Detroit Muscle Featured Projects

Detroit Muscle Builds

Want more content like this?

Join the PowerNation Email NewsletterEpisode Transcript

[ Tommy ] You're watching Powernation.

[ Tommy ] Today on Detroit Muscle Project Starstruck steps back into the batter's box but it's not looking good for this old muscle car. [ Music ] [ engines revving ] [ Music ] [ Tommy ] Hey guys, welcome to Detroit Muscle. Today we've got projects in the shop for days. Yeah, I know these two aren't nowhere near close to being finished and we're about to start a new one. You know how our gearheads are. You could call us a bit ambitious. This next ride has a name plate on it that some argue started the whole muscle car craze. [ Peyton ] If you're into 500 horses of late model e-f-i power what we've got coming up next is right up your alley. Then we'll take you through some tips and tricks to get you running through the gears. [ Tommy ] Let me give you a little bit of an update on our '66 Nova. I've got some good news and some bad. We've made a little bit of progress. Out back we found that someone had attempted to hide some sins with body filler on the rear frame rails, which is never good. After throwing a bunch of sparks it was time to slide in some new parts to set us up for a solid foundation. We knew that this old car had had some work done on it. Some of it turned out pretty nice and then others not so much. Finding all that dough in the frame rail, whenever we were installing that front suspension I noticed some filler up here. That had me a little worried and curious. So I grabbed a grinder, dove in, and turns out all bad news. There is rust and more rust, and patches on patches. The firewall is a lot like an old quilt. Just made from scraps. If you look in here the inner structure has holes and looks crunchy, not good. The worst thing about all of this is the time that it takes to make the repair. A '66, '67 Nova is on my bucket list to build, and this one is gonna take a lot of effort. I'm not saying it can't be fixed. I'm just saying it's fighting us the entire way. We really wanted to keep moving on this but have struck out. We need parts. Some are ordered and on the way, and others are on back order with no e-t-a. You can say this thing is going to the corner. [ ] Strike three, you're out! [ Tommy ] Let me introduce you guys to the newest addition to the family, a '69 Pontiac GTO. You might be thinking that it's a little rough with the front end missing off of it but don't worry. We have most of those parts, and I'm here to tell you this back piece is pretty nice. Let me show you what we're working with. [ Music ]

The exterior is the factory color, expresso brown with the painted black top. Yes, that was an option. This old car has lived a sheltered life. The body isn't all beat up. The trim is in nice shape, and when it comes to rust there really isn't any. When we picked this thing up it came with quite a bit of documentation, which is pretty cool. It's got the factory owner's manual, quite a few receipts of work that's been performed on it, and more so the window sticker. I really enjoy looking at these because it tells you every option that it came with. We mentioned to you guys about that brown and black paint scheme. That actually costs you on here $40.02. Also skimming through here we've got a rear speaker. That's about $15 dollars, and power steering. We often times think of everything you buy today has got power steering on it. Back then it cost $105 dollars. Back then in 1969 a loaf of bread cost you $0.23 cents. You do that math that's about 400-plus loaves of bread. That's a lot of bread. One of the things that made me really want this car is the condition of the upholstery. You can look through this thing and it will tell you how the car was taken care of. Now the instrument cluster looks amazing. Just check out the knobs. That chrome is extremely bright. We do have a crack or two over here on the dash pad but that's not bad for a car of this age. When it comes to the seats the only problem that I really know is back here on the back there's a thread that's turned loose. Our carpet, it has the factory carpet in it. It is a little bit sun faded but that's to be expected if you know what I mean. We are gonna do a couple of upgrades in here as we normally do. One other thing that I noticed. After we get this thing running we're definitely gonna have to service it. It's well overdue. 11/28 of '06. [ Music ] Does hearing LS swap make your ears perk up? Then you're gonna like what we've got up next.

