Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Cometic Gasket, Inc.

Head Gasket, MLS, 4.250 in. Bore, .027 in. Compressed Thickness, Ford, Each

Dupli-Color

Paint, Engine, Enamel with Ceramic Resin, Gloss, Old Ford Blue, 12 oz., Aerosol, Each

Edelbrock

Air Cleaner Assembly, Pro-Flo, Round, 14 in., Black Cotton Gauze, Pro-Charge Stripe, Black Trim, Each

Edelbrock

Intake Manifold, Performer RPM, Dual Plane, Aluminum, Black Powdercoated, Square Bore, Ford, Big Block FE,Each

Edelbrock

Timing Chain and Gear Set, Performer-Link, Double Roller, Iron/Steel Sprockets, Ford, Big Block FE, Set

Edelbrock

Valve Covers, Signature Series, Stock Height, Steel, Black Powdercoat, Edelbrock Logo, Ford FE Big Block, Pair

Harland Sharp

Rocker Arms, Roller Tip/Bronze Bushed Rockers, 1.76 Ratio, Aluminum, Shafts, End Supports, Ford, 390-428, Kit

JBA Performance Exhaust Co.

Headers, Competition Ready, Stainless Steel, Silver Ceramic Coated, Ford, Big Block FE, Pair

Meziere Enterprises,Inc.

Water Pump, Electric, 35 gpm, Billet Aluminum, Blue Anodized, Ford, Big Block FE, Each

Pertronix

Distributor, Plug and Play, Hall Effect Pickup, Mechanical Advance, Black Cap, Ford, 352-428 FE, Each

Pertronix

Spark Plug Wires, Flame-Thrower, RFI Suppression, 8mm, Black, Stock Boots, Ford, V8, Kit

Quick Fuel Technology Inc.

Carburetor, Black Diamond Q-Series, 750 cfm, Mechanical Secondary, 4-Barrel, Square Bore, Drag Race, Each

Summit Racing

Keith Black, KB Performance Pistons, Hypereutectic, Step, 4.090 in. Bore, 5/64 in., 3/32 in., 3/16 in. Ring Grooves, Ford, Set of 8

Comp Cams

Custom Grind, Hydraulic Roller Camshaft, Ford FE

Miller Electric Manufacturing Co.

Millermatic 211 MIG Welder

Safety-Kleen

JRI - Front Load, Medium Duty Parts Washer

The Industrial Depot

The Industrial Depot - Fasteners, Hardware, and Shop Supplies

Trend Performance

Custom Length 3/8 DIA, Pushrod Set

Episode Transcript

(ANNOUNCER)>> TODAY ON

ENGINE POWER WE REVITALIZE A FAN FAVORITE, FORD'S

390 FE, AND USEFUL INFORMATION ON

CRANKSHAFTS YOU MUST SEE.

(MIKE)>> WELCOME TO ANOTHER POWER PACKED EPISODE OF ENGINE POWER. TODAY WE'RE TAKING A STEP BACK IN AUTOMOTIVE ENGINE HISTORY WITH THE BIG BLOCK FORD FE. NOW FE STANDS FOR FORDETSELL, AND THESE ENGINES WERE MANUFACTURED FROM 1958 UNTIL PRODUCTION SEIZED IN 1976.

NOW THEY WERE USED IN CARS, TRUCKS, BUSES, BOATS, AND EVEN INDUSTRIAL PUMPS.

(PAT)>> THE AFTERMARKET STILL SUPPORTS THIS OLD POWER PLANT WITH PIECES AND PARTS THAT HAVE BEEN ENGINEERED FROM MILD TO WILD, AND OUR BUILD IS SOMEWHERE IN BETWEEN. OUR TOP END CONSISTS OF EDELBROCK'S PERFORMER RPM CYLINDER HEAD THAT FLOWED 270 CFM OF AIR AT 600 LIFT ON THE INTAKE SIDE ALONG WITH HARLAN SHARP'S SHAFT ROCKER SYSTEM WITH A ONE POINT SEVENSIX RATIO. SEALING THOSE HEADS TO THE BLOCK ARE COMEDIC'S MLS HEAD GASKETS THAT ARE 27 THOUSANDTHS THICK, AND CAPPING EVERYTHING OFF IS AN EDELBROCK PERFORMER RPM DUAL PLANE INTAKE WITH AN OPERATING RANGE

FROM 1,500 TO 6,500 RPM.

(MIKE)>> THE COMPONENTS WE'RE USING FOR THIS BUILD INCLUDE A PERTRONIX IGNITION SETUP THAT INCLUDE EIGHT MILLIMETER PLUG WIRES, A FLAME THROWER DISTRIBUTOR WITH THE IGNITOR THREE MODULE,

HC COIL.

NOW TO KEEP THE ENGINE COOL ON THE DYNO AND MAKE HOOKING IT UP A LOT EASIER IS A MAZIERE ELECTRIC WATER PUMP. HOLDING THE ENGINE'S LUBRICATION IS A SUMMIT RACING OIL PAN. NOW JBA COMPETITION READY HEADERS WITH A CERAMIC FINISH WILL LET IT BREATHE, AND MORE COMPONENTS FROM EDELBROCK INCLUDE VALVE COVERS, BREATHERS, AND THIS AWESOME AIR CLEANER. NOW FEEDING IT IS A 750 CFM QUICK FUEL TECHNOLOGIES CARBURETOR.

(PAT)>> THIS DEAL IS GONNA RELATE WELL WITH ALL OF YOU BECAUSE IT'S A MILD PERFORMANCE BUILD THAT'S TYPICAL OF YOU DIY'ERS. WE'RE STARTING WITH A 1968 FORD 390 TRUCK BLOCK

THAT'S BEEN BORED AND HONED 40 THOUSANDTHS OVER. NOW WE KNOW THAT YOU GUYS GET STUFF FROM SWAP MEETS AND ONLINE, SO WE DECIDED TO DO THE SAME. WE PICKED THIS UP AS AN UNFINISHED PROJECT, WHICH

GIVES US A CHANCE TO DO SOME PREP WORK OURSELVES.

(MIKE)>> AND THAT PREP WORK STARTS WITH A DIE GRINDER AND A CARBIDE BURR. TO REMOVE CASTING FLASH AND ENLARGE THE OIL DRAIN BACK AT THE REAR OF THE VALLEY. LET THE BURR DO THE WORK. USE LIGHT PRESSURE AND KEEP IT MOVING AROUND THE WHOLE TIME. THE PURPOSE IS TO MAKE A NICE RADIUS AND A SLIGHT CHAMFER WITH NO SHARP EDGES. I'LL ALSO DO THE SAME TO THE REST OF THE VALLEY DRAIN BACK HOLES. IF WE WERE BUILDING A RACE ENGINE WE WOULD PLUG THESE

SO NO OIL IS GETTING ON THE SPINNING CRANKSHAFT, WHICH IS HORSEPOWER ROBBING WINDAGE.

SINCE THIS IS A STREET ENGINE AND WE'LL SEE IDLING AND LOW RPM DRIVING, WE WANT THE EXTRA LUBRICATION.

(PAT)>> ANOTHER BIT OF PREP INVOLVES THE OIL INLET TO THE ENGINE FROM THE OIL PUMP. LOOK AT THE DIFFERENCE FROM THE OUTPUT SIDE OF THE OIL PUMP TO THE INLET SIDE OF THE BLOCK. THIS AREA DEFINITELY NEEDS SOME ATTENTION. ENLARGING THE HOLE AND MAKING A SMOOTH

TRANSITION IS THE TRICK. YOU WANT IT TO MATCH THE SIZE OF THE OIL PUMP PORT. DON'T GET CRAZY AND GO OVERBOARD. THIS WILL ALLOW THE OIL TO HAVE A SMOOTHER PATH OUT FO THE PUMP AND ELIMINATE TURBULENCE. DON'T FORGET TO DO THE OTHER SIDE WHERE THE OIL FILTER IS LOCATED, AND THEN SMOOTH EVERYTHING OUT WITH A FILE. FINALLY WE'LL REMOVE ANY BIG CASTING FLASHES FROM THE EXTERIOR OF THE BLOCK TO AID IN STRENGTH AND MAKE THE BLOCK EASIER TO HANDLE. USING A FLAT BAR AND A SHEET OF 220 GRIT SAND PAPER, WE'RE GONNA GO OVER ALL THE GASKET SURFACES TO MAKE SURE THEY ARE CLEAN AND UNIFORM.

