HorsePower Builds

Want more content like this?

Join the PowerNation Email NewsletterEpisode Transcript

Hey, we're seeing red here in the horsepower shop today for more reason than one. First of all, we got a pair of red hot rods like this 37 Ford Street Rod. Now, this thing is a fiberglass replica built by precision tricks customs

and it features such tricks as a handmade grill pt cruiser headlights, a chop, removable top suicide doors, of course and out back tail lights grafted from a Lexus no less.

This thing's got us seeing red under the hood too with its color coordinate engine compartment.

And it's also got an LS One Corvette engine with a custom induction and engine cover. But you know, a lack of performance can have you seeing red too. And that's just why my old wagon is in the shop here today.

Its performance just doesn't match its appearance.

Yeah, that 327 could use some help and you know what a small block Chevy is a perfect platform to show you guys how to pump up the power with a basic camshaft intake and carve swap. Oh, and to make it more real world, we'll do the work with the engine in the car

and that's the way most of you guys will be doing the work at home anyway. But let's take a look at the combination that we chose

for my old wagon here. Now, we know it's gonna be a dedicated pavement pounder. So we don't need a full race, full roller camshaft or a tunnel ram with a pair of dominators. Well, we do want those for all of our parts to work together in harmony and that's why we chose this Edelbrock performer plus camshaft. Now, this is a hydraulic flat tap it piece that makes good power from idle

to 5500 RPM. Now, whenever you change camshafts, it's always a good idea to replace your lifters, your timing set and of course, your push rods.

Then what about rocker options? You could install a set of roller rockers that'll work even with a stock camshaft and notice some gains thanks to reduce friction and more accurate rocker ratio. But those few extra horses will cost you

another option would be a basic stamp rocker like this one or how about a compromise? Now, this roller tip piece uses the same pivot ball design as the stalker, but we'll make that call a little bit later.

We'll check the rest of our power package too later on. But right now it looks like Mike's got a pretty good start here

since Joe's disconnected the battery already. I went ahead and drain the fluid out of the radiator. Now, let's get this thing torn apart

with the air cleaner all the way. We can go ahead and disconnect the linkage,

undo your fuel and vacuum lines

and remove the carburetor.

Next. Get rid of the alternator and the AC bracket

along with the coil and the distributor.

Now you can remove the valve covers

and finally remove 40 plus pounds of intake.

Now, we need to back off these rocker arm nuts so we can remove the push rods

and the lifters. But before we can pull that old cam shaft, we gotta get rid of the shroud and radiator.

And if the car has air conditioning like this wagon does, the condenser in front of the radiator has to go as well

along with the fan,

the two pulleys

water pump

and the balance.

Well, the only thing standing between us and that cam shaft now is the timing cover. Now, if you're doing the job in the car, here's a tip that'll make the job go a whole lot easier

from underneath the car, remove the first four bolts on either side of the oil pan and loosen the rest

that allow the oil pan to drop down later on.

Now, we can remove the timing cover bolts

and the cover itself.

There we go.

Now, that's gonna expose the timing set and the top gear is held on with these three bolts

and once we remove them

with the gear and the chain come off together,

well, now that Chuck's got the fuel pump out of the way. Here's a little tip. I wanna show you

if you take a long boat like this one and thread it into the stock cam shaft, it'll give you the leverage. You need to start easing it out of the engine.

Oh, I was hoping that wouldn't happen.

We're about one journal from clearing this bumper here. Hold on. I got an idea.

After removing the trans mount bolts, I can jack up the transmission a couple of inches

that should change the angle of the engine just enough.

There it is.

I guess we owe Mike lunch today. Of course, every car is a little bit different and good thing. We got lucky.

Now we get this new Edel rock cam shaft ready to install and of course, the kit comes with some of this assembly lube which you wanna smear on liberally, especially here on the lobes. Now, these lobes are lubricated by splash oiling and well, during initial start up, this Molly based lube prevents scuffing between the lobes and the lifters.

