More '74 Dodge Dart "Pro-Street Dodge" Episodes

More Hurst Olds Episodes

MuscleCar Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Competition Engineering

Coil-Over Shock Kit, Twin-Tube Shock, Universal, Drag Race, Rear, Kit

Dupli-Color

Paint, Engine, Enamel with Ceramic Resin, Semi-Gloss, Black, 12 oz., Aerosol, Each

Weld Racing LLC

Wheel, Classic RT, Aluminum, Polished, 15 in. x 16 in., 5 x 4.5 in. Bolt Circle, 6.5 in. Backspace, Each

Weld Racing LLC

Wheel, Classic RT, Aluminum, Polished, 15 in. x 4 in., 5 x 4.5 in. Bolt Circle, 1.5 in. Backspace, Each

Moser Engineering

DANA 60- 21 1/2 - 20 1/2, 5 X 4.5, 6.350,2.780 TORINO 35 SPLINE TRUE-TRAC, 4.56

Reilly Motorsports

AlterKtion Coil-Over System, Street/Strip, 67-76 A-body

Wilwood Engineering

Brake Kit, HD, Mustang II / Pinto

Wilwood Engineering

Brake Kit, Pro-Street, Rear, Big Ford Bearing

YearOne

Muscle Car Restoration and Performance Parts

Episode Transcript

(ANNOUNCER)>> TODAY ON MUSCLE

CAR, HOW TO GET A UNIBODY DODGE READY FOR MASSIVE

STREET/STRIP POWER WITH A TRICKED OUT FRONT SUSPENSION. PLUS HOW TO BACK HALF AND HANG

FOUR LINK SUSPENSION TO A DANA STYLE REAR AND A CUSTOM

SPOILER FROM SCRATCH.

(RICK)>> HEY GUYS, HOW'S IT GOING? I SURE HOPE YOU HAVE AN APPETITE FOR SUSPENSION TODAY BECAUSE WE HAVE A VEHICLE OVER HERE IN DIRE NEED OF SOME ATTENTION. NOW LAST TIME WE GOT STARTED ON CONVERTING THIS THING INTO OUR PRO STREET STYLE MOPAR.

IT'S A 1974 DODGE DART THAT WE AFFECTIONATELY

REFER TO AS BUSINESS TIME.

(TOMMY)>> WE PICKED THIS THING UP FOR $4,500 BUCKS, WHICH ISN'T HALF BAD CONSIDERING A PERSON COULD USE IT FOR A DAILY DRIVER.

(RICK)>> NOW SINCE WE'RE GONNA BE REPLACING THE 360, THE FRONT KMEMBER, WELL PRETTY MUCH EVERYTHING UNDERNEATH THIS THING, RATHER THAN TRY TO PIECE MEAL APART WE'RE JUST

GONNA DROP THE BOLTS OUT AND DROP THE WHOLE THING OUT FROM UNDERNEATH. JUST HAVE TO UNDO THAT AND THEN DROP OUT THE FOUR BOLTS RIGHT THERE AND THERE, AND THE WHOLE THING WILL DROP

RIGHT OUT THE BOTTOM. THE TORSION BARS CAN BE A REAL PAIN TO GET OUT. SINCE REPLACEMENTS ARE AVAILABLE IN THE AFTERMARKET, WE'RE GONNA GO AHEAD AND JUST TORCH THESE OUT.

(TOMMY)>> WE KNEW WE NEEDED TO UPGRADE OUR KMEMBER AND FRONT SUSPENSION BECAUSE WE'RE PLANNING ON THROWING ENOUGH POWER AT THIS OLD MOPAR TO DANG NEAR SEND IT TO THE MOON. SO WE GAVE RILEY MOTORSPORTS A CALL AND THEY HAD EXACTLY WHAT WE NEEDED.

IN ORDER TO MAKE ROOM FOR THE NEW KMEMBER WE'VE GOT TO GET RID OF THE FACTORY BUMP STOPS. DRILLING OUT THESE SPOT WELDS HELPS KEEP DOWN THE AMOUNT OF TORCHING I'LL HAVE TO DO. THAT REDUCES THE AMOUNT OF TORCH DAMAGE YOU COULD END UP WITH AND HAVE TO GO BACK AND FIX. MAKE SURE YOU DO FILL ANY HOLES. A COAT OF DUPLICOLOR ETCH PRIMER AND SOME SEMI GLOSS BLACK WILL PROTECT IT AND MAKE IT LOOK REAL NICE. AND THEN WE CAN PLUG IN OUR NEW SHINY KMEMBER.

(RICK)>> NOW WE'RE ALSO GONNA BE USING RILEY'S TUBULAR CONTROL ARMS. NOW THESE THINGS AREN'T JUST ADAPTED FROM OTHER VEHICLE TO WORK ON THIS. THESE ARE SPECIFICALLY DESIGNED AND BUILT FOR THIS KIT.

WE'RE USING A DAB OF BLUE LOCTITE ON ALL THE THREADS TO

KEEP EVERYTHING IN PLACE. NOW THIS GRADE IS ALSO GONNA ALLOW US TO BACK SOME OF THESE OUT IF WE EVER NEED TO IN THE FUTURE. RILEY ALSO SENT US THE SHOCKS. NOW THESE ARE FULLY ADJUSTABLE LAB COATS ALL WRAPPED UP IN QA ONE COILS.

OKAY, GOT THE SUSPENSION MOCKED UP. NOW THIS KIT'LL LET US GET RID OF THAT OLD STEERING BOX AND PUT A RACK AND PINION IN ITS PLACE. AND THAT'LL ALSO GIVE US A LOT BETTER TURNING RADIUS.

(TOMMY)>> I'M GONNA UPGRADE THE BRAKES WITH A SET THAT WE GOT FROM WILWOOD. DON'T FORGET WHEN YOU PUT ON YOUR NEW FRONT BRAKES THAT YOU'VE GOT TO PACK THE BEARINGS WITH GREASE. OTHERWISE YOU'LL CHEW THE SPINDLE RIGHT OFF

THE FRONT OF YOUR CAR.

THESE HUBS AND CALIPERS ARE MADE OUT OF ALUMINUM, WHICH WILL SAVE US ABOUT 20 POUNDS ON EACH SIDE OVER WHAT THE

STOCK BRAKES WOULD HAVE BEEN. WILWOOD ALSO HOOKED US UP WITH A SET OF THEIR PADS. THESE HAVE A VERY HIGH COEFFICIENT OF FRICTION, AND AT THE END OF THE DAY THAT MEANS MORE STOPPING POWER. WELL THAT OUGHT TO DRAMATICALLY IMPROVE THE DRIVABILITY OVER THAT 1974 TECHNOLOGY. WE'VE STILL GOT A HALF A CAR TO DO THOUGH, AND WE FOUND US AN EXPERT THAT KNOWS THE INS AND OUTS OF REAR SUSPENSION LIKE NOBODY'S BUSINESS.

(ANNOUNCER)>> AFTER THE BREAK, THE GUYS GET A HELPING HAND

FROM A PRO IN THE WORLD OF BACK HALVING AS PROJECT BUSINESS TIME MAKES ROOM FOR SOME HUGE REAR RUBBER.

