HorsePower Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Comp Cams

Xtreme Energy Hydraulic Flat Tappet Camshaft, Hydraulic-Street / Strip, needs 9:1 comp. 2800+ stall, headers, gears, rough idle. Pro Magnum Hydraulic Lifters; Olds (V8 260-455) Pontiac (V8 326-455). Both have been infused with Pro Plasma Nitriding Treatment.

Federal-Mogul Corporation

Piston. Oldsmobile 455, Forged Dish -.142cc, 4.155 in. Bore, .030.

Certified Auto Recycling

Used 455 Oldsmobile Complete

HorsepowerSales.net

Valley Girdle Pro, Ford Small Block.

Interdynamics Inc.

Motor Oil Super Seal, Coolant Super Seal, ATF Super Seal, Power Steering Super Seal.

Kimberly-Clark Professional

WYPALL* Red Shop Towels.

MAHLE Aftermarket

Connecting rod bearings, Main bearings, Cam bearings

Mondello Tech Center

Machining of block surfaces, align hone crank mains, hone cylinder bores, resize rods, balance rotating assembly, polish crank journals, port cylinder heads, valve angle grind, deburr block casting, install and measure bearing tolerances, install oil restrictors and oil galley plugs, modify timing set, file piston rings and degree camshaft.

O'Reilly Auto Parts

Oil Pump Driveshaft

O'Reilly Auto Parts

White acrylic enamel paint and reducer

O'Reilly Auto Parts

High Volume Oil Pump

O'Reilly Auto Parts

Valve Stem Seals

O'Reilly Auto Parts

Water Neck

Episode Transcript

Oh boy, what a great place to kick off this week's horsepower.

Today on the show, we're gonna build up a monumental motor.

In fact, it's a treatable version of the one that powers this famous door slammer called The Twister.

What's more the owner is gonna help us? He's a famous horsepower hero known worldwide as doctor

S.

The only place you find a helping hand is at the end of your own wrist. No free lunches

and nothing for nothing.

Nobody's gonna hand you anything

and nobody's gonna make you famous. You're gonna make yourself famous. It's that kind of work ethic that made Joe Manello famous as a racer, engine builder and technical innovator driving its way to comp illuminator championships in the sixties. Joe also had the drive to design better ways to make engine horsepower.

By the 19 seventies, all kinds of race cars were running and winning. Thanks to his innovative cylinder heads,

horsepower is limited by

the amount of air that can pass through the cylinder head. That is the controlling factor

period.

And the story and that's the way that works.

In 1968 Mandela started racing for Olds Mobile while also developing specialty engine parts for their 455 big block. Hence the name Doctor Olds,

they're just self driven

air pumps.

But when you do really good solar heads, I'm now they're dynamically driven.

Doctor

Oz is now a member of five halls of fame

and with a legacy like that, he could easily rest on his laurels. But years ago, a new mission emerged.

The lady you met today,

Manello

said, Joe,

I want you to start teaching people

what you know,

because when you die, it's all gonna go in the box with you.

So we decided to open a

one week class.

He used to say, learn 40 years in a week

and he tried to cram it all in too.

Things are turning out good.

He

got great grid control, but get around that front part of that guide a little bit better.

Yeah. When you walk in the front door, you're an engine assembler. When you leave on Friday, you're an engine builder.

Big difference.

That's the difference

before we could apply

Moo's magic to our own 455 build. We had to find a decent used block and we were pretty sure one was waiting under this motor we bought for a few 100 bucks.

So after a complete tear down and displacing a family of brown recluse spiders,

we had the foundation for a true classic motor creation

after cleaning in magna flux and the block were ready to start the machining process. Now, here at the tech center, they've got all the latest equipment and the guys that use it. Well, they were trained by Mondello himself. So, you know, everything's gonna be done right. The first time

after cutting the main caps to shrink the bores about 1000. The first major step is to line hone the block to make sure the mains are round and straight.

Then Brett loads are blocking an RNC block surfer.

First, the machine has to probe the block to learn where the holes are. Then it takes out 30,000 per each cylinder before the initial pass of surfacing

deck surfaces were not square this way.

And you can see being that it touched here and not here that it wasn't square this way.

