Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

ARP

Cylinder Head Studs, Pro Series, Hex Head, Chevy, 454, 502, Stock, Edelbrock Heads, Kit

Canton Racing Products

Oil Pan, Drag Race, Steel, Gold Iridited, 7 qt., Rear Sump, Chevy, Big Block, Each

Canton Racing Products

Valve Covers, Tall, Fabricated Aluminum, Natural, Chevy, Big Block, Pair

Cometic Gasket, Inc.

Head Gasket, MLS, 4.630 in. Bore, .032 in. Compressed Thickness, Chevy, Each

Comp Cams

Camshaft, Mechanical Roller Tappet, Advertised Duration 310/330, Lift .800/.800, Chevy, Big Block, Each

Crane Cams

Lifters, Mechanical Roller, Ultra-Pro, Vertical Link Bar, .842 in. Diameter, Chevy, Set of 16

Eagle Specialty Products

4340 Forged steel Crankshaft 4.500 Stroke, 6.700 H-Beam Rods, SRP Forged 41cc Dome Pistons, 1-PC Rear Seal , Tall Deck Height 10.200, ARP2000 Rod Bolts, ESP Armor Finished Crankshaft

Edelbrock

Cylinder Head, Musi/Victor 24 Degree, Aluminum, Assembled, 118cc Chamber, 377cc Intake Runner, Chevy, 454

Edelbrock

Intake Manifold, Super Victor II, Single Plane, Tall Deck, Aluminum, CNC Matched, Chevy, 454, 632, Each

Holley

Carburetor, 4 Barrel, Holley Gen 3 Ultra Dominator, Gasoline - Dual Inlet, 1,475 CFM, Gray Anodized, Each

Hooker Headers

Headers, Super Competition, Adjustable, Full-Length, Steel, Painted, Chevy, Big Block, V8, Pair

Jesel Inc.

Rocker System, Full Roller, 1.8 Ratio, Shims, for Edelbrock Victor 6140/Musi 7740 Heads, Chevy, Big Block, Kit

Horn Blasters

Conductor's Special 244 Nightmare Edition Train Horn Kit

The Industrial Depot

The Industrial Depot - Fasteners, Hardware, and Shop Supplies

Trend Performance

Custom Length 3/8 DIA, Pushrod Set

Episode Transcript

(MIKE)>> WELCOME

TO ENGINE POWER. TODAY WE'RE BUILDING A BIG

CUBIC INCH HIGH COMPRESSION

RACE BULLET THAT'S GONNA RUN ON RACE GAS. NOW OUR GOAL FOR THIS ONE IS 1,000 NATURALLY ASPIRATED HORSEPOWER. NOW THIS IS A GENTLEMAN'S ENGINE THAT WEARS A BOW TIE, AND IT CAN BE USED IN SEVERAL DIFFERENT FORMS OF RACING LIKE DRAG, TRUCK PULLING, OR EVEN HIGH PERFORMANCE MARINE.

(PAT)>> OUR PARTS SELECTION WAS BASED ON OFF THE SHELF PARTS SO EVERYTHING CAN BE PURCHASED AND ASSEMBLED WITH

EASE, BUT THIS BLOCK WE'VE HAD AROUND HERE FOR A WHILE.

IT IS A TALL DECK SPORTSMAN BLOCK FROM GM. IT'S A FOUR BOLT MAIN WITH THE OUTER THREE BOLTS IN THE CENTER SPLAYED AT 16 DEGREES. SO THAT ALLOWS FOR MORE MATERIAL TO HOLD THE CRANKSHAFT IN ITS PLACE. IT ACCEPTS A ONE PIECE REAR MAIN SEAL AND HAS A PRIORITY MAIN OILING SYSTEM, MEANING THE MAINS GET OILED FIRST, WHICH IS CRUCIAL IN A RACE ENGINE FOR LONGEVITY.

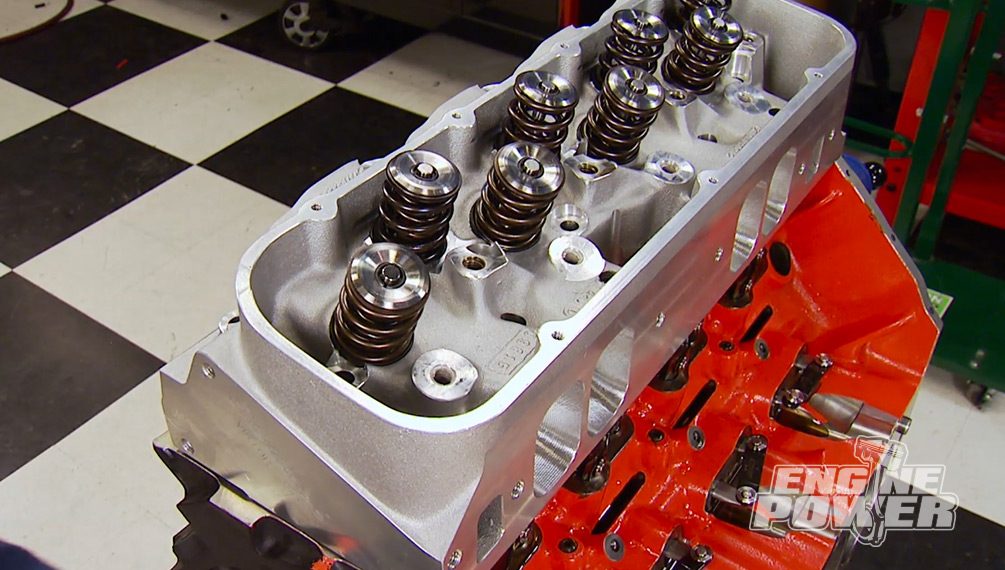

(MIKE)>> TO REACH OUR 1,000 HORSEPOWER GOAL WE NEED AN INDUCTION SETUP THAT WILL MOVE SOME SERIOUS AIR. NOW EDELBROCK MAKES THAT SIMPLE WITH THESE CYLINDER HEADS AND INTAKE MANIFOLD THAT ARE DESIGNED TO MAKE BIG POWER. NOW THEY WORKED REALLY CLOSE WITH A LEGENDARY RACER AND ENGINE BUILDER NAMED PAT MUSI TO DESIGN THESE EDELBROCK MUSI 24 DEGREE CNC HEADS. NOW THE INTAKE MANIFOLD IS A SUPER VICTOR TWO THAT IS PORT MATCHED TO THE INTAKE RUNNER, WHICH HAS A 377cc VOLUME.

NOW THE COMBUSTION CHAMBER MEASURES IN AT 119cc. INTAKE VALVE DIAMETERS ARE TWO-300 ON THE INTAKE,

ONE-900 ON THE EXHAUST.

NOW THE EXHAUST RUNNER COMES IN AT 128cc AND IT'S IN A RAISED LOCATION FOR BETTER FLOW NUMBERS.

NOW THE VALVE SPRINGS WILL HANDLE A CAM

WITH UP TO 880 LIFT. OUR CAM SHAFT HAS 800 GROSS LIFT AND THIS HEAD FLOWS 409 CFM AT THAT SPOT.

(MIKE)>> WE'VE ALREADY TAKEN CARE OF SOME OF THE TEDIOUS WORK, LIKE FULLY CLEANING THE BLOCK AND ALL THE INTERNAL

ENGINE PARTS, AS WELL AS SETTING ALL OF OUR MAIN BEARING CLEARANCES, BUT BEFORE WE CAN ASSEMBLE IT WE HAVE

TO PUT SOME EXTRA HOLES IN THE UPPER MAIN BEARING AND HERE'S WHY. LOTS OF RACE ENGINES HAVE AN ADDITIONAL GROOVE IN THE MAIN SADDLE FOR MORE OIL TO REACH THE MAINS, BUT TO ALLOW THIS TO HAPPEN EXTRA HOLES HAVE TO BE DRILLED IN THE MAIN BEARING ITSELF. IT'S AN EASY OPERATION. SIMPLY PLACE THE UPPER HALF OF THE BEARING IN A VICE AND DRILL FOUR 90 THOUSANDTHS HOLES, AND THEN DEBURR THEM. THE LAST STEP IS TO LIGHTLY SCOTCH BRITE THE BEARING SURFACE TO REMOVE THE MARKS ON THE DIAL BORE GAUGE AND MAKE A SMOOTH SURFACE.

