XOR - Xtreme Off-Road Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Automotive Workwear

The Official Workwear of Xtreme Off Road

Cummins

R2.8 Turbo Diesel: The First Cummins Crate Engine

Edwards

55 TON EDWARDS IRONWORKER with Hydraulic Accessory Pack option; 10 Ton Bender, 15 Ton Horizontal press,Tubing Roller and 40 Ton Shop Press.

ESAB

The Official Welding and Cutting Supplier of Xtreme Off Road, featuring the all-new Rebel 215 Multi-Process Welder

The Industrial Depot

INDUSTRIAL DEPOT - FASTENERS, HARDWARE, AND SHOP SUPPLIES

Episode Transcript

(NARRATOR)>> DIESEL ENGINES ARE KNOWN FOR BEING DURABLE AND FUEL EFFICIENT. SO PUTTING THE CUMMINS RTWO POINT EIGHT IN OUR EXPEDITION RIG MAKES PERFECT SENSE. TODAY ON XTREME OFF ROAD WE CHECK OUT CUMMINS HQ, AND BUILD OUR OWN TURBO DIESEL FROM THE GROUND UP. PLUS WE TAKE YOU INSIDE THE FACILITIES WHERE THE FIVE LITER VEIGHT AND THE TURBOCHARGED STRAIGHT SIX ARE MADE.

(IAN)>> WE'RE IN CENTRAL INDIANA, IN A SMALL CITY CALLED COLUMBUS. NOW WE'RE NOT ON THE ROAD TO GO FOUR WHEELING THIS TIME. WE'RE HERE BECAUSE COLUMBUS IS THE HOME TO CUMMINS DIESEL ENGINES. NOW WE'RE HERE TO ACTUALLY PUT TOGETHER OUR OWN CRATE RTWO POINT EIGHT FOUR CYLINDER. IT'S GONNA END UP IN OUR LAND ROVER D-90, BUT WHILE WE'RE IN TOWN WE THOUGHT WHY NOT CHECK OUT WHAT CUMMINS IS ALL ABOUT. TODAY CUMMINS IS A PREMIERE DESIGNER AND MANUFACTURER OF DIESEL ENGINES, WITH OVER 50,000 EMPLOYEES, BUT THE STORY BEGAN ALMOST 100 YEARS AGO WHEN A YOUNG MAN NAMED CLESSIE CUMMINS KNOCKED ON THE DOOR OF WG IRWIN, A PROMINENT LOCAL BUSINESSMAN. CUMMINS WAS SEEKING A JOB AS A CHAUFFEUR BUT THERE WAS A PROBLEM. CARS STILL NEEDED TO BE STARTED BY HAND AND THAT REQUIRED A LOT OF STRENGTH. IRWIN FELT THAT CUMMINS WAS TOO SMALL FOR THE JOB. CUMMINS HAD JUST ONE QUESTION.

(DAVID)>> IF I CAN GET THE ENGINE STARTED CAN I HAVE THE JOB? MISTER IRWIN SAID SURE, YEAH, ABSOLUTELY, AND HE WENT BACK AND HE KNEW THAT IF HE PULLED THE SPARK PLUG OUT OF ONE OF THE CYLINDERS, GOT THE PISTON JUST PAST TOP DEAD CENTER, PUT GASOLINE IN THE CYLINDER, PUT THE SPARK PLUG BACK IN, THEN HE COULD GO INSIDE AND THERE WAS ACTUALLY A TIMING ADVANCE LEVER ON THE COLUMN IN THOSE DAYS, AND IF YOU PULLED IT REAL FAST IT WOULD MAKE THE SPARK PLUG GO, FIRE THAT FIRST CYLINDER, START THE ENGINE, AND SO SURE ENOUGH HE WAS ABLE TO START THAT ENGINE, GOT THE JOB, AND THAT'S HOW IT STARTED THIS RELATIONSHIP BETWEEN CLESSIE AND WG IRWIN. CLESSIE HAD THE MECHANICAL GENIUS, MISTER IRWIN HAD THE MONEY.

(IAN)>> FOUNDED IN 1919, CUMMINS INC ORIGINALLY LICENSED SINGLE CYLINDER ENGINES THAT COULD RUN ON LAMP OIL.

(DAVID)>> STARTED SELLING FOR WATER PUMPS, AND OIL DRILLS, SAW MILLS, THINGS LIKE THAT, RAN OFF A BIG BELT.

(IAN)>> THESE EARLY ENGINES ONLY PUT OUT A COUPLE OF HORSEPOWER OR SO, BUT THEY WERE VERY RELIABLE. IN FACT, CUMMINS OWNS THE FIRST ONE AND IT STILL RUNS. BY THE MID '20'S CUMMINS WAS SELLING DIESEL ENGINES OF ITS OWN DESIGN, PRIMARILY FOR USE IN YACHTS AND OTHER MARINE APPLICATIONS, BUT CUMMINS FELT THAT THE FUTURE OF DIESEL ENGINES WAS NOT IN THE WATER.

(DAVID)>> HIS LATEST ENGINE WAS A "U" ENGINE THAT HE HAD BEEN PUTTING IN SOME OF THESE LUXURY YACHTS, AND SO HE TOOK THAT "U" ENGINE, PUT IT IN A PACKARD LIMOUSINE ON CHRISTMAS DAY 1929, AND DROVE IT JUST DOWN THE STREET TO MISTER IRWIN'S HOUSE, TOOK MISTER IRWIN AND HIS FAMILY ON A RIDE SAYING HERE'S THE FUTURE OF DIESEL ENGINES ON THE ROAD, NOT IN THE WATER, BUT ON THE ROAD IN CARS AND TRUCKS.

(IAN)>> WG IRWIN WAS IMPRESSED AND CUMMINS WAS OFF AND RUNNING, DESIGNING, BUILDING, AND TESTING GROUND BREAKING DIESEL ENGINES. IN 1931 THEIR DIESEL POWERED RACE CAR COMPLETED THE INDY 500 WITHOUT STOPPING FOR FUEL EVEN ONCE. IN 1952 A TURBOCHARGED CUMMINS RACE CAR TOOK POLE POSITION WITH A QUALIFYING SPEED OF 138.01 MILES PER HOUR.

(DAVID)>> THE NUMBER 28 CAR HAD A MODEL "J" ENGINE THAT WE LAID OVER ON ITS SIDE. THEY FIGURED OUT HOW TO USE A SCAVENGER PUMP AND PUMP OIL TO THE TOP OF THE ENGINE, LAY IT ON ITS SIDE SO IT'D BE VERY LOW SLUG, VERY AERODYNAMIC, AND CUMMINS ENGINEERS DID ALL THE WORK ON THE ENGINE, DID THE DESIGN OF INSTALLING THAT. THE FIRST CAR TO HAVE A TURBOCHARGER RUN AT INDIANAPOLIS. ONE OF THE FIRST CARS TO EVER BE WIND TUNNEL TESTED THAT RAN AT INDIANAPOLIS.