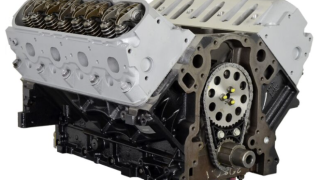

[ Tommy ] Welcome back to Detroit Muscle. I am very excited to get started on this old GTO. Problem is we're gonna have to hold off for just a few but I have some good news. We've got 500 horses heading your way. We've got several components stretched out here on the table, and today feels somewhat like Christmas. Just look at all this shiny stuff. You want to see the centerpiece to it all? This is our 5.3-liter LS from ATK High Performance Engines, and it's pumping out north of 500 horsepower. [ Peyton ] What should get you excited about an LS? Same thing that does me. They were reliable, they make plenty of power, and they won't break the bank. [ Tommy ] Some folks aren't a fan of the LS engines, and you'll hear the argument that it just seems like they don't have the soul that those old engines have. I don't want to get into that big, long debate. However I will say this. The description and benefits of this engine is almost the exact same words if you were to describe the small block Chevy way back when. [ Peyton ] Well I'm gonna get wrenching on our motor starting with our oil pan and timing cover, but first we need to rotate it over and take a look at the bottom side. [ Music ] I'm gonna kick this build off with a timing cover that we found at Summit Racing. [ Tommy ] If you have a crate engine for your project this is one of the common parts that you're gonna need to come up with. Summit offers parts like this to make your upgrade go smoothly. Going this route you don't have to worry about trying to remove old parts from a donor engine that are dirty, crusty, or even worn. We're also using a bolt kit from ARP to dress things up. Once everything is aligned we can cinch it down. [ Music ] [ Peyton ] Now that we've got our timing cover zipped up we can move on over to the oil pan. When deciding to do an LS swap an important thing to think about is your oil pan. A lot of your factory oil pans are a front sump. That doesn't work for our project. So the guys over at Holley sent us this rear sump that's designed specifically for your GM muscle cars. [ Tommy ] Oil starvation is a scary thought. Installing this component helps to eliminate oil slosh during heavy braking and hard accelerations, which is definitely a couple of things we're planning to do. You guys know how we are. [ Peyton ] Now that we've got our oil pan assembled we can put our pickup tube in, but I have a feeling that there might be some clearance issues with our windage tray. Shouldn't be a problem. We'll just pull it out, give it a little nip and tuck, and we'll be right as rain. The reason for cutting the tray is that the front corner actually interferes with the pickup tube sitting all the way down in the hole in the block. The instructions from Holley actually have a template that you can lay on your windage tray and cut out exactly how much you need to. [ Music ]

With the tray trimmed up the oil pan is ready to be installed, bolted, and torqued to 18-foot pounds. [ Music ]

[ Music ]

[ Music ] This FiTech kit comes with all the goodies, LS-3 style coil packs, direct injection manifold, and 102-millimeter throttle body to breath life into this 5.3. [ Tommy ] This setup is great for the home builder or the professional that wants the performance and reliability of fuel injection. The kit comes with everything you'll need for your induction system and is designed to get you cruising with ease. Plus the install is straightforward. [ ratchet clicking ] [ Music ] [ Tommy ] Next we jumped on the belt drive. [ Music ] If you've opted for the black components like we have there's a little step that you should do to help make sure everything goes smoothly. What I'm referring to is all your contact points of where it's gonna touch that accessory bracket make sure that it's raw aluminum. If it's got the powder coat on like this one does it won't make correct contact. Therefore the electronic side really won't work. All you've got to do is use one of these buffer wheels, skin it back, and you're ready to move forward. [ Music ] [ grinder buzzing ] [ Music ] [ Tommy ] The LS engines oftentimes get a bad wrap for not being a pretty engine. I don't know about you but this one isn't hard to look at. The black and silver here and there gives it quite a menacing appearance. I'd be proud to pop the hood of my ride to show off this jewel. [ Music ] [ Peyton ] GTO, GTX, one of those two is coming up next.

