More Xtreme Xpedition (D90) Episodes

XOR - Xtreme Off-Road Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Advance Adapters

AX15 Retro Fit Kit Complete

Automotive Workwear

The Official Workwear of Xtreme Offroad

Automotive Workwear

Official Workwear Of Xtreme Off Road

Cummins

R2.8 Turbo Diesel: The First Cummins Crate Engine

Edwards Ironworkers

55 TON EDWARDS IRONWORKER with Hydraulic Accessory Pack option; 10 Ton Bender, 15 Ton Horizontal press,Tubing Roller and 40 Ton Shop Press.

ESAB

The Cutmaster 60i with SL60QD 1Torch is the perfect combination of end-user insight, advanced technology, and intelligent design. Packed with power and offering the highest power-to-weight ratio in its class, the Cutmaster 60i with SL60QD 1Torch also has best in class cutting arc length and the most empowering and engaging user experience no matter the application

ESAB

The Official Welding and Cutting Supplier of Xtreme Off Road, featuring the all-new Rebel 215 Multi-Process Welder

The Industrial Depot

INDUSTRIAL DEPOT - Fasteners, Hardware, And Shop Supplies

Episode Transcript

(NARRATOR)>> OUR DEFENDER EXPEDITION RIG WILL SOON HAVE A BOMB PROOF DRIVETRAIN ONCE WE DROP IN A TURBOCHARGED DIESEL AND A TRANSMISSION CREATED TO HANDLE ALL THAT TORQUE. THIS WEEK ON XTREME OFF ROAD WE GIVE THE LAND ROVER A SHOT OF POWER. PLUS A GOOD PLASMA MACHINE MAKES A BIG DIFFERENCE IN ANY FAB SHOP, AND A WELL EQUIPPED LATE MODEL TACOMA BECOMES A CAPABLE DUAL PURPOSE RIG.

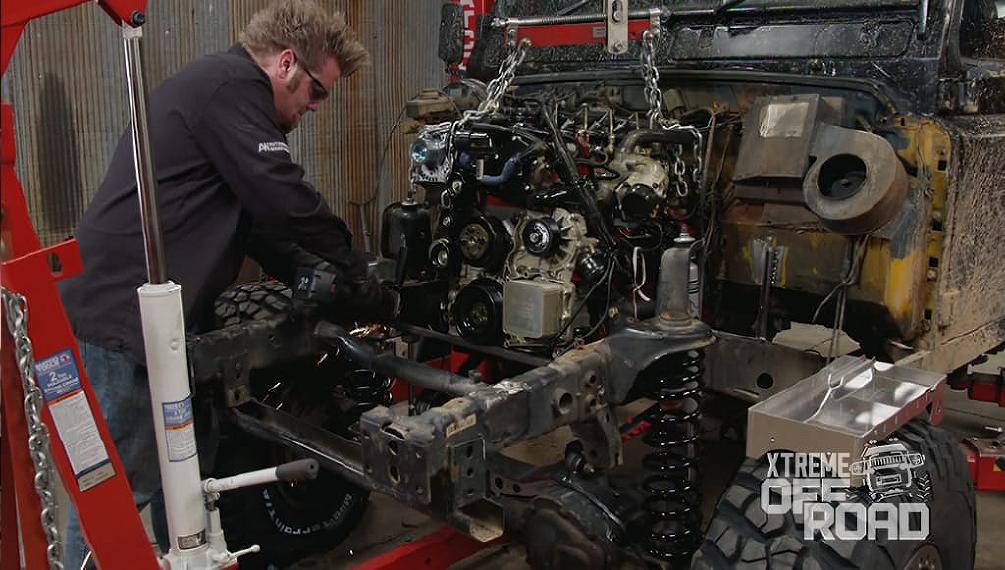

(IAN)>> WE'RE GONNA KICK THINGS OFF TODAY WITH OUR LAND ROVER D-90 PROJECT. NOW IF YOU GUYS REMEMBER, I'VE GOT THIS D-90 BODY JUST MOCKED UP ONTO A JEEP WRANGLER TWO DOOR FRAME, AND THE REASON IT'S JUST MOCKED UP IS BECAUSE BEFORE I COMMITTED TO BUILDING BODY MOUNTS I WANTED TO SEE HOW THE WHEEL AND TIRE FIT INTO THE WHEEL WELLS BECAUSE THE WHEEL BASE IS JUST A LITTLE BIT LONGER. NOW I'VE VERY HAPPY WITH HOW EVERYTHING HAS GONE TOGETHER SO FAR. OBVIOUSLY THE FRONT OF THE TRUCK IS SITTING A LITTLE HIGH IN THE AIR, AND THAT IS BECAUSE THERE'S NO DRIVETRAIN IN THIS CHASSIS PUSHING DOWN ON THE FRONT COIL SPRINGS. NOW THAT IS SOMETHING ELSE THAT COULD CAUSE ME ISSUES WITH THE BODY MOUNTS. I MAY HAVE TO SHIFT THE BODY AROUND A LITTLE BIT FOR THE TRANSMISSION TO FIT INSIDE THAT TUNNEL. SO BEFORE I GO AHEAD AND START BUILDING BODY MOUNTS I WANT TO GET AN ENGINE AND TRANSMISSION SITTING IN THIS FRAME, BUT WHAT ENGINE AND TRANSMISSION? WELL THIS TRUCK DROVE IN HERE WITH A DIESEL ENGINE UNDER THE HOOD. SO IT'S GOT TO DRIVE OUT WITH A DIESEL ENGINE UNDERNEATH THE HOOD, BUT NOT THE ORIGINAL LAND ROVER DIESEL, SOMETHING DIFFERENT. FOR YEARS WHENEVER ANYBODY WANTED TO SWAP A DIESEL ENGINE UNDERNEATH THE HOOD OF THEIR RIG THEY USUALLY WENT WITH TWO POPULAR ENGINE CHOICES, EITHER A FOUR BT OR A SIX BT CUMMINS. NOW THAT WAS FOR GOOD REASON. BOTH OF THOSE ENGINES ARE MECHANICALLY INJECTED DIESELS, MAKING IT VERY EASY TO GET THEM RUNNING UNDERNEATH THE HOOD OF ALMOST ANYTHING. THE PROBLEM IS THEY DON'T HAVE ALL THE BENEFITS THAT NEW MODERN DIESEL ENGINES HAVE. THAT IS WHY CUMMINS REPOWER LAUNCHED A NEW CRATE ENGINE PROGRAM. THESE ARE 100 PERCENT BRAND NEW, NOT REBUILT DIESEL ENGINES, AND THEY ARE DESIGNED FOR ANYBODY WHO WANTS TO SWAP A MODERN DIESEL ENGINE UNDERNEATH THE HOOD OF THEIR VEHICLE. THIS RTWO POINT EIGHT FOUR CYLINDER DIESEL IS A COMMON RAIL ELECTRONICALLY CONTROLLED DIESEL ENGINE, AND IT IS SPECIFICALLY DESIGNED FOR US FOUR WHEEL DRIVE GUYS. CUMMINS RTWO POINT EIGHT DIESEL IS A HIGH PRESSURE COMMON RAIL TURBO DIESEL WITH A WASTE GATED TURBOCHARGER TO PROVIDE A BROAD, EVEN TORQUE CURVE. THE ENGINE COMES READY TO INSTALL WITH ECU, WIRING, THROTTLE PEDAL, ENGINE MOUNTED OIL COOLER, AND A CAM DRIVEN VACUUM PUMP TO PROVIDE VACUUM FOR A BRAKE BOOSTER OR HVAC CONTROLS, AND ALSO A REMOTE OIL FILTER MOUNT TO EASE IN INSTALLATION. THE ENGINE IS PERFECT FOR OUR D-90, WITH 267 FOOT POUNDS OF TORQUE AND 160 HORSEPOWER. THIS DIESEL IS DESIGNED FOR LOW ENGINE SPEEDS WHEN CRAWLING OR CRUISING DOWN THE HIGHWAY, BUT WHAT TRANSMISSION GOES BEHIND THIS LITTLE CUMMINS? NONE OTHER THAN A BRAND NEW AX 15 FROM ADVANCE ADAPTERS. THIS TRANSMISSION IS THE SAME UNIT THAT ADVANCE ADAPTERS USES ON THEIR POPULAR JEEP VEIGHT SWAP PACKAGES. SO BEING ABLE TO HANDLE THE POWER OF OUR DIESEL WILL BE NO PROBLEM. ADVANCE ADAPTERS HAS WORKED WITH CUMMINS REPOWER TO DEVELOP A COMPLETE PACKAGE FOR THE RTWO POINT EIGHT ENGINE. IT INCLUDES AN ADAPTER PLATE FOR THE BLOCK AND THE JEEP FLYWHEEL, AS WELL AS A NEW BELL HOUSING, SHIFT FORK ASSEMBLY AND SLAVE CYLINDER.

