XOR - Xtreme Off-Road Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Competition Engineering

Motor Plate, Mid-Mount, Aluminum, 0.188 in. Thick, Ford, 289-351, Kit

Ford Performance Parts

5.0L (302 cubic inches),9.5:1 compression ratio for supercharged applications, Mahle Hard Anodized forged pistons with Graphal low friction coating, Manley H-beam connecting rods with ARP bolts, Uses production Mustang GT aluminum cylinder block Large rear sump oil pan with 8qt capacity,Tuned composite Mustang GT intake manifold with drive by wire 80mm throttle body, Four-valve-per-cylinder aluminum heads with roller-finger followers, Heads feature Boss 302 Valve Springs

Yukon Gear & Axle

Differential Pinion Yoke, 1350, U-Bolt Style, 29 Spline, Steel, Dana 60,70, Each

Barnes 4WD

Pro Series GM 14 Bolt Axle Trus

Edwards Ironworkers

55 Ton Edwards Ironworker with Hydraulic Accessory Pack option; 10 Ton Bender, 15 Ton Horizontal press,Tubing Roller and 40 Ton Shop Press.

ESAB

The Official Welding and Cutting Supplier of Xtreme Off Road, featuring the all-new Rebel 215 Multi-Process Welder

The Industrial Depot

The Industrial Depot - Fasteners, Hardware, and Shop Supplies

Trail Gear Inc.

Full Hydraulic Steering Kit. This kit comes with everything needed to build a fully hydraulic steering system

Wooly's Off-Road

Woolys Off Road Park

Yukon Gear & Axle

Yukon 4340 Chrome-Moly replacement outer stub for Dana 60, 77 and newer Ford

Yukon Gear & Axle

Yukon 4340 Chrome-Moly Replacement Outer Stub For Dana 60, 77 And Newer Ford

Yukon Gear & Axle

Yukon Hardcore Drive Flange Kit, W/O Engraved Caps

Yukon Gear & Axle

Yukon Minor Install Kit For Dana 60 And Gm 10.5

Yukon Gear & Axle

High performance Yukon replacement Ring & Pinion gear set for Dana 60 Reverse rotation in a 5.38 ratio

Episode Transcript

(ANNOUNCER)>> IT'S A BUSY

DAY IN THE XTREME SHOP. THE JUNKYARD AXLE FOR OUR

DISCOUNT DATSUN WON'T FIT, BUT WITH A LITTLE

PLANNING, A TORCH, AND A WELDER WE'LL BUILD A

CUSTOM SETUP FOR THE FRONT OF OUR RIG ON THE CHEAP. PLUS A STATE OF THE ART

POWER PLANT FOR OUR ULTRA FOUR INSPIRED RACE RIG.

AND WE INTRODUCE A WEST COAST KID TO EAST COAST ROCK BOUNCING.

(IAN)>> WE'RE KICKING THINGS OFF TODAY WITH PROJECT DISCOUNT DATSUN. NOW WE HAVE MADE A LOT OF HEADWAY ON OUR LITTLE MINI TRUCK THAT WE'RE CONVERTING INTO A $10,000 DOLLAR HARDCORE CRAWLER. WE'VE ALREADY LINKED THE BACK END OF THE TRUCK, CUT

IT UP, AND PUT IN A TUBE CHASSIS ON THE BACK, ADDED SOME 42 INCH TALL TIRES ON SOME BEADLOCKS, AND REBUILT A TRANSFER CASE TO CONVERT IT OVER TO FOUR WHEEL DRIVE. I'M SURE YOU'VE FIGURED OUT BY NOW THAT I'VE ONLY BEEN WORKING ON THE BACK HALF OF THE TRUCK, AND THAT IS BECAUSE ON THE FRONT END WE'RE GONNA NEED SOME TYPE OF CUSTOM AXLE BECAUSE THE DROP OF OUR

TRANSFER CASE IS ON THE PASSENGER SIDE AND I WANT TO USE A HIGH PINION FORD. BUT CAN YOU BUILD A CUSTOM AXLE ON THE CHEAP? WELL YOU CAN, YOU JUST BUILD IT A LITTLE BIT DIFFERENT.

TO START THE AXLE NEEDS TO BE STRIPPED OF ALL OF ITS FACTORY BRACKETS.

