HorsePower Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Cloyes Gear and Products

Timing Chain and Gear Set, True Roller, Single, Iron/Steel Sprockets, Cadillac, 368, 425, 472, 500, Set

Clevite

Main Bearing Sets - Undersize

Diamond Pistons

Forged piston 500, set of 8, .030 over. For 76cc head - 10 to 1 compression. Custom for MTS

Goodson Shop Supplies

Highly refined petroleum product

Contains no lead, graphite or minerals, Wont corrode fie surfaces, WOnT emulsify with cooling liquids, Surfaces stay lubed and protected, 4 oz tube

MTS

Cam button - with roller bearing.

MTS

MTS 7.1 Billet Connecting Rod Set

MTS

MTS Custom Aluminum 76cc "FR" Head Pair. Serial Number Matched.

MTS

MTS Roller Tipped Shaft Rocker system, ADJUSTABLE, full support - 1.70 ratio.

MTS

MTS Single Plane Aluminum Intake Manifold

MTS

OIL PAN, CADILLAC, 472-500, MTS

MTS

RPM range: 2,000 - 6,000 / Advertised duration range: 298* and higher / Duration @ .050 range: 240* and higher / Valve lift range: .550-590.

Episode Transcript

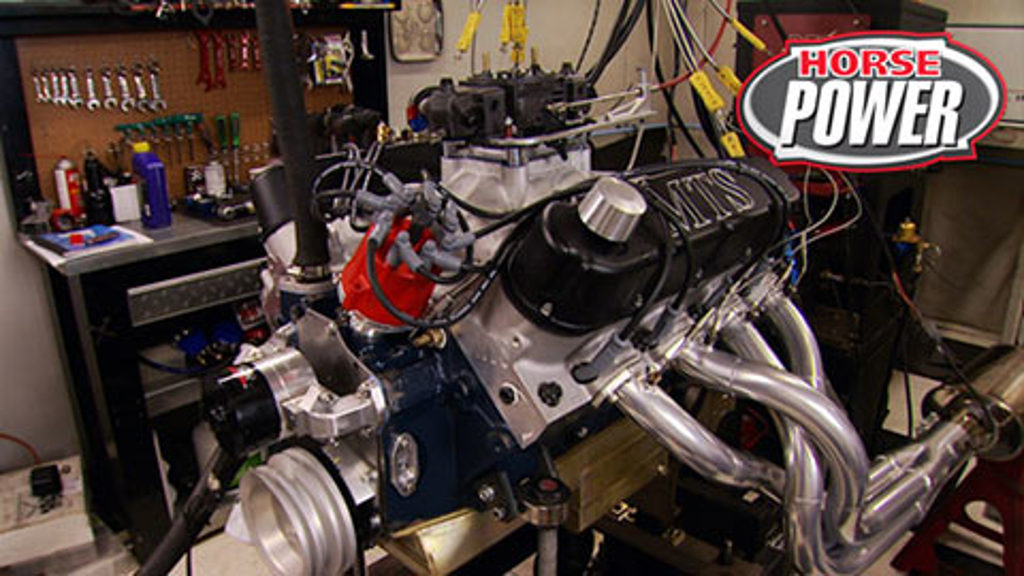

(ANNOUNCER)>> NO EVERYDAY

ENGINE BUILD TODAY. ONCE AGAIN HORSEPOWER'S TAKING

ON ONE OF "THE OTHER ENGINES" OF HIGH PERFORMANCE HISTORY. THIS TIME IT'S A CADILLAC 500,

THE BIGGEST BIG BLOCK FROM

GM'S LEGENDARY LUXURY RIDE!

(JOE)>> TODAY'S OTHER ENGINE BUILD BEGINS WITH AMERICA'S LARGEST PRODUCTION BLOCK OF ALL TIMES.

(JOHN W.)>> THESE ARE GOING ON IT.

(MIKE)>> THOSE ARE NICE! (JOHN W.)>> THANK YOU!

(JOE)>> AND A LITTLE HELP FROM MAXIMUM TORQUE SPECIALTIES AND

THEIR ENGINE GURU JOHN WALKER. (JOHN W.)>> IT WILL MAKE SOME POWER.

(JOE)>> IT'S A 500 CUBIC INCH BIG BLOCK THAT POWERED SOME OF OUR FAVORITE LUXURY LAND YACHTS BEGINNING BACK IN 1970, GM'S EVER CLASSIC CADILLAC. IT WAS THE FIRST CAR TO USE DESIGNER STYLE BODY WORK. 1948 WAS THE FIRST YEAR FOR THOSE LEGENDARY TAIL FINS

INSPIRED BY THE TWIN RUDDERS OF THE LOCKHEED P-38 LIGHTNING, EVER GROWING UNTIL THE TAIL FIN FINALE IN 1959. WHO KNOWS WHAT INSPIRED THOSE FAMOUS BULLET BUMPERS.

SOME SAY IT WAS A TV STAR FROM THE '50'S NAMED DAGMAR. UH, ANYONE SEE A RESEMBLANCE? CADILLAC WAS THE FIRST AUTOMAKER TO MASS PRODUCE A VEIGHT ENGINE, AND IT PRODUCED EIGHT GENERATIONS OF THEM STARTING IN 1914. BIG BLOCK SIZE AND HORSEPOWER INCREASED THROUGHOUT THE '50'S AND '60'S.

THEN FOR 1970 CADILLAC FITTED A CRANK SHAFT WITH A 430 STROKE INTO A 472 ENGINE TO CREATE A 500 CUBIC INCH BIG BLOCK RATED AT 400 HORSEPOWER. IT WAS THE PINNACLE OF POWER FOR GM'S LUXURY LEGEND. KNOWN FOR ITS TORQUE BUT NOT HORSEPOWER, AT LEAST AFTER THE FIRST YEAR, BY THE END OF THE PRODUCTION RUN IT WAS RATED AT ONLY 190. BUT WHY DIDN'T CADDY'S POWER THEIR WAY INTO THE WORLD OF AMERICAN HOT RODS? (JOHN W.)>> IT WAS NEVER PUT IN A PERFORMANCE VEHICLE. NOBODY EVER LOOKED AT AN ELDORADO, OR A COUPE, OR A

SEDAN DE VILLE, OR HEARSE, AS A PERFORMANCE VEHICLE IN ANY WAY, SHAPE, OR FORM.

(JOE)>> THERE WAS ALSO THE ISSUE OF AVAILABLE PARTS. THAT'S CHANGED WITH THE EMERGENCE OF MTS, ONE OF THE ONLY TWO EXISTING COMPANIES THAT SPECIALIZE IN CADILLAC 500 PARTS AND ENGINE PACKAGES. ( )>> WE FOUND IT MUCH EASIER TO PUT A LOT OF INVENTORY INTO ONE ENGINE, AND NOW WE'VE BROUGHT CADILLAC SPECIFIC

PRODUCTS TO THE MARKET THAT ARE A CUT ABOVE WHAT WAS AVAILABLE BEFORE. (JOHN W.)>> WE KEEP MAKING PARTS FOR THEM AND EVERY TIME WE MAKE NEW PARTS WE START SELLING THEM.