(RICK)>> HEY GUYS, WELL WE GOT THE KMEMBER ALL BOLTED UP AND THE FRONT SUSPENSION HUNG. TO KEEP ALL THOSE PARTS FROM SCRAPING DOWN THE DRAG STRIP WE ADDED A SET OF WELD RACING WHEELS AND SKINNY LITTLE FRONT

RUNNERS FROM MICKEY THOMPSON. NOW AS FAR AS THE BACK END GOES, WELL I DON'T KNOW OF A SKINNY TIRE ON THE MARKET THAT'S GONNA BE ABLE TO HANDLE ALL THE HORSEPOWER THAT WE WANT TO PUT DOWN. SO THAT MEANS IT'S TIME TO MAN UP AND GRAB THE BIG RUBBERS. NOW THESE ARE 33 BY 18.5 MICKEY THOMPSON ET STREETS, AND THEY'RE WRAPPED AROUND WELD RACING FORGED ALUMINUM WHEELS. NOW THOSE WHEELS ARE SUPER STRONG AND SUPER LIGHTWEIGHT. THESE STICKY MICKEYS HERE, THEY'RE GONNA DO A HECK OF A JOB GETTING ALL THAT HORSEPOWER TO THE GROUND.

AND YOU SEE THESE LITTLE SLITS RIGHT HERE, WELL THE DOT CONSIDERS THAT TREAD, AND THAT MEANS THAT THESE ARE STREET LEGAL.

(TOMMY)>> THOSE BAD BOYS ARE NEVER GONNA FIT, SO WE'VE GOT TO MAKE SOME ROOM UNDERNEATH. WE BROUGHT IN SOMEONE WHO'S A GO TO GUY WHEN IT COMES TO ROLL CAGES AND BACK HALVES. THIS IS SCOTT WENEY FROM S&W RACE CARS. SCOTT, TELL'EM WHAT WE'VE GOT GOING ON.

(SCOTT)>> WE'RE GONNA PUT THIS BACK HALF IN YOUR CAR. WHEN YOU GUYS CALLED US UP, WE CUSTOM BUILT A FRAME TO THE WIDTH THAT YOU NEED FOR YOUR CAR, FOUR LINK TUBES, ALL THE HARDWARE FOR THE FOUR LINK, AND THERE'S A COUPLE OF OTHER GOODIES WE INCLUDED THAT MAKE IT EASIER TO BUILD THE CAR.

(RICK)>> NOW WE'RE GONNA BE GOING WITH A FOUR LINK SETUP. NOW ANOTHER OPTION THE GUYS GO WITH IS A LADDER BAR, WHICH IS A GREAT WAY TO GO. LATER ON IN THE SHOW WE'RE GONNA BE EXPLAINING THE DIFFERENCE BETWEEN THOSE TWO TYPES OF SUSPENSIONS BUT FOR NOW OUR PRIORITY IS GETTING ALL THAT SHOVED UP INSIDE OF THAT.

(SCOTT)>> WE'RE GONNA FIND THE CENTER OF THIS WHEEL. IT'S A 16 INCH WHEEL. NOW WE'RE GONNA LEVEL UP FROM THE CENTER OF THE REAR WHEEL AND THEN WE'RE GONNA PUT OUR CENTER LINE HERE. THAT'LL BE OUR CENTER LINE. ALRIGHT, CUT IT UP. I'LL BE BACK TOMORROW, LET ME KNOW HOW YOU MAKE OUT.

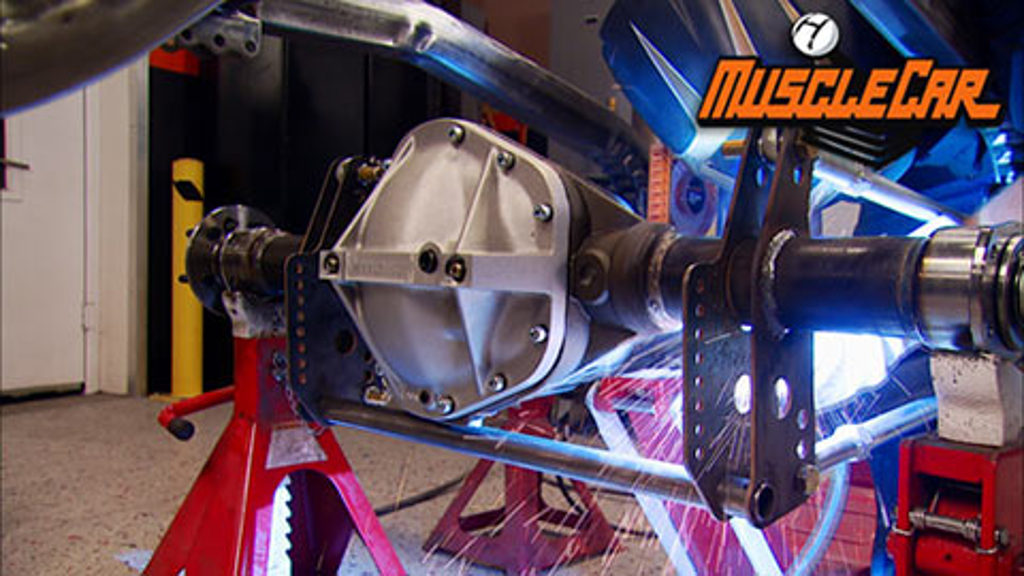

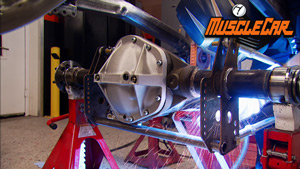

(TOMMY)>> A LOT OF TIMES WHEN PEOPLE ARE BUILDING A CAR LIKE

OURS THEY RESORT TO A NINE INCH SETUP FOR THE REAR END. THE FACT OF THE MATTER IS WE WANT TO KEEP OURS AS MUCH DODGE AS POSSIBLE, AND THERE ARE A FEW OPTIONS OUT THERE THAT CAN WITHSTAND THAT TYPE OF ABUSE. SO WE GAVE MOSSER ENGINEERING A CALL AND THEY SENT US THIS,

ONE OF THEIR M-60 BUILT TO ORDER REAR END PACKAGES. THIS IS A 35 SPLINE DANA 60 STYLE UNIT, AND THE AXLES AND HOUSINGS HAVE BEEN CUT DOWN TO A CUSTOM LENGTH TO MEET OUR NEEDS. IT HAS BEEFY QUARTER INCH WALL AXLE TUBES ALONG WITH THIS ALUMINUM DIFF COVER FOR ADDED STRENGTH.

(RICK)>> NOW WE ALREADY KNOW THAT WE WANT TO KEEP THE INTERIOR IN THIS THING AS STOCK AS POSSIBLE. SO THAT MEANS THAT WE'RE GONNA KEEP THE STOCK FLOOR PAN FROM HERE FORWARD. THAT WAY THE ORIGINAL SEAT, CARPET, EVERYTHING WILL JUST GO RIGHT BACK IN.

FROM HERE BACK ON THE OTHER HAND, THAT STUFF IS ALL GETTING GONE. I'M GONNA CUT IT RIGHT UP OVER THE TOP. THAT WAY WE HAVE A NICE PLATFORM HERE TO ATTACH OUR

TIN WORK ON TO WHEN WE DO ALL THE TUBS. NOW THIS CAN BE ONE OF THE SCARY PARTS OF THIS KIND OF A BUILD. IF IT MAKES YOU UNCOMFORTABLE TO DO THIS FOR THE FIRST TIME WITH A RARE OR EXPENSIVE CAR, HEY THERE'S NOTHING AT ALL WRONG WITH FINDING SOMETHING CHEAP TO RACE. SHOOT, YOU COULD EVEN BUY A RUSTED OUT PIECE OF JUNK FROM YOUR LOCAL SALVAGE YARD. THERE IT IS! CUT THAT THING UP INTO OBLIVION.

