Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

ARP

Assembly Lubricant, for Engine Assembly and Fastener Installation, Ultra Torque, 1.69 fluid oz., Each

ARP

Cylinder Head Bolts, High Performance Series, Hex, Chromoly, Black Oxide, Washers, Jeep, 4.0L, Kit

ARP

Bolts, Hex Head, Stainless 300, Polished, 1/4 in.-20 RH Thread, .750 in. UHL, Set of 5

Clevite

Main Bearings, Direct Replacement, .010 in. Undersize, TM-77, AMC, Jeep, 199, 232, 4.0L, 258, L6, Set of 7

Clevite

Rod Bearing, P Series, Standard Size, Tri Metal, AMC, 199, 242, 258, 290, 304, 343, 360, Each

Crane Cams

Camshaft, Hydraulic Flat Tappet, Advertised Duration 272/284, Lift .484/.512, AMC, Inline Six, Each

E3 Spark Plugs

Spark Plug, E3, Gasket Seat, 14mm Thread, .750 in. Reach, Projected Tip, Resistor, Each

FAST

Throttle Body Fuel Injection, EZ-EFI Self Tuning, Speed Density, 4-Barrel, Jeep, 4.2L, Inline Fuel Pump, Kit

Harland Sharp

Rocker Arms, Pedestal Mount, Full Roller, Alum. Adjustable, 1.6 Ratio, Jeep, 4.0L, Set of 12

Mac's Custom Tie Downs

Engine Lift Plate, Carburetor Pad Mount, Steel, Blue Powdercoated, Each

MSD Ignition

Distributor, Pro-Billet Street, Magnetic Trigger, Vacuum Advance, Jeep, 232, 258, L6, Each

MSD Ignition

Spark Plug Wires, Super Conductor, Spiral Core, 8.5mm, Red, Multi-Angle Boots, Jeep, 4.0L, Set

Professional Products

Harmonic Balancer, PowerForce, Neutral balance, Nodular Iron, Black Anodized, Jeep, 4.0L, Each

Quick Fuel Technology Inc.

Carburetor, Black Diamond Q-Series, 750 cfm, Mechanical Secondary, 4-Barrel, Square Bore, Drag Race, Each

AutoZone

Compressor Works, Water Outlet

AutoZone

3 piece set,Includes cam sprocket, chain, crank sprocket

AutoZone

Duralast, New, Water Pump

Dupli-Color

VHT, Paint, Wrinkle Plus, Gray, 11 oz., Aerosol Spray Can, Each

Kundel

Overhead Crane System

Miller Electric Manufacturing Co.

Diversion 165 Millers most affordable and easy to use AC DC TIG machine that was designed specifically for the personal user.

RockAuto.com

Schrader produces world-class TPMS sensors for both Original Equipment Manufacturers (OEM) as well as for Aftermarket service & replacement professionals

The Industrial Depot

Industrial Depot - Fasteners, Hardware, and Shop Supplies

Episode Transcript

(ANNOUNCER)>> TODAY ON

ENGINE POWER A PERFORMANCE UPGRADE ON THE HEART OF

JEEP'S HISTORY, THE FOUR LITER STRAIGHT SIX.

(MIKE)>> WELCOME TO ENGINE POWER. TODAY A NEW BUILD BEGINS WE'RE DUBBING PROJECT 242. NOW IT'S NOT A VEIGHT, IT'S AN INLINE SIX CYLINDER THAT HAD A HIGH PRODUCTION RUN THAT LASTED FOR 19 YEARS. NOW IT'S POWERED MILLIONS OF VEHICLES ACROSS THE

TRAIL, STREET, DESERTS, AND MOUNTAINS OF SEVERAL DIFFERENT COUNTRIES WHILE SETTING A STANDARD FOR RELIABILITY. NOW THAT MADE US WANT TO BUILD A MODERNIZED VERSION USING THE LATEST PERFORMANCE PARTS BUILT SPECIFICALLY FOR IT. THE SUPER RELIABLE 242 INCH STRAIGHT SIXES WERE FIRST INTRODUCED IN 1987 BY JEEP'S OWNER AMC. THESE ALL IRON WORK HORSES PROVIDED LOTS OF LOW END TORQUE FOR MILLIONS OF JEEPS FROM CHEROKEES TO GRAND CHEROKEES AND COMANCHES TO WRANGLERS. THAT GRUNT WENT FROM 173 HORSES WITH 220 POUND FEET IN '87 UP TO 190 HORSES AND 235 POUND FEET OF

TORQUE BY 2006. OVER ITS TWO DECADE RUN JEEP PRODUCED OVER FIVE MILLION FOUR LITERS AT ITS KENOSHA, WISCONSIN, PLANT.

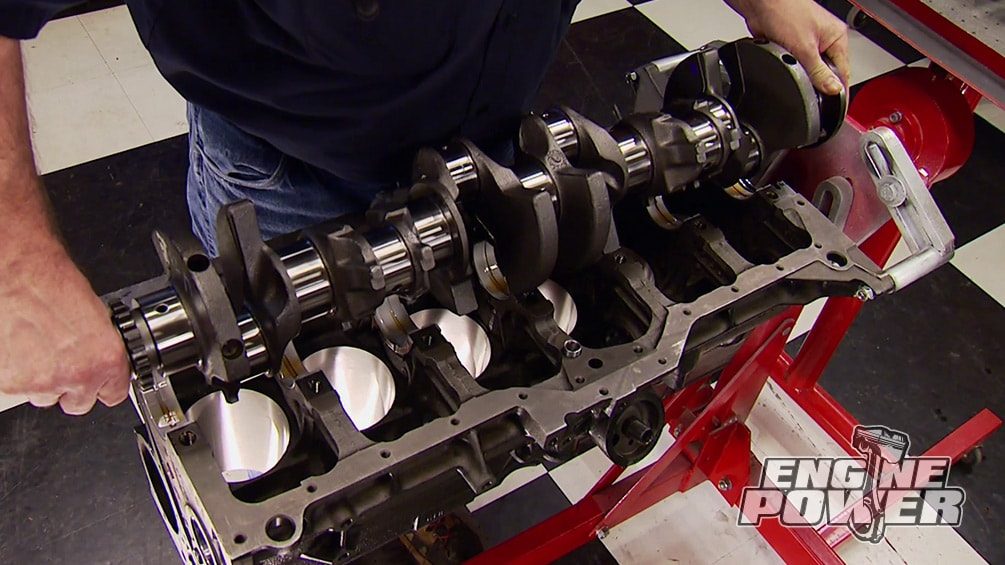

(PAT)>> STRENGTHS AND WEAKNESSES ARE ALWAYS NICE TO KNOW, AND THIS BLOCK FROM 1987 WAS THE FIRST YEAR FOR THE FOUR LITER AND IT WAS DESIGNED WITH SEVEN MAIN BEARINGS TO RETAIN THAT LONG CRANK SHAFT.

STOCK THEY HAD A THREEEIGHT-80 BORE WITH A THREEFOUR-40 STROKE MAKING THE ENGINE OVER SQUARE. LONGEVITY WAS KEY AND THE INLINE DESIGN ALLOWED FOR

MINIMAL CYLINDER WEAR, ALLOWING THESE ENGINES TO RUN SEVERAL HUNDRED THOUSAND MILES. THE ONLY REAL WEAKNESSES THAT EMERGED WERE FROM LACK OF MAINTENANCE LIKE RUNNING THEM OUT OF OIL, LETTING THEM OVERHEAT, OR JUST PURE NEGLECT.

(MIKE)>> WITH A PROJECT NAME LIKE 242, YOU MAY THINK WE'RE TALKING ABOUT CUBIC INCHES. BUT IT'S ACTUALLY THE HORSEPOWER NUMBER WE'RE GONNA CHASE AT THE CRANKSHAFT. NOW OUR GOAL IS TO MAKE ONE HORSEPOWER PER CUBIC INCH OUT OF THIS RUGGED, RELIABLE, BUT SOMEWHAT ANEMIC POWER PLANT. NOW WE'RE NOT STROKING IT AND WE'RE NOT STROKING YOU. THIS IS ALL ABOUT REAL WORLD HORSEPOWER NUMBERS BASED OFF OF A STOCK SHORT BLOCK.