(MIKE)>> AFTER GRINDING AND SANDING ON THE BLOCK IT NEEDS TO BE CLEANED. WE'RE USING OUR SAFETY CLEAN HOT TANK. THE SAME CAN BE DONE WITH HOT SOAPY WATER AND A HOSE

FOR YOU GUYS AT HOME.

WITH ANY UNFINISHED PROJECT YOU ACQUIRE, YOU ALWAYS HAVE TO TREAT THE PARTS WITH A LITTLE BIT OF SUSPICION. DON'T JUST ASSUME EVERYTHING'S CORRECT. HERE'S A PERFECT EXAMPLE.

THE PISTONS WE PICKED UP WITH THE PARTS WE PURCHASED FIT THE BORES JUST FINE BUT THESE ARE

NOT THE RIGHT ONES. THESE ARE ACTUALLY FOR A 410 CUBIC INCH FE AND YOU

CAN TELL BY THE COMPRESSION HEIGHT DUE TO THE PIN LOCATION. THE 410 PISTON IS 100 THOUSANDTHS SHORTER, AND WHEN USED IN THE 390 CONFIGURATION THERE'S A SIGNIFICANT COMPRESSION DROP. SO WE ORDERED THESE KEITH BLACK'S FROM SUMMIT RACING AND THEY'RE 100 THOUSANDTHS INCH TALLER. NOW MIXED WITH THE EDELBROCK HEADS WE'RE USING WE'LL HAVE A NINE TO ONE COMPRESSION RATIO.

(PAT)>> WITH THE BLOCK WASHED THE ASSEMBLY STARTS AFTER THIS BREAK.

(MIKE)>> WE'RE BACK AND OUR 390 FE IS ABOUT TO GET JAZZED UP. USING MASKING TAPE, I'M COVERING UP ALL THE INTERNALS SO WE CAN ADD SOME COLOR, WHICH IS DUPLICOLOR'S 500 DEGREE ENGINE ENAMEL WITH CERAMIC. THE COLOR GOES HAND IN HAND WITH THE PROJECT, OLD FORD BLUE. A COUPLE OF COATS GIVES THE BLOCK EXCELLENT COVERAGE.

(PAT)>> NOW IT'S READY FOR ITS GUTS.

WITH THE MAINS IN AND ALL THE BEARING CLEARANCES CHECKED WE'LL SLICK'EM UP WITH SOME HIGH VISCOSITY ASSEMBLY LUBE. NEXT UP IS THE UPPER HALF OF THE REAR MAIN SEAL. WHEN IT'S INSTALLED IT NEEDS TO BE SLIGHTLY OFFSET FROM THE PARTING LINE OF THE BLOCK TO AVOID AN OIL LEAK. THE CRANK IS NODULAR IRON AND HAS A THREESEVEN-80 STROKE, WHICH IS FOUND IN ALL PRODUCTION 390'S. THESE CRANKS ARE STOUT ENOUGH TO HANDLE MID-500 HORSEPOWER NUMBERS WHEN MIXED WITH RACY PARTS.

THE OTHER HALF OF THE SEAL PROTRUDES OUT OF THE REAR MAIN CAP. NOW YOU KNOW HOW THEY'RE INSTALLED. THE REST OF THE MAIN CAPS ARE PUT IN PLACE AND SNUGGED. THEY'RE TORQUED TO 90 POUND FEET WITH

EXTREME PRESSURE LUBE. THEY'RE TIGHTENED FROM THE CENTER OUT IN A CIRCULAR PATTERN.

(MIKE)>> WE'RE USING THE STOCK RODS, WHICH HAVE SURPRISINGLY BEEFY MAIN BEAM AND A FULL FLOATING WRIST PIN. NOW THESE WERE TWO OF THE REASONS THESE ENGINES WERE SO DURABLE IN SO MANY DIFFERENT APPLICATIONS. PLUS FOR THE POWER LEVEL AND BUDGET WE HAVE SET THESE WERE A VERY SMART CHOICE. NOW YOU GUYS HAVE SEEN US INSTALL PISTONS AND RODS BEFORE, BUT FOR THOSE OF YOU WHO HAVEN'T HERE'S A QUICK RUN DOWN. FIRST LUBE THE CYLINDERS WITH MOTOR OIL AS WELL AS THE SKIRTS AND RINGS ON THE PISTONS. ASSEMBLY LUBE IS PLACED ON THE BEARING, AND WITH THE WHOLE SETUP IN THE RING COMPRESSOR, ALIGN IT AND SQUARE UP THE COMPRESSOR WITH THE DECK. NOW TAP IT IN MAKING SURE TO KEEP THE COMPRESSOR SEATED. IF YOU FEEL ANY EXCESSIVE RESISTANCE SUCH AS THE PISTON STOPPING DEAD, YOU NEED TO STOP AND REGROUP. THERE'S A CHANCE A RING DIDN'T INDEX THE BORE PROPERLY AND WILL BE DAMAGED IF YOU CONTINUE. ONCE THE BIG END IS RESTED ON THE ROD JOURNAL, INSTALL THE CAP AND SNUG IT DOWN. ONCE ALL EIGHT ARE IN PLACE, TORQUE THEM DOWN. IN OUR CASE IT'S 40 POUND FEET WITH EXTREME PRESSURE LUBE.

(PAT)>> WE LIKE TO OPTIMIZE EVERY ENGINE'S PURPOSE THAT WE BUILD IN HERE. THAT'S WHY WE SPEC OUT A LOT OF OUR OWN CAMS AND SHARE THOSE SPECS WITH YOU. WE'RE GONNA MODERNIZE THAT FE WITH A HYDRAULIC ROLLER CAM SHAFT THAT WE HAD COMP GRIND UP FOR US. THE SPECS ARE 238 DEGREES AT 50 THOUSANDTHS LIFT ON

THE INTAKE AND 244 DEGREES ON THE EXHAUST, AND THE LOBE SEPARATION IS 110 DEGREES. THE LIFT IS 618 THOUSANDTHS ON BOTH INTAKE AND EXHAUST WITH A ONE POINT SEVENSIX ROCKER RATIO WE'LL BE USING. HYDRAULIC CAMS ARE INSTALLED WITH ENGINE OIL ON THE JOURNALS AND THE LOBES UNLIKE A FLAT TAPPET THAT USES A SPECIAL MOLY BASED BREAK IN LUBE TO ESTABLISH A WEAR PATTERN. EDELBROCK SENT US THIS DOUBLE ROLLER TIMING SET WITH AN ADJUSTABLE CRANK GEAR THAT HAS THREE LOCATIONS, ADVANCED, STRAIGHT UP, OR RETARDED FOUR DEGREES.

(MIKE)>> WE KNOW THE LOCATION OF EVERY CAM SHAFT WE INSTALL.

PAT COULDN'T SLEEP AT NIGHT IF WE DIDN'T. NOW USING THE FOUR DEGREE ADVANCED KEY WAY ON THE CRANK SPROCKET, THIS ONE'S IN AT 104 DEGREES OF INTAKE CENTER LINE. A LITTLE MORE OIL WILL LUBE THE TIMING SET. NOW ALL METAL TO METAL CONTACT SURFACES SHOULD

BE TREATED THIS WAY. COVERING THE FRONT UP IS A FACTORY TIMING COVER AND TIMING POINTER. THE OIL PUMP DRIVESHAFT CAN GO IN NOW, FOLLOWED BY THE MELLING STANDARD VOLUME PUMP THAT WE ALREADY PORT MATCHED TO THE BLOCK. THE PICK UP IS A BOLT ON STYLE. IT USES A GASKET AND BLUE THREAD LOCKER ON THE FASTENERS IS A MUST. YOU DON'T WANT IT TO LOOSEN UP. I'M APPLYING WEATHER STRIP ADHESIVE TO THE BLOCK'S PAN RAIL. THIS PRACTICE WILL ALMOST GUARANTEE A LEAK FREE SEAL. NOW A LITTLE MORE ON THE GASKET TO PAN SURFACE. THIS FIVE QUART FRONT SUMP STEEL PAN HAS A GOLD ZINC FINISH.