Notice how Joe is using that long bolt again to install the new cam

and for a Ford guy, he's even being pretty careful not to nick those bearings while he slides it into place while Joe finishes up with that cam shaft. Let me show you the timing set that we're gonna use. It's a double roller set up from Edelbrock with a pretty neat feature here. It's got three different slots right down here on the small sprocket. And what that allows us to do is install this thing straight up

four degrees advanced or four degrees retarded. Now, the benefit of that is when you advance your cam timing, you're gonna pump up your bottom end power and torque and when you retard it, well, you're gonna move that power band further up the RPM scale. Now, since we're gonna install our straight up, all we have to do is line up the dots

on the big sprocket and the smallest sprocket.

And while Chuck installs that timing set, good timing for us to take a little break. We'll continue our power package installation though. So you continue watching.

Hey, you're back just in time. Well, I just finished installing our new timing set. But if you're doing this job on a late model small block, Chevy, well, here's a little heads up for you,

check the clearance here at the 12 o'clock position on the block behind the cam gear. Now, on some blocks, the oil galley back here actually interferes with that cam gear. So you'll have to grind the block a little bit to get the clearance you need.

Hey, good advice there, Chevy Boy.

But I got a couple more tips for you. First of all, always install a new front seal. It's pretty cheap insurance against an oil leak. And secondly, before you install this gasket that seals the timing cover to the pan. Well, snip the ends of this lip right here

and right here,

that'll make it easier to slide this thing in place over the oil pan. Now, I wanna run some of this silicone down in the groove here

before I install that gasket.

After cinching down the timing cover, we reinstall the balancer,

then the water pump,

the police,

the fan,

plus the shroud and radiator.

We can install the lifters now, but I like to prime them first by pumping oil into this bleed hole.

Then I dip it in assembly lobe,

slide it into the lifter bore

and drop in the push rod.

Now, we're ready to install the rockers. Now, since this is a pretty basic build up, we're gonna use these magnum roller tip rockers from comp cams.

Now, you can get these in a 1.6 and a 1.52 ratio like the ones we're using.

Now, these are investment castings, which means that the ratios are gonna be a little more accurate.

And the 1.5 twos that we're using, they'll give us a little more lift in the 1.5 zeros that came stock on the Chevrolet.

Hey, I like your choice of rockers, but you know, now we've got to adjust them and it's pretty easy with the intake. What

we wanna do is bring each cylinder to top dead center and you can determine that by looking at where the lifters are in their bores when they're both down and

we're ready to do some adjusting. Now, what I like to do is wiggle on the push rod while I take the slack out of the rocker

and we wanna get the zero lash. Here.

There we go. Now, we'll give it a half a turn past that

and we can move on to the next rocker.

Well, it shouldn't take those guys too long to adjust those rockers. Meanwhile, let me show you the next component of our power package.

It's an

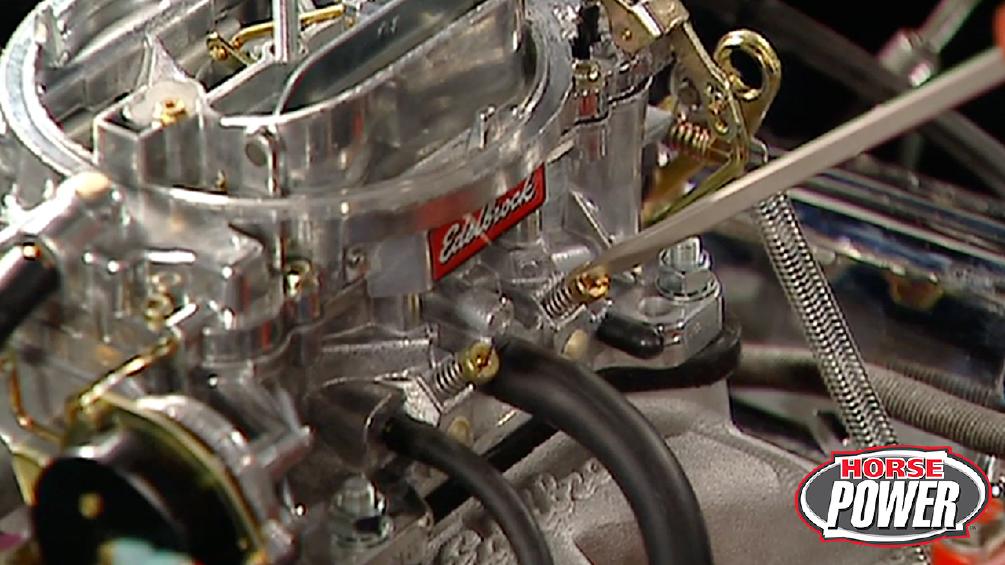

rock performer. Eps intake manifold that matches our camshaft's power band of 0 to 5500, which is very important. Now, check out these ridges that are cast into the plenum floor. That means this intake is designed to work best with a performer carburetor

