HorsePower Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Summit Racing

Camshaft, Hydraulic Roller Tappet, Advertised Duration 296/300, Lift .539/.548, Chevy, 5.0, 5.7L., Lifters, Hydraulic Roller, Chevy, Small Block, V6.

Summit Racing

Carburetor, Summit, 750 cfm, Square Bore, 4-Barrel, Manual Choke, Mechanical Secondary.

Summit Racing

Cylinder Head Bolts, Hex Head, Chevy, Small Block, Stock, Edelbrock Performer/RPM Heads, Kit.

Summit Racing

Cylinder Head, Performer RPM, Aluminum, Assembled, 64cc Chamber, 185cc Intake Runner.

Summit Racing

Distributor, Blueprinted HEI, Magnetic Pickup, Adjustable Vacuum Advance, Black Cap, Chevy, Big/Small Block., Spark Plug Wires, Spiro Wound, 8mm, Blue, 90 Degree Boots, GM, V8., Distributor Hold-Down Clamp, Steel, Chrome, Bolt Mount, Chevy, Small/Big Block., Distributor Gear, Aluminum, Bronze, Race, .491 in. Diameter Shaft, Small Block, Big Block, V6

Summit Racing

Eagle Specialty Products Balanced Rotating Assembly, Street, Cast Crank, Hypereutectic Pistons, I-Beam Rods, Chevy, Small Block, Kit., Eagle rotating kits feature a crankshaft and connecting rods, Sealed Power pistons, Perfect Circle piston rings, Mahle-Clevite rod and main bearings and 168 tooth flexplate for automatic transmission and harmonic balancer.

Summit Racing

Engine Block, Cast Iron, 4-Bolt Mains, 4.030 in. Diameter Bore, 1-Piece Rear Main Seal, Chevy, Small Block,383.

Summit Racing

Intake Manifold, Stage 3, Dual Plane, Aluminum, Natural, Square Bore Flange, Chevy, Small Block 1955-86.

Summit Racing

Moroso Oil Pan, Steel, Clear Zinc, 6 qt., Chevy, Small Block., Moroso Oil Pickup, Press Fit, Aftermarket Pan Style, Chevy, Small Block.

Summit Racing

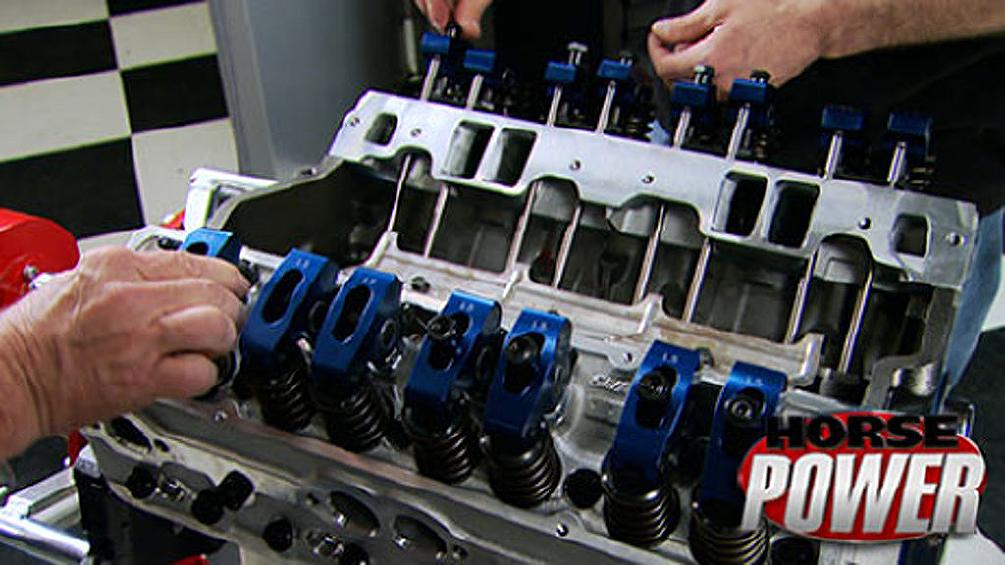

Rocker Arms, Stud Mount, Full Roller, Aluminum, 1.5 Ratio, Fits 3/8 in. Stud, Chevy, Small Block, Set of 16.