(JOE)>> JOHN BROUGHT US EVERYTHING WE NEED TO BUILD A PUMP GAS FRIENDLY 500, INCLUDING SEVERAL PARTS MTS DESIGNS AND MANUFACTURES. WE PLAN TO BUILD AN ENGINE THAT'LL HAVE ENOUGH TORQUE TO PULL A HOUSE DOWN, AND HORSEPOWER, WE'LL ALL FIND THAT OUT LATER.

(MIKE)>> THE BLOCK WAS MACHINED BY MIKE GRAHAM IN BOWLING GREEN, OHIO. IT'S 90 OVER, HAS A 4304 STROKE WITH A 4390 BORE FOR 520 INCHES. NOW IT MEASURES IN AT 25 AND THREE QUARTER INCHES LONG AND WEIGHS 595 POUNDS CARB TO PAN. FOR REFERENCE, A SMALL BLOCK CHEVY IS 21 AND A HALF INCHES LONG. IF A CADDY SWAP IS ON YOUR MIND, DON'T BE AFRAID, THEY'RE IN FOX BODY MUSTANGS. THE CAM IS INSTALLED. NOW FACTORY CAMS HAVE A FUEL PUMP ECCENTRIC, THIS ONE DOES NOT. SO MTS DESIGNED THIS CAM BUTTON TO TAKE THE PLACE OF THE ECCENTRIC SINCE WE'RE USING THE HYDRAULIC ROLLER CAM SHAFT. IT HAS A LOBE SEPARATION ANGLE OF 110 DEGREES, DURATION AT 50

IS 248 ON THE INTAKE, 248 ON THE EXHAUST. LIFT AT THE VALVE WITH A ONESEVEN ROCKER ARM IS 640. THE UPPER CLEAVITE BEARINGS CAN GO INTO PLACE, FOLLOWED BY THE UPPER HALF OF THE REAR MAIN SEAL THAT GETS INSTALLED OFFSET AND A FILM OF OIL TO PREVENT THE SEAL FROM PREMATURE FAILURE. WITH ALL THE BEARINGS LUBED, THIS MASSIVE STOCK CRANK CAREFULLY FINDS ITS HOME.

(MARTY)>>THERE WE GO.

(MIKE)>> OKAY, LONG ONE GOES HERE. OIL THE STUDS BEFORE INSTALLING AND DROP ON THE MAIN CAPS. WITH THE CAP SEATED, APPLY SOME GOODSON EXTREME PRESSURE LUBE TO THE WASHERS AND STUDS AND TORQUE THEM IN THREE STEPS, 50, 80, AND FINALLY 115 FOOT POUNDS. IT'S ALWAYS IMPORTANT TO CHECK THE END PLAY OF THE CRANK SHAFT.

(MARTY)>>THERE'S ACTUALLY SEVEN THOUSANDTHS TOTAL, WE'RE GOOD. (JOHN B.)>> ALRIGHT I'M GONNA GO OVER THIS PISTON DESIGN WITH YOU GUYS TODAY. NOW IT'S PRETTY COOL THE GUYS FROM MTS ACTUALLY GOT TOGETHER WITH THE GUYS FROM DIAMOND TO CREATE THEIR OWN PROFILE. NOW WHAT IT ENTAILS IS A TOP RING OFF ONE SIXTEENTH, SECOND RING OF ONE SIXTEENTH, AND A THIRD RING OF THREE SIXTEENTHS ALONG WITH AN ANTIDETONATION GROOVE IN BETWEEN THE TOP AND SECOND RING LAND.

NOW WE WENT WITH THE TRADITIONAL MOLY COATING ON THE SKIRTS BUT A CERAMIC COATING ON THE HEAD. NOW THIS IS A TWO VALVE RELIEF PISTON WITH A POSITIVE 22cc DISH. AND WHAT THAT'S GONNA DO IS PUT US RIGHT AT 10.8 TO ONE COMPRESSION FOR OUR STREET MOTOR.

(MIKE)>> THE RINGS ARE FROM HASTINGS AND HAVE ALREADY BEEN FILE FITTED.

NOW MTS DESIGNED THE HBEAM RODS AS WELL. THEY'RE SIXSEVEN-50 LONG AND FILLED WITH CLEAVITE BEARINGS. ALL THESE PARTS ARE THE REASON WE CAN DOUBLE THE CADDY'S RPM RANGE. (JOHN W.)>> IT WAS NEVER IN ITS ORIGINAL FORM DESIGNED TO REV OVER 3,000 RPM. IT WAS DESIGNED TO LAST A HALF A MILLION MILES ON A HUGE CAR. (JOHN B.)>> OH, THAT'S NICE.

(MIKE)>> FEEL GOOD? (JOHN B.)>> YEP. GET GOOD END PLAY? (JOHN B.)>> SIDE CLEARANCE, ALL THE WAY BACK.

(MIKE)>> VERY NICE.

(JOE)>> WE'RE STILL AT IT LOOKING FOR THE OVERLOOKED

POTENTIAL IN THIS 500 CADDY. (JOHN W.)>> IT WILL MAKE SOME POWER.

(JOE)>> ALONG WITH THE PROS FROM MTS AND ALL

THE BEST PARTS POSSIBLE.

(MIKE)>> CLOYES SUPPLIED THE TRUE ROLLER TIMING SET. IT'S A PRESS FIT ON THE CRANK AND A SINGLE ROW, THE ONLY ONE THAT CAN BE USED ON A CADILLAC. NOW WE CAN PUT THE OIL SLINGER ON THE CRANK SNOUT TO PROPERLY OIL THE TIMING CHAIN AND DISTRIBUTOR GEAR. BEFORE WE GO ANY FURTHER, WE'RE GOING TO DEGREE THE CAM TO ASSURE US IT'S INSTALLED CORRECTLY AND THE CAM CARD IS ACCURATE. THE STAINLESS TIMING COVER CAN GO ON NEXT AND SECURE IT WITH A COUPLE OF BOLTS TO LET THE SILICONE SET UP. GASKETS ARE USED ON THE FRONT AND BACK OF THE PAN LIPS. ONCE THE FOUR CORNERS OF THE BLOCK HAVE A DAB OF SILICONE, WE CAN INSTALL SOME ALIGNMENT STUDS TO HOLD THE PAN RAIL GASKETS. WEATHER STRIP ADHESIVE IS THEN APPLIED TO THE PAN SIDE OF THEM, WHICH WILL PREVENT LEAKS. NOW WE CAN DROP ON THE MTS SIX QUART OIL PAN AND TIGHTEN IT DOWN IN AN EVEN CRISS CROSS PATTERN. FOR A BALANCER WE'RE USING AN SFI RATED POWERBOND ONE PIECE UNIT THAT IS NEUTRAL BALANCED. TO FINISH UP THE SHORT BLOCK A MELING STANDARD VOLUME PUMP THAT WAS BLUE PRINTED BY THE GUYS AT MTS. AND NEXT UP ARE THESE ALUMINUM CYLINDER HEADS. NOW THESE THINGS ARE SPECED OUT BY MTS BUT CAST AND MACHINED AT HIGH TECH CASTINGS. NOW THEY HAVE 72cc COMBUSTION CHAMBERS AND THE VALVES