(ANNOUNCER)>> COMING UP, THE DODGE LANDS BACK ON ITS FEET,

AND TOMMY DOES SOME SERIOUS FAB WORK.

(TOMMY)>> WHILE RICK'S BEEN CUTTING UP OUR DODGE, I'VE BEEN BUSY MOCKING UP OUR MOSSER REAR TO OUR S&W BACK HALF KIT. WE DECIDED TO GO WITH A FOUR LINK SETUP BECAUSE OF THE

ADJUSTABILITY, BUT S&W ALSO OFFERS A LADDER BAR SETUP, WHICH IS COMMONLY USED. SCOTT, LETS TALK ABOUT THE DIFFERENCES OF THE TWO. WHILE THEY'RE BOTH PERFORMANCE ORIENTED, A LADDER BAR AND A FOUR LINK ARE TWO DIFFERENT WAYS OF LEVERAGING THE REAR TIRE ONTO THE GROUND. A LADDER BAR HAS VERY LIMITED ADJUSTABILITY, USUALLY FOR THE PINION ANGLE IF AT ALL. A FOUR LINK ON THE OTHER HAND HAS A MULTITUDE OF DIFFERENT WAYS TO ADJUST POWER LEVERAGE AND LAUNCH BEHAVIOR DEPENDING ON YOUR CARS TIRES AND CENTER OF GRAVITY. WE'RE READY TO SET OUR PINION ANGLE AND OUR BRACKET PLACEMENT ON THE HOUSING. YOU COULD DO THIS UNDER THE CAR BUT IT'S A LOT EASIER TO

GET TO EVERYTHING OUT IN THE OPEN.

(SCOTT)>> WE'RE GONNA BRING THE PINION UP TO MATCH THE ANGLE OF OUR BRACKETS. BRING HER UP SOME MORE.

(TOMMY)>> NEED TO MEASURE OUR HOUSING WIDTH. WHAT DO YOU GOT?

(SCOTT)>> 39!

(TOMMY)>> 39!

(SCOTT)>> 25 AND A HALF IS OUTSIDE TO OUTSIDE ON THE BRACKETS WITH A DIFFERENCE OF 13 AND A HALF INCHES, DIVIDED BY TWO GIVES US SIX AND THREE QUARTERS.

(TOMMY)>> SO WE NEED SIX AND THREE QUARTER INCHES FROM THE OUTSIDE OF OUR BRACKET TO OUR HOUSING FLANGE. COME MY WAY ABOUT FIVEEIGHTHS OF AN INCH. WHOA, THEN WE NEED TO CHECK OUR BRACKET.

IF YOU REMEMBER BACK, THE VERY FIRST MARK THAT SCOTT MADE,

I'M DOING THE OTHER SIDE OF IT. THIS RIGHT HERE'S GONNA BE THE AXLE CENTER LINE WE'RE GONNA LINE BACK UP ON THE QUARTER. MEASURE BACK HALF THE DIAMETER OF YOUR TUBE. THAT GIVES YOU THE CENTER.

(SCOTT)>> WE MEASURED OUR ROCKER WIDTH. NOW WE'RE GONNA TRIM THE MAIN CROSS MEMBER SO

IT FITS RIGHT IN. WE'RE GONNA TAKE FOUR INCHES OFF OF EACH SIDE AND WE'LL BE READY TO GO.

(RICK)>> WELL I GOT ALL THE GUTS CHOPPED OUT OF OUR DODGE HERE AND WE GOT A HOLE JUST ABOUT BIG ENOUGH TO DRIVE A SMART CAR THROUGH, BUT NOW THE FUN PART STARTS AND THAT'S PUTTING ALL THE NEW GUTS BACK IN. IT ALL STARTS OUT WITH THESE SIX BY SIX BY EIGHTH INCH STEEL PLATES. NOW THESE THINGS GET MOUNTED IN BETWEEN THE BACK HALF KIT AND THE ORIGINAL BODY. THEY HELP DISTRIBUTE THE LOAD, MAKES THE WHOLE THING A LOT STRONGER. NOW BEFORE WE TOOK ANYTHING APART, WE MARKED THE AXLE CENTER LINE ON A PIECE OF TAPE ON THE QUARTER PANEL. WELL SCOTT TRANSFERRED THAT TO THE FLOOR DOWN HERE, THEN MEASURED FORWARD TO WHERE THE LEADING EDGE OF THE BACK HALF KIT IS GONNA BE. NOW YOU'VE GOT TO REMEMBER THAT THAT FRONT CROSS MEMBER IS TWO INCHES WIDE. SO YOU TAKE THAT TWO INCHES, CUT IT DOWN TO ONE INCH OFF OF THIS MARK, AND RIGHT ABOUT THERE IS GONNA BE THE CENTER OF OUR SIX INCH PLATE. I'M ALSO TACKING IN A REAR CROSS MEMBER THAT SCOTT CUT OUT FOR US, AND THEN WE CAN MEASURE FROM THERE TO OUR AXLE CENTER MARK.

(SCOTT)>> WE'RE GONNA MEASURE FROM OUR AXLE CENTER LINE MARK BACK OUR 42 INCHES THAT WE JUST MEASURED IN THE CAR AND MARK OUR FRAME RAIL. SO WE CAN TRIM THE BACK OFF AND IT'LL PLUG RIGHT IN.

(TOMMY)>> WHILE WE SET IN OUR FRAME RAILS WE NEED TO LEVEL THEM OUT.

(SCOTT)>> THERE YOU GO, THAT'S MORE LIKE IT.

(TOMMY)>> AND USE A PLUMB BOB TO SET THEM IN POSITION HORIZONTALLY.

(RICK)>> SOME EIGHTH INCH WALL RECTANGULAR TUBING WILL MAKE FOR SOME GREAT FRAME CONNECTORS.

WE'VE JUST GOT TO MAKE A LITTLE ROOM FOR THEM TO POKE THROUGH THE FLOOR.

AT THE END OF THE DAY IT'LL ADD A LOT OF

STRENGTH TO THE CAR.

(SCOTT)>> THAT'S WHAT ONE OF OUR BACK HALF KITS LOOK LIKE IN A '74 DART.

(RICK)>> NOW I HAVEN'T FLATTENED THESE TIRES BUT THERE IS NO AMOUNT OF PUSHING AND SHOVING THAT'S GONNA GET THIS TIRE THROUGH THAT WHEEL WELL. SO THAT MEANS WE'RE GONNA HAVE TO GET RID OF SOME MORE OF THAT DODGE SHEET METAL.

(TOMMY)>> ONCE WE GET THE MOTOR IN IT, IT'LL MASH THE FRONT DOWN JUST ABOUT WHERE IT NEEDS TO BE SITTING. OUT BACK WE USED A SET OF SCOTT'S MOCK UP SHOCKS SO IT'S SITTING RIGHT AT RIDE HEIGHT.