IT'S A SUMMIT RACING BRAND AND CAN BE YOURS FOR UNDER $50 BUCKS.

(PAT)>> WITH THIS PORTION DONE THE TOP END IS NEXT, BUT AFTER THIS BREAK OF COURSE.

(PAT)>> WE'RE BACK AND WE DON'T HAVE MUCH TIME TO

FINISH UP THIS BULLET, ESPECIALLY IF YOU WANT TO SEE IT ON THE SUPER FLOW DYNO. TO HELP GET THE COMPRESSION RATIO WHERE WE WANT IT WE ORDERED A SET OF COMEDIC MLS HEAD GASKETS IN A THINK 27 THOUSANDTHS COMPRESSED THICKNESS.

THESE EDELBROCK PERFORMER RPM HEADS ARE A DIRECT

BOLT ON FOR 1961 THROUGH 1976 FE'S.

THEY SPORT A TWOZERO-90 INTAKE VALVE, AND A ONESIX-60 EXHAUST VALVE, AND THEY'RE NESTLED IN A 72cc COMBUSTION CHAMBER. THE INTAKE'S PORT VOLUME IS 170cc, WHILE THE EXHAUST COMES IN AT 125cc. AS WE MENTIONED EARLIER, THE INTAKE PORT FLOWS 270 CFM AT 600 THOUSANDTHS VALVE LIFT. WITH THE COMBUSTION CHAMBER SIZE, PISTON, AND HEAD GASKET COMBINATION, OUR COMPRESSION RATIO IS NINE POINT TWOEIGHT TO ONE.

WE'RE TORQUEING THEM DOWN TO 100 POUND FEET WITH EPL.

(MIKE)>> IT'S ALWAYS A GOOD IDEA TO MATCH THE CAM SHAFT WITH THE HOUSE BRAND LIFTERS. NOW COMP OFFERS A RETRO FIT HYDRAULIC ROLLER LIFTER FOR THE FE. A TIE BAR KEEPS THEM ALIGNED, AND A PATENT PENDING PISTON ALLOWS TRAPPED AIR TO ESCAPE FOR A FASTER PUMP UP. LAYING ON VICTOR REINZ GASKETS, THIS EDELBROCK

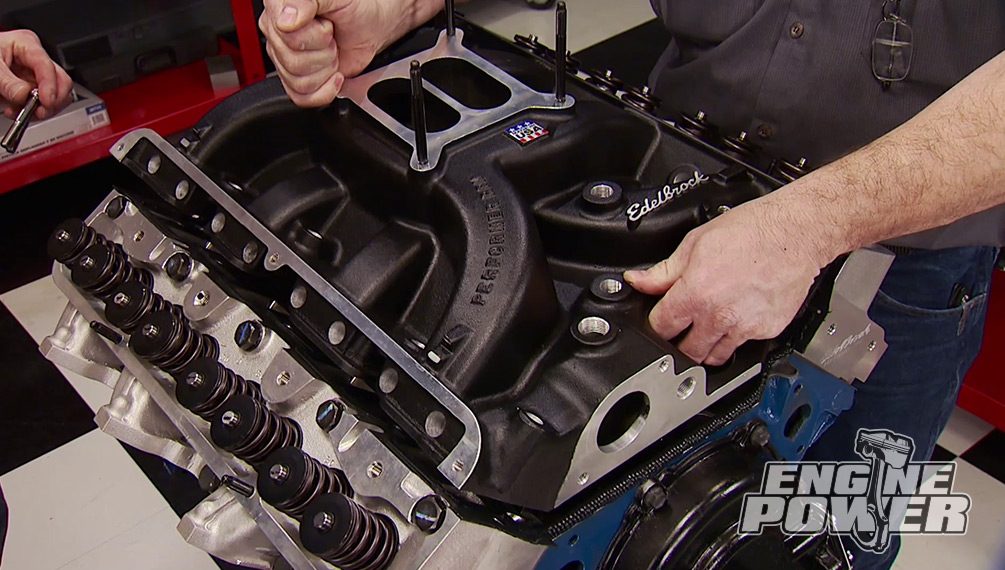

PERFORMER RPM DUAL PLANE HAS AN OPERATING RANGE FROM 1,500 TO 6,500 RPM. THE BLACK FINISH GOES WITH OUR COLOR SCHEME. WE HAD TO CUSTOM ORDER THE PUSH RODS FOR THIS ENGINE BECAUSE THERE WASN'T AN OFF THE SHELF PART FOR THIS EXACT APPLICATION. SO WE MADE A CALL TO A COMPANY THAT SPECIALIZES IN VALVETRAIN TECHNOLOGY, TRENT PERFORMANCE, AND THEY MADE THIS SET FOR US. THEY HAVE A THREEEIGHTHS BALL END ON THE LIFTER SIDE AND A THREEEIGHTHS CUP AT THE OTHER END TO MATCH OUR NEW ROCKER ARM SETUP. THE WALL THICKNESS IS 80 THOUSANDTHS.

(PAT)>> WE UPGRADED FROM THE NONADJUSTABLE STOCK ROCKER SETUP TO THESE ADJUSTABLE HARLAN SHARP ROCKERS. THEY HAVE A ONE POINT SEVENSIX RATIO, HARDENED

SHAFTS, TOOL STEEL ADJUSTORS, AND THE ROCKER BODIES ARE EXTRUDED ALUMINUM AND IT'S ALL MADE AND MACHINED IN THE USA.

WE'LL ADJUST THEM TO HALF TURN PAST ZERO LASH.

(MIKE)>> NOW WE HAVE TO GET THIS BLUE OVAL BIG

BLOCK ON THE DYNO AND READY TO FIRE UP. WE OUTFITTED THE ENGINE WITH INCH AND THREE

QUARTER JBA HEADERS WITH A TRIY DESIGN. THE COLLECTOR IS THREE INCHES IN DIAMETER. UP FRONT IS A MAZIERE ELECTRIC WATER PUMP SUITED

FOR THE STREET OR THE DRAG STRIP. IT FLOWS 42 GALLONS PER MINUTE AND ONLY WEIGHS SIX POINT NINE POUNDS.

(PAT)>> PERTRONIX SENT US A BILLET FLAME THROWER PLUG AND PLAY DISTRIBUTOR. WE LIMITED THE ADVANCE USING THE SUPPLIED HARDWARE. THE BUILT IN REV LIMITER IS INCREASED TO 6,500 RPM. SUPPLYING IT WITH ENERGY IS A FLAME THROWER HC COIL. THEIR WIRES CONNECT TO ETHREE SPARK PLUGS, AND FOR FUEL DELIVERY OUR TRUSTY QUICK FUEL 750 CFM DYNO CARBURETOR.

(MIKE)>> I'M ALL SETUP, YOU READY?

(PAT)>> ALWAYS!

[ ENGINE STARTS ]

(MIKE)>> TOTAL TIMING IS SET AT 30 DEGREES.

(PAT)>> THIS SOUNDS LIKE PAW PAW'S PICK UP TRUCK RIGHT NOW.

(MIKE)>> ALRIGHT, LET'S DO IT! THE FIRST PULL IS TO 4,500 RPM TO MAKE SURE EVERYTHING IS SOUND.

(PAT)>> OH GOOD! THAT IS NOT TOO SHABBY FOR 30 DEGREES OF TIMING.

(MIKE)>> THAT TORQUE IS PRETTY GOOD, 436 POUND FEET, POWER RIGHT NOW IS 364 AT 4,500.

(PAT)>> HEY THAT'S A SPECTACULAR START.

(MIKE)>> VERY NICE! WHEN WE COME BACK FROM THE BREAK WE'RE MAKING THE POWER PULLS.

SO MAKE SURE YOU STICK WITH US.

(MIKE)>> WE'RE BACK AND SO IS OUR TEMPERATURE, SO LET'S HEAR IT ZIP. SETUP FOR 2,500 TO 6,000.

(PAT)>> PERFECT!

(MIKE)>> 93 OCTANE IN THE CELL, 30 DEGREES OF TOTAL TIMING. LET'S SEE WHAT SHE'S GOT TO 6,000. [ ENGINE REVVING ]

(PAT)>> I THINK WE MIGHT HAVE BROKE 400 FIRST PULL.

