More Hurst Olds Episodes

MuscleCar Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Currie Enterprises

Axles, Custom Order, Available in 30, 31, 33, 35, Spline, Axle Bearings and Seals, Custom Bolt Pattern, Kit

Art Morrison Enterprises

GT-Sport Chassis For

1968-1972 Chevelle

Loctite

Loctite Extend Rust Treatment Coating

Miller Electric Manufacturing Co.

Millermatic 210 MIG Arc Welding Power Source

Performance Design

Cross-ram style dual plenum, dual throttle intake manifold,

All carbon fiber and billet aluminum construction, Fits LS7 Port; LS3 port following release of LS7

The Industrial Depot

Industrial Depot - Fasteners, Hardware, and Shop Supplies

Episode Transcript

(ANNOUNCER)>> TODAY ON MUSCLE

CAR, WE SHOW YOU HOW TO CONVERT AN EXTERNAL FUEL PUMP

SETUP TO AN IN TANK JUGGERNAUT THAT'LL KEEP YOUR POWER PLANT

FROM EVER GETTING THIRSTY. THEN SOME METAL WORKING TECH

AS WE DO A HARD TO DETECT PATCH PANEL ON A DOOR SKIN. AND FINALLY THREE DIFFERENT

WAYS TO PERSONALIZE YOUR GLASS

FOR THAT ONE OF A KIND LOOK.

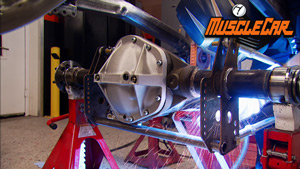

(STEVE)>> OUR '69 HURST OLDSMOBILE RESTO MOD CAR IS MAKING PROGRESS EVERY DAY. IF YOU REMEMBER, OUR INTENT WAS TO KEEP THE CLASSIC LINES OF THE HURST OLDSMOBILES WHILE TRENDING TOWARDS A MODERN DAY HIGH END MUSCLE CAR. WE'RE GOING TO DO THAT WITH THE HELP OF AN ART MORRISON G/T SPORT CHASSIS. A TOP OF THE LINE FOUNDATION FOR OUR OLDSMOBILE BUILD MADE TO ACCEPT '64 TO '72 CHEVELLE STYLE APPLICATIONS. LIKE OUR OLDS, THEY CAN BE BUILT TO ACCOMMODATE THE

ENTIRE SPECTRUM OF GM MOTORS. MATED TO A CURRIE NINE INCH REAR AXLE, COIL OVER SUSPENSION ALL AROUND, AND TUBULAR AARMS, THIS SYSTEM IS GOING TO BE A GREAT START TO OUR BUILD.

(TOMMY)>> OF COURSE BESIDES THE FACT THAT WE WANT THIS THING TO HANDLE LIKE A SLOT CAR, WE ALSO WANT IT TO BE ABLE TO HOLD UP TO THE POWER PLANT THAT WE'RE GONNA TOSS INTO IT. THAT POWER PLANT IS A 454 LSX FROM CHEVROLET PERFORMANCE. LIKE THE CLASSIC BIG BLOCKS, IT'S A 454 CUBIC INCH IRON BLOCK BUT WITH MODERN ENGINEERING AND AN 11 TO ONE COMPRESSION RATIO, YOUR OLE PAPPY'S OLD TOW TRUCK MOTOR PROBABLY WON'T HANG WITH THE 620 HORSEPOWER THAT THIS THING WILL PRODUCE RIGHT OUT OF THE BOX. OF COURSE, SINCE THAT'S THE BASE LINE NUMBER, THERE'S A GOOD AMOUNT OF WIGGLE ROOM TO PUSH YOUR NUMBERS EVEN HIGHER THAN THAT.

(STEVE)>> ONE WAY WE'RE GONNA MAKE THAT HAPPEN IS WITH THIS BAD BOY RIGHT HERE.

THIS IS A CARBON XR INTAKE FROM PERFORMANCE DESIGN. ONE LOOK AT IT AND YOU CAN TELL WE'RE PRETTY SERIOUS ABOUT WHAT WE'RE GONNA DO WITH THE TOP END OF OUR LSX. WITH THE DIMENSIONS OF 21 INCHES WIDE, OVER 20 INCHES LONG, AND 10 INCHES HIGH, THIS THING IS GOING TO MAKE ONE HECK OF AN IMPRESSION. ANYBODY WHO OPENS THE HOOD ON THIS CAR IS DEFINITELY GONNA GO WHOA, BECAUSE I'LL TELL YOU WHAT, THAT'S PRETTY MUCH BEEN THE REACTION AROUND THIS PLACE. BUT THE GOOD THING IS IT'S NOT JUST GONNA BE

ANOTHER PRETTY FACE. YOUR THROTTLE BODY CHOICES ON THESE UNITS ARE DUAL 75 MILLIMETER, 87 MILLIMETER, OR LIKE THESE 90 MILLIMETER GM PIECES WHICH WERE ORIGINALLY BUILT FOR FIVETHREE, SIXZERO, AND SIXTWO GM MOTORS. THEN THE AIR TRAVELS THROUGH A SET OF 12.5 INCH RUNNERS WITH A 2.75 INCH BELL MOUNT ENTRANCE DIAMETER, WHICH TERMINATE DIRECTLY AT THE INTAKE VALVES. WHAT'S GREAT IS THAT THERE'S A LOT OF POWER TO BE HAD HERE BECAUSE THE INTAKE RUNNERS RUN ALMOST STRAIGHT DOWN TO THE CYLINDERS, VERSUS THE STOCK MANIFOLDS, WHICH CAN CAUSE A LOT OF TURBULENCE ON THEIR WAY DOWN TO THE PISTONS. WHEN THE GUYS AT HORSEPOWER COMBO'ED OUR BLOCK UP WITH THIS INTAKE, THEY WERE QUICKLY ABLE TO GET ANOTHER 30 PONIES OUT OF IT. PERFORMANCE DESIGN, THE MAKERS OF THIS INTAKE, REPORT THAT THEY'VE HAD INCREASES OF 50 HORSEPOWER OR MORE. THE FUEL RAILS COME DIRECTLY FROM PERFORMANCE DESIGN AS PART OF THE SYSTEM AND GET COUPLED TO A SET OF LS SEVEN / LS THREE STYLE INJECTORS. WELL WE'RE GONNA GET STARTED ON THE FUEL SYSTEM OF OUR OLD CUTLASS TODAY. AND WHEN WE DO, WE'RE GONNA HAVE ONE DISTINCTIVE POWER PLANT UNDERNEATH THE GOOD AND PUT OUT SOMEWHERE IN THE NEIGHBORHOOD OF 650 HORSEPOWER.

