More '78 Buick Century Wagon "Sucker Punch" Episodes

HorsePower Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

RideTech

Control Arms, StrongArm, Steel, Black Powdercoated, Buick, Chevy, Oldsmobile, Pontiac, Front Lower, Kit

RideTech

Control Arms, StrongArm, Steel, Black Powdercoated, Buick, Chevy, Oldsmobile, Pontiac, Front Upper, Kit

Rocket Performance Machine, Inc.

Wheel, Hyper Shot, Aluminum, Matte Silver, 18 in. x 8 in., 5 x 4.75 in. Bolt Circle, 4.75 in. Backspace, Each

Drive Train Specialist

Axle, Complete, GM 12-BOLT, Custom, 5x4.75, 5/8" stud, 40-spline gun-drilled axle shafts

Matco Tools

13PC KIT, (9) hole saws (3/4", 7/8", 1-1/8", 1-3/8", 1-1/2", 1-3/4", 2", 2-1/4", and 2-1/2"), and all the necessary accessories including an adapter, pilot drill, small mandrel and quick-change mandrel

RideTech

1978-88 Chevy G-Body, Complete Coil-over System,includes single adjustable Coil-Overs, StrongARM Control Arms, and a rear AirBar.

TRZ Motorsports

G-Body Rack Kit- Narrowed Rack, Strg Shaft, Joints, Bumpsteer kit for use w/ Stock or Aftermarket Spindles

Tube Shark

TubeShark Bender with air/hydraulic power unit

Episode Transcript

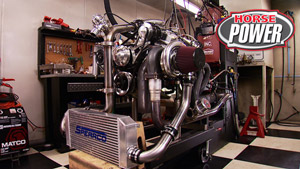

(ANNOUNCER)>> TODAY'S

HORSEPOWER IS ON A ROLL WITH A STOCK BUICK WAGON,

THEIR NEWEST PROJECT CALLED SUCKER PUNCH. THEY START WITH ALL OUT

CHASSIS MODS TO MAKE THIS THING READY FOR 800

TURBO CHARGED HORSEPOWER.

(JOE)>> HEY HONK IF YOU LOVE STATION WAGONS. THIS ONE'S A 1978 BUICK CENTURY, ONE OF GM'S LAST FULL FRAME WAGONS. WE'RE PROUD TO SAY IT'S OUR NEWEST PROJECT BUILD. WHY? WELL FIRST WE THOUGHT IT'D MAKE A PERFECT MUSTANG AND

CAMARO KILLER IN A PLAIN BROWN WRAPPER. ALSO BECAUSE WHY NOT. AS A RULE, WAGONS ARE COOL.

STATION WAGONS HAD SOME IMAGE ISSUES DURING THEIR PEAK YEARS. IN SOME TV COMMERCIALS BACK THEN IT SEEMED THE MEASURE OF A GOOD WAGON WAS HOW MANY KIDS IT COULD HAUL. HARDLY A YOUNG HOT RODDER'S IDEA OF A COOL STREET MACHINE. THIS 1929 FORD MODELA IS AN EARLY VERSION OF THE STATION WAGON, AND WHAT'S NOT TO LOVE ABOUT THOSE WONDERFUL WOODY

VERSIONS, LIKE THIS PIECE OF FINE FURNITURE ON WHEELS FROM THE '40'S SOON TO BE TREASURED BY SURFERS AND TERMITES. JEEP INTRODUCED AMERICA'S FIRST ALL STEEL WAGON IN 1946. DURING THE NEXT TWO DECADES THE NUMBER OF MAKES

AND MODELS WOULD SOAR.

TURN A CLASSIC BEL AIR INTO A SHOW AND SHINE ENTRY AND IT GETS ADMIRING STARES FROM THOSE WHO REMEMBER AND THOSE WHO DON'T. NOW DAYS TURN ANY WAGON INTO A RACE CAR AND YOU GET INSTANT

ATTENTION AT THE DRAG STRIP. WHAT USED TO BE A HO HUM HAULER IS NOW A NOVEL NOSTALGIC HOT ROD.

(MIKE)>> YOU KNOW WHAT'S FUNNY? I CANNOT BELIEVE I'M IN A STATION WAGON AND I ACTUALLY FEEL COOL. THIS '78 REPRESENTS BOTH THE END OF AN ERA AND THE BEGINNING OF ONE OF OUR WILDEST PROJECT CAR BUILDS EVER.

(JOHN)>> THIS THING HAS NO GET UP AND GO.

(MIKE)>> NO, IT'S VERY SAD, IT'S VERY SAD. THAT WAS ACTUALLY TO THE FLOOR.

(JOHN)>> WHOA!

(MIKE)>> WHAT WAS THAT?

(JOHN)>> WEATHER STRIPPING.

(MIKE)>> THE BODY IS IN GREAT SHAPE, BUT THE 34 YEAR OLD SUSPENSION.

(JOHN)>> OH!

(MIKE)>> ALRIGHT, WE'RE DONE. IT'S BEEN ALTERED FOR THIS LOWER STANCE, NOT VERY WELL.

(JOHN)>> OH MAN, THAT WAS A HARD ONE.

(MIKE)>> THE GUY WHO OWNED THE CAR BEFORE OBVIOUSLY HAD TOO WIDE OF A REAR TIRE ON. THIS IS WHERE THE TIRE CAUGHT THE LIP RIGHT HERE AND IT ROLLED IT OUT. HOPEFULLY WE'LL GET IT BACK WITH AIR STILL IN THE TIRE.

(JOHN)>> MAN, WE'RE GONNA HAVE TO LIMP HER HOME.

(MIKE)>> OR YOU COULD JUST FINISH IT OFF. CLEARANCED IT!

(JOHN)>> WE'RE GOOD NOW! [ scraping noise ]

(JOHN)>> BOTH SIDES NOW! [ scraping noise ]

(MIKE)>> OH, I SAW A CHUNK FLY! BUT DON'T FEEL SORRY FOR THIS WAGON. WE ALREADY ORDERED A HIGH PERFORMANCE SUSPENSION PACKAGE FROM RIDE TECH BECAUSE THIS 110 HORSEPOWER 231 VSIX WILL GET REPLACED WITH A STROKED 461 INCH PONTIAC TOPPED OFF WITH A TURBONETICS TURBO CHARGER. WITH MILD BOOST OUR GOAL IS TO MAKE OVER 800 HORSEPOWER AT THE TIRE. THE BEAUTY OF NOT REUSING ANYTHING UNDER HERE IS BEING ABLE TO SPEED UP THE TEAR DOWN PROCESS. EVER WONDER HOW THEY GOT THE RIDE HEIGHT FOR THIS WAGON? HERE IT IS, THE OLD SCHOOL WAY AND PRETTY STUPID. THESE CLAMPS TOOK HALF THE PURPOSE OUT OF THESE SPRINGS. NOW WE KNOW WHY CHUNKS ARE MISSING OUT OF THE REAR TIRES. NOW WE CAN UNBOLT THE CONTROL ARMS AND REMOVE EVERYTHING ATTACHED TO THE REAR END, WHICH IS COMING DOWN FOR A REPLACEMENT LATER ON TODAY. WITH IT OUT OF THE WAY, WE CAN FINISH BACK HERE REMOVING THE CONTROL ARMS AND SHOCKS. THERE SHE BLOWS.