(MIKE)>> THIS CRANK SHAFT HAS A FOUR AND A HALF INCH STROKE. NOW PAIR THAT UP WITH OUR FOURFIVE-60 BORE AND WE'VE GOT A 588 CUBIC INCH COMBO, WHICH IS THE BIGGEST WE'VE DONE HERE IN THE SHOP. NOW THIS IS AN EAGLE SPECIALTY PRODUCTS 43-40 FORGED STEEL CRANK SHAFT. NOW IT HAS THEIR SECRET ESP ARMOR PROCESS THAT GIVES IT A MIRROR LIKE FINISH, WHICH INCREASES OIL SHEDDING AND DECREASES WINDAGE, WHICH IS PROVEN TO GIVE YOU MORE HORSEPOWER. NOW THE UPPERS CAN GO IN THE BLOCK, AND ARE COATED WITH

ROYAL PURPLE MAX TOUGH ASSEMBLY LUBE. THE CRANK IS INTERNALLY BALANCED AND RATED TO HANDLE UP TO 1,500 HORSEPOWER.

NOW THE LOWER HALF OF THE MAIN BEARINGS CAN GO IN THE CAPS, GET SLICKED UP, AND THE CAP CAN DROP IN PLACE USING

ARP MAIN BOLTS AS GUIDES. A COUPLE OF TAPS SEATS THE CAP. BEFORE TORQUING, TAP THE CRANK FROM THE FRONT TO REAR, WHICH CENTERS THE THRUST BEARING. NOW TORQUE EVERYTHING TO 95 POUND FEET. FINALLY WE'LL CHECK THE CRANK'S THRUST.

THE TARGET RANGE IS BETWEEN FOUR AND NINE THOUSANDTHS. WE ARE AT FIVE THOUSANDTHS, WHICH GIVES US A GREEN FLAG.

(PAT)>> WE'RE GONNA TAKE A QUICK BREAK BUT WHEN WE COME BACK THERE'S A LOT MORE ASSEMBLY THAT'S GONNA GET DONE BUT IN A LITTLE DIFFERENT ORDER THAN YOU'RE USED TO SEEING. SO STICK WITH US.

(MIKE)>> WE'RE BACK AND READY TO CONTINUE. NOW NORMALLY THE CAM WOULD GO IN NOW BUT NOT IN THIS CASE. WE'RE GONNA BE USING A JESEL BELT DRIVE. NOW THIS THING WILL GIVE US MORE ACCURATE CAM TIMING AND BETTER ADJUSTABILITY. SO THIS COVER GOES ON FIRST. THIS TRICK RACE PIECE USES AN ORING TO SEAL TO THE BLOCK. NO GASKET OR MESSY SILICONE TO DEAL WITH WHEN IT HAS TO COME OFF. THE LOWER TIMING GEAR IS NEXT, WHICH DOES NOT GET ANY LUBE BECAUSE THERE IS A TEFLON SEAL IN THE COVER.

(PAT)>> NOW IT'S TIME FOR THE CAM SHAFT. TO MAKE BIG POWER YOU NEED A BIG CAM SHAFT, AND THIS BUMP STICK IS A SOLID ROLLER WITH A FOURSEVEN FIRING ORDER SWAP. DURATION AT 50 THOUSANDTHS LIFT IS 277 DEGREES ON THE INTAKE AND 292 DEGREES ON THE EXHAUST, AND BOTH HAVE 471 THOUSANDTHS LOBE LIFT. WE MENTIONED BEFORE THAT OUR GROSS VALVE LIFT WAS 800 THOUSANDTHS BUT THAT IS WITH A STOCK ONE POINT SEVEN ROCKER RATIO.

WE WILL BE RUNNING A ONE POINT EIGHT ROCKER RATIO ON A ROCKER THAT'S FAR FROM STOCK. SO THAT WILL PUT OUR GROSS VALVE LIFT AT 848 THOUSANDTHS, AND FINALLY THE LOBE SEPARATION ANGLE IS 114 DEGREES. THE TIMING GEAR ADAPTER BOLTS TO THE NOSE OF THE CAM. IT WILL BE TORQUED IN PLACE BEFORE THE CAM GOES IN.

SINCE THIS CAM REQUIRES MORE SPRING PRESSURE BEING A RACE ENGINE, WE ARE GONNA SPIFF IT UP WITH MORE MAX TOUGH TO KEEP IT WELL LUBED.

(MIKE)>> NOW THE OUTER THRUST WASHER GOES ON, FOLLOWED BY THE CAM RETAINER, WHICH HAS BEEN SHIMMED FOR PROPER CAM SHAFT END PLAY. JUST SO YOU KNOW, WE HAVE FIVE THOUSANDTHS. THE BELT AND ADJUSTABLE CAM GEAR GO ON TOGETHER AND WE'LL LEAVE IT FOR NOW UNTIL WE DEGREE THE CAM. SRP PISTONS WILL FILL THE BORES. NOW THESE ARE AN EXCELLENT QUALITY OFF THE SHELF PART THAT CAME WITH OUR COMPETITION ROTATING ASSEMBLY. THEY'RE A FORGED PIECE WITH A LARGE 39cc DOME. THEY HAVE A 16TH, 16TH, THREESIXTEENTH RING PACKAGE AND A ONETWO-45 COMPRESSION HEIGHT. THEY COME WITH A LIGHT WEIGHT HEAVY DUTY WRIST PIN THAT MEASURES IN A 990 THOUSANDTHS IN DIAMETER. NOW COMBINED WITH OUR COMBUSTION CHAMBER VOLUME AND

HEAD GASKET THICKNESS, WE HAVE A CALCULATED COMPRESSION RATIO OF 14.3 TO ONE. THESE ARE EAGLE FORGED RODS WITH AN HBEAM DESIGN. NOW ARP 2,000 ROD BOLTS WILL HOLD THE CAP IN PLACE AND THE OVERALL LENGTH IS SIX-700 CENTER TO CENTER. NOW THE SMALL END IS BUSHED AND DESIGNED FOR A FREE FLOATING PIN.

(PAT)>> WE DEGREE THE CAM IN EVERYTHING THAT WE BUILD HERE, AND THAT IS ESPECIALLY IMPORTANT IN A RACE ENGINE

WHEN A LARGE DOME IS INVOLVED. THAT'S BECAUSE THE ACTUAL VALVE CLEARANCE WILL BE TIGHTER BECAUSE OF THE BIG LIFT AND DURATION OF THE CAM SHAFT, AND AFTER WE'RE DONE DEGREEING WE'RE GONNA MOCK THE ENGINE UP WITH THE CYLINDER HEAD ON IT TO CHECK THAT CRITICAL PISTON TO VALVE CLEARANCE. TO DEGREE THE CAM A PISTON AND ROD ASSEMBLY GOES IN THE NUMBER ONE CYLINDER. USING A DEGREE WHEEL, TIMING POINTER, AND DIAL INDICATOR, THE PROCESS BEGINS. SINCE OUR CAM'S LOBE SEPARATION IS 114 WE'LL

INSTALL THE CAM THERE, WHICH IS STRAIGHT UP, AND THAT WILL BE OUR STARTING POINT.

(MIKE)>> NOW COMES THE MOCK UP PHASE TO CHECK "P" TO "V". THIS REQUIRES A HEAD GASKET, A SET OF LIFTERS, CYLINDER HEAD WITH TWO CHECKER SPRINGS ON NUMBER ONE, A FEW STUDS TO HOLD IT DOWN, AND WITH THE ROCKER STANDS, PUSH RODS, AND ROCKER ASSEMBLIES IN PLACE, WE'LL USE A STEEL PLATE TO MOUNT A MAGNETIC BASE AND DIAL GAUGE.