[ drill spinning ]

(IAN)>> RIGHT NOW I'M JUST GONNA MOCK THE ENGINE AND TRANSMISSION TOGETHER TO GET IT IN BETWEEN THE FRAME RAILS. NOW THIS PACKAGE FROM ADVANCE ADAPTERS DOES USE A FACTORY JEEP FOUR LITER FLYWHEEL, CLUTCH, AND PRESSURE PLATE ASSEMBLY, BUT I'M NOT GONNA BOLT THAT ONTO THE BACK OF OUR LITTLE DIESEL RIGHT NOW CAUSE I'D HAVE TO GO THROUGH THE HASSLE OF LINING UP THE CLUTCH DISC WITH THE INPUT SHAFT, PUTTING IN OUR CLUTCH FORK, AND OUR SLAVE CYLINDER. THAT'S JUST EXTRA WORK THAT I DON'T NEED TO DO RIGHT CONSIDERING THAT THIS PACKAGE IS PROBABLY GONNA GO IN AND OUT OF THAT FRAME RAIL MULTIPLE TIMES WHILE I BUILD THE MOTOR MOUNTS.

[ drill spinning ]

(IAN)>> WOO!

NOW I KNEW THIS MOTOR WASN'T JUST GONNA DROP IN BETWEEN THESE FRAME RAILS BECAUSE IF YOU GUYS REMEMBER, FROM THE FACTORY, THE DIESEL INSIDE THE D-90 WAS PUSHED ALL THE WAY TO WHAT WOULD BE THE LEFT SIDE, OR PASSENGER SIDE, PART OF THE ENGINE COMPARTMENT IN THIS VEHICLE. SO THE TUNNEL IS WAY OVER TO ONE SIDE. THE AREAS OF CONTACT WE HAVE A PROBLEM WITH RIGHT NOW ARE BASICALLY THE TRANSMISSION IS CONTACTING THAT EXISTING TRANSMISSION TUNNEL, AND THE TURBO OUTLET IS HITTING ON WHAT WOULD BASICALLY BE CALLED THIS FRONT PEDAL BOX ON THE FIREWALL. NOW IT'S NOT A HUGE DEAL BECAUSE THE PEDAL BOX HAS GOT A LOT OF RUST IN IT. I WAS GONNA HAVE TO REPAIR IT ANY WAY. SO I CAN GO AHEAD AND JUST CUT A LITTLE BIT OF AWAY, AND I KNEW THAT I WAS PROBABLY GONNA HAVE MODIFY THAT TUNNEL. ASIDE FROM THAT THE MOTOR IS FITTING IN THERE VERY WELL. I'M SURE SOME OF YOU HAVE NOTICED THAT OUR OIL PAN IS VERY CLOSE TO OUR JEEP JK'S FRONT CROSSMEMBER, AND THAT'S BECAUSE THIS OIL PAN IS ACTUALLY NOT THE OIL PAN THAT'S GONNA END UP ON THE CRATE MOTORS THAT CUMMINS REPOWER SENDS OUT. IT'LL BE THE SAME PAN BUT IT'LL ACTUALLY BE FLIPPED 180 DEGREES. SO MY PLAN RIGHT NOW IS SIMPLE. I'M GONNA PULL THE MOTOR BACK OUT FROM THE FRAME. I'M ACTUALLY GONNA PULL THE STARTER OFF BECAUSE THAT WAS GETTING IN THE WAY WHEN THE MOTOR WAS GOING IN. I'LL SPIN THE OIL PAN, AND THEN START CUTTING.

(NARRATOR)>> UP NEXT WE MAKE OUR D-90 DEPENDABLE BUT DRIVABLE WITH HEAVY DUTY DRIVETRAIN MOUNTS.

(IAN)>> WE ARE BACK ON XTREME WITH OUR D-90 EXPEDITION PROJECT. OH DEAR! PULLING THE CUMMINS FOUR CYLINDER ENGINE AND MANUAL TRANSMISSION OUT FOR A FEW MODIFICATIONS BEFORE THE FINAL MOCK UP CAN TAKE PLACE. MAKING ROOM IN THE TRANSMISSION TUNNEL BY REMOVING THE FLOOR...

...AND TRIMMING OUR TRUCK'S FIREWALL. [ saw cutting metal ]

(IAN)>> ON THE ENGINE THE PAN IS FLIPPED 180 DEGREES. WOO! I WAS ABOUT TO SAY!

AND THE ENTIRE PACKAGE GOES BACK INTO THE TRUCK, SUPPORTED WITH A TEMPORARY BRACE UNDER THE FRONT PULLEY. EVERY NOW AND THEN WHEN YOU'RE TACKLING A HUGE JOB, LIKE FRAME SWAPPING A D-90 ONTO A RIG WITH NEW CUSTOM ONE TON AXLES AND A CUMMINS ENGINE THAT'S NEVER BEEN INSTALLED IN A PROJECT LIKE THIS BEFORE, YOU'RE JUST GONNA GET LUCKY, AND THAT'S EXACTLY WHAT HAPPENED WITH OUR MOTOR MOUNTS. I DIDN'T CUT THE FACTORY MOTOR MOUNT OFF THE FRAME OF THE JK CAUSE I JUST HAD A GOOD FEELING ABOUT WHERE IT WAS LOCATED, AND YOU CAN SEE IT LINES UP PERFECTLY WITH THE FOUR BOSSES ON THE SIDE OF THE BLOCK THAT THE MOTOR MOUNT HAS TO BE BUILT TO. HONESTLY THE EASIEST PART OF THIS JOB IS GONNA BE BUILDING THE MOTOR MOUNTS CAUSE THE MOTOR RIGHT NOW IS IN THE PERFECT POSITION. IT'S LEANING BACK ABOUT THREE DEGREES, IT'S CENTERED IN THE FRAME, THE TRANSMISSION IS CENTERED IN WHAT WILL SOON BE A NEW TRANSMISSION TUNNEL. ALL I HAVE TO DO NOW IS TAKE SOME MEASUREMENTS, START CUTTING SOME STEEL.