(PAT)>> TO MAKE THAT HAPPEN WE'RE GONNA USE

THIS ALL NEW EDELBROCK PERFORMER ALUMINUM CYLINDER HEAD SPECIFICALLY DESIGNED FOR 1987 THROUGH 2006 FOUR LITERS. IT HAS 144cc INTAKE RUNNER AND A 77cc EXHAUST RUNNER. ON THE VALVE SIDE THE INTAKES ARE ONENINE-10 AND THE EXHAUST ARE ONE-500 JUST LIKE THE STOCK ONES. THE COMBUSTION CHAMBER IS 55cc VERSUS THE STOCK HEAD'S 57, BUT THE MOST IMPORTANT PART IS AT 500 THOUSANDTHS VALVE LIFT THE HEAD OUT FLOWS THE STOCK HEAD BY 52 CFM.

(MIKE)>> IN ORDER TO PUT IT TO USE WE HAVE TO GET THE SHORT BLOCK TOGETHER. NOW WE ALREADY CHECKED ALL OF OUR MAIN BEARING CLEARANCES AND RECORDED THOSE NUMBERS DOWN ON OUR

ENGINE BUILD SHEET YOU CAN FIND ON THE WEBSITE.

(PAT)>> OEM CLEARANCES ARE VERY FORGIVING, UNLIKE RACING ENGINES. CLEARANCES FOR THIS FOUR LITER RANGE FROM 29 TO 32 TEN THOUSANDTHS. DURING MACHINING OUR CRANK'S ROD AND MAIN JOURNALS WERE GROUND UNDERSIZE 10 THOUSANDTHS.

SO THAT REQUIRES A SPECIFIC BEARING TO COMPENSATE FOR THE SMALLER JOURNAL. CLEVITE PSERIES MAINS AND RODS WILL FILL UP THE SADDLES. SINCE OUR ENGINES ARE ALWAYS PRIMED BEFORE START UP, WE'RE USING DRIVEN BR 30 BREAK IN OIL TO LUBE THE BEARINGS.

(MIKE)>> BEFORE THE CAST CRANK SHAFT GOES IN, WE WANT TO SEE WHAT IT WEIGHS. IT COMPRESSES THE SCALE WITH 57 POUNDS. THIS ENGINE IN COMPLETE FACTORY FORM WEIGHS 483 POUNDS. NOW ANY TIME YOU CAN SAVE WEIGHT WHILE BUILDING THE ACTUAL ENGINE, IT'S GONNA HELP THE WHOLE VEHICLE PERFORM BETTER. AND WE HAVE PLENTY OF WEIGHT SAVINGS WITH THE PARTS WE CHOSE UP ON THE TOP END.

(PAT)>> LAYING THE CRANK IN NICE AND FLAT

IS THE WAY TO DO IT. YOU'RE NOT MOVING FURNITURE HERE, YOU'RE BUILDING AN ENGINE.

SO GO EASY! THE SEVEN MAIN CAPS CAN BE REGISTERED IN PLACE AND SNUGGED UP FROM THE CENTER OUT. THEY GET TORQUED TO 70 FOOT POUNDS WITH CMD

EXTREME PRESSURE LUBE IN THE SAME CENTER OUT PATTERN. THE LAST MEASUREMENT ON THE CRANK IS TO CHECK THE THRUST CLEARANCE. WE HAVE SIX THOUSANDTHS, NOT A BAD START.

(ANNOUNCER)>> NEXT A MIX OF OLD AND NEW COMPONENTS TO REACH OUR GOAL.

(MIKE)>> WE'RE BACK WITH PROJECT 242. NOW THE CAM SHAFT FOR THIS ENGINE WAS A FAIRLY EASY CHOICE FROM CRANE CAMS. NOW WE WANT THIS ENGINE TO PRODUCE GOOD LOW END TORQUE AND ALSO HAVE A NICE USABLE POWER BAND.

NOW IT'S A HYDRAULIC FLAT TAPPET PIECE THAT HAS A FAIRLY AGGRESSIVE PROFILE FOR AN INLINE SIX ENGINE. BUT THAT'S NEEDED TO COMPLIMENT THE FLOW NUMBERS THE EDELBROCK CYLINDER HEAD PRODUCES AND

CAPITALIZE ON THIS COMBO. FLAT TAPPET CAMS PRODUCT A LOT MORE HEAT BETWEEN THE CAM LOBE AND THE LIFTER FACE DUE TO THE ADDITIONAL FRICTION. SO A LUBE WITH HIGH LEVELS OF CDDP IS NECESSARY TO PREVENT LOBE DAMAGE DURING BREAK IN. THE CAM'S DURATION AT 50 THOUSANDTHS ON THE INTAKE IS 216 DEGREES, EXHAUST IS 228. LIFT AT THE VALVE IS 484 ON THE INTAKE, 512 ON THE EXHAUST. NOW THE RPM RANGE IS FROM 1,800 TO 5,400. AND JUST LIKE THE CRANK, THE CAM SHOULD SPIN FREELY WITH NO BINDING.

(PAT)>> THE TIMING SET ONLY GOES ON ONE WAY. SO WHILE WE'RE HERE IT'S GETTING INSTALLED. STOCK UNITS ARE NOT KNOWN FOR FAILURE AND WE PICKED ONE UP AT AUTOZONE. SUMMIT RACING WAS OUR SOURCE FOR THIS OMIX TIMING COVER. IT'S CAST ALUMINUM AND HAS THE TIMING MARKS BUILT INTO IT. ARP FASTENERS WILL SNUG IT DOWN. THE BALANCER IS NEXT. MADE BY PROFESSIONAL PRODUCTS, IT WILL COMPLIMENT ALL THE OTHER MOVING PARTS THAT ALLOW THIS ENGINE TO RUN SMOOTH.

(MIKE)>> AND THE ONLY WAY TO MAKE IT RUN IS WITH THE PISTONS AND RODS. THESE ARE AS BARE BONES AS IT GETS. THE RODS ARE CAST, HAVE A PRESS FIT PIN, WEIGH 660 GRAMS, AND HAVE A SIX-125 CENTER TO CENTER LENGTH. THE PISTONS ARE CAST ALUMINUM THAT HAVE BEEN HEAT TREATED AND CNC MACHINED. NOW UP TOP THEY HAVE A DISH WITH A DSHAPED CUP AND SPORT A 564THS, 564THS, 316THS RING PACK TO SEAL UP THE CYLINDERS. SLICKED UP WITH MOTOR OIL, WE CAN DROP THEM IN USING A RING COMPRESSOR. UNDERNEATH THE CAPS GO ON AND SNUGGING THEM UP WILL

PUT SUFFICIENT CRUST TO THE BEARING, WHICH LETS US ROTATE IT WITHOUT HARMING IT. NOW OUR CLEARANCES ARE ALL IN RANGE JUST LIKE THE MAINS.

ONCE ALL SIX ARE IN WE CAN TORQUE THE NUTS TO 33 POUND FEET.

(PAT)>> THE HEART OF THE ENGINE IS JUST LIKE YOURS AND MINE. ITS JOB IS TO PUMP FLUIDS TO ALL THE VITALS TO KEEP THEM GOING OVER TIME. OURS IS AN M-81 STANDARD VOLUME MELLING THAT'LL DO JUST THAT FOR OUR FOUR LITER. A GASKET AND TWO BOLTS SECURE IT. THE PICK UP MATCHES THE DORMAN OIL PAN WE ORDERED FROM SUMMIT RACING. IT'S CORROSION RESISTANT AND GUARANTEED TO FIT. LIKE ALL PANS INSTALLED HERE, ARP BOLTS WILL CINCH IT DOWN. WITH THE SAME LUBE WE PUT ON THE CAM LOBES FOR PROPER BREAK IN, THE HYDRAULIC FLAT TAPPET LIFTERS CAN DROP IN NOW.