(PAT)>> WHAT WE'RE GONNA FIND IS THE CLOSEST POINT BETWEEN THE VALVES AND THE TOP OF THE PISTON, AND ON THE INTAKE SIDE THAT WILL HAPPEN AROUND 10 DEGREES AFTER TDC, AND ON THE EXHAUST SIDE AROUND 10 DEGREES BEFORE TDC, AND THAT IS ON SPLIT OVERLAP, NOT ON THE COMPRESSION STROKE. NOW WHAT SPLIT OVERLAP IS IS WHEN THE EXHAUST VALVE IS ALMOST CLOSED AND THE INTAKE VALVE IS JUST STARTING TO OPEN. NOW THE GAUGE IS CAREFULLY SET TO ZERO, AND BY PUSHING DOWN ON THE ROCKER THE FACE OF THE VALVE MAKES CONTACT WITH THE TOP OF THE PISTON. THERE IS 60 THOUSANDTHS PISTON TO VALVE CLEARANCE. A SAFE MINIMUM HERE IS 50 THOUSANDTHS. NOW THE SAME THING HAPPENS TO MEASURE THE EXHAUST SIDE. IT HAS 90 THOUSANDTHS, WHICH IS A LITTLE ON THE TIGHT SIDE. THE ABSOLUTE MINIMUM TO BE SAFE HERE IS 100 THOUSANDTHS. SO HERE'S HOW TO FIX IT. WITH THE FOUR NUTS LOOSE ON THE CAME SPROCKET, WE CAN ADVANCE THE INTAKE CENTER LINE OF THE CAM BY TWO DEGREES, AND THIS WILL DO TWO THINGS.

INCREASE THE EXHAUST SIDE'S CLEARANCE, AND DECREASE THE INTAKE SIDE'S CLEARANCE. SO IT WILL NEED TO BE RECHECKED. NOW WE HAVE 50 THOUSANDTHS ON THE INTAKE, WHICH IS DECREASED FROM THE ORIGINAL 60, BUT STILL IN THE GOOD. THE EXHAUST SIDE INCREASED TO 102 THOUSANDTHS FROM OUR ORIGINAL 90.

SO WE'RE GOOD TO GO AFTER THE BREAK.

(MIKE)>> WE'RE BACK AND THE PISTON AND ROD ASSEMBLIES ARE CLOSE TO GOING IN, BUT FIRST SOME HIGH QUALITY RING SPECIFIC LUBE HAS TO GO ON. THESE RINGS ARE FROM MOLY AND THE TOP AND SECOND HAVE BEEN GAPPED TO 32 THOUSANDTHS. THE OIL RING IS A LOW TENSION SETUP FOR REDUCED DRAG.

OUR STANDARD OPERATING PROCEDURE IS TO USE A TAPERED RING COMPRESSOR AND PISTON KNOCKER TO GET THEM IN. THE ARP 2,000 ROD BOLTS ARE TORQUE TO 75 POUND FEET. WE CAN BOLT UP THE HIGH VOLUME, HIGH PRESSURE OIL PUMP, WHICH HAS THE PICK UP ALREADY ATTACHED. A ONE PIECE COMETIC OIL PAN GASKET WILL SEAL THIS CANTON DRAG RACE OIL PAN TO THE BLOCK. IT HAS AN INTEGRATED WINDAGE TRAY AND HOLDS EIGHT QUARTERS.

(PAT)>> UP FRONT A FLUID DAMPER BALANCER GOES ON, AND WE'LL SET THE TIMING POINTER AT TRUE TDC. NOW THESE CRANE SOLID ROLLER LIFTERS FROM SUMMIT RACING CAN DROP IN, FOLLOWED BY A COMETIC MLS HEAD GASKET WITH A 32 THOUSANDTHS COMPRESSED THICKNESS. LAYING ON IT IS THE EDELBROCK MUSI 24 DEGREE CYLINDER HEAD WE SHOWED YOU EARLIER. ARP STUDS WILL CINCH IT DOWN AND ARE TORQUED TO 80 POUND FEET.

(MIKE)>> VALVETRAIN STABILITY IS CRITICAL IN A HIGH RPM RACE ENGINE. NOW IN A SITUATIONS WITH HIGH OPEN SPRING PRESSURES, THE BENEFITS OF A SHAFT ROCKER SYSTEM OVER A STUD MOUNT ARE INCREASED RIGIDITY AND ACCURACY OF GEOMETRY.

NOW THIS IS A JESEL SPORTSMAN SERIES THAT IS DESIGNED SPECIFICALLY FOR OUR CYLINDER HEAD. THE BILLET STANDS AND ALIGNMENT BARS GO ON FIRST, ONE FOR THE INTAKE, ONE FOR THE EXHAUST.

TRENT PERFORMANCE SENT US SOME KILLER PUSH RODS. THESE ARE THREEEIGHTHS IN DIAMETER WITH 135 THOUSANDTHS WALL THICKNESS, AND HAVE FIVESIXTEENTHS BALL ENDS. THE ROCKERS ARE A ONE POINT EIGHT RATIO AND HAVE A PROFILED ROCKER TAIL, WHICH REDUCES THE ROCKER'S MOMENT OF INERTIA. NOW THE EDELBROCK MANIFOLD CAN DROP ON, ALONG WITH A JESEL FRONT DRIVE DISTRIBUTOR THAT IS DRIVEN BY A SMALL BELT OFF THE CAM. AT THIS POINT IT'S READY FOR THE DOCKING CART, THEN GOES TO THE DYNO ROOM, WHERE WE ARE CONTINUING WITH SHEET METAL VALVE COVERS. THESE ARE CANTON'S AND WE OUTFITTED THEM WITH THE NECESSARY PIECES TO RUN A VACUUM PUMP. NOW THESE MASSIVE TWO AND THREEEIGHTHS INCH TO TWO AND A HALF INCH HOOKER SUPER COMP RACE HEADERS CAN GO ON. SINCE A VACUUM PUMP WILL BE RAN ON THIS ENGINE, A JONES RACING TEST GAUGE WILL BE USED TO SEE HOW WELL WE SEALED THE ENGINE UP. IT WILL HAVE A LITTLE LEAKAGE PAST THE RINGS DUE TO THE LARGE GAP. WITH FUEL GOING TO A 1,475 CFM HOLLEY DOMINATOR, A BEAST IS BORN. NOW THIS IS THE TIME THE ENGINE GETS SOME TEMPERATURE, THE RINGS SEAT, AND WE MAKE SURE THERE ARE NO LEAKS. NOW A LASH CHECK ON THE VALVES, WHICH GIVES US THE GO AHEAD TO MAKE THE FIRST PULL. THIS THING'S GONNA MAKE A TON OF POWER.

(PAT)>> I THINK SO!

(MIKE)>> THE BIG NUMBERS AFTER THE BREAK.

(MIKE)>> WE'RE BACK AND NOT WASTING ANY TIME. WITH OIL TEMPERATURE IN IT, HERE'S THE FIRST PULL FROM 4,000 TO 6,000 RPM AND 28 DEGREES OF TIMING. 851 ON POWER, 745 POUND FEET. YOU READY?

(PAT)>> LET HER EAT!

(MIKE)>> THIS NEXT RUN IS AT 30 DEGREES AND THE RPM FROM 5,000 TO 7,000.

(PAT)>> NOW WE'RE GETTING SOMEWHERE.

(MIKE)>> 926 ON POWER, 750 POUND FEET AND SHE'S CLIMBING FAST.

(PAT)>> ALL RIGHT, I LIKE IT.

(MIKE)>> WE MADE ANOTHER AT 32 DEGREES OF TIMING.