(MIKE)>> 402 HORSEPOWER, 438 POUND FEET OF TORQUE.

(PAT)>> NOT SHABBY!

(MIKE)>> PRETTY GOOD LOOKING GRAPH FOR ONLY 30 DEGREES OF TIMING.

(PAT)>> YEAH WE'VE GOT A LITTLE BIT OF WORK TO DO, AND IT IS PUMP GAS. SO THIS IS NOT A RACE ENGINE BY ANY STRETCH OF THE IMAGINATION. IT'S GONNA BE A FUN STREET ENGINE, SO MAKING A LITTLE ADJUSTMENT TO HER.

(MIKE)>> BY ADDING THREE DEGREES OF TIMING FOR A TOTAL OF 33.

WE'VE GOT 2,500 TO 6,000, SAME RPM, 33 DEGREES OF TIMING, EVERYTHING ELSE STAYS THE SAME.

(PAT)>> BIG TIMING SWING, THREE DEGREES.

(MIKE)>> WHOA, HERE WE GO. [ ENGINE REVVING ]

(MIKE)>> THIS THING'S NICE AND SMOOTH, GOOD MANNERS.

(PAT)>> I LIKE IT.

(MIKE)>> 411 WITH 439 POUND FEET.

(PAT)>> SWEET!

(MIKE)>> LOOKS GOOD, IT HOLDS POWER REALLY NICE TO THE MID RANGE.

(PAT)>> RIGHT, NO THIS IS A FUN ENGINE. PRETTY AMAZING WHAT YOU CAN DO WITH SOME MOSTLY STOCK COMPONENTS, LIKE THE CRANK'S STOCK, THE RODS ARE STOCK, IT'S GOT A HYPER EUTECTIC PISTON IN IT.

(MIKE)>> AND THESE ENGINES WERE NEVER MADE BIG POWER EVEN IN THEIR PERFORMANCE.

(PAT)>> NOT PARTICULAR UNLESS YOU GO ON THE REAL RACE SIDE OF IT WITH THE 427 STUFF. NO, AWESOME MAN!

(MIKE)>> OUR LAST PULL FOR THE DAY WE'RE GOING TO 35 AND LEAVING IT THERE. THIS FE IS A GREAT EXAMPLE OF HOW THE AFTER MARKET HAS MODERNIZED THE CLASSIC BLUE OVAL BIG BLOCK. LOW COMPRESSION AND GOOD PARTS CAN YIELD GOOD POWER.

(PAT)>> YEAH BUDDY.

(MIKE)>> 413 ON POWER, 445 ON TORQUE, GRAPH LOOKS GOOD. HOLDS THE TORQUE TO THE MID RANGE REALLY NICE.

(PAT)>> YOU WON'T BE ABLE TO KEEP THE TIRES ON PAW

PAW'S TRUCK IF THIS THING WAS IN IT, RIGHT?

IT'D JUST BURN THEM CLEAN TO THE CORDS.

(MIKE)>> AND IT'LL RUN FOREVER.

(PAT)>> YEAH, GREAT OIL PRESSURE, I'M EXTREMELY HAPPY WITH THIS THING, NICE JOB.

(MIKE)>> IF YOU'RE INTO LIGHT FABRICATION, AUTO BODY, OR ARE JUST LOOKING FOR A WELDER FOR YOUR HOME OR FARM, THE REDESIGNED MILLERMATIC 211 IS A GREAT CHOICE. NOW IT HAS THE HIGHEST OUTPUT IN ITS CLASS AND CAN WELD FROM 24 GAUGE TO THREEEIGHTHS OF AN INCH IN A SINGLE PASS. IT'S 50 PERCENT LIGHTER THAN THE ORIGINAL DESIGN AT ONLY 38 POUNDS FOR EASE OF PORTABILITY. NOW IT'LL WELD EITHER SOLID OR FLUX CORE WIRE, AND HERE'S A REALLY COOL FEATURE. YOU CAN PLUG IT INTO A 230 RECEPTACLE OR A 120 BY JUST SWAPPING OUT THE PLUGS. THERE'S NO NEED FOR ANY EXTRA WIRING. NOW IT ALSO HAS THE AUTO SET FEATURE AND COMES WITH EVERYTHING YOU NEED MINUS THE BOTTLE OF GAS FOR RIGHT AT $1,100 DOLLARS.

(PAT)>> WHEN IT COMES TO MANUAL TRANSMISSIONS AND THE ACCESSORIES TO INSTALL THEM, OUR GO TO PLACE IS AMERICAN POWERTRAIN. THIS IS THEIR HYDROMAX HYDRAULIC CLUTCH SYSTEM WHERE THE PARTS ARE ENGINEERED TO ALL WORK TOGETHER, AND THEY'RE FOR MOST FOUR, FIVE, AND SIX SPEED TRANSMISSIONS IN ANY VEHICLE. IT FEATURES THEIR PATENTED FIREWALL MOUNT WITH AN INTEGRATED PEDAL STOP, A PREBLED HYDRAULIC RELEASE BEARING, PLUS ALL THE HARDWARE, LINES, AND EVEN A RESERVOIR FOR A COMPLETE SETUP. GO TO AMERICAN POWERTRAIN DOT COM FOR KITS AND PRICES FOR YOUR RIDE.

(MIKE)>> FROM THE TRACK TO THE STREET, AND EVEN YOUR YARD, ETHREE HAS A SPARK PLUG TO SUIT YOUR NEEDS. NOW THESE THINGS WILL IMPROVE POWER AND WHATEVER YOU RUN THEM IN WILL BURN LESS FUEL. SO FOR THE BEST OF BOTH WORLDS PICK UP ETHREES FOR YOUR GAS BURNERS AT YOUR LOCAL AUTO PARTS STORE.

PERFORMANCE ENGINE PARTS HAVE COME A LONG WAY IN

THE LAST 10 YEARS. STREET CARS WITH 1,000 PLUS HORSEPOWER ARE BECOMING MORE AND MORE COMMON. NOW THE PARTS ARE STRONGER, GIVING ENGINES MORE STRENGTH AS WELL AS MORE RUN TIME IN BETWEEN REFRESHES. NOW THIS IS ALL THANKS TO BETTER METALLURGY AND MANUFACTURING TECHNIQUES. NOW WE BELIEVE THERE ARE TWO ENGINE PARTS IN PARTICULAR THAT HAVE RECEIVED THE MOST ATTENTION TO IMPROVEMENTS FOR MAKING MORE HORSEPOWER. THOSE ARE CRANK SHAFTS AND CYLINDER HEADS, WHICH ARE IMPROVING BY THE DAY. NOW COMPANIES ARE DESIGNING NEW PORT PROFILES AND IMPROVING THE CURTAIN AREAS, AND NEW AND IMPROVED TRICKS TO THE VALVE JOBS FOR EVEN BETTER FLOW NUMBERS. KEEP IN MIND AN ENGINE IS A GLORIFIED AIR PUMP. THE MORE AIR YOU CAN GET IN AND OUT, THE MORE

EFFICIENT THE ENGINE'S GOING TO BE AND THE MORE

HORSEPOWER IT'S GOING TO MAKE. CRANK SHAFTS HAVE ALSO COME A LONG WAY IN RECENT YEARS, NOT ONLY IN STRENGTH BUT ALSO AFFORDABILITY. NOW BACK IN THE DAY IF YOU WERE LOOKING FOR A FORGED CRANK IT WAS GOING TO BE EXPENSIVE AND SOMETIMES HARD TO COME BY, AND IF YOU WERE LOOKING FOR A CUSTOM PIECE IT WOULD ALMOST HAVE TO BE BILLET, AND THAT WOULD BE EXTREMELY EXPENSIVE SINCE IT WOULD BE A ONE OFF PIECE. CAST IRON CRANKS HAVE BEEN THE INDUSTRY STANDARD FOR OE VEHICLES FOR YEARS BECAUSE THEY'RE CHEAP TO MANUFACTURE.