(MIKE)>> BEFORE WE INSTALL THE CYLINDER HEAD, WE WANT TO DO A WEIGHT COMPARISON BETWEEN THE STOCK AND ALUMINUM HEAD. COULD IT BE HALF? THE STOCK HEAD WEIGHS IN AT 66 POUNDS. OUR NEW EDELBROCK PIECE IS 37 POUNDS, FOR A REDUCTION OF 29. SEALING IT TO THE DECK IS THIS EDELBROCK MLS HEAD GASKET. NOW THERE ARE NO DOWELS ON FOURZERO OR FOUR POINT TWO LITER AMC ENGINES TO ALIGN THE GASKET AND THE CYLINDER HEAD. SO HERE'S A QUICK TIP. CUTTING THE HEAD OFF A HALF INCH BOLT AND PUTTING A SMALL NOTCH IN THE TOP FOR A FLATHEAD SCREW DRIVER POINT WILL ALLOW YOU TO ALIGN BOTH. IT'S AN EASY WAY TO INSURE PROPER ALIGNMENT. ARP FASTENERS ARE THE ONLY WAY TO GO. WITH ULTRA TORQUE LUBE WE'LL CINCH THEM DOWN IN THREE STEPS, 35, 70, AND FINALLY 100 POUND FEET.

(PAT)>> LUBING THE BALL ENDS OF THE PUSH RODS PROTECT THEM DURING INITIAL START UP. ANYWHERE HIGH PRESSURE IS PRESENT THIS SHOULD BE DONE, ESPECIALLY THE VALVE STEM. HARLAND SHARP OFFERS A ROLLER ROCKER CONVERSION FOR FOUR LITER ENGINES. THEY'RE A FULL ROLLER PEDESTAL MOUNT WITH THEIR ONE POINT SIX RATIO. LASH IS TOUGH TO SET BECAUSE THE LIFTER PLUNGERS ARE COLLAPSED. SO WE'RE GETTING IT CLOSE. NOW THEY ALL GET TORQUED DOWN AND WHEN WE GET TO THE DYNO ROOM WE'LL PRIME IT AND RELASH.

(ANNOUNCER)>> MANIFOLD GENIUS OR MADNESS?

THE MOTHER OF INVENTION, THAT'S NEXT.

(MIKE)>> WE'RE BACK AT IT AND MOVING ON WITH INDUCTION. NOW WE DID A LITTLE RESEARCH AND FOUND OUT THAT THE '99 AND LATER CHEROKEE INTAKE MANIFOLD HAS A LARGER PLENUM AREA AND SMOOTHER TRANSITION IN THE RUNNERS. AND ALL THAT EQUALS BETTER AIR FLOW. FOR FUEL DELIVERY WE ORDERED THIS FAST EZ EFI SELF LEARNING FUEL INJECTION SYSTEM THAT'S SPECIFICALLY DESIGNED FOR JEEP CJ AND YJ ENGINES

FROM 1972 TO 1991. THE SUPPLIED ADAPTER FROM THE INTAKE TO THE THROTTLE BODY WON'T WORK WITH THE NEWER CHEROKEE INTAKE MANIFOLD. SO WE'RE GONNA PERFORM SOME MAJOR SURGERY UP HERE IN THE PLENUM AREA, AND YOU'RE GONNA LOVE IT.

(PAT)>> AIR AND FUEL DELIVERY ARE THE KEYS TO MAKING POWER, AND THE LESS RESTRICTION YOU HAVE ON THE INTAKE SIDE, THE MORE POWER POTENTIAL YOU HAVE. WE WERE GONNA HAVE TO MODIFY THIS INTAKE ANYWAYS TO ACCEPT THE FAST ADAPTER, SO WHY NOT TAKE IT A STEP FURTHER BY USING THIS ALUMINUM ADAPTER WE FOUND IN OUR PARTS CAGE. AND WE'RE GONNA RECESS IT INTO THE MANIFOLDS PLENUM, AND THAT WILL GIVE US BETTER BREATHING POTENTIAL.

THE PROCESS STARTS BY GRINDING DOWN A COUPLE OF BOSSES. THAT ALLOWS THE ADAPTER TO SIT FLUSH ON PLENUM. TRACING THE OD OF THE ADAPTER TO THE INTAKE HAPPENS NOW. THE TIGHTER THE LINE THE BETTER. TIME TO LET THE CHIPS FLY. WITH A CARBIDE BURR AND A LITTLE TRANS FLUID, THE MATERIAL NOT NEEDED IS GOING AWAY. LET THE BURR DO THE WORK AND TAKE YOUR TIME.

AFTER GOUGING OUT A PATH AND STRUGGLING A BIT, IT'S TIME TO MAKE A BATTLEFIELD DECISION AND SWITCH TO THE AIR SAW. IT'S A BIT MORE PRECISE AND A WHOLE LOT LESS MESSY FOR NOW. WITH THE MIDDLE PART FINALLY OUT I'LL FINE TUNE WITH A CARBIDE AND A FLAPPER ROLL. LET'S SEE HOW IT FITS, OR DOESN'T. BE VERY CAREFUL NOT TO REMOVE TOO MUCH. CHECK OFTEN AND TAKE YOUR TIME. YOU WANT A GOOD FIT SO THE WELDING WILL GO EASIER. COME ON BABY, BONANZA!

(MIKE)>> USING OUR MILLER TIG WELDER, WE'LL TACK IT IN A COUPLE OF PLACES.

THEN BURN IT IN USING FILLER ROD. NOW THERE ARE A COUPLE OF TIGHT SPOTS THAT ARE REALLY TRICKY TO GET WITH THE TIG, BUT IT DIDN'T SLOW US DOWN. NOW CLEAN IT OFF WITH A WIRE BRUSH AND LET IT COOL. IN THE MEAN TIME WE'RE READY FOR OUR FRESHLY PAINTED VALVE COVER. NOW DUPLICOLOR'S WRINKLE PLUS GRAY GAVE THIS

THING A KILLER LOOK. AND ON THE INSIDE PAT REMOVED ALL THE BAFFLING TO CLEAR OUR TALLER ROCKER ARMS.

THE EDELBROCK HEAD ACCEPTS EARLY AND LATE MODEL VALVE COVERS. WE'RE HOLDING OURS ON WITH THE FACTORY HARDWARE.

(PAT)>> THE WATER PUMP CAN GO ON NOW. IT'S A NEW UNIT WE PICKED UP FROM AUTOZONE. THE WATER NECK ALSO CAME FROM THEIR PARTS HOUSE. WE DON'T RUN A THERMOSTAT ON THE DYNO, IT HAS ONE BUILT IN. SINCE THERE AREN'T ANY ACCESSORIES, WE'RE USING A MISTER GASKET ELECTRIC MOTOR AND WATER PUMP PULLEY. IT'S A UNIVERSAL KIT THAT COMES WITH SPACERS AND LOTS OF HARDWARE. THE BRACKET ATTACHES TO TWO BOSSES ON THE BLOCK. IT ALSO ACTS AS A LOCATOR, WHICH DOESN'T GET ANY TENSION DUE TO THE COG DESIGN.

NOW IT'S TIME FOR OUR MODIFIED INDUCTION

AND SOME EXHAUST. RUGGED RIDGE SENT US THIS 304 STAINLESS HEADER THAT'S BEEN POLISHED TO A BEAUTIFUL FINISH. THE PRIMARIES ARE INCH AND A HALF AND WILL COMPLIMENT

OUR FOUR LITER'S POWER POTENTIAL.