(TOMMY)>> THE FOUNDATION FOR OUR FUEL SYSTEM IS GOING TO BE THIS. IT'S AN RCI FUEL CELL THAT WE GOT FROM SUMMIT RACING. NOW THIS THING'S ALL ALUMINUM AND IT COMES WITH A COMMON 90 OHM SENDER ALREADY INSTALLED. NOW SUMMIT RACING OFFERS ALL TYPES OF FUEL CELLS RANGING FROM BIG TO SMALL, STARTING AT ONE GALLON AND GOING UP FROM THEIR. THIS ONE'S GOT A PICK UP PORT, RETURN PORT, AND A VENT PORT, BUT THE PICK UP PORT ISN'T GONNA SEE ANY ACTION BECAUSE WE'VE GOT OTHER PLANS FOR GETTING FUEL OUT OF THERE. TO KEEP THE GOGO JUICES FLOWING WE'RE GONNA USE ONE OF THESE, AN AEROMOTIVE A-1,000 FUEL PUMP. NOW THIS PUMP IS UTILIZED BY THE BIG THREE IN THEIR HEAVY HITTER CARS LIKE THE COBRA JETS, THE COPO CAMAROS, AND THE DRAG PACK MOPARS. THE COOL THING THAT AEROMOTIVE HAS DONE HAS TAKEN THIS

AWESOME PUMP AND ADAPTED IT SO IT CAN BE INSTALLED EASILY IN A UNIVERSAL FUEL TANK. THIS PUMP CARRIES 90 PSI AND IS CAPABLE OF SUPPORTING 1,000 HORSEPOWER ON A FORCED INDUCTION ENGINE, AND 1,300 HORSEPOWER ON NATURALLY ASPIRATED. WITH THIS SETUP WE'LL NEVER HAVE TO WORRY ABOUT GETTING ENOUGH FUEL TO THAT LSX. THIS PUMP IS ALSO AVAILABLE IN KITS TO SUPPORT HIGH HORSEPOWER AND HIGH PERFORMANCE VEHICLES LIKE CAMAROS, MUSTANGS, AND CORVETTES. SO IF YOU'RE IN THE MARKET FOR SOMETHING LIKE THIS, IT'S SOMETHING YOU'LL WANT TO CHECK OUT.

(ANNOUNCER)>> STILL AHEAD, MODIFYING A FUEL CELL FOR AN INTERNAL PUMP AND ADDING A BAFFLE. PLUS A VARIETY OF GLASS ETCHING METHODS FOR A CUSTOM LOOK.

(TOMMY)>> WELL WE GOT OUR TANK STRIPPED DOWN, READY TO CUT INTO IT TO START MAKING ROOM FOR OUR NEW PUMP. JUST NEED TO MAKE A FEW MEASUREMENTS TO DETERMINE THE LOCATION OF WHERE WE NEED TO CUT. THE TOP OF OUR PUMP IS ABOUT FOUR AND A HALF INCHES. SO HALF OF THAT WOULD GIVE US TWO AND A QUARTER, BUT I WANT TWO INCHES OF CLEARANCE FROM THE SIDE OF THE TANK. SO I ADD THAT BACK TO IT, THAT'S WHERE OUR CENTER WOULD BE. I'M GONNA TRY TO KEEP THE SHAVINGS CLEANED OFF OF THE TANK WHILE I WORK. IT'S EASIER THAN VACUUMING THEM FROM THE INSIDE IF THEY FALL IN.

NOW I MADE A MARK ON EACH SIDE OF IT WHENEVER IT'S PUSHED ALL THE WAY TO ONE SIDE. THAT WAY I CAN FIND CENTER. ALL YOU DO IS KINDA BALANCE OUT THE DISTANCE BETWEEN ALL FOUR MARKS. GIVES YOU A REALLY CLOSE ESTIMATE OF WHERE IT NEEDS TO BE. CAREFULLY MARK EACH HOLE.

I'LL MAKE TWO INITIAL HOLES THAT CAN BE USED TO ALIGN THE TOP OF THE PUMP AND KEEP IT STATIONARY. SO THAT I CAN MARCH THE REST OF THE HOLES AND THEY'LL ALL LINE UP REAL NICE. I'VE GOT TO ALSO MAKE THE HOLES FOR THE RETAINING RING'S FASTENERS. IT'S A MATTER OF TWO MORE HOLES, BUT THESE HAVE TO BE COUNTER SUNK SO THAT THE RING SCREWS WILL BE FLUSH ON THE TOP OF THE TANK. WITH OUR MOUNTING HOLES ALL DONE, WE'RE READY TO MOVE ON TO THE NEXT STEP, AND THAT IS INSTALLING A BAFFLE. NOW IT'S NOT REALLY MANDATORY BUT IT IS HIGHLY RECOMMENDED BECAUSE WITHOUT THIS YOU'RE GONNA RUN INTO PREMATURE FAILURE BECAUSE THIS PUMP NEEDS KINDA A SURPLUS OF FUEL AROUND ITSELF BECAUSE OTHERWISE IT'LL RUN DRY AND THEN JUST MESS UP ON ITSELF. THE WAY THAT I'M PLANNING ON ATTACHING A BAFFLE TO THE TANK IS BY DRILLING TWO HOLES ON EACH SIDE OF THE TANK AND THEN SIMPLY PLUG WELDING.

THE BAFFLE IS GONNA SIT ABOUT TWO INCHES AWAY FROM THE BOTTOM OF THE PUMP. THIS WILL GIVE US THE RECOMMENDED EIGHT BY EIGHT SIZE CHAMBER FOR THE BAFFLE FUEL SUPPLY TO THE PUMP.

NOW WITH A BAFFLE YOU WANT TO MAKE SURE TO PUT A SMALL HOLE OR A NOTCH HERE ON THE BOTTOM OF IT. THAT WAY IF YOUR FUEL LEVEL IS LOWER THAN THE HEIGHT OF THE BAFFLE, IT'S GOT A WAY TO GET IN THERE TO THE PUMP. AFTER THE BAFFLE IS IN, FOUR QUICK PLUG WELDS WITH THE TIG MACHINE AND SHE'S ALL GOOD. WITH OUR BAFFLE WELDED IN PLACE AND OUR TANK CLEANED OUT, WE'RE JUST ABOUT READY TO INSTALL OUR PUMP. BUT BEFORE WE DO THAT WE NEED TO ASSEMBLE OUR PICK UP. THE FIRST THING YOU WANT TO DO IS TO MEASURE FROM THE TOP OF THE TANK TO THE FLOOR OF THE TANK. YOU DON'T WANT IT EXACTLY ON THE BOTTOM OF IT. YOU WANT TO GIVE YOURSELF ABOUT A QUARTER TO AN

EIGHTH INCH CLEARANCE.