THE BLOCK HAS FOUR THREADED BOSSES ON EACH SIDE THAT CAN BE USED FOR THE ENGINE SIDE MOUNT. THREESIXTEENTHS INCH STEEL PLATE IS CUT, PUNCHED, AND BOLTED UP TO THE BLOCK. TUBES ARE THEN CUT TO CONNECT THE TUBE AND THE PLATE TOGETHER.

[ welder crackling ]

(IAN)>> ONCE TACKED, THE MOUNT IS REMOVED TO ADD GUSSETS TO THE TOP AND SIDES OUT OF THREESIXTEENTHS INCH STEEL PLATE, AND THE MOUNT IS THEN FINISH WELDED BEFORE BEING BOLTED BACK INTO THE CHASSIS.

THE FRONT TEMPORARY MOUNT IS THEN REMOVED, AND THE TRUCK IS RAISED UP TO DEAL WITH THE TRANSMISSION. I'M GONNA FABRICATE OUR NEW TRANSMISSION MOUNT RIGHT ON TOP OF THE FACTORY JEEP JK CROSSMEMBER. I'LL JUST MOCK EVERYTHING IN PLACE WITH A STOCK JEEP TJ RUBBER TRANSMISSION MOUNT THAT I'LL LATER SWAP OUT FOR A POLY MOUNT. SO I HAVE BOTH POLY MOUNTS ON THE ENGINE AND THE TRANSMISSION. THE FABRICATED MOUNT WON'T CHANGE BECAUSE THE POLY MOUNT WILL JUST BE A FACTORY REPLACEMENT PIECE.

THREESIXTEENTHS INCH PLATE IS CUT, BENT, AND THE TRANSMISSION IS LOWERED INTO PLACE. THE MOUNT THEN HAS A GUSSET ADDED, OF COURSE, WITH SOME DIMPLE DYES FOR STYLE AND STRENGTH. [ welder crackling ]

(IAN)>> WHEN IT COMES TIME TO BUILD MOUNTS FOR YOUR CUSTOM DRIVETRAIN IN YOUR PROJECT YOU REALLY HAVE THREE DIFFERENT OPTIONS. THE FIRST IS AN OEM RUBBER TYPE MOUNT. NEXT IS SOME TYPE OF POLY URETHANE MOUNT, AND LASTLY IS TO SOLID MOUNT THE DRIVETRAIN IN PLACE WITH SOME THING LIKE THIS MID PLATE THAT GOES BETWEEN THE ENGINE AND THE TRANSMISSION. NOW THERE'S BENEFITS AND DRAWBACKS TO EACH SYSTEM. YOUR CAR PROBABLY LEFT THE FACTORY WITH SOME TYPE OF RUBBER MOUNT. NOW THESE ARE DESIGNED WITH DRIVER COMFORT IN MIND. THEY'RE THERE TO ELIMINATE ANY ENGINE AND DRIVELINE VIBRATION FROM BEING TRANSMITTED INTO THE CHASSIS, AND THEN THEREFORE INTO THE PASSENGER COMPARTMENT. THAT'S GREAT ON A DAILY DRIVING VEHICLE. ON A HIGH HORSEPOWER APPLICATION, WELL YOU'RE ACTUALLY NOT DELIVERING ALL OF THE ENGINE'S POWER INTO THE CHASSIS BECAUSE THE MOUNT CAN FLEX. ON A SERIOUS HIGH HORSEPOWER APPLICATION IT'S VERY EASY FOR THESE MOUNTS TO FAIL. BASICALLY TEAR AWAY FROM THE METAL VULCANIZED MOUNT, AND THEN YOU MOTOR'S BASICALLY FLOPPING AROUND UNDERNEATH YOUR HOOD. SO IF YOU WANT TO GET EVERY INCH OF POWER OUT OF YOUR MOTOR YOU THINK THE NEXT LOGICAL STEP IS SIMPLE. WE'LL JUST SOLID MOUNT THAT ENTIRE DRIVETRAIN INTO THE CHASSIS. NOW YES, 100 PERCENT OF THAT ENGINE'S TORQUE IS NOW TRANSMITTED INTO THE CHASSIS WHERE YOU WANT IT. THE DOWNFALL IS, IS 100 PERCENT OF THE VIBRATIONS ARE PUT THERE AS WELL. THAT'S FINE FOR SOMETHING LIKE A ROCK BOUNCER OR A DRAG RACER. SO WHAT'S THE BEST MIDDLE OF THE ROAD OPTION? WELL SOME TYPE OF POLYURETHANE MOUNT. NOW THIS IS A UNIVERSAL TYPE POLY MOUNT. IT FITS INSIDE A PIECE OF TUBING. THEY DO MAKE FACTORY REPLACEMENT MOUNTS OUT OF POLYURETHANE THAT WILL SIMPLY BOLT IN PLACE OF A STOCK MOTOR MOUNT OR TRANSMISSION MOUNT, BUT THERE IS ONE THING YOU DO NEED TO REMEMBER. IF YOU SWAP OUT YOUR RUBBER MOUNT ON YOUR ENGINE FOR A POLYURETHANE MOUNT YOU HAVE TO DO THE SAME FOR THE TRANSMISSION MOUNT. NO MATTER HOW THE DRIVETRAIN IS MOUNTED, WHETHER IT'S RUBBER, POLY, OR SOLID, EVERY COMPONENT OF THAT ENGINE, TRANSMISSION, AND TRANSFER CASE NEED TO BE MOUNTED THE SAME.

(NARRATOR)>> COMING UP, THIS PLASMA MACHINE IS PORTABLE, PRACTICAL, AND POWERFUL!

(NARRATOR)>> WELDING TECH IS FUELED BY ESAB, MAKER OF THE ALL NEW REBEL AND OFFICIAL WELDING AND CUTTING SUPPLIER OF XTREME OFF ROAD.

