Truck Tech Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Lizard Skin LLC

SuperPro Spray Gun Kits, 32 oz. Canister, 90 Degree Tip, Mixing Paddle, Each

AutoZone

AutoZone Antifreeze and Coolant

AutoZone

Duralast Serpentine Belt

AutoZone

Duralast Thermostat

AutoZone

Duralast New Water Pump

Coleman Taylor Transmissions

Coleman Taylor Transmissions, Franklin, TN transmission repair shop

EBC Brakes

EBC Stage 3 Truck and SUV Brake Kit, Axle Set of 6000 Series Brake Pads & Axle Pair of GD Sport Slotted & Dimpled Rotors

JKS Manufacturing

Wrangler JK, 2007-2015, J-Flex Adjustable Control Arms, Front Lower Control Arm

Loctite

Anti Seize Compound, Copper, 8-Oz. Can

Matco Tools

SP56 - Seal Puller

Matco Tools

FTLD8 - 8 Piece Fuel & Transmission Line Disconnect Set

Matco Tools

AC91200 - Air Operated Light Duty Vacuum Pump

Matco Tools

AC293996 - Deluxe Dual Aluminum A/C Manifold Gauge Set

The Industrial Depot

Fasteners, Hardware, and Shop Supplies

Episode Transcript

(ANNOUNCER)>> TODAY WE'RE

SHOWING YOU HOW TO SAVE BIG BUCKS BY SPENDING MORE

OF YOUR TIME THAN YOUR MONEY ON COSTLY REPAIRS. WE'LL SHOW YOU HOW TO

REPLACE A LEAKING C/V AXLE SEAL AND BUSHING. HOW TO REPLACE A WATER

PUMP THAT'S GONE BAD WITHOUT BUSTING

YOUR KNUCKLES. AND WE'LL TAKE THE TIME TO

REPLACE AN A/C CONDENSER AND DRIER TO MAKE YOUR

AIR BLOW COLD AGAIN. IT'S ALL TODAY

HERE ON TRUCK TECH.

(RYAN)>> HEY GUYS, WELCOME BACK TO TRUCK TECH. NOW IN THE SHOP TODAY IS A 2011 MERCURY MARINER. ESSENTIALLY THE SAME THING AS THE

POPULAR FORD ESCAPE.

NOW THE REASON ITS HERE IS NOT TOO LONG AGO THE AUTOMATIC TRANSMISSION STARTED SHIFTING A LITTLE BIT WEIRD. THE OWNER BROUGHT IT TO THE DEALER IN CASE IT WAS SOFTWARE ISSUE BUT THE DEALERSHIP INFORMED HIM THAT IT WAS AN AUTOMATIC TRANSMISSION FLUID LEVEL

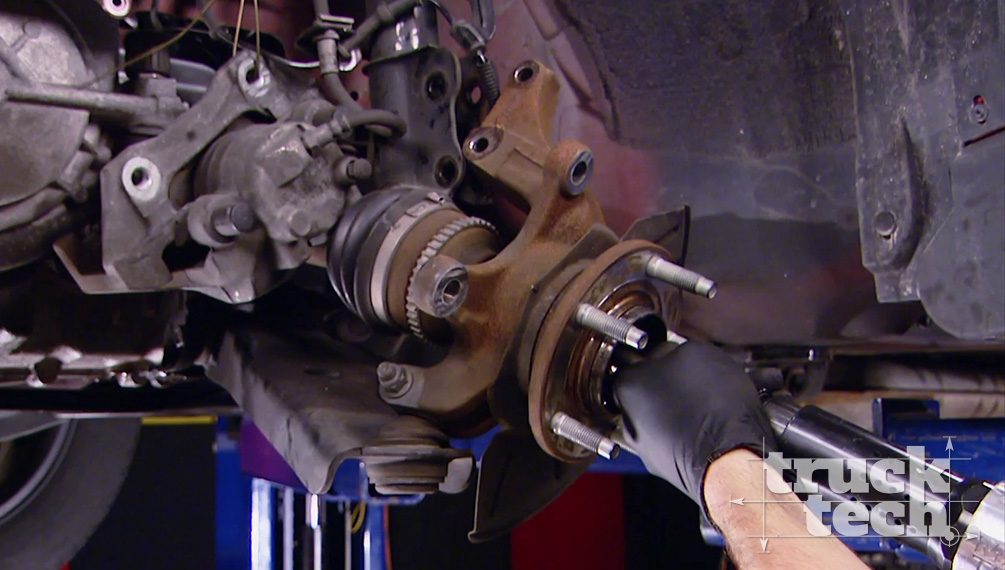

PROBLEM DUE TO A LEAKING TRANSMISSION SEAL. BUT ONCE THE OWNER WAS PRESENTED WITH A NEARLY $1,000 DOLLAR REPAIR BILL, I TOLD HIM WE COULD DO BETTER AND WALK YOU GUYS THROUGH THE PROCESS OF THE REPAIR JUST IN CASE YOU HAVE ONE OF THESE PARKED IN YOUR DRIVEWAY. STEP ONE IS REMOVING THIS PLASTIC SPLASH SHIELD SO WE CAN SEE WHAT WE'RE DOING AND GAIN ACCESS. NOW AT FIRST IT LOOKS LIKE THIS IS JUST A BAD HALF SHAFT SEAL, BUT AFTER A QUICK INSPECTION WELL IT'S PRETTY CLEAR THERE'S MORE TO IT THAN THAT. I THINK THE SUPPORT BUSHING IS WORN OUT. IN FACT IF I HOLD THIS HALF SHAFT UP LONG ENOUGH IT STARTS WEEPING TRANSMISSION FLUID OUT PRETTY QUICK.

ONLY ONE WAY TO FIX THAT IS REPLACE THE BUSHING. NEXT WE'RE GONNA REMOVE THE DRAIN PLUG AND LET ALL THE TRANSMISSION FLUID DRAIN OUT. YUMMY! NOW THE MAJORITY OF THE COST OF THIS REPAIR IS IN THE LABOR, AND BY SHOWING YOU GUYS HOW TO DO IT MAYBE YOU'LL REALIZE THAT IF YOU'VE GOT THE TIME YOU

CAN SAVE A LOT OF MONEY TOO. NOW TO SEPARATE THE SPLINED HALF SHAFT FROM THE WHEEL BEARING I'M USING AN IMPACT HAMMER, BUT A REGULAR HAMMER WILL GET THE JOB DONE AS WELL, JUST MIGHT TAKE A LITTLE LONGER. THEN WE CAN SEPARATE THE KNUCKLE FROM THE STRUT AND FINISH REMOVING THE HALF SHAFT. ONCE THAT'S DONE WE'RE JUST ABOUT THERE. ALL WE'VE GOT TO DO IS PRY THE HALF SHAFT OUT OF THE

TRANSMISSION. NOW I'M USING A PIECE OF WOOD TO INSULATE

THE ALUMINUM PAN FROM THE PRY BAR. YOU DON'T WANT TO CAUSE DAMAGE IN THE

PROCESS OF A REPAIR. NOW I'M USING OUR MATCO SEAL PULLER TO GET THIS

SEAL OUT OF THE CASE, BUT A SMALL PRY BAR OR SCREW DRIVER WILL WORK AS WELL. NOW THIS JOB DOES REQUIRE A SPECIAL TOOL TO SAFELY REMOVE THE BUSHING FROM THE TRANSMISSION CASE,

BUT DON'T LET THAT DISCOURAGE YOU FROM TACKLING THIS JOB. I'LL EXPLAIN MORE IN A SECOND. AFTER DRIVING THE SPECIAL TOOL INTO PLACE IT EXPANDS AND GRABS ON TO THE END OF THE BUSHING.