BACK UP FRONT THE SAME GOES. WITH THE WHEELS REMOVED WE CAN GET TO THE FACTORY SWAY BAR. THEN USING VARIOUS TOOLS OF PERSUASION WE CAN FREE UP ALL THE LINKAGE AND REMOVE IT. NEXT WE SEPARATE THE STEERING COLUMN FROM THE STEERING BOX SO IT CAN COME OUT FROM THE TOP. WE HAVE TO REMOVE 30 YEARS OF GUNK JUST TO GET A WRENCH ON THE BOLTS HOLDING THE LOWER CONTROL ARMS IN PLACE. EVENTUALLY THOUGH WE CAN DROP THE SHOCKS, USE A CHAIN AROUND THE SPRINGS TO HOLD THEM IN PLACE FOR SAFETY, AND DROP THE ARM AND SPINDLE TOGETHER AND PULL OUT THE ORIGINAL SPRING. THEY MUST HAVE BEEN OUT OF THE CLAMPS THOUGH. SO THE OLD HOT WRENCH WAS USED. IT KINDA TAKES THE GOOD OUT OF THE GOOD OLE DAYS. FINALLY EACH LOWER CONTROL ARM, SPINDLE, AND ROTOR CAN COME OUT AS ONE BIG FAT ASSEMBLY AND OUR TEAR DOWN'S OFFICIALLY FINISHED.

(JOHN)>> WHOA!

(MIKE)>> WHAT WAS THAT?

(JOHN)>> JUST WEATHER STRIPPING.

(MIKE)>> WE'RE BACK AT IT. WE SHOWED YOU THE WAGON.

(JOHN)>> OH!

(MIKE)>> HOW WE DESTROYED THE REAR TIRES.

(JOHN)>> BOTH SIDES NOW.

(MIKE)>> AND HOW IT GOT THAT LOWERED STANCE. HERE'S THE RIGHT WAY TO LOWER A VEHICLE.

THIS IS RIDE TECH'S NEW COIL OVER SYSTEM FOR '78

THROUGH '88 GM GBODIES. NOW IF YOU HAVEN'T NOTICED, THE GBODIES ARE THE LAST FULL

FRAME REAR WHEEL DRIVE CARS GM PRODUCED. THEY'RE READILY AVAILABLE, CHEAP TO BUY, AND YOU CAN FIND PERFORMANCE PARTS FOR THEM ALL OVER THE PLACE. NOW WE'RE NOT GONNA TALK ABOUT EACH PART IN THE SUSPENSION SYSTEM RIGHT NOW, BUT MORE ABOUT THE TERMINOLOGY USED WITH IT. SOME OF THE TERMS USED WHEN WE TALK ABOUT SHOCKS IS REBOUND AND COMPRESSION.

NOW COMPRESSION IS THE AMOUNT OF FORCE IT TAKES TO CLOSE THE SHOCK OR COMPRESS IT. REBOUND IS THE AMOUNT OF FORCE IT TAKES TO OPEN THE SHOCK OR BRING IT BACK TO ITS RIDE HEIGHT POSITION. NOW SOME OF THE OTHER TERMS ARE SINGLE AND DOUBLE ADJUSTABLE. THIS IS A SINGLE ADJUSTABLE, SO THE COMPRESSION IS PRESET

AT THE FACTORY WHILE WE'RE ABLE TO CONTROL THE REBOUND BY THIS KNOB. THEY'RE USUALLY IN SETTINGS FROM ONE TO 10, ONE BEING THE SOFTEST, 10 BEING THE HARDEST. NOW A DOUBLE ADJUSTABLE SHOCK WORKS THE SAME WAY BUT IT CONTROLS BOTH REBOUND AND COMPRESSION. ONE OF THE MOST OVER LOOKED YET MOST IMPORTANT COMPONENTS TO THE WHOLE SUSPENSION SYSTEM ARE THE SWAY BARS. IF THEY'RE NOT MADE TO MATCH ALL THE OTHER COMPONENTS OR THE WEIGHT OF THE CAR, YOU'RE GONNA HAVE A HANDLING NIGHTMARE. NOW WE GOT EVERYTHING IN THIS SYSTEM TO DO ALL THE REAR SUSPENSION AND EVERYTHING UP FRONT. NOW SOME OF YOU MAY HAVE NOTICED, THIS IS SOME PRETTY BEEFY STUFF AND THERE'S GOOD REASON FOR THAT. WE'RE GONNA BE MAKING OVER 1,100 FOOT POUNDS OF TORQUE. SO THIS REAR END'S GOTTA HANDLE IT. NOW THIS IS A CUSTOM DANA 60 FROM DTS. IT USES ONE OF THE REAR SUPPORT COVERS AS WELL AS A SET OF 4.11 GEARS AND A SPOOL. NOW THE SPOOL'S GONNA ALLOW BOTH REAR TIRES TO TURN AT THE SAME TIME AND THE SAME SPEED ALL THE TIME. NOW THIS THING USES TIMKEN BEARINGS AND SEALS THROUGHOUT, AS WELL AS A CHROMOLY 1350 YOKE AND STRAPS. NOW TO TRANSFER THE POWER FROM THE SPOOL TO THE TIRES ARE THESE MASSIVE 40 SPLINE GUN DRILLED ALLOY AXLES. NOW THEY DON'T USE A CCLIP TO HOLD THEM INTO THE SPOOL. THEY SLIDE RIGHT INTO THE SPLINE AND THEY GET RETAINED TO THE AXLE HOUSING WITH THIS BRACKET THAT ALSO DOUBLES AS A CALIPER BRACKET. ATTACH THE REAR LOWER STRONG ARMS MAKING SURE THE SWAY BAR HOLES ARE CLOSEST TO THE AXLE. CHECK OUT THE STRENGTH OF THIS COIL OVER BRACKET. THE ADJUSTABLE UPPERS CAN GO ON, AND NOTICE THE KEVLAR LINED HEIMS. THIS WILL AVOID ANY BINDING. UP ON THE FRAME WE CAN BOLT UP THE UPPER COIL OVER BRACKETS IN THE EXISTING HOLES.

MAKE SURE TO APPLY A LITTLE LITHIUM GREASE TO ALL THE URETHANE BUSHINGS.

NOW USING THE TRANS TRACK WE CAN RAISE THE REAR END AS AN

ASSEMBLY AND MAKE OUR CONNECTIONS. MAKE SURE TO LEAVE ALL THE BOLTS LOOSE UNTIL ALL OF THE ARMS ARE IN PLACE. THIS WILL MAKE LINING UP THE CONTROL ARMS WITH THE FRAME A LOT EASIER. THE REAR COIL OVERS USE A 200 POUND SPRING, A WHOLE LOT DIFFERENT THAN WHAT WE TOOK OUT. EVEN THOUGH IT'S A PREFIT, IT'S IMPORTANT TO TIGHTEN EVERYTHING UP. NOW NEVER USE AIR TOOLS OR OVER TORQUE ANY OF THESE CONNECTIONS. THIS THING HAS SEVERAL PARTS THAT ARE DESIGNED TO MOVE. OVER TIGHTENING COULD CAUSE PREMATURE BUSHING FAILURE AND SEVERE SUSPENSION BINDING. TO WRAP IT UP THE REAR MUSCLE BAR SWAY BAR GETS BOLTED TO THE LOWER CONTROL ARMS.