Summit Racing

Timing Chain and Gear Set, Performer-Link, Double Roller, Iron/Steel Sprockets, Chevy, V6/Small Block.

Summit Racing

Timing Cover, 1-Piece, Steel, Chrome Plated, Chevy, Small Block., Timing Pointer, Steel, Chrome, 6.75/7.0/8.0 in. Balancers, Chevy, Small Block.

Summit Racing

Valve Covers, Tall, Steel, Chrome, Plain, Chevy, Small Block., Valve Cover Breather, Push-In, Round, Steel, Chrome., Valve Cover Grommet, PCV, 1.22 in. Outside Diameter, .75 in. Inside Diameter., Oil Fill Cap, Steel, Round, Chrome, Push-In, Universal, Summit Logo., Valve Cover Wing Nuts, Extra Long, 1/4-20 Thread, 5 in. Long, Chrome, Set of 4. takes two packs, Valve Cover Gaskets, Rubber with Steel Core, Chevy, Small Block.

Summit Racing

Water Pump Pulley, V-Belt, 1-Groove, Steel, Chrome, Chevy, Small Block, Short Pump., Crankshaft Pulley, V-Belt, 1-Groove, 6.76 in., Steel, Chrome, Chevy, Small Block, Short Pump.

Summit Racing

Water Pump, Mechanical, Short, High-Volume, Iron, Black Powdercoated, Chevy, Small Block.

[none]

Royal Purple Motor Oil delivers superior protection and improves performance in four-cycle gasoline and diesel engines. It increases horsepower and torque, saves fuels and reduces heat, wear and emissions.

[none]

Royal Purple oil filters provide superior particle removal, high-performance and optimized flow characteristics for maximum performance and longer filter life.

CounterAct

CounterAct electronic rust protection is demonstrably different from more traditional forms of electronic rust protection because it was designed from the outset to operate in a free open air environment unlike traditional electronic rust protection methods which require a relatively abundant moisture content in a continuous layer on or near the metal object being protected. The point is the ability of traditional electronic rust protection to inhibit rust and corrosion ends at the waterline or

O'Reilly Auto Parts

Champion Spark Plugs (8)

RapidAir Products

RapidAir offers an easy and flexible way to customize your workshop with applications from automotive to woodworking. RapidAir is a complete compressed air distribution system that is designed to easily install beneath walls of new construction, or on wall surfaces of existing workshops. Our garage compressed air piping system is designed for a lifetime of service.

Tennessee Speed Sport

Pushrods, High Energy, Steel, Heat-Treated, 5/16 in. Diameter, 7.290 in. Length, Universal, Set of 16.

Episode Transcript

Hey, did you ever hear that expression? There's more than one way to skin a cat.

I used to hear that all the time growing up in Arkansas. And I can't tell you if it's true or not because

I never saw any skinless cats.

I did see a lot of guys go to the junkyard to start an engine pill.

Then there was lots of machining before finishing the job.

Since then, I've known guys who traded an engine core for a remand short block to build it up.

Well, nowadays, of course, if you've got the cash,

you can also buy a new crate engine, but most of the work already done for you,

then again, if you're watching your funds, you wanna work with new parts and make good power.

There might be one more way to skin that cat.

Sorry Peter. We're just joking. Now, let's go build a motor

today. We're gonna put together our performance Street Slow

Block V8 from scratch,

all with parts purchased right out of the Summit racing catalog

and we're sure it's gonna be cheaper than a crate engine.

Of course, it all starts with the foundation and summit racing now offers a 383 block

this machine to accept a 375 Stroker crank. It's also got four bolt mains.

The 1st 760 bucks we spent went for this block. A cast iron oe spec block with four inch diameter bores and one piece rear main seal.