(IAN)>> IN THE WORLD OF HARDCORE OFF ROAD RIGS YOU COULD SAY THAT WHEN WE'RE BUILDING SOMETHING WE OFTEN START FROM SCRATCH. ACTUALLY WE START FROM BEFORE SCRATCH. I LIKE TO SAY WE START FROM ITCH BECAUSE EVERY SINGLE PIECE OF A CUSTOM SUSPENSION SYSTEM, ROLL CAGE, OR CHASSIS STARTS LIFE AT THE ESSENCE OF A PART, AND THAT IS BASICALLY FLAT PLATE STEEL OR SOME TYPE OF TUBING. NOW BEFORE YOU CAN BEGIN BUILDING WITH EITHER ONE OF THESE MATERIALS THE FIRST STEP IS QUITE OFTEN CUTTING THE MATERIAL, AND THAT IS WHAT WE'RE GONNA LOOK AT TODAY. DIFFERENT WAYS TO CUT THIS MATERIAL BECAUSE AFTER IT'S BEEN CUT THERE'S USUALLY A SPECIFIC PROCESS THAT NEEDS TO BE FOLLOWED BEFORE YOU START WELDING IT. THE EASIEST WAY TO CUT BRACKETS AND TABS FOR YOUR PROJECT IS WITH YOUR WALLET. YOU CAN ORDER PRECUT TABS AND BRACKETS FROM MANY ONLINE RETAILERS FOR MOST COMMON APPLICATIONS. QUITE OFTEN THEY'RE LASER CUT FROM HIGH QUALITY STEEL READY TO WELD. ANOTHER OPTION IS A VERTICAL BAND SAW. IT MAKES QUICK WORK OF MOST FLAT PLATE AND TUBE. ALTHOUGH PRECISE IT IS A SLOWER PROCESS AND A GOOD BAND SAW WILL EAT UP SOME FLOOR SPACE IN YOUR SHOP. THE GOOD NEWS IS PREP FOR WELDING BOTH OF THESE TYPES OF BRACKETS IS VERY EASY. A QUICK WIPE DOWN TO REMOVE ANY CONTAMINANTS AND YOU'RE READY TO WELD, BUT THERE ARE SOME LIMITATIONS TO THESE TAB CHOICES. OFF THE SHELF TABS HAVE LIMITED DESIGN OPTIONS, AND TABS CUT ON YOUR BAND SAW, YOU CAN MAKE THEM ANY STYLE YOU WANT BUT ADDING A HOLE IS FAIRLY DIFFICULT. SO IF YOU PLAN TO CUT BRACKETS OUT FOR YOUR PROJECT THERE'S A REASON THAT PLASMA CUTTERS ARE KING IN THE FAB SHOP. THEY CAN CUT OUT ANY SHAPE YOU CAN POSSIBLY DRAW WITH YOUR HAND ON MANY DIFFERENT TYPES OF MATERIAL. PLASMA CUTTERS HAVE BENEFITED FROM THE SAME ADVANCES IN TECHNOLOGY THAT MODERN WELDING MACHINES HAVE WITH THE INTRODUCTION OF INVERTER TECHNOLOGY. THE NEWEST MACHINE FROM THERMAL DYNAMICS IS THE CUT MASTER 60-I, AND WE WERE ABLE TO GET OUR HANDS ON ONE THANKS TO OUR PARTNERSHIP WITH ESAB WELDING AND CUTTING. IT'S A MULTI VOLTAGE SINGLE PHASE MACHINE THAT'S CAPABLE OF CUTTING THIN SHEET METAL UP TO AN INCH AND A QUARTER THICK STEEL WITH A 50 PERCENT DUTY CYCLE. THE NEWLY DESIGNED MACHINE IS A VERSATILE, PORTABLE CUTTING BEAST THAT'S EASY TO USE AND POWERFUL. IF YOU'RE PUTTING TOGETHER YOUR FAB SHOP ON A BUDGET THERE'S NO MORE VERSATILE TOOL THAN A PLASMA CUTTER. YEAH, SURE, A BAND SAW CAN CUT STEEL AND SO CAN EVEN AN ANGLE GRINDER WITH A CUTOFF WHEEL, BUT IT'S WHAT ELSE A PLASMA CUTTER CAN CUT THAT MAKES IT A GOOD CHOICE. AXLE TUBES, BRACKETS ON THOSE TUBES, THICK STEEL, THIN STEEL, TUBING, ALUMINUM, AND THE THERMAL DYNAMICS 60-I CAN EVEN BE USED FOR PLASMA ARC GOUGING. A GREAT WAY TO REMOVE A BRACKET FROM A FRAME RAIL WITHOUT DAMAGING THE FRAME. THERE IS A LITTLE BIT OF ADDITIONAL CLEAN UP WITH A PLASMA CUT BRACKET. YOU'LL WANT TO GRIND THE EDGE JUST TO DRESS IT UP AND GET RID OF ANY SLAG OR DRAWS, BUT ONCE YOU GET THE PARAMETERS FINE TUNED FOR YOUR MACHINE YOU CAN MINIMIZE THAT CLEAN UP. IT'S EASY TO SEE WHY A HIGH QUALITY PLASMA CUTTER, LIKE THE THERMAL DYNAMICS 60-I, IS A GREAT ASSET TO YOUR SHOP, AND IT'S NOT ONLY IN THE SHOP. WITH ITS MULTIPLE CARRYING HANDLES AND SMALL DESIGN YOU CAN EASILY TAKE IT OUT IN THE FIELD TO WORK ON YOUR RIG, OR MAYBE KNOCK OUT SOME PROJECTS AT YOUR BUDDY'S HOUSE.

(NARRATOR)>> UP NEXT, A 2011 TACOMA WILL BE TRANSFORMED INTO A SERIOUS DUAL PURPOSE MACHINE.

(IAN)>> NORMALLY IN THE XTREME SHOP WHEN WE SAY WE'RE BRINGING IN A TOYOTA PICK UP TRUCK, WE'RE NORMALLY BRINGING IN A MID '80'S, MAYBE EARLY '90'S PICK UP TRUCK THAT THE PLAN IS TO TURN INTO A HARDCORE ROCK CRAWLER. USUALLY INVOLVES CUTTING THE FRONT SUSPENSION OFF, DOING A SOLID AXLE SWAP, SOME LOCKERS AND SOME TIRES, BUT THE MODERN TOYOTAS, SPECIFICALLY TACOMAS, WELL THEY ARE INCREDIBLY POPULAR AND FOR GOOD REASON. THEY'RE DEFINITELY A GOOD LOOKING TRUCK. THESE ARE POPULAR PRERUNNER TYPE TRUCKS. NOW THAT MEANS LONG TRAVEL SUSPENSION AS WELL AS SOME TYPE OF LONG TRAVEL REAR SUSPENSION, INCREASING THE TRACK WIDTH WITH SOME LARGER WHEELS AND TIRES, NOT HUGE WHEELS AND TIRES. USUALLY SOMEWHERE IN A 33 TO A 35 INCH TIRE. IT HAS A VSIX ENGINE. IT'S AN ALL ALUMINUM VSIX WITH LOTS OF POWER. IT'S ACTUALLY PRETTY IMPRESSIVE WHEN YOU PUT YOUR FOOT DOWN. I MEAN THE TRUCK WOULD GET UP AND GO, AND THAT SAYS A LOT. IT'S A GREAT BASE TRUCK FOR THE PLAN THAT WE HAVE FOR IT. WHAT'S THAT PLAN? WELL THE PLAN IS A LONG TRAVEL PRERUNNER PICK UP. THE SECOND GENERATION OF THE TOYOTA TACOMA WAS INTRODUCED IN 2005 WITH MULTIPLE ENGINE, TRANSMISSION, AND BODY STYLES, AND IT IMMEDIATELY BECAME A HIT WITH THE MID SIZE IMPORT TRUCK MARKET. THE INDEPENDENT FRONT SUSPENSION GAVE THE TRUCK GREAT ON ROAD MANNERS BUT ALSO PROVIDED A STABLE PLATFORM FOR OFF HIGHWAY EXPLORATION. FOR DECADES THE SOLID FRONT AXLE WAS THE FOUNDATION FOR TRUCK SUSPENSION. IT OFFERED DEPENDABLE PERFORMANCE FOR WORK AND OFF ROAD APPLICATIONS. THE MOVE TO IFS OCCURRED WHEN THE ROLE OF THE TRUCK CHANGED. BY ADDING THE INDEPENDENT FRONT SUSPENSION THE TRUCK COULD HANDLE BUMPS A LOT BETTER. IT WAS EASIER TO DRIVE EVERY SINGLE DAY. ADVANCES IN THE FRONT AXLE MEANT THAT WE COULD SHIFT IN AND OUT OF FOUR WHEEL DRIVE JUST FORM INSIDE THE CAB. WE DON'T HAVE TO GET OUT AND LOCK AND UNLOCK THE HUBS. THAT MAKES A HUGE DIFFERENCE TO SOMEONE WHO'S DRIVING THEIR TRUCK AS A FORM OF EVERYDAY TRANSPORTATION VERSUS AN ACTUAL WORK TRUCK, AND WHILE THE SOLID FRONT AXLE REMAINS THE GOLD STANDARD OF RUGGEDNESS AND RELIABILITY, MODERN IFS SETUPS OFFER GREAT DRIVABILITY AND SUSPENSION PERFORMANCE. OUR TACOMA IS A TRD OFF ROAD PACKAGE FOUR WHEEL DRIVE MODEL, MEANING IT LEFT THE FACTORY WITH A SLIGHTLY MORE AGGRESSIVE STANCE, LARGER BF GOODRICH ALL TERRAIN TIRES, AN INBED POWER OUTLET AND DRIVER OPTIONS THAT INCLUDE HILL START ASSIST AND DOWN HILL ASSIST. OUR VERSION COMES WITH A LOCKING REAR DIFFERENTIAL HOUSED INSIDE A DROPOUT STYLE REAR AXLE WITH AN EIGHT INCH RING GEAR AND 30 SPLINE SHAFTS, HUNG ON A SET OF LEAF SPRINGS. UP FRONT IS A SIMILAR EIGHT INCH RING GEAR DIFFERENTIAL WITH 30 SPLINE STUD SHAFTS. WELL WE HAVE PARTNERED WITH THE TEAM FROM BF GOODRICH, THE WINNINGEST TIRE IN OFF ROAD RACING. WITH PODIUMS IN PLACES LIKE SCORE BAJA 1,000, KING OF THE HAMMERS, DAKKAR, AND COMPETITIVE ROCK CRAWLING. TO BUILD A TRUCK TO CELEBRATE THE 40TH ANNIVERSARY OF CREATING THE ALL TERRAIN TIRE CLASS WITH THE KO TWO ALL TERRAIN TIRE, AND ONE OF YOU IS GONNA OWN IT.