and they claim that from three 1000 to 4500, you're gonna see an average of about 5 ft pounds more torque with that intake there. And man, that's just where you need it the most. Now, we're gonna match that intake manifold with an Edelbrock 600 CFM vacuum secondary car. Now, this thing is smog legal in all 50 states for GM vehicles 1980

later, plus it has an electric choke and it's already been calibrated for emissions and economy.

The new guy does all the dirty work. Now, I just finished scraping the old gasket material off of the cylinder head. We're gonna replace those with these ultra seals from Mr gasket. Now notice the beat of silicone ran around each of the ports. They come this way straight from the factory

instead of using the rubber and gaskets that are supplied in the kit. I like to use a thick beat of silicone on each end of the block to keep the lifter valley sealed.

Now I can put the manifold into place

next coat the new bolts with silicone to prevent oil seepage and thread them hand tight,

tighten them down in a crisscross pattern

with a final torque of 25 ft pounds.

Well, now we can go ahead and drop on our carburetor and plummet. But first, I want to show you something Edelbrock makes this really cool fuel line with a built in filter. Now, what's really neat about this thing is, has a reusable metal disk. It'll trap particles down to 40 microns.

Now, we can reconnect the throttle linkage

and wire the electric choke.

We're gonna reconnect the hoses and both the brackets back up. So why don't you stay put? We'll finish up our work on the wagon and fire it up after this.

Well, time for the finishing touches of our power package installation on Chuck's red wagon here and now we can reinstall the distributor first though, of course, we gotta bring the number one cylinder to top dead center. First thing to do is remove the number one plug,

stick a finger in the hole while you have a buddy bump the starter

until it comes up on the compression stroke

and the timing marks on the balance are lined up.

Denmark.

The location of the number one plug wire on the distributor body

slide the distributor into place. So the rotor points to the mark on the body.

Then after installing the cap, we can route the wires according to the firing order. Oh If it's your first time, I wanna mark these with a piece of tape to avoid any confusion. Well, there's no confusion about wanting to have an engine that looks as good as it runs. So we're gonna go ahead and dress ours up with these chrome valve covers and air cleaner from Edelbrock.

Now, our engine has an air conditioner on it and a bunch of extra brackets. So we need to have these low valve covers. But if you've got a set of roller rockers or even a stud girdle, well, they're also available in a tall version.

Oh, man, this stuff's gonna look good on here. It's amazing what a little chrome can do for a motor. Yeah, if I didn't know better, I wouldn't even think this was the same engine.

But you know what? I think I got this last plug wire on here.

We're ready to fire this thing up. All right, Mike. Go for it.

Hey, sounds pretty good. Huh. Go ahead and kill it, Mike.

We're gonna go ahead and adjust our eye left to at least 1500 RPM. And we're gonna let the engine run at that speed for about 15 minutes. Give that cam plenty of time to break in.

And while we're doing that, we're gonna be checking for any fuel or fluid leaks and everything turns out fine. Well, then we can go ahead and adjust our carb and set our timing.

All right, Mike hit it

once the camshaft is broken in disconnect the vacuum line to the distributor

and connect the timing light lead to the number one plug wire

with the engine running, rotate the distributor until the timing marks line up to factory specs.

We set our at eight degrees advanced.

The settings on these

rock carbs are pretty close right out of the box, but we're going to fine tune our idle adjustments just to make sure.

Now we've already backed the idle speed back to 700 RPM on the engine. So we can adjust these idle mixture screws, turning them clockwise, leans it out counterclockwise, fattens it up,

start by turning the screw clockwise until the motor starts to stumble.