THAT PUTS US AT 11 AND THREE QUARTER. THIS IS THE PART OF THE PUMP THAT I WAS REFERRING TO AS BEING ADAPTABLE FOR DIFFERENT SETUPS. THE PICK UP TUBE COMES WITH EXTRA LINKS THAT YOU CUT TO SIZE FOR YOUR SPECIFIC TANK.

MAKE SURE YOU ACCOUNT FOR THE SIZE OF THE FITTING THAT SCREWS ONTO THE PUMP.

AND THIS PICK UP FILTER ASSEMBLY, WHICH WILL DO A NICE JOB OF KEEPING ANY DEBRIS OUT OF YOUR PUMP. WITH THE RETAINER RING IN PLACE LAY DOWN THE GASKET,

SLIDE IN THE PUMP, AND TIGHTEN DOWN YOUR SCREWS IN A STAR PATTERN. PUMP INSTALLED!

(ANNOUNCER)>> STICK AROUND TO SEE HOW TO MAKE A STEALTH PATCH REPAIR THAT MAKES YOUR RIDE GOOD AS NEW.

(TOMMY)>> WELCOME BACK FOLKS. WE'VE MOVED OVER TO THE DOORS OF OUR OLD OLDSMOBILE BECAUSE I WANT TO SHOW YOU HOW TO MAKE A REPAIR THAT'S SUPER COMMON TO THESE OLD MUSCLE CARS. THE FRONT CORNER HAS STARTED TO ROT AWAY, AND IF IT'S LEFT UNCHECKED, THEN THE PROBLEM WILL CONTINUE TO MAKE ITSELF WORSE UNTIL YOU FIND YOURSELF NEEDING AN ENTIRE DOOR. WE'RE GONNA SHOW YOU HOW TO FIX IT AND PRETTY MUCH ALL YOU'RE GONNA HAVE TO INVESTS IN IT IS THE TIME TO DO IT. MY PLAN IS TO CUT OUT JUST ABOVE THIS ROTTEN SPOT AND RIGHT ACROSS THIS EDGE, AND THERE'S A REASON FOR THAT. WE WERE ABLE TO SAVE THIS INNER LIP. AND DOING THAT, ONCE IT'S GROUND DOWN, IT'LL BE REALLY HARD TO TELL THERE WAS EVEN A REPAIR MADE. FIRST I'LL EYEBALL THE AREA THAT I WANT TO CUT OUT. THIS ISN'T AN EXACT SCIENCE. YOU PRETTY MUCH JUST LOOKING TO GET RID

OF THE HONOREE PARTS. I'M TRYING NOT TO MESS UP MY PATCH SO I HAVE A GOOD TEMPLATE TO MAKE IT. WITH MY BAD SPOT CUT OUT, I'VE GOT TO DO A LITTLE BIT OF GRINDING AND THEN FOLLOW IT UP WITH SOME WIRE BRUSH ON TOP OF THAT RUST. AND THEN TREAT IT WITH SOME EXTEND FROM LOCTITE.

THIS EXTEND WILL NEUTRALIZE ANY CORROSION AND PREVENT PROBLEMS LATER DOWN THE ROAD. I'LL USE A PIECE THAT I CUT OUT AS A TEMPLATE FOR THE NEW METAL THAT I'LL BE PLUGGING INTO THE HOLE. I'LL DO A LITTLE MORE FINE TUNING WITH A FILE, GET IT TO A GOOD FIT. IT'S AT LEAST EASIER TO KEEP FILE FITTING THIS THING THAN TO TRY TO STRETCH IF I MADE IT TOO SMALL. THIS PANELS GOT A LITTLE BIT OF A CURVE TO IT ALSO, SO I'VE

GOT TO DO A LITTLE SHAPING WITH IT. NOW WITH THIS BIG HEAVY TABLE THAT I'VE GOT, JUST A LIGHT TAP OF A HAMMER, YOU CAN HOLD IT UP JUST ON ITS EDGE, MOVE THE HAMMER ACROSS IT, AND IT'LL SLOWLY PUT A CURVE INTO THAT PIECE OF METAL. GETTING CLOSER, NEED A LITTLE MORE CURVE

IN THE MIDDLE OF IT.

JUST ABOUT THERE. NOW YOU CAN USE A PAIR OF TIN SNIPS, A DIE

GRINDER, OR EVEN A FILE. I LIKE A FILE BECAUSE IT'S A LITTLE SLOWER BUT IT'S A LOT MORE PRECISE.

NOW THIS TYPE OF JOINT THAT WE'RE GONNA BE DOING IS CALLED A BUTT WELD JOINT, AND WHAT THAT REFERS TO IS YOU'RE BUTTING TWO PIECES OF METAL TOGETHER AND YOU'RE WELDING AROUND IT.