MEASURE IN AT 2250 ON THE INTAKE, 181 ON THE EXHAUST. NOW CHECK THIS OUT, LOOK AT THE SIZE OF THE INTAKE RUNNERS. THEY MEASURE IN AT 272cc'S VERSUS 170 IN A STOCK HEAD. NOW THEY WERE PORTED BY MIKE STARK AT CFM PERFORMANCE AND FLOW 365 CFM AT 600 INCH LIFT. THE VALVE SPRINGS ARE BEE HIVES FROM COMP CAMS AS WELL AS THE RETAINERS, LOCKS, AND SPRING CUPS. USING MORE GOODSON COMPRESSION LUBE, WE CAN TORQUE THE HEADS IN THREE STEPS, 50, 80, AND 115 FOOT POUNDS. THE LIFTERS ARE HYDRAULIC ROLLERS MADE BY PBM. THEY FEATURE A TIE BAR TO KEEP THEM ALIGNED AND WE DROP THEM IN WITH PLENTY OF OIL. PUSH RODS ARE COMP CAM'S HIGH TECHS, AND ARE FIVESIXTEENTHS DIAMETER WITH A 9350 LENGTH. (JOHN B.)>> NOW HERE'S THE ROCKER ARM SETUP WE GOT GOING

ON THIS BIG INCH CADDY. NOW THEY WE'RE MADE HARLAND SHARP DESIGNED BY THE GUYS AT MTS. NOW IT'S A FULL ROLLER ONESEVEN RATIO ROCKER ARM,

7075 ALUMINUM BASE WITH A HARDENED STEEL TUBING FOR SUPERIOR STRENGTH. NOW THESE WILL ACTUALLY FIT THE ORIGINAL CAST IRON CYLINDER HEADS OR THE ALUMINUMS MADE BY MTS.

(MIKE)>> THE FIRST THING TO DO IS TIGHTEN THE SHAFT BOLTS IN SMALL INCREMENTS. WE'RE USING WIPE ALL TOWELS BEHIND THE PUSH RODS TO HOLD THEM IN PLACE. NOW MAKE SURE THE PUSH RODS ARE SEATED IN THE ROCKER CUPS AND THIS SYSTEM OILS THE ROCKERS THROUGH THE PUSH RODS, NOT THE SHAFTS.

WE'LL SET THE LATCH HALF TURN PAST ZERO LASH. MTS' INTAKE MANIFOLD IS AN ALUMINUM PIECE THAT HOUSES

A 4150 STYLE CARBURETOR. THE RUNNERS AT THE CENTER MEASURE IN AT THREE POINT THREEFOUR INCHES AND IT'S BEEN PORT MATCHED TO THE CYLINDER HEADS. NOW THIS THING HAS A RPM RANGE OF 2,200 TO 8,000 RPM.

(JOE)>> AND FINALLY WITH THEIR CUSTOM VALVE COVERS, JOHN'S PARTS PALLET IS EMPTY. YEAH, YOU KNOW WHAT'S NEXT.

(JOE)>> EVERYONE HAS A FAVORITE ENGINE. FOR THE GUYS AT MTS IT'S CADILLAC'S 500 CUBIC INCH BIG BLOCK. LOADED WITH THEIR PARTS AMONG OTHERS, TIME TO SEE WHAT THAT PASSION LED TO. (JOHN W.)>> IT'S A BIG MOTOR, OUGHT TO MAKE SOME GOOD POWER.

(MIKE)>> THEY CARB WE'RE RUNNING ON OUR 520 IS ONE OF HOLLEY'S NEW ULTRA HP'S IN A 950 CFM. NOW WE ORDERED OURS IN THE HARDCORE GRAY FINISH, AND THIS THING IS 30 PERCENT LIGHTER THAN EARLIER CARBS AND HAS A

20 PERCENT LARGER FUEL CAPACITY IN THE BOWLS. NOW THEY TIED IN SOME REALLY COOL RACE ORIENTED FEATURES, LIKE HERE ON THE THROTTLE LINKAGE THERE'S NO TANGS TO HANG UP ON YOUR THROTTLE CABLE. NOW ANOTHER THING IS NEURALED ADJUSTMENT SCREWS FOR EASY TOOL FREE ADJUSTMENTS, AND THEY EVEN HAVE PYREX SITE WINDOWS ON BOTH SIDES OF THE BOWL FOR EASY AND SAFE FLOAT LEVEL ADJUSTMENTS. AN MSD PRO BILLET DISTRIBUTOR AND MATCHING WIRES WILL GIVE US SPARK. MTS BROUGHT THEIR DYNO HEADERS WE HAD RECOATED AT NITRO PLATE. WITH THE EGT BUNGS INSTALLED, WE'LL BE ABLE TO WATCH INDIVIDUAL CYLINDER TEMPS. GOOD FIRE UP! THAT THING JUST SOUNDS LIKE A BIG MOTOR, IT'S THROATY. WITH THE INITIAL TIMING SET AT 31 DEGREES, WE START OFF WITH A 2,500 TO 5,000 RPM RUN JUST TO PLAY IT SAFE. THAT THING MAKES GREAT NOISE, 544 HORSE AT 5,000, 577 FOOT POUNDS OF TORQUE AT 4,600. THAT'LL GET A BIG OLE CADDY MOVING, THAT'S AWESOME! (JOHN W.)>> LETS GO ANOTHER 500.

(MIKE)>> ALRIGHT! [ engine revving ]

(MIKE)>> MY LEGS WERE SHAKING.

MY LEGS WERE SHAKING ON THE CHAIR!

571, 575, THIS CADDY IS SOLID AND READY FOR MORE. WE'RE GONNA TAKE IT TO ITS RPM LIMIT, 6,000. 585, 585, I MEAN ON THE MONEY, TORQUE AND HORSEPOWER EVEN. (MIKE W.)>> WE WANT 33? (JOHN B.)>> YEP.

(MIKE)>> 591, 583. (JOHN W.)>> HOW ABOUT ONE MORE. (JOHN B.)>> YEAH, WHATEVER YOU WANT MAN.

(MIKE)>> JOHN'S TARGET IS 600. (JOHN W.)>> YOU KNOW WHAT, GO TWO, GO TWO.

(MIKE)>> AND HE'S GOING FOR IT. OIL PRESSURE LOOKS GOOD, AIR/FUEL'S GOOD, WATER TEMP. 598, 584, IT'S LIKING IT, IT IS LIKING IT FOR SURE. TIME TO REPLACE THE BREAK IN OIL WITH SOME ROYAL PURPLE SYNTHETIC, AND AFTER A BRIEF COOL DOWN, MAN THAT THING SOUNDS GOOD, WE'LL GIVE IT ONE MORE TRY JUST FOR JOHN. THROUGHOUT THE 1970'S, THE STOCK 500 MADE 260 HORSEPOWER. THIS PUMP GAS STREET VERSION ALREADY IMPRESSED US. 598, 587, DEAD ON THE MONEY. THEIR FULL RACE COMBO WILL TOP 2,000 HORSEPOWER.

