Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

ARP

Rod Bolt Stretch Gauge, Steel, Dial Indicator, .0005 in. Increments, Adjustable Length, Storage Case, Kit

Comp Cams

Camshaft, Hydraulic Roller Tappet, Advertised Duration 273/277, Lift .547/.550, Mopar, 5.7/6.1L, Hemi, Each

Dupli-Color

Paint, Engine, Enamel with Ceramic Resin, Flat Gray Primer, 12 oz., Aerosol, Each

Edelbrock

E-Force Supercharger, Stage 1, Street, Black Powdercoated, Scion FR-S, Subaru BRZ, 2.0L, With Tuner, Kit

Howards Cams,Inc.

Timing Chain and Gear Set, Double Roller, Billet Steel Sprockets, Chrysler, Dodge, 5.7, 6.1L, Set

Mopar Performance

Lifters, Hydraulic Roller, Chrysler, Dodge, 5.7L Hemi, 6.1L Hemi, MDS Delete, Set of 4

Eagle Specialty Products

6.1L modern Hemi, Rotating assembly, 426 Cubic Inch Stroker Kit, 4340 Crank with ESP Armor, H-Beam Rods, and Mahle Forged Pistons

Goodson Shop Supplies

Powered Ring Filer with Integral Deburring Wheel

Kimberly-Clark Professional

Scott Heavy Duty Towels-Blue, Solvent Resistant, 200 Count, Pegboard Dispenser Feature

School of Automotive Machinists

School of Automotive Machinists in Houston, TX

The Industrial Depot

The Industrial Depot - Fasteners, Hardware, and Shop Supplies

Episode Transcript

(MIKE)>> WELCOME

TO ENGINE POWER. TODAY WE'RE HELPING OUT

TOMMY AND MARC OF DETROIT MUSCLE WITH A RATHER

AMBITIOUS PROJECT,

TRANSFORMING THIS STOCK 2010 DODGE CHALLENGER

INTO AN 800 PLUS HORSEPOWER STRAY CAT. THIS SRT IS ALREADY AN IMPRESSIVE PERFORMER WITH CLAIMS OF 425 HORSEPOWER, BUT THE NEW HELLCAT BOASTS OVER 700. THAT'S WHERE WE COME IN. LET'S SEE WHAT THIS THING WILL DO THROUGH AN AUTOMATIC.

(PAT)>> ALRIGHT LET HER RIP TATER CHIP.

(MIKE)>> AND IT STARTS WITH A DYNO TO SEE WHAT THIS SIX POINT ONE LITER HEMI CAN GENERATE

AT THE REAR WHEELS.

(PAT)>> 364 ON HORSEPOWER, 370 POUND FEET OF TORQUE.

(MIKE)>> LET'S BACK IT UP.

(PAT)>> YOU KNOW WHAT I LIKE ABOUT CHASSIS DYNO'S? IT'S LIKE THE LIE DETECTOR.

(MIKE)>> YOU GOT THAT RIGHT.

(PAT)>> IT ALMOST OVERLAID, 364 HORSE AGAIN, 371 POUND FEET OF TORQUE.

(MIKE)>> LET'S CONSIDER IT DONE.

(PAT)>> CONSIDER IT DONE, I LIKE IT.

(MIKE)>> WE LEARNED WHAT WE HOPED TO. THIS HEMI IS SUITABLE FOR THE MAJOR UPGRADE WE HAVE PLANNED. WITH THE UNDERSIDE STRIPPED, WE SUPPORT THE ENGINE AND UNBOLTED THE CRADLE ON THE GROUND.

(PAT)>> I GOT IT NOW.

(MIKE)>> FREEING UP ALL THE TOP SIDE COMPONENTS, WE CAN SLOWLY LIFT THE CHALLENGER AWAY FROM IT.

(PAT)>> THERE WE GO.

(MIKE)>> DISCONNECT THE TRANNY, AND SEPARATE THE ENGINE FROM THE CRADLE, LOWER THE BODY BACK ON THE EMPTY CRADLE, AND GIVE THIS ROLLER BACK TO TOMMY AND MARK.

THEIR TASKED WITH THIS YEAR'S POWERSTOP

SWEEPSTAKES GIVEAWAY AND THIS IS IT. WITH THE SUCCESS OF OUR ZO SIX LAST SEASON WE HAD TO BE A PART OF THIS ONE AS WELL. WHILE THEY WORK ON THE CHASSIS, WE HAVE OUR OWN PLANS FOR THE ENGINE.

WE TORE IT DOWN AND IT'S GETTING SHIPPED TO THE SCHOOL OF AUTOMOTIVE MACHINISTS FOR MACHINING. WHILE THE BLOCK WAS AWAY WE COMPLETED PART ONE OF GREY HAIR, WHITE KNUCKLE. NOW IT'S BACK AND READY FOR A WASH CYCLE IN THE HOT TANK. THIS IS THE FOUNDATION FOR A STROKED TWIN TURBO POWER HOUSE.

(PAT)>> A PROPERLY MACHINED ENGINE BLOCK IS A MUST FOR A BUILD LIKE THIS, AND IT TAKES SPECIALIZED EQUIPMENT TO DO THE JOB RIGHT, LIKE TORQUE PLATES AND ACCURATE HONING MACHINES. PLUS AND EXPERIENCED MACHINIST TO SET IT UP. THE SCHOOL OF AUTOMOTIVE MACHINISTS AND TECHNOLOGY, OR SAM TECH, HAS IT ALL AND CAN TEACH YOU EVERYTHING THAT YOU NEED TO KNOW ABOUT ENGINE MACHINING, PLUS A WHOLE LOT MORE.

(MIKE)>> THIS ENGINE IS GONNA MAKE BIG POWER UNDER BOOST. NOW PAT AND I WERE PUT TO THE TASK OF ORDERING ALL THE PARTS AND BUILDING A LONG BLOCK THAT WILL LAST. NOW WE'VE HAD AWESOME SUCCESS WITH EAGLE

ROTATING ASSEMBLIES AND MAHLE PISTONS.

SO WE'RE USING THEM AGAIN. NOW THIS KIT IS DESIGNED TO TAKE THE FACTORY 370 CUBIC INCH HEMI ALL THE WAY UP TO 426. IT'S OUR LITTLE WAY TO PAY TRIBUTE TO THAT OLD SCHOOL MONSTER. NOW THE RODS ARE A FORGED HBEAM DESIGN WITH A SIX-125 CENTER TO CENTER LENGTH.

WE ALSO HAD THE BOLTS UPGRADED TO ARP 2,000. NOW THE CRANK SHAFT IS A FORGED 4340 UNIT THAT'S RATED TO HANDLE 1,500 HORSEPOWER. IT ALSO HAS THEIR SIGNATURE ESP ARMOR FINISH ON IT. TO LEARN MORE ABOUT IT LOG ONTO THEIR WEBSITE. IT'S REALLY INTERESTING.

(PAT)>> MAHLE MOTORSPORTS NEVER DISAPPOINTS WHEN IT COMES TO THE QUALITY OF THEIR PISTONS. THESE ARE FORGED FROM SUPER TOUGH 4032 LOW EXPANSION ALUMINUM ALLOY AND ALSO HAVE A CNC'ED INVERTED DOME WITH DUAL VALVE RELIEFS. THEY HAVE ULTRA FLAT ONE POINT FIVE, ONE POINT

FIVE, THREE MILLIMETER RING LANDS, AND ARE SET UP AT A ONEZERO-95 COMPRESSION HEIGHT TO WORK

WITH OUR FOURZERO-50 STROKE CRANK. THEY'RE BUILT TO ACCEPT A 927 WRIST PIN, WHICH IS A STANDARD SMALL BLOCK CHEVY SIZE. THEY HAVE A PHOSPHATE COATING OVER THE ENTIRE PISTON, BUT ALSO HAVE A PROPRIETARY ANTIFRICTION GRAFEL COATING ON THE SKIRT TO PROTECT THEM FROM WEAR.

(MIKE)>> EVEN THOUGH IT WAS A 22,000 MILE CAR, THE BLOCK'S PAINT WAS A LITTLE WORE. SO WE'RE PRIMING IT AND PAINTING IT WITH DUPLICOLOR PRODUCTS.