THE BEST JOB FOR THIS IS THE GOOD OLE OXY FUEL TORCH.

IT MAKES QUICK WORK OF THIS RUSTY AXLE.

THE SHORT SIDE TUBE IS THEN CUT OFF THE AXLE USING THE PLASMA CUTTER. IT'S GROUND FLAT WITH A BEVEL AROUND THE OUTER EDGE OF THE TUBE. WE'RE BUILDING A CUSTOM WIDTH FRONT AXLE FOR A COUPLE OF DIFFERENT REASONS. THE 14 BOLT THAT'S IN THE BACK OF OUR PROJECT IS NOT A FULL WIDTH 14 BOLT. IT'S OUT OF A DUAL REAR WHEEL CAB AND CHASSIS TRUCK. NOW THEY ARE ABOUT FOUR INCHES NARROWER THAN A FULL WIDTH AXLE, AND THAT'S WHAT THIS FRONT SUPERDUTY 60 IS. IT'S FULL WIDTH, RIGHT AROUND 67 INCHES. THE OTHER PROBLEM IS THE SAMURAI TRANSFER CASE I'M USING TO TURN THIS TRUCK INTO A FOUR WHEEL DRIVE,

THE DROP IS ON THE OPPOSITE SIDE, AND THESE

BIG FORD SUPERDUTY HIGH PINION 60'S, THEY'RE

WHAT'S CALLED A DRIVER'S SIDE DROP. SO THE PUMPKIN IS ON THE DRIVER'S SIDE OF THE TRUCK. I BASICALLY NEED TO MOVE IT OVER TO THE PASSENGER SIDE OF THE TRUCK. THAT MEANS THAT THE LONG TUBE NEEDS TO BE ON THIS SIDE AND THE SHORT TUBE NEEDS TO BE ON THIS SIDE. NOW THE CORRECT WAY TO DO THIS WOULD BE TO DRILL OUT

ALL THE SPOT WELDS, PRESS THE TUBES OUT OF THE HOUSING, REPLACE THEM WITH SOME BRAND NEW BEEFY HALF INCH WALLED DOM, UPGRADE TO SOME KINGPIN KNUCKLES, A WHOLE NEW BRAKE SYSTEM, AND THEN INSTALL A LOCKER AND GEAR SET. BASICALLY BUILD A BOMBPROOF TRAIL AXLE, BUT THAT WILL BASICALLY DECIMATE THE BUDGET THAT WE HAVE FOR THIS TRUCK. I'M GONNA RETAIN THE MAJORITY OF THE STOCK COMPONENTS, AND I AM GONNA NARROW THIS AXLE USING A SYSTEM CALLED SLEEVE AND TRUSS. BECAUSE WE'RE WORKING ON A BUDGET, I NEED TO MAKE SURE THAT THE NEW HOUSING WORKS WITH A SET OF OFF

THE SHELF AXLE SHAFTS. SO I AM MEASURING INTO THE FACTORY DIFFERENTIAL TO DETERMINE THE LOCATION OF THE LOWER BALL JOINT. THE LONG SIDE AXLE WILL BE 34.5 FIVE INCHES LONG, AND KNOWING THIS MEANS THAT I NEED TO ADD 24 AND A HALF INCHES TO THE DRIVER'S SIDE OF THE HOUSING.

THIS IS WHAT I WILL CUT OFF OF THE EXISTING LONG SIDE TUBE.

WITH THE INNER "C" REMOVED FROM THE KNUCKLE, THE

ORIGINAL AXLE SHAFT IS CUT AND THEN HAMMERED OUT. THE SHORT SIDE AXLE WILL BE ONLY 16 INCHES LONG. SO I WILL GRIND WHAT IS LEFT OF THE ORIGINAL LONG SIDE AXLE TUBE FOR THE STOCK INNER "C" TO SLIDE OVER.

NOW THIS FIRST STEP IN CHANGING THE DROP OF THE FRONT AXLE WAS OBVIOUSLY PRETTY EASY.