(JOHN W.)>> THIS THING'S EVIL RIGHT OUT OF THE GATE.

(MIKE)>> BIG CADILLAC CAR MOVER, STUMP PULLER, WHATEVER YOU WANT TO CALL IT, THAT IS AWESOME TORQUE, VERY COOL.

(ANNOUNCER)>> YOU KNOW WHO MAKES THE BEST ENGINE FASTENERS, BUT YOU'LL BE AMAZED AT WHAT GOES INTO THE MAKING OF SUPREME HIGH PERFORMANCE STUDS AND BOLTS. A VISIT INSIDE THE HOME OF ARP IS COMING RIGHT UP.

(JOE)>> IT'S A SIMPLE FACT, WHEN PERFORMANCE PARTS WIN AT THE TRACK, THEY FIND THEIR WAY TO THE SHOPS OF GEARHEADS. CASE IN POINT, ARP FASTENERS. IN THE LATE 1960'S, GARY HOLZAPFEL SET OUT TO MAKE STRONGER, MORE RELIABLE STUDS AND BOLTS FOR RACE ENGINES. SINCE THEN AUTOMOTIVE RACING PRODUCTS HAS GROWN FROM HIS GARAGE TO A WORLD FAMOUS COMPANY. GARY'S SON MIKE IS NOW IN CHARGE OF ARP OPERATIONS WHERE ALL THEY DO IS MAKE PRECISION EXTREME STREET FASTENERS, AN INTRICATE PAIN STAKING PROCESS ALL IN HOUSE AT THEIR CALIFORNIA COMPLEX. HERE'S WHERE IT ALL STARTS WITH MILES OF 8740 CHROMOLY COILS. AFTER THE COILS ARE STRAIGHTENED, ARP'S PROGRESSIVE FORGING STARTS WITH COLD HEADING.

(CHRIS)>> AND IT TAKES RAW COIL AND IT ACTUALLY GOES THROUGH A SERIES OF CUTTING, UPSETS, AND FORMING THAT ACTUALLY MAKES THE HEAD ONTO THE BOLT.

(JOE)>> FOR STUDS AND LARGER SIZE BOLTS 12 FOOT BAR STOCK IS CUT TO LINKS AND SENT TO A HOT HEAD STATION LIKE THIS. TODAY VETERAN EMPLOYEE DANNY BARRERA IS FORMING HEADS ON HONDA BALANCER BOLTS.

(DANNY)>> THERE'S ELECTRICAL INDUCTION HERE THAT HEATS THE PARTS TO 1,850 DEGREES IN 15 SECONDS. I WILL THEN PLACE IT IN THIS LOWER DIE AND I WILL HIT THE PRESS AND IT WILL COME DOWN AND FORM THE PART.

(JOE)>> HEAT TREATING IS PERHAPS THE MOST CRITICAL, PRECISELY CONTROLLED PROCESS AT ARP. TEMPERATURES CAN REACH 1,800 DEGREES FOR

QUENCHING AND TEMPERING. AGING TAKES UP TO 16 HOURS, ALL IN VERTICAL RACKS THAT HOLD EACH PIECE INDIVIDUALLY FOR COMPLETE PENETRATION. SHOT PEENING REMOVES ALL SURFACE IRREGULARITIES LIKE STRESS RISERS WHILE IMPROVING OVERALL EXTERIOR INTEGRITY. QUITE A DIFFERENCE ALREADY. NEXT STOP, A FACILITY WHERE ARP CHROMOLY FASTENERS UNDERGO SOME ESPECIALLY CRITICAL MANUFACTURING STEPS, LIKE CENTERLESS GRINDING. THIS INSURES BOLTS AND STUDS ARE PERFECTLY CONCENTRIC.

(CHRIS)>> WE GAVE IT A STRAIGHT GRIND, AN UNDERCUT GRIND, AND NOW WE'RE DOING THE TD GRIND.

(JOE)>> MOST ARP BOLTS ARE FILLET ROLLED WITH A 30 DEGREE CHAMFER BETWEEN THE HEAD AND THE SHANK.

(MIKE)>> FILLET ROLL DIES COME IN AND PRESSURIZE UNDERNEATH THE HEAD, WHICH STRENGTHENS IT. IT REALLY SQUEEZES THE MICROSTRUCTURE OF THE MATERIAL AND GIVES IT A LOT OF FATIGUE STRENGTH.

(JOE)>> FILLET ROLLING FURTHER COMPRESSES THE GRAIN FLOW. THIS ADDS MORE STRENGTH WHERE IT REALLY COUNTS.

CUTTING THREADS WEAKENS THE PART. ARP ROLLS THEIR THREADS, WHICH ALSO ADDS FATIGUE STRENGTH. WHILE ARP HAS A DEDICATED QUALITY CONTROL DEPARTMENT

OVERSEEING ACCURACY OF TOOLS, PROCEDURES, AND PRODUCT, WE DISCOVERED THAT WORKERS ON THE FLOOR FREQUENTLY INSPECT AND MEASURE FASTENERS AS PART OF ONGOING QUALITY CONTROL AND COMPANY PRIDE.

(MIKE)>> A LOT OF THOSE GUYS HAVE BEEN WITH US FOR MANY YEARS. I MEAN THEY STARTED OUT FAIRLY YOUNG WITH US AND STUCK WITH US.

(JOE)>> ARP MANUFACTURES NUTS IN A MULTISTEP PROCESS THAT BEGINS WITH BLANKING EACH HEX AND 12 POINT NUT. THEN SOPHISTICATED AUTOMATED THREADING EQUIPMENT TAPS

EACH ONE WITHIN ACCURACY OF ONE THOUSANDTH OF AN INCH. PETE IS A VETERAN MACHINES WHO NOT ONLY HELPED REFINE THE NUT MAKING PROCESS, HE ALSO MENTORS YOUNGER, NEWER EMPLOYEES.

(PETE)>> I'M HAPPY TO WORK WITH THESE KIDS. I AM HAPPY THAT I AM ABLE TO SHOW WHAT I KNOW.

(JOE)>> IN SURFACE PREP, STEEL PARTS LIKE THESE NUTS ARE PLACED IN TUMBLERS FULL OF ONE OF FIVE DIFFERENT MEDIA, FROM VARIOUS CERAMIC PARTICLES DOWN TO WALNUT SHELLS AND CORN HUSKS. THE RESULTS, A MICRO POLISHED FLAWLESS FINISH. MOST STUDS AND MANY BOLTS GO THROUGH A MULTISTAGE FINISHING PROCESS AND APPLICATION OF A BLACK OXIDE PERMANENT FINISH. SO ARE THEY TOTALLY FINISHED?