FIRST IS THEIR ENGINE ENAMEL PRIMER WITH CERAMIC. IT WITHSTANDS TEMPS TO 500 DEGREES, IS OIL AND FLUID RESISTANT, AND WORKS GREAT ON NOT ONLY BLOCKS BUT ENGINE ACCESSORIES TOO. FOR COLOR WE'RE GOING RED TO MATCH THE CAR. IT'S DUPLICOLOR'S ENGINE ENAMEL WITH CERAMIC. IT'S BEEN DYNO HEAT TESTED TO 500 DEGREES AS WELL. WITH A FLASHY RED BLOCK IT'S BREAK TIME. NOW PAT'S GONNA FINISH UP THE CAM BEARINGS AND WHEN WE RETURN, WE'LL BE CHECKING BEARING CLEARANCES.

(PAT)>> WE'RE BACK AND OUR CLEVITE MAIN BEARINGS

ARE GOING IN FIRST.

THIS IS THE PREP WORK REQUIRED IN ANY ENGINE BUILD. CLEARANCES MUST BE CHECKED TO ENSURE WE GET ADEQUATE

OIL PRESSURE AND AVOID PREMATURE FAILURE DUE TO LACK OF CLEARANCE.

THE MAIN CAPS ARE A SIX BOLT DESIGN FOR THIS ENGINE JUST LIKE AN LS. SAM ALIGN HONED IT WITH ARP STUDS WE SUPPLIED DUE TO THE ADDITIONAL CLAMPING FORCE OVER THE STOCK BOLTS. THE TORQUE SPEC IS 100 POUND FEET FOR THE MAINS AND 25 POUND FEET FOR THE SIDE BOLTS.

THE CRANK'S MAIN JOURNALS ARE CHECKED FIRST. THIS IS DONE WITH A MICROMETER. MAKE SURE TO CHECK EACH JOURNAL. DON'T RELY ON MEASURING JUST ONE BECAUSE THEY CAN AND WILL DIFFER SLIGHTLY IN SIZE. EACH READING IS RECORDED TO OUR ENGINE POWER BUILD SHEET, WHICH YOU CAN PRINT TO ACCOMPLISH YOUR ENGINE BUILDS. NOW THE MICROMETER CAN BE USED TO SETUP THE DIAL BORE GAUGE, AND THE INNER DIAMETER OF THE BEARINGS CAN BE CHECKED WITH IT. MAKE SURE TO DO THEM ALL. DON'T THINK IF ONE IS GOOD THEY WILL ALL CHECK OUT. THE DIAL BORE GAUGE DIRECTLY MEASURES THE

AMOUNT OF VERTICAL OIL CLEARANCE. WE NEED A MINIMUM OF ONE THOUSANDTHS CLEARANCE PER INCH OF SHAFT DIAMETER, AND WE HAVE THAT SO WE'RE GOOD TO GO.

(MIKE)>> NOW THE CAPS ARE REMOVED AND THE MOCK UP STARTS, BEGINNING WITH THE FACTORY OIL SQUIRTERS. NOW JUST LIKE OUR LSA BUILD, THERE'S A CHANCE WE MAY HAVE A CLEARANCE ISSUE, BUT WE'LL SEE. WE'RE USING ENGINE OIL FOR LUBE DURING THE MOCK UP STAGE. MAKE SURE THE BEARINGS ARE FULLY COATED AND NO

FOREIGN MATTER MADE ITS WAY IN. NOW THE BACKBONE OF THE ENGINE IS LAID IN PLACE. IT HAS A FOURZERO-50 STROKE AND COMES WITH A 32 TOOTH RELUCTOR WHEEL INSTALLED. JUST AN FYI, ALL SIXONE HEMIS USE A

32 TOOTH RELUCTOR.

(PAT)>> ANY TIME A LARGER STROKE CRANK SHAFT IS USED THERE'S A GOOD POSSIBILITY OF A CLEARANCE ISSUE BETWEEN THE ROD BOLT AND THE BOTTOM OF THE CYLINDER WALL. WE KNOW THIS BLOCK WILL NEED IT, BUT WE DIDN'T MAKE IT THAT FAR. THE BIG END OF THE ROD IS INTERFERING WITH A SQUIRTER, AND THEY INTERFERE IN A BIG WAY. SO WE'RE OPTING NOT TO PUT THEM BACK IN BUT IT'S NO BIG DEAL. DUE TO OUR PISTON'S DESIGN AND MATERIALS THEY'LL EASILY HANDLE THE EXTRA HEAT AND HORSEPOWER. WE'LL TAP IN A SEVENSIXTEENTHS SMALL BLOCK CHEVY OIL GALLERY PLUG TO BLOCK THE SQUIRTER'S OIL SUPPLY HOLE. WITHOUT IT THE ENGINE WOULD NOT HAVE

ANY OIL PRESSURE. USING A PUNCH TO PEEN THE BLOCK TO LOCK THE PLUG IN PLACE. USING A GRINDER AND A CARBIDE BURR, WE REMOVED THE MATERIAL THAT INTERFERED WITH THE ROD BOLTS AS WELL. ROYAL PURPLE'S MAX TOUGH ASSEMBLY LUBE WILL COAT THE BEARINGS, NOW READY FOR FINAL ASSEMBLY, AND THE CRANK GOES IN FOR GOOD. DON'T FORGET TO TAKE INTO ACCOUNT THE ROD'S

SIDE TO SIDE MOVEMENT. THESE PARTS MOVE AROUND. SO HAVE A MINIMUM OF 60 THOUSANDTHS CLEARANCE EVERYWHERE. NOW THESE ARE COMMON ISSUES YOU'RE GONNA RUN INTO WHEN YOU'RE PUTTING AFTERMARKET PARTS INTO A BLOCK THAT WASN'T DESIGNED TO HANDLE QUITE SO MUCH STROKE, BUT DON'T LET IT SCARE YOU. IT'S ALL PART OF ENGINE BUILDING, AND JUST SO YOU KNOW, OUR CRANK SHAFT END PLAY IS SEVEN THOUSANDTHS.

(MIKE)>> THE NEXT STEP IN THIS ENGINE BUILD IS FILE FITTING THE PISTON RINGS. NOW SINCE THIS ENGINE IS GETTING EQUIPPED WITH TWIN TURBOS, THE RING END GAP IS A LITTLE DIFFERENT THAN THAT OF A NATURALLY ASPIRATED ENGINE. NOW FOR TURBOS WE LIKE TO SET THEM UP AT ABOUT SIX THOUSANDTHS PER INCH OF BORE ON THE TOP RING AND ABOUT SIX AND A HALF THOUSANDTHS PER INCH OF BORE ON THE SECOND RING. SO THAT PUTS OUR TOP RING GAP AT 24 THOUSANDTHS AND OUR SECOND RING GAP RIGHT AT ABOUT 26. NOW I ALREADY HAVE THE SECONDS DONE, SO HERE'S HOW WE DO THE TOPS. WITH THE RING SITTING IN THE BORE WE CAN SEE THERE'S NO END GAP THE RING WILL NOT GO IN ANY FURTHER. SO WE NEED TO DO SOME FILING. BY LOCKING IT IN THE GOODSON RING FILER, WE CAN REMOVE MATERIAL FROM ONE SIDE. NOW PLACE THE RING BACK IN THE BORE, SQUARE IT UP. USING A 22 THOUSANDTHS FEELER GAUGE WE'LL CHECK THE GAP AND IT'S A NICE TIGHT FIT.

TWO MORE THOUSANDTHS TO GO. WITH A 24 THOUSANDTHS FEELER GAUGE WE CAN CHECK

IT AND IT'S GOOD TO GO. WITH THE NUMBER ONE RING FINISHED, I'M GONNA MOVE ON TO THE NEXT CYLINDER. NOW WE LIKE TO DO EACH RING INDIVIDUALLY AND KEEP IT WITH ITS RESPECTIVE CYLINDER FOR CONSISTENCY. NOW WE'RE GONNA GO AHEAD AND TAKE A BREAK, BUT WHEN

WE COME BACK PAT'S GONNA BE HANGING SOME PISTONS.