Then back it out to obtain the highest RPM and repeat on the other screw.

Now, you may have to repeat that procedure several times to get the mixture right. But it's no big deal a project like this. Well, you can plan on spending the better part of the weekend to get it done.

Plus you can count on dropping about $400 for the valve train upgrade another 4.5 for the intake and carb. Now, don't you go away? We got more horsepower TV coming at you.

Thanks to technology. The wheels and tires you run on are safer and better performing than ever.

But if you put them through the paces, proper balance is more critical than ever as well.

Di

teaches automotive technology at

Wyotech

and he took me to school on how this DFC 9700 balancer does its measuring magic.

Back in the olden days, we had to set measurements for the rim

um

using a caliper much like this.

This machine actually eliminates the need for it.

Now, all you do is bring down these two sensing arms, set them in the place and touch the pedal one time. And if you look at the screen, it actually brings up our measurements and has them locked in the memory

at this point,

we have some decisions to make whether we want to do a static balance of dynamic balance

or a dynamic balance with road force. At this point, we've chosen road force and all we have to do is bring down the hood,

the machine will do the rest.

The machine is telling us that we're three quarters of an ounce of weight out on the inside rim. And we need to add one and three quarters ounces to the outside of the rim.

So all we do to get that thing to index for us is we press the start button

and it brings us right to where we need the place to wait.

Next, we take our weight

there.

Now, we've got a wheel and tire combination and we're pretty sure we got a bent rim. Right. Oh, yeah, we got some kind of damage there and this machine will actually tell us if it's the tire or the rim. Ok. Let's do it.

Now, it's asking us to bring in the data arms so we can measure the rim run out.

So we bring those into place and we press the start button

and at this time, it's suggesting rim replacement.

That's a neat feature. But is there anything to say won't do?

Yeah, it won't break the tire assembly down

and that's my job. That's your job. Thanks pal.

You're quite welcome.

Fuel delivery technology. Sure changed a lot over the years since the mechanical pump did the job on cars like this wagon here

today, electric is the only way to go, especially in high performance racing applications.

Well, now this BG 220 series pump for Barry Grant is designed to flow over 220 gallons an hour while drawing only eight amps at 13.6 volts. Now, it comes with this separate return style regulator that sends unwanted fuel back to the cell so that the pump can operate at cooler temperatures. Price is pretty cool too. It, just over 200 bucks.

Here's a way to improve the power in your stock to mildly modified. 64 to 87 Chevy Small block hooker has these universal shorty headers that'll take the place of your stock manifolds. Now, they're made from 16 gauge and 58 steel tubing

with a three inch collector. They come with all your gaskets and hardware you need to install them and the price is pretty fair starting at 100 and 45 for the baked on black paint

and 325 for this. Nice

he

finish.

Hey, there's nothing cool about a coating on your car's glass, especially after you've used the cleaner on it.

Well, here's a product we found called Invisible Glass that cleans windshields, windows and mirrors with a non streaking formula that evaporates completely. Now, it uses no foams or soaps that can leave a residue and well, when you're done, you might think your windshield is. Well, just like the name says, Invisible.

Well, that's about it for hot parts. Make sure you join us next week for more horsepower TV.

Show Full Transcript

and it features such tricks as a handmade grill pt cruiser headlights, a chop, removable top suicide doors, of course and out back tail lights grafted from a Lexus no less.

This thing's got us seeing red under the hood too with its color coordinate engine compartment.

And it's also got an LS One Corvette engine with a custom induction and engine cover. But you know, a lack of performance can have you seeing red too. And that's just why my old wagon is in the shop here today.

Its performance just doesn't match its appearance.

Yeah, that 327 could use some help and you know what a small block Chevy is a perfect platform to show you guys how to pump up the power with a basic camshaft intake and carve swap. Oh, and to make it more real world, we'll do the work with the engine in the car

and that's the way most of you guys will be doing the work at home anyway. But let's take a look at the combination that we chose

for my old wagon here. Now, we know it's gonna be a dedicated pavement pounder. So we don't need a full race, full roller camshaft or a tunnel ram with a pair of dominators. Well, we do want those for all of our parts to work together in harmony and that's why we chose this Edelbrock performer plus camshaft. Now, this is a hydraulic flat tap it piece that makes good power from idle

to 5500 RPM. Now, whenever you change camshafts, it's always a good idea to replace your lifters, your timing set and of course, your push rods.

