The race is won in the pits. Only thing you're doing when you go out to the track, you're showcasing the work that you have done in the pits, and for us we rebuild these engines in 35 minutes. You need the best tools to do the job, and that's where Matco has come in over all the years, and all the championships, and allof our national event wins.

(Mike)>> Each year the new item showcase is always a hit. From true timber welding helmets and the Synergic welder with l-c-d screen, to this very portable belt sander. There's a wide variety of tools and accessories to make work easier.

(Melissa)>> Being new and innovative is really important to us. So this is just a great place for our distributors to see what's new for the show.

(Pat)>> Let's be honest. We think removing ball joints can be a pain. Lots of people must agree with us based on the crowd gathered around the Matco exclusive VJP 18-100 ball joint press.

(Chad)>> This tool has a two to one leverage ratio. So at a lower input torque we get a much higher pressure on the actual ball joint. And that's kind of the name of the game with getting these things out. They just rusted in there and they're just not wanting to pop out anymore.

(Pat)>> At 50 pound feet a typical press creates two point five tons of pressure. The Matco version provides over seven tons of pressure at the same torque output. With a much lower tool height the press easily fits into tight spaces, saving you time and hassle.

(Chad)>> Wow, just like that.

(Pat)>> It doesn't get any easier than that. Another time saver is the Matco Hyper Step drill bit. This step bit lets you drill your pilot and final holes in one pass.

(Chris)>> What's nice about it is you could drill a hole without a pilot hole. You don't need to center punch the piece. You don't need to drill a pilot hole and then your final hole. We developed them for use on the hand drill specifically. They take a lot of beating from guys not being able to get the right angle.

(Pat)>> That's guys like me you know?

(Chris)>> Well I assume so. I assume that's why you're looking at them.

(Mike)>> RRR stands for recover, recycle, recharge, and the Matco AC 439 machine handles R-134A refrigerant with ease. It includes automatic air purge, fast charging action, and vacuum pump oil that lasts up to 1,000 hours. Free Wi-Fi updates are just one of its many high tech features.

(Chuck)>> You can do things on this unit that we could never do in the past with the Wi-Fi and Bluetooth connectivity. So I can screen mirror from my tech support group, come in, take control over the unit. It helps with service, trouble shooting, training.

(Mike)>> From driver assist technology to full autonomous vehicles computers play an increasing role in our cars, and Matco stands ready.

(Ben)>> Advanced driver assist systems are coming on very quickly, and that means extra sensors, which means calibration and it requires specialized tools to handle those. So we're spending a lot of time on research and development to make sure that we're always staying ahead of those curves.

(Pat)>> The Maximus 3.0 diagnostic scan tool gathers massive amounts of computer data and delivers it on a 10.1 inch touch screen display. It runs an open android system with full Bluetooth and Wi-Fi capability. Features include data sampling, which lets you compare a poorly running car with a good one. And Maximus fix, a comprehensive online database with crucial repair information.

(Eric)>> Technicians can't repair cars without information, and now with the biggest addition with Maximus Fix we've added the capability with our software to get to the information for repairs with t-s-b's, wiring diagrams, component locations. You know anything that you would need to repair and finish the job.

(Tim)>> You know I think the interesting thing for Matco Tools in the future as we read all the papers is things are going to change from a technology standpoint to electric vehicles, autonomous vehicles, and I think it's going to present a great deal of opportunity for the tool business.

(Mike)>> For 40 years now Matco distributors have delivered the finest in tools and customer service. This is a family and the Matco Tool expo is their reunion. If you want to take charge of your future and do work you truly love consider becoming a Matco Tools distributor. Matco provides all the training and support you need.

(John)>> You know a line in our mission statement really drives home why we're here, and that's to give everyone an opportunity to own a franchise and be a successful business owner, and that's what we do.

(Alaina)>> If you're looking for the freedom to work for yourself and have the time to do what you want in life aside from work, it's the best decision that we've ever made.

(Narrator)>> For our stroker Windsor the math is simple. More air equals more power.

(Pat)>> Hey we're back at the shop and ready to put our Matco tools to use on our "Old Gray Mare" project. Now if you remember this engine started out as a stock cubic inch Windsor, and we put a top end kit on it from Trick Flow. And we ran it against a six liter LS that had comparable parts.