[ Peyton ] Before we jump into work on our GTO let's take a little look at the Plymouth GTX. [ Tommy ] In the mid to late '60s your choices for muscle car performance were virtually endless. Pontiac had engineered the concept of a total muscle car package with the GTO back in '64 and now Plymouth wanted a piece of the action. So for '67 they came out with a car built to be raced right off the showroom floor with a wink and a nod to its inspiration. They called it the GTX. [ Peyton ] Before the GTX if you walked into a Plymouth dealer you could get a muscle car. You just had to know what options to pick out. The GTX removed all the guess work. To boost interest Richard Petty had already began racing one on the circuits, breaking records and picking up 27 trophies along the way. [ Tommy ] Plymouth started with its popular Belvedere model and gave it a race car look by adding hood scoops, dual tail pipes, and a pit stop style gas cap. Inside you got bucket seats and a beefy torque-flite transmission. A heavy duty suspension was added combining stiffened shocks and six leaf rear springs so it could handle tight turns with ease. To top it all off they dropped in a brand new Super Commando engine with 440 cubes of raw power churning out 375 horses. This car was instantly transformed into a road rocket. [ Peyton ] Mopar had used a similar 440 in its big cars like the Chrysler Imperial, but they made a few changes to up the power and torque. By revising the cam shaft and valvetrain and adding free flow intake and exhaust they were able to coax 100 more horsepower out of it. The GTX only weighed in around 3,500 pounds, meaning it got one horsepower for every nine pounds. No wonder it's so fast! [ Tommy ] The GTX only had one other engine option available, the Hemi, but it would cost you an extra $564 bucks. When you compare the zero to 60 times the 440 was actually faster with seven seconds versus the Hemi's 7.4. This was because the 440 reached its peak torque at 3,200 r-p-m while the Hemi took 4,000 r-p-m. The Hemi did outrun the 440 on the quarter mile though, 15 seconds to the 440's 15.4. [ Peyton ] In '67 all Belvederes, including the GTX, received some minor styling changes. The front grille now featured two dual headlights and a more prominent center horizontal bar. GTXs though featured a red, white, and blue emblem in the center. Both cars had a redesigned lower deck panel with more fluid horizontal sweep and featured a brushed metal center section. [ Tommy ] This GTX is tricked out with some cool factory options as well like the bullet style turn signals on top of the front fenders, outfitted with an embossed vinyl upholstery, and the optional factory tach. [ Peyton ] Despite its racing pedigree Plymouth only managed to move 12,500 GTXs in '67. Just had a hard time competing against more established names out there in the muscle car field. Style was probably also a factor. GM and Ford were adding more curves to their cars, which customers loved while Plymouth stuck with the same straight body lines and angular styling. But this uniqueness combined with low production numbers are what make it a highly sought after car today. Good luck trying to get your hands on this one. [ Music ] Up next, we'll help you get on the last piece you'll need to start dumping the clutch. [ Tommy ] Maybe your just too stubborn to ask for it.

[ Tommy ] Hey guys, welcome back to Detroit Muscle. We've got our 5-3 500-horsepower power plant that we got from ATK up here on the work bench. If you remember back we bolted on quite a few performance goodies like this FiTech fuel injection unit. We've made several different procedures trying to tie this American Powertrain TKX back here to the back side of the block. With this final step we're gonna set the proper air gap between your clutch release bearing and the fingers here on your pressure plate. You don't want it pushing against or touching the fingers of the pressure plate and too far out is bad as well. If you have one of these setups and you've got the car. Whenever you crank it up and try to put it in gear it grinds or doesn't shift properly there's a chance that your tolerance is off. You're gonna have to make two measurements. To do this I like to use a combination square with a caliper. The first thing that we're gonna measure is the distance from your mating surface on your bell housing to the finger of your pressure plate. I like to use this thing because when you put it up there if you notice it keeps it nice and true. Then all you have to do is slide your little ruler in to touch one of the fingers. Now let's see what this thing measures out to be. [ Music ] We are three-zero-two. Now we need to measure from the clutch release bearing surface to where the transmission would bolt up to the bell housing. I'm gonna spray a little bit of slickem here onto this O-ring inside of there and onto this little shaft. Make it a little bit easier to go on. [ Music ]