Um Also you're seeing how un flat

the deck surface was, um, in the high spots and the low spots there.

After several passes, the machine has taken off about 13 thousands of surface material.

Then David and his son in SV 10 take over to hone out the cylinder boards to make them perfectly round with a cross hatch to allow the rings to see properly.

That's pretty much telling you a basic idea of what the boar is looking like.

We're reusing the stock rods, but only after Brett resizes them with new A RP bolts,

the stock crank shafts in pretty good shape. But David will need to do a little drilling to bring it into perfect balance.

Then a little polish on the journals and the cranks ready to go in.

It's about time for the master engine builder himself to take over and he's got a bag full of tricks and tech gems that'll make any motor last longer and make more power.

The,

we set out to build a piece of horsepower history. The Olds 455

by first tearing down a boneyard beast to render a usable bottom end.

Then we took the block to Joe Mandela's tech center for a complete machining

at the crank balance

and the stock rods reside for use with new speed

Pro pistons.

Now it's time for doctor

S himself to step in for his basic cleanup porting of our Edelbrock performer. RPM heads.

The biggest thing

about doing these heads

is mastering this grinder

because the grinder gets away from people.

You gotta have grinder control.

Remember you on the grinder? The

no, you,

no doubt who's in charge of the grinder here and after roughing out the short side radius time for a little polishing.

And here Mondello uses a creation of his own called a flapper stick. It leaves one consistent texture

in the port

which helps

to have a much more better homogenous fuel mixture

and a lot better

strad of layer of incoming fuel in the port runner.

Our heads are also treated to a basic valve job to make sure the valve seal to the combustion chambers but that's not the only reason.

The different angles on the valve seat are going to change the wet flow characteristics and the dry flow characteristics of the cylinder head.

What we're doing here is pressure testing the seat to make sure it's sealing properly. So we're well into the green here at 0.8

back in the porting room,

manello meticulously de burs the block to eliminate the smallest possible obstruction of oil flow Like here smoothing out an oil hole that lubricates the timing chain

done.

He even goes into the water jackets to clean out the rust and calcium

by getting in there with this thing and cleaning it up and you run cooler to break in and cooler through the whole life of the engine.

Hey, before we start building up our bottom B I want you to meet the real boss of the tech center. This is the cisco kit.

He's uh, dressed for speed and born to run.

Meanwhile, I think the doctor is ready to operate

and the first or procedure is to knock in the new cam bearings

before anything else happens. Joe installs the rear main to measure it with a gauge.

Hey, check out the tool he invented for getting the main back off.

Vlo spent years coming up with innovations that improve the Oldsmobile engines, notorious oil return issues. Well, like the four oil restrictors he puts into the mains.

It keeps more oil down in the main bearings.

And around the rod bearings because of the large capacity

of oil flow. Of course, you have to modify the main bearings in order for the restrictors to work

in goes the cam. Now, which by the way is a cop hydraulic roller with their special pro

plasma nitrite treatment.

Next, installing special front and back oil galley plugs,

make sure that the oil galley plug in the back has got a 40,000 oiling hole in it.

If it's a three inch pipe plug, you will burn up the cam and you will burn up the distributor gear

guaranteed.

Now, the crank shaft can go in

along with main caps and a RP bolts.

Then using a feeler gauge, he makes sure thrust is between six and 12 thousands. It's a six.

Can you check the tar

and they also check the bottom?

Next, he pulls the crank forward to tighten the bolts before torquing

90 pounds with Molly

Joe uses timing gears that change the olds from a slit fit to a press fit, set up.

It's plain to see that Mondello doesn't use any part right out of the box that definitely goes for piston rings

after precisely checking the end gaps

and in many cases, grinding them down a little,

he uses a special stone to smooth out the sharp edges.

The biggest scratches in the cylinder board

are the sharp edges

on these oil rings.

This side is for opening and closing events.