(MIKE)>> AT THE END OF THE DAY, ALL THE ROLLING, AND FILLER ROLLING, AND GRINDING, AND FORGING JUST GOES RIGHT TO THAT ROOM AND THAT'S WHERE IT'S ALL PUT TO THE TEST.

(JOE)>> IN FACT RANDOM SAMPLES FROM EVERY PRODUCTION RUN GO THROUGH DESTRUCTIVE TESTING. THEY FATIGUE TEST FASTENERS TO ELEVATED LOADS THAT ARE 10 PERCENT ABOVE AEROSPACE REQUIREMENTS, USUALLY TO ONE MILLION CYCLES. TENSILE TESTING IS SIMPLY BOLTING ON A FASTENER UNTIL IT BREAKS. THAT'S AN OEM STUD ON THE LEFT AND THE ARP HAS A TENSILE STRENGTH OF OVER 190,00 PSI. SO IT'LL BE A WHILE BEFORE IT LETS GO. FINALLY THIS IS WHERE MORE THAN 1,000 DIFFERENT ENGINE KITS ARE SHIPPED TO RACE TEAMS AND BUILDERS AROUND THE WORLD.

(ROBERT)>> IT WASN'T ALWAYS THAT WAY. THOSE WERE ALL HARD FOUGHT FOR CUSTOMERS.

(JOE)>> SO BUILDING A BETTER BOLT, IF YOU WILL, IS AN ENORMOUS ENDEAVOR. THAT'S WHAT IT TAKES TO KEEP THE MOST POWERFUL ENGINES TOGETHER AND WINNING.

(MIKE)>> WHEN YOU FIND WORK THAT YOU ENJOY DOING AND YOU DO IT AS BEST AS YOU CAN, WE'VE ALWAYS LIKED BEING

BETTER THAN THE OTHER GUYS.

Show Full Transcript

GM'S LEGENDARY LUXURY RIDE!

(JOE)>> TODAY'S OTHER ENGINE BUILD BEGINS WITH AMERICA'S LARGEST PRODUCTION BLOCK OF ALL TIMES.

(JOHN W.)>> THESE ARE GOING ON IT.

(MIKE)>> THOSE ARE NICE! (JOHN W.)>> THANK YOU!

(JOE)>> AND A LITTLE HELP FROM MAXIMUM TORQUE SPECIALTIES AND

THEIR ENGINE GURU JOHN WALKER. (JOHN W.)>> IT WILL MAKE SOME POWER.

(JOE)>> IT'S A 500 CUBIC INCH BIG BLOCK THAT POWERED SOME OF OUR FAVORITE LUXURY LAND YACHTS BEGINNING BACK IN 1970, GM'S EVER CLASSIC CADILLAC. IT WAS THE FIRST CAR TO USE DESIGNER STYLE BODY WORK. 1948 WAS THE FIRST YEAR FOR THOSE LEGENDARY TAIL FINS

INSPIRED BY THE TWIN RUDDERS OF THE LOCKHEED P-38 LIGHTNING, EVER GROWING UNTIL THE TAIL FIN FINALE IN 1959. WHO KNOWS WHAT INSPIRED THOSE FAMOUS BULLET BUMPERS.

SOME SAY IT WAS A TV STAR FROM THE '50'S NAMED DAGMAR. UH, ANYONE SEE A RESEMBLANCE? CADILLAC WAS THE FIRST AUTOMAKER TO MASS PRODUCE A VEIGHT ENGINE, AND IT PRODUCED EIGHT GENERATIONS OF THEM STARTING IN 1914. BIG BLOCK SIZE AND HORSEPOWER INCREASED THROUGHOUT THE '50'S AND '60'S.

THEN FOR 1970 CADILLAC FITTED A CRANK SHAFT WITH A 430 STROKE INTO A 472 ENGINE TO CREATE A 500 CUBIC INCH BIG BLOCK RATED AT 400 HORSEPOWER. IT WAS THE PINNACLE OF POWER FOR GM'S LUXURY LEGEND. KNOWN FOR ITS TORQUE BUT NOT HORSEPOWER, AT LEAST AFTER THE FIRST YEAR, BY THE END OF THE PRODUCTION RUN IT WAS RATED AT ONLY 190. BUT WHY DIDN'T CADDY'S POWER THEIR WAY INTO THE WORLD OF AMERICAN HOT RODS? (JOHN W.)>> IT WAS NEVER PUT IN A PERFORMANCE VEHICLE. NOBODY EVER LOOKED AT AN ELDORADO, OR A COUPE, OR A

SEDAN DE VILLE, OR HEARSE, AS A PERFORMANCE VEHICLE IN ANY WAY, SHAPE, OR FORM.

(JOE)>> THERE WAS ALSO THE ISSUE OF AVAILABLE PARTS. THAT'S CHANGED WITH THE EMERGENCE OF MTS, ONE OF THE ONLY TWO EXISTING COMPANIES THAT SPECIALIZE IN CADILLAC 500 PARTS AND ENGINE PACKAGES. ( )>> WE FOUND IT MUCH EASIER TO PUT A LOT OF INVENTORY INTO ONE ENGINE, AND NOW WE'VE BROUGHT CADILLAC SPECIFIC

PRODUCTS TO THE MARKET THAT ARE A CUT ABOVE WHAT WAS AVAILABLE BEFORE. (JOHN W.)>> WE KEEP MAKING PARTS FOR THEM AND EVERY TIME WE MAKE NEW PARTS WE START SELLING THEM.

(JOE)>> JOHN BROUGHT US EVERYTHING WE NEED TO BUILD A PUMP GAS FRIENDLY 500, INCLUDING SEVERAL PARTS MTS DESIGNS AND MANUFACTURES. WE PLAN TO BUILD AN ENGINE THAT'LL HAVE ENOUGH TORQUE TO PULL A HOUSE DOWN, AND HORSEPOWER, WE'LL ALL FIND THAT OUT LATER.

(MIKE)>> THE BLOCK WAS MACHINED BY MIKE GRAHAM IN BOWLING GREEN, OHIO. IT'S 90 OVER, HAS A 4304 STROKE WITH A 4390 BORE FOR 520 INCHES. NOW IT MEASURES IN AT 25 AND THREE QUARTER INCHES LONG AND WEIGHS 595 POUNDS CARB TO PAN. FOR REFERENCE, A SMALL BLOCK CHEVY IS 21 AND A HALF INCHES LONG. IF A CADDY SWAP IS ON YOUR MIND, DON'T BE AFRAID, THEY'RE IN FOX BODY MUSTANGS. THE CAM IS INSTALLED. NOW FACTORY CAMS HAVE A FUEL PUMP ECCENTRIC, THIS ONE DOES NOT. SO MTS DESIGNED THIS CAM BUTTON TO TAKE THE PLACE OF THE ECCENTRIC SINCE WE'RE USING THE HYDRAULIC ROLLER CAM SHAFT. IT HAS A LOBE SEPARATION ANGLE OF 110 DEGREES, DURATION AT 50

IS 248 ON THE INTAKE, 248 ON THE EXHAUST. LIFT AT THE VALVE WITH A ONESEVEN ROCKER ARM IS 640. THE UPPER CLEAVITE BEARINGS CAN GO INTO PLACE, FOLLOWED BY THE UPPER HALF OF THE REAR MAIN SEAL THAT GETS INSTALLED OFFSET AND A FILM OF OIL TO PREVENT THE SEAL FROM PREMATURE FAILURE. WITH ALL THE BEARINGS LUBED, THIS MASSIVE STOCK CRANK CAREFULLY FINDS ITS HOME.