THEN YOU CAN THREAD IN THE LARGE BOLT UNTIL IT BOTTOMS OUT AGAINST THE DIFFERENTIAL CROSS SHAFT. NOW I'M USING AN ELECTRIC IMPACT JUST TO RUN THE BOLT IN. ONCE IT BOTTOMS OUT I'LL GO AHEAD AND TIGHTEN IT DOWN BY HAND. I DON'T WANT TO DAMAGE THE THREADS OF THE SPECIAL TOOL. AS YOU CAN SEE IT DOESN'T TAKE A TON OF PRESSURE EITHER. GOT IT!

NOW DON'T LET THE REQUIREMENT OF A SPECIAL TOOL DERAIL YOU FROM TACKLING A JOB LIKE THIS. IF YOU'RE LOOKING AT HUNDREDS AND HUNDREDS OF DOLLARS TO PAY SOMEBODY ELSE TO DO THE JOB, FORKING OVER $150 OR $200 BUCKS FOR A SPECIAL TOOL ISN'T THAT BAD IN COMPARISON. NOW WE GOT LUCKY AND WE BORROWED OURS FROM THE LOCAL COLEMAN TAYLOR TRANSMISSION SHOP. THE SAME PLACE WE PICKED UP THE REPLACEMENT SEAL AND BUSHING, BUT IT'S NOT JUST A STOCK REPLACEMENT. NOW HERE'S THE STOCK BUSHING COMPARED TO THE REPLACEMENT, AND THIS ONE IS CLEARLY WORN OUT, NOT TO MENTION IT'S NOT NEARLY AS WIDE AS THE UPGRADED BUSHING, WHICH HELPS TO DISTRIBUTE THE LOAD. NOW YOU CAN SEE THE ORIGINAL BUSHING ON THE C/V SHAFT AND WHERE ALL THAT PLAY WAS COMING FROM. THAT SUCKER IS WORN OUT. WITH A REPLACEMENT IT FITS A LOT TIGHTER AND WILL ELIMINATE THAT PROBLEM. MAKE SURE THE OIL NOTCH IS LINED UP WITH THE NOTCH ON

THE TOOL, AND IN THE SIX O'CLOCK POSITION. IT'S POINTING STRAIGHT DOWN. MAKE SURE EVERYTHING LINES UP PROPERLY. MAKE SURE IT'S FLUSH WITH THE SEAL SURFACE. SOLID NOISE TELLS ME WE'RE DONE.

NOW THE BUSHING IS FULLY INSTALLED BUT THE SPECIAL TOOL'S A LITTLE STUCK IN THE CASE.

SO I'M USING PARTS AND PIECES FROM A BALL JOINT PRESS TO GET IT OUT OF THERE.

COOL, FLUSH WITH THE SURFACE LIKE IT'S SUPPOSED TO BE, WE'RE GOOD. NOW IT LOOKS LIKE SOMEBODY'S PRIED THE SEAL OUT BEFORE AND REPLACED IT, BUT SINCE THEY DIDN'T REPLACE THE BUSHING THE BEST SEAL IN THE WORLD ISN'T GONNA FIX THAT PROBLEM. THERE'S THE NEW SEAL ON THE TOOL SO IT GOES IN SQUARE AND SEATS EVENLY.

[ hammer tapping ]

(RYAN)>> JUST MAKE SURE YOU APPLY A LITTLE ATF

TO THE SEAL SURFACE BEFORE YOU INSTALL THE HALF SHAFT.

ALL THE WAY IN AND LOOK AT THAT, NICE, THAT'S HOW

IT'S SUPPOSED TO BE. NOW BEFORE I REINSTALL THE OUTER END OF THE HALF SHAFT I'M APPLYING A LITTLE LOCTITE ANTISEIZE TO MAKE SURE THIS THING DISASSEMBLES EASILY IN THE FUTURE. THEN IT'S SIMPLY A MATTER OF REASSEMBLING THE FRONT END.

ALRIGHT NOW WITH EVERYTHING BUTTONED UP THE LAST STEP IS FILLING THE TRANS WITH FLUID. NOW THIS SIXF-35 TAKES A VERY SPECIFIC TYPE OF ATF, SO MAKE SURE YOU'RE USING THE RIGHT STUFF. AND IF YOU'RE WONDERING WHY WE DIDN'T PUT A FILTER ON THE TRANSMISSION WHILE WE WERE WORKING ON IT, WELL SOME ENGINEER HAD THE BRIGHT IDEA TO PUT THE FILTER INSIDE THE TRANSMISSION WHERE YOU HAVE TO SPLIT THE CASE TO ACCESS IT. NOT A GREAT IDEA, BUT ALL THE MORE REASON TO CHANGE THE FLUID MORE OFTEN SO THE FILTER DOESN'T GET CLOGGED UP AND GIVE YOU DRIVABILITY PROBLEMS.

(ANNOUNCER)>> AFTER THE BREAK WE'LL REPLACE THAT WORN OUT WATER PUMP, AND LATER WE'LL GET THE A/C WORKING AGAIN WITH A NEW CONDENSER AND DRIER, STAY TUNED!

(RYAN)>> HEY GUYS, WELCOME BACK TO THE SHOP. NOW RECENTLY WE WALKED OUT TO THE PARKING LOT AND SAW A PUDDLE OF COOLANT UNDERNEATH THIS CHEROKEE.