But first, we need to get rid of the rust inhibitor coating they use for storing and shipping.

Then a good coat of WD 40 to prevent it from any new rust.

With our budget and power goals in mind,

the tech guys at summit hooked us up with a 383 rotating assembly that includes the crank

set of connecting rods,

aluminum pistons,

flex plate, harmonic balancer piston rings and set of full bearings

on top of those clevite bearings we're driving in the Stroker crank from eagle which is cast steel and externally balanced.

Well, next to our pistons are 30 over hyper eutectic from seal power that made up to these I beam connecting rods with floating pins.

Now, some of you newcomers may be wondering, well, what's the difference in floating pins and press fit and which is better?

Well, that's actually two questions, but here's your answer.

Press fit is pretty much what the name

implies. You have to use heat to expand the small end of the rod. So the pin can go in

with a floating pin. It installs rather easily and moves freely inside the connecting rod. Most after market pistons have grooves to accept locks for a floating pin set up,

there's less friction, which is a definite advantage in high performance.

Next, we can install our perfect circle rings. We picked up from Molly Clevite after we set the gaps. Now this is a procedure that can be confusing, but it's gotta be done. And in general, it's really not that difficult.

The first step is to install the ring in the board with the dot up

and square it up to find out the initial size using the feeler gauge.

Now put it into the ring filer,

making sure the filing direction is toward the inside of the ring.

Take a little material off, reinstall it,

check it

and continue till you get it right.

What's right?

If it's a street motor, you just multiply the bore size by 0.0045 for the top ring, which came up to 18 thousands.

He multiplied the bore size by 0.0035 for the second ring, 14 thousands in our case.

And the oil ring, it should be a minimum of 15 thousands.

The final step take an oil soak stone and just knock the edges off the ring opening to prevent scarring of the cylinder.

So what if you're building a nitrous or blower motor? Well, we put a ring gap chart up on our website that covers just about every combination.

Well, next step is to

put some oil in the grooves here,

install the rings

and stagger them to prevent blow by.

Now, when you hear the term blow by that means combustion forcing gasses into the crank case and oil well literally blows out the valve covers. Here's the correct way to stagger those rings

place the oil ring spacer gap between the 90 degree arc labeled a

then position the oil ring rail gaps at the spot mark B,

the lower compression ring gap gets rotated to the C position

and the top compression ring gap at the deposition.

If you follow those simple steps for gapping and ring staggering, you're gonna have a pretty nice little motor one that has good sealed cylinders, makes good power and last but not least,

doesn't have any blow by. Now. In the meantime, we have to take a break and I'm gonna go ahead and fill these cylinders

that

welcome back to horsepower. Well, it all started with engine parts we ordered from a summit racing catalog

including our foundation of 383 block.

Our order also included an eagle rotating assembly. And after we prepped the rings, we installed the rods with seal power pistons.

The next item from our high performance wish book the camshaft. Now, ours is a performance hydraulic roller with a duration of 234 on the intake 238 at the exhaust at 50,000 slip.

Then after installing the double roller timing chain, we go bottoms up to install our oil pump and pick up.

Now, the pump is a high volume piece and it delivers about 20% more oil than a standard one.

Next, we have to install our timing cover since we're using a one piece oil pan gasket.

The cool thing about this gasket from our

fro kit is the compression stops around the bolt holes that prevent over tightening.

Finally, we can close up the bottom end with a deep sump six quart street strip panned for moroso

and bolt up the oil filter adapter.

Now, back on top, we can drop in the hydraulic lifters

and remember here, plenty of assembly lube on the rollers and the sides of the lifters.

We ordered an installation kit that includes dog bones and a steel spider to hold those lifters in place.

There are lots of ways to cut corners when you're budgeting an engine build like ours. But

if you wanna make some serious power don't go cheap on your cylinder heads. These aluminum performers go for about 570 a piece. And for that, you get some obvious features like CNC machine 1 85 CC intake runners for better flow

and some smaller premium features like in here, bronze valve guides that transfer heat better and resist C

with 64 CC combustion chambers. We expect our combination to yield about 10 to 1 compression ratio.