(IAN)>> THESE ACHIEVEMENTS AT THE COUNTRY'S MOST WELL KNOWN AUTOMOBILE RACE PEAKED THE PUBLIC'S INTEREST IN DIESEL TECHNOLOGY, AND SERVED AS AN EFFECTIVE MARKETING TOOL. FOR ALMOST A CENTURY CUMMINS HAS MADE ENGINES FOR EVERY APPLICATION, FROM INDUSTRIAL EQUIPMENT AND TRAINS, TO COMMERCIAL AND CONSUMER TRUCKS. THE NEWEST CUMMINS ENGINE IS THE FIVE LITER VEIGHT UNDER THE HOOD OF THE NISSAN TITAN. WITH 310 HORSEPOWER AND 555 FOOT POUNDS OF TORQUE THIS HIGH TECH DIESEL IS ASSEMBLED IN THE ORIGINAL CUMMINS ENGINE PLANT WHERE THE VERY FIRST ENGINE WAS BORN. THE ONE POINT FOUR MILLION SQUARE FOOT FACILITY CAN MANUFACTURE 150,000 ENGINES PER YEAR. TAKING A BARE EIGHT CYLINDER BLOCK, DROPPING IN A HEAVY DUTY CRANK, ROTATING ASSEMBLY, ALUMINUM CYLINDER HEADS, FRONT COVER, VALVE COVERS, AND INTAKE BEFORE GOING INTO A SPIN TESTER THAT SIMULATES THE ENGINE RUNNING WITHOUT ACTUALLY FIRING IT TO VERIFY THAT EVERYTHING IS GOOD TO GO. CUMMINS EVALUATES ALL OF ITS ENGINES IN CLOSED TEST CELLS. THIS ENSURES GREAT DURABILITY, FUEL ECONOMY, COLD AND WARM WEATHER OPERATION, ALONG WITH LOW ENGINE EMISSIONS, MAKING SURE THAT EACH ENGINE DELIVERS OPTIMAL PERFORMANCE FOR A LONG TIME. AS THE LARGEST EMPLOYER IN COLUMBUS, CUMMINS HAS A MAJOR IMPACT ON THE SURROUNDING COMMUNITY. THIS COULD BE SEEN ALL AROUND DOWNTOWN. FOR A SMALL TOWN, COLUMBUS HAS LOTS OF UNIQUE ARCHITECTURE.

(STEVE)>> AND ALL THAT KIND OF STEMS FROM THE CUMMINS FOUNDATION THAT SETUP AN ORGANIZATION THAT WOULD FLOAT THE BILL FOR SIGNIFICANT WORLD RENOWNED ARCHITECTS TO COME IN AND DESIGN PUBLIC BUILDINGS, SCHOOLS, LIBRARIES, CHURCHES, ETCETERA. SO A REALLY UNIQUE PLACE.

(NARRATOR)>> UP NEXT, SIX IN A ROW AND YOU'RE READY TO GO. INSIDE THE TURBO DIESEL STRAIGHT SIX.

(IAN)>> IT'S PROBABLY ONE OF THE MOST RECOGNIZABLE CUMMINS ENGINES IN THE WORLD, WHETHER YOU CALL IT A SIXBT, 12 VALVE, OR 24 VALVE. IT IS THE STRAIGHT SIX CUMMINS DIESEL ENGINE THAT YOU FIND UNDERNEATH THE HOOD OF RAM PICK UP TRUCKS, AND IT'S BUILT RIGHT HERE IN COLUMBUS, INDIANA. WE ARE NO STRANGER TO THE CUMMINS SIXSEVEN IN THE XTREME SHOP. PROJECT BIG RIG RAM STARTED LIFE AS A TRADESMAN TRIM RAM 2,500, AND I DRIVE THAT MONSTER EVERY SINGLE DAY AND LOVE IT. SO GETTING TO SEE WHERE THAT ENGINE CAME TO LIFE IS LIKE GETTING THE GOLDEN TICKET TO THE WILLIE WONKA CHOCOLATE FACTORY. EACH ENGINE STARTS AS A RAW CASTING AS IT ENTERS THE PLANT, AND IS MACHINED IN CLOSED MACHINE CELLS TO ENSURE NO CONTAMINATION INTO THE BLOCK. THE FINAL STEP IS HONING THE CYLINDERS USING TORQUE PLATES THAT ARE COMPUTER CODED AND REGULATED TO ENSURE THE BEST POSSIBLE CYLINDER SIZE AND PATTERN. THE EMPTY BLOCK IS THEN GIVEN A LASER ETCHED ID TAG THAT IS SCANNED DURING THE ASSEMBLY PROCESS. THIS IS ALSO DONE TO EVERY SINGLE PART THAT IS INSTALLED INTO THE BLOCK TO TRACK IT DURING ASSEMBLY. THE ENGINE BUILD IS DIVIDED INTO DOZENS OF STATIONS WITH MULTIPLE WORKERS AT EACH ONE PERFORMING DIFFERENT TASKS. OVER A PERIOD OF SIX HOURS THE ENGINE WILL SPEND LESS THAN 70 SECONDS IN EACH STATION, AND BE FINAL ASSEMBLED AND READY TO SHIP. THE SIX POINT SEVEN CUMMINS PLANT CAN PUMP OUT 500 ENGINES PER DAY. ASSEMBLY IS A MIXTURE OF ROBOTS AND PEOPLE. THE PEOPLE DROP ON MAJOR COMPONENTS AND INSTALL ITEMS THAT REQUIRE EXTRA ATTENTION, LIKE THE ROTATING ASSEMBLY, PISTONS AND RODS, AND CYLINDER HEADS. ROBOTS TAKE CARE OF ALL THE TORQUE SPECS IN THE MOTOR, TIGHTENING ALL THE FASTENERS AND STRETCHING THE BOLTS. THEN TIGHTENING TO THE FINAL SPECIFICATION. SETTING VALVE LASH ON THE MOTOR IS ENTIRELY DONE BY A ROBOTIC STATION, ROTATING THE ENGINE WHILE A SECOND SET OF ROBOTIC ARMS ADJUST THE ROCKER SHAFTS, AND A FINAL ROTATION TO CHECK CLEARANCE FOR EVERYTHING. THIS PROCESS TAKES THREE MINUTES, ALMOST 10 TIMES FASTER THAN A PERSON COULD DO IT. ONCE THE ENGINE IS COMPLETELY ASSEMBLED IT HEADS INTO A PAINT BOOTH TO BE SPRAYED WITH A PROTECTIVE COATING. IT GOES ON BLUE TO ENSURE GOOD COVERAGE BUT DRIES CLEAR TO PREVENT OXIDATION OF THE IRON BLOCK AND ALUMINUM COMPONENTS. THE SIX POINT SEVEN CUMMINS HAS A TRUE CULT FOLLOWING IN THE WORLD OF DIESEL ENGINES. ALTHOUGH A STRAIGHT SIX DIESEL ENGINE WAS COMMON PLACE IN THE WORLD OF OVER THE ROAD TRUCKS, IT WAS NEW TO THE PASSENGER TRUCK GAME. WHEN CUMMINS INSTALLED THE FIRST FIVENINE INTO A RAM PICK UP FOR DODGE IT WAS A GAME CHANGER, AND PEOPLE WHO WORK AT THIS PLANT KNOW THEY ARE BUILDING AN ENGINE THAT THE OWNERS FALL IN LOVE WITH.