[ engine revving ]

(PAT)>> HOW ABOUT THAT, AND IT MADE 937 HORSE AND 756 POUND FEET OF TORQUE, NICE, INCREASE. AT THIS POINT WE ARE STILL CHASING TIMING. SO WE'LL ADD ANOTHER TWO DEGREES FOR A TOTAL OF 34 AND MAKE ANOTHER HIT. WE ARE STILL RUNNING THE SAME RPM RANGE OF 5,000 TO 7,000. [ engine revving ]

(MIKE)>> WHAT YOU GOT?

(PAT)>> LOOK AT THAT, PICKED UP A LITTLE BIT OF TORQUE. 762 POUND FEET OF TORQUE AND 936 HORSE. IT'S LIKE A GIGANTIC SEWING MACHINE.

(MIKE)>> THROW A SPACER ON IT?

(PAT)>> YEAH, ONE TUNING TRICK WE ALWAYS LIKE TO TRY

IS ADDING A CARB SPACER. IT DOES A COUPLE OF THINGS. IT INCREASES THE PLENUM VOLUME OF THE INTAKE AND HELPS STRAIGHTEN OUT AIR FLOW, ALLOWING FOR A BETTER TRANSITION INTO THE INTAKE RUNNERS. THIS ONE IS TWO INCHES.

WELL THERE YOU GO, 946 FOR POWER BUT LOOK WHAT THE TORQUE DID.

(MIKE)>> STEPPED UP.

(PAT)>> 770 POUND FEET, THIS IS AN EXCELLENT, EXCELLENT BRACKET CAR, RELIABLE, NO MAINTENANCE TYPE ENGINE OTHER

THAT ITS REGULAR STUFF. NOW IT HASN'T PEAKED ON POWER YET. WE'VE GOT TO TURN IT 7,500.

(MIKE)>> SOUNDS GOOD TO ME. [ engine revving ]

(MIKE)>> MAN THAT'S SWEET.

(PAT)>> SOUNDS AWESOME!

WELL THERE IT IS. THERE'S PEAK POWER FINALLY.

(MIKE)>> ALL RIGHT, 953 ON POWER, 764 ON TORQUE.

(PAT)>> HAD A LITTLE BIT OF HEAT SOAK IN

IT BUT THAT'S OKAY.

(MIKE)>> PEAK TORQUE WAS AT 6,000 RPM.

SITTING THERE ON THE TRANS BRAKE.

(PAT)>> 588 INCHES AND THE PEAK TORQUE IS AT 6,000.

(MIKE)>> PEAK POWER, 7,300. EVERYTHING WAS DOING ITS JOB.

(PAT)>> NICE.

(MIKE)>> GOOD JOB.

(PAT)>> EXCELLENT, WELL OUR 588 INCH BIG BLOCK CHEVY TURNED OUT PRETTY WELL I MUST SAY. NOW WE DID FALL A LITTLE BIT SHORT OF OUR 1,000 HORSEPOWER GOAL BUT KEEP IN MIND THESE ARE OUT OF THE BOX PARTS THAT ARE UNMODIFIED, AND WITH A LITTLE RUBBING ON IT WE WOULD BE ABLE TO REACH THAT GOAL BUT WE DON'T HAVE ENOUGH TIME TO DO THAT THIS TIME AROUND.

(MIKE)>> THAT WAS A COOL BUILD.

(PAT)>> THIS THING MADE GREAT POWER EVERYWHERE.

(MIKE)>> NOW WE'RE GOING TO DO SOMETHING A LITTLE DIFFERENT. INSTEAD OF A TECH TIP WE'RE GOING TO TAKE A LOOK BACK AT

SOME OF THE COOL BUILDS WE DID THIS YEAR.

(PAT)>> ONE THAT WE REALLY ENJOYED AND SHOWED YOU A TON OF TECH ON WAS IN HOUSE POWER MOUSE. NOW THE REASON WE BUILT IT IS WE GOT A LOT OF REQUESTS FROM YOU VIEWERS TO TAKE AN ENGINE FROM THE BARE BASICS TO A FULL BLOWN POWERHOUSE. WE STARTED OFF WITH A BARE BONES BASIC SMALL BLOCK CHEVY BUILD. WE USED BUDGET FRIENDLY PARTS FROM SUMMIT RACING, WHICH CONSTRUCTED A GREAT RUNNING STREET ENGINE. ONCE ASSEMBLED WE HOOKED IT UP TO OUR SUPER FLOW DYNO, YIELDING AN IMPRESSIVE 357 HORSEPOWER ON THE CHEAP. FOR STAGE TWO WE TORE IT DOWN AND STEPPED UP ON THE PARTS SELECTION. WE INCREASED THE CUBES TO 383 INCHES, INSTALLED A HYDRAULIC ROLLER CAM, AND CAPPED IT OFF WITH BETTER INDUCTION. RUNNING ON 93 OCTANE PUMP GAS, IT CRANKED OUT 547 HORSE.

(MIKE)>> STAGE THREE IS WHERE WE THREW OUT THE BUDGET AND

WENT FOR MAXIMUM POWER. A DART LITTLE "M" BLOCK RECEIVED THE CRANK AND RODS FROM THE 383 BUT IT HAD A LARGER BORE FILLED WITH A CUSTOM MOLY PISTON. THE CYLINDER HEAD STAYED THE SAME BUT THE INTAKE CHANGED TO AN EDELBROCK VICTOR.

NOW THIS ENGINE WAS BUILT FOR BOOST. A PROCHARGER FONEA FLOW THROUGH SYSTEM WAS BOLTED ON. THIS USED ONE OF THEIR AIR TO AIR INTERCOOLERS, BUT WE DYNO'ED IT NATURALLY ASPIRATED FIRST TO SEE WHAT THE DIFFERENCE WOULD BE WITH THE BOOST. IT MADE 554 HORSEPOWER WITH A NINE TO ONE COMPRESSION RATIO. HERE'S WHAT IT MADE ON 15 POUNDS OF BOOST.

(PAT)>> 993 HORSE, 917 POUND FEET OF TORQUE.

(MIKE)>> GREAT COMBO, GREAT JOB.

(PAT)>> AWESOME, AWESOME, AWESOME!

(MIKE)>> FROM OLD SCHOOL SMALL BLOCK POWER TO LATE MODEL TECHNOLOGY, THIS NEXT ONE REALLY GOT OUR EXCITEMENT GOING. IT'S THE SUPERCHARGED LSA THAT POWERS GRAY HAIR, WHITE KNUCKLE. NOW WE CAPITALIZED ON A LOT OF THE STOCK PARTS TO MAKE A BIG POWER PRODUCER.

(PAT)>> THE STOCK BLOCK WAS USED AND FILLED WITH 427 CUBIC INCHES OF FORGED ROTATING ASSEMBLY. THE FACTORY HEADS AND BLOWER WERE CNC PORTED AND PORT MATCHED. AFTER MARKET PULLEYS WERE INSTALLED, A LARGER HEAT EXCHANGER WAS USED, AND THE COMBO WAS DESIGNED TO MAKE 15

POUNDS OF BOOST JUST LIKE THE SMALL BLOCK.

ON 93 OCTANE GAS STRAIGHT FROM THE PUMP IT MADE AN IMPRESSIVE 797 POUND FEET OF TORQUE AND 816 HORSEPOWER.

(MIKE)>> THERE'S MORE AWESOME BUILDS LIKE THIS

COMING UP IN THE FUTURE. DOES YOUR CAR OR TRUCK LACK IN THE HORN DEPARTMENT? WELL HERE'S A SYSTEM THAT'LL LET EVERYONE AROUND

YOU KNOW YOU'RE THERE. THIS IS HORN BLASTER'S CONDUCTOR SPECIAL 244 NIGHTMARE EDITION TRAIN HORN KIT. NOW THE SHOCKER FOUR SERIES HORNS ARE MADE OUT OF ABS SERIES PLASTIC AND HAVE A STAINLESS STEEL DIAPHRAGM THAT WILL NOT RUST. NOW THE COMPRESSOR IS A VIAIR 444-C, WHICH IS OVERKILL FOR THE BEST RELIABILITY AND LOUDEST TRAIN HORN KIT IN ITS CLASS ON THE MARKET. IT COMES WITH A TWO GALLON TANK AND ALL THE HARDWARE YOU NEED TO INSTALL IT. THIS KIT CAN BE HEARD UP TO FOUR MILES AWAY. NOW TO FIND OUT THE SYSTEM THAT SUITS YOUR NEEDS LOG ON TO HORN BLASTERS DOT COM WHERE THEIR PHILOSOPHY IS DON'T BLOW YOUR TEMPER, BLOW YOUR HORNS.