THE PROCESS STARTS WITH THE MOLTEN LIQUID OF IRON OR STEEL, AND THEN THAT'S POURED INTO A MOLD. WHEN THEY ARE REMOVED THEY LOOK CLOSE TO THE FINAL SHAPE, WHICH CUTS WAY DOWN ON MACHINING TIME, KEEPING THEM CHEAP. THESE ARE THE MOST BASIC AND HAVE A TENSILE STRENGTH BETWEEN 70,000 AND 80,000 PSI. INCREASE OF THE CARBON CONTENT AND YOU GET NODULAR IRON LIKE THIS, WHICH INCREASES THE TENSILE STRENGTH TO ABOUT 95,000 PSI. NOW THE MOST POWER WE WOULD RUN THROUGH ONE OF THESE IS ABOUT 400. CAST STEEL IS USED FOR ENTRY LEVEL CRANKS FROM AFTERMARKET COMPANIES. NOW CAST STEEL HAS A GREATER CARBON CONTENT AND A HIGHER TENSILE STRENGTH OF AROUND 105,000 PSI. NOW WE'RE COMFORTABLE MAKING AROUND 500 TO 530 HORSEPOWER WITH THESE. ENGINES PRODUCING MORE THAN THAT SHOULD BE OUTFITTED WITH A FORGED STEEL CRANK SHAFT. NOW THE MANUFACTURING TECHNIQUE THAT GOES INTO THESE IS WAY MORE INVOLVED. THE COMMON MATERIAL THESE ARE MADE OUT OF IS 4340 STEEL.

THEY START OUT AS CYLINDRICAL PIECE OF STEEL. THEN THEY'RE PUT IN MASSIVE HOT DYE PRESSES THAT APPLY AROUND 8,000 TONS. THIS COMPRESSES THE GRAINS INTO ONE UNIFORM GRAIN FLOW. AFTER SEVERAL ROUNDS OF HEAT TREATING THE OUTCOME IS A CRANK WITH A TENSILE STRENGTH OF AROUND 156,000 PSI, ALLOWING THESE CRANKS TO HANDLE IN EXCESS OF 1,500 HORSEPOWER. NO MATTER WHAT THE POWER GOAL IS FOR YOUR NEXT ENGINE AT LEAST NOW YOU'LL KNOW WHICH CRANK SHAFT WILL WORK BEST FOR YOU.

(PAT)>> WELL THAT'S IT FOR US AND REMEMBER, IF YOU PULL UP TO A STOP LIGHT AND YOU'RE NEXT TO PAW PAW'S OLD PICK UP TRUCK AND IT SOUNDED LIKE THIS DID, YOU DON'T WANT TO CHALLENGE HIM. WE'LL SEE YOU NEXT TIME.

Show Full Transcript

(MIKE)>> WELCOME TO ANOTHER POWER PACKED EPISODE OF ENGINE POWER. TODAY WE'RE TAKING A STEP BACK IN AUTOMOTIVE ENGINE HISTORY WITH THE BIG BLOCK FORD FE. NOW FE STANDS FOR FORDETSELL, AND THESE ENGINES WERE MANUFACTURED FROM 1958 UNTIL PRODUCTION SEIZED IN 1976.

NOW THEY WERE USED IN CARS, TRUCKS, BUSES, BOATS, AND EVEN INDUSTRIAL PUMPS.

(PAT)>> THE AFTERMARKET STILL SUPPORTS THIS OLD POWER PLANT WITH PIECES AND PARTS THAT HAVE BEEN ENGINEERED FROM MILD TO WILD, AND OUR BUILD IS SOMEWHERE IN BETWEEN. OUR TOP END CONSISTS OF EDELBROCK'S PERFORMER RPM CYLINDER HEAD THAT FLOWED 270 CFM OF AIR AT 600 LIFT ON THE INTAKE SIDE ALONG WITH HARLAN SHARP'S SHAFT ROCKER SYSTEM WITH A ONE POINT SEVENSIX RATIO. SEALING THOSE HEADS TO THE BLOCK ARE COMEDIC'S MLS HEAD GASKETS THAT ARE 27 THOUSANDTHS THICK, AND CAPPING EVERYTHING OFF IS AN EDELBROCK PERFORMER RPM DUAL PLANE INTAKE WITH AN OPERATING RANGE

FROM 1,500 TO 6,500 RPM.

(MIKE)>> THE COMPONENTS WE'RE USING FOR THIS BUILD INCLUDE A PERTRONIX IGNITION SETUP THAT INCLUDE EIGHT MILLIMETER PLUG WIRES, A FLAME THROWER DISTRIBUTOR WITH THE IGNITOR THREE MODULE,

HC COIL.

NOW TO KEEP THE ENGINE COOL ON THE DYNO AND MAKE HOOKING IT UP A LOT EASIER IS A MAZIERE ELECTRIC WATER PUMP. HOLDING THE ENGINE'S LUBRICATION IS A SUMMIT RACING OIL PAN. NOW JBA COMPETITION READY HEADERS WITH A CERAMIC FINISH WILL LET IT BREATHE, AND MORE COMPONENTS FROM EDELBROCK INCLUDE VALVE COVERS, BREATHERS, AND THIS AWESOME AIR CLEANER. NOW FEEDING IT IS A 750 CFM QUICK FUEL TECHNOLOGIES CARBURETOR.

(PAT)>> THIS DEAL IS GONNA RELATE WELL WITH ALL OF YOU BECAUSE IT'S A MILD PERFORMANCE BUILD THAT'S TYPICAL OF YOU DIY'ERS. WE'RE STARTING WITH A 1968 FORD 390 TRUCK BLOCK

THAT'S BEEN BORED AND HONED 40 THOUSANDTHS OVER. NOW WE KNOW THAT YOU GUYS GET STUFF FROM SWAP MEETS AND ONLINE, SO WE DECIDED TO DO THE SAME. WE PICKED THIS UP AS AN UNFINISHED PROJECT, WHICH

GIVES US A CHANCE TO DO SOME PREP WORK OURSELVES.

(MIKE)>> AND THAT PREP WORK STARTS WITH A DIE GRINDER AND A CARBIDE BURR. TO REMOVE CASTING FLASH AND ENLARGE THE OIL DRAIN BACK AT THE REAR OF THE VALLEY. LET THE BURR DO THE WORK. USE LIGHT PRESSURE AND KEEP IT MOVING AROUND THE WHOLE TIME. THE PURPOSE IS TO MAKE A NICE RADIUS AND A SLIGHT CHAMFER WITH NO SHARP EDGES. I'LL ALSO DO THE SAME TO THE REST OF THE VALLEY DRAIN BACK HOLES. IF WE WERE BUILDING A RACE ENGINE WE WOULD PLUG THESE

SO NO OIL IS GETTING ON THE SPINNING CRANKSHAFT, WHICH IS HORSEPOWER ROBBING WINDAGE.

SINCE THIS IS A STREET ENGINE AND WE'LL SEE IDLING AND LOW RPM DRIVING, WE WANT THE EXTRA LUBRICATION.

(PAT)>> ANOTHER BIT OF PREP INVOLVES THE OIL INLET TO THE ENGINE FROM THE OIL PUMP. LOOK AT THE DIFFERENCE FROM THE OUTPUT SIDE OF THE OIL PUMP TO THE INLET SIDE OF THE BLOCK. THIS AREA DEFINITELY NEEDS SOME ATTENTION. ENLARGING THE HOLE AND MAKING A SMOOTH

TRANSITION IS THE TRICK. YOU WANT IT TO MATCH THE SIZE OF THE OIL PUMP PORT. DON'T GET CRAZY AND GO OVERBOARD. THIS WILL ALLOW THE OIL TO HAVE A SMOOTHER PATH OUT FO THE PUMP AND ELIMINATE TURBULENCE. DON'T FORGET TO DO THE OTHER SIDE WHERE THE OIL FILTER IS LOCATED, AND THEN SMOOTH EVERYTHING OUT WITH A FILE. FINALLY WE'LL REMOVE ANY BIG CASTING FLASHES FROM THE EXTERIOR OF THE BLOCK TO AID IN STRENGTH AND MAKE THE BLOCK EASIER TO HANDLE. USING A FLAT BAR AND A SHEET OF 220 GRIT SAND PAPER, WE'RE GONNA GO OVER ALL THE GASKET SURFACES TO MAKE SURE THEY ARE CLEAN AND UNIFORM.

(MIKE)>> AFTER GRINDING AND SANDING ON THE BLOCK IT NEEDS TO BE CLEANED. WE'RE USING OUR SAFETY CLEAN HOT TANK. THE SAME CAN BE DONE WITH HOT SOAPY WATER AND A HOSE

FOR YOU GUYS AT HOME.