(Mike)>> Now recently we increased the cubic inches by adding an Eagle rotating assembly while keeping the cylinder heads, cam shaft, intake, and carburetor the same. This allowed us to show you what gains to expect by just increasing the cubic inches, and the results were impressive. In the 351 cubic inch version this engine pumped out 448 horsepower and 423 pound feet of torque. With the increased stroke, a nice hone job, and a gain of 57 cubic inches our new version we dubbed "Old Gray Mare" increased the power and torque numbers to 522 on the horsepower side, and 530 pound feet of torque.

(Pat)>> Now currently we are running a dual plane intake manifold, and with this air stack on that has an air turbine that measures air flow, and this line in the back that measures manifold vacuum, we can tell by our dyno data that we have some sort of air restriction. Now we know this because the carburetor will flow up to 950 c-f-m but the air turbine is telling us only about 680 c-f-m is going by it. Now couple that with the one point seven inches of manifold vacuum. In this case it looks like our intake is the air restriction.

(Mike)>> With that being said this engine has more potential and we have the parts to show it. Now we will be swapping the hydraulic roller cam shaft out for a solid roller with the more aggressive profile, but first let's see what potential this engine has by increasing the air flow with a single plane manifold.

(Pat)>> To pull the dual plane manifold we have to remove the air stack, carburetor, drain the water level of the block, remove the temp sensor adapter, the thermostat housing, and pull the distributor cap for a little extra room.

(Mike)>> Finally the manifold bolts are loosened and Pat gets a little workout to get the manifold separated.

(Pat)>> A little cleanup work is necessary to remove the gasket material from the heads and the silicone from the China rails. Do yourself a favor and always lay a few paper towels down to catch as much debris as possible.

(Mike)>> With the clean surfaces new Fel-Pro gaskets from Summit can go on, followed by a fancy bead of Permatex Right Stuff silicone. The manifold going on is a Trick Flow "R" series single plane we picked up from Summit Racing. This manifold has a larger volume and larger cross sectional areas in the runners. A straighter path for the air/fuel mix to enter the cylinders creates a high velocity for more efficient cylinder filling at all r-p-m's.

(Pat)>> What do you think?

(Mike)>> Let her rip tater chip.

(Pat)>> Just make a bang on it? [ engine revving ]

(Mike)>> Whoa, whoa!

(Pat)>> That was pretty mean right there.

(Mike)>> That was really mean. A 66, a 66 and a 31 on torque.

(Pat)>> That is nice, nice, nice. We've got to run it higher because now we're not even shutting down at peak power yet. At 6,500 it's going up. It's probably leveling off right there.

(Mike)>> Add another 300 to it.

(Pat)>> Yeah let's add a little r-p-m to it. No I'm gonna add 500 to it.

(Mike)>> Alright, remember we still have to do a cam swap in this thing.

(Pat)>> I know.

(Mike)>> Mister beat it until it's dead. And you know what it's kinda funny because it is an old gray mare. You're gonna beat the horse until it's dead.

(Pat)>> She ain't what she used to be. [ engine revving ]

(Mike)>> I saw it.

(Pat)>> It carries power well.

(Mike)>> It carries it real well. A 71, yes, yes, yes!

(Pat)>> 530 for torque.

(Mike)>> In that 500 additional r-p-m it fell off to 496.

(Pat)>> You know what that's a function of? I can already tell you. That's a function of cam shaft.

(Narrator)>> And if the man wants a cam shaft give him a camshaft.

(Pat)>> Back in the dyno room the hydraulic roller cam shaft is ready to come out. It is being replaced with a solid roller. That requires new lifters and push rods, which you'll see after we tell you about the new cam, which is a Comp Cam from Summit Racing. Duration at 50 thousandths lift is 254 degrees on the intake and 260 degrees on the exhaust. That's a gain of 18 degrees on the intake and 12 degrees on the exhaust. Lobe separation angle is 110 degrees and the lift at the valve with our one point seven-two rocker ratio is 669 on the intake and 676 on the exhaust. That's a difference of 52 thousandths more on the intake and 34 more thousandths on the exhaust.

(Mike)>> This cam shaft is going to make power higher in the r-p-m range. It's also going to increase our peak numbers. Now the operating range of this engine is going to drastically change. More towards drag racing and wide open throttle operation. Now between the intake swap and the cam shaft change we're going to see and engine with a totally different attitude, and the dyno is going to prove it. What you got?

(Pat)>> It's in at 107 like the other one.