(PAT)>> HOLLEY HAS REVOLUTIONIZED THE WAY FUEL IS PICKED AND DELIVERED TO A FUEL PUMP WITH THEIR HYDROMAT FUEL RESERVOIR. IT'S DESIGNED TO REDUCE OR ELIMINATE FUEL STARVATION PROBLEMS FROM HARD CORNERING, ACCELERATION, INCLINES, OR EVEN A LOW FUEL CONDITION. THIS DEMONSTRATION SHOWS AS AN AREA OF THE MAT IS UNCOVERED, TINY PORES SEAL OFF FROM SURFACE TENSION ALLOWING FUEL TO STILL BE DRAWN FROM OTHER AREAS. IT'S AVAILABLE IN SEVERAL SHAPES AND SIZES, AND ELIMINATES THE NEED FOR SPECIALTY SUMPS OR PICK UPS SAVING COST. GET YOURS AT ANY HOLLEY DEALER.

(MIKE)>> ROYAL PURPLE'S PURPLE ICE REDUCES SURFACE TENSION OF

ENGINE COOLANT, ALLOWING MORE HEAT TO TRANSFER OUTSIDE OF THE RADIATOR. NOW THIS ALSO HAS A CORROSION INHIBITOR THAT LASTS YEAR ROUND. WHEN THE DIRECTIONS ARE FOLLOWED IT'LL LOWER COOLANT TEMPERATURES UP TO 22 DEGREES. NOW YOU CAN FIND IT AT YOUR LOCAL AUTO PARTS RETAILER. THAT'S ALL THE TIME WE HAVE FOR THIS WEEK'S SHOW, SEE YOU AROUND.

Show Full Transcript

RACE BULLET THAT'S GONNA RUN ON RACE GAS. NOW OUR GOAL FOR THIS ONE IS 1,000 NATURALLY ASPIRATED HORSEPOWER. NOW THIS IS A GENTLEMAN'S ENGINE THAT WEARS A BOW TIE, AND IT CAN BE USED IN SEVERAL DIFFERENT FORMS OF RACING LIKE DRAG, TRUCK PULLING, OR EVEN HIGH PERFORMANCE MARINE.

(PAT)>> OUR PARTS SELECTION WAS BASED ON OFF THE SHELF PARTS SO EVERYTHING CAN BE PURCHASED AND ASSEMBLED WITH

EASE, BUT THIS BLOCK WE'VE HAD AROUND HERE FOR A WHILE.

IT IS A TALL DECK SPORTSMAN BLOCK FROM GM. IT'S A FOUR BOLT MAIN WITH THE OUTER THREE BOLTS IN THE CENTER SPLAYED AT 16 DEGREES. SO THAT ALLOWS FOR MORE MATERIAL TO HOLD THE CRANKSHAFT IN ITS PLACE. IT ACCEPTS A ONE PIECE REAR MAIN SEAL AND HAS A PRIORITY MAIN OILING SYSTEM, MEANING THE MAINS GET OILED FIRST, WHICH IS CRUCIAL IN A RACE ENGINE FOR LONGEVITY.

(MIKE)>> TO REACH OUR 1,000 HORSEPOWER GOAL WE NEED AN INDUCTION SETUP THAT WILL MOVE SOME SERIOUS AIR. NOW EDELBROCK MAKES THAT SIMPLE WITH THESE CYLINDER HEADS AND INTAKE MANIFOLD THAT ARE DESIGNED TO MAKE BIG POWER. NOW THEY WORKED REALLY CLOSE WITH A LEGENDARY RACER AND ENGINE BUILDER NAMED PAT MUSI TO DESIGN THESE EDELBROCK MUSI 24 DEGREE CNC HEADS. NOW THE INTAKE MANIFOLD IS A SUPER VICTOR TWO THAT IS PORT MATCHED TO THE INTAKE RUNNER, WHICH HAS A 377cc VOLUME.

NOW THE COMBUSTION CHAMBER MEASURES IN AT 119cc. INTAKE VALVE DIAMETERS ARE TWO-300 ON THE INTAKE,

ONE-900 ON THE EXHAUST.

NOW THE EXHAUST RUNNER COMES IN AT 128cc AND IT'S IN A RAISED LOCATION FOR BETTER FLOW NUMBERS.

NOW THE VALVE SPRINGS WILL HANDLE A CAM

WITH UP TO 880 LIFT. OUR CAM SHAFT HAS 800 GROSS LIFT AND THIS HEAD FLOWS 409 CFM AT THAT SPOT.

(MIKE)>> WE'VE ALREADY TAKEN CARE OF SOME OF THE TEDIOUS WORK, LIKE FULLY CLEANING THE BLOCK AND ALL THE INTERNAL

ENGINE PARTS, AS WELL AS SETTING ALL OF OUR MAIN BEARING CLEARANCES, BUT BEFORE WE CAN ASSEMBLE IT WE HAVE

TO PUT SOME EXTRA HOLES IN THE UPPER MAIN BEARING AND HERE'S WHY. LOTS OF RACE ENGINES HAVE AN ADDITIONAL GROOVE IN THE MAIN SADDLE FOR MORE OIL TO REACH THE MAINS, BUT TO ALLOW THIS TO HAPPEN EXTRA HOLES HAVE TO BE DRILLED IN THE MAIN BEARING ITSELF. IT'S AN EASY OPERATION. SIMPLY PLACE THE UPPER HALF OF THE BEARING IN A VICE AND DRILL FOUR 90 THOUSANDTHS HOLES, AND THEN DEBURR THEM. THE LAST STEP IS TO LIGHTLY SCOTCH BRITE THE BEARING SURFACE TO REMOVE THE MARKS ON THE DIAL BORE GAUGE AND MAKE A SMOOTH SURFACE.

(MIKE)>> THIS CRANK SHAFT HAS A FOUR AND A HALF INCH STROKE. NOW PAIR THAT UP WITH OUR FOURFIVE-60 BORE AND WE'VE GOT A 588 CUBIC INCH COMBO, WHICH IS THE BIGGEST WE'VE DONE HERE IN THE SHOP. NOW THIS IS AN EAGLE SPECIALTY PRODUCTS 43-40 FORGED STEEL CRANK SHAFT. NOW IT HAS THEIR SECRET ESP ARMOR PROCESS THAT GIVES IT A MIRROR LIKE FINISH, WHICH INCREASES OIL SHEDDING AND DECREASES WINDAGE, WHICH IS PROVEN TO GIVE YOU MORE HORSEPOWER. NOW THE UPPERS CAN GO IN THE BLOCK, AND ARE COATED WITH

ROYAL PURPLE MAX TOUGH ASSEMBLY LUBE. THE CRANK IS INTERNALLY BALANCED AND RATED TO HANDLE UP TO 1,500 HORSEPOWER.

NOW THE LOWER HALF OF THE MAIN BEARINGS CAN GO IN THE CAPS, GET SLICKED UP, AND THE CAP CAN DROP IN PLACE USING

ARP MAIN BOLTS AS GUIDES. A COUPLE OF TAPS SEATS THE CAP. BEFORE TORQUING, TAP THE CRANK FROM THE FRONT TO REAR, WHICH CENTERS THE THRUST BEARING. NOW TORQUE EVERYTHING TO 95 POUND FEET. FINALLY WE'LL CHECK THE CRANK'S THRUST.

THE TARGET RANGE IS BETWEEN FOUR AND NINE THOUSANDTHS. WE ARE AT FIVE THOUSANDTHS, WHICH GIVES US A GREEN FLAG.