(MARTY)>>THERE WE GO.

(MIKE)>> OKAY, LONG ONE GOES HERE. OIL THE STUDS BEFORE INSTALLING AND DROP ON THE MAIN CAPS. WITH THE CAP SEATED, APPLY SOME GOODSON EXTREME PRESSURE LUBE TO THE WASHERS AND STUDS AND TORQUE THEM IN THREE STEPS, 50, 80, AND FINALLY 115 FOOT POUNDS. IT'S ALWAYS IMPORTANT TO CHECK THE END PLAY OF THE CRANK SHAFT.

(MARTY)>>THERE'S ACTUALLY SEVEN THOUSANDTHS TOTAL, WE'RE GOOD. (JOHN B.)>> ALRIGHT I'M GONNA GO OVER THIS PISTON DESIGN WITH YOU GUYS TODAY. NOW IT'S PRETTY COOL THE GUYS FROM MTS ACTUALLY GOT TOGETHER WITH THE GUYS FROM DIAMOND TO CREATE THEIR OWN PROFILE. NOW WHAT IT ENTAILS IS A TOP RING OFF ONE SIXTEENTH, SECOND RING OF ONE SIXTEENTH, AND A THIRD RING OF THREE SIXTEENTHS ALONG WITH AN ANTIDETONATION GROOVE IN BETWEEN THE TOP AND SECOND RING LAND.

NOW WE WENT WITH THE TRADITIONAL MOLY COATING ON THE SKIRTS BUT A CERAMIC COATING ON THE HEAD. NOW THIS IS A TWO VALVE RELIEF PISTON WITH A POSITIVE 22cc DISH. AND WHAT THAT'S GONNA DO IS PUT US RIGHT AT 10.8 TO ONE COMPRESSION FOR OUR STREET MOTOR.

(MIKE)>> THE RINGS ARE FROM HASTINGS AND HAVE ALREADY BEEN FILE FITTED.

NOW MTS DESIGNED THE HBEAM RODS AS WELL. THEY'RE SIXSEVEN-50 LONG AND FILLED WITH CLEAVITE BEARINGS. ALL THESE PARTS ARE THE REASON WE CAN DOUBLE THE CADDY'S RPM RANGE. (JOHN W.)>> IT WAS NEVER IN ITS ORIGINAL FORM DESIGNED TO REV OVER 3,000 RPM. IT WAS DESIGNED TO LAST A HALF A MILLION MILES ON A HUGE CAR. (JOHN B.)>> OH, THAT'S NICE.

(MIKE)>> FEEL GOOD? (JOHN B.)>> YEP. GET GOOD END PLAY? (JOHN B.)>> SIDE CLEARANCE, ALL THE WAY BACK.

(MIKE)>> VERY NICE.

(JOE)>> WE'RE STILL AT IT LOOKING FOR THE OVERLOOKED

POTENTIAL IN THIS 500 CADDY. (JOHN W.)>> IT WILL MAKE SOME POWER.

(JOE)>> ALONG WITH THE PROS FROM MTS AND ALL

THE BEST PARTS POSSIBLE.

(MIKE)>> CLOYES SUPPLIED THE TRUE ROLLER TIMING SET. IT'S A PRESS FIT ON THE CRANK AND A SINGLE ROW, THE ONLY ONE THAT CAN BE USED ON A CADILLAC. NOW WE CAN PUT THE OIL SLINGER ON THE CRANK SNOUT TO PROPERLY OIL THE TIMING CHAIN AND DISTRIBUTOR GEAR. BEFORE WE GO ANY FURTHER, WE'RE GOING TO DEGREE THE CAM TO ASSURE US IT'S INSTALLED CORRECTLY AND THE CAM CARD IS ACCURATE. THE STAINLESS TIMING COVER CAN GO ON NEXT AND SECURE IT WITH A COUPLE OF BOLTS TO LET THE SILICONE SET UP. GASKETS ARE USED ON THE FRONT AND BACK OF THE PAN LIPS. ONCE THE FOUR CORNERS OF THE BLOCK HAVE A DAB OF SILICONE, WE CAN INSTALL SOME ALIGNMENT STUDS TO HOLD THE PAN RAIL GASKETS. WEATHER STRIP ADHESIVE IS THEN APPLIED TO THE PAN SIDE OF THEM, WHICH WILL PREVENT LEAKS. NOW WE CAN DROP ON THE MTS SIX QUART OIL PAN AND TIGHTEN IT DOWN IN AN EVEN CRISS CROSS PATTERN. FOR A BALANCER WE'RE USING AN SFI RATED POWERBOND ONE PIECE UNIT THAT IS NEUTRAL BALANCED. TO FINISH UP THE SHORT BLOCK A MELING STANDARD VOLUME PUMP THAT WAS BLUE PRINTED BY THE GUYS AT MTS. AND NEXT UP ARE THESE ALUMINUM CYLINDER HEADS. NOW THESE THINGS ARE SPECED OUT BY MTS BUT CAST AND MACHINED AT HIGH TECH CASTINGS. NOW THEY HAVE 72cc COMBUSTION CHAMBERS AND THE VALVES

MEASURE IN AT 2250 ON THE INTAKE, 181 ON THE EXHAUST. NOW CHECK THIS OUT, LOOK AT THE SIZE OF THE INTAKE RUNNERS. THEY MEASURE IN AT 272cc'S VERSUS 170 IN A STOCK HEAD. NOW THEY WERE PORTED BY MIKE STARK AT CFM PERFORMANCE AND FLOW 365 CFM AT 600 INCH LIFT. THE VALVE SPRINGS ARE BEE HIVES FROM COMP CAMS AS WELL AS THE RETAINERS, LOCKS, AND SPRING CUPS. USING MORE GOODSON COMPRESSION LUBE, WE CAN TORQUE THE HEADS IN THREE STEPS, 50, 80, AND 115 FOOT POUNDS. THE LIFTERS ARE HYDRAULIC ROLLERS MADE BY PBM. THEY FEATURE A TIE BAR TO KEEP THEM ALIGNED AND WE DROP THEM IN WITH PLENTY OF OIL. PUSH RODS ARE COMP CAM'S HIGH TECHS, AND ARE FIVESIXTEENTHS DIAMETER WITH A 9350 LENGTH. (JOHN B.)>> NOW HERE'S THE ROCKER ARM SETUP WE GOT GOING

ON THIS BIG INCH CADDY. NOW THEY WE'RE MADE HARLAND SHARP DESIGNED BY THE GUYS AT MTS. NOW IT'S A FULL ROLLER ONESEVEN RATIO ROCKER ARM,

7075 ALUMINUM BASE WITH A HARDENED STEEL TUBING FOR SUPERIOR STRENGTH. NOW THESE WILL ACTUALLY FIT THE ORIGINAL CAST IRON CYLINDER HEADS OR THE ALUMINUMS MADE BY MTS.