(RICK)>> WELL WE'RE STARTING TO GET A PRETTY GOOD IDEA THE AMOUNT OF ATTITUDE THIS THING IS GONNA HAVE WHEN IT HITS THE STREET. NOW WE'VE STILL GOT TO DO WHEEL TUBS, A BUNCH OF INTERIOR TIN, AND A FULL ROLL CAGE WILL DEFINITELY HELP STIFFEN UP THE SPINE IN THIS OLD GIRL. ONE STITCH AT A TIME AND SHE'LL GET THERE.

(ANNOUNCER)>> STICK AROUND AND SEE HOW YOU CAN BUILD YOUR OWN ONE OF A KIND STEEL SPOILER.

(TOMMY)>> WELL WE PLUGGED IN OUR FRONT AND REAR INTO OUR DODGE AND IT'S WELL ON ITS WAY TO SCARING SOME LAW ABIDING CITIZENS, BUT WE'RE GONNA LEAVE IT ALONE FOR NOW AND HOP OVER TO ONE OF OUR OTHER PROJECTS. IT'S TIME FOR AN UPDATE ON OUR OLDSMOBILE. THERE'S STILL A LOT OF SHEET METAL WORK LEFT TO DO TO OUR CAR. WE WANT IT TO HAVE SEVERAL CUSTOM TOUCHES. THE HURST EDITION CARS THAT WE'RE BASING OURS OFF OF CAME WITH THE REAR SPOILER, AND YOU CAN GET A REPOPPED ONE FROM OUR BUDDIES DOWN AT YEAR. BUT WE WANTED OURS TO HAVE A LITTLE MORE OF A CUSTOM FEEL. SO I'M GONNA FAB ONE UP FROM SCRATCH. THE FIRST THING YOU WANT TO DO IS TO MAKE SURE YOUR TRUNK LID'S FIT BECAUSE IF IT'S CROOKED AND YOU BUILD A SPOILER OFF IT, WHENEVER YOU GO TO FIT IT LATER DOWN THE ROAD, YOUR SPOILER'S GONNA BE OFF. SO JUST MAKE SURE IT'S IN GOOD SHAPE. OKAY THE NEXT THING YOU WANT TO DO IS KINDA START DETERMINING WHAT YOU WANT IN YOUR DESIGN. I'M GONNA PLAY OFF THE BACK SIDE OF THIS BODY LINE, KINDA GIVING IT A LEANING FORWARD MOTION. AND WITH THIS REPRESENTING THE BACK EDGE OF THE SPOILER, YOU

CAN DETERMINE YOUR WIDTH. HOW WIDE YOU WANT THE TOP TO BE, AND I DON'T THINK I'D WANT IT ANY WIDER THAN SAY FIVE AND A HALF INCHES. THIS'LL BE YOUR FRONT EDGE FOR THE TOP OF THE SPOILER. ALSO I WANT TO DETERMINE MY HEIGHT THAT I'D WANT THE

SPOILER WITHIN ABOUT TWO INCHES OUGHT TO BE GOOD. OKAY NOW ALL I'VE GOT TO DO IS DUPLICATE THIS ON THE OTHER SIDE AND WE CAN START BENDING SOME METAL. I'M GONNA USE QUARTER INCH ROD TO BUILD THE GENERAL SHAPE OF MY SPOILER. SO I'VE GOT TO DETERMINE THE WIDTH TO KNOW HOW WIDE I NEED TO CUT THE METAL, AND THEN ADD ABOUT THREE INCHES PER SIDE FOR THE SIDES. SO THAT'S 69 AND A HALF. OKAY NOW I NEED TO FIND THE CENTER OF THE TRUNK LID, WHICH WOULD BE 31 AND THREE QUARTERS. I'VE GOT TO FIND THE CENTER OF THE ROD, HALF OF 69 AND A HALF, WHICH IS 34 AND THREE QUARTERS. NOW I LINE UP MY TWO CENTERS AND I CAN DETERMINE WHERE I WANT MY BEND TO START. I'M GONNA PUT THAT MARK AT THE EDGE OF THE JAWS OF THE VICE AND MARK ABOUT AN INCH FROM IT. THEN USE A WRENCH ON THAT LAST MARK. YOU CAN CONTROL YOUR BEND IN BETWEEN THE TWO MARKS KEEPING THEM CONSISTENT. A SIMPLE WAY TO CHECK YOUR BENDS TO SEE IF THEY BOTH MATCH, USE A FLAT SURFACE, SLIP IT AROUND, CAN'T GET MUCH BETTER THAN THAT, AND FIRST TRY, THAT'S NOT BAD. OKAY NOW'S A GOOD TIME FOR US TO SET OUR HEIGHT AND MARK THIS ROD. I WANT MY SPOILER TO BE TWO INCHES HIGH. THEN WE CAN MARK THE ROD TO THE TOP OF THE QUARTER. I ALSO WANT TO TAKE THE ROD AND BEND IT FORWARD SIMILAR TO THE WAY WE DID THIS, GIVE IT A LITTLE MORE SHAPE. WHAT WE'RE GONNA DO IS SHAPE THE ROD TO MATCH THE CONTOUR OF THE TRUNK LID. WHAT WE'RE LOOKING FOR IS KIND OF A GRADUAL BEND.

YOU DON'T WANT TO USE ANYTHING SHARP TO BEND IT LIKE A CORNER BECAUSE WHAT THIS WILL DO, IT'LL KINDA PUT A KINK INTO IT. SO WHAT I'M GONNA USE IS A SQUISHY SURFACE, THIS TUMMY. SEE, NOT BAD AT ALL. I MADE THE REAR BAR JUST LIKE I SHOWED YOU ON THE FRONT ONE. THIS PIECE HERE MAY LOOK A LITTLE ODD, BUT WHAT I'M DOING IS USING IT AS A GUIDE, THAT WAY I CAN SET THIS ROD AT THE SAME ANGLE OF MY QUARTER. I'VE GOT TO BUILD A COUPLE OF LEGS FOR MY SPOILER.