(Mike)>> We also had to change the valve springs for a solid roller application. With an inch 900 installed height these springs are 260 pounds on the seat with a 460 pound per inch rate. That means at full lift we will have almost 600 pounds of open pressure. Summit also sent us Comp solid roller lifters with a tie bar design. They are eight-75 in diameter, and because of the different push rod cup location new Trent push rods had to be ordered. These new push rods are chro-moly and have 105 thousandths wall thickness. They're five-sixteenths out diameter and are eight-500 long, with five-sixteenths ball ends.

(Pat)>> Once we get this bullet back together it's time for some dyno runs. On the first run we made and impressive 613 horsepower and 534 pound feet of torque, but we wanted to see what she'd make with a second inch of spacer under the carb. [ engine revving ]

(Mike)>> A 17 and a 37.

(Pat)>> That's a little more.

(Mike)>> And vacuum did drop a hair at the top end. About two tenths.

(Pat)>> Yeah and that's a little bit of a function of just sheer plenum volume.

(Mike)>> So the engine's up to its potential. We're making killer power. It shows a good difference between a hydraulic roller a solid roller as far as carrying the power through the r-p-m.

(Pat)>> And this applies to all engines. It doesn't, Ford, Chevy, Dodge, Mitsubishi, it really doesn't matter. When you increase air flow, you increase cylinder pressure, you will increase power.

(Mike)>> Briggs and Stratton?

(Pat)>> Absolutely, absolutely. Alright, nice job.

(Mike)>> Hey good one. Another one bites the dust. For more information on anything you've seen today check out Powernation TV dot com. ♪ ♪

(Pat)>> Jason Line is with us today to talk go fast parts and the performance industry. Now he really needs no introduction but for those of you living under a rock he is the three time NHRA Pro Stock champion and he's sponsored by our favorite parts source, Summit Racing.

(Mike)>> We're going to discuss a few different things today, from pistons and cylinder heads, to high end lubes, and how the industry standards have been reset thanks to racing innovation and development over the last few years.

(Pat)>> So the first thing I want to talk about is pistons and how pistons have evolved over the last 20 years or so.

(Jason)>> Piston technology has changed drastically and probably more so from the manufacturing side because we have much better machining equipment, which allows the piston manufacturer to make the ring land, the finish much better, and the parallel of the ring land to the pin boss, which ultimately results in more power for not only race engines but again is transferred to the street cars.

(Pat)>> What about the design of the piston from the old coffee can style to the new style?

(Jason)>> You know over the years we just didn't know. So through trial and error, and obviously now better methods using science, we have much better programs to tell us where the piston needs to be strong and where it doesn't need to be strong. So the weight's moved to the place it needs to be and away from the places it doesn't.

(Pat)>> Now what about the total shape of the piston itself?

(Jason)>> The shape is definitely, you know there's certainly some magic there as far as making power goes, and obviously through a lot of trial and error testing. You're working on one specific engine, like a Pro Stock engine, we've figured out where it needs more material and where it needs less.

(Pat)>> And along with that the ring, physical size has changed.

(Jason)>> Yeah it's changed a lot over the years. You know back in the day a 1970 Buick had a five-sixty-fourths ring in it, which is a real big, heavy ring. It applied a lot of friction to the cylinder wall, and now that technology has changed a lot and everything is nice light weight, low tension ring packages that still seal much better.

(Mike)>> Moving on to the cylinder head we heard through the grape vine KB Racing and Trick Flow are going to be working together.

(Jason)>> We are actually. We've got some cool projects coming up, some LS stuff, and some small block Chevy stuff. So we're trying to apply a little racing technology into some other types of cylinder heads.

(Mike)>> I know this stuff is pretty good out of the box. So it's gonna be really neat to see what you guys come up with.

(Jason)>> It is, gonna be kinda fun.

(Pat)>> And last but certainly not least, oil technology.

(Jason)>> Yeah there's a lot of good oils on the market today with a lot of different oil additive packages. So the best thing to do is test them in your engine and see what flavor it likes, and they're all available at Summit.

(Pat)>> And they have a variety of weights and viscosities, like the zero-eight both for racing and some o-e-m applications, all the way up to 50 weight and everything in between.

(Jason)>> Exactly!

(Mike)>> Jason thanks a lot for coming in today and sharing your expertise. We really appreciate it.

(Jason)>> You bet, thanks for having me here.

(Pat)>> And I hope to see you out at a race very soon.

(Jason)>> Absolutely, thanks!