(STEVE)>> IT WAS A LONG TIME BEFORE WE PICKED UP OUR PARTNERSHIP WITH RAM. YOU KNOW THAT WASN'T UNTIL THE '80'S. SO WE WERE IN BUSINESS A LONG TIME BEFORE WE HAD A HIGH VISIBILITY AUTOMOTIVE OEM. IN THAT TIME BETWEEN, YOU KNOW, WE WERE A POWER GENERATION COMPANY. WE HAD LOCOMOTIVES, CONSTRUCTION EQUIPMENT, MARINE EQUIPMENT, AND ONLY DID WE BECOME A HOUSEHOLD NAME ONCE WE REALLY ENTERED INTO THE AUTOMOTIVE MARKET.

(IAN)>> THE SIXSEVEN CUMMINS PLANT IS ONE OF THE MOST REQUESTED PLANTS FROM PEOPLE WHO WANT A TOUR, AND NOT JUST BECAUSE IT'S AN ARCHITECTURAL MARVEL BURIED HALF UNDERGROUND TO CONTROL INTERNAL TEMPERATURES WITH A PARKING LOT ON THE ROOF. THEY, JUST LIKE ME, WANT TO SEE WHERE THEIR SIX POINT SEVEN ENGINE WAS BORN.

(NARRATOR)>> UP NEXT, A CRATE ENGINE PACKAGE THAT GETS YOU UP AND RUNNING FAST.

(IAN)>> NOW WE DID NOT JUST COME UP TO COLUMBUS, INDIANA, TO SEE A BUNCH OF ENGINES GET ASSEMBLED AT PLANTS. WE WANTED TO GET AN INSIDE LOOK AT OUR RTWO POINT EIGHT FOUR CYLINDER THAT'S GONNA END UP UNDERNEATH THE HOOD OF OUR LAND ROVER D-90 PROJECT. NOW ALTHOUGH THIS ENGINE IS NOT ASSEMBLED HERE IN COLUMBUS, THE CREW AT CUMMINS HOOKED US UP WITH THIS TOP SECRET ENGINE ASSEMBLY AREA, A PILE OF PARTS, AND A SHORT BLOCK SO WE COULD BUILD OUR OWN FOUR CYLINDER ENGINE. WE ARE GOING TO ASSEMBLE THIS ENGINE THE SAME WAY IT WOULD BE DONE ON THE ASSEMBLY LINE, BY INSTALLING MAJOR COMPONENTS ONTO THE SHORT BLOCK, AND I WON'T BE DOING IT ALONE. HELPING ME OUT IS BRITTANY BORELLA, AN ENGINEER AT CUMMINS.

(BRITTANY)>> I MAINLY DO PERFORMANCE AND DRIVABILITY TESTING ON PICK UP TRUCKS. SO THAT INVOLVES GOING OUT AND TIMING HOW FAST THEY ACCELERATE, HOW QUICKLY THEY SLOW DOWN, THEN JUST GENERAL DRIVABILITY.

(IAN)>> EVERY SINGLE PART TO ASSEMBLE OUR ENGINE IS LAID OUT NEATLY ON THE BENCH, FROM THE CYLINDER HEAD, CAM SHAFT, TIMING CHAIN AND GEAR, ROCKER ARMS, INJECTORS, AND COMMON RAIL FUEL SYSTEM, TO THE COMPLETE ENGINE AND VEHICLE WIRING HARNESS, THROTTLE PEDAL, AND MURPHY GAUGE TO MONITOR THE ECU. ONCE ASSEMBLED THIS WILL BE THE EXACT SAME ENGINE THAT CUMMINS REPOWER WILL SHIP DIRECTLY TO YOU FOR YOUR PROJECT.

(STEVE)>> THE TWO POINT EIGHT IS A GREAT CRATE MOTOR FOR ANY KIND OF SMALL FOUR WHEEL DRIVE TRUCK BECAUSE NUMBER ONE, IT ONLY WEIGHS AROUND 500 POUNDS. SO YOUR STOCK SUSPENSION PROBABLY WON'T EVEN NOTICE A DIFFERENCE THAT IT'S THERE. NUMBER TWO, IT'S QUIET, IT'S A COMMON RAIL ENGINE. SO WHAT WE WANTED TO DO IS REALLY GIVE THEM AN OPTION FOR SOMETHING NEW, SOMETHING RIGHT OFF THE ASSEMBLY LINE, SOMETHING THAT'S A BETTER FIT, AND A LOT EASIER TO INTEGRATE INTO THEIR PLATFORM.

(IAN)>> ALL RIGHT BRITTANY, WHERE DO WE START?

(BRITTANY)>> LET'S START WITH THE CYLINDER HEAD.

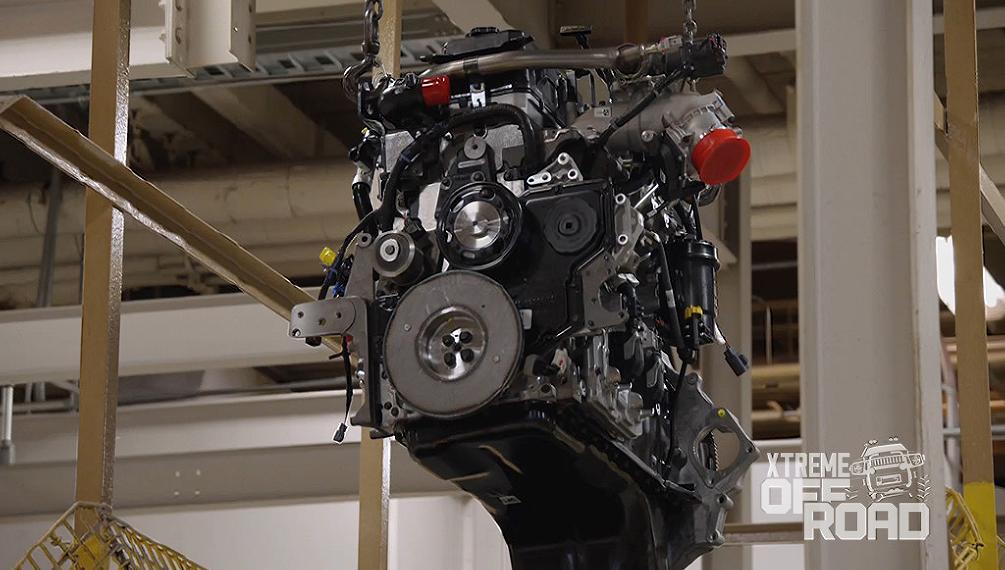

(IAN)>> SOUNDS LIKE A PLAN. THE CAST IRON HEAD IS FULLY LOADED WITH INTAKE AND EXHAUST VALVES, ALONG WITH SPRING, AND THE EXHAUST MANIFOLD, EGR COOLER, AND INTAKE MANIFOLD. BECAUSE OF THE WEIGHT OF THE HEAD, AN OVERHEAD CRANE IS USED TO LOWER IT ONTO THE BLOCK, AND AFTER LUBING THE THREADS ON THE HEAD BOLTS THEY ARE TORQUED TO SPEC. WITH A COMPRESSION RATIO OF 16.9 TO ONE, THE RTWO POINT EIGHT HAS SOME SERIOUS HEAD BOLT TORQUE TO CONTAIN THE PRESSURES OF A MODERN DIRECT INJECTED COMMON RAIL DIESEL.