(PAT)>> WE'RE GONNA TAKE A QUICK BREAK BUT WHEN WE COME BACK THERE'S A LOT MORE ASSEMBLY THAT'S GONNA GET DONE BUT IN A LITTLE DIFFERENT ORDER THAN YOU'RE USED TO SEEING. SO STICK WITH US.

(MIKE)>> WE'RE BACK AND READY TO CONTINUE. NOW NORMALLY THE CAM WOULD GO IN NOW BUT NOT IN THIS CASE. WE'RE GONNA BE USING A JESEL BELT DRIVE. NOW THIS THING WILL GIVE US MORE ACCURATE CAM TIMING AND BETTER ADJUSTABILITY. SO THIS COVER GOES ON FIRST. THIS TRICK RACE PIECE USES AN ORING TO SEAL TO THE BLOCK. NO GASKET OR MESSY SILICONE TO DEAL WITH WHEN IT HAS TO COME OFF. THE LOWER TIMING GEAR IS NEXT, WHICH DOES NOT GET ANY LUBE BECAUSE THERE IS A TEFLON SEAL IN THE COVER.

(PAT)>> NOW IT'S TIME FOR THE CAM SHAFT. TO MAKE BIG POWER YOU NEED A BIG CAM SHAFT, AND THIS BUMP STICK IS A SOLID ROLLER WITH A FOURSEVEN FIRING ORDER SWAP. DURATION AT 50 THOUSANDTHS LIFT IS 277 DEGREES ON THE INTAKE AND 292 DEGREES ON THE EXHAUST, AND BOTH HAVE 471 THOUSANDTHS LOBE LIFT. WE MENTIONED BEFORE THAT OUR GROSS VALVE LIFT WAS 800 THOUSANDTHS BUT THAT IS WITH A STOCK ONE POINT SEVEN ROCKER RATIO.

WE WILL BE RUNNING A ONE POINT EIGHT ROCKER RATIO ON A ROCKER THAT'S FAR FROM STOCK. SO THAT WILL PUT OUR GROSS VALVE LIFT AT 848 THOUSANDTHS, AND FINALLY THE LOBE SEPARATION ANGLE IS 114 DEGREES. THE TIMING GEAR ADAPTER BOLTS TO THE NOSE OF THE CAM. IT WILL BE TORQUED IN PLACE BEFORE THE CAM GOES IN.

SINCE THIS CAM REQUIRES MORE SPRING PRESSURE BEING A RACE ENGINE, WE ARE GONNA SPIFF IT UP WITH MORE MAX TOUGH TO KEEP IT WELL LUBED.

(MIKE)>> NOW THE OUTER THRUST WASHER GOES ON, FOLLOWED BY THE CAM RETAINER, WHICH HAS BEEN SHIMMED FOR PROPER CAM SHAFT END PLAY. JUST SO YOU KNOW, WE HAVE FIVE THOUSANDTHS. THE BELT AND ADJUSTABLE CAM GEAR GO ON TOGETHER AND WE'LL LEAVE IT FOR NOW UNTIL WE DEGREE THE CAM. SRP PISTONS WILL FILL THE BORES. NOW THESE ARE AN EXCELLENT QUALITY OFF THE SHELF PART THAT CAME WITH OUR COMPETITION ROTATING ASSEMBLY. THEY'RE A FORGED PIECE WITH A LARGE 39cc DOME. THEY HAVE A 16TH, 16TH, THREESIXTEENTH RING PACKAGE AND A ONETWO-45 COMPRESSION HEIGHT. THEY COME WITH A LIGHT WEIGHT HEAVY DUTY WRIST PIN THAT MEASURES IN A 990 THOUSANDTHS IN DIAMETER. NOW COMBINED WITH OUR COMBUSTION CHAMBER VOLUME AND

HEAD GASKET THICKNESS, WE HAVE A CALCULATED COMPRESSION RATIO OF 14.3 TO ONE. THESE ARE EAGLE FORGED RODS WITH AN HBEAM DESIGN. NOW ARP 2,000 ROD BOLTS WILL HOLD THE CAP IN PLACE AND THE OVERALL LENGTH IS SIX-700 CENTER TO CENTER. NOW THE SMALL END IS BUSHED AND DESIGNED FOR A FREE FLOATING PIN.

(PAT)>> WE DEGREE THE CAM IN EVERYTHING THAT WE BUILD HERE, AND THAT IS ESPECIALLY IMPORTANT IN A RACE ENGINE

WHEN A LARGE DOME IS INVOLVED. THAT'S BECAUSE THE ACTUAL VALVE CLEARANCE WILL BE TIGHTER BECAUSE OF THE BIG LIFT AND DURATION OF THE CAM SHAFT, AND AFTER WE'RE DONE DEGREEING WE'RE GONNA MOCK THE ENGINE UP WITH THE CYLINDER HEAD ON IT TO CHECK THAT CRITICAL PISTON TO VALVE CLEARANCE. TO DEGREE THE CAM A PISTON AND ROD ASSEMBLY GOES IN THE NUMBER ONE CYLINDER. USING A DEGREE WHEEL, TIMING POINTER, AND DIAL INDICATOR, THE PROCESS BEGINS. SINCE OUR CAM'S LOBE SEPARATION IS 114 WE'LL

INSTALL THE CAM THERE, WHICH IS STRAIGHT UP, AND THAT WILL BE OUR STARTING POINT.

(MIKE)>> NOW COMES THE MOCK UP PHASE TO CHECK "P" TO "V". THIS REQUIRES A HEAD GASKET, A SET OF LIFTERS, CYLINDER HEAD WITH TWO CHECKER SPRINGS ON NUMBER ONE, A FEW STUDS TO HOLD IT DOWN, AND WITH THE ROCKER STANDS, PUSH RODS, AND ROCKER ASSEMBLIES IN PLACE, WE'LL USE A STEEL PLATE TO MOUNT A MAGNETIC BASE AND DIAL GAUGE.

(PAT)>> WHAT WE'RE GONNA FIND IS THE CLOSEST POINT BETWEEN THE VALVES AND THE TOP OF THE PISTON, AND ON THE INTAKE SIDE THAT WILL HAPPEN AROUND 10 DEGREES AFTER TDC, AND ON THE EXHAUST SIDE AROUND 10 DEGREES BEFORE TDC, AND THAT IS ON SPLIT OVERLAP, NOT ON THE COMPRESSION STROKE. NOW WHAT SPLIT OVERLAP IS IS WHEN THE EXHAUST VALVE IS ALMOST CLOSED AND THE INTAKE VALVE IS JUST STARTING TO OPEN. NOW THE GAUGE IS CAREFULLY SET TO ZERO, AND BY PUSHING DOWN ON THE ROCKER THE FACE OF THE VALVE MAKES CONTACT WITH THE TOP OF THE PISTON. THERE IS 60 THOUSANDTHS PISTON TO VALVE CLEARANCE. A SAFE MINIMUM HERE IS 50 THOUSANDTHS. NOW THE SAME THING HAPPENS TO MEASURE THE EXHAUST SIDE. IT HAS 90 THOUSANDTHS, WHICH IS A LITTLE ON THE TIGHT SIDE. THE ABSOLUTE MINIMUM TO BE SAFE HERE IS 100 THOUSANDTHS. SO HERE'S HOW TO FIX IT. WITH THE FOUR NUTS LOOSE ON THE CAME SPROCKET, WE CAN ADVANCE THE INTAKE CENTER LINE OF THE CAM BY TWO DEGREES, AND THIS WILL DO TWO THINGS.

INCREASE THE EXHAUST SIDE'S CLEARANCE, AND DECREASE THE INTAKE SIDE'S CLEARANCE. SO IT WILL NEED TO BE RECHECKED. NOW WE HAVE 50 THOUSANDTHS ON THE INTAKE, WHICH IS DECREASED FROM THE ORIGINAL 60, BUT STILL IN THE GOOD. THE EXHAUST SIDE INCREASED TO 102 THOUSANDTHS FROM OUR ORIGINAL 90.