This side over here is for intake center line

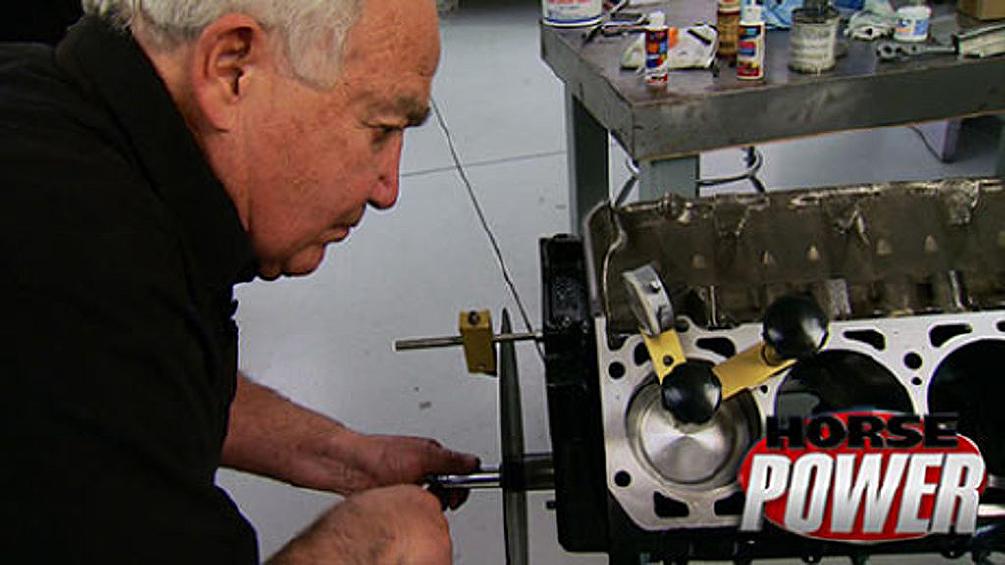

is a strong advocate of degree in the cam at four cylinders

two on the right bank and two on the left.

If your degree, your c

chef, you, you have worked on the heart of the engine.

If the CT is right,

everything else will fall in place.

After installing the oil pump and pick up, we'll be good to go and finish the build back home at our shop.

Meanwhile, it was mesmerizing to spend a couple of days with this icon of engine building.

Still going strong after 50 years of high performance, perfection.

Questions always asked to my wife when she

gonna retire,

Joe is not going to retire.

We're gonna have the funeral and retirement party the same day.

So show up,

that's the way it's gonna work.

Well, our 455 olds motor is back in the shop and ready for us to finish the build next week with all these parts and,

and we'll even take it back to the

dyno and pound on it.

You know, I guess it goes without saying when you build a motor, the best way to save money in the long run is to build it right and build it to last.

We certainly witnessed that at Mandela's Place. Those guys are meticulous with every step of the process, including degrading the cam and why not? When you degree the cam shaft, you're making sure it's synchronized with the crank shaft.

Well, it's been a while since we've done this drill. So let's review the steps of one of the more popular methods. Of course, you gotta have some tools like a degree wheel,

a

dial indicator, a

pointer. And hey, what better use of an old code hanger than this

and some kind of positive stop device. And you could even make one of these with an old spark plug

with your timing set and cylinder heads installed, rotate the crank clockwise till number one piston is at top dead center.

Then after aligning the pointer with T DC on the wheel,

install the piston stop. So the boat protrudes about an inch.

Rotate the crank till it touches the piston stop,

record the degree wheel number

and rotate counterclockwise till you contact the stop again.

The number should match

with the dial indicator mounted to the block and directly over the lifter or intake side spring, rotate the crank clockwise till the lifter is at maximum lift and zero. The indicator

now rotate the crank and as the lifter moves up, stop when the indicator shows 50,000 surprise record that number from the degree wheel.

Ok. Continue rotating past maximum lift till the indicator again shows 50 thousands and record that number.

Both should match the numbers on your C

card

as we saw at Mandela's tech center. Joe insists on agreeing at four cylinders two on each bank of the motor.

So why is it one enough. Doesn't tell you whether or not the lifter boards are straight. Doesn't tell you whether or not your camp tunnel is straight, doesn't tell you whether it is

slanted front to back.

So,

when I teach somebody here in my engine blueprinting course

I make all my students degree four cylinders two on the right bank, two on the left bank.

Oh, well, one thing I've learned over the years is no, two engine builders do everything exactly the same.

But I think they all agree that

some degree is better than no degree. We'll be right back.