[ Music ] Five-two-nine. That's five hundred thousandths. Basically we're looking at about a half of an inch. What we're gonna have to do is use some of these shims, space this thing out for our proper tolerance. What we're looking for is anywhere from 100 to 200 thousandths clearance. So I'm gonna use four of these little shims, and that should put us right at that sweet spot. [ Music ]

Let's remeasure that. [ Music ]

[ Music ] Looking at this, this is 283 and we're needing. That's 200. Technically we need one more. [ Music ]

290, that will give us 121 thousandths. That'll do it. Now the next thing we need to do is remove this bolt so that we can install our retainer stud. [ Music ]

Finally we're ready to install our transmission. Now to do this you can do it one of two ways. One, slide your release bearing off, put it inside of the bell housing, and then snake the transmission in here while trying to keep all that aligned, or remove the bell housing and install it first. That's what I'm gonna do since I'm working solo. [ Music ]

[ Music ] [ ratchet clicking ] [ Music ] [ Tommy ] This is probably one of those instances that you should ask for help but maybe you're just too stubborn to ask for it. [ Music ]

[ Music ] There it is! Look at that! Yes sir! [ Music ]

That's really what you want. Don't really want to fight it. If you have everything lined up it goes right into place. This was a little bit snug but that's mainly because everything's new. [ Music ]

When you're cinching these down like that you want it to pull up with no pressure on it. If you go to tighten it up and you really have to get on that ratchet you've got something misaligned. There you go guys! I know we've been tinkering on this setup for quite awhile but it's finally together. I'm pretty excited about this entire unit. It looks like it's gonna be a whole lot of fun once we put it into something. Curious, can you guess where it's going? I would tell you but you're just gonna have to come back and see us. Hope you enjoyed watching ole Detroit Muscle.

Show Full Transcript

[ Tommy ] Today on Detroit Muscle Project Starstruck steps back into the batter's box but it's not looking good for this old muscle car. [ Music ] [ engines revving ] [ Music ] [ Tommy ] Hey guys, welcome to Detroit Muscle. Today we've got projects in the shop for days. Yeah, I know these two aren't nowhere near close to being finished and we're about to start a new one. You know how our gearheads are. You could call us a bit ambitious. This next ride has a name plate on it that some argue started the whole muscle car craze. [ Peyton ] If you're into 500 horses of late model e-f-i power what we've got coming up next is right up your alley. Then we'll take you through some tips and tricks to get you running through the gears. [ Tommy ] Let me give you a little bit of an update on our '66 Nova. I've got some good news and some bad. We've made a little bit of progress. Out back we found that someone had attempted to hide some sins with body filler on the rear frame rails, which is never good. After throwing a bunch of sparks it was time to slide in some new parts to set us up for a solid foundation. We knew that this old car had had some work done on it. Some of it turned out pretty nice and then others not so much. Finding all that dough in the frame rail, whenever we were installing that front suspension I noticed some filler up here. That had me a little worried and curious. So I grabbed a grinder, dove in, and turns out all bad news. There is rust and more rust, and patches on patches. The firewall is a lot like an old quilt. Just made from scraps. If you look in here the inner structure has holes and looks crunchy, not good. The worst thing about all of this is the time that it takes to make the repair. A '66, '67 Nova is on my bucket list to build, and this one is gonna take a lot of effort. I'm not saying it can't be fixed. I'm just saying it's fighting us the entire way. We really wanted to keep moving on this but have struck out. We need parts. Some are ordered and on the way, and others are on back order with no e-t-a. You can say this thing is going to the corner. [ ] Strike three, you're out! [ Tommy ] Let me introduce you guys to the newest addition to the family, a '69 Pontiac GTO. You might be thinking that it's a little rough with the front end missing off of it but don't worry. We have most of those parts, and I'm here to tell you this back piece is pretty nice. Let me show you what we're working with. [ Music ]