THEY INSTALL AT THE SAME TIME SINCE THEY SHARE SEVERAL OF THE SAME FASTENERS. CINCHING DOWN THE ARP'S WILL COMPRESS THE GASKET FOR A GOOD SEAL. AN MSD PRO BILLET DISTRIBUTOR DESIGNED FOR STREET PERFORMANCE IS DROPPING IN. IT HAS BOTH MECHANICAL AND VACUUM ADVANCE. TO KEEP THE TIMING ROCK STEADY AT EVERY RPM WE

LOCKED IT OUT FOR THE DYNO RUNS. ETHREE DIAMOND FIRE SPARK PLUGS WILL IGNITE THE AIR AND FUEL MIX. AND MSD'S PRETERMINATED EIGHT POINT FIVE MILLIMETER SUPER CONDUCTOR WIRES WILL SUPPLY THE VOLT JUICE TO THEM. WITH THE ENGINE AT THIS STAGE OF THE ASSEMBLY WE NEED TO GET IT ON THE DOCKING CART. MAKING IT A SIMPLE TASK FOR US IS OUR KUNDEL OVERHEAD CRANE AND OUR PIT PAL ENGINE SLING.

(ANNOUNCER)>> THE DYNO IS NEXT ON OUR QUEST FOR ONE HORSEPOWER PER CUBIC INCH.

(MIKE)>> WE'RE BACK AND REALLY CLOSE TO HEARING PROJECT 242'S HEARTBEAT COME ALIVE ON THE DYNO.

(PAT)>> THESE LIFTERS ARE PUMPED UP NOW.

(MIKE)>> YEAH, NEED TO CHECK THAT LASH. IT'S PUMPED UP GOOD AT TOP. WHILE PAT'S RELASHING THE VALVES, HERE COMES THE GASKETS AND THROTTLE BRACKET, WHICH GETS COVERED UP BY THIS EFI THROTTLE BODY WHICH HOUSES THE INJECTORS, FUEL RAILS, AND A FEW SENSORS. THE HARNESS IS PRELABELED, MAKING

IT SELF EXPLANATORY. WITH THE THREE POWER LEADS HOOKED UP ALONG WITH THE WEATHERPROOF ECU AND HAND HELD, WE CAN FILL THE CELL WITH 87 OCTANE FUEL.

(PAT)>> AN INSTANT FIRE UP IS ENCOURAGING. WE'LL START THIS SESSION AT 28 DEGREES OF TIMING.

(MIKE)>> BY APPLYING LIGHT LOAD AT MULTIPLE THROTTLE POSITIONS, WE'RE SIMULATING A VEHICLE DRIVING DOWN THE ROAD AS BEST WE CAN. NOW THE INJECTION NEEDS TO SEE THIS FOR ITS ADAPTIVE LEARNING PROCESS. THAT'S 20 MINUTES. COME ON BABY!

(PAT)>> LETS SEE WHAT IT DOES.

(MIKE)>> WE'LL MAKE THE FIRST PULL FROM 2,500 TO 4,000 TO SEE IF THE INJECTION SYSTEM AND OUR HIGHLY MODIFIED MANIFOLD JIVE TOGETHER. 220 FOOT POUNDS OF TORQUE, 133 ON POWER.

(PAT)>> I'M THINKING IT'S NOT THE INJECTION, I'M THINKING IT'S OUR CRAZINESS THAT DID THIS.

(MIKE)>> LET'S SEE WHAT IT DOES. [ engine revving ]

(MIKE)>> OUR MANIFOLD MAGIC MAY HAVE...

(PAT)>> IT'S NOT MAGIC!

(MIKE)>> THERE'S A SERIOUS PROBLEM HERE.

(PAT)>> WELL IT'S NOT THE FAULT OF THE INJECTION.

(MIKE)>> NO, NOT AT ALL.

(PAT)>> UNFORTUNATELY SOME TIMES THINGS DON'T WORK OUT LIKE YOU PLANNED. CASE IN POINT, OUR HIGHLY MODIFIED MANIFOLD.

THE INJECTION SYSTEM WORKS PERFECT. IT STARTS, IT IDLES, IT DOES EVERYTHING IT'S SUPPOSED TO. WHAT THE BIG PROBLEM IS IS OUR MODIFICATIONS TO THE MANIFOLD HAVE CHANGED THE CHARACTERISTICS SO MUCH IT DOESN'T LIKE TO RUN IN THIS CONFIGURATION. SO WHAT WE'RE GONNA DO IS WE'RE GONNA GO OLD SCHOOL ON IT. WE'RE GONNA PUT ON A CARBURETOR AND WE'RE GONNA TRY AND MAKE SOME NOISE WITH IT, AND WE'LL SEE WHAT HAPPENS. THIS IS OUR TRIED AND TRUE 750 CFM DYNO UNIT THAT WAS LAST SEEN ON LITTLE BLACK AND BLUE. IT'S SITTING ON A ONE INCH HVH SPACER AND THE FAST ADAPTER.

WE DON'T KNOW HOW IT'S GONNA ACT ON THIS ENGINE BECAUSE OF ITS SIZE BUT WE KNOW IT'S A GREAT CARB. COME ON, BE GOOD TO US. [ engine revving ]

(MIKE)>> LOADS UP GOOD!

[ engine revving ]

(MIKE)>> YES SIR. WOW, WOW!

LOOK AT THAT TORQUE, 273 FOOT POUNDS, 213 HORSEPOWER. TIMING?

(PAT)>> YEAH, LET'S PUT SOME TIMING IN IT.

AS WITH ANY ENGINE, WE'LL DO OUR NORMAL TUNING PROCEDURE AND ADVANCE THE TIMING IN SMALL INCREMENTS TO FIND ITS THRESHOLD FOR TORQUE, WHICH ENDED

UP AT 34 DEGREES. MAN, RIGHT STRAIGHT THROUGH IT.

(MIKE)>> 228, 283, THRESHOLD.

(PAT)>> THAT'S THRESHOLD, OKAY. SO WE BACKED IT DOWN TO 33 AND MADE A SUBSTANTIAL JET CHANGE FOR OUR LAST ATTEMPT.

(MIKE)>> OUR LAST CHANCE, YOU READY?

(PAT)>> I HOPE SOMETHING GOOD HAPPENS. [ engine revving ]

(MIKE)>> ALRIGHT!

(PAT)>> COME ON!

(MIKE)>> CLEAN PULL! YES, GOT IT, ONE HORSE PER CUBE.

(PAT)>> OH MY GOD THAT'S NICE.

(MIKE)>> HOW IN THE HELL?

(PAT)>> I FEEL SO MUCH BETTER NOW. WE GOT IT BUT WE DIDN'T GET IT BUT WE GOT IT.

(MIKE)>> LOOK AT THE TORQUE, 286.

(PAT)>> THAT IS EXTREMELY IMPRESSIVE.

(MIKE)>> 177, THAT'S 66 HORSEPOWER GAIN.

220, AND 66 ON TORQUE, DOUBLE 66'S.

(PAT)>> HEY IT'S A SIX CYLINDER. WE'RE DONE, WE'RE DONE. LS SWAPS AREN'T SLOWING DOWN AND NEITHER ARE THE COMPANIES THAT SUPPORT THEM. THAT'S WHY DOUG'S ARE OFFERING THESE ONE AND SEVENEIGHTHS LONG TUBES THAT FIT '67 TO '69

CAMAROS AND '68 TO '74 NOVAS THAT ARE GETTING AN LS TRANSPLANT. THE TUBES ARE CNC BENT FOR BETTER FLOW AND

FITMENT, AND THEY'RE MADE OUT OF 16 GAUGE STEEL FOR LONGER LIFE. THEY EVEN HAVE THEIR METALLIC CERAMIC COATING. THEY'RE DESIGNED TO DECREASE BACK PRESSURE AND INCREASE HORSEPOWER AT HIGH RPM. AND THEY EVEN COME WITH EVERYTHING TO INSTALL THEM, LIKE OTWO EXTENSIONS, GASKET, AND THE REST OF THE HARDWARE. THE PRICE, RIGHT AT $650 BUCKS.