WE DIDN'T NEED TO REDRILL ANY HOLES OR CUT AND MODIFY ANY OF THE PIECES.

KEEP IN MIND THIS WAS A CUSTOM AXLE HOUSING AS WELL.

IT JUST GOES TO SHOW HOW GOOD THINGS CAN FIT IF THE ENGINEERING IS THOUGHT OUT. WE'LL SEE HOW THE FRONT GOES TOGETHER IN A MINUTE.

(JOE)>> HORSEPOWER'S BACK AFTER BEEFING UP OUR WAGON'S BACK END WITH A DTS AXLE ASSEMBLY, SPOOL, AND SET OF 4.11 GEARS. WE GAVE IT COIL OVER SHOCKS, UPPER AND LOWER CONTROL ARMS,

AND A MUSCLE CAR SWAY BAR. AND NOT TO WASTE ANY TIME WE'RE ALREADY ON THE CASE FILLING UP THE FRONT END WITH SUSPENSION PIECES.

FOR CONTROL ARMS WE JUST INSTALLED MORE STRONG ARM UPPER AND LOWERS FROM RIDE TECH. AND EVEN THOUGH WE'RE USING A COIL OVER SYSTEM, THESE LOWERS ARE THE SAME ONES USED WITH THE SHOCKWAVE AIR SPRINGS. NOW OUR COIL OVER SPRINGS ARE RATED AT 900 POUNDS AND THEY'RE A SINGLE ADJUSTABLE DESIGN. AND THAT GETS US TO THE SPINDLES AND BRAKES THAT JUST CAME IN FROM SSBC, ALL MADE IN THE USA. NOW THESE TWO INCH DROP SPINDLES WILL HOUSE A PAIR OF BIG BITE 13 INCH CROSS DRILLED AND SLOTTED ROTORS AND A PAIR OF THREE PISTON TRIPOWER CALIPERS THAT USE THESE PREMIUM HOT PADS. NOW WE HAD OUR CALIPERS PAINTED BLACK FOR A REASON. THAT'S TO GO WITH THAT STEALTHY, SUBDUED, SLEEPER LOOK.

(MIKE)>> JUST LIKE THE REAR, WE CAN ADJUST THE RIDE HEIGHT OF THE CAR USING A COIL OVER BUT THERE'S A CERTAIN AREA THE STROKE OF THE SHOCK NEEDS TO BE IN TO MAINTAIN THAT RIDE PERFORMANCE. SO INSTEAD OF DOING IT IN HERE, WE'RE GONNA DO IT WITH THIS TWO INCH DROP SPINDLE. NOW THIS THING WAS DESIGNED FOR AN S-10, AND IT'S BEEN

MACHINED BY SSBC TO ACCEPT ALL THE BRAKES. PLUS IT'S A LOT BETTER THAN MELTING A SPRING. NOW WE CAN PACK THE REAR BEARING WITH GREASE. AND USING A SUPPLIED SEAL, KNOCK IT INTO PLACE IN THE ROTOR. THEN THE ROTOR GOES ON TO THE SPINDLE, FOLLOWED BY THE FRONT BEARING, WASHER, AND NUT. INSTALL A COTTER PIN AND POP ON THE DUST COVER.

(JOE)>> THEN WE CAN SLIDE THOSE NEW SSBC CALIPERS ONTO THE ROTORS AND ADD THESE STOKE TYPE BANJO FITTINGS. WE'RE USING A THREE PIECE MUSCLE BAR SWAY BAR MADE FOR GBODIES. IT'S WAY STRONGER THAN STOCK. IT'S DESIGNED TO WORK SPECIFICALLY WITH THE LOWER STRONG ARMS, AND IT'S A DIRECT BOLT IN. ANYTIME YOU ADD WEIGHT TO THE FRONT END OF A VEHICLE, WELL LIKE WITH AN ENGINE SWAP IN OUR CASE, IT'S ALWAYS A GOOD IDEA TO TAKE SOME OFF AS WELL. AND A GOOD WAY TO DO THAT IS WITH A RACK AND PINION KIT LIKE THIS MANUAL KIT FROM TRZ MOTORSPORTS. IT COMES WITH A FLAMING RIVER RACK, PLUS ALL THESE

ACCESSORIES YOU'LL NEED TO KEEP IT IN PLACE. NOW YOU'LL HAVE TO DO SOME WELDING. IN ADDITION TO LOSING WEIGHT THOUGH, YOU'LL ALSO GET A BETTER FEEL FOR THE ROAD AND PREVENT BUMP STEER. HERE ARE THE SUPPLIED BRACKETS FROM THE KIT

YOU'LL BE WELDING. HERE'S WHAT YOU'RE GONNA BE WELDING THEM TO.

(MIKE)>> THE FRONT SUSPENSION IS AT RIDE HEIGHT THANKS TO A PAIR OF SCREW JACKS. WE CAN POSITION THE RACK MAKING SURE IT IS AS HIGH AS POSSIBLE BUT NOT TO INTERFERE WITH THE OIL PAN. WE'RE GOING A LITTLE HIGHER THAN THE TOP OF THE ENGINE CROSS MEMBER. WITH A LEVEL ON THE TOP OF THE RACK MAKE SURE IT'S EVEN. WITH THE MOUNTING PLATE ATTACHED TO THE RACK, WE CAN TACK IT IN PLACE. MAKING SURE IT'S SQUARED UP, WE CAN BEGIN TO CUT THE MOUNTING TUBE FOR THE OTHER SIDE. REMEMBER THIS SETUP IS FOREIGN TO THIS CHASSIS. SO THERE'S NO EXISTING HOLES OR TEMPLATE TO WORK FROM. ALRIGHT, LOOKING GOOD. THE INSTRUCTIONS ARE HELPFUL, BUT COMMON SENSE AND LOTS OF MEASURING WILL GET YOU THERE.

ONCE YOU'RE HAPPY, FINISH IT OFF. TO ATTACH THE RACK TO THE STEERING COLUMN WE NEED TO CUT SOME HOLES IN THE FRAME FOR THE STEERING SHAFT TO PASS THROUGH. WE'RE USING A TWO INCH HOLE SAW.

WITH THAT TACKLED WE'LL HAVE TO WAIT UNTIL THE ENGINE IS IN TO MAKE SURE WE CLEAR OUR HEADERS. TO FINISH IT NOW COULD RESULT IN A LOT OF EXTRA WORK THEN.

(JOE)>> WELL HERE ARE THE FINISHING TOUCHES FOR THE FRONT OF THE WAGON. FOR WHEELS WE WANTED SOMETHING COOL BUT SUBDUED ENOUGH FOR A SLEEPER. SO WE WENT WITH THESE ROCKET BOOSTER HYPER SHOTS FROM ROCKET RACING, 18 BY NINES FRONT AND BACK. NOW FOR FRONT RUBBER THOUGH WE WENT WITH A NITTO 245/40 18'S BUT CAN'T PUT THEM ON JUST YET. WE'VE GOT MORE WORK TO DO OUT BACK COMING UP.