Show Full Transcript

(IAN)>> WE'RE GONNA KICK THINGS OFF TODAY WITH OUR LAND ROVER D-90 PROJECT. NOW IF YOU GUYS REMEMBER, I'VE GOT THIS D-90 BODY JUST MOCKED UP ONTO A JEEP WRANGLER TWO DOOR FRAME, AND THE REASON IT'S JUST MOCKED UP IS BECAUSE BEFORE I COMMITTED TO BUILDING BODY MOUNTS I WANTED TO SEE HOW THE WHEEL AND TIRE FIT INTO THE WHEEL WELLS BECAUSE THE WHEEL BASE IS JUST A LITTLE BIT LONGER. NOW I'VE VERY HAPPY WITH HOW EVERYTHING HAS GONE TOGETHER SO FAR. OBVIOUSLY THE FRONT OF THE TRUCK IS SITTING A LITTLE HIGH IN THE AIR, AND THAT IS BECAUSE THERE'S NO DRIVETRAIN IN THIS CHASSIS PUSHING DOWN ON THE FRONT COIL SPRINGS. NOW THAT IS SOMETHING ELSE THAT COULD CAUSE ME ISSUES WITH THE BODY MOUNTS. I MAY HAVE TO SHIFT THE BODY AROUND A LITTLE BIT FOR THE TRANSMISSION TO FIT INSIDE THAT TUNNEL. SO BEFORE I GO AHEAD AND START BUILDING BODY MOUNTS I WANT TO GET AN ENGINE AND TRANSMISSION SITTING IN THIS FRAME, BUT WHAT ENGINE AND TRANSMISSION? WELL THIS TRUCK DROVE IN HERE WITH A DIESEL ENGINE UNDER THE HOOD. SO IT'S GOT TO DRIVE OUT WITH A DIESEL ENGINE UNDERNEATH THE HOOD, BUT NOT THE ORIGINAL LAND ROVER DIESEL, SOMETHING DIFFERENT. FOR YEARS WHENEVER ANYBODY WANTED TO SWAP A DIESEL ENGINE UNDERNEATH THE HOOD OF THEIR RIG THEY USUALLY WENT WITH TWO POPULAR ENGINE CHOICES, EITHER A FOUR BT OR A SIX BT CUMMINS. NOW THAT WAS FOR GOOD REASON. BOTH OF THOSE ENGINES ARE MECHANICALLY INJECTED DIESELS, MAKING IT VERY EASY TO GET THEM RUNNING UNDERNEATH THE HOOD OF ALMOST ANYTHING. THE PROBLEM IS THEY DON'T HAVE ALL THE BENEFITS THAT NEW MODERN DIESEL ENGINES HAVE. THAT IS WHY CUMMINS REPOWER LAUNCHED A NEW CRATE ENGINE PROGRAM. THESE ARE 100 PERCENT BRAND NEW, NOT REBUILT DIESEL ENGINES, AND THEY ARE DESIGNED FOR ANYBODY WHO WANTS TO SWAP A MODERN DIESEL ENGINE UNDERNEATH THE HOOD OF THEIR VEHICLE. THIS RTWO POINT EIGHT FOUR CYLINDER DIESEL IS A COMMON RAIL ELECTRONICALLY CONTROLLED DIESEL ENGINE, AND IT IS SPECIFICALLY DESIGNED FOR US FOUR WHEEL DRIVE GUYS. CUMMINS RTWO POINT EIGHT DIESEL IS A HIGH PRESSURE COMMON RAIL TURBO DIESEL WITH A WASTE GATED TURBOCHARGER TO PROVIDE A BROAD, EVEN TORQUE CURVE. THE ENGINE COMES READY TO INSTALL WITH ECU, WIRING, THROTTLE PEDAL, ENGINE MOUNTED OIL COOLER, AND A CAM DRIVEN VACUUM PUMP TO PROVIDE VACUUM FOR A BRAKE BOOSTER OR HVAC CONTROLS, AND ALSO A REMOTE OIL FILTER MOUNT TO EASE IN INSTALLATION. THE ENGINE IS PERFECT FOR OUR D-90, WITH 267 FOOT POUNDS OF TORQUE AND 160 HORSEPOWER. THIS DIESEL IS DESIGNED FOR LOW ENGINE SPEEDS WHEN CRAWLING OR CRUISING DOWN THE HIGHWAY, BUT WHAT TRANSMISSION GOES BEHIND THIS LITTLE CUMMINS? NONE OTHER THAN A BRAND NEW AX 15 FROM ADVANCE ADAPTERS. THIS TRANSMISSION IS THE SAME UNIT THAT ADVANCE ADAPTERS USES ON THEIR POPULAR JEEP VEIGHT SWAP PACKAGES. SO BEING ABLE TO HANDLE THE POWER OF OUR DIESEL WILL BE NO PROBLEM. ADVANCE ADAPTERS HAS WORKED WITH CUMMINS REPOWER TO DEVELOP A COMPLETE PACKAGE FOR THE RTWO POINT EIGHT ENGINE. IT INCLUDES AN ADAPTER PLATE FOR THE BLOCK AND THE JEEP FLYWHEEL, AS WELL AS A NEW BELL HOUSING, SHIFT FORK ASSEMBLY AND SLAVE CYLINDER.