Oh no pension pennies on head boats either these are a RPS with seal it on the threads.

Well time now for the premeasured push rods from our summit valve train

and don't forget to put a dab of assim lube on the tops to prevent scarring during start up.

Lastly, a set of 1.5 ratio aluminum rockers,

they're stud mounted, which is a popular choice in high performance bills for both strength and adjust ability

with the lock nuts loosely in place. We can take out the slack and the push rods and lash the

bows

the intake manifold we chose for our 383 is one of Summit Street strip stage threes. Now it's a high rise, dual plane design with separated runners to prevent heat soak and it's got a power range from 1500 to 6500 RPM.

That open area under the plenum also keeps the fuel and air charge cooler to help make more power.

On top of this power bond harmonic balancer. We're installing a high flow mechanical water pump, our pulley set and finally the V belt with these chrome valve covers bolted in place. We're finished out here and ready to transfer the engine to a dyno card.

We're feeding our small block with the help of the Summit Street Strip 750 car that's fitted with a manual choke and mechanical secondary

to get started. Some royal purple break in formula.

It's holding 55 pounds just keep going, let it circulate for a minute

and for fire an HE I distributor

and eight millimeter spiral we,

wires,

he goes,

we're burning 89 octane pump gas in our 383. It's got good oil pressure and after a 20 minute break in at 2000 RPM, we're gonna dump the break in oil and get ready for the run.

We were going at, uh

45 1st or

we go 55.

We got six grand

right away. Huh?

Damn,

you're brave.

460 ft pounds of torque. 400 horsepower.

Yeah, we got a little ways to go

pretty good. Especially the torque, watch fingers,

but good enough. Never after

rashing the valves

and swapping two carb jets on the right bank to 70 eights

time for run. Number two,

4, 18, 4, 66.

We're getting somewhere.

But let's see what one more degree of timing gets us.

So we're not a little rich. I'm gonna go ahead and put another degree in it

3.5 in it.

429 with 465 ft pounds and over 425.

It's not a bad little piece.

You know, Galley gotta go for one more this time with 70 sixes in all four quarters. All right. Final run on this thing. Here we go. Are you sure? I hope so.

443 horsepower, 485 ft pounds of torque. I'm happy with that.

I don't think we could really improve on that unless we put 100 and 50 shot in it. There is a

time to quit. This. Is it? All right,

man. That's awesome. We started this parts catalog Motor Build with a claim that we could pull it off and put out less cash than we'd pay for a comparable crate motor which would be uh ZZ 383. In this case, did we do it?

That crate motor loaded with our carb intake distributor and water pump would set you back about 5800 bucks.

Our complete parts staff from Summit was about 4600.

That's a saving of over $1200. Pretty nice trade off for our labor.

Meanwhile, this would be a great motor for a hot rod street rod, even a daily driver. Well, that may be up to you because see, we're gonna give it away soon and

we'll keep you posted on how to get your name in the hat. Stay with us.

Say when you were a kid, did you enjoy taking things apart just to see what was inside of them?

I know I did. I used to take apart my toys, clocks. Uh My mom's toaster one time

that didn't go over too well. Well, I guess things haven't changed much here. I'm taking apart these oil filters and tell you what, while the design is basically the same,

I can see the technology that goes into one is far superior.

Maybe a lot like the synthetic oil that goes through it.

Well, now that we got it apart,

let's see how they put it together

for that. We have to travel here to a 355,000 square foot facility in Southeast Illinois.

Well, when someone makes a decision to upgrade to a super premium lubricant, one of the first questions we get asked is, well, what filter should I use?

And it's really that

question that prompted us to do the research and bring to market a truly synthetic ultra premium

filter

to develop an ultra premium filter. The element inside has to provide almost perfect particle removal

while also allowing maximum

most filters

compromise with a synthetic cellulose blend.