A QUICK INSPECTION REVEALED A FAILING WATER PUMP. AND WITH THE SYSTEM NOT HOLDING COOLANT AND A WATER PUMP ON ITS WAY OUT, DRIVING IT IS NOT A GOOD IDEA. SO IT LEAVES YOU WITH A COUPLE OF OPTIONS. YOU CAN TOW IT TO A REPAIR SHOP, PAY THEM A FEW HOURS LABOR AND PARTS MARK UP, AND SPEND $300, $400, MAYBE EVEN $500 DOLLARS HAVING THEM FIX IT. OR YOU CAN SPEND A COUPLE OF HOURS, GETS YOUR HANDS

DIRTY, AND SPEND LESS THAN $100 BUCKS AND FIX IT YOURSELF. NOW ACCORDING TO THE OWNER THERE WERE A COUPLE OF WARNING SIGNS WITH THIS FAILURE. HE HAD SOME SQUEALY NOISES COMING FROM THE ENGINE BAY, AND THAT'S BECAUSE THE BELT WAS SLIPPING ON THE PULLEYS FROM BEING CONTAMINATED BY THE COOLANT. AND AFTER IT'S BEEN PARCHED FOR ANY PERIOD OF TIME IT'S MARKING ITS SPOT. [ air ratchet spinning ]

(RYAN)>> I CAN TAKE THE TENSION OFF THE BELT.

IF YOU DON'T HAVE A BELT ROUTING DIAGRAM ON THE RADIATOR SUPPORT TAKE A PICTURE OR JUST REMEMBER HOW THE BELT GETS ROUTED.

IT'S IN DECENT SHAPE BUT ONCE THESE GET CONTAMINATED THEY NEED TO BE EITHER CLEANED REALLY GOOD OR REPLACED. NOW WE CAN REMOVE THE WATER PUMP PULLEY.

YEAH YOU CAN SEE THE COOLANT INSIDE THE PULLEY. THAT THING'S BEEN LEAKING FOR A GOOD LITTLE BIT NOW. OH YEAH, THAT THING'S TOAST. [ air ratchet spinning ]

(RYAN)>> NOW WITH THE PUMP OFF WE CAN TAKE A CLOSER LOOK. YOU ALREADY SAW THE PLAY IN THE HUB. WHAT HAPPENS IS THE BEARING STARTS TO WEAR OUT AND COOLANT GETS PAST THE SEAL AND STARTS COMING OUT OF THE WEEP HOLE. YOU CAN ALSO SEE MORE EVIDENCE HERE WHERE THE PULLEY'S ACTUALLY BEEN EATING INTO THE ALUMINUM HOUSING. SO WE WENT TO AUTOZONE AND PICKED UP

SOME REPLACEMENT PARTS. WE'VE GOT A NEW PUMP AND GASKET FOR ABOUT $35 BUCKS. SINCE WE'RE ALREADY INTO THE SYSTEM MIGHT AS WELL ADD A THERMOSTAT FOR ABOUT EIGHT BUCKS, NEW COOLANT FOR ABOUT EIGHT OR $10 DOLLARS, AND AROUND $30 DOLLARS FOR A NEW BELT, WHICH ISN'T EVEN A NECESSITY. IF YOU CLEAN YOUR OLD ONE REALLY GOOD YOU CAN GET AWAY WITH REUSING IT. BUT BEFORE WE INSTALL THESE PARTS I'VE GOT TO SCRAPE OFF THE OLD GASKET.

(LT)>> RYAN STARTS WITH A GENERAL PURPOSE SCRAPER TO REMOVE THE BIG CHUNKS OF GASKET FROM THE THERMOSTAT HOUSING AND THE WATER PUMP FLANGE.

(RYAN)>> ALRIGHT, THE REST I CAN GET WITH A RAZOR BLADE.

I'LL CLEAN THE SURFACE, THROW SOME RTV ON THERE AND A GASKET, WE'LL BE GOOD.

(LT)>> RYAN'S GOING TO REMOVE THE ORIGINAL HEATER HOSE ADAPTER AND CLEAN THE THREADS BEFORE REINSTALLING IT INTO THE NEW WATER PUMP. THIS ADAPTER HAS A UNIQUE PATH THAT IT HAS TO FOLLOW. SO PAY ATTENTION TO THE ORIENTATION AS YOU REMOVE IT FROM THE PUMP AND BE SURE TO DUPLICATE THAT

AS YOU REINSTALL IT.

(RYAN)>> SOMEBODY USED TEFLON TAPE.

I ACTUALLY PREFER THE LIQUID.

(LT)>> REGARDLESS OF THE METHOD YOU PREFER, IT'S IMPORTANT TO HAVE SOME SORT OF THREAD SEALANT ON THESE TAPERED PIPE THREAD, OR NPT FITTINGS.

(RYAN)>> EVEN THOUGH I'M USING A GASKET I LIKE TO USE A LITTLE SEALER AS WELL JUST TO MAKE SURE WE DON'T HAVE ANY LEAKS. IT MIGHT BE A LITTLE OVERKILL I'D RATHER NOT DO THIS JOB TWICE.

A JOB LIKE THIS, IT DOESN'T TAKE ANY SPECIAL TOOLS.

(LT)>> MAKE SURE THAT THE TEMPERATURE RATING ON YOUR

NEW THERMOSTAT MATCHES THAT OF YOUR ORIGINAL ONE.

(RYAN)>> I'M ACTUALLY GONNA LET THAT SET UP FOR JUST A COUPLE OF MINUTES. START TO SKIN OVER THEN WE CAN INSTALL IT. ONCE THE RTV HAS SKINNED OVER A LITTLE BIT WE CAN INSTALL IT WITHOUT ALL THE GASKET SMUSHING OUT THE SIDES AS WE TIGHTEN THE BOLTS.

(LT)>> THE BIGGEST REASON FOR WANTING TO USE NEW COOLANT IS THAT OVER TIME IT CAN BECOME CONTAMINATED BY CORROSION INSIDE THE ENGINE AND

BECOME LESS EFFECTIVE. ALSO IF YOU'VE USED ANY SORT OF RADIATOR LEAK PREVENTATIVE IN THE PAST, THIS IS A GREAT TIME TO FLUSH IT OUT.

(RYAN)>> ALRIGHT NOW WITH THE SYSTEM FILLED UP GIVE EVERYTHING A ONCE OVER, FIRE UP THE ENGINE, TURN THE HEATER ON, AND LET THE COOLANT CIRCULATE AS IT GETS UP TO OPERATING TEMPERATURE. THEN LET IT COOL OFF FOR A FEW MINUTES, CHECK THE COOLANT LEVEL, TOP OFF IF NECESSARY, AND TAKE IT FOR A SPIN AROUND THE BLOCK. THEN GIVE YOURSELF A PAT ON THE BACK FOR A JOB WELL DONE AND FOR SAVING A FEW BUCKS.