[ drill spinning ]

(IAN)>> RIGHT NOW I'M JUST GONNA MOCK THE ENGINE AND TRANSMISSION TOGETHER TO GET IT IN BETWEEN THE FRAME RAILS. NOW THIS PACKAGE FROM ADVANCE ADAPTERS DOES USE A FACTORY JEEP FOUR LITER FLYWHEEL, CLUTCH, AND PRESSURE PLATE ASSEMBLY, BUT I'M NOT GONNA BOLT THAT ONTO THE BACK OF OUR LITTLE DIESEL RIGHT NOW CAUSE I'D HAVE TO GO THROUGH THE HASSLE OF LINING UP THE CLUTCH DISC WITH THE INPUT SHAFT, PUTTING IN OUR CLUTCH FORK, AND OUR SLAVE CYLINDER. THAT'S JUST EXTRA WORK THAT I DON'T NEED TO DO RIGHT CONSIDERING THAT THIS PACKAGE IS PROBABLY GONNA GO IN AND OUT OF THAT FRAME RAIL MULTIPLE TIMES WHILE I BUILD THE MOTOR MOUNTS.

[ drill spinning ]

(IAN)>> WOO!

NOW I KNEW THIS MOTOR WASN'T JUST GONNA DROP IN BETWEEN THESE FRAME RAILS BECAUSE IF YOU GUYS REMEMBER, FROM THE FACTORY, THE DIESEL INSIDE THE D-90 WAS PUSHED ALL THE WAY TO WHAT WOULD BE THE LEFT SIDE, OR PASSENGER SIDE, PART OF THE ENGINE COMPARTMENT IN THIS VEHICLE. SO THE TUNNEL IS WAY OVER TO ONE SIDE. THE AREAS OF CONTACT WE HAVE A PROBLEM WITH RIGHT NOW ARE BASICALLY THE TRANSMISSION IS CONTACTING THAT EXISTING TRANSMISSION TUNNEL, AND THE TURBO OUTLET IS HITTING ON WHAT WOULD BASICALLY BE CALLED THIS FRONT PEDAL BOX ON THE FIREWALL. NOW IT'S NOT A HUGE DEAL BECAUSE THE PEDAL BOX HAS GOT A LOT OF RUST IN IT. I WAS GONNA HAVE TO REPAIR IT ANY WAY. SO I CAN GO AHEAD AND JUST CUT A LITTLE BIT OF AWAY, AND I KNEW THAT I WAS PROBABLY GONNA HAVE MODIFY THAT TUNNEL. ASIDE FROM THAT THE MOTOR IS FITTING IN THERE VERY WELL. I'M SURE SOME OF YOU HAVE NOTICED THAT OUR OIL PAN IS VERY CLOSE TO OUR JEEP JK'S FRONT CROSSMEMBER, AND THAT'S BECAUSE THIS OIL PAN IS ACTUALLY NOT THE OIL PAN THAT'S GONNA END UP ON THE CRATE MOTORS THAT CUMMINS REPOWER SENDS OUT. IT'LL BE THE SAME PAN BUT IT'LL ACTUALLY BE FLIPPED 180 DEGREES. SO MY PLAN RIGHT NOW IS SIMPLE. I'M GONNA PULL THE MOTOR BACK OUT FROM THE FRAME. I'M ACTUALLY GONNA PULL THE STARTER OFF BECAUSE THAT WAS GETTING IN THE WAY WHEN THE MOTOR WAS GOING IN. I'LL SPIN THE OIL PAN, AND THEN START CUTTING.

(NARRATOR)>> UP NEXT WE MAKE OUR D-90 DEPENDABLE BUT DRIVABLE WITH HEAVY DUTY DRIVETRAIN MOUNTS.

(IAN)>> WE ARE BACK ON XTREME WITH OUR D-90 EXPEDITION PROJECT. OH DEAR! PULLING THE CUMMINS FOUR CYLINDER ENGINE AND MANUAL TRANSMISSION OUT FOR A FEW MODIFICATIONS BEFORE THE FINAL MOCK UP CAN TAKE PLACE. MAKING ROOM IN THE TRANSMISSION TUNNEL BY REMOVING THE FLOOR...

...AND TRIMMING OUR TRUCK'S FIREWALL. [ saw cutting metal ]

(IAN)>> ON THE ENGINE THE PAN IS FLIPPED 180 DEGREES. WOO! I WAS ABOUT TO SAY!

AND THE ENTIRE PACKAGE GOES BACK INTO THE TRUCK, SUPPORTED WITH A TEMPORARY BRACE UNDER THE FRONT PULLEY. EVERY NOW AND THEN WHEN YOU'RE TACKLING A HUGE JOB, LIKE FRAME SWAPPING A D-90 ONTO A RIG WITH NEW CUSTOM ONE TON AXLES AND A CUMMINS ENGINE THAT'S NEVER BEEN INSTALLED IN A PROJECT LIKE THIS BEFORE, YOU'RE JUST GONNA GET LUCKY, AND THAT'S EXACTLY WHAT HAPPENED WITH OUR MOTOR MOUNTS. I DIDN'T CUT THE FACTORY MOTOR MOUNT OFF THE FRAME OF THE JK CAUSE I JUST HAD A GOOD FEELING ABOUT WHERE IT WAS LOCATED, AND YOU CAN SEE IT LINES UP PERFECTLY WITH THE FOUR BOSSES ON THE SIDE OF THE BLOCK THAT THE MOTOR MOUNT HAS TO BE BUILT TO. HONESTLY THE EASIEST PART OF THIS JOB IS GONNA BE BUILDING THE MOTOR MOUNTS CAUSE THE MOTOR RIGHT NOW IS IN THE PERFECT POSITION. IT'S LEANING BACK ABOUT THREE DEGREES, IT'S CENTERED IN THE FRAME, THE TRANSMISSION IS CENTERED IN WHAT WILL SOON BE A NEW TRANSMISSION TUNNEL. ALL I HAVE TO DO NOW IS TAKE SOME MEASUREMENTS, START CUTTING SOME STEEL.

THE BLOCK HAS FOUR THREADED BOSSES ON EACH SIDE THAT CAN BE USED FOR THE ENGINE SIDE MOUNT. THREESIXTEENTHS INCH STEEL PLATE IS CUT, PUNCHED, AND BOLTED UP TO THE BLOCK. TUBES ARE THEN CUT TO CONNECT THE TUBE AND THE PLATE TOGETHER.

[ welder crackling ]

(IAN)>> ONCE TACKED, THE MOUNT IS REMOVED TO ADD GUSSETS TO THE TOP AND SIDES OUT OF THREESIXTEENTHS INCH STEEL PLATE, AND THE MOUNT IS THEN FINISH WELDED BEFORE BEING BOLTED BACK INTO THE CHASSIS.

THE FRONT TEMPORARY MOUNT IS THEN REMOVED, AND THE TRUCK IS RAISED UP TO DEAL WITH THE TRANSMISSION. I'M GONNA FABRICATE OUR NEW TRANSMISSION MOUNT RIGHT ON TOP OF THE FACTORY JEEP JK CROSSMEMBER. I'LL JUST MOCK EVERYTHING IN PLACE WITH A STOCK JEEP TJ RUBBER TRANSMISSION MOUNT THAT I'LL LATER SWAP OUT FOR A POLY MOUNT. SO I HAVE BOTH POLY MOUNTS ON THE ENGINE AND THE TRANSMISSION. THE FABRICATED MOUNT WON'T CHANGE BECAUSE THE POLY MOUNT WILL JUST BE A FACTORY REPLACEMENT PIECE.