Then what about rocker options? You could install a set of roller rockers that'll work even with a stock camshaft and notice some gains thanks to reduce friction and more accurate rocker ratio. But those few extra horses will cost you

another option would be a basic stamp rocker like this one or how about a compromise? Now, this roller tip piece uses the same pivot ball design as the stalker, but we'll make that call a little bit later.

We'll check the rest of our power package too later on. But right now it looks like Mike's got a pretty good start here

since Joe's disconnected the battery already. I went ahead and drain the fluid out of the radiator. Now, let's get this thing torn apart

with the air cleaner all the way. We can go ahead and disconnect the linkage,

undo your fuel and vacuum lines

and remove the carburetor.

Next. Get rid of the alternator and the AC bracket

along with the coil and the distributor.

Now you can remove the valve covers

and finally remove 40 plus pounds of intake.

Now, we need to back off these rocker arm nuts so we can remove the push rods

and the lifters. But before we can pull that old cam shaft, we gotta get rid of the shroud and radiator.

And if the car has air conditioning like this wagon does, the condenser in front of the radiator has to go as well

along with the fan,

the two pulleys

water pump

and the balance.

Well, the only thing standing between us and that cam shaft now is the timing cover. Now, if you're doing the job in the car, here's a tip that'll make the job go a whole lot easier

from underneath the car, remove the first four bolts on either side of the oil pan and loosen the rest

that allow the oil pan to drop down later on.

Now, we can remove the timing cover bolts

and the cover itself.

There we go.

Now, that's gonna expose the timing set and the top gear is held on with these three bolts

and once we remove them

with the gear and the chain come off together,

well, now that Chuck's got the fuel pump out of the way. Here's a little tip. I wanna show you

if you take a long boat like this one and thread it into the stock cam shaft, it'll give you the leverage. You need to start easing it out of the engine.

Oh, I was hoping that wouldn't happen.

We're about one journal from clearing this bumper here. Hold on. I got an idea.

After removing the trans mount bolts, I can jack up the transmission a couple of inches

that should change the angle of the engine just enough.

There it is.

I guess we owe Mike lunch today. Of course, every car is a little bit different and good thing. We got lucky.

Now we get this new Edel rock cam shaft ready to install and of course, the kit comes with some of this assembly lube which you wanna smear on liberally, especially here on the lobes. Now, these lobes are lubricated by splash oiling and well, during initial start up, this Molly based lube prevents scuffing between the lobes and the lifters.

Notice how Joe is using that long bolt again to install the new cam

and for a Ford guy, he's even being pretty careful not to nick those bearings while he slides it into place while Joe finishes up with that cam shaft. Let me show you the timing set that we're gonna use. It's a double roller set up from Edelbrock with a pretty neat feature here. It's got three different slots right down here on the small sprocket. And what that allows us to do is install this thing straight up

four degrees advanced or four degrees retarded. Now, the benefit of that is when you advance your cam timing, you're gonna pump up your bottom end power and torque and when you retard it, well, you're gonna move that power band further up the RPM scale. Now, since we're gonna install our straight up, all we have to do is line up the dots

on the big sprocket and the smallest sprocket.

And while Chuck installs that timing set, good timing for us to take a little break. We'll continue our power package installation though. So you continue watching.

Hey, you're back just in time. Well, I just finished installing our new timing set. But if you're doing this job on a late model small block, Chevy, well, here's a little heads up for you,

check the clearance here at the 12 o'clock position on the block behind the cam gear. Now, on some blocks, the oil galley back here actually interferes with that cam gear. So you'll have to grind the block a little bit to get the clearance you need.

Hey, good advice there, Chevy Boy.

But I got a couple more tips for you. First of all, always install a new front seal. It's pretty cheap insurance against an oil leak. And secondly, before you install this gasket that seals the timing cover to the pan. Well, snip the ends of this lip right here

and right here,

that'll make it easier to slide this thing in place over the oil pan. Now, I wanna run some of this silicone down in the groove here

before I install that gasket.