WITH ANY UNFINISHED PROJECT YOU ACQUIRE, YOU ALWAYS HAVE TO TREAT THE PARTS WITH A LITTLE BIT OF SUSPICION. DON'T JUST ASSUME EVERYTHING'S CORRECT. HERE'S A PERFECT EXAMPLE.

THE PISTONS WE PICKED UP WITH THE PARTS WE PURCHASED FIT THE BORES JUST FINE BUT THESE ARE

NOT THE RIGHT ONES. THESE ARE ACTUALLY FOR A 410 CUBIC INCH FE AND YOU

CAN TELL BY THE COMPRESSION HEIGHT DUE TO THE PIN LOCATION. THE 410 PISTON IS 100 THOUSANDTHS SHORTER, AND WHEN USED IN THE 390 CONFIGURATION THERE'S A SIGNIFICANT COMPRESSION DROP. SO WE ORDERED THESE KEITH BLACK'S FROM SUMMIT RACING AND THEY'RE 100 THOUSANDTHS INCH TALLER. NOW MIXED WITH THE EDELBROCK HEADS WE'RE USING WE'LL HAVE A NINE TO ONE COMPRESSION RATIO.

(PAT)>> WITH THE BLOCK WASHED THE ASSEMBLY STARTS AFTER THIS BREAK.

(MIKE)>> WE'RE BACK AND OUR 390 FE IS ABOUT TO GET JAZZED UP. USING MASKING TAPE, I'M COVERING UP ALL THE INTERNALS SO WE CAN ADD SOME COLOR, WHICH IS DUPLICOLOR'S 500 DEGREE ENGINE ENAMEL WITH CERAMIC. THE COLOR GOES HAND IN HAND WITH THE PROJECT, OLD FORD BLUE. A COUPLE OF COATS GIVES THE BLOCK EXCELLENT COVERAGE.

(PAT)>> NOW IT'S READY FOR ITS GUTS.

WITH THE MAINS IN AND ALL THE BEARING CLEARANCES CHECKED WE'LL SLICK'EM UP WITH SOME HIGH VISCOSITY ASSEMBLY LUBE. NEXT UP IS THE UPPER HALF OF THE REAR MAIN SEAL. WHEN IT'S INSTALLED IT NEEDS TO BE SLIGHTLY OFFSET FROM THE PARTING LINE OF THE BLOCK TO AVOID AN OIL LEAK. THE CRANK IS NODULAR IRON AND HAS A THREESEVEN-80 STROKE, WHICH IS FOUND IN ALL PRODUCTION 390'S. THESE CRANKS ARE STOUT ENOUGH TO HANDLE MID-500 HORSEPOWER NUMBERS WHEN MIXED WITH RACY PARTS.

THE OTHER HALF OF THE SEAL PROTRUDES OUT OF THE REAR MAIN CAP. NOW YOU KNOW HOW THEY'RE INSTALLED. THE REST OF THE MAIN CAPS ARE PUT IN PLACE AND SNUGGED. THEY'RE TORQUED TO 90 POUND FEET WITH

EXTREME PRESSURE LUBE. THEY'RE TIGHTENED FROM THE CENTER OUT IN A CIRCULAR PATTERN.

(MIKE)>> WE'RE USING THE STOCK RODS, WHICH HAVE SURPRISINGLY BEEFY MAIN BEAM AND A FULL FLOATING WRIST PIN. NOW THESE WERE TWO OF THE REASONS THESE ENGINES WERE SO DURABLE IN SO MANY DIFFERENT APPLICATIONS. PLUS FOR THE POWER LEVEL AND BUDGET WE HAVE SET THESE WERE A VERY SMART CHOICE. NOW YOU GUYS HAVE SEEN US INSTALL PISTONS AND RODS BEFORE, BUT FOR THOSE OF YOU WHO HAVEN'T HERE'S A QUICK RUN DOWN. FIRST LUBE THE CYLINDERS WITH MOTOR OIL AS WELL AS THE SKIRTS AND RINGS ON THE PISTONS. ASSEMBLY LUBE IS PLACED ON THE BEARING, AND WITH THE WHOLE SETUP IN THE RING COMPRESSOR, ALIGN IT AND SQUARE UP THE COMPRESSOR WITH THE DECK. NOW TAP IT IN MAKING SURE TO KEEP THE COMPRESSOR SEATED. IF YOU FEEL ANY EXCESSIVE RESISTANCE SUCH AS THE PISTON STOPPING DEAD, YOU NEED TO STOP AND REGROUP. THERE'S A CHANCE A RING DIDN'T INDEX THE BORE PROPERLY AND WILL BE DAMAGED IF YOU CONTINUE. ONCE THE BIG END IS RESTED ON THE ROD JOURNAL, INSTALL THE CAP AND SNUG IT DOWN. ONCE ALL EIGHT ARE IN PLACE, TORQUE THEM DOWN. IN OUR CASE IT'S 40 POUND FEET WITH EXTREME PRESSURE LUBE.

(PAT)>> WE LIKE TO OPTIMIZE EVERY ENGINE'S PURPOSE THAT WE BUILD IN HERE. THAT'S WHY WE SPEC OUT A LOT OF OUR OWN CAMS AND SHARE THOSE SPECS WITH YOU. WE'RE GONNA MODERNIZE THAT FE WITH A HYDRAULIC ROLLER CAM SHAFT THAT WE HAD COMP GRIND UP FOR US. THE SPECS ARE 238 DEGREES AT 50 THOUSANDTHS LIFT ON

THE INTAKE AND 244 DEGREES ON THE EXHAUST, AND THE LOBE SEPARATION IS 110 DEGREES. THE LIFT IS 618 THOUSANDTHS ON BOTH INTAKE AND EXHAUST WITH A ONE POINT SEVENSIX ROCKER RATIO WE'LL BE USING. HYDRAULIC CAMS ARE INSTALLED WITH ENGINE OIL ON THE JOURNALS AND THE LOBES UNLIKE A FLAT TAPPET THAT USES A SPECIAL MOLY BASED BREAK IN LUBE TO ESTABLISH A WEAR PATTERN. EDELBROCK SENT US THIS DOUBLE ROLLER TIMING SET WITH AN ADJUSTABLE CRANK GEAR THAT HAS THREE LOCATIONS, ADVANCED, STRAIGHT UP, OR RETARDED FOUR DEGREES.

(MIKE)>> WE KNOW THE LOCATION OF EVERY CAM SHAFT WE INSTALL.

PAT COULDN'T SLEEP AT NIGHT IF WE DIDN'T. NOW USING THE FOUR DEGREE ADVANCED KEY WAY ON THE CRANK SPROCKET, THIS ONE'S IN AT 104 DEGREES OF INTAKE CENTER LINE. A LITTLE MORE OIL WILL LUBE THE TIMING SET. NOW ALL METAL TO METAL CONTACT SURFACES SHOULD

BE TREATED THIS WAY. COVERING THE FRONT UP IS A FACTORY TIMING COVER AND TIMING POINTER. THE OIL PUMP DRIVESHAFT CAN GO IN NOW, FOLLOWED BY THE MELLING STANDARD VOLUME PUMP THAT WE ALREADY PORT MATCHED TO THE BLOCK. THE PICK UP IS A BOLT ON STYLE. IT USES A GASKET AND BLUE THREAD LOCKER ON THE FASTENERS IS A MUST. YOU DON'T WANT IT TO LOOSEN UP. I'M APPLYING WEATHER STRIP ADHESIVE TO THE BLOCK'S PAN RAIL. THIS PRACTICE WILL ALMOST GUARANTEE A LEAK FREE SEAL. NOW A LITTLE MORE ON THE GASKET TO PAN SURFACE. THIS FIVE QUART FRONT SUMP STEEL PAN HAS A GOLD ZINC FINISH.

IT'S A SUMMIT RACING BRAND AND CAN BE YOURS FOR UNDER $50 BUCKS.

(PAT)>> WITH THIS PORTION DONE THE TOP END IS NEXT, BUT AFTER THIS BREAK OF COURSE.