(LT)>> NOW THAT WE'VE GOT THE WATER PUMP KEEPING THE ENGINE COOL ON THIS JEEP LET'S SEE WHAT WE CAN DO ABOUT KEEPING THE INTERIOR COOL. NOW WE'RE GONNA BE REPLACING THE AIR CONDITIONING CONDENSER AND RECEIVER DRIER, AS WELL AS USING THESE TOOLS FROM MATCO TO EVACUATE AND RECHARGE THE SYSTEM WITH THIS REFRIGERANT FROM AUTOZONE. WE KNEW THERE WAS DAMAGE ON THE CONDENSER, WHICH HAD CAUSED THE REFRIGERANT TO LEAK OUT. SO TO GET ACCESS TO IT WE REMOVED THE GRILL FOLLOWED BY THE UPPER RADIATOR SUPPORT. WITH THE UPPER RADIATOR HOSE CLAMPED OFF AND SWUNG OUT OF THE WAY, WE CAN ACCESS THE RETAINING CLIPS THAT HOLD THE AIR CONDITIONING CONDENSER CONNECTIONS TIGHT. THESE THINGS CAN BE A LITTLE TRICKY. DISCONNECTING THE FITTINGS AT THE CONDENSER DOES REQUIRE A LINE DISCONNECT TOOL, AND WE GOT OURS FROM MATCO. AND WITH THAT THE CONDENSER IS READY TO LIFT OUT.

THAT RIGHT THERE IS WHY WE'VE GOT NO AIR CONDITIONING.

INSTALLATION IS JUST THE REVERSE OF THE DISASSEMBLY.

NOW THESE INCLUDED THREAD CUTTING NUTS TAKE ADVANTAGE OF THE SOFT ALUMINUM TO SECURE THE AIR CONDITIONING CONDENSER TO THE RADIATOR. MAKES THEIR OWN THREADS.

WHEN REASSEMBLING THE CONDENSER FITTINGS BE SURE TO USE A SPECIFIC AIR CONDITIONING LUBRICANT INSTEAD OF MOTOR OIL. IT WILL CONTAMINATE THE SYSTEM AND CAUSE POOR PERFORMANCE. DON'T FORGET TO INSTALL THESE SAFETY CLIPS

OVER THE CONNECTION. ANOTHER COOL TIP IS TO ALWAYS LINE THESE CLAMPS UP EXACTLY WHERE THEY CAME OFF CAUSE THESE HOSES GET HARD AND THEY MIGHT NOT SEAL JUST RIGHT IF YOU DON'T. THE RECEIVER DRIER ACTS AS A RESERVOIR FOR THE REFRIGERANT AND ALSO FILTERS OUT ANY CONTAMINATION AND MOISTURE. NOW THE RECEIVER DRIER SHOULD BE REPLACED ANY TIME YOU BREACH THE SYSTEM FOR MAINTENANCE. NOW AT $35 BUCKS IT'S NOT THAT BIG OF A DEAL.

AS A PRECAUTION AGAINST FUTURE LEAKS WE'RE REPLACING THE ORINGS AND GASKETS WITH THE NEW ONES PROVIDED.

BE CAREFUL NOT TO NICK THE NEW ORINGS WHEN YOU'RE INSTALLING THEM.

WE'RE INSTALLING A NEW LOW PRESSURE SWITCH ON THE

RECEIVER DRIER. THESE THINGS ARE MADE OF PLASTIC, SO BE VERY CAREFUL WHEN YOU TIGHTEN THEM. THEY'RE SUPER EASY TO DAMAGE.

(LT)>> HEY GUYS, WELCOME BACK TO TRUCK TECH. NOW THAT WE'VE GOT OUR AIR CONDITIONING CONDENSER AND RECEIVER DRIER REPLACED WE CAN CONTINUE TO RECHARGE THE SYSTEM WITH REFRIGERANT. WITH OUR HIGH AND LOW SIDE LINES CONNECTED WE CAN USE OUR MATCO VACUUM PUMP TO EVACUATE THE SYSTEM. ONCE THE SYSTEM REACHES ABOUT 25 INCHES OF VACUUM LEAVE THE PUMP ON FOR ANOTHER 10 MINUTES OR SO TO MAKE SURE IT'S THOROUGHLY EVACUATED. THEN CLOSE THE LOW SIDE VALVE AND WAIT ANOTHER 15

TO 20 MINUTES TO MAKE SURE THERE'S NO LEAKS. IF THE VACUUM ESCAPES THAT'S HOW YOU'LL KNOW. OURS WAS GOOD TO GO, SO IT'S TIME TO ADD THE REFRIGERANT. CHECK YOUR OWNERS MANUAL FOR THE SPECIFIED AMOUNT OF REFRIGERANT. OURS TAKES ABOUT 20 OUNCES, WHICH IS ROUGHLY A CAN AND A HALF. BE SURE TO BLEED ANY REMAINING AIR FROM THE SUCTION LINE BEFORE INTRODUCING THE REFRIGERANT TO THE SYSTEM. ONCE THE SYSTEM EQUALIZES WITH PRESSURE YOU CAN START THE CAR AND TURN ON THE AIR CONDITIONING. ONCE THE AIR CONDITIONING RUNS IT'LL SLOWLY START TO SUCK REFRIGERANT FROM THE CAN INTO THE SYSTEM. EACH TIME THE COMPRESSOR KICKS ON IT'LL DRAW A LITTLE BIT MORE REFRIGERANT IN THE AIR CONDITIONING SYSTEM. NOW THIS MAY TAKE AWHILE, UP TO 15 TO 20 MINUTES BEFORE THE PUMP WILL RUN CONSTANTLY AND YOU CAN START WORRYING ABOUT PRESSURE. THE GOAL IS TO KEEP THE HIGH SIDE PRESSURES IN CHECK WHILE KEEPING THE EVAPORATOR AS COOL AS POSSIBLE. THE GAUGES WILL LET YOU KNOW HOW YOU'RE DOING BY READING TEMPERATURE AND PRESSURE. GOING ABOUT 38 DEGREES AT THE EVAPORATOR. AS SOON AS THAT ELECTRIC FAN KICKS ON IT SHOULD DROP DOWN QUITE A BIT, AND HOPEFULLY PRETTY CLOSE TO ABOUT 32 DEGREES. AND WHEN THE HEAD PRESSURE DROPS THAT MEANS THE SYSTEM WILL BE OPERATING IN ITS PEAK EFFICIENCY. THERE IT GOES! GONNA DROP, SLOWLY DROPPING, TEMPERATURE AND PRESSURE, JUST A TAD OVER 30. IT'LL BE NICE AND COLD INSIDE. EVEN IN OUR WARM SHOP YOU CAN TELL THE SYSTEM IS WORKING AND PUMPING OUT SOME NICE FROSTY AIR.

(JEREMY)>> THIS IS JKS MANUFACTURING LOWER CONTROL ARMS FOR AN '07 THROUGH '16 JEEP WRANGLER JK. THEY'RE A HEAVY DUTY DESIGN, SO THEY'LL DEFINITELY TAKE A BEATING ON THE TRAIL. AND WITH THEIR ADJUSTABILITY AND LENGTH IT HELPS TO CONTROL CASTOR ALONG WITH PINION ANGLE. AND WITH THIS ROTATING DESIGN SUSPENSION TRAVEL IS ALMOST UNLIMITED. SO IF YOU'RE LOOKING TO UPGRADE THE LOWER CONTROL ARMS ON YOUR JEEP JK, CHECK OUT

JKS MANUFACTURING.