(BRITTANY)>> DIESEL ENGINES ARE BUILT TO WITHSTAND HIGHER COMPRESSION RATIOS. SO THE ENTIRE ENGINE IS JUST BUILT MORE DURABLE FROM THE GET GO. CUMMINS REALLY PRIDES ITSELF ON DURABILITY. SO ALL OF OUR MANUFACTURING, AND ALL OF OUR PART SOURCING, AND ALL OF OUR DESIGN IS ALL REALLY BASED ON DURABILITY.

(IAN)>> THE INJECTION PUMP BOLTS ONTO THE BACK OF THE BLOCK. BECAUSE THIS ENGINE IS A COMMON RAIL DIESEL AND INJECTION IS CONTROLLED BY THE COMPUTER, THE PUMP DOES NOT NEED TO BE TIMED LIKE OLDER DIESELS. OKAY READY?

(BRITTANY)>> READY.

(IAN)>> COMING AT YOU.

THE ENGINE IS THEN ROTATED IN PREPARATION FOR? WHAT'S NEXT?

(BRITTANY)>> FRONT COVER.

(IAN)>> I LIKE HOW SHE WENT, FRONT COVER!

ON AN ASSEMBLY LINE ROBOTS TAKE CARE OF TORQUEING ALL THE FASTENERS, BUT WHEN ASSEMBLING AN ENGINE BY HAND YOU HAVE TO USE A TORQUE WRENCH, AND WHEN YOU'RE WORKING IN THE CUMMINS TOP SECRET ENGINE FACILITY EVERYTHING GETS TORQUED, REAR COVER, FLYWHEEL, DAMPENER BOLTS, EVERY SINGLE FASTENER. THE CAM SHAFT IS THEN INSTALLED AND THE VALVE BRIDGES THAT ALLOW BOTH THE INTAKE AND EXHAUST VALVES TO OPERATE BY A SINGLE ROCKER ARM. [ phone ringing ] IS THAT YOUR PHONE?

(BRITTANY)>> NOPE.

(IAN)>> GOOD JOB. HELLO, THANK YOU FOR CALLING CUMMINS TOP SECRET ENGINE FACILITY. AND NOW WE HAVE A LONG BLOCK. [ drill spinning ]

(IAN)>> WE ARE IN COLUMBUS, INDIANA, HOME OF CUMMINS ENGINES, PUTTING TOGETHER OUR OWN RTWO POINT EIGHT FOUR CYLINDER FOR OUR D-90 PROJECT. THE ENGINE IS THE FIRST IN A SERIES OF ENGINES THAT ARE PART OF A NEW CUMMINS CRATE ENGINE PROGRAM CALLED CUMMINS REPOWER.

(BRITTANY)>> I THINK IT'S A REALLY GOOD OPPORTUNITY FOR US AND PEOPLE ARE REALLY EXCITED ABOUT IT. WE'RE REALLY GOOD AT SELLING ENGINES THROUGH OEM'S AND THIS IS OUR FIRST CHANCE AT SELLING DIRECT TO THE CONSUMER. PEOPLE ARE REALLY EXCITED TO BE ABLE TO GET ENGINES STRAIGHT FROM US THAT ARE PACKAGE READY TO DROP IN YOUR VEHICLE AND START. RATHER THAN HAVING TO PULL ENGINES OUT OF BREAD TRUCKS OR FIND THEM IN JUNKYARDS AND TRY TO MAKE THEM WORK YOURSELF.

(IAN)>> SO FAR BRITTANY AND I HAVE ASSEMBLED A COMPLETE LONG BLOCK, AND NOW IT'S TIME TO DROP ON THE VALVE COVER, HIGH PRESSURE INJECTORS, FUEL RAIL, AND PIPING TO THE INJECTORS. THE ENGINE IS THEN FLIPPED OVER FOR THE OIL PAN TO BE INSTALLED WITH THE SUMP AT THE REAR FOR CLEARANCE ON OUR FRONT AXLE, AND FINALLY THE COMPLETE ENGINE WIRING HARNESS TO CONTROL THIS FOUR CYLINDER DIESEL ONCE UNDER THE HOOD. CONSIDERING THAT THE RTWO POINT EIGHT CRATE ENGINE IS RIGHT AROUND 500 POUNDS WITH OVER 260 POUND FEET OF TORQUE, IT IS A PERFECT ENGINE FOR ANY OFF ROAD RIG.

(STEVE)>> IF YOU OVERLAY THE TORQUE CURVE OF YOUR FACTORY GAS ENGINE VERSUS WHAT WE'RE OFFERING AS A DIESEL, ODDS ARE YOU'RE GONNA BE HAPPIER OFF ROAD AND ON ROAD WITH THE LOWER TORQUE CURVE THAT A DIESEL OFFERS. YOU AREN'T DOWNSHIFTING TO CLIMB GRADES. YOU CAN KINDA IDLE OVER THINGS. IT'S REALLY A DIFFERENT EXPERIENCE THAN A GAS ENGINE.

(BRITTANY)>> I THINK IT'S REALLY FUN TO DRIVE. IT GETS GREAT FUEL ECONOMY. THERE'S GREAT LOW END TORQUE, AND IT'S JUST KIND OF A LITTLE PEPPY ENGINE THAT'S DIFFERENT THAN WHAT'S OUT ON THE MARKET. SO IT'S DIFFERENT AND FUN TO DRIVE.

(IAN)>> BEFORE WE HIT THE ROAD, THERE'S ONE MORE THING THAT WE NEED TO DO. WITH THE ENGINE ON A PALLET, WE MOVED IT CLOSER TO ONE OF THE SHOP DOORS, HOOKED UP SOME FUEL LINES, A COUPLE OF WIRES, AND IT'S TIME TO FIRE THIS ENGINE UP. [ engine cranking ] [ engine firing and idling ]

(IAN)>> OHH! GIVE ME SOME DOOWAH VALVE.

[ engine revving ]

(IAN)>> OH HOO HOO!

THAT'S PRETTY AWESOME! OH THAT'S BEAUTIFUL! ALL RIGHT, PULL THAT WIRE OFF.

(BRITTANY)>> WOO HOO!

(IAN)>> LET'S LOAD IT ON A PALLET, OR NO, IT'S ALREADY ON A PALLET. LET'S PUT IT IN THE TRUCK.

WE'VE SHOWN YOU A TON OF DIESEL ENGINES, AND WE'D LIKE TO TAKE A CLOSER LOOK AT CUMMINS MODELC, BUILT CIRCA 1920.