The royal purple filter is 100% synthetic. It's primarily fiberglass

with some polyester for structural support.

On top of that, there's screen wire to back up that media.

That is the best, longest lasting media, the best longest lasting filter on the market.

After the filter elements are pleated and cut to length.

Workers insert the center tubes that prevent collapses

metal in caps with high strength adhesive provide positive seals for the filter element assemblies.

Now with both ends of the filter housing complete

the units are heated to 400 degrees for curing.

Meanwhile, in another part of the flat rolls of mile steel are being used to make the extra thick shells.

Magnetic conveyor belt carries the shells to a machine that cuts off the rings.

Then there's steam cleaned,

loaded onto an automatic palletize

and moved on to an assembly area

where each one is placed upside down in a fixture

and loaded with the spring.

Finally, the shelves and filter elements come together with the help of this machine.

The entire process is a combination of automation and hand work.

These hands are installing silicone anti drain back valves that prevent dry start.

Now, riding on pedestals, the filters are ready for that trademark color

spinning as the machine sprays on the purple powder coating.

Then they're heat treated to 400 degrees.

And while they're still hot rounded to a machine that applies the heavy duty nitrile rubber based gasket

samples from production runs undergo a severe sequence of test.

Here. It's for vibration and shock at six GS

to make sure they'll stay together

in this part of the lab. They undergo 150,000 continual start ups to check for fatigue.

Royal purple filters weigh 40% more than standard filters.

Thanks in part to a stronger steel back plate

here in a test of first string

a conventional filter. Let's go at 260 P. Si,

the oil purple filter

still intact at 600 P si

perhaps the most important trial is the multi pass test

where ultra

fine dust is introduced to the oil before it flows through the filter.

Presently. Right now is running about 99.99% efficient at 25 micron which is virtually 100%. It's virtually removing all of the contaminant and the dust that we are challenging it with the royal purple filter is a super premium filter.

It is at the very peak of all filter options that are available to the consumer today.

Whether your engine power is a hot rod or a daily driver.

When you spin one of these filters onto it,

it's gonna have the same high quality as the synthetic oil that runs through it.

Air tools are essential for fast efficient work in your home shop. But don't you hate dragging around a compressor with a bunch of tangled hoses? Well, rapid air products has a new economical 100 ft master kit made with you in mind. Now, it comes with this durable lightweight nylon tubing compressor manifold kit

into air outlet kits. Now it's easy to install the hoses attached to the fittings in a breeze

and you can get all types of accessories to customize the master kit to make your system at home neat, clean and efficient.

Now, the master kit will set you back about 100 and 40 bucks. Not a bad price for air anywhere

you can run, but you can't hide from it. Rust. That is, it's one of your ride's worst enemies.

We now an industrial technology developed in 1986 to prevent extreme rust and salt. Mining equipment is available for cars and trucks too.

It's called counteract

and it's a patented electrostatic technology with a module that connects to your battery.

It sends minute electrical charges through these two couplers that deploy a very slight negative charge to the body surfaces of the vehicle that charge prevents and inhibits rust and corrosion protecting body panels, paint

even bolt on accessories made from dissimilar metals.

Basically, the counteracts system eliminates the tendency of oxygen and iron to result in rust. These things are ideal for everything from daily drivers to show cars and they come with a guarantee that's good. Even if you swap it from one vehicle to another with prices starting at just under 300 bucks.

Well, hope you stay dry and rust free until next week. We'll see you then.

Show Full Transcript

I used to hear that all the time growing up in Arkansas. And I can't tell you if it's true or not because

I never saw any skinless cats.

I did see a lot of guys go to the junkyard to start an engine pill.

Then there was lots of machining before finishing the job.

Since then, I've known guys who traded an engine core for a remand short block to build it up.

Well, nowadays, of course, if you've got the cash,

you can also buy a new crate engine, but most of the work already done for you,

then again, if you're watching your funds, you wanna work with new parts and make good power.