(MIKE)>> WE'RE BACK BUT NOT DONE YET. NOW HERE'S THE REASONS WE PREFIT ALL THE REAR SUSPENSION. THE FIRST ONE'S PRETTY OBVIOUS, TO MAKE SURE EVERYTHING FIT.

WITH ALL THIS EXTRA HEAVY HARDWARE, THE OLD GBODY CHASSIS' GONNA NEED SOME UPDATES. IT'S KINDA LIKE TRYING TO KEEP A BULL IN A CHICKEN COOP. WE NEEDED TO SEE WHERE WE HAD CLEARANCE TO DO SOME SERIOUS TORQUE, BOX, AND FRAME STIFFENING LIKE RIGHT HERE WHERE THE UPPER CONTROL ARM BOLTS TO THE FRAME. NOW NOTICE HOW THIN THIS METAL IS.

THE FIRST TIME THE TIRES REALLY HOOK, THAT CAN GET RIPPED OUT. NOW HERE ON THE LOWER ARM WHERE IT ATTACHES TO THE TORQUE BOX, THIS THING IS ONLY WELDED IN A FEW SPOTS AND THERE'S PLENTY OF OPEN AREAS. SO WE'RE GONNA GO AHEAD AND PLATE ALL THAT IN AND IT'LL BE SUPER STRONG AS WELL. WE'RE ALSO GONNA RUN A TUBE FROM THE FRAME RAIL TO THE FRAME RAIL RIGHT THROUGH HERE, WHICH WILL STIFFEN IT UP. WE'RE ALSO GONNA HAVE A DROP IN IT RIGHT HERE THAT'LL DOUBLE AS OUR DRIVESHAFT LOOP. THESE CROSS BRACES ARE PRETTY WEAK TOO.

SO WE'LL CUT THESE OUT AND REPLACE IT WITH STRONGER MATERIAL.

USING A WHEEL SPACER TO ACT AS A ROTOR, WE NEED TO THROW ON THE REAR WHEELS AND CHECK FOR CLEARANCE. WITH A TRANS TRACK UNDER THE REAR END, UNBOLT THE REAR SHOCKS FROM THE HOUSING AND LET THEM HANG. NOW BY PUMPING THE JACK, WE'RE RAISING THE TIRE INTO THE FENDER WELL. ONCE WE HAVE THE REAR AT RIDE HEIGHT, ROTATE THE TIRE AND CHECK FOR PROPER CLEARANCE ALL THE WAY AROUND. EVERYTHING LOOKS GOOD FROM THE FRONT OF THE WHEEL WELL ALL THE WAY TO RIGHT HERE. WE'VE GOT A QUARTER OF AN INCH.

IF WE END UP RUBBING, A HAMMER WILL TAKE CARE OF IT. THIS CAR HAS A TAPERED WHEEL WELL, WHICH MAKES TIRE FITMENT AN ISSUE. NOW WE DID OUR HOMEWORK AND IT SHOWS. TO MAKE ROOM FOR THE FAB WORK, I'M LOWERING THE REAR END AND UNBOLTING THE UPPER CONTROL ARMS FROM THE CHASSIS. THIS WILL LET THE REAR END HANG FAIRLY LOW AND OUT OF THE WAY. USING A PIECE OF CARDBOARD, I'M MAKING A TEMPLATE TO FIT THE UPPER CONTROL ARM MOUNT. NOW ONCE FITTED, WE'LL MARK THE LOCATION OF THE BOLT HOLE. USING THREESIXTEENTHS STEEL PLATE, TRACE THE TEMPLATE ONTO IT. NOTICE THE TWO RACE TABS COMING OFF THE PLATE NOW.

WELL KEEP WATCHING. NOW JOHN IS PREPPING THE AREAS TO BE WELDED, MAKING SURE THEY'RE FREE FROM ANY CHASSIS COATING OR OIL. NOW BACK TO THOSE TABS FROM EARLIER. WITH A SLICER WHEEL I'M CUTTING SLOTS IN THE PLATE SO THEY WILL BEND EASIER. WITH IT IN A VICE I'LL BEND THE TABS, TEST FIT IT, CLEAN UP THE EDGES, AND DRILL ONE MORE HOLE FOR THE BOLT AND A FEW MORE FOR PLUG WELDS. BOLT THE PLATE TO THE CONTROL ARM MOUNT AND SNUG IT UP.

NOW TACK THE PLATE IN PLACE AND MAKE SURE THE TABS ARE

FLUSH WITH THE FRAME. THE TABS ARE TO STRENGTHEN THE PLATE AND IMPROVE ITS SIDE LOAD. THE LAST THING TO DO IS WELD THE HOLES IN SO THERE WILL BE

NO FLEXING BETWEEN THEM. REPEAT ON THE OTHER SIDE. AFTER CLEANING THE LOWER CONTROL ARM MOUNTS AND MAKING SOME MORE TEMPLATES, JOHN IS CUTTING SOME NOTCHED PLATES OUT OF THE SAME STEEL PLATE. THE PLATE IS RECESSED TO FIT INTO THE CONTROL ARM MOUNT GIVING US MORE AREAS TO WELD. WITH THE PLATE LEVEL, I CAN TACK IT IN PLACE ON THE TOP AND BOTTOM, THEN WELD IT IN. IT'S TWIN GOES IN NEXT FOLLOWED BY THE SAME STEPS. TO BRIDGE THE TWO, WE'LL MAKE A TEMPLATE TO CUT OUT A PIECE OF THREE SIXTEENTHS PLATE. TACK IT AND WELD IT IN AS WELL. ONE MORE PIECE WILL BE USED TO BOX IT ALL IN. I'M GOOD. A NEW CROSS BAR IS NEXT. USING INCH AND FIVEEIGHTHS 120 WALL TUBING AND OUR TUBE SHARK BENDER, WE MADE A 45 DEGREE BEND, AND BY FLIPPING IT OVER ANOTHER TWO 25 DEGREE BENDS ON BOTH SIDES. ALRIGHT, LETS SEE WHAT WE'VE GOT. HOLD IT UP AGAINST THAT INNER.

(JOHN)>> NOPE, AGAINST THE FRAME RAIL RIGHT THERE OKAY. SO WE'RE GONNA BEND THIS AND PUT THEM RIGHT THERE?

(MIKE)>> YEP, RIGHT ONTO THE BOXES. IT LOOKS LIKE THE RADIUS IS GONNA BE PERFECT UP IN THIS AREA. WHAT WE NEED TO DO IS RUN AND DO THE BEND BEFORE WE CUT, THAT WAY WE WON'T COME UP SHORT. MAKING SURE THE TUBE IS LEVEL AND FLAT WITH THE OTHER BENDS, WE'LL GO 37 DEGREES. GIVE IT ANOTHER TEST FIT TO MAKE SURE THE ANGLE IS ENOUGH.

(JOHN)>> OH THAT'LL WORK.

(MIKE)>> THAT'S GONNA BE PERFECT. BEND THE OTHER SIDE. CUT IT TO LENGTH ON THE COLD SAW AND WELD IT IN PLACE. TO FINISH OFF THE BAR WE'LL BEND THE LOWER PORTION OF THE LOOP, NOTCH THE ENDS TO FIT THE TUBE'S CIRCUMFERENCE, AND WELD IT IN TOO.