The exterior is the factory color, expresso brown with the painted black top. Yes, that was an option. This old car has lived a sheltered life. The body isn't all beat up. The trim is in nice shape, and when it comes to rust there really isn't any. When we picked this thing up it came with quite a bit of documentation, which is pretty cool. It's got the factory owner's manual, quite a few receipts of work that's been performed on it, and more so the window sticker. I really enjoy looking at these because it tells you every option that it came with. We mentioned to you guys about that brown and black paint scheme. That actually costs you on here $40.02. Also skimming through here we've got a rear speaker. That's about $15 dollars, and power steering. We often times think of everything you buy today has got power steering on it. Back then it cost $105 dollars. Back then in 1969 a loaf of bread cost you $0.23 cents. You do that math that's about 400-plus loaves of bread. That's a lot of bread. One of the things that made me really want this car is the condition of the upholstery. You can look through this thing and it will tell you how the car was taken care of. Now the instrument cluster looks amazing. Just check out the knobs. That chrome is extremely bright. We do have a crack or two over here on the dash pad but that's not bad for a car of this age. When it comes to the seats the only problem that I really know is back here on the back there's a thread that's turned loose. Our carpet, it has the factory carpet in it. It is a little bit sun faded but that's to be expected if you know what I mean. We are gonna do a couple of upgrades in here as we normally do. One other thing that I noticed. After we get this thing running we're definitely gonna have to service it. It's well overdue. 11/28 of '06. [ Music ] Does hearing LS swap make your ears perk up? Then you're gonna like what we've got up next.

[ Tommy ] Welcome back to Detroit Muscle. I am very excited to get started on this old GTO. Problem is we're gonna have to hold off for just a few but I have some good news. We've got 500 horses heading your way. We've got several components stretched out here on the table, and today feels somewhat like Christmas. Just look at all this shiny stuff. You want to see the centerpiece to it all? This is our 5.3-liter LS from ATK High Performance Engines, and it's pumping out north of 500 horsepower. [ Peyton ] What should get you excited about an LS? Same thing that does me. They were reliable, they make plenty of power, and they won't break the bank. [ Tommy ] Some folks aren't a fan of the LS engines, and you'll hear the argument that it just seems like they don't have the soul that those old engines have. I don't want to get into that big, long debate. However I will say this. The description and benefits of this engine is almost the exact same words if you were to describe the small block Chevy way back when. [ Peyton ] Well I'm gonna get wrenching on our motor starting with our oil pan and timing cover, but first we need to rotate it over and take a look at the bottom side. [ Music ] I'm gonna kick this build off with a timing cover that we found at Summit Racing. [ Tommy ] If you have a crate engine for your project this is one of the common parts that you're gonna need to come up with. Summit offers parts like this to make your upgrade go smoothly. Going this route you don't have to worry about trying to remove old parts from a donor engine that are dirty, crusty, or even worn. We're also using a bolt kit from ARP to dress things up. Once everything is aligned we can cinch it down. [ Music ] [ Peyton ] Now that we've got our timing cover zipped up we can move on over to the oil pan. When deciding to do an LS swap an important thing to think about is your oil pan. A lot of your factory oil pans are a front sump. That doesn't work for our project. So the guys over at Holley sent us this rear sump that's designed specifically for your GM muscle cars. [ Tommy ] Oil starvation is a scary thought. Installing this component helps to eliminate oil slosh during heavy braking and hard accelerations, which is definitely a couple of things we're planning to do. You guys know how we are. [ Peyton ] Now that we've got our oil pan assembled we can put our pickup tube in, but I have a feeling that there might be some clearance issues with our windage tray. Shouldn't be a problem. We'll just pull it out, give it a little nip and tuck, and we'll be right as rain. The reason for cutting the tray is that the front corner actually interferes with the pickup tube sitting all the way down in the hole in the block. The instructions from Holley actually have a template that you can lay on your windage tray and cut out exactly how much you need to. [ Music ]