(PAT)>> WE'RE CONTINUING ON WITH OUR GEN THREE 426 INCH STROKER HEMI BUILD, AND THE NEXT ORDER OF BUSINESS IS PUTTING OUR MOLY PISTONS

ONTO OUR EAGLE RODS. THE PISTONS HAVE AN ARROW ON THE TOP THAT POINTS TOWARD THE FRONT OF THE ENGINE WHEN IT'S ASSEMBLED. THIS SIGNIFIES THAT THE WRIST PIN BORE IS OFFSET

TO MINIMIZE SKIRT NOISE ON COLD START UP.

IT'S IMPORTANT TO MAKE ABSOLUTELY SURE YOU ASSEMBLE THEM ON THE RODS CORRECTLY. ON THE BIG END OF THE ROD THERE'S A LARGE CHAMFER ON ONE SIDE AND A SMALL ONE ON THE OTHER. THE BIG CHAMFER MUST FACE THE RADIUS ON THE CRANK. IF NOT THE ROD WILL BIND FROM INSUFFICIENT SIDE CLEARANCE. DON'T FORGET TO LUBE THE PIN BORE, PIN, AND SMALL

END OF THE ROD BEFORE EVERYTHING GOES TOGETHER. CIRCLIPS RETAIN THE PIN. A SMALL SCREWDRIVER HELPS WITH THE INSTALL. IF YOU TAKE YOUR TIME IT JUST MIGHT KEEP THE CUSSING TO A MINIMUM. WE DRESSED ALL THE PISTONS UP WITH RINGS, MAKING SURE THEY WERE ORIENTED CORRECTLY. A QUALITY RING LUBE SHOULD BE USED TO PROMOTE RING SEALING AND ELIMINATE RING LAND WELD THAT CAN BE CAUSED BY INITIAL START UP. ARP JUST DOESN'T SELL FASTENERS, THEY HAVE SOME OF THE BEST ENGINE ASSEMBLY TOOLS TOO, LIKE

TAPERED RING COMPRESSORS. THEY COME IN A VARIETY OF BORE SIZES TO FIT YOUR SETUP. NOW WE'LL PLACE A LITTLE MORE ASSEMBLY LUBE ON THE ROD BEARING AND THE ASSEMBLY IS GOING IN ITS NEW HOME.

(MIKE)>> WITH IT SEATED ON THE CRANK, THE CAP IS

ATTACHED AND THE ARP 2,000 BOLTS ARE SNUGGED UP. YOU'VE SEEN US INSTALL THESE SEVERAL TIMES. NOW MAKE SURE TO BE PATIENT AND PAY ATTENTION TO HOW EVERYTHING FEELS. IF THERE IS ANY BINDING OR IF SOMETHING FEELS TIGHT, CHECK IT OUT. BETTER TO DO IT NOW THAN PAY LATER WHEN A FAILURE HAPPENS.

(PAT)>> ANY ENGINE AT THIS POWER LEVEL REQUIRES PROPER TORQUE SPECS AND CLAMPING FORCE, AND TO

ENSURE THAT THE ROD BOLTS GET THAT AN ARP ROD BOLT STRETCH GAUGE IS GETTING USED. NOW ARP'S RANGE FOR THIS PARTICULAR 2,000 SERIES BOLT IS 64 TO 68 TEN THOUSANDTHS.

(MIKE)>> FIRST WE'LL MEASURE THE BOLT WITHOUT ANY LOAD ON IT. THEN WE'LL SNUG IT DOWN AND TORQUE IT TO 75 POUND FEET PER THEIR RECOMMENDATION. THEN CHECK THE STRETCH. OUR READING IS RIGHT KEY. WE ORDERED THIS CAM SHAFT FROM SUMMIT RACING AND

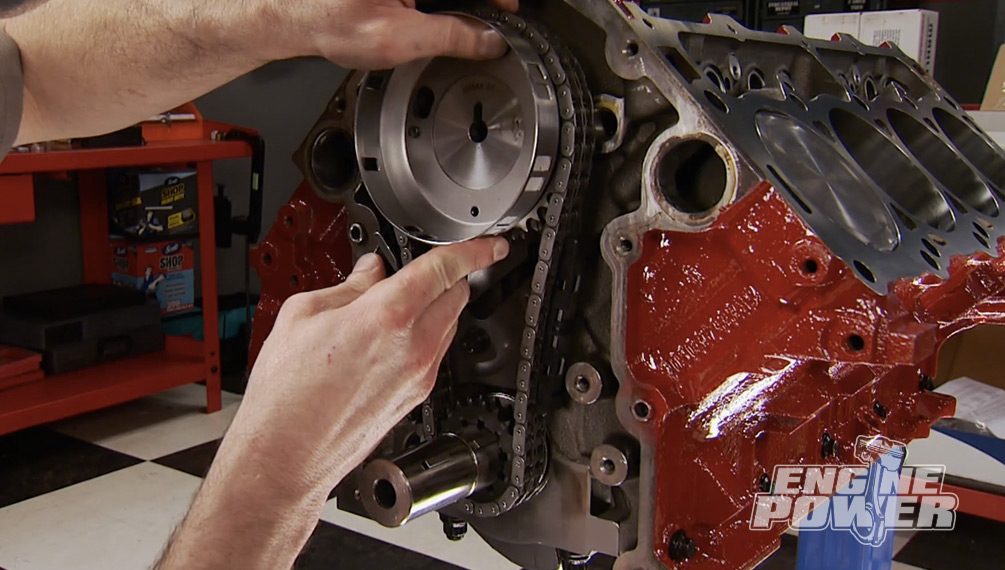

IT'S A HYDRAULIC ROLLER JUST LIKE THE ONE WE REMOVED FROM THIS ENGINE. NOW WE SPEC'ED IT OUT WITH THE TURBOS IN MIND. NOW DUE TO THE EFFICIENCY OF QUALITY TURBOS ON THE MARKET THESE DAYS, YOU DON'T HAVE TO HAVE A REALLY AGGRESSIVE CAM PROFILE TO MAKE BIG POWER

UNDER BOOST LIKE IN THE OLD DAYS. GROSS VALVE LIFT ON THIS ONE IS 547 ON THE INTAKE AND 550 ON THE EXHAUST. IT HAS 114 DEGREE LOBE SEPARATION ANGLE. DURATION AT 50 THOUSANDTHS IS 224 ON THE INTAKE AND 228 ON THE EXHAUST. A NEW CAM RETAINER AND CHAIN TENSIONER PLATE GOES ON NOW, AND IT CAME IN A KIT FROM HOWARD'S CAMS ALONG WITH THIS DOUBLE ROW TIMING SET WITH MULTIADJUSTABLE KEYWAY. WE'LL INSTALL IT AT ZERO. THEN TORQUE THE CAM BOLT TO 90 POUND FEET, AND PULL THE PIN FOR THE TENSIONER. NOW IT'S TIME TO DEGREE THE CAM.

(PAT)>> THIS IS A MUST FOR ANY ENGINE BUILD. IT ENSURES THE CAM SHAFT'S INTAKE CENTER LINE IS POSITIONED WHERE YOU, THE ENGINE BUILDER, WANTS IT. IF YOU'RE A BEGINNER AND HAVE QUESTIONS, CALL SUMMIT RACING'S TECH LINE. THE ACCURACY OF ALL THE PARTS INVOLVED ARE EXCELLENT. THE INTAKE CENTER LINE COMES IN AT 117.5 DEGREES, WHICH IS WHERE WE WANT IT ON THIS BIG INCH TWIN TURBO HEMI. MOPAR PERFORMANCE LIFTERS ARE GOING IN. THEY COME IN SETS OF FOUR WITH THE RETAINERS.

THESE ARE HYDRAULIC ROLLERS AND SUMMIT RACING WAS OUR SOURCE AND WE GOT IT REALLY QUICK EVEN WITH STANDARD SHIPPING. WE'LL BE RIGHT BACK.

(MIKE)>> PART ONE OF OUR 426 CUBIC INCH LATE MODEL HEMI IS ALMOST WRAPPED UP. NO IN CASE YOU'VE NEVER SEEN THE INTERNALS OF ONE OF THESE, THEY SHARE A LOT OF THE SAME DESIGN CHARACTERISTICS AS A LATE MODEL GM LS ENGINE.