(MIKE)>> IT'S BLUE, HAS AN ACME SCREW, AND WILL HELP YOU INSTALL ENGINES AND TRANSMISSIONS. NOW THIS IS MAX PIVOT ARTICULATING ENGINE LIFT PLATE THAT REACHES ANGLES UP TO 35 DEGREES. NOW IT ACCEPTS MOST TWO AND FOUR BARREL CARBURETOR PATTERNS. AND IF YOU'VE GOT A LATE MODEL EFI ENGINE, NO WORRIES. THEY MAKE SEVERAL ADAPTERS TO HAVE YOU COVERED. NOW THIS THING IS MADE OUT OF QUARTER INCH THICK STEEL PLATE AND ALL HARDENED HARDWARE. PLUS THE BLUE POWDER COAT FINISH GIVES IT A GREAT LOOK.

NOW WITH THE WEIGHT OF THE ENGINE HANGING, ALL YOU DO IS ADJUST THE ACME SCREW TO CHANGE THE ANGLE FOR EASY INSTALL. PRICING AS YOU SEE IT HERE IS $159 BUCKS AT SUMMIT RACING.

(PAT)>> SINCE 2007, ALL VEHICLES PRODUCED IN THE US ARE REQUIRED TO HAVE A TIRE PRESSURE MONITORING SYSTEM OR TPMS. IT'S LOCATED ON THE WHEEL INSIDE THE TIRE. SO IT'S IN A PRETTY TOUGH ENVIRONMENT. AND LIKE ALL SENSORS, THEY CAN GO BAD AND THAT CAN REALLY ATTACK YOUR WALLET. SO ROCK AUTO OFFERS SCHRADER TPMS SENSORS THAT ARE A ONE FOR ONE REPLACEMENT FOR THE ONES THAT COME OFF THE ASSEMBLY LINE FOR YOUR VEHICLE. THE COST VARIES ON WHAT RIDE YOU HAVE. SO LOG ONTO ROCK AUTO DOT COM TO GET YOUR LOW PRICE. WELL THAT'S IT FOR US AND WE HOPE IF YOU LEARNED ANYTHING TODAY IS DON'T BE AFRAID TO DO A

LITTLE EXPERIMENTING. AFTER ALL, THAT'S HOW THIS INDUSTRY WAS CREATED. WE'LL SEE YOU NEXT TIME.

Show Full Transcript

(MIKE)>> WELCOME TO ENGINE POWER. TODAY A NEW BUILD BEGINS WE'RE DUBBING PROJECT 242. NOW IT'S NOT A VEIGHT, IT'S AN INLINE SIX CYLINDER THAT HAD A HIGH PRODUCTION RUN THAT LASTED FOR 19 YEARS. NOW IT'S POWERED MILLIONS OF VEHICLES ACROSS THE

TRAIL, STREET, DESERTS, AND MOUNTAINS OF SEVERAL DIFFERENT COUNTRIES WHILE SETTING A STANDARD FOR RELIABILITY. NOW THAT MADE US WANT TO BUILD A MODERNIZED VERSION USING THE LATEST PERFORMANCE PARTS BUILT SPECIFICALLY FOR IT. THE SUPER RELIABLE 242 INCH STRAIGHT SIXES WERE FIRST INTRODUCED IN 1987 BY JEEP'S OWNER AMC. THESE ALL IRON WORK HORSES PROVIDED LOTS OF LOW END TORQUE FOR MILLIONS OF JEEPS FROM CHEROKEES TO GRAND CHEROKEES AND COMANCHES TO WRANGLERS. THAT GRUNT WENT FROM 173 HORSES WITH 220 POUND FEET IN '87 UP TO 190 HORSES AND 235 POUND FEET OF

TORQUE BY 2006. OVER ITS TWO DECADE RUN JEEP PRODUCED OVER FIVE MILLION FOUR LITERS AT ITS KENOSHA, WISCONSIN, PLANT.

(PAT)>> STRENGTHS AND WEAKNESSES ARE ALWAYS NICE TO KNOW, AND THIS BLOCK FROM 1987 WAS THE FIRST YEAR FOR THE FOUR LITER AND IT WAS DESIGNED WITH SEVEN MAIN BEARINGS TO RETAIN THAT LONG CRANK SHAFT.

STOCK THEY HAD A THREEEIGHT-80 BORE WITH A THREEFOUR-40 STROKE MAKING THE ENGINE OVER SQUARE. LONGEVITY WAS KEY AND THE INLINE DESIGN ALLOWED FOR

MINIMAL CYLINDER WEAR, ALLOWING THESE ENGINES TO RUN SEVERAL HUNDRED THOUSAND MILES. THE ONLY REAL WEAKNESSES THAT EMERGED WERE FROM LACK OF MAINTENANCE LIKE RUNNING THEM OUT OF OIL, LETTING THEM OVERHEAT, OR JUST PURE NEGLECT.

(MIKE)>> WITH A PROJECT NAME LIKE 242, YOU MAY THINK WE'RE TALKING ABOUT CUBIC INCHES. BUT IT'S ACTUALLY THE HORSEPOWER NUMBER WE'RE GONNA CHASE AT THE CRANKSHAFT. NOW OUR GOAL IS TO MAKE ONE HORSEPOWER PER CUBIC INCH OUT OF THIS RUGGED, RELIABLE, BUT SOMEWHAT ANEMIC POWER PLANT. NOW WE'RE NOT STROKING IT AND WE'RE NOT STROKING YOU. THIS IS ALL ABOUT REAL WORLD HORSEPOWER NUMBERS BASED OFF OF A STOCK SHORT BLOCK.

(PAT)>> TO MAKE THAT HAPPEN WE'RE GONNA USE

THIS ALL NEW EDELBROCK PERFORMER ALUMINUM CYLINDER HEAD SPECIFICALLY DESIGNED FOR 1987 THROUGH 2006 FOUR LITERS. IT HAS 144cc INTAKE RUNNER AND A 77cc EXHAUST RUNNER. ON THE VALVE SIDE THE INTAKES ARE ONENINE-10 AND THE EXHAUST ARE ONE-500 JUST LIKE THE STOCK ONES. THE COMBUSTION CHAMBER IS 55cc VERSUS THE STOCK HEAD'S 57, BUT THE MOST IMPORTANT PART IS AT 500 THOUSANDTHS VALVE LIFT THE HEAD OUT FLOWS THE STOCK HEAD BY 52 CFM.

(MIKE)>> IN ORDER TO PUT IT TO USE WE HAVE TO GET THE SHORT BLOCK TOGETHER. NOW WE ALREADY CHECKED ALL OF OUR MAIN BEARING CLEARANCES AND RECORDED THOSE NUMBERS DOWN ON OUR

ENGINE BUILD SHEET YOU CAN FIND ON THE WEBSITE.

(PAT)>> OEM CLEARANCES ARE VERY FORGIVING, UNLIKE RACING ENGINES. CLEARANCES FOR THIS FOUR LITER RANGE FROM 29 TO 32 TEN THOUSANDTHS. DURING MACHINING OUR CRANK'S ROD AND MAIN JOURNALS WERE GROUND UNDERSIZE 10 THOUSANDTHS.

SO THAT REQUIRES A SPECIFIC BEARING TO COMPENSATE FOR THE SMALLER JOURNAL. CLEVITE PSERIES MAINS AND RODS WILL FILL UP THE SADDLES. SINCE OUR ENGINES ARE ALWAYS PRIMED BEFORE START UP, WE'RE USING DRIVEN BR 30 BREAK IN OIL TO LUBE THE BEARINGS.