(MIKE)>> THE FIRST THING TO DO IS TIGHTEN THE SHAFT BOLTS IN SMALL INCREMENTS. WE'RE USING WIPE ALL TOWELS BEHIND THE PUSH RODS TO HOLD THEM IN PLACE. NOW MAKE SURE THE PUSH RODS ARE SEATED IN THE ROCKER CUPS AND THIS SYSTEM OILS THE ROCKERS THROUGH THE PUSH RODS, NOT THE SHAFTS.

WE'LL SET THE LATCH HALF TURN PAST ZERO LASH. MTS' INTAKE MANIFOLD IS AN ALUMINUM PIECE THAT HOUSES

A 4150 STYLE CARBURETOR. THE RUNNERS AT THE CENTER MEASURE IN AT THREE POINT THREEFOUR INCHES AND IT'S BEEN PORT MATCHED TO THE CYLINDER HEADS. NOW THIS THING HAS A RPM RANGE OF 2,200 TO 8,000 RPM.

(JOE)>> AND FINALLY WITH THEIR CUSTOM VALVE COVERS, JOHN'S PARTS PALLET IS EMPTY. YEAH, YOU KNOW WHAT'S NEXT.

(JOE)>> EVERYONE HAS A FAVORITE ENGINE. FOR THE GUYS AT MTS IT'S CADILLAC'S 500 CUBIC INCH BIG BLOCK. LOADED WITH THEIR PARTS AMONG OTHERS, TIME TO SEE WHAT THAT PASSION LED TO. (JOHN W.)>> IT'S A BIG MOTOR, OUGHT TO MAKE SOME GOOD POWER.

(MIKE)>> THEY CARB WE'RE RUNNING ON OUR 520 IS ONE OF HOLLEY'S NEW ULTRA HP'S IN A 950 CFM. NOW WE ORDERED OURS IN THE HARDCORE GRAY FINISH, AND THIS THING IS 30 PERCENT LIGHTER THAN EARLIER CARBS AND HAS A

20 PERCENT LARGER FUEL CAPACITY IN THE BOWLS. NOW THEY TIED IN SOME REALLY COOL RACE ORIENTED FEATURES, LIKE HERE ON THE THROTTLE LINKAGE THERE'S NO TANGS TO HANG UP ON YOUR THROTTLE CABLE. NOW ANOTHER THING IS NEURALED ADJUSTMENT SCREWS FOR EASY TOOL FREE ADJUSTMENTS, AND THEY EVEN HAVE PYREX SITE WINDOWS ON BOTH SIDES OF THE BOWL FOR EASY AND SAFE FLOAT LEVEL ADJUSTMENTS. AN MSD PRO BILLET DISTRIBUTOR AND MATCHING WIRES WILL GIVE US SPARK. MTS BROUGHT THEIR DYNO HEADERS WE HAD RECOATED AT NITRO PLATE. WITH THE EGT BUNGS INSTALLED, WE'LL BE ABLE TO WATCH INDIVIDUAL CYLINDER TEMPS. GOOD FIRE UP! THAT THING JUST SOUNDS LIKE A BIG MOTOR, IT'S THROATY. WITH THE INITIAL TIMING SET AT 31 DEGREES, WE START OFF WITH A 2,500 TO 5,000 RPM RUN JUST TO PLAY IT SAFE. THAT THING MAKES GREAT NOISE, 544 HORSE AT 5,000, 577 FOOT POUNDS OF TORQUE AT 4,600. THAT'LL GET A BIG OLE CADDY MOVING, THAT'S AWESOME! (JOHN W.)>> LETS GO ANOTHER 500.

(MIKE)>> ALRIGHT! [ engine revving ]

(MIKE)>> MY LEGS WERE SHAKING.

MY LEGS WERE SHAKING ON THE CHAIR!

571, 575, THIS CADDY IS SOLID AND READY FOR MORE. WE'RE GONNA TAKE IT TO ITS RPM LIMIT, 6,000. 585, 585, I MEAN ON THE MONEY, TORQUE AND HORSEPOWER EVEN. (MIKE W.)>> WE WANT 33? (JOHN B.)>> YEP.

(MIKE)>> 591, 583. (JOHN W.)>> HOW ABOUT ONE MORE. (JOHN B.)>> YEAH, WHATEVER YOU WANT MAN.

(MIKE)>> JOHN'S TARGET IS 600. (JOHN W.)>> YOU KNOW WHAT, GO TWO, GO TWO.

(MIKE)>> AND HE'S GOING FOR IT. OIL PRESSURE LOOKS GOOD, AIR/FUEL'S GOOD, WATER TEMP. 598, 584, IT'S LIKING IT, IT IS LIKING IT FOR SURE. TIME TO REPLACE THE BREAK IN OIL WITH SOME ROYAL PURPLE SYNTHETIC, AND AFTER A BRIEF COOL DOWN, MAN THAT THING SOUNDS GOOD, WE'LL GIVE IT ONE MORE TRY JUST FOR JOHN. THROUGHOUT THE 1970'S, THE STOCK 500 MADE 260 HORSEPOWER. THIS PUMP GAS STREET VERSION ALREADY IMPRESSED US. 598, 587, DEAD ON THE MONEY. THEIR FULL RACE COMBO WILL TOP 2,000 HORSEPOWER.

(JOHN W.)>> THIS THING'S EVIL RIGHT OUT OF THE GATE.

(MIKE)>> BIG CADILLAC CAR MOVER, STUMP PULLER, WHATEVER YOU WANT TO CALL IT, THAT IS AWESOME TORQUE, VERY COOL.

(ANNOUNCER)>> YOU KNOW WHO MAKES THE BEST ENGINE FASTENERS, BUT YOU'LL BE AMAZED AT WHAT GOES INTO THE MAKING OF SUPREME HIGH PERFORMANCE STUDS AND BOLTS. A VISIT INSIDE THE HOME OF ARP IS COMING RIGHT UP.

(JOE)>> IT'S A SIMPLE FACT, WHEN PERFORMANCE PARTS WIN AT THE TRACK, THEY FIND THEIR WAY TO THE SHOPS OF GEARHEADS. CASE IN POINT, ARP FASTENERS. IN THE LATE 1960'S, GARY HOLZAPFEL SET OUT TO MAKE STRONGER, MORE RELIABLE STUDS AND BOLTS FOR RACE ENGINES. SINCE THEN AUTOMOTIVE RACING PRODUCTS HAS GROWN FROM HIS GARAGE TO A WORLD FAMOUS COMPANY. GARY'S SON MIKE IS NOW IN CHARGE OF ARP OPERATIONS WHERE ALL THEY DO IS MAKE PRECISION EXTREME STREET FASTENERS, AN INTRICATE PAIN STAKING PROCESS ALL IN HOUSE AT THEIR CALIFORNIA COMPLEX. HERE'S WHERE IT ALL STARTS WITH MILES OF 8740 CHROMOLY COILS. AFTER THE COILS ARE STRAIGHTENED, ARP'S PROGRESSIVE FORGING STARTS WITH COLD HEADING.