I MADE ME A TEMPLATE OF WHAT I WANT MY BASE PLATE TO LOOK LIKE. SO I'VE GOT TO CUT THAT OUT OF STEEL AND THEN I'LL CUT A FEW RODS TO CONNECT IT, DRILL A COUPLE OF HOLES TO MOUNT IT, THEN MOVE ON TO THE NEXT SIDE. A COUPLE OF FIVESIXTEENTHS BOLTS DROPPED INTO PLACE, TACKED IN PLACE, WORKS GREAT, THERE'S A COUPLE OF STUDS. THIS IS THE FIRST PIECE THAT'S GONNA CONNECT OUR BASE TO OUR UPPER FRAME. THIS IS A PIECE THAT CONNECTS THE FRONT TWO TOGETHER. I MADE ME A TEMPLATE THAT'S GONNA BE THE SIDE OF THE LEGS. CUT IT OUT IN A PIECE OF STEEL, AND ALL YOU'VE GOT TO DO IS SHAPE IT TO FIT AND THEN TACK IT INTO PLACE. AND DON'T BE SURPRISED IF A PROJECT LIKE THIS TAKES YOU SEVERAL DAYS. WE'RE AT THE POINT TO START SKINNING THE FRAME WORK OF OUR SPOILER. WE WANT TO WORK FROM THE BOTTOM SIDE OF IT TO THE TOP. THAT WAY IT MAKES IT EASIER TO GET TO EVERYTHING AS YOU'RE FABBING IT UP. I'VE FOUND THAT THE BEST WAY TO CONSTRUCT SOMETHING LIKE THIS IS TO GO SLOW AND WORK WITH SMALL PIECES. DON'T BE AFRAID TO GET AFTER IT WITH A GRINDER OR A BODY HAMMER IF YOU NEED MOVE OR REMOVE SOME METAL. I'M ALSO A BIG FAN OF USING CARDBOARD TEMPLATES TO HELP ME GET THE METAL CLOSE TO SOMETHING TO START WITH. JUST TAKE YOUR TIME WITH IT EVEN IF YOUR WIFE IS TRYING TO HURRY UP AND GET YOU OUT OF THE GARAGE. OR IF YOU'RE LIKE ME AND HAVE A TV PRODUCER, WHICH IS KINDA LIKE A SECOND WIFE TRYING TO HURRY YOU ALONG. THE LAST THING I NEED TO DO IS SLICE THE SPOILER FREE SO THE TRUNK WILL OPEN. THAT'S HOW YOU BUILD A CUSTOM SPOILER. I'VE STILL GOT TO DO SOME WELDING AND GRINDING, AND THEN CAP OFF BOTH ENDS FROM WHERE I CUT IT LOOSE. THEN FOLLOW THAT UP WITH SOME BODY WORK. BUT IF I DID MY METAL WORK RIGHT, THERE WON'T BE A WHOLE LOT OF THAT REQUIRED.

IF YOU GUYS HAVE ANY QUESTIONS ABOUT WHAT YOU'VE SEEN ON TODAY'S SHOW, CHECK OUT POWERBLOCK TV DOT COM. WE'RE ALL OUT OF TIME FOR THIS WEEK. SO UNTIL NEXT WEEK, Y'ALL KEEP IT BETWEEN THE DITCHES.

Show Full Transcript

(RICK)>> HEY GUYS, HOW'S IT GOING? I SURE HOPE YOU HAVE AN APPETITE FOR SUSPENSION TODAY BECAUSE WE HAVE A VEHICLE OVER HERE IN DIRE NEED OF SOME ATTENTION. NOW LAST TIME WE GOT STARTED ON CONVERTING THIS THING INTO OUR PRO STREET STYLE MOPAR.

IT'S A 1974 DODGE DART THAT WE AFFECTIONATELY

REFER TO AS BUSINESS TIME.

(TOMMY)>> WE PICKED THIS THING UP FOR $4,500 BUCKS, WHICH ISN'T HALF BAD CONSIDERING A PERSON COULD USE IT FOR A DAILY DRIVER.

(RICK)>> NOW SINCE WE'RE GONNA BE REPLACING THE 360, THE FRONT KMEMBER, WELL PRETTY MUCH EVERYTHING UNDERNEATH THIS THING, RATHER THAN TRY TO PIECE MEAL APART WE'RE JUST

GONNA DROP THE BOLTS OUT AND DROP THE WHOLE THING OUT FROM UNDERNEATH. JUST HAVE TO UNDO THAT AND THEN DROP OUT THE FOUR BOLTS RIGHT THERE AND THERE, AND THE WHOLE THING WILL DROP

RIGHT OUT THE BOTTOM. THE TORSION BARS CAN BE A REAL PAIN TO GET OUT. SINCE REPLACEMENTS ARE AVAILABLE IN THE AFTERMARKET, WE'RE GONNA GO AHEAD AND JUST TORCH THESE OUT.

(TOMMY)>> WE KNEW WE NEEDED TO UPGRADE OUR KMEMBER AND FRONT SUSPENSION BECAUSE WE'RE PLANNING ON THROWING ENOUGH POWER AT THIS OLD MOPAR TO DANG NEAR SEND IT TO THE MOON. SO WE GAVE RILEY MOTORSPORTS A CALL AND THEY HAD EXACTLY WHAT WE NEEDED.

IN ORDER TO MAKE ROOM FOR THE NEW KMEMBER WE'VE GOT TO GET RID OF THE FACTORY BUMP STOPS. DRILLING OUT THESE SPOT WELDS HELPS KEEP DOWN THE AMOUNT OF TORCHING I'LL HAVE TO DO. THAT REDUCES THE AMOUNT OF TORCH DAMAGE YOU COULD END UP WITH AND HAVE TO GO BACK AND FIX. MAKE SURE YOU DO FILL ANY HOLES. A COAT OF DUPLICOLOR ETCH PRIMER AND SOME SEMI GLOSS BLACK WILL PROTECT IT AND MAKE IT LOOK REAL NICE. AND THEN WE CAN PLUG IN OUR NEW SHINY KMEMBER.

(RICK)>> NOW WE'RE ALSO GONNA BE USING RILEY'S TUBULAR CONTROL ARMS. NOW THESE THINGS AREN'T JUST ADAPTED FROM OTHER VEHICLE TO WORK ON THIS. THESE ARE SPECIFICALLY DESIGNED AND BUILT FOR THIS KIT.

WE'RE USING A DAB OF BLUE LOCTITE ON ALL THE THREADS TO

KEEP EVERYTHING IN PLACE. NOW THIS GRADE IS ALSO GONNA ALLOW US TO BACK SOME OF THESE OUT IF WE EVER NEED TO IN THE FUTURE. RILEY ALSO SENT US THE SHOCKS. NOW THESE ARE FULLY ADJUSTABLE LAB COATS ALL WRAPPED UP IN QA ONE COILS.

OKAY, GOT THE SUSPENSION MOCKED UP. NOW THIS KIT'LL LET US GET RID OF THAT OLD STEERING BOX AND PUT A RACK AND PINION IN ITS PLACE. AND THAT'LL ALSO GIVE US A LOT BETTER TURNING RADIUS.

(TOMMY)>> I'M GONNA UPGRADE THE BRAKES WITH A SET THAT WE GOT FROM WILWOOD. DON'T FORGET WHEN YOU PUT ON YOUR NEW FRONT BRAKES THAT YOU'VE GOT TO PACK THE BEARINGS WITH GREASE. OTHERWISE YOU'LL CHEW THE SPINDLE RIGHT OFF

THE FRONT OF YOUR CAR.

THESE HUBS AND CALIPERS ARE MADE OUT OF ALUMINUM, WHICH WILL SAVE US ABOUT 20 POUNDS ON EACH SIDE OVER WHAT THE

STOCK BRAKES WOULD HAVE BEEN. WILWOOD ALSO HOOKED US UP WITH A SET OF THEIR PADS. THESE HAVE A VERY HIGH COEFFICIENT OF FRICTION, AND AT THE END OF THE DAY THAT MEANS MORE STOPPING POWER. WELL THAT OUGHT TO DRAMATICALLY IMPROVE THE DRIVABILITY OVER THAT 1974 TECHNOLOGY. WE'VE STILL GOT A HALF A CAR TO DO THOUGH, AND WE FOUND US AN EXPERT THAT KNOWS THE INS AND OUTS OF REAR SUSPENSION LIKE NOBODY'S BUSINESS.

(ANNOUNCER)>> AFTER THE BREAK, THE GUYS GET A HELPING HAND

FROM A PRO IN THE WORLD OF BACK HALVING AS PROJECT BUSINESS TIME MAKES ROOM FOR SOME HUGE REAR RUBBER.