(PAT)>> WE'RE BACK AND WE DON'T HAVE MUCH TIME TO

FINISH UP THIS BULLET, ESPECIALLY IF YOU WANT TO SEE IT ON THE SUPER FLOW DYNO. TO HELP GET THE COMPRESSION RATIO WHERE WE WANT IT WE ORDERED A SET OF COMEDIC MLS HEAD GASKETS IN A THINK 27 THOUSANDTHS COMPRESSED THICKNESS.

THESE EDELBROCK PERFORMER RPM HEADS ARE A DIRECT

BOLT ON FOR 1961 THROUGH 1976 FE'S.

THEY SPORT A TWOZERO-90 INTAKE VALVE, AND A ONESIX-60 EXHAUST VALVE, AND THEY'RE NESTLED IN A 72cc COMBUSTION CHAMBER. THE INTAKE'S PORT VOLUME IS 170cc, WHILE THE EXHAUST COMES IN AT 125cc. AS WE MENTIONED EARLIER, THE INTAKE PORT FLOWS 270 CFM AT 600 THOUSANDTHS VALVE LIFT. WITH THE COMBUSTION CHAMBER SIZE, PISTON, AND HEAD GASKET COMBINATION, OUR COMPRESSION RATIO IS NINE POINT TWOEIGHT TO ONE.

WE'RE TORQUEING THEM DOWN TO 100 POUND FEET WITH EPL.

(MIKE)>> IT'S ALWAYS A GOOD IDEA TO MATCH THE CAM SHAFT WITH THE HOUSE BRAND LIFTERS. NOW COMP OFFERS A RETRO FIT HYDRAULIC ROLLER LIFTER FOR THE FE. A TIE BAR KEEPS THEM ALIGNED, AND A PATENT PENDING PISTON ALLOWS TRAPPED AIR TO ESCAPE FOR A FASTER PUMP UP. LAYING ON VICTOR REINZ GASKETS, THIS EDELBROCK

PERFORMER RPM DUAL PLANE HAS AN OPERATING RANGE FROM 1,500 TO 6,500 RPM. THE BLACK FINISH GOES WITH OUR COLOR SCHEME. WE HAD TO CUSTOM ORDER THE PUSH RODS FOR THIS ENGINE BECAUSE THERE WASN'T AN OFF THE SHELF PART FOR THIS EXACT APPLICATION. SO WE MADE A CALL TO A COMPANY THAT SPECIALIZES IN VALVETRAIN TECHNOLOGY, TRENT PERFORMANCE, AND THEY MADE THIS SET FOR US. THEY HAVE A THREEEIGHTHS BALL END ON THE LIFTER SIDE AND A THREEEIGHTHS CUP AT THE OTHER END TO MATCH OUR NEW ROCKER ARM SETUP. THE WALL THICKNESS IS 80 THOUSANDTHS.

(PAT)>> WE UPGRADED FROM THE NONADJUSTABLE STOCK ROCKER SETUP TO THESE ADJUSTABLE HARLAN SHARP ROCKERS. THEY HAVE A ONE POINT SEVENSIX RATIO, HARDENED

SHAFTS, TOOL STEEL ADJUSTORS, AND THE ROCKER BODIES ARE EXTRUDED ALUMINUM AND IT'S ALL MADE AND MACHINED IN THE USA.

WE'LL ADJUST THEM TO HALF TURN PAST ZERO LASH.

(MIKE)>> NOW WE HAVE TO GET THIS BLUE OVAL BIG

BLOCK ON THE DYNO AND READY TO FIRE UP. WE OUTFITTED THE ENGINE WITH INCH AND THREE

QUARTER JBA HEADERS WITH A TRIY DESIGN. THE COLLECTOR IS THREE INCHES IN DIAMETER. UP FRONT IS A MAZIERE ELECTRIC WATER PUMP SUITED

FOR THE STREET OR THE DRAG STRIP. IT FLOWS 42 GALLONS PER MINUTE AND ONLY WEIGHS SIX POINT NINE POUNDS.

(PAT)>> PERTRONIX SENT US A BILLET FLAME THROWER PLUG AND PLAY DISTRIBUTOR. WE LIMITED THE ADVANCE USING THE SUPPLIED HARDWARE. THE BUILT IN REV LIMITER IS INCREASED TO 6,500 RPM. SUPPLYING IT WITH ENERGY IS A FLAME THROWER HC COIL. THEIR WIRES CONNECT TO ETHREE SPARK PLUGS, AND FOR FUEL DELIVERY OUR TRUSTY QUICK FUEL 750 CFM DYNO CARBURETOR.

(MIKE)>> I'M ALL SETUP, YOU READY?

(PAT)>> ALWAYS!

[ ENGINE STARTS ]

(MIKE)>> TOTAL TIMING IS SET AT 30 DEGREES.

(PAT)>> THIS SOUNDS LIKE PAW PAW'S PICK UP TRUCK RIGHT NOW.

(MIKE)>> ALRIGHT, LET'S DO IT! THE FIRST PULL IS TO 4,500 RPM TO MAKE SURE EVERYTHING IS SOUND.

(PAT)>> OH GOOD! THAT IS NOT TOO SHABBY FOR 30 DEGREES OF TIMING.

(MIKE)>> THAT TORQUE IS PRETTY GOOD, 436 POUND FEET, POWER RIGHT NOW IS 364 AT 4,500.

(PAT)>> HEY THAT'S A SPECTACULAR START.

(MIKE)>> VERY NICE! WHEN WE COME BACK FROM THE BREAK WE'RE MAKING THE POWER PULLS.

SO MAKE SURE YOU STICK WITH US.

(MIKE)>> WE'RE BACK AND SO IS OUR TEMPERATURE, SO LET'S HEAR IT ZIP. SETUP FOR 2,500 TO 6,000.

(PAT)>> PERFECT!

(MIKE)>> 93 OCTANE IN THE CELL, 30 DEGREES OF TOTAL TIMING. LET'S SEE WHAT SHE'S GOT TO 6,000. [ ENGINE REVVING ]

(PAT)>> I THINK WE MIGHT HAVE BROKE 400 FIRST PULL.

(MIKE)>> 402 HORSEPOWER, 438 POUND FEET OF TORQUE.

(PAT)>> NOT SHABBY!

(MIKE)>> PRETTY GOOD LOOKING GRAPH FOR ONLY 30 DEGREES OF TIMING.

(PAT)>> YEAH WE'VE GOT A LITTLE BIT OF WORK TO DO, AND IT IS PUMP GAS. SO THIS IS NOT A RACE ENGINE BY ANY STRETCH OF THE IMAGINATION. IT'S GONNA BE A FUN STREET ENGINE, SO MAKING A LITTLE ADJUSTMENT TO HER.

(MIKE)>> BY ADDING THREE DEGREES OF TIMING FOR A TOTAL OF 33.

WE'VE GOT 2,500 TO 6,000, SAME RPM, 33 DEGREES OF TIMING, EVERYTHING ELSE STAYS THE SAME.

(PAT)>> BIG TIMING SWING, THREE DEGREES.

(MIKE)>> WHOA, HERE WE GO. [ ENGINE REVVING ]

(MIKE)>> THIS THING'S NICE AND SMOOTH, GOOD MANNERS.

(PAT)>> I LIKE IT.

(MIKE)>> 411 WITH 439 POUND FEET.

(PAT)>> SWEET!

(MIKE)>> LOOKS GOOD, IT HOLDS POWER REALLY NICE TO THE MID RANGE.

(PAT)>> RIGHT, NO THIS IS A FUN ENGINE. PRETTY AMAZING WHAT YOU CAN DO WITH SOME MOSTLY STOCK COMPONENTS, LIKE THE CRANK'S STOCK, THE RODS ARE STOCK, IT'S GOT A HYPER EUTECTIC PISTON IN IT.

(MIKE)>> AND THESE ENGINES WERE NEVER MADE BIG POWER EVEN IN THEIR PERFORMANCE.

(PAT)>> NOT PARTICULAR UNLESS YOU GO ON THE REAL RACE SIDE OF IT WITH THE 427 STUFF. NO, AWESOME MAN!

(MIKE)>> OUR LAST PULL FOR THE DAY WE'RE GOING TO 35 AND LEAVING IT THERE. THIS FE IS A GREAT EXAMPLE OF HOW THE AFTER MARKET HAS MODERNIZED THE CLASSIC BLUE OVAL BIG BLOCK. LOW COMPRESSION AND GOOD PARTS CAN YIELD GOOD POWER.