With the tray trimmed up the oil pan is ready to be installed, bolted, and torqued to 18-foot pounds. [ Music ]

[ Music ]

[ Music ] This FiTech kit comes with all the goodies, LS-3 style coil packs, direct injection manifold, and 102-millimeter throttle body to breath life into this 5.3. [ Tommy ] This setup is great for the home builder or the professional that wants the performance and reliability of fuel injection. The kit comes with everything you'll need for your induction system and is designed to get you cruising with ease. Plus the install is straightforward. [ ratchet clicking ] [ Music ] [ Tommy ] Next we jumped on the belt drive. [ Music ] If you've opted for the black components like we have there's a little step that you should do to help make sure everything goes smoothly. What I'm referring to is all your contact points of where it's gonna touch that accessory bracket make sure that it's raw aluminum. If it's got the powder coat on like this one does it won't make correct contact. Therefore the electronic side really won't work. All you've got to do is use one of these buffer wheels, skin it back, and you're ready to move forward. [ Music ] [ grinder buzzing ] [ Music ] [ Tommy ] The LS engines oftentimes get a bad wrap for not being a pretty engine. I don't know about you but this one isn't hard to look at. The black and silver here and there gives it quite a menacing appearance. I'd be proud to pop the hood of my ride to show off this jewel. [ Music ] [ Peyton ] GTO, GTX, one of those two is coming up next.

[ Peyton ] Before we jump into work on our GTO let's take a little look at the Plymouth GTX. [ Tommy ] In the mid to late '60s your choices for muscle car performance were virtually endless. Pontiac had engineered the concept of a total muscle car package with the GTO back in '64 and now Plymouth wanted a piece of the action. So for '67 they came out with a car built to be raced right off the showroom floor with a wink and a nod to its inspiration. They called it the GTX. [ Peyton ] Before the GTX if you walked into a Plymouth dealer you could get a muscle car. You just had to know what options to pick out. The GTX removed all the guess work. To boost interest Richard Petty had already began racing one on the circuits, breaking records and picking up 27 trophies along the way. [ Tommy ] Plymouth started with its popular Belvedere model and gave it a race car look by adding hood scoops, dual tail pipes, and a pit stop style gas cap. Inside you got bucket seats and a beefy torque-flite transmission. A heavy duty suspension was added combining stiffened shocks and six leaf rear springs so it could handle tight turns with ease. To top it all off they dropped in a brand new Super Commando engine with 440 cubes of raw power churning out 375 horses. This car was instantly transformed into a road rocket. [ Peyton ] Mopar had used a similar 440 in its big cars like the Chrysler Imperial, but they made a few changes to up the power and torque. By revising the cam shaft and valvetrain and adding free flow intake and exhaust they were able to coax 100 more horsepower out of it. The GTX only weighed in around 3,500 pounds, meaning it got one horsepower for every nine pounds. No wonder it's so fast! [ Tommy ] The GTX only had one other engine option available, the Hemi, but it would cost you an extra $564 bucks. When you compare the zero to 60 times the 440 was actually faster with seven seconds versus the Hemi's 7.4. This was because the 440 reached its peak torque at 3,200 r-p-m while the Hemi took 4,000 r-p-m. The Hemi did outrun the 440 on the quarter mile though, 15 seconds to the 440's 15.4. [ Peyton ] In '67 all Belvederes, including the GTX, received some minor styling changes. The front grille now featured two dual headlights and a more prominent center horizontal bar. GTXs though featured a red, white, and blue emblem in the center. Both cars had a redesigned lower deck panel with more fluid horizontal sweep and featured a brushed metal center section. [ Tommy ] This GTX is tricked out with some cool factory options as well like the bullet style turn signals on top of the front fenders, outfitted with an embossed vinyl upholstery, and the optional factory tach. [ Peyton ] Despite its racing pedigree Plymouth only managed to move 12,500 GTXs in '67. Just had a hard time competing against more established names out there in the muscle car field. Style was probably also a factor. GM and Ford were adding more curves to their cars, which customers loved while Plymouth stuck with the same straight body lines and angular styling. But this uniqueness combined with low production numbers are what make it a highly sought after car today. Good luck trying to get your hands on this one. [ Music ] Up next, we'll help you get on the last piece you'll need to start dumping the clutch. [ Tommy ] Maybe your just too stubborn to ask for it.