THE FINAL PIECES FOR THE REAR ARE THE ONE AND A HALF INCH TUBES USED TO TIE THE UPPER CONTROL ARM MOUNTS TO THE FRAME RAIL FOR ADDED STRENGTH AND TO KEEP THEM IN PLACE. ALL THAT WORK TO HELP US HANDLE OVER 1,000

FOOT POUNDS OF TORQUE. I'M REALLY HAPPY WITH ALL THIS FAB WORK. NOW ONCE WE GET THE DRIVETRAIN IN THE CAR, WE'RE GONNA DO SOME MORE BRACING AND TUBE WORK IN THE CENTER AND VERY FRONT OF THE CAR. NOW THIS NOT ONLY IMPROVES THE STRENGTH BUT ALSO THE HANDLING. NOW FOR THOSE OF YOU THAT PLAN ON GETTING A GBODY OR ALREADY HAVE ONE AND YOU'RE GONNA PUT SOME BIG POWER TO THE REAR, YOU GUYS HAVE TO DO THIS. IF YOU DON'T, YOU'RE GONNA BE SORRY.

Show Full Transcript

(JOE)>> HEY HONK IF YOU LOVE STATION WAGONS. THIS ONE'S A 1978 BUICK CENTURY, ONE OF GM'S LAST FULL FRAME WAGONS. WE'RE PROUD TO SAY IT'S OUR NEWEST PROJECT BUILD. WHY? WELL FIRST WE THOUGHT IT'D MAKE A PERFECT MUSTANG AND

CAMARO KILLER IN A PLAIN BROWN WRAPPER. ALSO BECAUSE WHY NOT. AS A RULE, WAGONS ARE COOL.

STATION WAGONS HAD SOME IMAGE ISSUES DURING THEIR PEAK YEARS. IN SOME TV COMMERCIALS BACK THEN IT SEEMED THE MEASURE OF A GOOD WAGON WAS HOW MANY KIDS IT COULD HAUL. HARDLY A YOUNG HOT RODDER'S IDEA OF A COOL STREET MACHINE. THIS 1929 FORD MODELA IS AN EARLY VERSION OF THE STATION WAGON, AND WHAT'S NOT TO LOVE ABOUT THOSE WONDERFUL WOODY

VERSIONS, LIKE THIS PIECE OF FINE FURNITURE ON WHEELS FROM THE '40'S SOON TO BE TREASURED BY SURFERS AND TERMITES. JEEP INTRODUCED AMERICA'S FIRST ALL STEEL WAGON IN 1946. DURING THE NEXT TWO DECADES THE NUMBER OF MAKES

AND MODELS WOULD SOAR.

TURN A CLASSIC BEL AIR INTO A SHOW AND SHINE ENTRY AND IT GETS ADMIRING STARES FROM THOSE WHO REMEMBER AND THOSE WHO DON'T. NOW DAYS TURN ANY WAGON INTO A RACE CAR AND YOU GET INSTANT

ATTENTION AT THE DRAG STRIP. WHAT USED TO BE A HO HUM HAULER IS NOW A NOVEL NOSTALGIC HOT ROD.

(MIKE)>> YOU KNOW WHAT'S FUNNY? I CANNOT BELIEVE I'M IN A STATION WAGON AND I ACTUALLY FEEL COOL. THIS '78 REPRESENTS BOTH THE END OF AN ERA AND THE BEGINNING OF ONE OF OUR WILDEST PROJECT CAR BUILDS EVER.

(JOHN)>> THIS THING HAS NO GET UP AND GO.

(MIKE)>> NO, IT'S VERY SAD, IT'S VERY SAD. THAT WAS ACTUALLY TO THE FLOOR.

(JOHN)>> WHOA!

(MIKE)>> WHAT WAS THAT?

(JOHN)>> WEATHER STRIPPING.

(MIKE)>> THE BODY IS IN GREAT SHAPE, BUT THE 34 YEAR OLD SUSPENSION.

(JOHN)>> OH!

(MIKE)>> ALRIGHT, WE'RE DONE. IT'S BEEN ALTERED FOR THIS LOWER STANCE, NOT VERY WELL.

(JOHN)>> OH MAN, THAT WAS A HARD ONE.

(MIKE)>> THE GUY WHO OWNED THE CAR BEFORE OBVIOUSLY HAD TOO WIDE OF A REAR TIRE ON. THIS IS WHERE THE TIRE CAUGHT THE LIP RIGHT HERE AND IT ROLLED IT OUT. HOPEFULLY WE'LL GET IT BACK WITH AIR STILL IN THE TIRE.

(JOHN)>> MAN, WE'RE GONNA HAVE TO LIMP HER HOME.

(MIKE)>> OR YOU COULD JUST FINISH IT OFF. CLEARANCED IT!

(JOHN)>> WE'RE GOOD NOW! [ scraping noise ]

(JOHN)>> BOTH SIDES NOW! [ scraping noise ]

(MIKE)>> OH, I SAW A CHUNK FLY! BUT DON'T FEEL SORRY FOR THIS WAGON. WE ALREADY ORDERED A HIGH PERFORMANCE SUSPENSION PACKAGE FROM RIDE TECH BECAUSE THIS 110 HORSEPOWER 231 VSIX WILL GET REPLACED WITH A STROKED 461 INCH PONTIAC TOPPED OFF WITH A TURBONETICS TURBO CHARGER. WITH MILD BOOST OUR GOAL IS TO MAKE OVER 800 HORSEPOWER AT THE TIRE. THE BEAUTY OF NOT REUSING ANYTHING UNDER HERE IS BEING ABLE TO SPEED UP THE TEAR DOWN PROCESS. EVER WONDER HOW THEY GOT THE RIDE HEIGHT FOR THIS WAGON? HERE IT IS, THE OLD SCHOOL WAY AND PRETTY STUPID. THESE CLAMPS TOOK HALF THE PURPOSE OUT OF THESE SPRINGS. NOW WE KNOW WHY CHUNKS ARE MISSING OUT OF THE REAR TIRES. NOW WE CAN UNBOLT THE CONTROL ARMS AND REMOVE EVERYTHING ATTACHED TO THE REAR END, WHICH IS COMING DOWN FOR A REPLACEMENT LATER ON TODAY. WITH IT OUT OF THE WAY, WE CAN FINISH BACK HERE REMOVING THE CONTROL ARMS AND SHOCKS. THERE SHE BLOWS.

BACK UP FRONT THE SAME GOES. WITH THE WHEELS REMOVED WE CAN GET TO THE FACTORY SWAY BAR. THEN USING VARIOUS TOOLS OF PERSUASION WE CAN FREE UP ALL THE LINKAGE AND REMOVE IT. NEXT WE SEPARATE THE STEERING COLUMN FROM THE STEERING BOX SO IT CAN COME OUT FROM THE TOP. WE HAVE TO REMOVE 30 YEARS OF GUNK JUST TO GET A WRENCH ON THE BOLTS HOLDING THE LOWER CONTROL ARMS IN PLACE. EVENTUALLY THOUGH WE CAN DROP THE SHOCKS, USE A CHAIN AROUND THE SPRINGS TO HOLD THEM IN PLACE FOR SAFETY, AND DROP THE ARM AND SPINDLE TOGETHER AND PULL OUT THE ORIGINAL SPRING. THEY MUST HAVE BEEN OUT OF THE CLAMPS THOUGH. SO THE OLD HOT WRENCH WAS USED. IT KINDA TAKES THE GOOD OUT OF THE GOOD OLE DAYS. FINALLY EACH LOWER CONTROL ARM, SPINDLE, AND ROTOR CAN COME OUT AS ONE BIG FAT ASSEMBLY AND OUR TEAR DOWN'S OFFICIALLY FINISHED.