I NOW HAVE THE PINION ON THE PASSENGER SIDE OF THE TRUCK BY MAKING THE LONG SIDE AXLE TUBE A LOT SHORTER. SIMPLY MOVED THE INNER "C" FURTHER DOWN THE TUBE. BUT MAKING THE SHORT SIDE AXLE TUBE LONGER, THAT'S WHERE THINGS GET A LITTLE BIT MORE DIFFICULT. NOW WHEN YOU'RE WORKING ON A BUDGET, IT STARTS BY CUTTING A SLEEVE TO FIT INSIDE THE HOUSING. [ GRINDER SPINNING ]

[ WELDER CRACKLING ] [ GRINDER SPINNING ]

(IAN)>> THE MAIN PURPOSE OF THE SLEEVE IS JUST TO ALIGN THE TWO AXLE TUBES. NOW IT DOES GIVE A LITTLE BIT MORE STRENGTH TO THE BUTT JOINT THAT I'M GONNA BE WELDING IN PLACE HERE, BUT WE DO NEED TO ADD A LITTLE BIT MORE. IF YOU REMEMBER, WHEN WE GOT OUR FOUR LINK KITS FROM BARNES FOUR WHEEL DRIVE, THEY SENT US TRUSSES FOR BOTH AXLES, AND THAT IS WHERE THE REAL STRENGTH WILL COME INTO PLAY ON THIS AXLE.

THIS TRUSS WILL NOT ONLY BRIDGE THE GAP OVER THE CENTER SECTION, BASICALLY ATTACHING BOTH TUBES TOGETHER, BUT THE TRUSS ITSELF WILL ACTUALLY COVER UP THE FINISH WELDED JOINT, GIVING IT EVEN MORE STRENGTH. ONCE ALL THIS WELDING IS DONE I HAVE FLIPPED THE DRIVER'S SIDE TO THE PASSENGER SIDE DROP ON THE

AXLE AND NARROWED IT THREE INCHES TO MATCH THE REAR. WITH THE SLEEVE IN PLACE, THIS JOINT NEEDS A MULTIPASS WELD.

THE ROOT WILL LOCK THE SLEEVE INTO PLACE AND THE COVER PASSES WILL FINISH OUT THE JOINT AND IT IS GROUND SMOOTH. [ WELDER CRACKLING ]

(ANNOUNCER)>> UP NEXT, OUR DATSUN GETS FULL HYDRAULIC STEERING, GEARS, AND A LOCKED DIFF.

(IAN)>> ANOTHER WAY TO STRENGTHEN UP THAT FRONT AXLE IS TO ADD A TUBE TRUSS ACROSS THE FRONT OF IT. NOW THAT TUBE TRUSS IS USED TO MOUNT A FULL HYDRAULIC STEERING SYSTEM. NOW YES, THIS IS NOT CHEAP, BUT WE HAVE ROOM IN OUR BUDGET FOR IT AND IT'S THE RIGHT DECISION TO MAKE WITH A 42 INCH TALL TIRE. NOW THE KIT THAT I HAVE CHOSEN FOR DISCOUNT DATSUN IS A COMPLETE KIT FROM TRAIL GEAR OFF ROAD. IT COMES WITH THE RAM, ORBITAL VALVE, EVEN A PUMP, AND ALL THE HEIM JOINTS AND ALL THE

FITTINGS AND EVERYTHING TO MAKE IT WORK.

BUT WHAT'S REALLY COOL IS THEY ALSO INCLUDE A PIECE OF TUBING TO WELD ONTO THE FRONT AXLE AS WELL AS THE PADS TO MOUNT THE RAM. SO YOU'RE NOT ON THE HOOK TO FABRICATE ANYTHING. IT BASICALLY COMES READY TO GO. THIS TUBE WILL BRIDGE ACROSS THE CENTER SECTION, CONNECT OUR TWO AXLE TUBES TOGETHER MAKING OUR AXLE EVEN STRONGER. THE TUBE IS A UNIVERSAL LENGTH AND NEEDS TO BE SHORTENED TO FIT THE AXLE. [ SAW CUTTING ]

(IAN)>> WITH IT CUT TO THE CORRECT LENGTH, IT IS THEN GROUND TO FIT THE PROFILE OF THE AXLE TUBE AND TACKED INTO PLACE. [ GRINDER SPINNING ]