SO WE'RE GOOD TO GO AFTER THE BREAK.

(MIKE)>> WE'RE BACK AND THE PISTON AND ROD ASSEMBLIES ARE CLOSE TO GOING IN, BUT FIRST SOME HIGH QUALITY RING SPECIFIC LUBE HAS TO GO ON. THESE RINGS ARE FROM MOLY AND THE TOP AND SECOND HAVE BEEN GAPPED TO 32 THOUSANDTHS. THE OIL RING IS A LOW TENSION SETUP FOR REDUCED DRAG.

OUR STANDARD OPERATING PROCEDURE IS TO USE A TAPERED RING COMPRESSOR AND PISTON KNOCKER TO GET THEM IN. THE ARP 2,000 ROD BOLTS ARE TORQUE TO 75 POUND FEET. WE CAN BOLT UP THE HIGH VOLUME, HIGH PRESSURE OIL PUMP, WHICH HAS THE PICK UP ALREADY ATTACHED. A ONE PIECE COMETIC OIL PAN GASKET WILL SEAL THIS CANTON DRAG RACE OIL PAN TO THE BLOCK. IT HAS AN INTEGRATED WINDAGE TRAY AND HOLDS EIGHT QUARTERS.

(PAT)>> UP FRONT A FLUID DAMPER BALANCER GOES ON, AND WE'LL SET THE TIMING POINTER AT TRUE TDC. NOW THESE CRANE SOLID ROLLER LIFTERS FROM SUMMIT RACING CAN DROP IN, FOLLOWED BY A COMETIC MLS HEAD GASKET WITH A 32 THOUSANDTHS COMPRESSED THICKNESS. LAYING ON IT IS THE EDELBROCK MUSI 24 DEGREE CYLINDER HEAD WE SHOWED YOU EARLIER. ARP STUDS WILL CINCH IT DOWN AND ARE TORQUED TO 80 POUND FEET.

(MIKE)>> VALVETRAIN STABILITY IS CRITICAL IN A HIGH RPM RACE ENGINE. NOW IN A SITUATIONS WITH HIGH OPEN SPRING PRESSURES, THE BENEFITS OF A SHAFT ROCKER SYSTEM OVER A STUD MOUNT ARE INCREASED RIGIDITY AND ACCURACY OF GEOMETRY.

NOW THIS IS A JESEL SPORTSMAN SERIES THAT IS DESIGNED SPECIFICALLY FOR OUR CYLINDER HEAD. THE BILLET STANDS AND ALIGNMENT BARS GO ON FIRST, ONE FOR THE INTAKE, ONE FOR THE EXHAUST.

TRENT PERFORMANCE SENT US SOME KILLER PUSH RODS. THESE ARE THREEEIGHTHS IN DIAMETER WITH 135 THOUSANDTHS WALL THICKNESS, AND HAVE FIVESIXTEENTHS BALL ENDS. THE ROCKERS ARE A ONE POINT EIGHT RATIO AND HAVE A PROFILED ROCKER TAIL, WHICH REDUCES THE ROCKER'S MOMENT OF INERTIA. NOW THE EDELBROCK MANIFOLD CAN DROP ON, ALONG WITH A JESEL FRONT DRIVE DISTRIBUTOR THAT IS DRIVEN BY A SMALL BELT OFF THE CAM. AT THIS POINT IT'S READY FOR THE DOCKING CART, THEN GOES TO THE DYNO ROOM, WHERE WE ARE CONTINUING WITH SHEET METAL VALVE COVERS. THESE ARE CANTON'S AND WE OUTFITTED THEM WITH THE NECESSARY PIECES TO RUN A VACUUM PUMP. NOW THESE MASSIVE TWO AND THREEEIGHTHS INCH TO TWO AND A HALF INCH HOOKER SUPER COMP RACE HEADERS CAN GO ON. SINCE A VACUUM PUMP WILL BE RAN ON THIS ENGINE, A JONES RACING TEST GAUGE WILL BE USED TO SEE HOW WELL WE SEALED THE ENGINE UP. IT WILL HAVE A LITTLE LEAKAGE PAST THE RINGS DUE TO THE LARGE GAP. WITH FUEL GOING TO A 1,475 CFM HOLLEY DOMINATOR, A BEAST IS BORN. NOW THIS IS THE TIME THE ENGINE GETS SOME TEMPERATURE, THE RINGS SEAT, AND WE MAKE SURE THERE ARE NO LEAKS. NOW A LASH CHECK ON THE VALVES, WHICH GIVES US THE GO AHEAD TO MAKE THE FIRST PULL. THIS THING'S GONNA MAKE A TON OF POWER.

(PAT)>> I THINK SO!

(MIKE)>> THE BIG NUMBERS AFTER THE BREAK.

(MIKE)>> WE'RE BACK AND NOT WASTING ANY TIME. WITH OIL TEMPERATURE IN IT, HERE'S THE FIRST PULL FROM 4,000 TO 6,000 RPM AND 28 DEGREES OF TIMING. 851 ON POWER, 745 POUND FEET. YOU READY?

(PAT)>> LET HER EAT!

(MIKE)>> THIS NEXT RUN IS AT 30 DEGREES AND THE RPM FROM 5,000 TO 7,000.

(PAT)>> NOW WE'RE GETTING SOMEWHERE.

(MIKE)>> 926 ON POWER, 750 POUND FEET AND SHE'S CLIMBING FAST.

(PAT)>> ALL RIGHT, I LIKE IT.

(MIKE)>> WE MADE ANOTHER AT 32 DEGREES OF TIMING.

[ engine revving ]

(PAT)>> HOW ABOUT THAT, AND IT MADE 937 HORSE AND 756 POUND FEET OF TORQUE, NICE, INCREASE. AT THIS POINT WE ARE STILL CHASING TIMING. SO WE'LL ADD ANOTHER TWO DEGREES FOR A TOTAL OF 34 AND MAKE ANOTHER HIT. WE ARE STILL RUNNING THE SAME RPM RANGE OF 5,000 TO 7,000. [ engine revving ]

(MIKE)>> WHAT YOU GOT?

(PAT)>> LOOK AT THAT, PICKED UP A LITTLE BIT OF TORQUE. 762 POUND FEET OF TORQUE AND 936 HORSE. IT'S LIKE A GIGANTIC SEWING MACHINE.

(MIKE)>> THROW A SPACER ON IT?

(PAT)>> YEAH, ONE TUNING TRICK WE ALWAYS LIKE TO TRY

IS ADDING A CARB SPACER. IT DOES A COUPLE OF THINGS. IT INCREASES THE PLENUM VOLUME OF THE INTAKE AND HELPS STRAIGHTEN OUT AIR FLOW, ALLOWING FOR A BETTER TRANSITION INTO THE INTAKE RUNNERS. THIS ONE IS TWO INCHES.

WELL THERE YOU GO, 946 FOR POWER BUT LOOK WHAT THE TORQUE DID.

(MIKE)>> STEPPED UP.

(PAT)>> 770 POUND FEET, THIS IS AN EXCELLENT, EXCELLENT BRACKET CAR, RELIABLE, NO MAINTENANCE TYPE ENGINE OTHER

THAT ITS REGULAR STUFF. NOW IT HASN'T PEAKED ON POWER YET. WE'VE GOT TO TURN IT 7,500.

(MIKE)>> SOUNDS GOOD TO ME. [ engine revving ]

(MIKE)>> MAN THAT'S SWEET.

(PAT)>> SOUNDS AWESOME!

WELL THERE IT IS. THERE'S PEAK POWER FINALLY.

(MIKE)>> ALL RIGHT, 953 ON POWER, 764 ON TORQUE.

(PAT)>> HAD A LITTLE BIT OF HEAT SOAK IN

IT BUT THAT'S OKAY.

(MIKE)>> PEAK TORQUE WAS AT 6,000 RPM.

SITTING THERE ON THE TRANS BRAKE.