After cinching down the timing cover, we reinstall the balancer,

then the water pump,

the police,

the fan,

plus the shroud and radiator.

We can install the lifters now, but I like to prime them first by pumping oil into this bleed hole.

Then I dip it in assembly lobe,

slide it into the lifter bore

and drop in the push rod.

Now, we're ready to install the rockers. Now, since this is a pretty basic build up, we're gonna use these magnum roller tip rockers from comp cams.

Now, you can get these in a 1.6 and a 1.52 ratio like the ones we're using.

Now, these are investment castings, which means that the ratios are gonna be a little more accurate.

And the 1.5 twos that we're using, they'll give us a little more lift in the 1.5 zeros that came stock on the Chevrolet.

Hey, I like your choice of rockers, but you know, now we've got to adjust them and it's pretty easy with the intake. What

we wanna do is bring each cylinder to top dead center and you can determine that by looking at where the lifters are in their bores when they're both down and

we're ready to do some adjusting. Now, what I like to do is wiggle on the push rod while I take the slack out of the rocker

and we wanna get the zero lash. Here.

There we go. Now, we'll give it a half a turn past that

and we can move on to the next rocker.

Well, it shouldn't take those guys too long to adjust those rockers. Meanwhile, let me show you the next component of our power package.

It's an

rock performer. Eps intake manifold that matches our camshaft's power band of 0 to 5500, which is very important. Now, check out these ridges that are cast into the plenum floor. That means this intake is designed to work best with a performer carburetor

and they claim that from three 1000 to 4500, you're gonna see an average of about 5 ft pounds more torque with that intake there. And man, that's just where you need it the most. Now, we're gonna match that intake manifold with an Edelbrock 600 CFM vacuum secondary car. Now, this thing is smog legal in all 50 states for GM vehicles 1980

later, plus it has an electric choke and it's already been calibrated for emissions and economy.

The new guy does all the dirty work. Now, I just finished scraping the old gasket material off of the cylinder head. We're gonna replace those with these ultra seals from Mr gasket. Now notice the beat of silicone ran around each of the ports. They come this way straight from the factory

instead of using the rubber and gaskets that are supplied in the kit. I like to use a thick beat of silicone on each end of the block to keep the lifter valley sealed.

Now I can put the manifold into place

next coat the new bolts with silicone to prevent oil seepage and thread them hand tight,

tighten them down in a crisscross pattern

with a final torque of 25 ft pounds.

Well, now we can go ahead and drop on our carburetor and plummet. But first, I want to show you something Edelbrock makes this really cool fuel line with a built in filter. Now, what's really neat about this thing is, has a reusable metal disk. It'll trap particles down to 40 microns.

Now, we can reconnect the throttle linkage

and wire the electric choke.

We're gonna reconnect the hoses and both the brackets back up. So why don't you stay put? We'll finish up our work on the wagon and fire it up after this.

Well, time for the finishing touches of our power package installation on Chuck's red wagon here and now we can reinstall the distributor first though, of course, we gotta bring the number one cylinder to top dead center. First thing to do is remove the number one plug,

stick a finger in the hole while you have a buddy bump the starter

until it comes up on the compression stroke

and the timing marks on the balance are lined up.

Denmark.

The location of the number one plug wire on the distributor body

slide the distributor into place. So the rotor points to the mark on the body.

Then after installing the cap, we can route the wires according to the firing order. Oh If it's your first time, I wanna mark these with a piece of tape to avoid any confusion. Well, there's no confusion about wanting to have an engine that looks as good as it runs. So we're gonna go ahead and dress ours up with these chrome valve covers and air cleaner from Edelbrock.

Now, our engine has an air conditioner on it and a bunch of extra brackets. So we need to have these low valve covers. But if you've got a set of roller rockers or even a stud girdle, well, they're also available in a tall version.

Oh, man, this stuff's gonna look good on here. It's amazing what a little chrome can do for a motor. Yeah, if I didn't know better, I wouldn't even think this was the same engine.

But you know what? I think I got this last plug wire on here.

We're ready to fire this thing up. All right, Mike. Go for it.