THREESIXTEENTHS INCH PLATE IS CUT, BENT, AND THE TRANSMISSION IS LOWERED INTO PLACE. THE MOUNT THEN HAS A GUSSET ADDED, OF COURSE, WITH SOME DIMPLE DYES FOR STYLE AND STRENGTH. [ welder crackling ]

(IAN)>> WHEN IT COMES TIME TO BUILD MOUNTS FOR YOUR CUSTOM DRIVETRAIN IN YOUR PROJECT YOU REALLY HAVE THREE DIFFERENT OPTIONS. THE FIRST IS AN OEM RUBBER TYPE MOUNT. NEXT IS SOME TYPE OF POLY URETHANE MOUNT, AND LASTLY IS TO SOLID MOUNT THE DRIVETRAIN IN PLACE WITH SOME THING LIKE THIS MID PLATE THAT GOES BETWEEN THE ENGINE AND THE TRANSMISSION. NOW THERE'S BENEFITS AND DRAWBACKS TO EACH SYSTEM. YOUR CAR PROBABLY LEFT THE FACTORY WITH SOME TYPE OF RUBBER MOUNT. NOW THESE ARE DESIGNED WITH DRIVER COMFORT IN MIND. THEY'RE THERE TO ELIMINATE ANY ENGINE AND DRIVELINE VIBRATION FROM BEING TRANSMITTED INTO THE CHASSIS, AND THEN THEREFORE INTO THE PASSENGER COMPARTMENT. THAT'S GREAT ON A DAILY DRIVING VEHICLE. ON A HIGH HORSEPOWER APPLICATION, WELL YOU'RE ACTUALLY NOT DELIVERING ALL OF THE ENGINE'S POWER INTO THE CHASSIS BECAUSE THE MOUNT CAN FLEX. ON A SERIOUS HIGH HORSEPOWER APPLICATION IT'S VERY EASY FOR THESE MOUNTS TO FAIL. BASICALLY TEAR AWAY FROM THE METAL VULCANIZED MOUNT, AND THEN YOU MOTOR'S BASICALLY FLOPPING AROUND UNDERNEATH YOUR HOOD. SO IF YOU WANT TO GET EVERY INCH OF POWER OUT OF YOUR MOTOR YOU THINK THE NEXT LOGICAL STEP IS SIMPLE. WE'LL JUST SOLID MOUNT THAT ENTIRE DRIVETRAIN INTO THE CHASSIS. NOW YES, 100 PERCENT OF THAT ENGINE'S TORQUE IS NOW TRANSMITTED INTO THE CHASSIS WHERE YOU WANT IT. THE DOWNFALL IS, IS 100 PERCENT OF THE VIBRATIONS ARE PUT THERE AS WELL. THAT'S FINE FOR SOMETHING LIKE A ROCK BOUNCER OR A DRAG RACER. SO WHAT'S THE BEST MIDDLE OF THE ROAD OPTION? WELL SOME TYPE OF POLYURETHANE MOUNT. NOW THIS IS A UNIVERSAL TYPE POLY MOUNT. IT FITS INSIDE A PIECE OF TUBING. THEY DO MAKE FACTORY REPLACEMENT MOUNTS OUT OF POLYURETHANE THAT WILL SIMPLY BOLT IN PLACE OF A STOCK MOTOR MOUNT OR TRANSMISSION MOUNT, BUT THERE IS ONE THING YOU DO NEED TO REMEMBER. IF YOU SWAP OUT YOUR RUBBER MOUNT ON YOUR ENGINE FOR A POLYURETHANE MOUNT YOU HAVE TO DO THE SAME FOR THE TRANSMISSION MOUNT. NO MATTER HOW THE DRIVETRAIN IS MOUNTED, WHETHER IT'S RUBBER, POLY, OR SOLID, EVERY COMPONENT OF THAT ENGINE, TRANSMISSION, AND TRANSFER CASE NEED TO BE MOUNTED THE SAME.

(NARRATOR)>> COMING UP, THIS PLASMA MACHINE IS PORTABLE, PRACTICAL, AND POWERFUL!

(NARRATOR)>> WELDING TECH IS FUELED BY ESAB, MAKER OF THE ALL NEW REBEL AND OFFICIAL WELDING AND CUTTING SUPPLIER OF XTREME OFF ROAD.

(IAN)>> IN THE WORLD OF HARDCORE OFF ROAD RIGS YOU COULD SAY THAT WHEN WE'RE BUILDING SOMETHING WE OFTEN START FROM SCRATCH. ACTUALLY WE START FROM BEFORE SCRATCH. I LIKE TO SAY WE START FROM ITCH BECAUSE EVERY SINGLE PIECE OF A CUSTOM SUSPENSION SYSTEM, ROLL CAGE, OR CHASSIS STARTS LIFE AT THE ESSENCE OF A PART, AND THAT IS BASICALLY FLAT PLATE STEEL OR SOME TYPE OF TUBING. NOW BEFORE YOU CAN BEGIN BUILDING WITH EITHER ONE OF THESE MATERIALS THE FIRST STEP IS QUITE OFTEN CUTTING THE MATERIAL, AND THAT IS WHAT WE'RE GONNA LOOK AT TODAY. DIFFERENT WAYS TO CUT THIS MATERIAL BECAUSE AFTER IT'S BEEN CUT THERE'S USUALLY A SPECIFIC PROCESS THAT NEEDS TO BE FOLLOWED BEFORE YOU START WELDING IT. THE EASIEST WAY TO CUT BRACKETS AND TABS FOR YOUR PROJECT IS WITH YOUR WALLET. YOU CAN ORDER PRECUT TABS AND BRACKETS FROM MANY ONLINE RETAILERS FOR MOST COMMON APPLICATIONS. QUITE OFTEN THEY'RE LASER CUT FROM HIGH QUALITY STEEL READY TO WELD. ANOTHER OPTION IS A VERTICAL BAND SAW. IT MAKES QUICK WORK OF MOST FLAT PLATE AND TUBE. ALTHOUGH PRECISE IT IS A SLOWER PROCESS AND A GOOD BAND SAW WILL EAT UP SOME FLOOR SPACE IN YOUR SHOP. THE GOOD NEWS IS PREP FOR WELDING BOTH OF THESE TYPES OF BRACKETS IS VERY EASY. A QUICK WIPE DOWN TO REMOVE ANY CONTAMINANTS AND YOU'RE READY TO WELD, BUT THERE ARE SOME LIMITATIONS TO THESE TAB CHOICES. OFF THE SHELF TABS HAVE LIMITED DESIGN OPTIONS, AND TABS CUT ON YOUR BAND SAW, YOU CAN MAKE THEM ANY STYLE YOU WANT BUT ADDING A HOLE IS FAIRLY DIFFICULT. SO IF YOU PLAN TO CUT BRACKETS OUT FOR YOUR PROJECT THERE'S A REASON THAT PLASMA CUTTERS ARE KING IN THE FAB SHOP. THEY CAN CUT OUT ANY SHAPE YOU CAN POSSIBLY DRAW WITH YOUR HAND ON MANY DIFFERENT TYPES OF MATERIAL. PLASMA CUTTERS HAVE BENEFITED FROM THE SAME ADVANCES IN TECHNOLOGY THAT MODERN WELDING MACHINES HAVE WITH THE INTRODUCTION OF INVERTER TECHNOLOGY. THE NEWEST MACHINE FROM THERMAL DYNAMICS IS THE CUT MASTER 60-I, AND WE WERE ABLE TO GET OUR HANDS ON ONE THANKS TO OUR PARTNERSHIP WITH ESAB WELDING AND CUTTING. IT'S A MULTI VOLTAGE SINGLE PHASE MACHINE THAT'S CAPABLE OF CUTTING THIN SHEET METAL UP TO AN INCH AND A QUARTER THICK STEEL WITH A 50 PERCENT DUTY CYCLE. THE NEWLY DESIGNED MACHINE IS A VERSATILE, PORTABLE CUTTING BEAST THAT'S EASY TO USE AND POWERFUL. IF YOU'RE PUTTING TOGETHER YOUR FAB SHOP ON A BUDGET THERE'S NO MORE VERSATILE TOOL THAN A PLASMA CUTTER. YEAH, SURE, A BAND SAW CAN CUT STEEL AND SO CAN EVEN AN ANGLE GRINDER WITH A CUTOFF WHEEL, BUT IT'S WHAT ELSE A PLASMA CUTTER CAN CUT THAT MAKES IT A GOOD CHOICE. AXLE TUBES, BRACKETS ON THOSE TUBES, THICK STEEL, THIN STEEL, TUBING, ALUMINUM, AND THE THERMAL DYNAMICS 60-I CAN EVEN BE USED FOR PLASMA ARC GOUGING. A GREAT WAY TO REMOVE A BRACKET FROM A FRAME RAIL WITHOUT DAMAGING THE FRAME. THERE IS A LITTLE BIT OF ADDITIONAL CLEAN UP WITH A PLASMA CUT BRACKET. YOU'LL WANT TO GRIND THE EDGE JUST TO DRESS IT UP AND GET RID OF ANY SLAG OR DRAWS, BUT ONCE YOU GET THE PARAMETERS FINE TUNED FOR YOUR MACHINE YOU CAN MINIMIZE THAT CLEAN UP. IT'S EASY TO SEE WHY A HIGH QUALITY PLASMA CUTTER, LIKE THE THERMAL DYNAMICS 60-I, IS A GREAT ASSET TO YOUR SHOP, AND IT'S NOT ONLY IN THE SHOP. WITH ITS MULTIPLE CARRYING HANDLES AND SMALL DESIGN YOU CAN EASILY TAKE IT OUT IN THE FIELD TO WORK ON YOUR RIG, OR MAYBE KNOCK OUT SOME PROJECTS AT YOUR BUDDY'S HOUSE.