ONE THING THAT YOU WANT TO KEEP IN MIND WHEN YOU'RE DOING

SOMETHING LIKE THIS IS YOU WANT TO LEAVE A LITTLE BIT OF ROOM AROUND THE PERIMETER OF YOUR WELD. BECAUSE IF YOU DON'T AND YOUR PENETRATION OF YOUR WELDS ARE NOT REALLY ALL THAT GREAT. WHEN YOU GRIND OFF ALL THAT WELD THE PATCH WILL LITERALLY FALL RIGHT OUT. FOR THOSE OF YOU THAT ARE STARTING TO DIP YOUR TOE INTO THE WORLD OF WELDING, HERE'S A LITTLE TIP FOR YOU. OUR MILLER- MATIC 210 HAS A CHART HERE ON THE INSIDE OF THE CASE THAT LETS YOU KNOW WHAT YOUR WELDING SETTINGS NEED TO BE FOR WHAT YOU'RE WELDING. BASED ON THE METAL THICKNESS, WIRE DIAMETER, AND INERT GAS BEING USED., WE CAN FIND A BASE LINE SETTING FOR THE POWER LEVEL AND WIRE SPEED. ONCE YOU GET A LITTLE BIT OF EXPERIENCE UNDER YOUR BELT, KINDA GET A FEEL FOR YOUR WELDER, YOU CAN TWEAK YOUR SETTINGS TO DIAL IT IN FOR THE PERFECT WELD. WE'RE READY TO GO AHEAD AND BURN IN OUR LITTLE PATCH. AND IF YOU WAS TO STRETCH ALL THAT WELDING OUT, IT'LL BE GETTING THAN 10 INCHES. SO WE NEED TO MAKE SURE THAT WE DON'T PUT TOO MUCH HEAT IN OUR PANEL, OR OTHERWISE WE'RE RUNNING THE RISK OF WARPING IT ALL UP. LIKE WE ALWAYS SAY, DON'T SIT THERE AND RUN A BEAD IN ONE SPOT OR YOU'LL WARP THE METAL INTO OBLIVION. PATIENCE IS A VIRTUE. MOVE YOU TACK AROUND, AND BEFORE YOU KNOW YOU'LL HAVE NICE NEW PATCH PANEL IN PLACE. GRIND THE WELDS DOWN NICE AND FLAT, THEN SHE'S READY FOR SOME PLASTIC AND SOME PRIMER. WELL WE MANAGED TO REPAIR OUR DOOR AND AT THE SAME TIME SAVE THAT STOCK PINCH WELD HERE ON THE BOTTOM THAT WE WERE TALKING ABOUT EARLIER. WHAT THAT MEANS IS THIS DOOR'S GONNA LOOK STOCK WHETHER IT'S OPEN OR CLOSED, WITH A LITTLE BODY WORK OF COURSE.

(ANNOUNCER)>> EVER THINK OF TAKING UP THE

HOBBY OF GLASS ETCHING? WELL THERE'S MONEY TO BE MADE IF YOU KNOW HOW TO DO IT.

(STEVE)>> HEY GUYS, I WANT TO TAKE A SECOND TO SHOW YOU SOMETHING THAT TOMMY DID ON OLD PROJECT BUSINESS TIME THAT'S PRETTY COOL, PERSONALIZED THE CAR, AND BROUGHT IT UP TO THAT NEXT LEVEL. TOMMY HAS ETCHED THESE WORDS INTO THE PASSENGER SIDE MIRROR OF THE CAR. INSTEAD OF "OBJECTS MAY BE CLOSER THAN THEY APPEAR" IT SAYS "OBJECTS WILL APPEAR SMALLER DURING ACCELERATION". NOW ONLY IS THAT A ONE OF A KIND ADDITION TO THE CAR, IT'S JUST PLAIN COOL. BUT LIKE MANY OTHER THINGS THAT WE DO, THERE'S MORE THAN ONE WAY TO ACHIEVE THAT RESULT. SO IN A MINUTE WE'RE GONNA SHOW YOU GUYS THREE DIFFERENT WAYS TO DO GLASS ETCHING WHICH ARE BOTH AFFORDABLE AND SIMPLE. BACK WHEN A FEW MORE OF THE HAIRS THAT LAY ON MY BACK WERE UP ON TOP OF MY HEAD, I USED TO HAVE ONE OF THESE $20 DOLLAR ENGRAVERS. I'D GO TO CAR SHOWS ON THE WEEKEND, PLUG IN MY EXTENSION CORD, MAKE A FEW EXTRA BUCKS. IT'S KINDA BECOME A LOST ART THOUGH, BUT EVERY NOW AND THEN I'LL SHOW UP AT A CAR SHOW. IT'S KINDA FUN TO SEE.

(TOMMY)>> BEFORE YOU GRAB A LAWN CHAIR AND CAMP OUT AT YOUR LOCAL CAR SHOW TO MAKE SOME EXTRA CASH DOING THIS, YOU'LL WANT TO SPEND A GOOD AMOUNT OF TIME LEARNING HOW TO DO IT. AFTER ALL, THIS IS KINDA LIKE GETTING A TATTOO. ONCE YOU LAY DOWN THE LINES, THERE'S REALLY NO GOING BACK. AND IF YOU BUGGER UP SOMEBODY'S WINDOW ON THEIR RAMBLER, THEY MIGHT BE GIVING YOU THE BUSINESS, AND NOT THE GOOD KIND IF YOU KNOW WHAT I MEAN.

(STEVE)>> WELL GUYS, THERE YOU GO. THERE'S A QUICK EXAMPLE OF HOW YOU CAN ETCH GLASS WITH AN ELECTRIC ENGRAVER. TOMMY'S GOT A COUPLE OF OTHER WAYS HE'S GONNA SHOW YOU WHICH ARE JUST AS EASY AND JUST AS EFFECTIVE.

(TOMMY)>> I LIKE THAT BEAR RIGHT THERE BUD.

(STEVE)>> YOU THINK, IT'S NOT TOO BAD.

(TOMMY)>> NOW ANOTHER WAY YOU CAN DO SOME GLASS ETCHING IS WITH A CHEMICAL. NOW IF YOU'RE A LITTLE BIT WORRIED ABOUT YOUR ARTISTIC SKILLS YOU CAN DO IT WITH THIS VINYL DECAL.

THIS STUFF MIGHT BE KINDA HARD TO FIND AT THE PART STORES,

BUT YOU CAN FOR SURE GET IT AT ONE OF THEM FLOWERY HOBBY STORES WITH THE PLASTIC BIRDS AND THE WHICKER BUCKETS. BRUSH IT ON AND LET IT DO ITS JOB. THE HEAVIER YOU APPLY IT, THE GREATER THE EFFECT. I'VE GOT A HANDY DANDY BUCKET TO WASH IT OFF WITH, THE

REGULAR KIND, NOT THE WHICKER KIND. BUT MAKE SURE TO WEAR SOME GLOVES AND EYE PROTECTION BECAUSE IT'S A CAUSTIC MATERIAL AFTER ALL. WELL THAT'S THE WAY TO DO IT IF YOU WANTED TO USE THE CHEMICAL, BUT WE'VE GOT ONE MORE WAY TO SHOW YOU.

THIS IS PRETTY STRAIGHT FORWARD, BUT IF YOU WANT TO DO

THIS, YOU'LL WANT TO TURN YOUR BLASTER WAY DOWN SO YOU DON'T BLOW THE MASK PLUM OFF THE GLASS. WELL THERE YOU GO. WE SHOWED YOU A FEW DIFFERENT WAYS TO ETCH GLASS AND ALL THREE HAVE A DIFFERENT EFFECT. SO DEPENDING ON WHAT YOU'RE GOING AFTER, USE THE

ONE YOU NEED TO GO WITH.