(JOHN)>> WHOA!

(MIKE)>> WHAT WAS THAT?

(JOHN)>> JUST WEATHER STRIPPING.

(MIKE)>> WE'RE BACK AT IT. WE SHOWED YOU THE WAGON.

(JOHN)>> OH!

(MIKE)>> HOW WE DESTROYED THE REAR TIRES.

(JOHN)>> BOTH SIDES NOW.

(MIKE)>> AND HOW IT GOT THAT LOWERED STANCE. HERE'S THE RIGHT WAY TO LOWER A VEHICLE.

THIS IS RIDE TECH'S NEW COIL OVER SYSTEM FOR '78

THROUGH '88 GM GBODIES. NOW IF YOU HAVEN'T NOTICED, THE GBODIES ARE THE LAST FULL

FRAME REAR WHEEL DRIVE CARS GM PRODUCED. THEY'RE READILY AVAILABLE, CHEAP TO BUY, AND YOU CAN FIND PERFORMANCE PARTS FOR THEM ALL OVER THE PLACE. NOW WE'RE NOT GONNA TALK ABOUT EACH PART IN THE SUSPENSION SYSTEM RIGHT NOW, BUT MORE ABOUT THE TERMINOLOGY USED WITH IT. SOME OF THE TERMS USED WHEN WE TALK ABOUT SHOCKS IS REBOUND AND COMPRESSION.

NOW COMPRESSION IS THE AMOUNT OF FORCE IT TAKES TO CLOSE THE SHOCK OR COMPRESS IT. REBOUND IS THE AMOUNT OF FORCE IT TAKES TO OPEN THE SHOCK OR BRING IT BACK TO ITS RIDE HEIGHT POSITION. NOW SOME OF THE OTHER TERMS ARE SINGLE AND DOUBLE ADJUSTABLE. THIS IS A SINGLE ADJUSTABLE, SO THE COMPRESSION IS PRESET

AT THE FACTORY WHILE WE'RE ABLE TO CONTROL THE REBOUND BY THIS KNOB. THEY'RE USUALLY IN SETTINGS FROM ONE TO 10, ONE BEING THE SOFTEST, 10 BEING THE HARDEST. NOW A DOUBLE ADJUSTABLE SHOCK WORKS THE SAME WAY BUT IT CONTROLS BOTH REBOUND AND COMPRESSION. ONE OF THE MOST OVER LOOKED YET MOST IMPORTANT COMPONENTS TO THE WHOLE SUSPENSION SYSTEM ARE THE SWAY BARS. IF THEY'RE NOT MADE TO MATCH ALL THE OTHER COMPONENTS OR THE WEIGHT OF THE CAR, YOU'RE GONNA HAVE A HANDLING NIGHTMARE. NOW WE GOT EVERYTHING IN THIS SYSTEM TO DO ALL THE REAR SUSPENSION AND EVERYTHING UP FRONT. NOW SOME OF YOU MAY HAVE NOTICED, THIS IS SOME PRETTY BEEFY STUFF AND THERE'S GOOD REASON FOR THAT. WE'RE GONNA BE MAKING OVER 1,100 FOOT POUNDS OF TORQUE. SO THIS REAR END'S GOTTA HANDLE IT. NOW THIS IS A CUSTOM DANA 60 FROM DTS. IT USES ONE OF THE REAR SUPPORT COVERS AS WELL AS A SET OF 4.11 GEARS AND A SPOOL. NOW THE SPOOL'S GONNA ALLOW BOTH REAR TIRES TO TURN AT THE SAME TIME AND THE SAME SPEED ALL THE TIME. NOW THIS THING USES TIMKEN BEARINGS AND SEALS THROUGHOUT, AS WELL AS A CHROMOLY 1350 YOKE AND STRAPS. NOW TO TRANSFER THE POWER FROM THE SPOOL TO THE TIRES ARE THESE MASSIVE 40 SPLINE GUN DRILLED ALLOY AXLES. NOW THEY DON'T USE A CCLIP TO HOLD THEM INTO THE SPOOL. THEY SLIDE RIGHT INTO THE SPLINE AND THEY GET RETAINED TO THE AXLE HOUSING WITH THIS BRACKET THAT ALSO DOUBLES AS A CALIPER BRACKET. ATTACH THE REAR LOWER STRONG ARMS MAKING SURE THE SWAY BAR HOLES ARE CLOSEST TO THE AXLE. CHECK OUT THE STRENGTH OF THIS COIL OVER BRACKET. THE ADJUSTABLE UPPERS CAN GO ON, AND NOTICE THE KEVLAR LINED HEIMS. THIS WILL AVOID ANY BINDING. UP ON THE FRAME WE CAN BOLT UP THE UPPER COIL OVER BRACKETS IN THE EXISTING HOLES.

MAKE SURE TO APPLY A LITTLE LITHIUM GREASE TO ALL THE URETHANE BUSHINGS.

NOW USING THE TRANS TRACK WE CAN RAISE THE REAR END AS AN

ASSEMBLY AND MAKE OUR CONNECTIONS. MAKE SURE TO LEAVE ALL THE BOLTS LOOSE UNTIL ALL OF THE ARMS ARE IN PLACE. THIS WILL MAKE LINING UP THE CONTROL ARMS WITH THE FRAME A LOT EASIER. THE REAR COIL OVERS USE A 200 POUND SPRING, A WHOLE LOT DIFFERENT THAN WHAT WE TOOK OUT. EVEN THOUGH IT'S A PREFIT, IT'S IMPORTANT TO TIGHTEN EVERYTHING UP. NOW NEVER USE AIR TOOLS OR OVER TORQUE ANY OF THESE CONNECTIONS. THIS THING HAS SEVERAL PARTS THAT ARE DESIGNED TO MOVE. OVER TIGHTENING COULD CAUSE PREMATURE BUSHING FAILURE AND SEVERE SUSPENSION BINDING. TO WRAP IT UP THE REAR MUSCLE BAR SWAY BAR GETS BOLTED TO THE LOWER CONTROL ARMS.

WE DIDN'T NEED TO REDRILL ANY HOLES OR CUT AND MODIFY ANY OF THE PIECES.

KEEP IN MIND THIS WAS A CUSTOM AXLE HOUSING AS WELL.

IT JUST GOES TO SHOW HOW GOOD THINGS CAN FIT IF THE ENGINEERING IS THOUGHT OUT. WE'LL SEE HOW THE FRONT GOES TOGETHER IN A MINUTE.

(JOE)>> HORSEPOWER'S BACK AFTER BEEFING UP OUR WAGON'S BACK END WITH A DTS AXLE ASSEMBLY, SPOOL, AND SET OF 4.11 GEARS. WE GAVE IT COIL OVER SHOCKS, UPPER AND LOWER CONTROL ARMS,

AND A MUSCLE CAR SWAY BAR. AND NOT TO WASTE ANY TIME WE'RE ALREADY ON THE CASE FILLING UP THE FRONT END WITH SUSPENSION PIECES.