A well prepped block is the critical starting point for any engine build. But it can also be an expensive one when you get your build back from the machine shop. So today we're gonna show you a couple budget tech tips that'll save you money in the short run and extend the life of your block in the long run.

For the first one. All we need is a dye grinder, a grinding stone and some burs

this 5 L Ford has a good oiling system.

However, the oil return holes here in the Lifter Valley have sharp edges and raise points that can slow the oil down from getting back in the pan.

Now using the grinder and the stone, I'm gonna champ for the holes in the valley. So the oil has a nice smooth passage back to the pan

with the burr.

I'm gonna smooth down the area around the rear lifter boards where oil can puddle.

Now, be careful not to remove too much material. Remember, we're just smoothing out the rough edges.

One more thing, the rough forest surface of the valley can be restrictive itself. So for the icing on the cake, we're just gonna cover it with some acrylic enamel to give it a smooth slick, unrestricted surface.

Well, now that Mike's, uh, icing or rather paint has dried,

let's be a little bit more block specific.

These 5 L blocks do have one drawback that's worth pointing out the material here in the Lifter Valley is pretty thin

at high RPM. S some of these blocks have been known to split

and it usually starts right in the Lifter Valley.

So how does that happen

in a high performance set up? The engine can actually twist

the cylinders will distort

and since the Valley is the weak point,

guess where the crack starts.

Well, here's an affordable ounce of prevention called a Valley Girdle Pro and it comes from horsepower sales.

Now you stall them here reaching the valley and they strengthen the top of the block.

Reduce stress and dampen harmonics.

You just tighten down the allen head bolts,

drill a quarter inch holes at each end of the girdles

tap in these roll pins and that's it.

In addition to Fords, they've got them for other high

revving engine applications. Any place where a little extra strength

might prevent a not so simple twist of fate.

Yeah. I don't mind cleaning shop tools. I'm off the floor.

What I even do windows.

There's one place I draw the line though and that's doing laundry.

That's one of the reasons we've given up cloth shop towels for these disposable white balls. Now, these things are tough and durable. Even when wet check this out cast iron manifold,

it ain't heavy.

They're also absorb it and will soak up just about any oils greases or other liquids. We throw at them. Now, we like the pop up box here, but like their other towels. You can also get them on a roll. Any car with a high performance engine needs a suspension that can handle the straightaways as well as the curves. Now, Atco Engineering has been in the

way our bi since 1961 with over 2000 applications. Now this set up appears for a mustang and it's made a sturdy tubular steel, comes with all the hardware and urethane pushings. You need to put it on your ride to keep it handling like a true sports car. Now, the price, well, it's pretty easy to handle. Two at 300 bucks

build on a budget horsepower projects that save you time and money.

Uh You finally found your dream, right?

But after the first night in the driveway, you realize you're still chasing rainbows.

Of course the rainbow in this case is oil.

Well, most leaks aren't the result of mechanical failures. In fact, this one could be the result of a pinhole in the oil pan. A less than perfect seal, who knows well, to try to find and fix this Camaro's leak. We're gonna try out a new product we found called super seal.

It's actually a two step process and the first step is to pour in the ultraviolet die.

After running the motor about 15 minutes, you shut it off and take a UV light

to look for the leak.

Ok. It looks like we've got a little leak here at the oil pan gasket.

Now, time for step two,

the fix a leak sealer.

After that, you just drive the car around a few days, check the source again. And if you don't see green,

you've saved some green at the repair shop. By the way, a bigger leak might take a second application.

Now Super Seal makes their stop leak stuff for radiators, transmissions and power steering pumps. And the parent company quest even makes the UV light that doubles as a flashlight.

Right now. I wanna leak some information about upcoming horsepower shows. Next week we've taken on the challenge of hot rodding, one of America's most popular police cars, the Dodge

hemi charge

later on, we'll correct the gearing in our turbo mustang before we take it to the strip for some serious testing to see you next time.

Show Full Transcript

Today on the show, we're gonna build up a monumental motor.

In fact, it's a treatable version of the one that powers this famous door slammer called The Twister.

What's more the owner is gonna help us? He's a famous horsepower hero known worldwide as doctor

S.

The only place you find a helping hand is at the end of your own wrist. No free lunches

and nothing for nothing.