There might be one more way to skin that cat.

Sorry Peter. We're just joking. Now, let's go build a motor

today. We're gonna put together our performance Street Slow

Block V8 from scratch,

all with parts purchased right out of the Summit racing catalog

and we're sure it's gonna be cheaper than a crate engine.

Of course, it all starts with the foundation and summit racing now offers a 383 block

this machine to accept a 375 Stroker crank. It's also got four bolt mains.

The 1st 760 bucks we spent went for this block. A cast iron oe spec block with four inch diameter bores and one piece rear main seal.

But first, we need to get rid of the rust inhibitor coating they use for storing and shipping.

Then a good coat of WD 40 to prevent it from any new rust.

With our budget and power goals in mind,

the tech guys at summit hooked us up with a 383 rotating assembly that includes the crank

set of connecting rods,

aluminum pistons,

flex plate, harmonic balancer piston rings and set of full bearings

on top of those clevite bearings we're driving in the Stroker crank from eagle which is cast steel and externally balanced.

Well, next to our pistons are 30 over hyper eutectic from seal power that made up to these I beam connecting rods with floating pins.

Now, some of you newcomers may be wondering, well, what's the difference in floating pins and press fit and which is better?

Well, that's actually two questions, but here's your answer.

Press fit is pretty much what the name

implies. You have to use heat to expand the small end of the rod. So the pin can go in

with a floating pin. It installs rather easily and moves freely inside the connecting rod. Most after market pistons have grooves to accept locks for a floating pin set up,

there's less friction, which is a definite advantage in high performance.

Next, we can install our perfect circle rings. We picked up from Molly Clevite after we set the gaps. Now this is a procedure that can be confusing, but it's gotta be done. And in general, it's really not that difficult.

The first step is to install the ring in the board with the dot up

and square it up to find out the initial size using the feeler gauge.

Now put it into the ring filer,

making sure the filing direction is toward the inside of the ring.

Take a little material off, reinstall it,

check it

and continue till you get it right.

What's right?

If it's a street motor, you just multiply the bore size by 0.0045 for the top ring, which came up to 18 thousands.

He multiplied the bore size by 0.0035 for the second ring, 14 thousands in our case.

And the oil ring, it should be a minimum of 15 thousands.

The final step take an oil soak stone and just knock the edges off the ring opening to prevent scarring of the cylinder.

So what if you're building a nitrous or blower motor? Well, we put a ring gap chart up on our website that covers just about every combination.

Well, next step is to

put some oil in the grooves here,

install the rings

and stagger them to prevent blow by.

Now, when you hear the term blow by that means combustion forcing gasses into the crank case and oil well literally blows out the valve covers. Here's the correct way to stagger those rings

place the oil ring spacer gap between the 90 degree arc labeled a

then position the oil ring rail gaps at the spot mark B,

the lower compression ring gap gets rotated to the C position

and the top compression ring gap at the deposition.

If you follow those simple steps for gapping and ring staggering, you're gonna have a pretty nice little motor one that has good sealed cylinders, makes good power and last but not least,

doesn't have any blow by. Now. In the meantime, we have to take a break and I'm gonna go ahead and fill these cylinders

that

welcome back to horsepower. Well, it all started with engine parts we ordered from a summit racing catalog

including our foundation of 383 block.

Our order also included an eagle rotating assembly. And after we prepped the rings, we installed the rods with seal power pistons.

The next item from our high performance wish book the camshaft. Now, ours is a performance hydraulic roller with a duration of 234 on the intake 238 at the exhaust at 50,000 slip.

Then after installing the double roller timing chain, we go bottoms up to install our oil pump and pick up.

Now, the pump is a high volume piece and it delivers about 20% more oil than a standard one.

Next, we have to install our timing cover since we're using a one piece oil pan gasket.

The cool thing about this gasket from our

fro kit is the compression stops around the bolt holes that prevent over tightening.

Finally, we can close up the bottom end with a deep sump six quart street strip panned for moroso

and bolt up the oil filter adapter.