(LT)>> IF YOU'RE LOOKING FOR AN INEXPENSIVE BRAKE UPGRADE FOR YOUR LIGHT TRUCK OR SUV, CHECK OUT

THESE EBC 6,000 GREEN STUFF PADS.

THEY'RE A GREAT ENTRY LEVEL UPGRADE AND THEY OFFER ABOUT A 15 PERCENT INCREASE IN STOPPING POWER WITH MINIMUM BRAKE DUST. NOW THESE EBC ROTORS ARE DIMPLE DRILLED AND SLOTTED FOR QUIET AND SMOOTH COOL OPERATION. THEY'RE ALSO COATED IN THIS NICE RUST PROTECTIVE COATING AND THEY'RE A GREAT INEXPENSIVE PERFORMANCE UPGRADE FOR YOUR BRAKING SYSTEM, ESPECIALLY WHEN YOU CONSIDER THE COST.

(JEREMY)>> THIS IS LIZARD SKIN SUPER PRO APPLICATION KIT, AND IT COMES WITH EVERYTHING YOU NEED TO LAY DOWN THESE PRODUCTS. IT COMES WITH THE GUY ITSELF, A ONE QUART CUP, THE MIXER THAT JUST ATTACHES TO THE DRILL WHEN

YOU USE THESE TWO GALLON SETUPS, AND A

MILL THICKNESS GAUGE. THE GREAT THING ABOUT THIS GUN IS THE LARGE ORIFICE, SO IT EASILY SPRAYS THESE THICK MATERIALS. SO IF YOU'RE LOOKING TO PUT THIS APPLICATION IN YOUR TRUCK CHECK OUT LIZARD SKIN. GUYS THANKS FOR WATCHING TRUCK TECH, SEE YOU NEXT TIME.

Show Full Transcript

(RYAN)>> HEY GUYS, WELCOME BACK TO TRUCK TECH. NOW IN THE SHOP TODAY IS A 2011 MERCURY MARINER. ESSENTIALLY THE SAME THING AS THE

POPULAR FORD ESCAPE.

NOW THE REASON ITS HERE IS NOT TOO LONG AGO THE AUTOMATIC TRANSMISSION STARTED SHIFTING A LITTLE BIT WEIRD. THE OWNER BROUGHT IT TO THE DEALER IN CASE IT WAS SOFTWARE ISSUE BUT THE DEALERSHIP INFORMED HIM THAT IT WAS AN AUTOMATIC TRANSMISSION FLUID LEVEL

PROBLEM DUE TO A LEAKING TRANSMISSION SEAL. BUT ONCE THE OWNER WAS PRESENTED WITH A NEARLY $1,000 DOLLAR REPAIR BILL, I TOLD HIM WE COULD DO BETTER AND WALK YOU GUYS THROUGH THE PROCESS OF THE REPAIR JUST IN CASE YOU HAVE ONE OF THESE PARKED IN YOUR DRIVEWAY. STEP ONE IS REMOVING THIS PLASTIC SPLASH SHIELD SO WE CAN SEE WHAT WE'RE DOING AND GAIN ACCESS. NOW AT FIRST IT LOOKS LIKE THIS IS JUST A BAD HALF SHAFT SEAL, BUT AFTER A QUICK INSPECTION WELL IT'S PRETTY CLEAR THERE'S MORE TO IT THAN THAT. I THINK THE SUPPORT BUSHING IS WORN OUT. IN FACT IF I HOLD THIS HALF SHAFT UP LONG ENOUGH IT STARTS WEEPING TRANSMISSION FLUID OUT PRETTY QUICK.

ONLY ONE WAY TO FIX THAT IS REPLACE THE BUSHING. NEXT WE'RE GONNA REMOVE THE DRAIN PLUG AND LET ALL THE TRANSMISSION FLUID DRAIN OUT. YUMMY! NOW THE MAJORITY OF THE COST OF THIS REPAIR IS IN THE LABOR, AND BY SHOWING YOU GUYS HOW TO DO IT MAYBE YOU'LL REALIZE THAT IF YOU'VE GOT THE TIME YOU

CAN SAVE A LOT OF MONEY TOO. NOW TO SEPARATE THE SPLINED HALF SHAFT FROM THE WHEEL BEARING I'M USING AN IMPACT HAMMER, BUT A REGULAR HAMMER WILL GET THE JOB DONE AS WELL, JUST MIGHT TAKE A LITTLE LONGER. THEN WE CAN SEPARATE THE KNUCKLE FROM THE STRUT AND FINISH REMOVING THE HALF SHAFT. ONCE THAT'S DONE WE'RE JUST ABOUT THERE. ALL WE'VE GOT TO DO IS PRY THE HALF SHAFT OUT OF THE

TRANSMISSION. NOW I'M USING A PIECE OF WOOD TO INSULATE

THE ALUMINUM PAN FROM THE PRY BAR. YOU DON'T WANT TO CAUSE DAMAGE IN THE

PROCESS OF A REPAIR. NOW I'M USING OUR MATCO SEAL PULLER TO GET THIS

SEAL OUT OF THE CASE, BUT A SMALL PRY BAR OR SCREW DRIVER WILL WORK AS WELL. NOW THIS JOB DOES REQUIRE A SPECIAL TOOL TO SAFELY REMOVE THE BUSHING FROM THE TRANSMISSION CASE,

BUT DON'T LET THAT DISCOURAGE YOU FROM TACKLING THIS JOB. I'LL EXPLAIN MORE IN A SECOND. AFTER DRIVING THE SPECIAL TOOL INTO PLACE IT EXPANDS AND GRABS ON TO THE END OF THE BUSHING.

THEN YOU CAN THREAD IN THE LARGE BOLT UNTIL IT BOTTOMS OUT AGAINST THE DIFFERENTIAL CROSS SHAFT. NOW I'M USING AN ELECTRIC IMPACT JUST TO RUN THE BOLT IN. ONCE IT BOTTOMS OUT I'LL GO AHEAD AND TIGHTEN IT DOWN BY HAND. I DON'T WANT TO DAMAGE THE THREADS OF THE SPECIAL TOOL. AS YOU CAN SEE IT DOESN'T TAKE A TON OF PRESSURE EITHER. GOT IT!