(STEVE)>> THE SAND BLASTING AND THE CHEMICAL ARE DEFINITELY THE ONES TO USE IF YOU'RE LOOKING FOR UNIFORMITY SUCH AS DOING LETTERING AND BANNERING.

I PREFER THE GLASS ETCHING DONE WITH THE ELECTRIC ENGRAVER FOR ONE OFF ITEMS THAT ARE MORE ARTISTIC. IF YOU'VE GOT ANY QUESTIONS ABOUT ANYTHING YOU SAW ON THE SHOW TODAY.

(TOMMY)>> GO OVER TO POWERBLOCK TV DOT COM.

Show Full Transcript

FOR THAT ONE OF A KIND LOOK.

(STEVE)>> OUR '69 HURST OLDSMOBILE RESTO MOD CAR IS MAKING PROGRESS EVERY DAY. IF YOU REMEMBER, OUR INTENT WAS TO KEEP THE CLASSIC LINES OF THE HURST OLDSMOBILES WHILE TRENDING TOWARDS A MODERN DAY HIGH END MUSCLE CAR. WE'RE GOING TO DO THAT WITH THE HELP OF AN ART MORRISON G/T SPORT CHASSIS. A TOP OF THE LINE FOUNDATION FOR OUR OLDSMOBILE BUILD MADE TO ACCEPT '64 TO '72 CHEVELLE STYLE APPLICATIONS. LIKE OUR OLDS, THEY CAN BE BUILT TO ACCOMMODATE THE

ENTIRE SPECTRUM OF GM MOTORS. MATED TO A CURRIE NINE INCH REAR AXLE, COIL OVER SUSPENSION ALL AROUND, AND TUBULAR AARMS, THIS SYSTEM IS GOING TO BE A GREAT START TO OUR BUILD.

(TOMMY)>> OF COURSE BESIDES THE FACT THAT WE WANT THIS THING TO HANDLE LIKE A SLOT CAR, WE ALSO WANT IT TO BE ABLE TO HOLD UP TO THE POWER PLANT THAT WE'RE GONNA TOSS INTO IT. THAT POWER PLANT IS A 454 LSX FROM CHEVROLET PERFORMANCE. LIKE THE CLASSIC BIG BLOCKS, IT'S A 454 CUBIC INCH IRON BLOCK BUT WITH MODERN ENGINEERING AND AN 11 TO ONE COMPRESSION RATIO, YOUR OLE PAPPY'S OLD TOW TRUCK MOTOR PROBABLY WON'T HANG WITH THE 620 HORSEPOWER THAT THIS THING WILL PRODUCE RIGHT OUT OF THE BOX. OF COURSE, SINCE THAT'S THE BASE LINE NUMBER, THERE'S A GOOD AMOUNT OF WIGGLE ROOM TO PUSH YOUR NUMBERS EVEN HIGHER THAN THAT.

(STEVE)>> ONE WAY WE'RE GONNA MAKE THAT HAPPEN IS WITH THIS BAD BOY RIGHT HERE.

THIS IS A CARBON XR INTAKE FROM PERFORMANCE DESIGN. ONE LOOK AT IT AND YOU CAN TELL WE'RE PRETTY SERIOUS ABOUT WHAT WE'RE GONNA DO WITH THE TOP END OF OUR LSX. WITH THE DIMENSIONS OF 21 INCHES WIDE, OVER 20 INCHES LONG, AND 10 INCHES HIGH, THIS THING IS GOING TO MAKE ONE HECK OF AN IMPRESSION. ANYBODY WHO OPENS THE HOOD ON THIS CAR IS DEFINITELY GONNA GO WHOA, BECAUSE I'LL TELL YOU WHAT, THAT'S PRETTY MUCH BEEN THE REACTION AROUND THIS PLACE. BUT THE GOOD THING IS IT'S NOT JUST GONNA BE

ANOTHER PRETTY FACE. YOUR THROTTLE BODY CHOICES ON THESE UNITS ARE DUAL 75 MILLIMETER, 87 MILLIMETER, OR LIKE THESE 90 MILLIMETER GM PIECES WHICH WERE ORIGINALLY BUILT FOR FIVETHREE, SIXZERO, AND SIXTWO GM MOTORS. THEN THE AIR TRAVELS THROUGH A SET OF 12.5 INCH RUNNERS WITH A 2.75 INCH BELL MOUNT ENTRANCE DIAMETER, WHICH TERMINATE DIRECTLY AT THE INTAKE VALVES. WHAT'S GREAT IS THAT THERE'S A LOT OF POWER TO BE HAD HERE BECAUSE THE INTAKE RUNNERS RUN ALMOST STRAIGHT DOWN TO THE CYLINDERS, VERSUS THE STOCK MANIFOLDS, WHICH CAN CAUSE A LOT OF TURBULENCE ON THEIR WAY DOWN TO THE PISTONS. WHEN THE GUYS AT HORSEPOWER COMBO'ED OUR BLOCK UP WITH THIS INTAKE, THEY WERE QUICKLY ABLE TO GET ANOTHER 30 PONIES OUT OF IT. PERFORMANCE DESIGN, THE MAKERS OF THIS INTAKE, REPORT THAT THEY'VE HAD INCREASES OF 50 HORSEPOWER OR MORE. THE FUEL RAILS COME DIRECTLY FROM PERFORMANCE DESIGN AS PART OF THE SYSTEM AND GET COUPLED TO A SET OF LS SEVEN / LS THREE STYLE INJECTORS. WELL WE'RE GONNA GET STARTED ON THE FUEL SYSTEM OF OUR OLD CUTLASS TODAY. AND WHEN WE DO, WE'RE GONNA HAVE ONE DISTINCTIVE POWER PLANT UNDERNEATH THE GOOD AND PUT OUT SOMEWHERE IN THE NEIGHBORHOOD OF 650 HORSEPOWER.