LIKE UP FRONT WHERE THE ACTUAL PUMP MOUNTS. NOW THERE IS A CORRECT WAY TO INSTALL THIS THING, SO LET'S GET STARTED. THE FIRST THING TO GO ON IS THE SPROCKET THAT DRIVES THE OIL PUMP ON THE CRANK SHAFT. NOW I'LL APPLY A LITTLE CMD TO THE SUPPLIED SPACERS FROM HOWARDS SO THE PUMP CLEARS THE DOUBLE ROW TIMING CHAIN, AND STICK THEM TO THE BLOCK. NOW CENTER THE PUMP AND START THE FASTENERS. USING A FEW 15 TEN THOUSANDTHS FEELER GAUGES AS SHIMS, I'LL CENTER THE PUMP ON THE CRANK'S SPROCKET.

THIS WILL ELIMINATE ANY PREMATURE WEAR ONE THE PUMP. NOW TORQUE IT TO 25 POUND FEET AND IT'S GOOD TO GO. IT'S LIGHTS OUT FOR THE TIMING SET AND OIL PUMP. THE FACTORY FRONT COVER IS GOING BACK ON WITH A NEW SEAL OF COURSE. NOW WE'LL ROLL THE ENGINE OVER, LUBE UP THE ORING FOR THE OIL PICK UP, AND DROP IT IN, PLACE THE WINDAGE TRAY, WHICH ALSO THE PAN GASKET IN PLACE, AND LOCATE THE PICK UP IN THE PUMP AND ON THE STUD. NOTICE THE LITTLE BIT OF CLEARANCING ON THE PICK UP. THAT IS NEEDED DUE TO THE SPACERS ON THE PUMP.

FINALLY THE PAN GOES ON FOR GOOD AND IS HELD IN

PLACE WITH MORE ARP FASTENERS. OIL PAN'S NOT GONNA FALL OFF.

(PAT)>> THIS WILL NOT FALL OFF.

(MIKE)>> JUST LIKE AN LS ENGINE, THE PAN NEEDS TO BE ALIGNED WITH THE BACK OF THE BLOCK WITH A STRAIGHT EDGE. THIS ELIMINATES THE RISK OF PAN DAMAGE WHEN THE TRANSMISSION IS ATTACHED.

FINAL TORQUE IS 12 POUND FEET.

(PAT)>> WELL THAT'S IT FOR STAGE ON AND OUR STROKER

MOPAR IS GOING TOGETHER AWESOME. THANKS TO SAM TECH FOR THE ACCURATE MACHINING. NOW WE ACTUALLY SHOWED YOU SOME OF THE PITFALLS WHEN ASSEMBLING A STROKER ENGINE, BUT WITH SOME BASIC HAND TOOLS AND A LITTLE PATIENCE, NOTHING IS AS BAD AS IT SEEMS AND YOU'LL LEARN SOMETHING WHILE DOING IT.

IF YOU'RE LIKE US, YOU KNOW THAT THE FLAT WORK SURFACES OF YOUR GARAGE OR SHOP GET TAKEN UP PRETTY FAST, BUT WE ALSO UNDERSTAND THE IMPORTANCE

OF HAVING QUALITY SHOP TOWELS AROUND. SCOTT TOWELS HAS DESIGNED THIS BOX TO CATER TO GUYS LIKE US. INSIDE ARE 200 OF THEIR HEAVY DUTY SOLID RESISTANT PRO TOWELS THAT ARE THREE TIMES STRONGER WET THAN NORMAL TOWELS, BUT THE COOL THING IS IS

HOW THE BOX WORKS. SIMPLY SLIDE ONTO TWO PEGS ON YOUR PEG BOARD, OPEN UP THE DISPENSING PORT, AND NOW YOU HAVE ACCESS TO QUALITY TOWELS WITHOUT HAVING ANY OF YOUR VALUABLE WORK SPACE TAKEN UP.

(MIKE)>> EDELBROCK HAS CLEARLY BECOME THE LEADER IN BOLT ON ROOTS TYPE SUPER CHARGER SYSTEMS OVER THE LAST FEW YEARS, AND THEIR APPLICATIONS ARE EXPANDING IN RAPID FASHION. THIS IS THEIR NEW EFORCE SYSTEM FOR THE MODELS YOU SEE LISTED. NOW IT FEATURES A TVS 1320 SUPERCHARGER AND EXTRA LONG RUNNERS TO MAXIMIZE AIR FLOW AND HORSEPOWER AT HIGH RPM'S. NOW ITS COMPACT DESIGN FITS UNDER THE FACTORY HOOD. NOW IT COMES WITH A HIGH FLOW AIR BOX AND FILTER, PLUS AN ECU TECH PROGRAMMING SYSTEM WITH A PREINSTALLED EDELBROCK TUNE. NOW IT ALSO COMES WITH ALL THE ODDS AND ENDS YOU NEED FOR A TRUE BOLT ON INSTALLATION. NOW YOU CAN PICK THE WHOLE SYSTEM UP AT SUMMIT RACING FOR $5,399 DOLLARS.

THIS TECH TIP IS ALL ABOUT LUBRICATION. PRETTY MUCH ALL MACHINERY HAS METAL TO METAL CONTACT DURING ITS OPERATION. IN OUR CASE, WE PRIMARILY DEAL WITH ENGINES. [ ENGINE REVVING ]

(MIKE)>> AND DRIVETRAINS! [ ENGINE REVVING ]

(MIKE)>> NOW THESE PIECES ARE RELATIVELY COMPLEX EQUIPMENT AND HAVE METALLIC PARTS THAT RUB ON EACH OTHER IN DIFFERENT WAYS. THIS REQUIRES A SCIENTIFIC APPROACH TO KEEP THINGS FROM WEARING OR FLAT OUT BEING DESTROYED. NOW HERE'S AN EXAMPLE OF PARTS THAT REQUIRE DIFFERENT LUBRICATION DEMANDS. ON THE ENGINE SIDE WE HAVE MAIN, ROD, AND CAM BEARINGS, PISTON RINGS, AND VALVETRAIN COMPONENTS LIKE THE CAM SHAFT, LIFTERS, AND TIMING SET. NOW ALL OF THESE REQUIRE THE SAME TYPE OF LUBRICATION, ENGINE OIL.

(PAT)>> THEN WE HAVE THE DRIVELINE SIDE, LIKE WHEEL BEARINGS, RING AND PINIONS, UJOINTS, AND OTHER CHASSIS COMPONENTS, AND THEY TAKE DIFFERENT TYPES OF LUBES LIKE OILS TO THICKER VISCOSITY ONES LIKE GREASE. ON THE ENGINE SIDE THERE ARE NUMEROUS BRANDS, VISCOSITIES, AND EVEN SPECIALIZED ONES USED FOR AIDING ASSEMBLY, START UP, AND INITIAL BREAK IN. ASSEMBLY LUBE IS HIGH IN VISCOSITY AND IT'S PURPOSE IS TO NOT ONLY PROTECT THE ENGINE DURING INITIAL FIRE UP, BUT TO STAY IN PLACE IF THE ENGINE HAS TO SET FOR ANY AMOUNT OF TIME. BREAK IN OIL IS EXACTLY THAT. IT CONTAINS HIGHER AMOUNTS OF SPECIFIC COMPOUNDS LIKE ZDDP OR ZINC. THIS IS SUPER IMPORTANT IN FLAT TAPPET CAM SHAFT SCENARIOS THAT HAVE VERY HIGH BOUNDARY LAYER PRESSURES AND SHEER FORCE AT THEIR CONTACT FACES. THE ZINC IS ATTRACTED TO THESE AREAS AND ADDS ADDITIONAL LUBRICATING PROPERTIES. IT ALSO ACTS AS A CORROSION INHIBITOR.

(MIKE)>> THERE'S ALMOST AN INFINITE AMOUNT OF OIL SELECTIONS NO MATTER YOUR APPLICATION. THERE'S OILS FOR RACE, STREET, EVEN HIGH MILEAGE. NOW THE MOST IMPORTANT PROPERTY OF A MOTOR OIL IN MAINTAINING ITS LUBRICATING FILM AGAINST MOVING PARTS IS CALLED ITS VISCOSITY. VISCOSITY IS THE FLUID'S RESISTANCE TO FLOW. NOW MULTIVISCOSITY OILS ARE CREATED SO OIL FLOWS ADEQUATELY AT DIFFERENT TEMPERATURES. WHEN YOU SEE THE FIVE W-30, HERE'S WHAT IT MEANS.