(PAT)>> YEAH BUDDY.

(MIKE)>> 413 ON POWER, 445 ON TORQUE, GRAPH LOOKS GOOD. HOLDS THE TORQUE TO THE MID RANGE REALLY NICE.

(PAT)>> YOU WON'T BE ABLE TO KEEP THE TIRES ON PAW

PAW'S TRUCK IF THIS THING WAS IN IT, RIGHT?

IT'D JUST BURN THEM CLEAN TO THE CORDS.

(MIKE)>> AND IT'LL RUN FOREVER.

(PAT)>> YEAH, GREAT OIL PRESSURE, I'M EXTREMELY HAPPY WITH THIS THING, NICE JOB.

(MIKE)>> IF YOU'RE INTO LIGHT FABRICATION, AUTO BODY, OR ARE JUST LOOKING FOR A WELDER FOR YOUR HOME OR FARM, THE REDESIGNED MILLERMATIC 211 IS A GREAT CHOICE. NOW IT HAS THE HIGHEST OUTPUT IN ITS CLASS AND CAN WELD FROM 24 GAUGE TO THREEEIGHTHS OF AN INCH IN A SINGLE PASS. IT'S 50 PERCENT LIGHTER THAN THE ORIGINAL DESIGN AT ONLY 38 POUNDS FOR EASE OF PORTABILITY. NOW IT'LL WELD EITHER SOLID OR FLUX CORE WIRE, AND HERE'S A REALLY COOL FEATURE. YOU CAN PLUG IT INTO A 230 RECEPTACLE OR A 120 BY JUST SWAPPING OUT THE PLUGS. THERE'S NO NEED FOR ANY EXTRA WIRING. NOW IT ALSO HAS THE AUTO SET FEATURE AND COMES WITH EVERYTHING YOU NEED MINUS THE BOTTLE OF GAS FOR RIGHT AT $1,100 DOLLARS.

(PAT)>> WHEN IT COMES TO MANUAL TRANSMISSIONS AND THE ACCESSORIES TO INSTALL THEM, OUR GO TO PLACE IS AMERICAN POWERTRAIN. THIS IS THEIR HYDROMAX HYDRAULIC CLUTCH SYSTEM WHERE THE PARTS ARE ENGINEERED TO ALL WORK TOGETHER, AND THEY'RE FOR MOST FOUR, FIVE, AND SIX SPEED TRANSMISSIONS IN ANY VEHICLE. IT FEATURES THEIR PATENTED FIREWALL MOUNT WITH AN INTEGRATED PEDAL STOP, A PREBLED HYDRAULIC RELEASE BEARING, PLUS ALL THE HARDWARE, LINES, AND EVEN A RESERVOIR FOR A COMPLETE SETUP. GO TO AMERICAN POWERTRAIN DOT COM FOR KITS AND PRICES FOR YOUR RIDE.

(MIKE)>> FROM THE TRACK TO THE STREET, AND EVEN YOUR YARD, ETHREE HAS A SPARK PLUG TO SUIT YOUR NEEDS. NOW THESE THINGS WILL IMPROVE POWER AND WHATEVER YOU RUN THEM IN WILL BURN LESS FUEL. SO FOR THE BEST OF BOTH WORLDS PICK UP ETHREES FOR YOUR GAS BURNERS AT YOUR LOCAL AUTO PARTS STORE.

PERFORMANCE ENGINE PARTS HAVE COME A LONG WAY IN

THE LAST 10 YEARS. STREET CARS WITH 1,000 PLUS HORSEPOWER ARE BECOMING MORE AND MORE COMMON. NOW THE PARTS ARE STRONGER, GIVING ENGINES MORE STRENGTH AS WELL AS MORE RUN TIME IN BETWEEN REFRESHES. NOW THIS IS ALL THANKS TO BETTER METALLURGY AND MANUFACTURING TECHNIQUES. NOW WE BELIEVE THERE ARE TWO ENGINE PARTS IN PARTICULAR THAT HAVE RECEIVED THE MOST ATTENTION TO IMPROVEMENTS FOR MAKING MORE HORSEPOWER. THOSE ARE CRANK SHAFTS AND CYLINDER HEADS, WHICH ARE IMPROVING BY THE DAY. NOW COMPANIES ARE DESIGNING NEW PORT PROFILES AND IMPROVING THE CURTAIN AREAS, AND NEW AND IMPROVED TRICKS TO THE VALVE JOBS FOR EVEN BETTER FLOW NUMBERS. KEEP IN MIND AN ENGINE IS A GLORIFIED AIR PUMP. THE MORE AIR YOU CAN GET IN AND OUT, THE MORE

EFFICIENT THE ENGINE'S GOING TO BE AND THE MORE

HORSEPOWER IT'S GOING TO MAKE. CRANK SHAFTS HAVE ALSO COME A LONG WAY IN RECENT YEARS, NOT ONLY IN STRENGTH BUT ALSO AFFORDABILITY. NOW BACK IN THE DAY IF YOU WERE LOOKING FOR A FORGED CRANK IT WAS GOING TO BE EXPENSIVE AND SOMETIMES HARD TO COME BY, AND IF YOU WERE LOOKING FOR A CUSTOM PIECE IT WOULD ALMOST HAVE TO BE BILLET, AND THAT WOULD BE EXTREMELY EXPENSIVE SINCE IT WOULD BE A ONE OFF PIECE. CAST IRON CRANKS HAVE BEEN THE INDUSTRY STANDARD FOR OE VEHICLES FOR YEARS BECAUSE THEY'RE CHEAP TO MANUFACTURE.

THE PROCESS STARTS WITH THE MOLTEN LIQUID OF IRON OR STEEL, AND THEN THAT'S POURED INTO A MOLD. WHEN THEY ARE REMOVED THEY LOOK CLOSE TO THE FINAL SHAPE, WHICH CUTS WAY DOWN ON MACHINING TIME, KEEPING THEM CHEAP. THESE ARE THE MOST BASIC AND HAVE A TENSILE STRENGTH BETWEEN 70,000 AND 80,000 PSI. INCREASE OF THE CARBON CONTENT AND YOU GET NODULAR IRON LIKE THIS, WHICH INCREASES THE TENSILE STRENGTH TO ABOUT 95,000 PSI. NOW THE MOST POWER WE WOULD RUN THROUGH ONE OF THESE IS ABOUT 400. CAST STEEL IS USED FOR ENTRY LEVEL CRANKS FROM AFTERMARKET COMPANIES. NOW CAST STEEL HAS A GREATER CARBON CONTENT AND A HIGHER TENSILE STRENGTH OF AROUND 105,000 PSI. NOW WE'RE COMFORTABLE MAKING AROUND 500 TO 530 HORSEPOWER WITH THESE. ENGINES PRODUCING MORE THAN THAT SHOULD BE OUTFITTED WITH A FORGED STEEL CRANK SHAFT. NOW THE MANUFACTURING TECHNIQUE THAT GOES INTO THESE IS WAY MORE INVOLVED. THE COMMON MATERIAL THESE ARE MADE OUT OF IS 4340 STEEL.

THEY START OUT AS CYLINDRICAL PIECE OF STEEL. THEN THEY'RE PUT IN MASSIVE HOT DYE PRESSES THAT APPLY AROUND 8,000 TONS. THIS COMPRESSES THE GRAINS INTO ONE UNIFORM GRAIN FLOW. AFTER SEVERAL ROUNDS OF HEAT TREATING THE OUTCOME IS A CRANK WITH A TENSILE STRENGTH OF AROUND 156,000 PSI, ALLOWING THESE CRANKS TO HANDLE IN EXCESS OF 1,500 HORSEPOWER. NO MATTER WHAT THE POWER GOAL IS FOR YOUR NEXT ENGINE AT LEAST NOW YOU'LL KNOW WHICH CRANK SHAFT WILL WORK BEST FOR YOU.

(PAT)>> WELL THAT'S IT FOR US AND REMEMBER, IF YOU PULL UP TO A STOP LIGHT AND YOU'RE NEXT TO PAW PAW'S OLD PICK UP TRUCK AND IT SOUNDED LIKE THIS DID, YOU DON'T WANT TO CHALLENGE HIM. WE'LL SEE YOU NEXT TIME.