NOW DON'T LET THE REQUIREMENT OF A SPECIAL TOOL DERAIL YOU FROM TACKLING A JOB LIKE THIS. IF YOU'RE LOOKING AT HUNDREDS AND HUNDREDS OF DOLLARS TO PAY SOMEBODY ELSE TO DO THE JOB, FORKING OVER $150 OR $200 BUCKS FOR A SPECIAL TOOL ISN'T THAT BAD IN COMPARISON. NOW WE GOT LUCKY AND WE BORROWED OURS FROM THE LOCAL COLEMAN TAYLOR TRANSMISSION SHOP. THE SAME PLACE WE PICKED UP THE REPLACEMENT SEAL AND BUSHING, BUT IT'S NOT JUST A STOCK REPLACEMENT. NOW HERE'S THE STOCK BUSHING COMPARED TO THE REPLACEMENT, AND THIS ONE IS CLEARLY WORN OUT, NOT TO MENTION IT'S NOT NEARLY AS WIDE AS THE UPGRADED BUSHING, WHICH HELPS TO DISTRIBUTE THE LOAD. NOW YOU CAN SEE THE ORIGINAL BUSHING ON THE C/V SHAFT AND WHERE ALL THAT PLAY WAS COMING FROM. THAT SUCKER IS WORN OUT. WITH A REPLACEMENT IT FITS A LOT TIGHTER AND WILL ELIMINATE THAT PROBLEM. MAKE SURE THE OIL NOTCH IS LINED UP WITH THE NOTCH ON

THE TOOL, AND IN THE SIX O'CLOCK POSITION. IT'S POINTING STRAIGHT DOWN. MAKE SURE EVERYTHING LINES UP PROPERLY. MAKE SURE IT'S FLUSH WITH THE SEAL SURFACE. SOLID NOISE TELLS ME WE'RE DONE.

NOW THE BUSHING IS FULLY INSTALLED BUT THE SPECIAL TOOL'S A LITTLE STUCK IN THE CASE.

SO I'M USING PARTS AND PIECES FROM A BALL JOINT PRESS TO GET IT OUT OF THERE.

COOL, FLUSH WITH THE SURFACE LIKE IT'S SUPPOSED TO BE, WE'RE GOOD. NOW IT LOOKS LIKE SOMEBODY'S PRIED THE SEAL OUT BEFORE AND REPLACED IT, BUT SINCE THEY DIDN'T REPLACE THE BUSHING THE BEST SEAL IN THE WORLD ISN'T GONNA FIX THAT PROBLEM. THERE'S THE NEW SEAL ON THE TOOL SO IT GOES IN SQUARE AND SEATS EVENLY.

[ hammer tapping ]

(RYAN)>> JUST MAKE SURE YOU APPLY A LITTLE ATF

TO THE SEAL SURFACE BEFORE YOU INSTALL THE HALF SHAFT.

ALL THE WAY IN AND LOOK AT THAT, NICE, THAT'S HOW

IT'S SUPPOSED TO BE. NOW BEFORE I REINSTALL THE OUTER END OF THE HALF SHAFT I'M APPLYING A LITTLE LOCTITE ANTISEIZE TO MAKE SURE THIS THING DISASSEMBLES EASILY IN THE FUTURE. THEN IT'S SIMPLY A MATTER OF REASSEMBLING THE FRONT END.

ALRIGHT NOW WITH EVERYTHING BUTTONED UP THE LAST STEP IS FILLING THE TRANS WITH FLUID. NOW THIS SIXF-35 TAKES A VERY SPECIFIC TYPE OF ATF, SO MAKE SURE YOU'RE USING THE RIGHT STUFF. AND IF YOU'RE WONDERING WHY WE DIDN'T PUT A FILTER ON THE TRANSMISSION WHILE WE WERE WORKING ON IT, WELL SOME ENGINEER HAD THE BRIGHT IDEA TO PUT THE FILTER INSIDE THE TRANSMISSION WHERE YOU HAVE TO SPLIT THE CASE TO ACCESS IT. NOT A GREAT IDEA, BUT ALL THE MORE REASON TO CHANGE THE FLUID MORE OFTEN SO THE FILTER DOESN'T GET CLOGGED UP AND GIVE YOU DRIVABILITY PROBLEMS.

(ANNOUNCER)>> AFTER THE BREAK WE'LL REPLACE THAT WORN OUT WATER PUMP, AND LATER WE'LL GET THE A/C WORKING AGAIN WITH A NEW CONDENSER AND DRIER, STAY TUNED!

(RYAN)>> HEY GUYS, WELCOME BACK TO THE SHOP. NOW RECENTLY WE WALKED OUT TO THE PARKING LOT AND SAW A PUDDLE OF COOLANT UNDERNEATH THIS CHEROKEE.

A QUICK INSPECTION REVEALED A FAILING WATER PUMP. AND WITH THE SYSTEM NOT HOLDING COOLANT AND A WATER PUMP ON ITS WAY OUT, DRIVING IT IS NOT A GOOD IDEA. SO IT LEAVES YOU WITH A COUPLE OF OPTIONS. YOU CAN TOW IT TO A REPAIR SHOP, PAY THEM A FEW HOURS LABOR AND PARTS MARK UP, AND SPEND $300, $400, MAYBE EVEN $500 DOLLARS HAVING THEM FIX IT. OR YOU CAN SPEND A COUPLE OF HOURS, GETS YOUR HANDS

DIRTY, AND SPEND LESS THAN $100 BUCKS AND FIX IT YOURSELF. NOW ACCORDING TO THE OWNER THERE WERE A COUPLE OF WARNING SIGNS WITH THIS FAILURE. HE HAD SOME SQUEALY NOISES COMING FROM THE ENGINE BAY, AND THAT'S BECAUSE THE BELT WAS SLIPPING ON THE PULLEYS FROM BEING CONTAMINATED BY THE COOLANT. AND AFTER IT'S BEEN PARCHED FOR ANY PERIOD OF TIME IT'S MARKING ITS SPOT. [ air ratchet spinning ]

(RYAN)>> I CAN TAKE THE TENSION OFF THE BELT.

IF YOU DON'T HAVE A BELT ROUTING DIAGRAM ON THE RADIATOR SUPPORT TAKE A PICTURE OR JUST REMEMBER HOW THE BELT GETS ROUTED.

IT'S IN DECENT SHAPE BUT ONCE THESE GET CONTAMINATED THEY NEED TO BE EITHER CLEANED REALLY GOOD OR REPLACED. NOW WE CAN REMOVE THE WATER PUMP PULLEY.