(STEVEN)>> I'VE GOT TO DO SOME FUEL LIFTING TO MAKE SURE THAT I'VE GOT FUEL UP HERE READY TO GO. BASICALLY GRAVITY DOES THE WORK, AND THIS IS NOT A TRUE DIESEL ENGINE. THIS HVID FUEL SYSTEM, HVID, AND ON THE INTAKE STROKE IT SUCKS IN DIESEL INTO THE CUP OF THE INJECTOR, AND THEN AS IT COMPRESSES IT ACTUALLY IGNITES A LITTLE BIT IN THE INJECTOR FIRST. THEN SHOOTS OUT THE REST OF THE FUEL INTO THE POWER CYLINDER AND DOES THE REST OF THE COMPRESSION IGNITION THERE. SO THE INJECTOR'S NOT FORCING THE FUEL IN LIKE IT DOES TODAY. IT KIND OF PREIGNITES IT AND USES THE ACTUAL IGNITION OF THE DIESEL TO FORCE THE DIESEL INTO THE REST OF THE FUEL SYSTEM. THERE'S NOT A LOT OF STUFF GOING ON INSIDE THE INJECTOR. IT'S ALL ABOUT METERING THE FUEL AND THEN LETTING THE ENGINE DO THE REST OF THE WORK. THIS ONE WAS IN OHIO, AND IT DID A PUMP JACK FOR AN OIL RIG. SO IT JUST RAN IT OFF OF THAT BELT FOR DECADES. A LOT OF THEM WERE WATER PUMPS FOR FARMERS. LOW SPEED, KINDA LOW HORSEPOWER. THIS GIANT THING, SINGLE CYLINDER, PUTS OUT SIX HORSEPOWER AT ITS MAXIMUM RATING. I'VE GOT TO CRANK IT UP TO SPEED, AND SO I'VE OPENED UP THE COMPRESSION RELEASE. SO IT'S NOT GONNA BUILD ANY COMPRESSION. I'M GONNA CRANK IT UP TO SPEED, FLIP IT OVER, AND HOPEFULLY SHE'LL GET GOING.

[ engine sputtering ] [ engine fires up and idling ]

(IAN)>> THIS MODELC IS AN ALMOST CENTURY OLD PIECE OF DIESEL HISTORY, AND IT'S STILL RUNNING STRONG!

Show Full Transcript

(IAN)>> WE'RE IN CENTRAL INDIANA, IN A SMALL CITY CALLED COLUMBUS. NOW WE'RE NOT ON THE ROAD TO GO FOUR WHEELING THIS TIME. WE'RE HERE BECAUSE COLUMBUS IS THE HOME TO CUMMINS DIESEL ENGINES. NOW WE'RE HERE TO ACTUALLY PUT TOGETHER OUR OWN CRATE RTWO POINT EIGHT FOUR CYLINDER. IT'S GONNA END UP IN OUR LAND ROVER D-90, BUT WHILE WE'RE IN TOWN WE THOUGHT WHY NOT CHECK OUT WHAT CUMMINS IS ALL ABOUT. TODAY CUMMINS IS A PREMIERE DESIGNER AND MANUFACTURER OF DIESEL ENGINES, WITH OVER 50,000 EMPLOYEES, BUT THE STORY BEGAN ALMOST 100 YEARS AGO WHEN A YOUNG MAN NAMED CLESSIE CUMMINS KNOCKED ON THE DOOR OF WG IRWIN, A PROMINENT LOCAL BUSINESSMAN. CUMMINS WAS SEEKING A JOB AS A CHAUFFEUR BUT THERE WAS A PROBLEM. CARS STILL NEEDED TO BE STARTED BY HAND AND THAT REQUIRED A LOT OF STRENGTH. IRWIN FELT THAT CUMMINS WAS TOO SMALL FOR THE JOB. CUMMINS HAD JUST ONE QUESTION.

(DAVID)>> IF I CAN GET THE ENGINE STARTED CAN I HAVE THE JOB? MISTER IRWIN SAID SURE, YEAH, ABSOLUTELY, AND HE WENT BACK AND HE KNEW THAT IF HE PULLED THE SPARK PLUG OUT OF ONE OF THE CYLINDERS, GOT THE PISTON JUST PAST TOP DEAD CENTER, PUT GASOLINE IN THE CYLINDER, PUT THE SPARK PLUG BACK IN, THEN HE COULD GO INSIDE AND THERE WAS ACTUALLY A TIMING ADVANCE LEVER ON THE COLUMN IN THOSE DAYS, AND IF YOU PULLED IT REAL FAST IT WOULD MAKE THE SPARK PLUG GO, FIRE THAT FIRST CYLINDER, START THE ENGINE, AND SO SURE ENOUGH HE WAS ABLE TO START THAT ENGINE, GOT THE JOB, AND THAT'S HOW IT STARTED THIS RELATIONSHIP BETWEEN CLESSIE AND WG IRWIN. CLESSIE HAD THE MECHANICAL GENIUS, MISTER IRWIN HAD THE MONEY.

(IAN)>> FOUNDED IN 1919, CUMMINS INC ORIGINALLY LICENSED SINGLE CYLINDER ENGINES THAT COULD RUN ON LAMP OIL.

(DAVID)>> STARTED SELLING FOR WATER PUMPS, AND OIL DRILLS, SAW MILLS, THINGS LIKE THAT, RAN OFF A BIG BELT.

(IAN)>> THESE EARLY ENGINES ONLY PUT OUT A COUPLE OF HORSEPOWER OR SO, BUT THEY WERE VERY RELIABLE. IN FACT, CUMMINS OWNS THE FIRST ONE AND IT STILL RUNS. BY THE MID '20'S CUMMINS WAS SELLING DIESEL ENGINES OF ITS OWN DESIGN, PRIMARILY FOR USE IN YACHTS AND OTHER MARINE APPLICATIONS, BUT CUMMINS FELT THAT THE FUTURE OF DIESEL ENGINES WAS NOT IN THE WATER.

(DAVID)>> HIS LATEST ENGINE WAS A "U" ENGINE THAT HE HAD BEEN PUTTING IN SOME OF THESE LUXURY YACHTS, AND SO HE TOOK THAT "U" ENGINE, PUT IT IN A PACKARD LIMOUSINE ON CHRISTMAS DAY 1929, AND DROVE IT JUST DOWN THE STREET TO MISTER IRWIN'S HOUSE, TOOK MISTER IRWIN AND HIS FAMILY ON A RIDE SAYING HERE'S THE FUTURE OF DIESEL ENGINES ON THE ROAD, NOT IN THE WATER, BUT ON THE ROAD IN CARS AND TRUCKS.

(IAN)>> WG IRWIN WAS IMPRESSED AND CUMMINS WAS OFF AND RUNNING, DESIGNING, BUILDING, AND TESTING GROUND BREAKING DIESEL ENGINES. IN 1931 THEIR DIESEL POWERED RACE CAR COMPLETED THE INDY 500 WITHOUT STOPPING FOR FUEL EVEN ONCE. IN 1952 A TURBOCHARGED CUMMINS RACE CAR TOOK POLE POSITION WITH A QUALIFYING SPEED OF 138.01 MILES PER HOUR.

(DAVID)>> THE NUMBER 28 CAR HAD A MODEL "J" ENGINE THAT WE LAID OVER ON ITS SIDE. THEY FIGURED OUT HOW TO USE A SCAVENGER PUMP AND PUMP OIL TO THE TOP OF THE ENGINE, LAY IT ON ITS SIDE SO IT'D BE VERY LOW SLUG, VERY AERODYNAMIC, AND CUMMINS ENGINEERS DID ALL THE WORK ON THE ENGINE, DID THE DESIGN OF INSTALLING THAT. THE FIRST CAR TO HAVE A TURBOCHARGER RUN AT INDIANAPOLIS. ONE OF THE FIRST CARS TO EVER BE WIND TUNNEL TESTED THAT RAN AT INDIANAPOLIS.