Nobody's gonna hand you anything

and nobody's gonna make you famous. You're gonna make yourself famous. It's that kind of work ethic that made Joe Manello famous as a racer, engine builder and technical innovator driving its way to comp illuminator championships in the sixties. Joe also had the drive to design better ways to make engine horsepower.

By the 19 seventies, all kinds of race cars were running and winning. Thanks to his innovative cylinder heads,

horsepower is limited by

the amount of air that can pass through the cylinder head. That is the controlling factor

period.

And the story and that's the way that works.

In 1968 Mandela started racing for Olds Mobile while also developing specialty engine parts for their 455 big block. Hence the name Doctor Olds,

they're just self driven

air pumps.

But when you do really good solar heads, I'm now they're dynamically driven.

Doctor

Oz is now a member of five halls of fame

and with a legacy like that, he could easily rest on his laurels. But years ago, a new mission emerged.

The lady you met today,

Manello

said, Joe,

I want you to start teaching people

what you know,

because when you die, it's all gonna go in the box with you.

So we decided to open a

one week class.

He used to say, learn 40 years in a week

and he tried to cram it all in too.

Things are turning out good.

He

got great grid control, but get around that front part of that guide a little bit better.

Yeah. When you walk in the front door, you're an engine assembler. When you leave on Friday, you're an engine builder.

Big difference.

That's the difference

before we could apply

Moo's magic to our own 455 build. We had to find a decent used block and we were pretty sure one was waiting under this motor we bought for a few 100 bucks.

So after a complete tear down and displacing a family of brown recluse spiders,

we had the foundation for a true classic motor creation

after cleaning in magna flux and the block were ready to start the machining process. Now, here at the tech center, they've got all the latest equipment and the guys that use it. Well, they were trained by Mondello himself. So, you know, everything's gonna be done right. The first time

after cutting the main caps to shrink the bores about 1000. The first major step is to line hone the block to make sure the mains are round and straight.

Then Brett loads are blocking an RNC block surfer.

First, the machine has to probe the block to learn where the holes are. Then it takes out 30,000 per each cylinder before the initial pass of surfacing

deck surfaces were not square this way.

And you can see being that it touched here and not here that it wasn't square this way.

Um Also you're seeing how un flat

the deck surface was, um, in the high spots and the low spots there.

After several passes, the machine has taken off about 13 thousands of surface material.

Then David and his son in SV 10 take over to hone out the cylinder boards to make them perfectly round with a cross hatch to allow the rings to see properly.

That's pretty much telling you a basic idea of what the boar is looking like.

We're reusing the stock rods, but only after Brett resizes them with new A RP bolts,

the stock crank shafts in pretty good shape. But David will need to do a little drilling to bring it into perfect balance.

Then a little polish on the journals and the cranks ready to go in.

It's about time for the master engine builder himself to take over and he's got a bag full of tricks and tech gems that'll make any motor last longer and make more power.

The,

we set out to build a piece of horsepower history. The Olds 455

by first tearing down a boneyard beast to render a usable bottom end.

Then we took the block to Joe Mandela's tech center for a complete machining

at the crank balance

and the stock rods reside for use with new speed

Pro pistons.

Now it's time for doctor

S himself to step in for his basic cleanup porting of our Edelbrock performer. RPM heads.

The biggest thing

about doing these heads

is mastering this grinder

because the grinder gets away from people.

You gotta have grinder control.

Remember you on the grinder? The

no, you,

no doubt who's in charge of the grinder here and after roughing out the short side radius time for a little polishing.

And here Mondello uses a creation of his own called a flapper stick. It leaves one consistent texture

in the port

which helps

to have a much more better homogenous fuel mixture

and a lot better

strad of layer of incoming fuel in the port runner.

Our heads are also treated to a basic valve job to make sure the valve seal to the combustion chambers but that's not the only reason.

The different angles on the valve seat are going to change the wet flow characteristics and the dry flow characteristics of the cylinder head.

What we're doing here is pressure testing the seat to make sure it's sealing properly. So we're well into the green here at 0.8

back in the porting room,

manello meticulously de burs the block to eliminate the smallest possible obstruction of oil flow Like here smoothing out an oil hole that lubricates the timing chain

done.