(RICK)>> HEY GUYS, WELL WE GOT THE KMEMBER ALL BOLTED UP AND THE FRONT SUSPENSION HUNG. TO KEEP ALL THOSE PARTS FROM SCRAPING DOWN THE DRAG STRIP WE ADDED A SET OF WELD RACING WHEELS AND SKINNY LITTLE FRONT

RUNNERS FROM MICKEY THOMPSON. NOW AS FAR AS THE BACK END GOES, WELL I DON'T KNOW OF A SKINNY TIRE ON THE MARKET THAT'S GONNA BE ABLE TO HANDLE ALL THE HORSEPOWER THAT WE WANT TO PUT DOWN. SO THAT MEANS IT'S TIME TO MAN UP AND GRAB THE BIG RUBBERS. NOW THESE ARE 33 BY 18.5 MICKEY THOMPSON ET STREETS, AND THEY'RE WRAPPED AROUND WELD RACING FORGED ALUMINUM WHEELS. NOW THOSE WHEELS ARE SUPER STRONG AND SUPER LIGHTWEIGHT. THESE STICKY MICKEYS HERE, THEY'RE GONNA DO A HECK OF A JOB GETTING ALL THAT HORSEPOWER TO THE GROUND.

AND YOU SEE THESE LITTLE SLITS RIGHT HERE, WELL THE DOT CONSIDERS THAT TREAD, AND THAT MEANS THAT THESE ARE STREET LEGAL.

(TOMMY)>> THOSE BAD BOYS ARE NEVER GONNA FIT, SO WE'VE GOT TO MAKE SOME ROOM UNDERNEATH. WE BROUGHT IN SOMEONE WHO'S A GO TO GUY WHEN IT COMES TO ROLL CAGES AND BACK HALVES. THIS IS SCOTT WENEY FROM S&W RACE CARS. SCOTT, TELL'EM WHAT WE'VE GOT GOING ON.

(SCOTT)>> WE'RE GONNA PUT THIS BACK HALF IN YOUR CAR. WHEN YOU GUYS CALLED US UP, WE CUSTOM BUILT A FRAME TO THE WIDTH THAT YOU NEED FOR YOUR CAR, FOUR LINK TUBES, ALL THE HARDWARE FOR THE FOUR LINK, AND THERE'S A COUPLE OF OTHER GOODIES WE INCLUDED THAT MAKE IT EASIER TO BUILD THE CAR.

(RICK)>> NOW WE'RE GONNA BE GOING WITH A FOUR LINK SETUP. NOW ANOTHER OPTION THE GUYS GO WITH IS A LADDER BAR, WHICH IS A GREAT WAY TO GO. LATER ON IN THE SHOW WE'RE GONNA BE EXPLAINING THE DIFFERENCE BETWEEN THOSE TWO TYPES OF SUSPENSIONS BUT FOR NOW OUR PRIORITY IS GETTING ALL THAT SHOVED UP INSIDE OF THAT.

(SCOTT)>> WE'RE GONNA FIND THE CENTER OF THIS WHEEL. IT'S A 16 INCH WHEEL. NOW WE'RE GONNA LEVEL UP FROM THE CENTER OF THE REAR WHEEL AND THEN WE'RE GONNA PUT OUR CENTER LINE HERE. THAT'LL BE OUR CENTER LINE. ALRIGHT, CUT IT UP. I'LL BE BACK TOMORROW, LET ME KNOW HOW YOU MAKE OUT.

(TOMMY)>> A LOT OF TIMES WHEN PEOPLE ARE BUILDING A CAR LIKE

OURS THEY RESORT TO A NINE INCH SETUP FOR THE REAR END. THE FACT OF THE MATTER IS WE WANT TO KEEP OURS AS MUCH DODGE AS POSSIBLE, AND THERE ARE A FEW OPTIONS OUT THERE THAT CAN WITHSTAND THAT TYPE OF ABUSE. SO WE GAVE MOSSER ENGINEERING A CALL AND THEY SENT US THIS,

ONE OF THEIR M-60 BUILT TO ORDER REAR END PACKAGES. THIS IS A 35 SPLINE DANA 60 STYLE UNIT, AND THE AXLES AND HOUSINGS HAVE BEEN CUT DOWN TO A CUSTOM LENGTH TO MEET OUR NEEDS. IT HAS BEEFY QUARTER INCH WALL AXLE TUBES ALONG WITH THIS ALUMINUM DIFF COVER FOR ADDED STRENGTH.

(RICK)>> NOW WE ALREADY KNOW THAT WE WANT TO KEEP THE INTERIOR IN THIS THING AS STOCK AS POSSIBLE. SO THAT MEANS THAT WE'RE GONNA KEEP THE STOCK FLOOR PAN FROM HERE FORWARD. THAT WAY THE ORIGINAL SEAT, CARPET, EVERYTHING WILL JUST GO RIGHT BACK IN.

FROM HERE BACK ON THE OTHER HAND, THAT STUFF IS ALL GETTING GONE. I'M GONNA CUT IT RIGHT UP OVER THE TOP. THAT WAY WE HAVE A NICE PLATFORM HERE TO ATTACH OUR

TIN WORK ON TO WHEN WE DO ALL THE TUBS. NOW THIS CAN BE ONE OF THE SCARY PARTS OF THIS KIND OF A BUILD. IF IT MAKES YOU UNCOMFORTABLE TO DO THIS FOR THE FIRST TIME WITH A RARE OR EXPENSIVE CAR, HEY THERE'S NOTHING AT ALL WRONG WITH FINDING SOMETHING CHEAP TO RACE. SHOOT, YOU COULD EVEN BUY A RUSTED OUT PIECE OF JUNK FROM YOUR LOCAL SALVAGE YARD. THERE IT IS! CUT THAT THING UP INTO OBLIVION.

(ANNOUNCER)>> COMING UP, THE DODGE LANDS BACK ON ITS FEET,

AND TOMMY DOES SOME SERIOUS FAB WORK.

(TOMMY)>> WHILE RICK'S BEEN CUTTING UP OUR DODGE, I'VE BEEN BUSY MOCKING UP OUR MOSSER REAR TO OUR S&W BACK HALF KIT. WE DECIDED TO GO WITH A FOUR LINK SETUP BECAUSE OF THE

ADJUSTABILITY, BUT S&W ALSO OFFERS A LADDER BAR SETUP, WHICH IS COMMONLY USED. SCOTT, LETS TALK ABOUT THE DIFFERENCES OF THE TWO. WHILE THEY'RE BOTH PERFORMANCE ORIENTED, A LADDER BAR AND A FOUR LINK ARE TWO DIFFERENT WAYS OF LEVERAGING THE REAR TIRE ONTO THE GROUND. A LADDER BAR HAS VERY LIMITED ADJUSTABILITY, USUALLY FOR THE PINION ANGLE IF AT ALL. A FOUR LINK ON THE OTHER HAND HAS A MULTITUDE OF DIFFERENT WAYS TO ADJUST POWER LEVERAGE AND LAUNCH BEHAVIOR DEPENDING ON YOUR CARS TIRES AND CENTER OF GRAVITY. WE'RE READY TO SET OUR PINION ANGLE AND OUR BRACKET PLACEMENT ON THE HOUSING. YOU COULD DO THIS UNDER THE CAR BUT IT'S A LOT EASIER TO

GET TO EVERYTHING OUT IN THE OPEN.