THE "W" MEANS THE OIL HAS A WINTER RATING. THE "5" IS THE VISCOSITY AT THAT TEMPERATURES.

THE "30" IS THE VISCOSITY AT 212 DEGREES FAHRENHEIT. THIS IS AN SAE RATING FOR MULTIVISCOSITY OIL.

(PAT)>> LUBRICANTS FOR DRIVELINE PARTS HAVE TO DEAL WITH THE EXTREME PRESSURES OF GEAR MESH AND BEARING LOADING. THEY HAD THE SAME SAE RATING AS MULTIWEIGHT OIL BUT AT MUCH HIGHER VISCOSITIES.

(MIKE)>> WE HOPE THIS GIVES YOU A BETTER UNDERSTANDING OF THE IMPORTANCE OF DIFFERENT LUBES, THEIR USES, THEIR VISCOSITIES, AND MORE IMPORTANTLY THE AMOUNT OF SCIENCE THAT GOES INTO THEM TO KEEP YOUR PARTS ALIVE. NEXT WEEK IS PART TWO AND ALL ABOUT THE TOP END OF THIS THIRD GEN HEMI. NOW WE HAVE A MIX OF FACTORY AND AFTERMARKET PARTS TO GET IT WRAPPED UP. THEN IT'S GOING BACK DOWN THE HALLWAY TO MARC, AND TOMMY, AND DETROIT MUSCLE, WHERE THEY'LL COMPLETE THE POWERSTOP ULTIMATE CHALLENGER SWEEPSTAKES.

Show Full Transcript

TRANSFORMING THIS STOCK 2010 DODGE CHALLENGER

INTO AN 800 PLUS HORSEPOWER STRAY CAT. THIS SRT IS ALREADY AN IMPRESSIVE PERFORMER WITH CLAIMS OF 425 HORSEPOWER, BUT THE NEW HELLCAT BOASTS OVER 700. THAT'S WHERE WE COME IN. LET'S SEE WHAT THIS THING WILL DO THROUGH AN AUTOMATIC.

(PAT)>> ALRIGHT LET HER RIP TATER CHIP.

(MIKE)>> AND IT STARTS WITH A DYNO TO SEE WHAT THIS SIX POINT ONE LITER HEMI CAN GENERATE

AT THE REAR WHEELS.

(PAT)>> 364 ON HORSEPOWER, 370 POUND FEET OF TORQUE.

(MIKE)>> LET'S BACK IT UP.

(PAT)>> YOU KNOW WHAT I LIKE ABOUT CHASSIS DYNO'S? IT'S LIKE THE LIE DETECTOR.

(MIKE)>> YOU GOT THAT RIGHT.

(PAT)>> IT ALMOST OVERLAID, 364 HORSE AGAIN, 371 POUND FEET OF TORQUE.

(MIKE)>> LET'S CONSIDER IT DONE.

(PAT)>> CONSIDER IT DONE, I LIKE IT.

(MIKE)>> WE LEARNED WHAT WE HOPED TO. THIS HEMI IS SUITABLE FOR THE MAJOR UPGRADE WE HAVE PLANNED. WITH THE UNDERSIDE STRIPPED, WE SUPPORT THE ENGINE AND UNBOLTED THE CRADLE ON THE GROUND.

(PAT)>> I GOT IT NOW.

(MIKE)>> FREEING UP ALL THE TOP SIDE COMPONENTS, WE CAN SLOWLY LIFT THE CHALLENGER AWAY FROM IT.

(PAT)>> THERE WE GO.

(MIKE)>> DISCONNECT THE TRANNY, AND SEPARATE THE ENGINE FROM THE CRADLE, LOWER THE BODY BACK ON THE EMPTY CRADLE, AND GIVE THIS ROLLER BACK TO TOMMY AND MARK.

THEIR TASKED WITH THIS YEAR'S POWERSTOP

SWEEPSTAKES GIVEAWAY AND THIS IS IT. WITH THE SUCCESS OF OUR ZO SIX LAST SEASON WE HAD TO BE A PART OF THIS ONE AS WELL. WHILE THEY WORK ON THE CHASSIS, WE HAVE OUR OWN PLANS FOR THE ENGINE.

WE TORE IT DOWN AND IT'S GETTING SHIPPED TO THE SCHOOL OF AUTOMOTIVE MACHINISTS FOR MACHINING. WHILE THE BLOCK WAS AWAY WE COMPLETED PART ONE OF GREY HAIR, WHITE KNUCKLE. NOW IT'S BACK AND READY FOR A WASH CYCLE IN THE HOT TANK. THIS IS THE FOUNDATION FOR A STROKED TWIN TURBO POWER HOUSE.

(PAT)>> A PROPERLY MACHINED ENGINE BLOCK IS A MUST FOR A BUILD LIKE THIS, AND IT TAKES SPECIALIZED EQUIPMENT TO DO THE JOB RIGHT, LIKE TORQUE PLATES AND ACCURATE HONING MACHINES. PLUS AND EXPERIENCED MACHINIST TO SET IT UP. THE SCHOOL OF AUTOMOTIVE MACHINISTS AND TECHNOLOGY, OR SAM TECH, HAS IT ALL AND CAN TEACH YOU EVERYTHING THAT YOU NEED TO KNOW ABOUT ENGINE MACHINING, PLUS A WHOLE LOT MORE.

(MIKE)>> THIS ENGINE IS GONNA MAKE BIG POWER UNDER BOOST. NOW PAT AND I WERE PUT TO THE TASK OF ORDERING ALL THE PARTS AND BUILDING A LONG BLOCK THAT WILL LAST. NOW WE'VE HAD AWESOME SUCCESS WITH EAGLE

ROTATING ASSEMBLIES AND MAHLE PISTONS.

SO WE'RE USING THEM AGAIN. NOW THIS KIT IS DESIGNED TO TAKE THE FACTORY 370 CUBIC INCH HEMI ALL THE WAY UP TO 426. IT'S OUR LITTLE WAY TO PAY TRIBUTE TO THAT OLD SCHOOL MONSTER. NOW THE RODS ARE A FORGED HBEAM DESIGN WITH A SIX-125 CENTER TO CENTER LENGTH.

WE ALSO HAD THE BOLTS UPGRADED TO ARP 2,000. NOW THE CRANK SHAFT IS A FORGED 4340 UNIT THAT'S RATED TO HANDLE 1,500 HORSEPOWER. IT ALSO HAS THEIR SIGNATURE ESP ARMOR FINISH ON IT. TO LEARN MORE ABOUT IT LOG ONTO THEIR WEBSITE. IT'S REALLY INTERESTING.

(PAT)>> MAHLE MOTORSPORTS NEVER DISAPPOINTS WHEN IT COMES TO THE QUALITY OF THEIR PISTONS. THESE ARE FORGED FROM SUPER TOUGH 4032 LOW EXPANSION ALUMINUM ALLOY AND ALSO HAVE A CNC'ED INVERTED DOME WITH DUAL VALVE RELIEFS. THEY HAVE ULTRA FLAT ONE POINT FIVE, ONE POINT

FIVE, THREE MILLIMETER RING LANDS, AND ARE SET UP AT A ONEZERO-95 COMPRESSION HEIGHT TO WORK

WITH OUR FOURZERO-50 STROKE CRANK. THEY'RE BUILT TO ACCEPT A 927 WRIST PIN, WHICH IS A STANDARD SMALL BLOCK CHEVY SIZE. THEY HAVE A PHOSPHATE COATING OVER THE ENTIRE PISTON, BUT ALSO HAVE A PROPRIETARY ANTIFRICTION GRAFEL COATING ON THE SKIRT TO PROTECT THEM FROM WEAR.

(MIKE)>> EVEN THOUGH IT WAS A 22,000 MILE CAR, THE BLOCK'S PAINT WAS A LITTLE WORE. SO WE'RE PRIMING IT AND PAINTING IT WITH DUPLICOLOR PRODUCTS.