(IAN)>> THESE ACHIEVEMENTS AT THE COUNTRY'S MOST WELL KNOWN AUTOMOBILE RACE PEAKED THE PUBLIC'S INTEREST IN DIESEL TECHNOLOGY, AND SERVED AS AN EFFECTIVE MARKETING TOOL. FOR ALMOST A CENTURY CUMMINS HAS MADE ENGINES FOR EVERY APPLICATION, FROM INDUSTRIAL EQUIPMENT AND TRAINS, TO COMMERCIAL AND CONSUMER TRUCKS. THE NEWEST CUMMINS ENGINE IS THE FIVE LITER VEIGHT UNDER THE HOOD OF THE NISSAN TITAN. WITH 310 HORSEPOWER AND 555 FOOT POUNDS OF TORQUE THIS HIGH TECH DIESEL IS ASSEMBLED IN THE ORIGINAL CUMMINS ENGINE PLANT WHERE THE VERY FIRST ENGINE WAS BORN. THE ONE POINT FOUR MILLION SQUARE FOOT FACILITY CAN MANUFACTURE 150,000 ENGINES PER YEAR. TAKING A BARE EIGHT CYLINDER BLOCK, DROPPING IN A HEAVY DUTY CRANK, ROTATING ASSEMBLY, ALUMINUM CYLINDER HEADS, FRONT COVER, VALVE COVERS, AND INTAKE BEFORE GOING INTO A SPIN TESTER THAT SIMULATES THE ENGINE RUNNING WITHOUT ACTUALLY FIRING IT TO VERIFY THAT EVERYTHING IS GOOD TO GO. CUMMINS EVALUATES ALL OF ITS ENGINES IN CLOSED TEST CELLS. THIS ENSURES GREAT DURABILITY, FUEL ECONOMY, COLD AND WARM WEATHER OPERATION, ALONG WITH LOW ENGINE EMISSIONS, MAKING SURE THAT EACH ENGINE DELIVERS OPTIMAL PERFORMANCE FOR A LONG TIME. AS THE LARGEST EMPLOYER IN COLUMBUS, CUMMINS HAS A MAJOR IMPACT ON THE SURROUNDING COMMUNITY. THIS COULD BE SEEN ALL AROUND DOWNTOWN. FOR A SMALL TOWN, COLUMBUS HAS LOTS OF UNIQUE ARCHITECTURE.

(STEVE)>> AND ALL THAT KIND OF STEMS FROM THE CUMMINS FOUNDATION THAT SETUP AN ORGANIZATION THAT WOULD FLOAT THE BILL FOR SIGNIFICANT WORLD RENOWNED ARCHITECTS TO COME IN AND DESIGN PUBLIC BUILDINGS, SCHOOLS, LIBRARIES, CHURCHES, ETCETERA. SO A REALLY UNIQUE PLACE.

(NARRATOR)>> UP NEXT, SIX IN A ROW AND YOU'RE READY TO GO. INSIDE THE TURBO DIESEL STRAIGHT SIX.

(IAN)>> IT'S PROBABLY ONE OF THE MOST RECOGNIZABLE CUMMINS ENGINES IN THE WORLD, WHETHER YOU CALL IT A SIXBT, 12 VALVE, OR 24 VALVE. IT IS THE STRAIGHT SIX CUMMINS DIESEL ENGINE THAT YOU FIND UNDERNEATH THE HOOD OF RAM PICK UP TRUCKS, AND IT'S BUILT RIGHT HERE IN COLUMBUS, INDIANA. WE ARE NO STRANGER TO THE CUMMINS SIXSEVEN IN THE XTREME SHOP. PROJECT BIG RIG RAM STARTED LIFE AS A TRADESMAN TRIM RAM 2,500, AND I DRIVE THAT MONSTER EVERY SINGLE DAY AND LOVE IT. SO GETTING TO SEE WHERE THAT ENGINE CAME TO LIFE IS LIKE GETTING THE GOLDEN TICKET TO THE WILLIE WONKA CHOCOLATE FACTORY. EACH ENGINE STARTS AS A RAW CASTING AS IT ENTERS THE PLANT, AND IS MACHINED IN CLOSED MACHINE CELLS TO ENSURE NO CONTAMINATION INTO THE BLOCK. THE FINAL STEP IS HONING THE CYLINDERS USING TORQUE PLATES THAT ARE COMPUTER CODED AND REGULATED TO ENSURE THE BEST POSSIBLE CYLINDER SIZE AND PATTERN. THE EMPTY BLOCK IS THEN GIVEN A LASER ETCHED ID TAG THAT IS SCANNED DURING THE ASSEMBLY PROCESS. THIS IS ALSO DONE TO EVERY SINGLE PART THAT IS INSTALLED INTO THE BLOCK TO TRACK IT DURING ASSEMBLY. THE ENGINE BUILD IS DIVIDED INTO DOZENS OF STATIONS WITH MULTIPLE WORKERS AT EACH ONE PERFORMING DIFFERENT TASKS. OVER A PERIOD OF SIX HOURS THE ENGINE WILL SPEND LESS THAN 70 SECONDS IN EACH STATION, AND BE FINAL ASSEMBLED AND READY TO SHIP. THE SIX POINT SEVEN CUMMINS PLANT CAN PUMP OUT 500 ENGINES PER DAY. ASSEMBLY IS A MIXTURE OF ROBOTS AND PEOPLE. THE PEOPLE DROP ON MAJOR COMPONENTS AND INSTALL ITEMS THAT REQUIRE EXTRA ATTENTION, LIKE THE ROTATING ASSEMBLY, PISTONS AND RODS, AND CYLINDER HEADS. ROBOTS TAKE CARE OF ALL THE TORQUE SPECS IN THE MOTOR, TIGHTENING ALL THE FASTENERS AND STRETCHING THE BOLTS. THEN TIGHTENING TO THE FINAL SPECIFICATION. SETTING VALVE LASH ON THE MOTOR IS ENTIRELY DONE BY A ROBOTIC STATION, ROTATING THE ENGINE WHILE A SECOND SET OF ROBOTIC ARMS ADJUST THE ROCKER SHAFTS, AND A FINAL ROTATION TO CHECK CLEARANCE FOR EVERYTHING. THIS PROCESS TAKES THREE MINUTES, ALMOST 10 TIMES FASTER THAN A PERSON COULD DO IT. ONCE THE ENGINE IS COMPLETELY ASSEMBLED IT HEADS INTO A PAINT BOOTH TO BE SPRAYED WITH A PROTECTIVE COATING. IT GOES ON BLUE TO ENSURE GOOD COVERAGE BUT DRIES CLEAR TO PREVENT OXIDATION OF THE IRON BLOCK AND ALUMINUM COMPONENTS. THE SIX POINT SEVEN CUMMINS HAS A TRUE CULT FOLLOWING IN THE WORLD OF DIESEL ENGINES. ALTHOUGH A STRAIGHT SIX DIESEL ENGINE WAS COMMON PLACE IN THE WORLD OF OVER THE ROAD TRUCKS, IT WAS NEW TO THE PASSENGER TRUCK GAME. WHEN CUMMINS INSTALLED THE FIRST FIVENINE INTO A RAM PICK UP FOR DODGE IT WAS A GAME CHANGER, AND PEOPLE WHO WORK AT THIS PLANT KNOW THEY ARE BUILDING AN ENGINE THAT THE OWNERS FALL IN LOVE WITH.