(PAT)>> 588 INCHES AND THE PEAK TORQUE IS AT 6,000.

(MIKE)>> PEAK POWER, 7,300. EVERYTHING WAS DOING ITS JOB.

(PAT)>> NICE.

(MIKE)>> GOOD JOB.

(PAT)>> EXCELLENT, WELL OUR 588 INCH BIG BLOCK CHEVY TURNED OUT PRETTY WELL I MUST SAY. NOW WE DID FALL A LITTLE BIT SHORT OF OUR 1,000 HORSEPOWER GOAL BUT KEEP IN MIND THESE ARE OUT OF THE BOX PARTS THAT ARE UNMODIFIED, AND WITH A LITTLE RUBBING ON IT WE WOULD BE ABLE TO REACH THAT GOAL BUT WE DON'T HAVE ENOUGH TIME TO DO THAT THIS TIME AROUND.

(MIKE)>> THAT WAS A COOL BUILD.

(PAT)>> THIS THING MADE GREAT POWER EVERYWHERE.

(MIKE)>> NOW WE'RE GOING TO DO SOMETHING A LITTLE DIFFERENT. INSTEAD OF A TECH TIP WE'RE GOING TO TAKE A LOOK BACK AT

SOME OF THE COOL BUILDS WE DID THIS YEAR.

(PAT)>> ONE THAT WE REALLY ENJOYED AND SHOWED YOU A TON OF TECH ON WAS IN HOUSE POWER MOUSE. NOW THE REASON WE BUILT IT IS WE GOT A LOT OF REQUESTS FROM YOU VIEWERS TO TAKE AN ENGINE FROM THE BARE BASICS TO A FULL BLOWN POWERHOUSE. WE STARTED OFF WITH A BARE BONES BASIC SMALL BLOCK CHEVY BUILD. WE USED BUDGET FRIENDLY PARTS FROM SUMMIT RACING, WHICH CONSTRUCTED A GREAT RUNNING STREET ENGINE. ONCE ASSEMBLED WE HOOKED IT UP TO OUR SUPER FLOW DYNO, YIELDING AN IMPRESSIVE 357 HORSEPOWER ON THE CHEAP. FOR STAGE TWO WE TORE IT DOWN AND STEPPED UP ON THE PARTS SELECTION. WE INCREASED THE CUBES TO 383 INCHES, INSTALLED A HYDRAULIC ROLLER CAM, AND CAPPED IT OFF WITH BETTER INDUCTION. RUNNING ON 93 OCTANE PUMP GAS, IT CRANKED OUT 547 HORSE.

(MIKE)>> STAGE THREE IS WHERE WE THREW OUT THE BUDGET AND

WENT FOR MAXIMUM POWER. A DART LITTLE "M" BLOCK RECEIVED THE CRANK AND RODS FROM THE 383 BUT IT HAD A LARGER BORE FILLED WITH A CUSTOM MOLY PISTON. THE CYLINDER HEAD STAYED THE SAME BUT THE INTAKE CHANGED TO AN EDELBROCK VICTOR.

NOW THIS ENGINE WAS BUILT FOR BOOST. A PROCHARGER FONEA FLOW THROUGH SYSTEM WAS BOLTED ON. THIS USED ONE OF THEIR AIR TO AIR INTERCOOLERS, BUT WE DYNO'ED IT NATURALLY ASPIRATED FIRST TO SEE WHAT THE DIFFERENCE WOULD BE WITH THE BOOST. IT MADE 554 HORSEPOWER WITH A NINE TO ONE COMPRESSION RATIO. HERE'S WHAT IT MADE ON 15 POUNDS OF BOOST.

(PAT)>> 993 HORSE, 917 POUND FEET OF TORQUE.

(MIKE)>> GREAT COMBO, GREAT JOB.

(PAT)>> AWESOME, AWESOME, AWESOME!

(MIKE)>> FROM OLD SCHOOL SMALL BLOCK POWER TO LATE MODEL TECHNOLOGY, THIS NEXT ONE REALLY GOT OUR EXCITEMENT GOING. IT'S THE SUPERCHARGED LSA THAT POWERS GRAY HAIR, WHITE KNUCKLE. NOW WE CAPITALIZED ON A LOT OF THE STOCK PARTS TO MAKE A BIG POWER PRODUCER.

(PAT)>> THE STOCK BLOCK WAS USED AND FILLED WITH 427 CUBIC INCHES OF FORGED ROTATING ASSEMBLY. THE FACTORY HEADS AND BLOWER WERE CNC PORTED AND PORT MATCHED. AFTER MARKET PULLEYS WERE INSTALLED, A LARGER HEAT EXCHANGER WAS USED, AND THE COMBO WAS DESIGNED TO MAKE 15

POUNDS OF BOOST JUST LIKE THE SMALL BLOCK.

ON 93 OCTANE GAS STRAIGHT FROM THE PUMP IT MADE AN IMPRESSIVE 797 POUND FEET OF TORQUE AND 816 HORSEPOWER.

(MIKE)>> THERE'S MORE AWESOME BUILDS LIKE THIS

COMING UP IN THE FUTURE. DOES YOUR CAR OR TRUCK LACK IN THE HORN DEPARTMENT? WELL HERE'S A SYSTEM THAT'LL LET EVERYONE AROUND

YOU KNOW YOU'RE THERE. THIS IS HORN BLASTER'S CONDUCTOR SPECIAL 244 NIGHTMARE EDITION TRAIN HORN KIT. NOW THE SHOCKER FOUR SERIES HORNS ARE MADE OUT OF ABS SERIES PLASTIC AND HAVE A STAINLESS STEEL DIAPHRAGM THAT WILL NOT RUST. NOW THE COMPRESSOR IS A VIAIR 444-C, WHICH IS OVERKILL FOR THE BEST RELIABILITY AND LOUDEST TRAIN HORN KIT IN ITS CLASS ON THE MARKET. IT COMES WITH A TWO GALLON TANK AND ALL THE HARDWARE YOU NEED TO INSTALL IT. THIS KIT CAN BE HEARD UP TO FOUR MILES AWAY. NOW TO FIND OUT THE SYSTEM THAT SUITS YOUR NEEDS LOG ON TO HORN BLASTERS DOT COM WHERE THEIR PHILOSOPHY IS DON'T BLOW YOUR TEMPER, BLOW YOUR HORNS.

(PAT)>> HOLLEY HAS REVOLUTIONIZED THE WAY FUEL IS PICKED AND DELIVERED TO A FUEL PUMP WITH THEIR HYDROMAT FUEL RESERVOIR. IT'S DESIGNED TO REDUCE OR ELIMINATE FUEL STARVATION PROBLEMS FROM HARD CORNERING, ACCELERATION, INCLINES, OR EVEN A LOW FUEL CONDITION. THIS DEMONSTRATION SHOWS AS AN AREA OF THE MAT IS UNCOVERED, TINY PORES SEAL OFF FROM SURFACE TENSION ALLOWING FUEL TO STILL BE DRAWN FROM OTHER AREAS. IT'S AVAILABLE IN SEVERAL SHAPES AND SIZES, AND ELIMINATES THE NEED FOR SPECIALTY SUMPS OR PICK UPS SAVING COST. GET YOURS AT ANY HOLLEY DEALER.

(MIKE)>> ROYAL PURPLE'S PURPLE ICE REDUCES SURFACE TENSION OF

ENGINE COOLANT, ALLOWING MORE HEAT TO TRANSFER OUTSIDE OF THE RADIATOR. NOW THIS ALSO HAS A CORROSION INHIBITOR THAT LASTS YEAR ROUND. WHEN THE DIRECTIONS ARE FOLLOWED IT'LL LOWER COOLANT TEMPERATURES UP TO 22 DEGREES. NOW YOU CAN FIND IT AT YOUR LOCAL AUTO PARTS RETAILER. THAT'S ALL THE TIME WE HAVE FOR THIS WEEK'S SHOW, SEE YOU AROUND.