(TOMMY)>> THE FOUNDATION FOR OUR FUEL SYSTEM IS GOING TO BE THIS. IT'S AN RCI FUEL CELL THAT WE GOT FROM SUMMIT RACING. NOW THIS THING'S ALL ALUMINUM AND IT COMES WITH A COMMON 90 OHM SENDER ALREADY INSTALLED. NOW SUMMIT RACING OFFERS ALL TYPES OF FUEL CELLS RANGING FROM BIG TO SMALL, STARTING AT ONE GALLON AND GOING UP FROM THEIR. THIS ONE'S GOT A PICK UP PORT, RETURN PORT, AND A VENT PORT, BUT THE PICK UP PORT ISN'T GONNA SEE ANY ACTION BECAUSE WE'VE GOT OTHER PLANS FOR GETTING FUEL OUT OF THERE. TO KEEP THE GOGO JUICES FLOWING WE'RE GONNA USE ONE OF THESE, AN AEROMOTIVE A-1,000 FUEL PUMP. NOW THIS PUMP IS UTILIZED BY THE BIG THREE IN THEIR HEAVY HITTER CARS LIKE THE COBRA JETS, THE COPO CAMAROS, AND THE DRAG PACK MOPARS. THE COOL THING THAT AEROMOTIVE HAS DONE HAS TAKEN THIS

AWESOME PUMP AND ADAPTED IT SO IT CAN BE INSTALLED EASILY IN A UNIVERSAL FUEL TANK. THIS PUMP CARRIES 90 PSI AND IS CAPABLE OF SUPPORTING 1,000 HORSEPOWER ON A FORCED INDUCTION ENGINE, AND 1,300 HORSEPOWER ON NATURALLY ASPIRATED. WITH THIS SETUP WE'LL NEVER HAVE TO WORRY ABOUT GETTING ENOUGH FUEL TO THAT LSX. THIS PUMP IS ALSO AVAILABLE IN KITS TO SUPPORT HIGH HORSEPOWER AND HIGH PERFORMANCE VEHICLES LIKE CAMAROS, MUSTANGS, AND CORVETTES. SO IF YOU'RE IN THE MARKET FOR SOMETHING LIKE THIS, IT'S SOMETHING YOU'LL WANT TO CHECK OUT.

(ANNOUNCER)>> STILL AHEAD, MODIFYING A FUEL CELL FOR AN INTERNAL PUMP AND ADDING A BAFFLE. PLUS A VARIETY OF GLASS ETCHING METHODS FOR A CUSTOM LOOK.

(TOMMY)>> WELL WE GOT OUR TANK STRIPPED DOWN, READY TO CUT INTO IT TO START MAKING ROOM FOR OUR NEW PUMP. JUST NEED TO MAKE A FEW MEASUREMENTS TO DETERMINE THE LOCATION OF WHERE WE NEED TO CUT. THE TOP OF OUR PUMP IS ABOUT FOUR AND A HALF INCHES. SO HALF OF THAT WOULD GIVE US TWO AND A QUARTER, BUT I WANT TWO INCHES OF CLEARANCE FROM THE SIDE OF THE TANK. SO I ADD THAT BACK TO IT, THAT'S WHERE OUR CENTER WOULD BE. I'M GONNA TRY TO KEEP THE SHAVINGS CLEANED OFF OF THE TANK WHILE I WORK. IT'S EASIER THAN VACUUMING THEM FROM THE INSIDE IF THEY FALL IN.

NOW I MADE A MARK ON EACH SIDE OF IT WHENEVER IT'S PUSHED ALL THE WAY TO ONE SIDE. THAT WAY I CAN FIND CENTER. ALL YOU DO IS KINDA BALANCE OUT THE DISTANCE BETWEEN ALL FOUR MARKS. GIVES YOU A REALLY CLOSE ESTIMATE OF WHERE IT NEEDS TO BE. CAREFULLY MARK EACH HOLE.

I'LL MAKE TWO INITIAL HOLES THAT CAN BE USED TO ALIGN THE TOP OF THE PUMP AND KEEP IT STATIONARY. SO THAT I CAN MARCH THE REST OF THE HOLES AND THEY'LL ALL LINE UP REAL NICE. I'VE GOT TO ALSO MAKE THE HOLES FOR THE RETAINING RING'S FASTENERS. IT'S A MATTER OF TWO MORE HOLES, BUT THESE HAVE TO BE COUNTER SUNK SO THAT THE RING SCREWS WILL BE FLUSH ON THE TOP OF THE TANK. WITH OUR MOUNTING HOLES ALL DONE, WE'RE READY TO MOVE ON TO THE NEXT STEP, AND THAT IS INSTALLING A BAFFLE. NOW IT'S NOT REALLY MANDATORY BUT IT IS HIGHLY RECOMMENDED BECAUSE WITHOUT THIS YOU'RE GONNA RUN INTO PREMATURE FAILURE BECAUSE THIS PUMP NEEDS KINDA A SURPLUS OF FUEL AROUND ITSELF BECAUSE OTHERWISE IT'LL RUN DRY AND THEN JUST MESS UP ON ITSELF. THE WAY THAT I'M PLANNING ON ATTACHING A BAFFLE TO THE TANK IS BY DRILLING TWO HOLES ON EACH SIDE OF THE TANK AND THEN SIMPLY PLUG WELDING.

THE BAFFLE IS GONNA SIT ABOUT TWO INCHES AWAY FROM THE BOTTOM OF THE PUMP. THIS WILL GIVE US THE RECOMMENDED EIGHT BY EIGHT SIZE CHAMBER FOR THE BAFFLE FUEL SUPPLY TO THE PUMP.

NOW WITH A BAFFLE YOU WANT TO MAKE SURE TO PUT A SMALL HOLE OR A NOTCH HERE ON THE BOTTOM OF IT. THAT WAY IF YOUR FUEL LEVEL IS LOWER THAN THE HEIGHT OF THE BAFFLE, IT'S GOT A WAY TO GET IN THERE TO THE PUMP. AFTER THE BAFFLE IS IN, FOUR QUICK PLUG WELDS WITH THE TIG MACHINE AND SHE'S ALL GOOD. WITH OUR BAFFLE WELDED IN PLACE AND OUR TANK CLEANED OUT, WE'RE JUST ABOUT READY TO INSTALL OUR PUMP. BUT BEFORE WE DO THAT WE NEED TO ASSEMBLE OUR PICK UP. THE FIRST THING YOU WANT TO DO IS TO MEASURE FROM THE TOP OF THE TANK TO THE FLOOR OF THE TANK. YOU DON'T WANT IT EXACTLY ON THE BOTTOM OF IT. YOU WANT TO GIVE YOURSELF ABOUT A QUARTER TO AN

EIGHTH INCH CLEARANCE.

THAT PUTS US AT 11 AND THREE QUARTER. THIS IS THE PART OF THE PUMP THAT I WAS REFERRING TO AS BEING ADAPTABLE FOR DIFFERENT SETUPS. THE PICK UP TUBE COMES WITH EXTRA LINKS THAT YOU CUT TO SIZE FOR YOUR SPECIFIC TANK.