He even goes into the water jackets to clean out the rust and calcium

by getting in there with this thing and cleaning it up and you run cooler to break in and cooler through the whole life of the engine.

Hey, before we start building up our bottom B I want you to meet the real boss of the tech center. This is the cisco kit.

He's uh, dressed for speed and born to run.

Meanwhile, I think the doctor is ready to operate

and the first or procedure is to knock in the new cam bearings

before anything else happens. Joe installs the rear main to measure it with a gauge.

Hey, check out the tool he invented for getting the main back off.

Vlo spent years coming up with innovations that improve the Oldsmobile engines, notorious oil return issues. Well, like the four oil restrictors he puts into the mains.

It keeps more oil down in the main bearings.

And around the rod bearings because of the large capacity

of oil flow. Of course, you have to modify the main bearings in order for the restrictors to work

in goes the cam. Now, which by the way is a cop hydraulic roller with their special pro

plasma nitrite treatment.

Next, installing special front and back oil galley plugs,

make sure that the oil galley plug in the back has got a 40,000 oiling hole in it.

If it's a three inch pipe plug, you will burn up the cam and you will burn up the distributor gear

guaranteed.

Now, the crank shaft can go in

along with main caps and a RP bolts.

Then using a feeler gauge, he makes sure thrust is between six and 12 thousands. It's a six.

Can you check the tar

and they also check the bottom?

Next, he pulls the crank forward to tighten the bolts before torquing

90 pounds with Molly

Joe uses timing gears that change the olds from a slit fit to a press fit, set up.

It's plain to see that Mondello doesn't use any part right out of the box that definitely goes for piston rings

after precisely checking the end gaps

and in many cases, grinding them down a little,

he uses a special stone to smooth out the sharp edges.

The biggest scratches in the cylinder board

are the sharp edges

on these oil rings.

This side is for opening and closing events.

This side over here is for intake center line

is a strong advocate of degree in the cam at four cylinders

two on the right bank and two on the left.

If your degree, your c

chef, you, you have worked on the heart of the engine.

If the CT is right,

everything else will fall in place.

After installing the oil pump and pick up, we'll be good to go and finish the build back home at our shop.

Meanwhile, it was mesmerizing to spend a couple of days with this icon of engine building.

Still going strong after 50 years of high performance, perfection.

Questions always asked to my wife when she

gonna retire,

Joe is not going to retire.

We're gonna have the funeral and retirement party the same day.

So show up,

that's the way it's gonna work.

Well, our 455 olds motor is back in the shop and ready for us to finish the build next week with all these parts and,

and we'll even take it back to the

dyno and pound on it.

You know, I guess it goes without saying when you build a motor, the best way to save money in the long run is to build it right and build it to last.

We certainly witnessed that at Mandela's Place. Those guys are meticulous with every step of the process, including degrading the cam and why not? When you degree the cam shaft, you're making sure it's synchronized with the crank shaft.

Well, it's been a while since we've done this drill. So let's review the steps of one of the more popular methods. Of course, you gotta have some tools like a degree wheel,

a

dial indicator, a

pointer. And hey, what better use of an old code hanger than this

and some kind of positive stop device. And you could even make one of these with an old spark plug

with your timing set and cylinder heads installed, rotate the crank clockwise till number one piston is at top dead center.

Then after aligning the pointer with T DC on the wheel,

install the piston stop. So the boat protrudes about an inch.

Rotate the crank till it touches the piston stop,

record the degree wheel number

and rotate counterclockwise till you contact the stop again.

The number should match

with the dial indicator mounted to the block and directly over the lifter or intake side spring, rotate the crank clockwise till the lifter is at maximum lift and zero. The indicator

now rotate the crank and as the lifter moves up, stop when the indicator shows 50,000 surprise record that number from the degree wheel.

Ok. Continue rotating past maximum lift till the indicator again shows 50 thousands and record that number.

Both should match the numbers on your C

card

as we saw at Mandela's tech center. Joe insists on agreeing at four cylinders two on each bank of the motor.

So why is it one enough. Doesn't tell you whether or not the lifter boards are straight. Doesn't tell you whether or not your camp tunnel is straight, doesn't tell you whether it is

slanted front to back.