FIRST IS THEIR ENGINE ENAMEL PRIMER WITH CERAMIC. IT WITHSTANDS TEMPS TO 500 DEGREES, IS OIL AND FLUID RESISTANT, AND WORKS GREAT ON NOT ONLY BLOCKS BUT ENGINE ACCESSORIES TOO. FOR COLOR WE'RE GOING RED TO MATCH THE CAR. IT'S DUPLICOLOR'S ENGINE ENAMEL WITH CERAMIC. IT'S BEEN DYNO HEAT TESTED TO 500 DEGREES AS WELL. WITH A FLASHY RED BLOCK IT'S BREAK TIME. NOW PAT'S GONNA FINISH UP THE CAM BEARINGS AND WHEN WE RETURN, WE'LL BE CHECKING BEARING CLEARANCES.

(PAT)>> WE'RE BACK AND OUR CLEVITE MAIN BEARINGS

ARE GOING IN FIRST.

THIS IS THE PREP WORK REQUIRED IN ANY ENGINE BUILD. CLEARANCES MUST BE CHECKED TO ENSURE WE GET ADEQUATE

OIL PRESSURE AND AVOID PREMATURE FAILURE DUE TO LACK OF CLEARANCE.

THE MAIN CAPS ARE A SIX BOLT DESIGN FOR THIS ENGINE JUST LIKE AN LS. SAM ALIGN HONED IT WITH ARP STUDS WE SUPPLIED DUE TO THE ADDITIONAL CLAMPING FORCE OVER THE STOCK BOLTS. THE TORQUE SPEC IS 100 POUND FEET FOR THE MAINS AND 25 POUND FEET FOR THE SIDE BOLTS.

THE CRANK'S MAIN JOURNALS ARE CHECKED FIRST. THIS IS DONE WITH A MICROMETER. MAKE SURE TO CHECK EACH JOURNAL. DON'T RELY ON MEASURING JUST ONE BECAUSE THEY CAN AND WILL DIFFER SLIGHTLY IN SIZE. EACH READING IS RECORDED TO OUR ENGINE POWER BUILD SHEET, WHICH YOU CAN PRINT TO ACCOMPLISH YOUR ENGINE BUILDS. NOW THE MICROMETER CAN BE USED TO SETUP THE DIAL BORE GAUGE, AND THE INNER DIAMETER OF THE BEARINGS CAN BE CHECKED WITH IT. MAKE SURE TO DO THEM ALL. DON'T THINK IF ONE IS GOOD THEY WILL ALL CHECK OUT. THE DIAL BORE GAUGE DIRECTLY MEASURES THE

AMOUNT OF VERTICAL OIL CLEARANCE. WE NEED A MINIMUM OF ONE THOUSANDTHS CLEARANCE PER INCH OF SHAFT DIAMETER, AND WE HAVE THAT SO WE'RE GOOD TO GO.

(MIKE)>> NOW THE CAPS ARE REMOVED AND THE MOCK UP STARTS, BEGINNING WITH THE FACTORY OIL SQUIRTERS. NOW JUST LIKE OUR LSA BUILD, THERE'S A CHANCE WE MAY HAVE A CLEARANCE ISSUE, BUT WE'LL SEE. WE'RE USING ENGINE OIL FOR LUBE DURING THE MOCK UP STAGE. MAKE SURE THE BEARINGS ARE FULLY COATED AND NO

FOREIGN MATTER MADE ITS WAY IN. NOW THE BACKBONE OF THE ENGINE IS LAID IN PLACE. IT HAS A FOURZERO-50 STROKE AND COMES WITH A 32 TOOTH RELUCTOR WHEEL INSTALLED. JUST AN FYI, ALL SIXONE HEMIS USE A

32 TOOTH RELUCTOR.

(PAT)>> ANY TIME A LARGER STROKE CRANK SHAFT IS USED THERE'S A GOOD POSSIBILITY OF A CLEARANCE ISSUE BETWEEN THE ROD BOLT AND THE BOTTOM OF THE CYLINDER WALL. WE KNOW THIS BLOCK WILL NEED IT, BUT WE DIDN'T MAKE IT THAT FAR. THE BIG END OF THE ROD IS INTERFERING WITH A SQUIRTER, AND THEY INTERFERE IN A BIG WAY. SO WE'RE OPTING NOT TO PUT THEM BACK IN BUT IT'S NO BIG DEAL. DUE TO OUR PISTON'S DESIGN AND MATERIALS THEY'LL EASILY HANDLE THE EXTRA HEAT AND HORSEPOWER. WE'LL TAP IN A SEVENSIXTEENTHS SMALL BLOCK CHEVY OIL GALLERY PLUG TO BLOCK THE SQUIRTER'S OIL SUPPLY HOLE. WITHOUT IT THE ENGINE WOULD NOT HAVE

ANY OIL PRESSURE. USING A PUNCH TO PEEN THE BLOCK TO LOCK THE PLUG IN PLACE. USING A GRINDER AND A CARBIDE BURR, WE REMOVED THE MATERIAL THAT INTERFERED WITH THE ROD BOLTS AS WELL. ROYAL PURPLE'S MAX TOUGH ASSEMBLY LUBE WILL COAT THE BEARINGS, NOW READY FOR FINAL ASSEMBLY, AND THE CRANK GOES IN FOR GOOD. DON'T FORGET TO TAKE INTO ACCOUNT THE ROD'S

SIDE TO SIDE MOVEMENT. THESE PARTS MOVE AROUND. SO HAVE A MINIMUM OF 60 THOUSANDTHS CLEARANCE EVERYWHERE. NOW THESE ARE COMMON ISSUES YOU'RE GONNA RUN INTO WHEN YOU'RE PUTTING AFTERMARKET PARTS INTO A BLOCK THAT WASN'T DESIGNED TO HANDLE QUITE SO MUCH STROKE, BUT DON'T LET IT SCARE YOU. IT'S ALL PART OF ENGINE BUILDING, AND JUST SO YOU KNOW, OUR CRANK SHAFT END PLAY IS SEVEN THOUSANDTHS.

(MIKE)>> THE NEXT STEP IN THIS ENGINE BUILD IS FILE FITTING THE PISTON RINGS. NOW SINCE THIS ENGINE IS GETTING EQUIPPED WITH TWIN TURBOS, THE RING END GAP IS A LITTLE DIFFERENT THAN THAT OF A NATURALLY ASPIRATED ENGINE. NOW FOR TURBOS WE LIKE TO SET THEM UP AT ABOUT SIX THOUSANDTHS PER INCH OF BORE ON THE TOP RING AND ABOUT SIX AND A HALF THOUSANDTHS PER INCH OF BORE ON THE SECOND RING. SO THAT PUTS OUR TOP RING GAP AT 24 THOUSANDTHS AND OUR SECOND RING GAP RIGHT AT ABOUT 26. NOW I ALREADY HAVE THE SECONDS DONE, SO HERE'S HOW WE DO THE TOPS. WITH THE RING SITTING IN THE BORE WE CAN SEE THERE'S NO END GAP THE RING WILL NOT GO IN ANY FURTHER. SO WE NEED TO DO SOME FILING. BY LOCKING IT IN THE GOODSON RING FILER, WE CAN REMOVE MATERIAL FROM ONE SIDE. NOW PLACE THE RING BACK IN THE BORE, SQUARE IT UP. USING A 22 THOUSANDTHS FEELER GAUGE WE'LL CHECK THE GAP AND IT'S A NICE TIGHT FIT.

TWO MORE THOUSANDTHS TO GO. WITH A 24 THOUSANDTHS FEELER GAUGE WE CAN CHECK

IT AND IT'S GOOD TO GO. WITH THE NUMBER ONE RING FINISHED, I'M GONNA MOVE ON TO THE NEXT CYLINDER. NOW WE LIKE TO DO EACH RING INDIVIDUALLY AND KEEP IT WITH ITS RESPECTIVE CYLINDER FOR CONSISTENCY. NOW WE'RE GONNA GO AHEAD AND TAKE A BREAK, BUT WHEN

WE COME BACK PAT'S GONNA BE HANGING SOME PISTONS.