(STEVE)>> IT WAS A LONG TIME BEFORE WE PICKED UP OUR PARTNERSHIP WITH RAM. YOU KNOW THAT WASN'T UNTIL THE '80'S. SO WE WERE IN BUSINESS A LONG TIME BEFORE WE HAD A HIGH VISIBILITY AUTOMOTIVE OEM. IN THAT TIME BETWEEN, YOU KNOW, WE WERE A POWER GENERATION COMPANY. WE HAD LOCOMOTIVES, CONSTRUCTION EQUIPMENT, MARINE EQUIPMENT, AND ONLY DID WE BECOME A HOUSEHOLD NAME ONCE WE REALLY ENTERED INTO THE AUTOMOTIVE MARKET.

(IAN)>> THE SIXSEVEN CUMMINS PLANT IS ONE OF THE MOST REQUESTED PLANTS FROM PEOPLE WHO WANT A TOUR, AND NOT JUST BECAUSE IT'S AN ARCHITECTURAL MARVEL BURIED HALF UNDERGROUND TO CONTROL INTERNAL TEMPERATURES WITH A PARKING LOT ON THE ROOF. THEY, JUST LIKE ME, WANT TO SEE WHERE THEIR SIX POINT SEVEN ENGINE WAS BORN.

(NARRATOR)>> UP NEXT, A CRATE ENGINE PACKAGE THAT GETS YOU UP AND RUNNING FAST.

(IAN)>> NOW WE DID NOT JUST COME UP TO COLUMBUS, INDIANA, TO SEE A BUNCH OF ENGINES GET ASSEMBLED AT PLANTS. WE WANTED TO GET AN INSIDE LOOK AT OUR RTWO POINT EIGHT FOUR CYLINDER THAT'S GONNA END UP UNDERNEATH THE HOOD OF OUR LAND ROVER D-90 PROJECT. NOW ALTHOUGH THIS ENGINE IS NOT ASSEMBLED HERE IN COLUMBUS, THE CREW AT CUMMINS HOOKED US UP WITH THIS TOP SECRET ENGINE ASSEMBLY AREA, A PILE OF PARTS, AND A SHORT BLOCK SO WE COULD BUILD OUR OWN FOUR CYLINDER ENGINE. WE ARE GOING TO ASSEMBLE THIS ENGINE THE SAME WAY IT WOULD BE DONE ON THE ASSEMBLY LINE, BY INSTALLING MAJOR COMPONENTS ONTO THE SHORT BLOCK, AND I WON'T BE DOING IT ALONE. HELPING ME OUT IS BRITTANY BORELLA, AN ENGINEER AT CUMMINS.

(BRITTANY)>> I MAINLY DO PERFORMANCE AND DRIVABILITY TESTING ON PICK UP TRUCKS. SO THAT INVOLVES GOING OUT AND TIMING HOW FAST THEY ACCELERATE, HOW QUICKLY THEY SLOW DOWN, THEN JUST GENERAL DRIVABILITY.

(IAN)>> EVERY SINGLE PART TO ASSEMBLE OUR ENGINE IS LAID OUT NEATLY ON THE BENCH, FROM THE CYLINDER HEAD, CAM SHAFT, TIMING CHAIN AND GEAR, ROCKER ARMS, INJECTORS, AND COMMON RAIL FUEL SYSTEM, TO THE COMPLETE ENGINE AND VEHICLE WIRING HARNESS, THROTTLE PEDAL, AND MURPHY GAUGE TO MONITOR THE ECU. ONCE ASSEMBLED THIS WILL BE THE EXACT SAME ENGINE THAT CUMMINS REPOWER WILL SHIP DIRECTLY TO YOU FOR YOUR PROJECT.

(STEVE)>> THE TWO POINT EIGHT IS A GREAT CRATE MOTOR FOR ANY KIND OF SMALL FOUR WHEEL DRIVE TRUCK BECAUSE NUMBER ONE, IT ONLY WEIGHS AROUND 500 POUNDS. SO YOUR STOCK SUSPENSION PROBABLY WON'T EVEN NOTICE A DIFFERENCE THAT IT'S THERE. NUMBER TWO, IT'S QUIET, IT'S A COMMON RAIL ENGINE. SO WHAT WE WANTED TO DO IS REALLY GIVE THEM AN OPTION FOR SOMETHING NEW, SOMETHING RIGHT OFF THE ASSEMBLY LINE, SOMETHING THAT'S A BETTER FIT, AND A LOT EASIER TO INTEGRATE INTO THEIR PLATFORM.

(IAN)>> ALL RIGHT BRITTANY, WHERE DO WE START?

(BRITTANY)>> LET'S START WITH THE CYLINDER HEAD.

(IAN)>> SOUNDS LIKE A PLAN. THE CAST IRON HEAD IS FULLY LOADED WITH INTAKE AND EXHAUST VALVES, ALONG WITH SPRING, AND THE EXHAUST MANIFOLD, EGR COOLER, AND INTAKE MANIFOLD. BECAUSE OF THE WEIGHT OF THE HEAD, AN OVERHEAD CRANE IS USED TO LOWER IT ONTO THE BLOCK, AND AFTER LUBING THE THREADS ON THE HEAD BOLTS THEY ARE TORQUED TO SPEC. WITH A COMPRESSION RATIO OF 16.9 TO ONE, THE RTWO POINT EIGHT HAS SOME SERIOUS HEAD BOLT TORQUE TO CONTAIN THE PRESSURES OF A MODERN DIRECT INJECTED COMMON RAIL DIESEL.

(BRITTANY)>> DIESEL ENGINES ARE BUILT TO WITHSTAND HIGHER COMPRESSION RATIOS. SO THE ENTIRE ENGINE IS JUST BUILT MORE DURABLE FROM THE GET GO. CUMMINS REALLY PRIDES ITSELF ON DURABILITY. SO ALL OF OUR MANUFACTURING, AND ALL OF OUR PART SOURCING, AND ALL OF OUR DESIGN IS ALL REALLY BASED ON DURABILITY.

(IAN)>> THE INJECTION PUMP BOLTS ONTO THE BACK OF THE BLOCK. BECAUSE THIS ENGINE IS A COMMON RAIL DIESEL AND INJECTION IS CONTROLLED BY THE COMPUTER, THE PUMP DOES NOT NEED TO BE TIMED LIKE OLDER DIESELS. OKAY READY?

(BRITTANY)>> READY.

(IAN)>> COMING AT YOU.

THE ENGINE IS THEN ROTATED IN PREPARATION FOR? WHAT'S NEXT?

(BRITTANY)>> FRONT COVER.

(IAN)>> I LIKE HOW SHE WENT, FRONT COVER!