FOR CONTROL ARMS WE JUST INSTALLED MORE STRONG ARM UPPER AND LOWERS FROM RIDE TECH. AND EVEN THOUGH WE'RE USING A COIL OVER SYSTEM, THESE LOWERS ARE THE SAME ONES USED WITH THE SHOCKWAVE AIR SPRINGS. NOW OUR COIL OVER SPRINGS ARE RATED AT 900 POUNDS AND THEY'RE A SINGLE ADJUSTABLE DESIGN. AND THAT GETS US TO THE SPINDLES AND BRAKES THAT JUST CAME IN FROM SSBC, ALL MADE IN THE USA. NOW THESE TWO INCH DROP SPINDLES WILL HOUSE A PAIR OF BIG BITE 13 INCH CROSS DRILLED AND SLOTTED ROTORS AND A PAIR OF THREE PISTON TRIPOWER CALIPERS THAT USE THESE PREMIUM HOT PADS. NOW WE HAD OUR CALIPERS PAINTED BLACK FOR A REASON. THAT'S TO GO WITH THAT STEALTHY, SUBDUED, SLEEPER LOOK.

(MIKE)>> JUST LIKE THE REAR, WE CAN ADJUST THE RIDE HEIGHT OF THE CAR USING A COIL OVER BUT THERE'S A CERTAIN AREA THE STROKE OF THE SHOCK NEEDS TO BE IN TO MAINTAIN THAT RIDE PERFORMANCE. SO INSTEAD OF DOING IT IN HERE, WE'RE GONNA DO IT WITH THIS TWO INCH DROP SPINDLE. NOW THIS THING WAS DESIGNED FOR AN S-10, AND IT'S BEEN

MACHINED BY SSBC TO ACCEPT ALL THE BRAKES. PLUS IT'S A LOT BETTER THAN MELTING A SPRING. NOW WE CAN PACK THE REAR BEARING WITH GREASE. AND USING A SUPPLIED SEAL, KNOCK IT INTO PLACE IN THE ROTOR. THEN THE ROTOR GOES ON TO THE SPINDLE, FOLLOWED BY THE FRONT BEARING, WASHER, AND NUT. INSTALL A COTTER PIN AND POP ON THE DUST COVER.

(JOE)>> THEN WE CAN SLIDE THOSE NEW SSBC CALIPERS ONTO THE ROTORS AND ADD THESE STOKE TYPE BANJO FITTINGS. WE'RE USING A THREE PIECE MUSCLE BAR SWAY BAR MADE FOR GBODIES. IT'S WAY STRONGER THAN STOCK. IT'S DESIGNED TO WORK SPECIFICALLY WITH THE LOWER STRONG ARMS, AND IT'S A DIRECT BOLT IN. ANYTIME YOU ADD WEIGHT TO THE FRONT END OF A VEHICLE, WELL LIKE WITH AN ENGINE SWAP IN OUR CASE, IT'S ALWAYS A GOOD IDEA TO TAKE SOME OFF AS WELL. AND A GOOD WAY TO DO THAT IS WITH A RACK AND PINION KIT LIKE THIS MANUAL KIT FROM TRZ MOTORSPORTS. IT COMES WITH A FLAMING RIVER RACK, PLUS ALL THESE

ACCESSORIES YOU'LL NEED TO KEEP IT IN PLACE. NOW YOU'LL HAVE TO DO SOME WELDING. IN ADDITION TO LOSING WEIGHT THOUGH, YOU'LL ALSO GET A BETTER FEEL FOR THE ROAD AND PREVENT BUMP STEER. HERE ARE THE SUPPLIED BRACKETS FROM THE KIT

YOU'LL BE WELDING. HERE'S WHAT YOU'RE GONNA BE WELDING THEM TO.

(MIKE)>> THE FRONT SUSPENSION IS AT RIDE HEIGHT THANKS TO A PAIR OF SCREW JACKS. WE CAN POSITION THE RACK MAKING SURE IT IS AS HIGH AS POSSIBLE BUT NOT TO INTERFERE WITH THE OIL PAN. WE'RE GOING A LITTLE HIGHER THAN THE TOP OF THE ENGINE CROSS MEMBER. WITH A LEVEL ON THE TOP OF THE RACK MAKE SURE IT'S EVEN. WITH THE MOUNTING PLATE ATTACHED TO THE RACK, WE CAN TACK IT IN PLACE. MAKING SURE IT'S SQUARED UP, WE CAN BEGIN TO CUT THE MOUNTING TUBE FOR THE OTHER SIDE. REMEMBER THIS SETUP IS FOREIGN TO THIS CHASSIS. SO THERE'S NO EXISTING HOLES OR TEMPLATE TO WORK FROM. ALRIGHT, LOOKING GOOD. THE INSTRUCTIONS ARE HELPFUL, BUT COMMON SENSE AND LOTS OF MEASURING WILL GET YOU THERE.

ONCE YOU'RE HAPPY, FINISH IT OFF. TO ATTACH THE RACK TO THE STEERING COLUMN WE NEED TO CUT SOME HOLES IN THE FRAME FOR THE STEERING SHAFT TO PASS THROUGH. WE'RE USING A TWO INCH HOLE SAW.

WITH THAT TACKLED WE'LL HAVE TO WAIT UNTIL THE ENGINE IS IN TO MAKE SURE WE CLEAR OUR HEADERS. TO FINISH IT NOW COULD RESULT IN A LOT OF EXTRA WORK THEN.

(JOE)>> WELL HERE ARE THE FINISHING TOUCHES FOR THE FRONT OF THE WAGON. FOR WHEELS WE WANTED SOMETHING COOL BUT SUBDUED ENOUGH FOR A SLEEPER. SO WE WENT WITH THESE ROCKET BOOSTER HYPER SHOTS FROM ROCKET RACING, 18 BY NINES FRONT AND BACK. NOW FOR FRONT RUBBER THOUGH WE WENT WITH A NITTO 245/40 18'S BUT CAN'T PUT THEM ON JUST YET. WE'VE GOT MORE WORK TO DO OUT BACK COMING UP.

(MIKE)>> WE'RE BACK BUT NOT DONE YET. NOW HERE'S THE REASONS WE PREFIT ALL THE REAR SUSPENSION. THE FIRST ONE'S PRETTY OBVIOUS, TO MAKE SURE EVERYTHING FIT.

WITH ALL THIS EXTRA HEAVY HARDWARE, THE OLD GBODY CHASSIS' GONNA NEED SOME UPDATES. IT'S KINDA LIKE TRYING TO KEEP A BULL IN A CHICKEN COOP. WE NEEDED TO SEE WHERE WE HAD CLEARANCE TO DO SOME SERIOUS TORQUE, BOX, AND FRAME STIFFENING LIKE RIGHT HERE WHERE THE UPPER CONTROL ARM BOLTS TO THE FRAME. NOW NOTICE HOW THIN THIS METAL IS.