(MIKE)>> BEFORE THE CAST CRANK SHAFT GOES IN, WE WANT TO SEE WHAT IT WEIGHS. IT COMPRESSES THE SCALE WITH 57 POUNDS. THIS ENGINE IN COMPLETE FACTORY FORM WEIGHS 483 POUNDS. NOW ANY TIME YOU CAN SAVE WEIGHT WHILE BUILDING THE ACTUAL ENGINE, IT'S GONNA HELP THE WHOLE VEHICLE PERFORM BETTER. AND WE HAVE PLENTY OF WEIGHT SAVINGS WITH THE PARTS WE CHOSE UP ON THE TOP END.

(PAT)>> LAYING THE CRANK IN NICE AND FLAT

IS THE WAY TO DO IT. YOU'RE NOT MOVING FURNITURE HERE, YOU'RE BUILDING AN ENGINE.

SO GO EASY! THE SEVEN MAIN CAPS CAN BE REGISTERED IN PLACE AND SNUGGED UP FROM THE CENTER OUT. THEY GET TORQUED TO 70 FOOT POUNDS WITH CMD

EXTREME PRESSURE LUBE IN THE SAME CENTER OUT PATTERN. THE LAST MEASUREMENT ON THE CRANK IS TO CHECK THE THRUST CLEARANCE. WE HAVE SIX THOUSANDTHS, NOT A BAD START.

(ANNOUNCER)>> NEXT A MIX OF OLD AND NEW COMPONENTS TO REACH OUR GOAL.

(MIKE)>> WE'RE BACK WITH PROJECT 242. NOW THE CAM SHAFT FOR THIS ENGINE WAS A FAIRLY EASY CHOICE FROM CRANE CAMS. NOW WE WANT THIS ENGINE TO PRODUCE GOOD LOW END TORQUE AND ALSO HAVE A NICE USABLE POWER BAND.

NOW IT'S A HYDRAULIC FLAT TAPPET PIECE THAT HAS A FAIRLY AGGRESSIVE PROFILE FOR AN INLINE SIX ENGINE. BUT THAT'S NEEDED TO COMPLIMENT THE FLOW NUMBERS THE EDELBROCK CYLINDER HEAD PRODUCES AND

CAPITALIZE ON THIS COMBO. FLAT TAPPET CAMS PRODUCT A LOT MORE HEAT BETWEEN THE CAM LOBE AND THE LIFTER FACE DUE TO THE ADDITIONAL FRICTION. SO A LUBE WITH HIGH LEVELS OF CDDP IS NECESSARY TO PREVENT LOBE DAMAGE DURING BREAK IN. THE CAM'S DURATION AT 50 THOUSANDTHS ON THE INTAKE IS 216 DEGREES, EXHAUST IS 228. LIFT AT THE VALVE IS 484 ON THE INTAKE, 512 ON THE EXHAUST. NOW THE RPM RANGE IS FROM 1,800 TO 5,400. AND JUST LIKE THE CRANK, THE CAM SHOULD SPIN FREELY WITH NO BINDING.

(PAT)>> THE TIMING SET ONLY GOES ON ONE WAY. SO WHILE WE'RE HERE IT'S GETTING INSTALLED. STOCK UNITS ARE NOT KNOWN FOR FAILURE AND WE PICKED ONE UP AT AUTOZONE. SUMMIT RACING WAS OUR SOURCE FOR THIS OMIX TIMING COVER. IT'S CAST ALUMINUM AND HAS THE TIMING MARKS BUILT INTO IT. ARP FASTENERS WILL SNUG IT DOWN. THE BALANCER IS NEXT. MADE BY PROFESSIONAL PRODUCTS, IT WILL COMPLIMENT ALL THE OTHER MOVING PARTS THAT ALLOW THIS ENGINE TO RUN SMOOTH.

(MIKE)>> AND THE ONLY WAY TO MAKE IT RUN IS WITH THE PISTONS AND RODS. THESE ARE AS BARE BONES AS IT GETS. THE RODS ARE CAST, HAVE A PRESS FIT PIN, WEIGH 660 GRAMS, AND HAVE A SIX-125 CENTER TO CENTER LENGTH. THE PISTONS ARE CAST ALUMINUM THAT HAVE BEEN HEAT TREATED AND CNC MACHINED. NOW UP TOP THEY HAVE A DISH WITH A DSHAPED CUP AND SPORT A 564THS, 564THS, 316THS RING PACK TO SEAL UP THE CYLINDERS. SLICKED UP WITH MOTOR OIL, WE CAN DROP THEM IN USING A RING COMPRESSOR. UNDERNEATH THE CAPS GO ON AND SNUGGING THEM UP WILL

PUT SUFFICIENT CRUST TO THE BEARING, WHICH LETS US ROTATE IT WITHOUT HARMING IT. NOW OUR CLEARANCES ARE ALL IN RANGE JUST LIKE THE MAINS.

ONCE ALL SIX ARE IN WE CAN TORQUE THE NUTS TO 33 POUND FEET.

(PAT)>> THE HEART OF THE ENGINE IS JUST LIKE YOURS AND MINE. ITS JOB IS TO PUMP FLUIDS TO ALL THE VITALS TO KEEP THEM GOING OVER TIME. OURS IS AN M-81 STANDARD VOLUME MELLING THAT'LL DO JUST THAT FOR OUR FOUR LITER. A GASKET AND TWO BOLTS SECURE IT. THE PICK UP MATCHES THE DORMAN OIL PAN WE ORDERED FROM SUMMIT RACING. IT'S CORROSION RESISTANT AND GUARANTEED TO FIT. LIKE ALL PANS INSTALLED HERE, ARP BOLTS WILL CINCH IT DOWN. WITH THE SAME LUBE WE PUT ON THE CAM LOBES FOR PROPER BREAK IN, THE HYDRAULIC FLAT TAPPET LIFTERS CAN DROP IN NOW.

(MIKE)>> BEFORE WE INSTALL THE CYLINDER HEAD, WE WANT TO DO A WEIGHT COMPARISON BETWEEN THE STOCK AND ALUMINUM HEAD. COULD IT BE HALF? THE STOCK HEAD WEIGHS IN AT 66 POUNDS. OUR NEW EDELBROCK PIECE IS 37 POUNDS, FOR A REDUCTION OF 29. SEALING IT TO THE DECK IS THIS EDELBROCK MLS HEAD GASKET. NOW THERE ARE NO DOWELS ON FOURZERO OR FOUR POINT TWO LITER AMC ENGINES TO ALIGN THE GASKET AND THE CYLINDER HEAD. SO HERE'S A QUICK TIP. CUTTING THE HEAD OFF A HALF INCH BOLT AND PUTTING A SMALL NOTCH IN THE TOP FOR A FLATHEAD SCREW DRIVER POINT WILL ALLOW YOU TO ALIGN BOTH. IT'S AN EASY WAY TO INSURE PROPER ALIGNMENT. ARP FASTENERS ARE THE ONLY WAY TO GO. WITH ULTRA TORQUE LUBE WE'LL CINCH THEM DOWN IN THREE STEPS, 35, 70, AND FINALLY 100 POUND FEET.

(PAT)>> LUBING THE BALL ENDS OF THE PUSH RODS PROTECT THEM DURING INITIAL START UP. ANYWHERE HIGH PRESSURE IS PRESENT THIS SHOULD BE DONE, ESPECIALLY THE VALVE STEM. HARLAND SHARP OFFERS A ROLLER ROCKER CONVERSION FOR FOUR LITER ENGINES. THEY'RE A FULL ROLLER PEDESTAL MOUNT WITH THEIR ONE POINT SIX RATIO. LASH IS TOUGH TO SET BECAUSE THE LIFTER PLUNGERS ARE COLLAPSED. SO WE'RE GETTING IT CLOSE. NOW THEY ALL GET TORQUED DOWN AND WHEN WE GET TO THE DYNO ROOM WE'LL PRIME IT AND RELASH.

(ANNOUNCER)>> MANIFOLD GENIUS OR MADNESS?