Now, back on top, we can drop in the hydraulic lifters

and remember here, plenty of assembly lube on the rollers and the sides of the lifters.

We ordered an installation kit that includes dog bones and a steel spider to hold those lifters in place.

There are lots of ways to cut corners when you're budgeting an engine build like ours. But

if you wanna make some serious power don't go cheap on your cylinder heads. These aluminum performers go for about 570 a piece. And for that, you get some obvious features like CNC machine 1 85 CC intake runners for better flow

and some smaller premium features like in here, bronze valve guides that transfer heat better and resist C

with 64 CC combustion chambers. We expect our combination to yield about 10 to 1 compression ratio.

Oh no pension pennies on head boats either these are a RPS with seal it on the threads.

Well time now for the premeasured push rods from our summit valve train

and don't forget to put a dab of assim lube on the tops to prevent scarring during start up.

Lastly, a set of 1.5 ratio aluminum rockers,

they're stud mounted, which is a popular choice in high performance bills for both strength and adjust ability

with the lock nuts loosely in place. We can take out the slack and the push rods and lash the

bows

the intake manifold we chose for our 383 is one of Summit Street strip stage threes. Now it's a high rise, dual plane design with separated runners to prevent heat soak and it's got a power range from 1500 to 6500 RPM.

That open area under the plenum also keeps the fuel and air charge cooler to help make more power.

On top of this power bond harmonic balancer. We're installing a high flow mechanical water pump, our pulley set and finally the V belt with these chrome valve covers bolted in place. We're finished out here and ready to transfer the engine to a dyno card.

We're feeding our small block with the help of the Summit Street Strip 750 car that's fitted with a manual choke and mechanical secondary

to get started. Some royal purple break in formula.

It's holding 55 pounds just keep going, let it circulate for a minute

and for fire an HE I distributor

and eight millimeter spiral we,

wires,

he goes,

we're burning 89 octane pump gas in our 383. It's got good oil pressure and after a 20 minute break in at 2000 RPM, we're gonna dump the break in oil and get ready for the run.

We were going at, uh

45 1st or

we go 55.

We got six grand

right away. Huh?

Damn,

you're brave.

460 ft pounds of torque. 400 horsepower.

Yeah, we got a little ways to go

pretty good. Especially the torque, watch fingers,

but good enough. Never after

rashing the valves

and swapping two carb jets on the right bank to 70 eights

time for run. Number two,

4, 18, 4, 66.

We're getting somewhere.

But let's see what one more degree of timing gets us.

So we're not a little rich. I'm gonna go ahead and put another degree in it

3.5 in it.

429 with 465 ft pounds and over 425.

It's not a bad little piece.

You know, Galley gotta go for one more this time with 70 sixes in all four quarters. All right. Final run on this thing. Here we go. Are you sure? I hope so.

443 horsepower, 485 ft pounds of torque. I'm happy with that.

I don't think we could really improve on that unless we put 100 and 50 shot in it. There is a

time to quit. This. Is it? All right,

man. That's awesome. We started this parts catalog Motor Build with a claim that we could pull it off and put out less cash than we'd pay for a comparable crate motor which would be uh ZZ 383. In this case, did we do it?

That crate motor loaded with our carb intake distributor and water pump would set you back about 5800 bucks.

Our complete parts staff from Summit was about 4600.

That's a saving of over $1200. Pretty nice trade off for our labor.

Meanwhile, this would be a great motor for a hot rod street rod, even a daily driver. Well, that may be up to you because see, we're gonna give it away soon and

we'll keep you posted on how to get your name in the hat. Stay with us.

Say when you were a kid, did you enjoy taking things apart just to see what was inside of them?

I know I did. I used to take apart my toys, clocks. Uh My mom's toaster one time

that didn't go over too well. Well, I guess things haven't changed much here. I'm taking apart these oil filters and tell you what, while the design is basically the same,

I can see the technology that goes into one is far superior.