THE FIRST TIME THE TIRES REALLY HOOK, THAT CAN GET RIPPED OUT. NOW HERE ON THE LOWER ARM WHERE IT ATTACHES TO THE TORQUE BOX, THIS THING IS ONLY WELDED IN A FEW SPOTS AND THERE'S PLENTY OF OPEN AREAS. SO WE'RE GONNA GO AHEAD AND PLATE ALL THAT IN AND IT'LL BE SUPER STRONG AS WELL. WE'RE ALSO GONNA RUN A TUBE FROM THE FRAME RAIL TO THE FRAME RAIL RIGHT THROUGH HERE, WHICH WILL STIFFEN IT UP. WE'RE ALSO GONNA HAVE A DROP IN IT RIGHT HERE THAT'LL DOUBLE AS OUR DRIVESHAFT LOOP. THESE CROSS BRACES ARE PRETTY WEAK TOO.

SO WE'LL CUT THESE OUT AND REPLACE IT WITH STRONGER MATERIAL.

USING A WHEEL SPACER TO ACT AS A ROTOR, WE NEED TO THROW ON THE REAR WHEELS AND CHECK FOR CLEARANCE. WITH A TRANS TRACK UNDER THE REAR END, UNBOLT THE REAR SHOCKS FROM THE HOUSING AND LET THEM HANG. NOW BY PUMPING THE JACK, WE'RE RAISING THE TIRE INTO THE FENDER WELL. ONCE WE HAVE THE REAR AT RIDE HEIGHT, ROTATE THE TIRE AND CHECK FOR PROPER CLEARANCE ALL THE WAY AROUND. EVERYTHING LOOKS GOOD FROM THE FRONT OF THE WHEEL WELL ALL THE WAY TO RIGHT HERE. WE'VE GOT A QUARTER OF AN INCH.

IF WE END UP RUBBING, A HAMMER WILL TAKE CARE OF IT. THIS CAR HAS A TAPERED WHEEL WELL, WHICH MAKES TIRE FITMENT AN ISSUE. NOW WE DID OUR HOMEWORK AND IT SHOWS. TO MAKE ROOM FOR THE FAB WORK, I'M LOWERING THE REAR END AND UNBOLTING THE UPPER CONTROL ARMS FROM THE CHASSIS. THIS WILL LET THE REAR END HANG FAIRLY LOW AND OUT OF THE WAY. USING A PIECE OF CARDBOARD, I'M MAKING A TEMPLATE TO FIT THE UPPER CONTROL ARM MOUNT. NOW ONCE FITTED, WE'LL MARK THE LOCATION OF THE BOLT HOLE. USING THREESIXTEENTHS STEEL PLATE, TRACE THE TEMPLATE ONTO IT. NOTICE THE TWO RACE TABS COMING OFF THE PLATE NOW.

WELL KEEP WATCHING. NOW JOHN IS PREPPING THE AREAS TO BE WELDED, MAKING SURE THEY'RE FREE FROM ANY CHASSIS COATING OR OIL. NOW BACK TO THOSE TABS FROM EARLIER. WITH A SLICER WHEEL I'M CUTTING SLOTS IN THE PLATE SO THEY WILL BEND EASIER. WITH IT IN A VICE I'LL BEND THE TABS, TEST FIT IT, CLEAN UP THE EDGES, AND DRILL ONE MORE HOLE FOR THE BOLT AND A FEW MORE FOR PLUG WELDS. BOLT THE PLATE TO THE CONTROL ARM MOUNT AND SNUG IT UP.

NOW TACK THE PLATE IN PLACE AND MAKE SURE THE TABS ARE

FLUSH WITH THE FRAME. THE TABS ARE TO STRENGTHEN THE PLATE AND IMPROVE ITS SIDE LOAD. THE LAST THING TO DO IS WELD THE HOLES IN SO THERE WILL BE

NO FLEXING BETWEEN THEM. REPEAT ON THE OTHER SIDE. AFTER CLEANING THE LOWER CONTROL ARM MOUNTS AND MAKING SOME MORE TEMPLATES, JOHN IS CUTTING SOME NOTCHED PLATES OUT OF THE SAME STEEL PLATE. THE PLATE IS RECESSED TO FIT INTO THE CONTROL ARM MOUNT GIVING US MORE AREAS TO WELD. WITH THE PLATE LEVEL, I CAN TACK IT IN PLACE ON THE TOP AND BOTTOM, THEN WELD IT IN. IT'S TWIN GOES IN NEXT FOLLOWED BY THE SAME STEPS. TO BRIDGE THE TWO, WE'LL MAKE A TEMPLATE TO CUT OUT A PIECE OF THREE SIXTEENTHS PLATE. TACK IT AND WELD IT IN AS WELL. ONE MORE PIECE WILL BE USED TO BOX IT ALL IN. I'M GOOD. A NEW CROSS BAR IS NEXT. USING INCH AND FIVEEIGHTHS 120 WALL TUBING AND OUR TUBE SHARK BENDER, WE MADE A 45 DEGREE BEND, AND BY FLIPPING IT OVER ANOTHER TWO 25 DEGREE BENDS ON BOTH SIDES. ALRIGHT, LETS SEE WHAT WE'VE GOT. HOLD IT UP AGAINST THAT INNER.

(JOHN)>> NOPE, AGAINST THE FRAME RAIL RIGHT THERE OKAY. SO WE'RE GONNA BEND THIS AND PUT THEM RIGHT THERE?

(MIKE)>> YEP, RIGHT ONTO THE BOXES. IT LOOKS LIKE THE RADIUS IS GONNA BE PERFECT UP IN THIS AREA. WHAT WE NEED TO DO IS RUN AND DO THE BEND BEFORE WE CUT, THAT WAY WE WON'T COME UP SHORT. MAKING SURE THE TUBE IS LEVEL AND FLAT WITH THE OTHER BENDS, WE'LL GO 37 DEGREES. GIVE IT ANOTHER TEST FIT TO MAKE SURE THE ANGLE IS ENOUGH.

(JOHN)>> OH THAT'LL WORK.

(MIKE)>> THAT'S GONNA BE PERFECT. BEND THE OTHER SIDE. CUT IT TO LENGTH ON THE COLD SAW AND WELD IT IN PLACE. TO FINISH OFF THE BAR WE'LL BEND THE LOWER PORTION OF THE LOOP, NOTCH THE ENDS TO FIT THE TUBE'S CIRCUMFERENCE, AND WELD IT IN TOO.

THE FINAL PIECES FOR THE REAR ARE THE ONE AND A HALF INCH TUBES USED TO TIE THE UPPER CONTROL ARM MOUNTS TO THE FRAME RAIL FOR ADDED STRENGTH AND TO KEEP THEM IN PLACE. ALL THAT WORK TO HELP US HANDLE OVER 1,000

FOOT POUNDS OF TORQUE. I'M REALLY HAPPY WITH ALL THIS FAB WORK. NOW ONCE WE GET THE DRIVETRAIN IN THE CAR, WE'RE GONNA DO SOME MORE BRACING AND TUBE WORK IN THE CENTER AND VERY FRONT OF THE CAR. NOW THIS NOT ONLY IMPROVES THE STRENGTH BUT ALSO THE HANDLING. NOW FOR THOSE OF YOU THAT PLAN ON GETTING A GBODY OR ALREADY HAVE ONE AND YOU'RE GONNA PUT SOME BIG POWER TO THE REAR, YOU GUYS HAVE TO DO THIS. IF YOU DON'T, YOU'RE GONNA BE SORRY.