ON AN ASSEMBLY LINE ROBOTS TAKE CARE OF TORQUEING ALL THE FASTENERS, BUT WHEN ASSEMBLING AN ENGINE BY HAND YOU HAVE TO USE A TORQUE WRENCH, AND WHEN YOU'RE WORKING IN THE CUMMINS TOP SECRET ENGINE FACILITY EVERYTHING GETS TORQUED, REAR COVER, FLYWHEEL, DAMPENER BOLTS, EVERY SINGLE FASTENER. THE CAM SHAFT IS THEN INSTALLED AND THE VALVE BRIDGES THAT ALLOW BOTH THE INTAKE AND EXHAUST VALVES TO OPERATE BY A SINGLE ROCKER ARM. [ phone ringing ] IS THAT YOUR PHONE?

(BRITTANY)>> NOPE.

(IAN)>> GOOD JOB. HELLO, THANK YOU FOR CALLING CUMMINS TOP SECRET ENGINE FACILITY. AND NOW WE HAVE A LONG BLOCK. [ drill spinning ]

(IAN)>> WE ARE IN COLUMBUS, INDIANA, HOME OF CUMMINS ENGINES, PUTTING TOGETHER OUR OWN RTWO POINT EIGHT FOUR CYLINDER FOR OUR D-90 PROJECT. THE ENGINE IS THE FIRST IN A SERIES OF ENGINES THAT ARE PART OF A NEW CUMMINS CRATE ENGINE PROGRAM CALLED CUMMINS REPOWER.

(BRITTANY)>> I THINK IT'S A REALLY GOOD OPPORTUNITY FOR US AND PEOPLE ARE REALLY EXCITED ABOUT IT. WE'RE REALLY GOOD AT SELLING ENGINES THROUGH OEM'S AND THIS IS OUR FIRST CHANCE AT SELLING DIRECT TO THE CONSUMER. PEOPLE ARE REALLY EXCITED TO BE ABLE TO GET ENGINES STRAIGHT FROM US THAT ARE PACKAGE READY TO DROP IN YOUR VEHICLE AND START. RATHER THAN HAVING TO PULL ENGINES OUT OF BREAD TRUCKS OR FIND THEM IN JUNKYARDS AND TRY TO MAKE THEM WORK YOURSELF.

(IAN)>> SO FAR BRITTANY AND I HAVE ASSEMBLED A COMPLETE LONG BLOCK, AND NOW IT'S TIME TO DROP ON THE VALVE COVER, HIGH PRESSURE INJECTORS, FUEL RAIL, AND PIPING TO THE INJECTORS. THE ENGINE IS THEN FLIPPED OVER FOR THE OIL PAN TO BE INSTALLED WITH THE SUMP AT THE REAR FOR CLEARANCE ON OUR FRONT AXLE, AND FINALLY THE COMPLETE ENGINE WIRING HARNESS TO CONTROL THIS FOUR CYLINDER DIESEL ONCE UNDER THE HOOD. CONSIDERING THAT THE RTWO POINT EIGHT CRATE ENGINE IS RIGHT AROUND 500 POUNDS WITH OVER 260 POUND FEET OF TORQUE, IT IS A PERFECT ENGINE FOR ANY OFF ROAD RIG.

(STEVE)>> IF YOU OVERLAY THE TORQUE CURVE OF YOUR FACTORY GAS ENGINE VERSUS WHAT WE'RE OFFERING AS A DIESEL, ODDS ARE YOU'RE GONNA BE HAPPIER OFF ROAD AND ON ROAD WITH THE LOWER TORQUE CURVE THAT A DIESEL OFFERS. YOU AREN'T DOWNSHIFTING TO CLIMB GRADES. YOU CAN KINDA IDLE OVER THINGS. IT'S REALLY A DIFFERENT EXPERIENCE THAN A GAS ENGINE.

(BRITTANY)>> I THINK IT'S REALLY FUN TO DRIVE. IT GETS GREAT FUEL ECONOMY. THERE'S GREAT LOW END TORQUE, AND IT'S JUST KIND OF A LITTLE PEPPY ENGINE THAT'S DIFFERENT THAN WHAT'S OUT ON THE MARKET. SO IT'S DIFFERENT AND FUN TO DRIVE.

(IAN)>> BEFORE WE HIT THE ROAD, THERE'S ONE MORE THING THAT WE NEED TO DO. WITH THE ENGINE ON A PALLET, WE MOVED IT CLOSER TO ONE OF THE SHOP DOORS, HOOKED UP SOME FUEL LINES, A COUPLE OF WIRES, AND IT'S TIME TO FIRE THIS ENGINE UP. [ engine cranking ] [ engine firing and idling ]

(IAN)>> OHH! GIVE ME SOME DOOWAH VALVE.

[ engine revving ]

(IAN)>> OH HOO HOO!

THAT'S PRETTY AWESOME! OH THAT'S BEAUTIFUL! ALL RIGHT, PULL THAT WIRE OFF.

(BRITTANY)>> WOO HOO!

(IAN)>> LET'S LOAD IT ON A PALLET, OR NO, IT'S ALREADY ON A PALLET. LET'S PUT IT IN THE TRUCK.

WE'VE SHOWN YOU A TON OF DIESEL ENGINES, AND WE'D LIKE TO TAKE A CLOSER LOOK AT CUMMINS MODELC, BUILT CIRCA 1920.

(STEVEN)>> I'VE GOT TO DO SOME FUEL LIFTING TO MAKE SURE THAT I'VE GOT FUEL UP HERE READY TO GO. BASICALLY GRAVITY DOES THE WORK, AND THIS IS NOT A TRUE DIESEL ENGINE. THIS HVID FUEL SYSTEM, HVID, AND ON THE INTAKE STROKE IT SUCKS IN DIESEL INTO THE CUP OF THE INJECTOR, AND THEN AS IT COMPRESSES IT ACTUALLY IGNITES A LITTLE BIT IN THE INJECTOR FIRST. THEN SHOOTS OUT THE REST OF THE FUEL INTO THE POWER CYLINDER AND DOES THE REST OF THE COMPRESSION IGNITION THERE. SO THE INJECTOR'S NOT FORCING THE FUEL IN LIKE IT DOES TODAY. IT KIND OF PREIGNITES IT AND USES THE ACTUAL IGNITION OF THE DIESEL TO FORCE THE DIESEL INTO THE REST OF THE FUEL SYSTEM. THERE'S NOT A LOT OF STUFF GOING ON INSIDE THE INJECTOR. IT'S ALL ABOUT METERING THE FUEL AND THEN LETTING THE ENGINE DO THE REST OF THE WORK. THIS ONE WAS IN OHIO, AND IT DID A PUMP JACK FOR AN OIL RIG. SO IT JUST RAN IT OFF OF THAT BELT FOR DECADES. A LOT OF THEM WERE WATER PUMPS FOR FARMERS. LOW SPEED, KINDA LOW HORSEPOWER. THIS GIANT THING, SINGLE CYLINDER, PUTS OUT SIX HORSEPOWER AT ITS MAXIMUM RATING. I'VE GOT TO CRANK IT UP TO SPEED, AND SO I'VE OPENED UP THE COMPRESSION RELEASE. SO IT'S NOT GONNA BUILD ANY COMPRESSION. I'M GONNA CRANK IT UP TO SPEED, FLIP IT OVER, AND HOPEFULLY SHE'LL GET GOING.

[ engine sputtering ] [ engine fires up and idling ]

(IAN)>> THIS MODELC IS AN ALMOST CENTURY OLD PIECE OF DIESEL HISTORY, AND IT'S STILL RUNNING STRONG!