MAKE SURE YOU ACCOUNT FOR THE SIZE OF THE FITTING THAT SCREWS ONTO THE PUMP.

AND THIS PICK UP FILTER ASSEMBLY, WHICH WILL DO A NICE JOB OF KEEPING ANY DEBRIS OUT OF YOUR PUMP. WITH THE RETAINER RING IN PLACE LAY DOWN THE GASKET,

SLIDE IN THE PUMP, AND TIGHTEN DOWN YOUR SCREWS IN A STAR PATTERN. PUMP INSTALLED!

(ANNOUNCER)>> STICK AROUND TO SEE HOW TO MAKE A STEALTH PATCH REPAIR THAT MAKES YOUR RIDE GOOD AS NEW.

(TOMMY)>> WELCOME BACK FOLKS. WE'VE MOVED OVER TO THE DOORS OF OUR OLD OLDSMOBILE BECAUSE I WANT TO SHOW YOU HOW TO MAKE A REPAIR THAT'S SUPER COMMON TO THESE OLD MUSCLE CARS. THE FRONT CORNER HAS STARTED TO ROT AWAY, AND IF IT'S LEFT UNCHECKED, THEN THE PROBLEM WILL CONTINUE TO MAKE ITSELF WORSE UNTIL YOU FIND YOURSELF NEEDING AN ENTIRE DOOR. WE'RE GONNA SHOW YOU HOW TO FIX IT AND PRETTY MUCH ALL YOU'RE GONNA HAVE TO INVESTS IN IT IS THE TIME TO DO IT. MY PLAN IS TO CUT OUT JUST ABOVE THIS ROTTEN SPOT AND RIGHT ACROSS THIS EDGE, AND THERE'S A REASON FOR THAT. WE WERE ABLE TO SAVE THIS INNER LIP. AND DOING THAT, ONCE IT'S GROUND DOWN, IT'LL BE REALLY HARD TO TELL THERE WAS EVEN A REPAIR MADE. FIRST I'LL EYEBALL THE AREA THAT I WANT TO CUT OUT. THIS ISN'T AN EXACT SCIENCE. YOU PRETTY MUCH JUST LOOKING TO GET RID

OF THE HONOREE PARTS. I'M TRYING NOT TO MESS UP MY PATCH SO I HAVE A GOOD TEMPLATE TO MAKE IT. WITH MY BAD SPOT CUT OUT, I'VE GOT TO DO A LITTLE BIT OF GRINDING AND THEN FOLLOW IT UP WITH SOME WIRE BRUSH ON TOP OF THAT RUST. AND THEN TREAT IT WITH SOME EXTEND FROM LOCTITE.

THIS EXTEND WILL NEUTRALIZE ANY CORROSION AND PREVENT PROBLEMS LATER DOWN THE ROAD. I'LL USE A PIECE THAT I CUT OUT AS A TEMPLATE FOR THE NEW METAL THAT I'LL BE PLUGGING INTO THE HOLE. I'LL DO A LITTLE MORE FINE TUNING WITH A FILE, GET IT TO A GOOD FIT. IT'S AT LEAST EASIER TO KEEP FILE FITTING THIS THING THAN TO TRY TO STRETCH IF I MADE IT TOO SMALL. THIS PANELS GOT A LITTLE BIT OF A CURVE TO IT ALSO, SO I'VE

GOT TO DO A LITTLE SHAPING WITH IT. NOW WITH THIS BIG HEAVY TABLE THAT I'VE GOT, JUST A LIGHT TAP OF A HAMMER, YOU CAN HOLD IT UP JUST ON ITS EDGE, MOVE THE HAMMER ACROSS IT, AND IT'LL SLOWLY PUT A CURVE INTO THAT PIECE OF METAL. GETTING CLOSER, NEED A LITTLE MORE CURVE

IN THE MIDDLE OF IT.

JUST ABOUT THERE. NOW YOU CAN USE A PAIR OF TIN SNIPS, A DIE

GRINDER, OR EVEN A FILE. I LIKE A FILE BECAUSE IT'S A LITTLE SLOWER BUT IT'S A LOT MORE PRECISE.

NOW THIS TYPE OF JOINT THAT WE'RE GONNA BE DOING IS CALLED A BUTT WELD JOINT, AND WHAT THAT REFERS TO IS YOU'RE BUTTING TWO PIECES OF METAL TOGETHER AND YOU'RE WELDING AROUND IT.

ONE THING THAT YOU WANT TO KEEP IN MIND WHEN YOU'RE DOING

SOMETHING LIKE THIS IS YOU WANT TO LEAVE A LITTLE BIT OF ROOM AROUND THE PERIMETER OF YOUR WELD. BECAUSE IF YOU DON'T AND YOUR PENETRATION OF YOUR WELDS ARE NOT REALLY ALL THAT GREAT. WHEN YOU GRIND OFF ALL THAT WELD THE PATCH WILL LITERALLY FALL RIGHT OUT. FOR THOSE OF YOU THAT ARE STARTING TO DIP YOUR TOE INTO THE WORLD OF WELDING, HERE'S A LITTLE TIP FOR YOU. OUR MILLER- MATIC 210 HAS A CHART HERE ON THE INSIDE OF THE CASE THAT LETS YOU KNOW WHAT YOUR WELDING SETTINGS NEED TO BE FOR WHAT YOU'RE WELDING. BASED ON THE METAL THICKNESS, WIRE DIAMETER, AND INERT GAS BEING USED., WE CAN FIND A BASE LINE SETTING FOR THE POWER LEVEL AND WIRE SPEED. ONCE YOU GET A LITTLE BIT OF EXPERIENCE UNDER YOUR BELT, KINDA GET A FEEL FOR YOUR WELDER, YOU CAN TWEAK YOUR SETTINGS TO DIAL IT IN FOR THE PERFECT WELD. WE'RE READY TO GO AHEAD AND BURN IN OUR LITTLE PATCH. AND IF YOU WAS TO STRETCH ALL THAT WELDING OUT, IT'LL BE GETTING THAN 10 INCHES. SO WE NEED TO MAKE SURE THAT WE DON'T PUT TOO MUCH HEAT IN OUR PANEL, OR OTHERWISE WE'RE RUNNING THE RISK OF WARPING IT ALL UP. LIKE WE ALWAYS SAY, DON'T SIT THERE AND RUN A BEAD IN ONE SPOT OR YOU'LL WARP THE METAL INTO OBLIVION. PATIENCE IS A VIRTUE. MOVE YOU TACK AROUND, AND BEFORE YOU KNOW YOU'LL HAVE NICE NEW PATCH PANEL IN PLACE. GRIND THE WELDS DOWN NICE AND FLAT, THEN SHE'S READY FOR SOME PLASTIC AND SOME PRIMER. WELL WE MANAGED TO REPAIR OUR DOOR AND AT THE SAME TIME SAVE THAT STOCK PINCH WELD HERE ON THE BOTTOM THAT WE WERE TALKING ABOUT EARLIER. WHAT THAT MEANS IS THIS DOOR'S GONNA LOOK STOCK WHETHER IT'S OPEN OR CLOSED, WITH A LITTLE BODY WORK OF COURSE.