THE MOTHER OF INVENTION, THAT'S NEXT.

(MIKE)>> WE'RE BACK AT IT AND MOVING ON WITH INDUCTION. NOW WE DID A LITTLE RESEARCH AND FOUND OUT THAT THE '99 AND LATER CHEROKEE INTAKE MANIFOLD HAS A LARGER PLENUM AREA AND SMOOTHER TRANSITION IN THE RUNNERS. AND ALL THAT EQUALS BETTER AIR FLOW. FOR FUEL DELIVERY WE ORDERED THIS FAST EZ EFI SELF LEARNING FUEL INJECTION SYSTEM THAT'S SPECIFICALLY DESIGNED FOR JEEP CJ AND YJ ENGINES

FROM 1972 TO 1991. THE SUPPLIED ADAPTER FROM THE INTAKE TO THE THROTTLE BODY WON'T WORK WITH THE NEWER CHEROKEE INTAKE MANIFOLD. SO WE'RE GONNA PERFORM SOME MAJOR SURGERY UP HERE IN THE PLENUM AREA, AND YOU'RE GONNA LOVE IT.

(PAT)>> AIR AND FUEL DELIVERY ARE THE KEYS TO MAKING POWER, AND THE LESS RESTRICTION YOU HAVE ON THE INTAKE SIDE, THE MORE POWER POTENTIAL YOU HAVE. WE WERE GONNA HAVE TO MODIFY THIS INTAKE ANYWAYS TO ACCEPT THE FAST ADAPTER, SO WHY NOT TAKE IT A STEP FURTHER BY USING THIS ALUMINUM ADAPTER WE FOUND IN OUR PARTS CAGE. AND WE'RE GONNA RECESS IT INTO THE MANIFOLDS PLENUM, AND THAT WILL GIVE US BETTER BREATHING POTENTIAL.

THE PROCESS STARTS BY GRINDING DOWN A COUPLE OF BOSSES. THAT ALLOWS THE ADAPTER TO SIT FLUSH ON PLENUM. TRACING THE OD OF THE ADAPTER TO THE INTAKE HAPPENS NOW. THE TIGHTER THE LINE THE BETTER. TIME TO LET THE CHIPS FLY. WITH A CARBIDE BURR AND A LITTLE TRANS FLUID, THE MATERIAL NOT NEEDED IS GOING AWAY. LET THE BURR DO THE WORK AND TAKE YOUR TIME.

AFTER GOUGING OUT A PATH AND STRUGGLING A BIT, IT'S TIME TO MAKE A BATTLEFIELD DECISION AND SWITCH TO THE AIR SAW. IT'S A BIT MORE PRECISE AND A WHOLE LOT LESS MESSY FOR NOW. WITH THE MIDDLE PART FINALLY OUT I'LL FINE TUNE WITH A CARBIDE AND A FLAPPER ROLL. LET'S SEE HOW IT FITS, OR DOESN'T. BE VERY CAREFUL NOT TO REMOVE TOO MUCH. CHECK OFTEN AND TAKE YOUR TIME. YOU WANT A GOOD FIT SO THE WELDING WILL GO EASIER. COME ON BABY, BONANZA!

(MIKE)>> USING OUR MILLER TIG WELDER, WE'LL TACK IT IN A COUPLE OF PLACES.

THEN BURN IT IN USING FILLER ROD. NOW THERE ARE A COUPLE OF TIGHT SPOTS THAT ARE REALLY TRICKY TO GET WITH THE TIG, BUT IT DIDN'T SLOW US DOWN. NOW CLEAN IT OFF WITH A WIRE BRUSH AND LET IT COOL. IN THE MEAN TIME WE'RE READY FOR OUR FRESHLY PAINTED VALVE COVER. NOW DUPLICOLOR'S WRINKLE PLUS GRAY GAVE THIS

THING A KILLER LOOK. AND ON THE INSIDE PAT REMOVED ALL THE BAFFLING TO CLEAR OUR TALLER ROCKER ARMS.

THE EDELBROCK HEAD ACCEPTS EARLY AND LATE MODEL VALVE COVERS. WE'RE HOLDING OURS ON WITH THE FACTORY HARDWARE.

(PAT)>> THE WATER PUMP CAN GO ON NOW. IT'S A NEW UNIT WE PICKED UP FROM AUTOZONE. THE WATER NECK ALSO CAME FROM THEIR PARTS HOUSE. WE DON'T RUN A THERMOSTAT ON THE DYNO, IT HAS ONE BUILT IN. SINCE THERE AREN'T ANY ACCESSORIES, WE'RE USING A MISTER GASKET ELECTRIC MOTOR AND WATER PUMP PULLEY. IT'S A UNIVERSAL KIT THAT COMES WITH SPACERS AND LOTS OF HARDWARE. THE BRACKET ATTACHES TO TWO BOSSES ON THE BLOCK. IT ALSO ACTS AS A LOCATOR, WHICH DOESN'T GET ANY TENSION DUE TO THE COG DESIGN.

NOW IT'S TIME FOR OUR MODIFIED INDUCTION

AND SOME EXHAUST. RUGGED RIDGE SENT US THIS 304 STAINLESS HEADER THAT'S BEEN POLISHED TO A BEAUTIFUL FINISH. THE PRIMARIES ARE INCH AND A HALF AND WILL COMPLIMENT

OUR FOUR LITER'S POWER POTENTIAL.

THEY INSTALL AT THE SAME TIME SINCE THEY SHARE SEVERAL OF THE SAME FASTENERS. CINCHING DOWN THE ARP'S WILL COMPRESS THE GASKET FOR A GOOD SEAL. AN MSD PRO BILLET DISTRIBUTOR DESIGNED FOR STREET PERFORMANCE IS DROPPING IN. IT HAS BOTH MECHANICAL AND VACUUM ADVANCE. TO KEEP THE TIMING ROCK STEADY AT EVERY RPM WE

LOCKED IT OUT FOR THE DYNO RUNS. ETHREE DIAMOND FIRE SPARK PLUGS WILL IGNITE THE AIR AND FUEL MIX. AND MSD'S PRETERMINATED EIGHT POINT FIVE MILLIMETER SUPER CONDUCTOR WIRES WILL SUPPLY THE VOLT JUICE TO THEM. WITH THE ENGINE AT THIS STAGE OF THE ASSEMBLY WE NEED TO GET IT ON THE DOCKING CART. MAKING IT A SIMPLE TASK FOR US IS OUR KUNDEL OVERHEAD CRANE AND OUR PIT PAL ENGINE SLING.

(ANNOUNCER)>> THE DYNO IS NEXT ON OUR QUEST FOR ONE HORSEPOWER PER CUBIC INCH.

(MIKE)>> WE'RE BACK AND REALLY CLOSE TO HEARING PROJECT 242'S HEARTBEAT COME ALIVE ON THE DYNO.

(PAT)>> THESE LIFTERS ARE PUMPED UP NOW.

(MIKE)>> YEAH, NEED TO CHECK THAT LASH. IT'S PUMPED UP GOOD AT TOP. WHILE PAT'S RELASHING THE VALVES, HERE COMES THE GASKETS AND THROTTLE BRACKET, WHICH GETS COVERED UP BY THIS EFI THROTTLE BODY WHICH HOUSES THE INJECTORS, FUEL RAILS, AND A FEW SENSORS. THE HARNESS IS PRELABELED, MAKING

IT SELF EXPLANATORY. WITH THE THREE POWER LEADS HOOKED UP ALONG WITH THE WEATHERPROOF ECU AND HAND HELD, WE CAN FILL THE CELL WITH 87 OCTANE FUEL.

(PAT)>> AN INSTANT FIRE UP IS ENCOURAGING. WE'LL START THIS SESSION AT 28 DEGREES OF TIMING.