(NARRATOR)>> UP NEXT, A 2011 TACOMA WILL BE TRANSFORMED INTO A SERIOUS DUAL PURPOSE MACHINE.

(IAN)>> NORMALLY IN THE XTREME SHOP WHEN WE SAY WE'RE BRINGING IN A TOYOTA PICK UP TRUCK, WE'RE NORMALLY BRINGING IN A MID '80'S, MAYBE EARLY '90'S PICK UP TRUCK THAT THE PLAN IS TO TURN INTO A HARDCORE ROCK CRAWLER. USUALLY INVOLVES CUTTING THE FRONT SUSPENSION OFF, DOING A SOLID AXLE SWAP, SOME LOCKERS AND SOME TIRES, BUT THE MODERN TOYOTAS, SPECIFICALLY TACOMAS, WELL THEY ARE INCREDIBLY POPULAR AND FOR GOOD REASON. THEY'RE DEFINITELY A GOOD LOOKING TRUCK. THESE ARE POPULAR PRERUNNER TYPE TRUCKS. NOW THAT MEANS LONG TRAVEL SUSPENSION AS WELL AS SOME TYPE OF LONG TRAVEL REAR SUSPENSION, INCREASING THE TRACK WIDTH WITH SOME LARGER WHEELS AND TIRES, NOT HUGE WHEELS AND TIRES. USUALLY SOMEWHERE IN A 33 TO A 35 INCH TIRE. IT HAS A VSIX ENGINE. IT'S AN ALL ALUMINUM VSIX WITH LOTS OF POWER. IT'S ACTUALLY PRETTY IMPRESSIVE WHEN YOU PUT YOUR FOOT DOWN. I MEAN THE TRUCK WOULD GET UP AND GO, AND THAT SAYS A LOT. IT'S A GREAT BASE TRUCK FOR THE PLAN THAT WE HAVE FOR IT. WHAT'S THAT PLAN? WELL THE PLAN IS A LONG TRAVEL PRERUNNER PICK UP. THE SECOND GENERATION OF THE TOYOTA TACOMA WAS INTRODUCED IN 2005 WITH MULTIPLE ENGINE, TRANSMISSION, AND BODY STYLES, AND IT IMMEDIATELY BECAME A HIT WITH THE MID SIZE IMPORT TRUCK MARKET. THE INDEPENDENT FRONT SUSPENSION GAVE THE TRUCK GREAT ON ROAD MANNERS BUT ALSO PROVIDED A STABLE PLATFORM FOR OFF HIGHWAY EXPLORATION. FOR DECADES THE SOLID FRONT AXLE WAS THE FOUNDATION FOR TRUCK SUSPENSION. IT OFFERED DEPENDABLE PERFORMANCE FOR WORK AND OFF ROAD APPLICATIONS. THE MOVE TO IFS OCCURRED WHEN THE ROLE OF THE TRUCK CHANGED. BY ADDING THE INDEPENDENT FRONT SUSPENSION THE TRUCK COULD HANDLE BUMPS A LOT BETTER. IT WAS EASIER TO DRIVE EVERY SINGLE DAY. ADVANCES IN THE FRONT AXLE MEANT THAT WE COULD SHIFT IN AND OUT OF FOUR WHEEL DRIVE JUST FORM INSIDE THE CAB. WE DON'T HAVE TO GET OUT AND LOCK AND UNLOCK THE HUBS. THAT MAKES A HUGE DIFFERENCE TO SOMEONE WHO'S DRIVING THEIR TRUCK AS A FORM OF EVERYDAY TRANSPORTATION VERSUS AN ACTUAL WORK TRUCK, AND WHILE THE SOLID FRONT AXLE REMAINS THE GOLD STANDARD OF RUGGEDNESS AND RELIABILITY, MODERN IFS SETUPS OFFER GREAT DRIVABILITY AND SUSPENSION PERFORMANCE. OUR TACOMA IS A TRD OFF ROAD PACKAGE FOUR WHEEL DRIVE MODEL, MEANING IT LEFT THE FACTORY WITH A SLIGHTLY MORE AGGRESSIVE STANCE, LARGER BF GOODRICH ALL TERRAIN TIRES, AN INBED POWER OUTLET AND DRIVER OPTIONS THAT INCLUDE HILL START ASSIST AND DOWN HILL ASSIST. OUR VERSION COMES WITH A LOCKING REAR DIFFERENTIAL HOUSED INSIDE A DROPOUT STYLE REAR AXLE WITH AN EIGHT INCH RING GEAR AND 30 SPLINE SHAFTS, HUNG ON A SET OF LEAF SPRINGS. UP FRONT IS A SIMILAR EIGHT INCH RING GEAR DIFFERENTIAL WITH 30 SPLINE STUD SHAFTS. WELL WE HAVE PARTNERED WITH THE TEAM FROM BF GOODRICH, THE WINNINGEST TIRE IN OFF ROAD RACING. WITH PODIUMS IN PLACES LIKE SCORE BAJA 1,000, KING OF THE HAMMERS, DAKKAR, AND COMPETITIVE ROCK CRAWLING. TO BUILD A TRUCK TO CELEBRATE THE 40TH ANNIVERSARY OF CREATING THE ALL TERRAIN TIRE CLASS WITH THE KO TWO ALL TERRAIN TIRE, AND ONE OF YOU IS GONNA OWN IT.