So,

when I teach somebody here in my engine blueprinting course

I make all my students degree four cylinders two on the right bank, two on the left bank.

Oh, well, one thing I've learned over the years is no, two engine builders do everything exactly the same.

But I think they all agree that

some degree is better than no degree. We'll be right back.

A well prepped block is the critical starting point for any engine build. But it can also be an expensive one when you get your build back from the machine shop. So today we're gonna show you a couple budget tech tips that'll save you money in the short run and extend the life of your block in the long run.

For the first one. All we need is a dye grinder, a grinding stone and some burs

this 5 L Ford has a good oiling system.

However, the oil return holes here in the Lifter Valley have sharp edges and raise points that can slow the oil down from getting back in the pan.

Now using the grinder and the stone, I'm gonna champ for the holes in the valley. So the oil has a nice smooth passage back to the pan

with the burr.

I'm gonna smooth down the area around the rear lifter boards where oil can puddle.

Now, be careful not to remove too much material. Remember, we're just smoothing out the rough edges.

One more thing, the rough forest surface of the valley can be restrictive itself. So for the icing on the cake, we're just gonna cover it with some acrylic enamel to give it a smooth slick, unrestricted surface.

Well, now that Mike's, uh, icing or rather paint has dried,

let's be a little bit more block specific.

These 5 L blocks do have one drawback that's worth pointing out the material here in the Lifter Valley is pretty thin

at high RPM. S some of these blocks have been known to split

and it usually starts right in the Lifter Valley.

So how does that happen

in a high performance set up? The engine can actually twist

the cylinders will distort

and since the Valley is the weak point,

guess where the crack starts.

Well, here's an affordable ounce of prevention called a Valley Girdle Pro and it comes from horsepower sales.

Now you stall them here reaching the valley and they strengthen the top of the block.

Reduce stress and dampen harmonics.

You just tighten down the allen head bolts,

drill a quarter inch holes at each end of the girdles

tap in these roll pins and that's it.

In addition to Fords, they've got them for other high

revving engine applications. Any place where a little extra strength

might prevent a not so simple twist of fate.

Yeah. I don't mind cleaning shop tools. I'm off the floor.

What I even do windows.

There's one place I draw the line though and that's doing laundry.

That's one of the reasons we've given up cloth shop towels for these disposable white balls. Now, these things are tough and durable. Even when wet check this out cast iron manifold,

it ain't heavy.

They're also absorb it and will soak up just about any oils greases or other liquids. We throw at them. Now, we like the pop up box here, but like their other towels. You can also get them on a roll. Any car with a high performance engine needs a suspension that can handle the straightaways as well as the curves. Now, Atco Engineering has been in the

way our bi since 1961 with over 2000 applications. Now this set up appears for a mustang and it's made a sturdy tubular steel, comes with all the hardware and urethane pushings. You need to put it on your ride to keep it handling like a true sports car. Now, the price, well, it's pretty easy to handle. Two at 300 bucks

build on a budget horsepower projects that save you time and money.

Uh You finally found your dream, right?

But after the first night in the driveway, you realize you're still chasing rainbows.

Of course the rainbow in this case is oil.

Well, most leaks aren't the result of mechanical failures. In fact, this one could be the result of a pinhole in the oil pan. A less than perfect seal, who knows well, to try to find and fix this Camaro's leak. We're gonna try out a new product we found called super seal.

It's actually a two step process and the first step is to pour in the ultraviolet die.

After running the motor about 15 minutes, you shut it off and take a UV light

to look for the leak.

Ok. It looks like we've got a little leak here at the oil pan gasket.

Now, time for step two,

the fix a leak sealer.

After that, you just drive the car around a few days, check the source again. And if you don't see green,

you've saved some green at the repair shop. By the way, a bigger leak might take a second application.

Now Super Seal makes their stop leak stuff for radiators, transmissions and power steering pumps. And the parent company quest even makes the UV light that doubles as a flashlight.

Right now. I wanna leak some information about upcoming horsepower shows. Next week we've taken on the challenge of hot rodding, one of America's most popular police cars, the Dodge

hemi charge

later on, we'll correct the gearing in our turbo mustang before we take it to the strip for some serious testing to see you next time.