(SCOTT)>> WE'RE GONNA BRING THE PINION UP TO MATCH THE ANGLE OF OUR BRACKETS. BRING HER UP SOME MORE.

(TOMMY)>> NEED TO MEASURE OUR HOUSING WIDTH. WHAT DO YOU GOT?

(SCOTT)>> 39!

(TOMMY)>> 39!

(SCOTT)>> 25 AND A HALF IS OUTSIDE TO OUTSIDE ON THE BRACKETS WITH A DIFFERENCE OF 13 AND A HALF INCHES, DIVIDED BY TWO GIVES US SIX AND THREE QUARTERS.

(TOMMY)>> SO WE NEED SIX AND THREE QUARTER INCHES FROM THE OUTSIDE OF OUR BRACKET TO OUR HOUSING FLANGE. COME MY WAY ABOUT FIVEEIGHTHS OF AN INCH. WHOA, THEN WE NEED TO CHECK OUR BRACKET.

IF YOU REMEMBER BACK, THE VERY FIRST MARK THAT SCOTT MADE,

I'M DOING THE OTHER SIDE OF IT. THIS RIGHT HERE'S GONNA BE THE AXLE CENTER LINE WE'RE GONNA LINE BACK UP ON THE QUARTER. MEASURE BACK HALF THE DIAMETER OF YOUR TUBE. THAT GIVES YOU THE CENTER.

(SCOTT)>> WE MEASURED OUR ROCKER WIDTH. NOW WE'RE GONNA TRIM THE MAIN CROSS MEMBER SO

IT FITS RIGHT IN. WE'RE GONNA TAKE FOUR INCHES OFF OF EACH SIDE AND WE'LL BE READY TO GO.

(RICK)>> WELL I GOT ALL THE GUTS CHOPPED OUT OF OUR DODGE HERE AND WE GOT A HOLE JUST ABOUT BIG ENOUGH TO DRIVE A SMART CAR THROUGH, BUT NOW THE FUN PART STARTS AND THAT'S PUTTING ALL THE NEW GUTS BACK IN. IT ALL STARTS OUT WITH THESE SIX BY SIX BY EIGHTH INCH STEEL PLATES. NOW THESE THINGS GET MOUNTED IN BETWEEN THE BACK HALF KIT AND THE ORIGINAL BODY. THEY HELP DISTRIBUTE THE LOAD, MAKES THE WHOLE THING A LOT STRONGER. NOW BEFORE WE TOOK ANYTHING APART, WE MARKED THE AXLE CENTER LINE ON A PIECE OF TAPE ON THE QUARTER PANEL. WELL SCOTT TRANSFERRED THAT TO THE FLOOR DOWN HERE, THEN MEASURED FORWARD TO WHERE THE LEADING EDGE OF THE BACK HALF KIT IS GONNA BE. NOW YOU'VE GOT TO REMEMBER THAT THAT FRONT CROSS MEMBER IS TWO INCHES WIDE. SO YOU TAKE THAT TWO INCHES, CUT IT DOWN TO ONE INCH OFF OF THIS MARK, AND RIGHT ABOUT THERE IS GONNA BE THE CENTER OF OUR SIX INCH PLATE. I'M ALSO TACKING IN A REAR CROSS MEMBER THAT SCOTT CUT OUT FOR US, AND THEN WE CAN MEASURE FROM THERE TO OUR AXLE CENTER MARK.

(SCOTT)>> WE'RE GONNA MEASURE FROM OUR AXLE CENTER LINE MARK BACK OUR 42 INCHES THAT WE JUST MEASURED IN THE CAR AND MARK OUR FRAME RAIL. SO WE CAN TRIM THE BACK OFF AND IT'LL PLUG RIGHT IN.

(TOMMY)>> WHILE WE SET IN OUR FRAME RAILS WE NEED TO LEVEL THEM OUT.

(SCOTT)>> THERE YOU GO, THAT'S MORE LIKE IT.

(TOMMY)>> AND USE A PLUMB BOB TO SET THEM IN POSITION HORIZONTALLY.

(RICK)>> SOME EIGHTH INCH WALL RECTANGULAR TUBING WILL MAKE FOR SOME GREAT FRAME CONNECTORS.

WE'VE JUST GOT TO MAKE A LITTLE ROOM FOR THEM TO POKE THROUGH THE FLOOR.

AT THE END OF THE DAY IT'LL ADD A LOT OF

STRENGTH TO THE CAR.

(SCOTT)>> THAT'S WHAT ONE OF OUR BACK HALF KITS LOOK LIKE IN A '74 DART.

(RICK)>> NOW I HAVEN'T FLATTENED THESE TIRES BUT THERE IS NO AMOUNT OF PUSHING AND SHOVING THAT'S GONNA GET THIS TIRE THROUGH THAT WHEEL WELL. SO THAT MEANS WE'RE GONNA HAVE TO GET RID OF SOME MORE OF THAT DODGE SHEET METAL.

(TOMMY)>> ONCE WE GET THE MOTOR IN IT, IT'LL MASH THE FRONT DOWN JUST ABOUT WHERE IT NEEDS TO BE SITTING. OUT BACK WE USED A SET OF SCOTT'S MOCK UP SHOCKS SO IT'S SITTING RIGHT AT RIDE HEIGHT.

(RICK)>> WELL WE'RE STARTING TO GET A PRETTY GOOD IDEA THE AMOUNT OF ATTITUDE THIS THING IS GONNA HAVE WHEN IT HITS THE STREET. NOW WE'VE STILL GOT TO DO WHEEL TUBS, A BUNCH OF INTERIOR TIN, AND A FULL ROLL CAGE WILL DEFINITELY HELP STIFFEN UP THE SPINE IN THIS OLD GIRL. ONE STITCH AT A TIME AND SHE'LL GET THERE.

(ANNOUNCER)>> STICK AROUND AND SEE HOW YOU CAN BUILD YOUR OWN ONE OF A KIND STEEL SPOILER.

(TOMMY)>> WELL WE PLUGGED IN OUR FRONT AND REAR INTO OUR DODGE AND IT'S WELL ON ITS WAY TO SCARING SOME LAW ABIDING CITIZENS, BUT WE'RE GONNA LEAVE IT ALONE FOR NOW AND HOP OVER TO ONE OF OUR OTHER PROJECTS. IT'S TIME FOR AN UPDATE ON OUR OLDSMOBILE. THERE'S STILL A LOT OF SHEET METAL WORK LEFT TO DO TO OUR CAR. WE WANT IT TO HAVE SEVERAL CUSTOM TOUCHES. THE HURST EDITION CARS THAT WE'RE BASING OURS OFF OF CAME WITH THE REAR SPOILER, AND YOU CAN GET A REPOPPED ONE FROM OUR BUDDIES DOWN AT YEAR. BUT WE WANTED OURS TO HAVE A LITTLE MORE OF A CUSTOM FEEL. SO I'M GONNA FAB ONE UP FROM SCRATCH. THE FIRST THING YOU WANT TO DO IS TO MAKE SURE YOUR TRUNK LID'S FIT BECAUSE IF IT'S CROOKED AND YOU BUILD A SPOILER OFF IT, WHENEVER YOU GO TO FIT IT LATER DOWN THE ROAD, YOUR SPOILER'S GONNA BE OFF. SO JUST MAKE SURE IT'S IN GOOD SHAPE. OKAY THE NEXT THING YOU WANT TO DO IS KINDA START DETERMINING WHAT YOU WANT IN YOUR DESIGN. I'M GONNA PLAY OFF THE BACK SIDE OF THIS BODY LINE, KINDA GIVING IT A LEANING FORWARD MOTION. AND WITH THIS REPRESENTING THE BACK EDGE OF THE SPOILER, YOU