YEAH YOU CAN SEE THE COOLANT INSIDE THE PULLEY. THAT THING'S BEEN LEAKING FOR A GOOD LITTLE BIT NOW. OH YEAH, THAT THING'S TOAST. [ air ratchet spinning ]

(RYAN)>> NOW WITH THE PUMP OFF WE CAN TAKE A CLOSER LOOK. YOU ALREADY SAW THE PLAY IN THE HUB. WHAT HAPPENS IS THE BEARING STARTS TO WEAR OUT AND COOLANT GETS PAST THE SEAL AND STARTS COMING OUT OF THE WEEP HOLE. YOU CAN ALSO SEE MORE EVIDENCE HERE WHERE THE PULLEY'S ACTUALLY BEEN EATING INTO THE ALUMINUM HOUSING. SO WE WENT TO AUTOZONE AND PICKED UP

SOME REPLACEMENT PARTS. WE'VE GOT A NEW PUMP AND GASKET FOR ABOUT $35 BUCKS. SINCE WE'RE ALREADY INTO THE SYSTEM MIGHT AS WELL ADD A THERMOSTAT FOR ABOUT EIGHT BUCKS, NEW COOLANT FOR ABOUT EIGHT OR $10 DOLLARS, AND AROUND $30 DOLLARS FOR A NEW BELT, WHICH ISN'T EVEN A NECESSITY. IF YOU CLEAN YOUR OLD ONE REALLY GOOD YOU CAN GET AWAY WITH REUSING IT. BUT BEFORE WE INSTALL THESE PARTS I'VE GOT TO SCRAPE OFF THE OLD GASKET.

(LT)>> RYAN STARTS WITH A GENERAL PURPOSE SCRAPER TO REMOVE THE BIG CHUNKS OF GASKET FROM THE THERMOSTAT HOUSING AND THE WATER PUMP FLANGE.

(RYAN)>> ALRIGHT, THE REST I CAN GET WITH A RAZOR BLADE.

I'LL CLEAN THE SURFACE, THROW SOME RTV ON THERE AND A GASKET, WE'LL BE GOOD.

(LT)>> RYAN'S GOING TO REMOVE THE ORIGINAL HEATER HOSE ADAPTER AND CLEAN THE THREADS BEFORE REINSTALLING IT INTO THE NEW WATER PUMP. THIS ADAPTER HAS A UNIQUE PATH THAT IT HAS TO FOLLOW. SO PAY ATTENTION TO THE ORIENTATION AS YOU REMOVE IT FROM THE PUMP AND BE SURE TO DUPLICATE THAT

AS YOU REINSTALL IT.

(RYAN)>> SOMEBODY USED TEFLON TAPE.

I ACTUALLY PREFER THE LIQUID.

(LT)>> REGARDLESS OF THE METHOD YOU PREFER, IT'S IMPORTANT TO HAVE SOME SORT OF THREAD SEALANT ON THESE TAPERED PIPE THREAD, OR NPT FITTINGS.

(RYAN)>> EVEN THOUGH I'M USING A GASKET I LIKE TO USE A LITTLE SEALER AS WELL JUST TO MAKE SURE WE DON'T HAVE ANY LEAKS. IT MIGHT BE A LITTLE OVERKILL I'D RATHER NOT DO THIS JOB TWICE.

A JOB LIKE THIS, IT DOESN'T TAKE ANY SPECIAL TOOLS.

(LT)>> MAKE SURE THAT THE TEMPERATURE RATING ON YOUR

NEW THERMOSTAT MATCHES THAT OF YOUR ORIGINAL ONE.

(RYAN)>> I'M ACTUALLY GONNA LET THAT SET UP FOR JUST A COUPLE OF MINUTES. START TO SKIN OVER THEN WE CAN INSTALL IT. ONCE THE RTV HAS SKINNED OVER A LITTLE BIT WE CAN INSTALL IT WITHOUT ALL THE GASKET SMUSHING OUT THE SIDES AS WE TIGHTEN THE BOLTS.

(LT)>> THE BIGGEST REASON FOR WANTING TO USE NEW COOLANT IS THAT OVER TIME IT CAN BECOME CONTAMINATED BY CORROSION INSIDE THE ENGINE AND

BECOME LESS EFFECTIVE. ALSO IF YOU'VE USED ANY SORT OF RADIATOR LEAK PREVENTATIVE IN THE PAST, THIS IS A GREAT TIME TO FLUSH IT OUT.

(RYAN)>> ALRIGHT NOW WITH THE SYSTEM FILLED UP GIVE EVERYTHING A ONCE OVER, FIRE UP THE ENGINE, TURN THE HEATER ON, AND LET THE COOLANT CIRCULATE AS IT GETS UP TO OPERATING TEMPERATURE. THEN LET IT COOL OFF FOR A FEW MINUTES, CHECK THE COOLANT LEVEL, TOP OFF IF NECESSARY, AND TAKE IT FOR A SPIN AROUND THE BLOCK. THEN GIVE YOURSELF A PAT ON THE BACK FOR A JOB WELL DONE AND FOR SAVING A FEW BUCKS.

(LT)>> NOW THAT WE'VE GOT THE WATER PUMP KEEPING THE ENGINE COOL ON THIS JEEP LET'S SEE WHAT WE CAN DO ABOUT KEEPING THE INTERIOR COOL. NOW WE'RE GONNA BE REPLACING THE AIR CONDITIONING CONDENSER AND RECEIVER DRIER, AS WELL AS USING THESE TOOLS FROM MATCO TO EVACUATE AND RECHARGE THE SYSTEM WITH THIS REFRIGERANT FROM AUTOZONE. WE KNEW THERE WAS DAMAGE ON THE CONDENSER, WHICH HAD CAUSED THE REFRIGERANT TO LEAK OUT. SO TO GET ACCESS TO IT WE REMOVED THE GRILL FOLLOWED BY THE UPPER RADIATOR SUPPORT. WITH THE UPPER RADIATOR HOSE CLAMPED OFF AND SWUNG OUT OF THE WAY, WE CAN ACCESS THE RETAINING CLIPS THAT HOLD THE AIR CONDITIONING CONDENSER CONNECTIONS TIGHT. THESE THINGS CAN BE A LITTLE TRICKY. DISCONNECTING THE FITTINGS AT THE CONDENSER DOES REQUIRE A LINE DISCONNECT TOOL, AND WE GOT OURS FROM MATCO. AND WITH THAT THE CONDENSER IS READY TO LIFT OUT.

THAT RIGHT THERE IS WHY WE'VE GOT NO AIR CONDITIONING.

INSTALLATION IS JUST THE REVERSE OF THE DISASSEMBLY.

NOW THESE INCLUDED THREAD CUTTING NUTS TAKE ADVANTAGE OF THE SOFT ALUMINUM TO SECURE THE AIR CONDITIONING CONDENSER TO THE RADIATOR. MAKES THEIR OWN THREADS.

WHEN REASSEMBLING THE CONDENSER FITTINGS BE SURE TO USE A SPECIFIC AIR CONDITIONING LUBRICANT INSTEAD OF MOTOR OIL. IT WILL CONTAMINATE THE SYSTEM AND CAUSE POOR PERFORMANCE. DON'T FORGET TO INSTALL THESE SAFETY CLIPS

OVER THE CONNECTION. ANOTHER COOL TIP IS TO ALWAYS LINE THESE CLAMPS UP EXACTLY WHERE THEY CAME OFF CAUSE THESE HOSES GET HARD AND THEY MIGHT NOT SEAL JUST RIGHT IF YOU DON'T. THE RECEIVER DRIER ACTS AS A RESERVOIR FOR THE REFRIGERANT AND ALSO FILTERS OUT ANY CONTAMINATION AND MOISTURE. NOW THE RECEIVER DRIER SHOULD BE REPLACED ANY TIME YOU BREACH THE SYSTEM FOR MAINTENANCE. NOW AT $35 BUCKS IT'S NOT THAT BIG OF A DEAL.