(PAT)>> WE'RE CONTINUING ON WITH OUR GEN THREE 426 INCH STROKER HEMI BUILD, AND THE NEXT ORDER OF BUSINESS IS PUTTING OUR MOLY PISTONS

ONTO OUR EAGLE RODS. THE PISTONS HAVE AN ARROW ON THE TOP THAT POINTS TOWARD THE FRONT OF THE ENGINE WHEN IT'S ASSEMBLED. THIS SIGNIFIES THAT THE WRIST PIN BORE IS OFFSET

TO MINIMIZE SKIRT NOISE ON COLD START UP.

IT'S IMPORTANT TO MAKE ABSOLUTELY SURE YOU ASSEMBLE THEM ON THE RODS CORRECTLY. ON THE BIG END OF THE ROD THERE'S A LARGE CHAMFER ON ONE SIDE AND A SMALL ONE ON THE OTHER. THE BIG CHAMFER MUST FACE THE RADIUS ON THE CRANK. IF NOT THE ROD WILL BIND FROM INSUFFICIENT SIDE CLEARANCE. DON'T FORGET TO LUBE THE PIN BORE, PIN, AND SMALL

END OF THE ROD BEFORE EVERYTHING GOES TOGETHER. CIRCLIPS RETAIN THE PIN. A SMALL SCREWDRIVER HELPS WITH THE INSTALL. IF YOU TAKE YOUR TIME IT JUST MIGHT KEEP THE CUSSING TO A MINIMUM. WE DRESSED ALL THE PISTONS UP WITH RINGS, MAKING SURE THEY WERE ORIENTED CORRECTLY. A QUALITY RING LUBE SHOULD BE USED TO PROMOTE RING SEALING AND ELIMINATE RING LAND WELD THAT CAN BE CAUSED BY INITIAL START UP. ARP JUST DOESN'T SELL FASTENERS, THEY HAVE SOME OF THE BEST ENGINE ASSEMBLY TOOLS TOO, LIKE

TAPERED RING COMPRESSORS. THEY COME IN A VARIETY OF BORE SIZES TO FIT YOUR SETUP. NOW WE'LL PLACE A LITTLE MORE ASSEMBLY LUBE ON THE ROD BEARING AND THE ASSEMBLY IS GOING IN ITS NEW HOME.

(MIKE)>> WITH IT SEATED ON THE CRANK, THE CAP IS

ATTACHED AND THE ARP 2,000 BOLTS ARE SNUGGED UP. YOU'VE SEEN US INSTALL THESE SEVERAL TIMES. NOW MAKE SURE TO BE PATIENT AND PAY ATTENTION TO HOW EVERYTHING FEELS. IF THERE IS ANY BINDING OR IF SOMETHING FEELS TIGHT, CHECK IT OUT. BETTER TO DO IT NOW THAN PAY LATER WHEN A FAILURE HAPPENS.

(PAT)>> ANY ENGINE AT THIS POWER LEVEL REQUIRES PROPER TORQUE SPECS AND CLAMPING FORCE, AND TO

ENSURE THAT THE ROD BOLTS GET THAT AN ARP ROD BOLT STRETCH GAUGE IS GETTING USED. NOW ARP'S RANGE FOR THIS PARTICULAR 2,000 SERIES BOLT IS 64 TO 68 TEN THOUSANDTHS.

(MIKE)>> FIRST WE'LL MEASURE THE BOLT WITHOUT ANY LOAD ON IT. THEN WE'LL SNUG IT DOWN AND TORQUE IT TO 75 POUND FEET PER THEIR RECOMMENDATION. THEN CHECK THE STRETCH. OUR READING IS RIGHT KEY. WE ORDERED THIS CAM SHAFT FROM SUMMIT RACING AND

IT'S A HYDRAULIC ROLLER JUST LIKE THE ONE WE REMOVED FROM THIS ENGINE. NOW WE SPEC'ED IT OUT WITH THE TURBOS IN MIND. NOW DUE TO THE EFFICIENCY OF QUALITY TURBOS ON THE MARKET THESE DAYS, YOU DON'T HAVE TO HAVE A REALLY AGGRESSIVE CAM PROFILE TO MAKE BIG POWER

UNDER BOOST LIKE IN THE OLD DAYS. GROSS VALVE LIFT ON THIS ONE IS 547 ON THE INTAKE AND 550 ON THE EXHAUST. IT HAS 114 DEGREE LOBE SEPARATION ANGLE. DURATION AT 50 THOUSANDTHS IS 224 ON THE INTAKE AND 228 ON THE EXHAUST. A NEW CAM RETAINER AND CHAIN TENSIONER PLATE GOES ON NOW, AND IT CAME IN A KIT FROM HOWARD'S CAMS ALONG WITH THIS DOUBLE ROW TIMING SET WITH MULTIADJUSTABLE KEYWAY. WE'LL INSTALL IT AT ZERO. THEN TORQUE THE CAM BOLT TO 90 POUND FEET, AND PULL THE PIN FOR THE TENSIONER. NOW IT'S TIME TO DEGREE THE CAM.

(PAT)>> THIS IS A MUST FOR ANY ENGINE BUILD. IT ENSURES THE CAM SHAFT'S INTAKE CENTER LINE IS POSITIONED WHERE YOU, THE ENGINE BUILDER, WANTS IT. IF YOU'RE A BEGINNER AND HAVE QUESTIONS, CALL SUMMIT RACING'S TECH LINE. THE ACCURACY OF ALL THE PARTS INVOLVED ARE EXCELLENT. THE INTAKE CENTER LINE COMES IN AT 117.5 DEGREES, WHICH IS WHERE WE WANT IT ON THIS BIG INCH TWIN TURBO HEMI. MOPAR PERFORMANCE LIFTERS ARE GOING IN. THEY COME IN SETS OF FOUR WITH THE RETAINERS.

THESE ARE HYDRAULIC ROLLERS AND SUMMIT RACING WAS OUR SOURCE AND WE GOT IT REALLY QUICK EVEN WITH STANDARD SHIPPING. WE'LL BE RIGHT BACK.

(MIKE)>> PART ONE OF OUR 426 CUBIC INCH LATE MODEL HEMI IS ALMOST WRAPPED UP. NO IN CASE YOU'VE NEVER SEEN THE INTERNALS OF ONE OF THESE, THEY SHARE A LOT OF THE SAME DESIGN CHARACTERISTICS AS A LATE MODEL GM LS ENGINE.

LIKE UP FRONT WHERE THE ACTUAL PUMP MOUNTS. NOW THERE IS A CORRECT WAY TO INSTALL THIS THING, SO LET'S GET STARTED. THE FIRST THING TO GO ON IS THE SPROCKET THAT DRIVES THE OIL PUMP ON THE CRANK SHAFT. NOW I'LL APPLY A LITTLE CMD TO THE SUPPLIED SPACERS FROM HOWARDS SO THE PUMP CLEARS THE DOUBLE ROW TIMING CHAIN, AND STICK THEM TO THE BLOCK. NOW CENTER THE PUMP AND START THE FASTENERS. USING A FEW 15 TEN THOUSANDTHS FEELER GAUGES AS SHIMS, I'LL CENTER THE PUMP ON THE CRANK'S SPROCKET.

THIS WILL ELIMINATE ANY PREMATURE WEAR ONE THE PUMP. NOW TORQUE IT TO 25 POUND FEET AND IT'S GOOD TO GO. IT'S LIGHTS OUT FOR THE TIMING SET AND OIL PUMP. THE FACTORY FRONT COVER IS GOING BACK ON WITH A NEW SEAL OF COURSE. NOW WE'LL ROLL THE ENGINE OVER, LUBE UP THE ORING FOR THE OIL PICK UP, AND DROP IT IN, PLACE THE WINDAGE TRAY, WHICH ALSO THE PAN GASKET IN PLACE, AND LOCATE THE PICK UP IN THE PUMP AND ON THE STUD. NOTICE THE LITTLE BIT OF CLEARANCING ON THE PICK UP. THAT IS NEEDED DUE TO THE SPACERS ON THE PUMP.

FINALLY THE PAN GOES ON FOR GOOD AND IS HELD IN

PLACE WITH MORE ARP FASTENERS. OIL PAN'S NOT GONNA FALL OFF.