(IAN)>> THE FACTORY KNUCKLE IS THEN INSTALLED TO DETERMINE THE LENGTH OF THE TIE ROD. AND WITH THE HEIM JOINTS IN PLACE ON THE RAM AND THE STEERING KNUCKLE, THE TIE ROD IS CUT FROM SOME QUARTER INCH WALL DOM. THE REASON I ONLY TACK WELDED ON OUR FULL HYDRAULIC STEERING RAM MOUNT IS BECAUSE I NEED TO MAKE SURE I CAN STILL GET THE DIFF COVER OFF AS WELL AS GET THE DIFFERENTIAL CARRIER OUT OF THE AXLE IN ORDER TO SERVICE IT. THAT'S WHY I WAIT UNTIL THE VERY END TO UPGRADE OUR RING AND PINION AS WELL AS LOCK UP THIS AXLE. NOW WHEN YOU'RE BUILDING AN AXLE ON A BUDGET LIKE WE ARE YOU'RE GONNA HAVE TO GO AT IT A

LITTLE BIT DIFFERENTLY. TRY TO REUSE AS MANY OF THE STOCK PARTS AS YOU CAN. I CAN REUSE MY OUTER STUBS. I HAVE ONE INNER SHAFT THAT IS THE CORRECT LENGTH. I DID NEED TO BUY A SINGLE SHORT SIDE AXLE SHAFT FROM YUKON BECAUSE I DIDN'T HAVE ANYTHING LAYING AROUND THE SHOP.

ALSO WHEN YOU'RE INSTALLING YOUR RING AND PINION, DON'T GO FOR THE FULL BLOWN INSTALL KIT. GET WHAT'S CALLED THE MINI INSTALL KIT. THIS IS JUST ENOUGH PARTS TO INSTALL A RING AND

PINION IN THE AXLE. YOU'LL HAVE TO REUSE THE MAJORITY OF YOUR BEARINGS. IF WHEN YOU'RE IN THE AXLE YOU FIND A BAD BEARING, JUST REPLACE THE SINGLE ONE. ALSO PLAN FOR A COUPLE OF SPARE PARTS. I CAN REUSE ALL MY OUTER SHAFTS BUT I DID GET ONE SINGLE CHROMOLY OUTER SHAFT THAT I'LL CARRY IN THE TRUCK AS A SPARE. THIS IS GONNA BE THE ONE FAILURE POINT ON OUR AXLE. I FULLY EXPECT THE STOCK SHAFTS TO BREAK AT SOME TIME. SO I'LL ONLY UPGRADE THEM TO CHROMOLY WHEN IT'S REQUIRED, AND BY CARRY ONE IN THE TRUCK I'LL BE ABLE TO GET OFF THE TRAIL.

I CHOSE A PRETTY DEEP GEAR RATIO FOR PROJECT DISCOUNT DATSUN. THAT'S BECAUSE I'M GONNA NEED ALL THE HELP I CAN GET TO TURN OUR 42 INCH TALL TIRES. I CHOSE A 5.38 TO ONE FROM YUKON GEAR AND AXLE. NOW WE'LL INSTALL THOSE IN BOTH THE REAR 14 BOLT AND OUR FRONT DANA 60. NOW IF PRICE WAS NO OBJECT I'D ALSO PICK UP A COUPLE

OF LOCKERS WHEN I GOT THOSE GEARS. MAYBE A ZIP LOCKER FOR THE BACK AND MAYBE A GRIZZLY LOCKER FOR THE FRONT. WHO KNOWS, BUT I'M PINCHING MY PENNIES. SO WE HAVE TO DO SOMETHING A LITTLE BIT DIFFERENTLY. I'M GOING TO WELD UP THE DIFFERENTIALS IN THIS AXLE, AND WHEN YOU SEE HOW THAT WORKS YOU'LL

UNDERSTAND WHY IT CREATES A LOCKER. WHEN YOU DRIVE AN OPEN CARRIER ON THE STREET, WHEN YOU DRIVE AROUND A CORNER, THE TIRES MOVE

INDEPENDENT OF EACH OTHER. NOW WHAT A LOCKER DOES IS IT WILL SENSE WHEEL SPEED.

SO IF ONE TIRE GETS OFF THE GROUND, IT'LL SENSE THAT TIRE SPINNING IN THE AIR AND WILL LOCK THE AXLE TOGETHER.