(MIKE)>> BY APPLYING LIGHT LOAD AT MULTIPLE THROTTLE POSITIONS, WE'RE SIMULATING A VEHICLE DRIVING DOWN THE ROAD AS BEST WE CAN. NOW THE INJECTION NEEDS TO SEE THIS FOR ITS ADAPTIVE LEARNING PROCESS. THAT'S 20 MINUTES. COME ON BABY!

(PAT)>> LETS SEE WHAT IT DOES.

(MIKE)>> WE'LL MAKE THE FIRST PULL FROM 2,500 TO 4,000 TO SEE IF THE INJECTION SYSTEM AND OUR HIGHLY MODIFIED MANIFOLD JIVE TOGETHER. 220 FOOT POUNDS OF TORQUE, 133 ON POWER.

(PAT)>> I'M THINKING IT'S NOT THE INJECTION, I'M THINKING IT'S OUR CRAZINESS THAT DID THIS.

(MIKE)>> LET'S SEE WHAT IT DOES. [ engine revving ]

(MIKE)>> OUR MANIFOLD MAGIC MAY HAVE...

(PAT)>> IT'S NOT MAGIC!

(MIKE)>> THERE'S A SERIOUS PROBLEM HERE.

(PAT)>> WELL IT'S NOT THE FAULT OF THE INJECTION.

(MIKE)>> NO, NOT AT ALL.

(PAT)>> UNFORTUNATELY SOME TIMES THINGS DON'T WORK OUT LIKE YOU PLANNED. CASE IN POINT, OUR HIGHLY MODIFIED MANIFOLD.

THE INJECTION SYSTEM WORKS PERFECT. IT STARTS, IT IDLES, IT DOES EVERYTHING IT'S SUPPOSED TO. WHAT THE BIG PROBLEM IS IS OUR MODIFICATIONS TO THE MANIFOLD HAVE CHANGED THE CHARACTERISTICS SO MUCH IT DOESN'T LIKE TO RUN IN THIS CONFIGURATION. SO WHAT WE'RE GONNA DO IS WE'RE GONNA GO OLD SCHOOL ON IT. WE'RE GONNA PUT ON A CARBURETOR AND WE'RE GONNA TRY AND MAKE SOME NOISE WITH IT, AND WE'LL SEE WHAT HAPPENS. THIS IS OUR TRIED AND TRUE 750 CFM DYNO UNIT THAT WAS LAST SEEN ON LITTLE BLACK AND BLUE. IT'S SITTING ON A ONE INCH HVH SPACER AND THE FAST ADAPTER.

WE DON'T KNOW HOW IT'S GONNA ACT ON THIS ENGINE BECAUSE OF ITS SIZE BUT WE KNOW IT'S A GREAT CARB. COME ON, BE GOOD TO US. [ engine revving ]

(MIKE)>> LOADS UP GOOD!

[ engine revving ]

(MIKE)>> YES SIR. WOW, WOW!

LOOK AT THAT TORQUE, 273 FOOT POUNDS, 213 HORSEPOWER. TIMING?

(PAT)>> YEAH, LET'S PUT SOME TIMING IN IT.

AS WITH ANY ENGINE, WE'LL DO OUR NORMAL TUNING PROCEDURE AND ADVANCE THE TIMING IN SMALL INCREMENTS TO FIND ITS THRESHOLD FOR TORQUE, WHICH ENDED

UP AT 34 DEGREES. MAN, RIGHT STRAIGHT THROUGH IT.

(MIKE)>> 228, 283, THRESHOLD.

(PAT)>> THAT'S THRESHOLD, OKAY. SO WE BACKED IT DOWN TO 33 AND MADE A SUBSTANTIAL JET CHANGE FOR OUR LAST ATTEMPT.

(MIKE)>> OUR LAST CHANCE, YOU READY?

(PAT)>> I HOPE SOMETHING GOOD HAPPENS. [ engine revving ]

(MIKE)>> ALRIGHT!

(PAT)>> COME ON!

(MIKE)>> CLEAN PULL! YES, GOT IT, ONE HORSE PER CUBE.

(PAT)>> OH MY GOD THAT'S NICE.

(MIKE)>> HOW IN THE HELL?

(PAT)>> I FEEL SO MUCH BETTER NOW. WE GOT IT BUT WE DIDN'T GET IT BUT WE GOT IT.

(MIKE)>> LOOK AT THE TORQUE, 286.

(PAT)>> THAT IS EXTREMELY IMPRESSIVE.

(MIKE)>> 177, THAT'S 66 HORSEPOWER GAIN.

220, AND 66 ON TORQUE, DOUBLE 66'S.

(PAT)>> HEY IT'S A SIX CYLINDER. WE'RE DONE, WE'RE DONE. LS SWAPS AREN'T SLOWING DOWN AND NEITHER ARE THE COMPANIES THAT SUPPORT THEM. THAT'S WHY DOUG'S ARE OFFERING THESE ONE AND SEVENEIGHTHS LONG TUBES THAT FIT '67 TO '69

CAMAROS AND '68 TO '74 NOVAS THAT ARE GETTING AN LS TRANSPLANT. THE TUBES ARE CNC BENT FOR BETTER FLOW AND

FITMENT, AND THEY'RE MADE OUT OF 16 GAUGE STEEL FOR LONGER LIFE. THEY EVEN HAVE THEIR METALLIC CERAMIC COATING. THEY'RE DESIGNED TO DECREASE BACK PRESSURE AND INCREASE HORSEPOWER AT HIGH RPM. AND THEY EVEN COME WITH EVERYTHING TO INSTALL THEM, LIKE OTWO EXTENSIONS, GASKET, AND THE REST OF THE HARDWARE. THE PRICE, RIGHT AT $650 BUCKS.

(MIKE)>> IT'S BLUE, HAS AN ACME SCREW, AND WILL HELP YOU INSTALL ENGINES AND TRANSMISSIONS. NOW THIS IS MAX PIVOT ARTICULATING ENGINE LIFT PLATE THAT REACHES ANGLES UP TO 35 DEGREES. NOW IT ACCEPTS MOST TWO AND FOUR BARREL CARBURETOR PATTERNS. AND IF YOU'VE GOT A LATE MODEL EFI ENGINE, NO WORRIES. THEY MAKE SEVERAL ADAPTERS TO HAVE YOU COVERED. NOW THIS THING IS MADE OUT OF QUARTER INCH THICK STEEL PLATE AND ALL HARDENED HARDWARE. PLUS THE BLUE POWDER COAT FINISH GIVES IT A GREAT LOOK.

NOW WITH THE WEIGHT OF THE ENGINE HANGING, ALL YOU DO IS ADJUST THE ACME SCREW TO CHANGE THE ANGLE FOR EASY INSTALL. PRICING AS YOU SEE IT HERE IS $159 BUCKS AT SUMMIT RACING.

(PAT)>> SINCE 2007, ALL VEHICLES PRODUCED IN THE US ARE REQUIRED TO HAVE A TIRE PRESSURE MONITORING SYSTEM OR TPMS. IT'S LOCATED ON THE WHEEL INSIDE THE TIRE. SO IT'S IN A PRETTY TOUGH ENVIRONMENT. AND LIKE ALL SENSORS, THEY CAN GO BAD AND THAT CAN REALLY ATTACK YOUR WALLET. SO ROCK AUTO OFFERS SCHRADER TPMS SENSORS THAT ARE A ONE FOR ONE REPLACEMENT FOR THE ONES THAT COME OFF THE ASSEMBLY LINE FOR YOUR VEHICLE. THE COST VARIES ON WHAT RIDE YOU HAVE. SO LOG ONTO ROCK AUTO DOT COM TO GET YOUR LOW PRICE. WELL THAT'S IT FOR US AND WE HOPE IF YOU LEARNED ANYTHING TODAY IS DON'T BE AFRAID TO DO A

LITTLE EXPERIMENTING. AFTER ALL, THAT'S HOW THIS INDUSTRY WAS CREATED. WE'LL SEE YOU NEXT TIME.