Hey, sounds pretty good. Huh. Go ahead and kill it, Mike.

We're gonna go ahead and adjust our eye left to at least 1500 RPM. And we're gonna let the engine run at that speed for about 15 minutes. Give that cam plenty of time to break in.

And while we're doing that, we're gonna be checking for any fuel or fluid leaks and everything turns out fine. Well, then we can go ahead and adjust our carb and set our timing.

All right, Mike hit it

once the camshaft is broken in disconnect the vacuum line to the distributor

and connect the timing light lead to the number one plug wire

with the engine running, rotate the distributor until the timing marks line up to factory specs.

We set our at eight degrees advanced.

The settings on these

rock carbs are pretty close right out of the box, but we're going to fine tune our idle adjustments just to make sure.

Now we've already backed the idle speed back to 700 RPM on the engine. So we can adjust these idle mixture screws, turning them clockwise, leans it out counterclockwise, fattens it up,

start by turning the screw clockwise until the motor starts to stumble.

Then back it out to obtain the highest RPM and repeat on the other screw.

Now, you may have to repeat that procedure several times to get the mixture right. But it's no big deal a project like this. Well, you can plan on spending the better part of the weekend to get it done.

Plus you can count on dropping about $400 for the valve train upgrade another 4.5 for the intake and carb. Now, don't you go away? We got more horsepower TV coming at you.

Thanks to technology. The wheels and tires you run on are safer and better performing than ever.

But if you put them through the paces, proper balance is more critical than ever as well.

Di

teaches automotive technology at

Wyotech

and he took me to school on how this DFC 9700 balancer does its measuring magic.

Back in the olden days, we had to set measurements for the rim

um

using a caliper much like this.

This machine actually eliminates the need for it.

Now, all you do is bring down these two sensing arms, set them in the place and touch the pedal one time. And if you look at the screen, it actually brings up our measurements and has them locked in the memory

at this point,

we have some decisions to make whether we want to do a static balance of dynamic balance

or a dynamic balance with road force. At this point, we've chosen road force and all we have to do is bring down the hood,

the machine will do the rest.

The machine is telling us that we're three quarters of an ounce of weight out on the inside rim. And we need to add one and three quarters ounces to the outside of the rim.

So all we do to get that thing to index for us is we press the start button

and it brings us right to where we need the place to wait.

Next, we take our weight

there.

Now, we've got a wheel and tire combination and we're pretty sure we got a bent rim. Right. Oh, yeah, we got some kind of damage there and this machine will actually tell us if it's the tire or the rim. Ok. Let's do it.

Now, it's asking us to bring in the data arms so we can measure the rim run out.

So we bring those into place and we press the start button

and at this time, it's suggesting rim replacement.

That's a neat feature. But is there anything to say won't do?

Yeah, it won't break the tire assembly down

and that's my job. That's your job. Thanks pal.

You're quite welcome.

Fuel delivery technology. Sure changed a lot over the years since the mechanical pump did the job on cars like this wagon here

today, electric is the only way to go, especially in high performance racing applications.

Well, now this BG 220 series pump for Barry Grant is designed to flow over 220 gallons an hour while drawing only eight amps at 13.6 volts. Now, it comes with this separate return style regulator that sends unwanted fuel back to the cell so that the pump can operate at cooler temperatures. Price is pretty cool too. It, just over 200 bucks.

Here's a way to improve the power in your stock to mildly modified. 64 to 87 Chevy Small block hooker has these universal shorty headers that'll take the place of your stock manifolds. Now, they're made from 16 gauge and 58 steel tubing

with a three inch collector. They come with all your gaskets and hardware you need to install them and the price is pretty fair starting at 100 and 45 for the baked on black paint

and 325 for this. Nice

he

finish.

Hey, there's nothing cool about a coating on your car's glass, especially after you've used the cleaner on it.

Well, here's a product we found called Invisible Glass that cleans windshields, windows and mirrors with a non streaking formula that evaporates completely. Now, it uses no foams or soaps that can leave a residue and well, when you're done, you might think your windshield is. Well, just like the name says, Invisible.

Well, that's about it for hot parts. Make sure you join us next week for more horsepower TV.