Maybe a lot like the synthetic oil that goes through it.

Well, now that we got it apart,

let's see how they put it together

for that. We have to travel here to a 355,000 square foot facility in Southeast Illinois.

Well, when someone makes a decision to upgrade to a super premium lubricant, one of the first questions we get asked is, well, what filter should I use?

And it's really that

question that prompted us to do the research and bring to market a truly synthetic ultra premium

filter

to develop an ultra premium filter. The element inside has to provide almost perfect particle removal

while also allowing maximum

most filters

compromise with a synthetic cellulose blend.

The royal purple filter is 100% synthetic. It's primarily fiberglass

with some polyester for structural support.

On top of that, there's screen wire to back up that media.

That is the best, longest lasting media, the best longest lasting filter on the market.

After the filter elements are pleated and cut to length.

Workers insert the center tubes that prevent collapses

metal in caps with high strength adhesive provide positive seals for the filter element assemblies.

Now with both ends of the filter housing complete

the units are heated to 400 degrees for curing.

Meanwhile, in another part of the flat rolls of mile steel are being used to make the extra thick shells.

Magnetic conveyor belt carries the shells to a machine that cuts off the rings.

Then there's steam cleaned,

loaded onto an automatic palletize

and moved on to an assembly area

where each one is placed upside down in a fixture

and loaded with the spring.

Finally, the shelves and filter elements come together with the help of this machine.

The entire process is a combination of automation and hand work.

These hands are installing silicone anti drain back valves that prevent dry start.

Now, riding on pedestals, the filters are ready for that trademark color

spinning as the machine sprays on the purple powder coating.

Then they're heat treated to 400 degrees.

And while they're still hot rounded to a machine that applies the heavy duty nitrile rubber based gasket

samples from production runs undergo a severe sequence of test.

Here. It's for vibration and shock at six GS

to make sure they'll stay together

in this part of the lab. They undergo 150,000 continual start ups to check for fatigue.

Royal purple filters weigh 40% more than standard filters.

Thanks in part to a stronger steel back plate

here in a test of first string

a conventional filter. Let's go at 260 P. Si,

the oil purple filter

still intact at 600 P si

perhaps the most important trial is the multi pass test

where ultra

fine dust is introduced to the oil before it flows through the filter.

Presently. Right now is running about 99.99% efficient at 25 micron which is virtually 100%. It's virtually removing all of the contaminant and the dust that we are challenging it with the royal purple filter is a super premium filter.

It is at the very peak of all filter options that are available to the consumer today.

Whether your engine power is a hot rod or a daily driver.

When you spin one of these filters onto it,

it's gonna have the same high quality as the synthetic oil that runs through it.

Air tools are essential for fast efficient work in your home shop. But don't you hate dragging around a compressor with a bunch of tangled hoses? Well, rapid air products has a new economical 100 ft master kit made with you in mind. Now, it comes with this durable lightweight nylon tubing compressor manifold kit

into air outlet kits. Now it's easy to install the hoses attached to the fittings in a breeze

and you can get all types of accessories to customize the master kit to make your system at home neat, clean and efficient.

Now, the master kit will set you back about 100 and 40 bucks. Not a bad price for air anywhere

you can run, but you can't hide from it. Rust. That is, it's one of your ride's worst enemies.

We now an industrial technology developed in 1986 to prevent extreme rust and salt. Mining equipment is available for cars and trucks too.

It's called counteract

and it's a patented electrostatic technology with a module that connects to your battery.

It sends minute electrical charges through these two couplers that deploy a very slight negative charge to the body surfaces of the vehicle that charge prevents and inhibits rust and corrosion protecting body panels, paint

even bolt on accessories made from dissimilar metals.

Basically, the counteracts system eliminates the tendency of oxygen and iron to result in rust. These things are ideal for everything from daily drivers to show cars and they come with a guarantee that's good. Even if you swap it from one vehicle to another with prices starting at just under 300 bucks.

Well, hope you stay dry and rust free until next week. We'll see you then.