(ANNOUNCER)>> EVER THINK OF TAKING UP THE

HOBBY OF GLASS ETCHING? WELL THERE'S MONEY TO BE MADE IF YOU KNOW HOW TO DO IT.

(STEVE)>> HEY GUYS, I WANT TO TAKE A SECOND TO SHOW YOU SOMETHING THAT TOMMY DID ON OLD PROJECT BUSINESS TIME THAT'S PRETTY COOL, PERSONALIZED THE CAR, AND BROUGHT IT UP TO THAT NEXT LEVEL. TOMMY HAS ETCHED THESE WORDS INTO THE PASSENGER SIDE MIRROR OF THE CAR. INSTEAD OF "OBJECTS MAY BE CLOSER THAN THEY APPEAR" IT SAYS "OBJECTS WILL APPEAR SMALLER DURING ACCELERATION". NOW ONLY IS THAT A ONE OF A KIND ADDITION TO THE CAR, IT'S JUST PLAIN COOL. BUT LIKE MANY OTHER THINGS THAT WE DO, THERE'S MORE THAN ONE WAY TO ACHIEVE THAT RESULT. SO IN A MINUTE WE'RE GONNA SHOW YOU GUYS THREE DIFFERENT WAYS TO DO GLASS ETCHING WHICH ARE BOTH AFFORDABLE AND SIMPLE. BACK WHEN A FEW MORE OF THE HAIRS THAT LAY ON MY BACK WERE UP ON TOP OF MY HEAD, I USED TO HAVE ONE OF THESE $20 DOLLAR ENGRAVERS. I'D GO TO CAR SHOWS ON THE WEEKEND, PLUG IN MY EXTENSION CORD, MAKE A FEW EXTRA BUCKS. IT'S KINDA BECOME A LOST ART THOUGH, BUT EVERY NOW AND THEN I'LL SHOW UP AT A CAR SHOW. IT'S KINDA FUN TO SEE.

(TOMMY)>> BEFORE YOU GRAB A LAWN CHAIR AND CAMP OUT AT YOUR LOCAL CAR SHOW TO MAKE SOME EXTRA CASH DOING THIS, YOU'LL WANT TO SPEND A GOOD AMOUNT OF TIME LEARNING HOW TO DO IT. AFTER ALL, THIS IS KINDA LIKE GETTING A TATTOO. ONCE YOU LAY DOWN THE LINES, THERE'S REALLY NO GOING BACK. AND IF YOU BUGGER UP SOMEBODY'S WINDOW ON THEIR RAMBLER, THEY MIGHT BE GIVING YOU THE BUSINESS, AND NOT THE GOOD KIND IF YOU KNOW WHAT I MEAN.

(STEVE)>> WELL GUYS, THERE YOU GO. THERE'S A QUICK EXAMPLE OF HOW YOU CAN ETCH GLASS WITH AN ELECTRIC ENGRAVER. TOMMY'S GOT A COUPLE OF OTHER WAYS HE'S GONNA SHOW YOU WHICH ARE JUST AS EASY AND JUST AS EFFECTIVE.

(TOMMY)>> I LIKE THAT BEAR RIGHT THERE BUD.

(STEVE)>> YOU THINK, IT'S NOT TOO BAD.

(TOMMY)>> NOW ANOTHER WAY YOU CAN DO SOME GLASS ETCHING IS WITH A CHEMICAL. NOW IF YOU'RE A LITTLE BIT WORRIED ABOUT YOUR ARTISTIC SKILLS YOU CAN DO IT WITH THIS VINYL DECAL.

THIS STUFF MIGHT BE KINDA HARD TO FIND AT THE PART STORES,

BUT YOU CAN FOR SURE GET IT AT ONE OF THEM FLOWERY HOBBY STORES WITH THE PLASTIC BIRDS AND THE WHICKER BUCKETS. BRUSH IT ON AND LET IT DO ITS JOB. THE HEAVIER YOU APPLY IT, THE GREATER THE EFFECT. I'VE GOT A HANDY DANDY BUCKET TO WASH IT OFF WITH, THE

REGULAR KIND, NOT THE WHICKER KIND. BUT MAKE SURE TO WEAR SOME GLOVES AND EYE PROTECTION BECAUSE IT'S A CAUSTIC MATERIAL AFTER ALL. WELL THAT'S THE WAY TO DO IT IF YOU WANTED TO USE THE CHEMICAL, BUT WE'VE GOT ONE MORE WAY TO SHOW YOU.

THIS IS PRETTY STRAIGHT FORWARD, BUT IF YOU WANT TO DO

THIS, YOU'LL WANT TO TURN YOUR BLASTER WAY DOWN SO YOU DON'T BLOW THE MASK PLUM OFF THE GLASS. WELL THERE YOU GO. WE SHOWED YOU A FEW DIFFERENT WAYS TO ETCH GLASS AND ALL THREE HAVE A DIFFERENT EFFECT. SO DEPENDING ON WHAT YOU'RE GOING AFTER, USE THE

ONE YOU NEED TO GO WITH.

(STEVE)>> THE SAND BLASTING AND THE CHEMICAL ARE DEFINITELY THE ONES TO USE IF YOU'RE LOOKING FOR UNIFORMITY SUCH AS DOING LETTERING AND BANNERING.

I PREFER THE GLASS ETCHING DONE WITH THE ELECTRIC ENGRAVER FOR ONE OFF ITEMS THAT ARE MORE ARTISTIC. IF YOU'VE GOT ANY QUESTIONS ABOUT ANYTHING YOU SAW ON THE SHOW TODAY.

(TOMMY)>> GO OVER TO POWERBLOCK TV DOT COM.