[ Tommy ] Hey guys, welcome back to Detroit Muscle. We've got our 5-3 500-horsepower power plant that we got from ATK up here on the work bench. If you remember back we bolted on quite a few performance goodies like this FiTech fuel injection unit. We've made several different procedures trying to tie this American Powertrain TKX back here to the back side of the block. With this final step we're gonna set the proper air gap between your clutch release bearing and the fingers here on your pressure plate. You don't want it pushing against or touching the fingers of the pressure plate and too far out is bad as well. If you have one of these setups and you've got the car. Whenever you crank it up and try to put it in gear it grinds or doesn't shift properly there's a chance that your tolerance is off. You're gonna have to make two measurements. To do this I like to use a combination square with a caliper. The first thing that we're gonna measure is the distance from your mating surface on your bell housing to the finger of your pressure plate. I like to use this thing because when you put it up there if you notice it keeps it nice and true. Then all you have to do is slide your little ruler in to touch one of the fingers. Now let's see what this thing measures out to be. [ Music ] We are three-zero-two. Now we need to measure from the clutch release bearing surface to where the transmission would bolt up to the bell housing. I'm gonna spray a little bit of slickem here onto this O-ring inside of there and onto this little shaft. Make it a little bit easier to go on. [ Music ]

[ Music ] Five-two-nine. That's five hundred thousandths. Basically we're looking at about a half of an inch. What we're gonna have to do is use some of these shims, space this thing out for our proper tolerance. What we're looking for is anywhere from 100 to 200 thousandths clearance. So I'm gonna use four of these little shims, and that should put us right at that sweet spot. [ Music ]

Let's remeasure that. [ Music ]

[ Music ] Looking at this, this is 283 and we're needing. That's 200. Technically we need one more. [ Music ]

290, that will give us 121 thousandths. That'll do it. Now the next thing we need to do is remove this bolt so that we can install our retainer stud. [ Music ]

Finally we're ready to install our transmission. Now to do this you can do it one of two ways. One, slide your release bearing off, put it inside of the bell housing, and then snake the transmission in here while trying to keep all that aligned, or remove the bell housing and install it first. That's what I'm gonna do since I'm working solo. [ Music ]

[ Music ] [ ratchet clicking ] [ Music ] [ Tommy ] This is probably one of those instances that you should ask for help but maybe you're just too stubborn to ask for it. [ Music ]

[ Music ] There it is! Look at that! Yes sir! [ Music ]

That's really what you want. Don't really want to fight it. If you have everything lined up it goes right into place. This was a little bit snug but that's mainly because everything's new. [ Music ]

When you're cinching these down like that you want it to pull up with no pressure on it. If you go to tighten it up and you really have to get on that ratchet you've got something misaligned. There you go guys! I know we've been tinkering on this setup for quite awhile but it's finally together. I'm pretty excited about this entire unit. It looks like it's gonna be a whole lot of fun once we put it into something. Curious, can you guess where it's going? I would tell you but you're just gonna have to come back and see us. Hope you enjoyed watching ole Detroit Muscle.