AS A PRECAUTION AGAINST FUTURE LEAKS WE'RE REPLACING THE ORINGS AND GASKETS WITH THE NEW ONES PROVIDED.

BE CAREFUL NOT TO NICK THE NEW ORINGS WHEN YOU'RE INSTALLING THEM.

WE'RE INSTALLING A NEW LOW PRESSURE SWITCH ON THE

RECEIVER DRIER. THESE THINGS ARE MADE OF PLASTIC, SO BE VERY CAREFUL WHEN YOU TIGHTEN THEM. THEY'RE SUPER EASY TO DAMAGE.

(LT)>> HEY GUYS, WELCOME BACK TO TRUCK TECH. NOW THAT WE'VE GOT OUR AIR CONDITIONING CONDENSER AND RECEIVER DRIER REPLACED WE CAN CONTINUE TO RECHARGE THE SYSTEM WITH REFRIGERANT. WITH OUR HIGH AND LOW SIDE LINES CONNECTED WE CAN USE OUR MATCO VACUUM PUMP TO EVACUATE THE SYSTEM. ONCE THE SYSTEM REACHES ABOUT 25 INCHES OF VACUUM LEAVE THE PUMP ON FOR ANOTHER 10 MINUTES OR SO TO MAKE SURE IT'S THOROUGHLY EVACUATED. THEN CLOSE THE LOW SIDE VALVE AND WAIT ANOTHER 15

TO 20 MINUTES TO MAKE SURE THERE'S NO LEAKS. IF THE VACUUM ESCAPES THAT'S HOW YOU'LL KNOW. OURS WAS GOOD TO GO, SO IT'S TIME TO ADD THE REFRIGERANT. CHECK YOUR OWNERS MANUAL FOR THE SPECIFIED AMOUNT OF REFRIGERANT. OURS TAKES ABOUT 20 OUNCES, WHICH IS ROUGHLY A CAN AND A HALF. BE SURE TO BLEED ANY REMAINING AIR FROM THE SUCTION LINE BEFORE INTRODUCING THE REFRIGERANT TO THE SYSTEM. ONCE THE SYSTEM EQUALIZES WITH PRESSURE YOU CAN START THE CAR AND TURN ON THE AIR CONDITIONING. ONCE THE AIR CONDITIONING RUNS IT'LL SLOWLY START TO SUCK REFRIGERANT FROM THE CAN INTO THE SYSTEM. EACH TIME THE COMPRESSOR KICKS ON IT'LL DRAW A LITTLE BIT MORE REFRIGERANT IN THE AIR CONDITIONING SYSTEM. NOW THIS MAY TAKE AWHILE, UP TO 15 TO 20 MINUTES BEFORE THE PUMP WILL RUN CONSTANTLY AND YOU CAN START WORRYING ABOUT PRESSURE. THE GOAL IS TO KEEP THE HIGH SIDE PRESSURES IN CHECK WHILE KEEPING THE EVAPORATOR AS COOL AS POSSIBLE. THE GAUGES WILL LET YOU KNOW HOW YOU'RE DOING BY READING TEMPERATURE AND PRESSURE. GOING ABOUT 38 DEGREES AT THE EVAPORATOR. AS SOON AS THAT ELECTRIC FAN KICKS ON IT SHOULD DROP DOWN QUITE A BIT, AND HOPEFULLY PRETTY CLOSE TO ABOUT 32 DEGREES. AND WHEN THE HEAD PRESSURE DROPS THAT MEANS THE SYSTEM WILL BE OPERATING IN ITS PEAK EFFICIENCY. THERE IT GOES! GONNA DROP, SLOWLY DROPPING, TEMPERATURE AND PRESSURE, JUST A TAD OVER 30. IT'LL BE NICE AND COLD INSIDE. EVEN IN OUR WARM SHOP YOU CAN TELL THE SYSTEM IS WORKING AND PUMPING OUT SOME NICE FROSTY AIR.

(JEREMY)>> THIS IS JKS MANUFACTURING LOWER CONTROL ARMS FOR AN '07 THROUGH '16 JEEP WRANGLER JK. THEY'RE A HEAVY DUTY DESIGN, SO THEY'LL DEFINITELY TAKE A BEATING ON THE TRAIL. AND WITH THEIR ADJUSTABILITY AND LENGTH IT HELPS TO CONTROL CASTOR ALONG WITH PINION ANGLE. AND WITH THIS ROTATING DESIGN SUSPENSION TRAVEL IS ALMOST UNLIMITED. SO IF YOU'RE LOOKING TO UPGRADE THE LOWER CONTROL ARMS ON YOUR JEEP JK, CHECK OUT

JKS MANUFACTURING.

(LT)>> IF YOU'RE LOOKING FOR AN INEXPENSIVE BRAKE UPGRADE FOR YOUR LIGHT TRUCK OR SUV, CHECK OUT

THESE EBC 6,000 GREEN STUFF PADS.

THEY'RE A GREAT ENTRY LEVEL UPGRADE AND THEY OFFER ABOUT A 15 PERCENT INCREASE IN STOPPING POWER WITH MINIMUM BRAKE DUST. NOW THESE EBC ROTORS ARE DIMPLE DRILLED AND SLOTTED FOR QUIET AND SMOOTH COOL OPERATION. THEY'RE ALSO COATED IN THIS NICE RUST PROTECTIVE COATING AND THEY'RE A GREAT INEXPENSIVE PERFORMANCE UPGRADE FOR YOUR BRAKING SYSTEM, ESPECIALLY WHEN YOU CONSIDER THE COST.

(JEREMY)>> THIS IS LIZARD SKIN SUPER PRO APPLICATION KIT, AND IT COMES WITH EVERYTHING YOU NEED TO LAY DOWN THESE PRODUCTS. IT COMES WITH THE GUY ITSELF, A ONE QUART CUP, THE MIXER THAT JUST ATTACHES TO THE DRILL WHEN

YOU USE THESE TWO GALLON SETUPS, AND A

MILL THICKNESS GAUGE. THE GREAT THING ABOUT THIS GUN IS THE LARGE ORIFICE, SO IT EASILY SPRAYS THESE THICK MATERIALS. SO IF YOU'RE LOOKING TO PUT THIS APPLICATION IN YOUR TRUCK CHECK OUT LIZARD SKIN. GUYS THANKS FOR WATCHING TRUCK TECH, SEE YOU NEXT TIME.