(PAT)>> THIS WILL NOT FALL OFF.

(MIKE)>> JUST LIKE AN LS ENGINE, THE PAN NEEDS TO BE ALIGNED WITH THE BACK OF THE BLOCK WITH A STRAIGHT EDGE. THIS ELIMINATES THE RISK OF PAN DAMAGE WHEN THE TRANSMISSION IS ATTACHED.

FINAL TORQUE IS 12 POUND FEET.

(PAT)>> WELL THAT'S IT FOR STAGE ON AND OUR STROKER

MOPAR IS GOING TOGETHER AWESOME. THANKS TO SAM TECH FOR THE ACCURATE MACHINING. NOW WE ACTUALLY SHOWED YOU SOME OF THE PITFALLS WHEN ASSEMBLING A STROKER ENGINE, BUT WITH SOME BASIC HAND TOOLS AND A LITTLE PATIENCE, NOTHING IS AS BAD AS IT SEEMS AND YOU'LL LEARN SOMETHING WHILE DOING IT.

IF YOU'RE LIKE US, YOU KNOW THAT THE FLAT WORK SURFACES OF YOUR GARAGE OR SHOP GET TAKEN UP PRETTY FAST, BUT WE ALSO UNDERSTAND THE IMPORTANCE

OF HAVING QUALITY SHOP TOWELS AROUND. SCOTT TOWELS HAS DESIGNED THIS BOX TO CATER TO GUYS LIKE US. INSIDE ARE 200 OF THEIR HEAVY DUTY SOLID RESISTANT PRO TOWELS THAT ARE THREE TIMES STRONGER WET THAN NORMAL TOWELS, BUT THE COOL THING IS IS

HOW THE BOX WORKS. SIMPLY SLIDE ONTO TWO PEGS ON YOUR PEG BOARD, OPEN UP THE DISPENSING PORT, AND NOW YOU HAVE ACCESS TO QUALITY TOWELS WITHOUT HAVING ANY OF YOUR VALUABLE WORK SPACE TAKEN UP.

(MIKE)>> EDELBROCK HAS CLEARLY BECOME THE LEADER IN BOLT ON ROOTS TYPE SUPER CHARGER SYSTEMS OVER THE LAST FEW YEARS, AND THEIR APPLICATIONS ARE EXPANDING IN RAPID FASHION. THIS IS THEIR NEW EFORCE SYSTEM FOR THE MODELS YOU SEE LISTED. NOW IT FEATURES A TVS 1320 SUPERCHARGER AND EXTRA LONG RUNNERS TO MAXIMIZE AIR FLOW AND HORSEPOWER AT HIGH RPM'S. NOW ITS COMPACT DESIGN FITS UNDER THE FACTORY HOOD. NOW IT COMES WITH A HIGH FLOW AIR BOX AND FILTER, PLUS AN ECU TECH PROGRAMMING SYSTEM WITH A PREINSTALLED EDELBROCK TUNE. NOW IT ALSO COMES WITH ALL THE ODDS AND ENDS YOU NEED FOR A TRUE BOLT ON INSTALLATION. NOW YOU CAN PICK THE WHOLE SYSTEM UP AT SUMMIT RACING FOR $5,399 DOLLARS.

THIS TECH TIP IS ALL ABOUT LUBRICATION. PRETTY MUCH ALL MACHINERY HAS METAL TO METAL CONTACT DURING ITS OPERATION. IN OUR CASE, WE PRIMARILY DEAL WITH ENGINES. [ ENGINE REVVING ]

(MIKE)>> AND DRIVETRAINS! [ ENGINE REVVING ]

(MIKE)>> NOW THESE PIECES ARE RELATIVELY COMPLEX EQUIPMENT AND HAVE METALLIC PARTS THAT RUB ON EACH OTHER IN DIFFERENT WAYS. THIS REQUIRES A SCIENTIFIC APPROACH TO KEEP THINGS FROM WEARING OR FLAT OUT BEING DESTROYED. NOW HERE'S AN EXAMPLE OF PARTS THAT REQUIRE DIFFERENT LUBRICATION DEMANDS. ON THE ENGINE SIDE WE HAVE MAIN, ROD, AND CAM BEARINGS, PISTON RINGS, AND VALVETRAIN COMPONENTS LIKE THE CAM SHAFT, LIFTERS, AND TIMING SET. NOW ALL OF THESE REQUIRE THE SAME TYPE OF LUBRICATION, ENGINE OIL.

(PAT)>> THEN WE HAVE THE DRIVELINE SIDE, LIKE WHEEL BEARINGS, RING AND PINIONS, UJOINTS, AND OTHER CHASSIS COMPONENTS, AND THEY TAKE DIFFERENT TYPES OF LUBES LIKE OILS TO THICKER VISCOSITY ONES LIKE GREASE. ON THE ENGINE SIDE THERE ARE NUMEROUS BRANDS, VISCOSITIES, AND EVEN SPECIALIZED ONES USED FOR AIDING ASSEMBLY, START UP, AND INITIAL BREAK IN. ASSEMBLY LUBE IS HIGH IN VISCOSITY AND IT'S PURPOSE IS TO NOT ONLY PROTECT THE ENGINE DURING INITIAL FIRE UP, BUT TO STAY IN PLACE IF THE ENGINE HAS TO SET FOR ANY AMOUNT OF TIME. BREAK IN OIL IS EXACTLY THAT. IT CONTAINS HIGHER AMOUNTS OF SPECIFIC COMPOUNDS LIKE ZDDP OR ZINC. THIS IS SUPER IMPORTANT IN FLAT TAPPET CAM SHAFT SCENARIOS THAT HAVE VERY HIGH BOUNDARY LAYER PRESSURES AND SHEER FORCE AT THEIR CONTACT FACES. THE ZINC IS ATTRACTED TO THESE AREAS AND ADDS ADDITIONAL LUBRICATING PROPERTIES. IT ALSO ACTS AS A CORROSION INHIBITOR.

(MIKE)>> THERE'S ALMOST AN INFINITE AMOUNT OF OIL SELECTIONS NO MATTER YOUR APPLICATION. THERE'S OILS FOR RACE, STREET, EVEN HIGH MILEAGE. NOW THE MOST IMPORTANT PROPERTY OF A MOTOR OIL IN MAINTAINING ITS LUBRICATING FILM AGAINST MOVING PARTS IS CALLED ITS VISCOSITY. VISCOSITY IS THE FLUID'S RESISTANCE TO FLOW. NOW MULTIVISCOSITY OILS ARE CREATED SO OIL FLOWS ADEQUATELY AT DIFFERENT TEMPERATURES. WHEN YOU SEE THE FIVE W-30, HERE'S WHAT IT MEANS.

THE "W" MEANS THE OIL HAS A WINTER RATING. THE "5" IS THE VISCOSITY AT THAT TEMPERATURES.

THE "30" IS THE VISCOSITY AT 212 DEGREES FAHRENHEIT. THIS IS AN SAE RATING FOR MULTIVISCOSITY OIL.

(PAT)>> LUBRICANTS FOR DRIVELINE PARTS HAVE TO DEAL WITH THE EXTREME PRESSURES OF GEAR MESH AND BEARING LOADING. THEY HAD THE SAME SAE RATING AS MULTIWEIGHT OIL BUT AT MUCH HIGHER VISCOSITIES.

(MIKE)>> WE HOPE THIS GIVES YOU A BETTER UNDERSTANDING OF THE IMPORTANCE OF DIFFERENT LUBES, THEIR USES, THEIR VISCOSITIES, AND MORE IMPORTANTLY THE AMOUNT OF SCIENCE THAT GOES INTO THEM TO KEEP YOUR PARTS ALIVE. NEXT WEEK IS PART TWO AND ALL ABOUT THE TOP END OF THIS THIRD GEN HEMI. NOW WE HAVE A MIX OF FACTORY AND AFTERMARKET PARTS TO GET IT WRAPPED UP. THEN IT'S GOING BACK DOWN THE HALLWAY TO MARC, AND TOMMY, AND DETROIT MUSCLE, WHERE THEY'LL COMPLETE THE POWERSTOP ULTIMATE CHALLENGER SWEEPSTAKES.