(CHRIS)>> AND IT TAKES RAW COIL AND IT ACTUALLY GOES THROUGH A SERIES OF CUTTING, UPSETS, AND FORMING THAT ACTUALLY MAKES THE HEAD ONTO THE BOLT.

(JOE)>> FOR STUDS AND LARGER SIZE BOLTS 12 FOOT BAR STOCK IS CUT TO LINKS AND SENT TO A HOT HEAD STATION LIKE THIS. TODAY VETERAN EMPLOYEE DANNY BARRERA IS FORMING HEADS ON HONDA BALANCER BOLTS.

(DANNY)>> THERE'S ELECTRICAL INDUCTION HERE THAT HEATS THE PARTS TO 1,850 DEGREES IN 15 SECONDS. I WILL THEN PLACE IT IN THIS LOWER DIE AND I WILL HIT THE PRESS AND IT WILL COME DOWN AND FORM THE PART.

(JOE)>> HEAT TREATING IS PERHAPS THE MOST CRITICAL, PRECISELY CONTROLLED PROCESS AT ARP. TEMPERATURES CAN REACH 1,800 DEGREES FOR

QUENCHING AND TEMPERING. AGING TAKES UP TO 16 HOURS, ALL IN VERTICAL RACKS THAT HOLD EACH PIECE INDIVIDUALLY FOR COMPLETE PENETRATION. SHOT PEENING REMOVES ALL SURFACE IRREGULARITIES LIKE STRESS RISERS WHILE IMPROVING OVERALL EXTERIOR INTEGRITY. QUITE A DIFFERENCE ALREADY. NEXT STOP, A FACILITY WHERE ARP CHROMOLY FASTENERS UNDERGO SOME ESPECIALLY CRITICAL MANUFACTURING STEPS, LIKE CENTERLESS GRINDING. THIS INSURES BOLTS AND STUDS ARE PERFECTLY CONCENTRIC.

(CHRIS)>> WE GAVE IT A STRAIGHT GRIND, AN UNDERCUT GRIND, AND NOW WE'RE DOING THE TD GRIND.

(JOE)>> MOST ARP BOLTS ARE FILLET ROLLED WITH A 30 DEGREE CHAMFER BETWEEN THE HEAD AND THE SHANK.

(MIKE)>> FILLET ROLL DIES COME IN AND PRESSURIZE UNDERNEATH THE HEAD, WHICH STRENGTHENS IT. IT REALLY SQUEEZES THE MICROSTRUCTURE OF THE MATERIAL AND GIVES IT A LOT OF FATIGUE STRENGTH.

(JOE)>> FILLET ROLLING FURTHER COMPRESSES THE GRAIN FLOW. THIS ADDS MORE STRENGTH WHERE IT REALLY COUNTS.

CUTTING THREADS WEAKENS THE PART. ARP ROLLS THEIR THREADS, WHICH ALSO ADDS FATIGUE STRENGTH. WHILE ARP HAS A DEDICATED QUALITY CONTROL DEPARTMENT

OVERSEEING ACCURACY OF TOOLS, PROCEDURES, AND PRODUCT, WE DISCOVERED THAT WORKERS ON THE FLOOR FREQUENTLY INSPECT AND MEASURE FASTENERS AS PART OF ONGOING QUALITY CONTROL AND COMPANY PRIDE.

(MIKE)>> A LOT OF THOSE GUYS HAVE BEEN WITH US FOR MANY YEARS. I MEAN THEY STARTED OUT FAIRLY YOUNG WITH US AND STUCK WITH US.

(JOE)>> ARP MANUFACTURES NUTS IN A MULTISTEP PROCESS THAT BEGINS WITH BLANKING EACH HEX AND 12 POINT NUT. THEN SOPHISTICATED AUTOMATED THREADING EQUIPMENT TAPS

EACH ONE WITHIN ACCURACY OF ONE THOUSANDTH OF AN INCH. PETE IS A VETERAN MACHINES WHO NOT ONLY HELPED REFINE THE NUT MAKING PROCESS, HE ALSO MENTORS YOUNGER, NEWER EMPLOYEES.

(PETE)>> I'M HAPPY TO WORK WITH THESE KIDS. I AM HAPPY THAT I AM ABLE TO SHOW WHAT I KNOW.

(JOE)>> IN SURFACE PREP, STEEL PARTS LIKE THESE NUTS ARE PLACED IN TUMBLERS FULL OF ONE OF FIVE DIFFERENT MEDIA, FROM VARIOUS CERAMIC PARTICLES DOWN TO WALNUT SHELLS AND CORN HUSKS. THE RESULTS, A MICRO POLISHED FLAWLESS FINISH. MOST STUDS AND MANY BOLTS GO THROUGH A MULTISTAGE FINISHING PROCESS AND APPLICATION OF A BLACK OXIDE PERMANENT FINISH. SO ARE THEY TOTALLY FINISHED?

(MIKE)>> AT THE END OF THE DAY, ALL THE ROLLING, AND FILLER ROLLING, AND GRINDING, AND FORGING JUST GOES RIGHT TO THAT ROOM AND THAT'S WHERE IT'S ALL PUT TO THE TEST.

(JOE)>> IN FACT RANDOM SAMPLES FROM EVERY PRODUCTION RUN GO THROUGH DESTRUCTIVE TESTING. THEY FATIGUE TEST FASTENERS TO ELEVATED LOADS THAT ARE 10 PERCENT ABOVE AEROSPACE REQUIREMENTS, USUALLY TO ONE MILLION CYCLES. TENSILE TESTING IS SIMPLY BOLTING ON A FASTENER UNTIL IT BREAKS. THAT'S AN OEM STUD ON THE LEFT AND THE ARP HAS A TENSILE STRENGTH OF OVER 190,00 PSI. SO IT'LL BE A WHILE BEFORE IT LETS GO. FINALLY THIS IS WHERE MORE THAN 1,000 DIFFERENT ENGINE KITS ARE SHIPPED TO RACE TEAMS AND BUILDERS AROUND THE WORLD.

(ROBERT)>> IT WASN'T ALWAYS THAT WAY. THOSE WERE ALL HARD FOUGHT FOR CUSTOMERS.

(JOE)>> SO BUILDING A BETTER BOLT, IF YOU WILL, IS AN ENORMOUS ENDEAVOR. THAT'S WHAT IT TAKES TO KEEP THE MOST POWERFUL ENGINES TOGETHER AND WINNING.

(MIKE)>> WHEN YOU FIND WORK THAT YOU ENJOY DOING AND YOU DO IT AS BEST AS YOU CAN, WE'VE ALWAYS LIKED BEING

BETTER THAN THE OTHER GUYS.