CAN DETERMINE YOUR WIDTH. HOW WIDE YOU WANT THE TOP TO BE, AND I DON'T THINK I'D WANT IT ANY WIDER THAN SAY FIVE AND A HALF INCHES. THIS'LL BE YOUR FRONT EDGE FOR THE TOP OF THE SPOILER. ALSO I WANT TO DETERMINE MY HEIGHT THAT I'D WANT THE

SPOILER WITHIN ABOUT TWO INCHES OUGHT TO BE GOOD. OKAY NOW ALL I'VE GOT TO DO IS DUPLICATE THIS ON THE OTHER SIDE AND WE CAN START BENDING SOME METAL. I'M GONNA USE QUARTER INCH ROD TO BUILD THE GENERAL SHAPE OF MY SPOILER. SO I'VE GOT TO DETERMINE THE WIDTH TO KNOW HOW WIDE I NEED TO CUT THE METAL, AND THEN ADD ABOUT THREE INCHES PER SIDE FOR THE SIDES. SO THAT'S 69 AND A HALF. OKAY NOW I NEED TO FIND THE CENTER OF THE TRUNK LID, WHICH WOULD BE 31 AND THREE QUARTERS. I'VE GOT TO FIND THE CENTER OF THE ROD, HALF OF 69 AND A HALF, WHICH IS 34 AND THREE QUARTERS. NOW I LINE UP MY TWO CENTERS AND I CAN DETERMINE WHERE I WANT MY BEND TO START. I'M GONNA PUT THAT MARK AT THE EDGE OF THE JAWS OF THE VICE AND MARK ABOUT AN INCH FROM IT. THEN USE A WRENCH ON THAT LAST MARK. YOU CAN CONTROL YOUR BEND IN BETWEEN THE TWO MARKS KEEPING THEM CONSISTENT. A SIMPLE WAY TO CHECK YOUR BENDS TO SEE IF THEY BOTH MATCH, USE A FLAT SURFACE, SLIP IT AROUND, CAN'T GET MUCH BETTER THAN THAT, AND FIRST TRY, THAT'S NOT BAD. OKAY NOW'S A GOOD TIME FOR US TO SET OUR HEIGHT AND MARK THIS ROD. I WANT MY SPOILER TO BE TWO INCHES HIGH. THEN WE CAN MARK THE ROD TO THE TOP OF THE QUARTER. I ALSO WANT TO TAKE THE ROD AND BEND IT FORWARD SIMILAR TO THE WAY WE DID THIS, GIVE IT A LITTLE MORE SHAPE. WHAT WE'RE GONNA DO IS SHAPE THE ROD TO MATCH THE CONTOUR OF THE TRUNK LID. WHAT WE'RE LOOKING FOR IS KIND OF A GRADUAL BEND.

YOU DON'T WANT TO USE ANYTHING SHARP TO BEND IT LIKE A CORNER BECAUSE WHAT THIS WILL DO, IT'LL KINDA PUT A KINK INTO IT. SO WHAT I'M GONNA USE IS A SQUISHY SURFACE, THIS TUMMY. SEE, NOT BAD AT ALL. I MADE THE REAR BAR JUST LIKE I SHOWED YOU ON THE FRONT ONE. THIS PIECE HERE MAY LOOK A LITTLE ODD, BUT WHAT I'M DOING IS USING IT AS A GUIDE, THAT WAY I CAN SET THIS ROD AT THE SAME ANGLE OF MY QUARTER. I'VE GOT TO BUILD A COUPLE OF LEGS FOR MY SPOILER.

I MADE ME A TEMPLATE OF WHAT I WANT MY BASE PLATE TO LOOK LIKE. SO I'VE GOT TO CUT THAT OUT OF STEEL AND THEN I'LL CUT A FEW RODS TO CONNECT IT, DRILL A COUPLE OF HOLES TO MOUNT IT, THEN MOVE ON TO THE NEXT SIDE. A COUPLE OF FIVESIXTEENTHS BOLTS DROPPED INTO PLACE, TACKED IN PLACE, WORKS GREAT, THERE'S A COUPLE OF STUDS. THIS IS THE FIRST PIECE THAT'S GONNA CONNECT OUR BASE TO OUR UPPER FRAME. THIS IS A PIECE THAT CONNECTS THE FRONT TWO TOGETHER. I MADE ME A TEMPLATE THAT'S GONNA BE THE SIDE OF THE LEGS. CUT IT OUT IN A PIECE OF STEEL, AND ALL YOU'VE GOT TO DO IS SHAPE IT TO FIT AND THEN TACK IT INTO PLACE. AND DON'T BE SURPRISED IF A PROJECT LIKE THIS TAKES YOU SEVERAL DAYS. WE'RE AT THE POINT TO START SKINNING THE FRAME WORK OF OUR SPOILER. WE WANT TO WORK FROM THE BOTTOM SIDE OF IT TO THE TOP. THAT WAY IT MAKES IT EASIER TO GET TO EVERYTHING AS YOU'RE FABBING IT UP. I'VE FOUND THAT THE BEST WAY TO CONSTRUCT SOMETHING LIKE THIS IS TO GO SLOW AND WORK WITH SMALL PIECES. DON'T BE AFRAID TO GET AFTER IT WITH A GRINDER OR A BODY HAMMER IF YOU NEED MOVE OR REMOVE SOME METAL. I'M ALSO A BIG FAN OF USING CARDBOARD TEMPLATES TO HELP ME GET THE METAL CLOSE TO SOMETHING TO START WITH. JUST TAKE YOUR TIME WITH IT EVEN IF YOUR WIFE IS TRYING TO HURRY UP AND GET YOU OUT OF THE GARAGE. OR IF YOU'RE LIKE ME AND HAVE A TV PRODUCER, WHICH IS KINDA LIKE A SECOND WIFE TRYING TO HURRY YOU ALONG. THE LAST THING I NEED TO DO IS SLICE THE SPOILER FREE SO THE TRUNK WILL OPEN. THAT'S HOW YOU BUILD A CUSTOM SPOILER. I'VE STILL GOT TO DO SOME WELDING AND GRINDING, AND THEN CAP OFF BOTH ENDS FROM WHERE I CUT IT LOOSE. THEN FOLLOW THAT UP WITH SOME BODY WORK. BUT IF I DID MY METAL WORK RIGHT, THERE WON'T BE A WHOLE LOT OF THAT REQUIRED.

IF YOU GUYS HAVE ANY QUESTIONS ABOUT WHAT YOU'VE SEEN ON TODAY'S SHOW, CHECK OUT POWERBLOCK TV DOT COM. WE'RE ALL OUT OF TIME FOR THIS WEEK. SO UNTIL NEXT WEEK, Y'ALL KEEP IT BETWEEN THE DITCHES.