IF YOU DON'T HAVE A LOCKER, IF YOU HAVE AN OPEN DIFFERENTIAL LIKE THIS, WHEN ONE TIRE GETS OFF THE GROUND YOU'RE NOT GOING ANYWHERE BECAUSE THAT SPIDER GEAR IS JUST GONNA SIT THERE AND SPIN. WHAT I'M GONNA DO IS WELD ALL THESE SPIDER GEARS TOGETHER AND PREVENT THEM FROM TURNING. IT'LL BASICALLY TURN OUR AXLES INTO SPOOLS FRONT AND REAR. NOW THIS IS OBVIOUSLY FOR OFF ROAD USE ONLY AND ONLY WHEN YOU'RE WORKING ON A BUDGET. LATER ON IF WE GET SOME MORE MONEY FOR THIS PROJECT THE BEST DECISION WOULD BE TO REPLACE THESE WITH SOME TYPE OF LOCKER. BUT FOR NOW WELDED DIFF, IT'S THE WAY TO GO. [ DRILL SPINNING ]

(IAN)>> TO WELD UP THE SPIDERS IN THESE DIFFERENTIALS I'M SWITCHING THE REBEL WELDER OVER TO STICK WELDING AND USING A 70-14 ROD IN THE ARC STINGER. [ WELDER CRACKLING ]

(IAN)>> THEN ALL WE HAVE LEFT TO DO IS INSTALL THE NEW GEARS AND DROP THE CARRIERS BACK INTO THE

HOUSING, AND THEN THESE AXLES WILL BE FINISHED. SO HOW MUCH DAMAGE DID WE DO TO OUR BUDGET TODAY? THE FULL HYDRO STEERING KIT WAS $1,300 BUCKS. OUR SINGLE NEW INNER AXLE, $130. RING AND PINION FRONT AND REAR, $550, AND OUR SPARE SINGLE CHROMOLY OUTER STUB, THAT WAS ANOTHER $150 BUCKS. WE SPENT $150 DOLLARS ON INSTALL KITS AND I UPGRADED THE YOKE ON THE DANA 60 FOR $175. AND I'LL BE FINISHING OFF THESE AXLES WITH A SET OF YUKON HEAVY DUTY DRIVE FLANGES AT JUST UNDER $270 DOLLARS. THE LOCKERS, THOSE WERE FREE, BRINGING TODAY'S TOTAL TO $2,725 BUCKS. A STEAL FOR A CUSTOM FRONT AXLE AND A REGEARED

REAR FULLY LOCKED.

(ANNOUNCER)>> COMING UP, SPEND A DAY ON THE TRAIL AT ONE OF OUR FAVORITE OFF ROAD PARKS.

(IAN)>> FOR THE PAST EIGHT YEARS ONE OF OUR FAVORITE PLACES TO GO WHEELING HAS BEEN WOOLEY'S OFF ROAD IN LYNNVILLE, TENNESSEE.

WITH A WIDE VARIETY OF TERRAIN AND TRAILS IT'S THE IDEAL PLACE TO PUT OUR PROJECTS THROUGH THE PACES. FROM DIRT CHEAP BUDGET BUILDS TO FULLY BLOWN TUBE BUGGIES. WE'VE DROPPED ALL KINDS OF RIGS ONTO THE TRAIL AND HAD A BLAST DOING IT. FROM THE BEGINNING THE OWNERS OF WOOLEY'S OFF ROAD WANTED TO BUILD A FOREST FULL OF EXCITING AND CHALLENGING TRAILS, BUT THEIR FIRST IDEA WAS QUITE DIFFERENT THAN THE PARK WE KNOW AND LOVE TODAY.

(VAN)>> MY DAD'S ALWAYS WANTED TO INVITE HORSE RIDERS HERE AND DO TRAIL RIDES AND I THOUGHT, YEAH, THEY ONLY COME OUT A COUPLE TIMES A YEAR, AND I SEE THESE PEOPLE ON FOUR WHEELS AND DIRT BIKES. WE ALWAYS LIKE TO DO THAT TOO. WE RODE OURS ALL THE TIME AND I NOTICED PEOPLE LOADING THEM UP AND GOING SOMEWHERE EVERY WEEKEND. SO WE DECIDED WE'D GO WITH THAT INSTEAD OF HORSES.

(IAN)>> FORTUNATELY FOR WHEELS WOOLEY'S EQUESTRIAN PARK BECAME WOOLEY'S OFF ROAD PARK. 500 ACRES OF PRIME TRAILS, A WEEKEND GETAWAY LESS THAN AN HOUR FROM NASHVILLE, TENNESSEE,

AND HUNTSVILLE, ALABAMA.

(VON)>> MOST TRAILS STARTED OUT AS LOGGING TRAILS. WE DRAGGED LOGS OUT OF THE WOODS WITH A SKIDDER, AND THAT'S HOW MOST OF THE TRAILS STARTED. AND THEN WE CLEANED THEM UP A LITTLE BIT WITH A CHAINSAW, AND THEN THERE WERE A FEW WE ACTUALLY MADE WITH JEEPS.

(IAN)>> IF YOU'RE TRAVELING LONG DISTANCE, WOOLEY'S AND THE SURROUNDING AREA HAVE PLENTY OF AMENITIES. ON SIDE THERE'S PRIMITIVE CAMPING, RESTROOMS, AND A SNACK BAR. NEARBY ARE SEVERAL HOTELS, RESTAURANTS, AND A FULL SERVICE CAMP GROUND. THERE'S ALSO PLENTY OF OPTIONS FOR ALL KINDS OF RIGS.

(VON)>> AND WE GET TO SEE A LOT OF ROCK CRAWLERS AND ROCK BOUNCERS. WE SEE A LOT OF SIDE BY SIDES AND ATV'S. SO THERE'S A WIDE RANGE OF VEHICLES, AND THEY ALL HAVE A GOOD TIME.

(IAN)>> THE TRAILS HERE RANGE FROM MODERATE RUNS

TO SERIOUS HILL CLIMBS, BUT WOOLEY'S IS RESPONDING

TO REQUESTS FOR MORE ENTRY LEVEL OPTIONS FOR NEW AND YOUNGER RIDERS.

(VON)>> WE'RE GONNA BUILD SOME EASIER AREAS, AND

I'VE GOT A FIELD ACROSS THE ROAD FROM THE BUILDING HERE, AND I'M JUST GONNA BUILD A LITTLE OBSTACLE COURSE IN THERE FOR BEGINNERS.

(IAN)>> TODAY WE'RE RIDING WITH A BUNCH OF FELLOW WHEELERS FROM THE MIDDLE TENNESSEE AREA, AS WELL AS NICK BARTON AND HIS FAMILY. THEY LIVE IN SACRAMENTO, AND ARE MAKING THEIR FIRST WHEELING TRIP OUT EAST.

(NICK)>> IT'S AWESOME! IT'S A TOTALLY DIFFERENT TERRAIN. ROCKS ARE DIFFERENT, REALLY SLICK, DON'T REALLY HOOK UP THAT GOOD IN SOME SPOTS, BUT OVERALL IT WAS A GOOD TIME.

(IAN)>> NICK'S REGULAR TRAIL RIG IS A '94 TOYOTA PICK UP. WE DECIDED TO GIVE HIM SOME SEAT TIME IN A FULL BLOWN TUBE BUGGY.

(NICK)>> YOU CAN SEE A LOT BETTER WHERE YOU'RE GOING INSTEAD OF BEING IN A CAB TRUCK, AND IT'S A LITTLE BIT EASIER TO POINT IN THE DIRECTION YOU WANT TO GO. AND OVERALL REALLY GOOD MACHINE.

(IAN)>> AND SINCE NICK TRAVELED ALL THE WAY ACROSS THE COUNTRY TO GO WHEELING WITH US, WE WANTED HIM TO EXPERIENCE THE ULTIMATE IN EAST COAST EXCITEMENT, ROCK BOUNCING. SO RICHIE KEITH, ONE OF THE PREMIER RACERS IN THE SPORT, BROUGHT OUT HIS RIG "PLOW BOY" AND AN EXTRA HELMET. FOR NICK, IT'S AN EXPERIENCE HE'LL NEVER FORGET.

(NICK)>> NUTS, IT WAS SUCH AN ADRENALINE RUSH. I MEAN JUST THAT FIRST HILL JUST BOUNCING OFF THOSE ROCKS. JUST LIKE I COULD FEEL MY HEAD SHAKING AROUND, AND IT WAS CRAZY. JUST LIKE THE MUD FLYING OFF THE TIRES. IT WAS AN EXPERIENCE LIKE NO OTHER, AND I'M GLAD

THAT I GOT TO EXPERIENCE THAT.

(IAN)>> SO THE NEXT TIME YOU'RE PLANNING A WHEELING TRIP, NO MATTER WHAT KIND OF RIG YOU'VE GOT, WOOLEY'S HAS A TRAIL FOR YOU. [ ENGINE REVVING ]

(ANNOUNCER)>> UP NEXT, IT'S BASED ON THE CLASSIC '66 BRONCO, BUT OUR DESERT RACER WILL HAVE PLENTY OF MODERN MUSCLE UNDER THE HOOD.

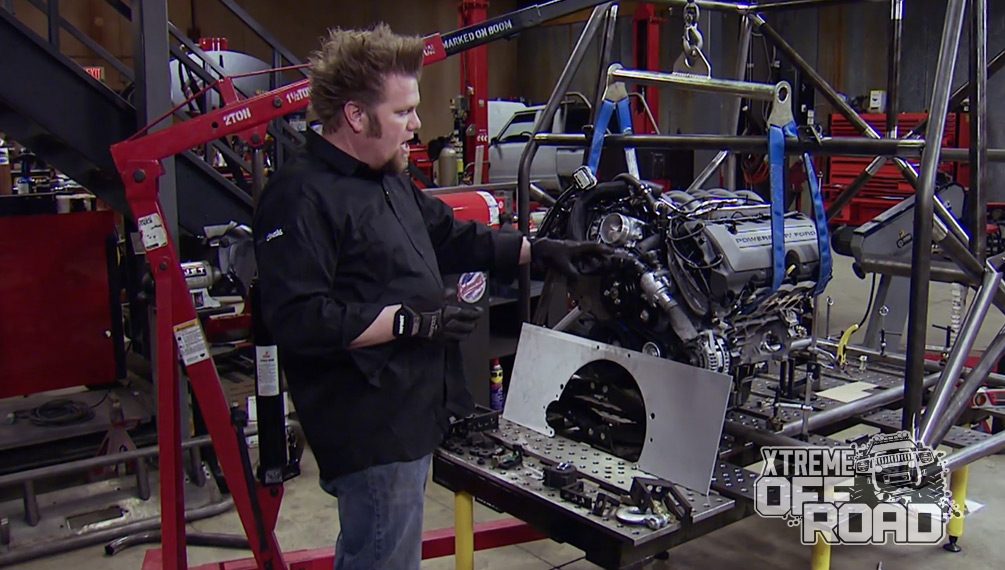

(IAN)>> THERE'S BEEN A LOT OF SPECULATION ABOUT WHAT ENGINE I PLAN TO PUT INSIDE OUR TUBE CHASSIS '66 BRONCO. WE WANTED TO HAVE LOTS OF POWER BECAUSE WE'RE BASICALLY BUILDING AN ULTRA FOUR RACE CAR WITH CLASSIC STYLING. WE WANTED IT TO BE A MODERN ENGINE SO IT'S LIGHTWEIGHT WITH A MODERN EFI SYSTEM INSIDE OF IT. NOW MOST PEOPLE WOULD THINK, WELL THE EASIEST SOLUTION THERE IS GONNA BE SOME TYPE OF LS BASED ENGINE, AND THAT IS VERY POPULAR IN ULTRA FOUR RACING BUT COME ON! THIS IS A '66 BRONCO, IT NEEDS FORD POWER, AND WHAT BETTER THAN A FORD PERFORMANCE PARTS ALUMINATOR COYOTE BASED ENGINE.

THIS IS NOT A BRAND NEW CRATE ENGINE, BUT AN ENGINE THAT WAS ORIGINALLY INSTALLED INTO AN ENGINE POWER FOX BODY MUSTANG PROJECT. THEY PULLED IT OUT FOR AN ENGINE SWAP AND I SNAGGED IT. THIS ALUMINATOR IS THE LOW COMPRESSION SUPERCHARGER READY VERSION WITH HBEAM CONNECTING RODS, ARP BOLTS, AND FORGED PISTONS. ON OUR ENGINE DYNO THIS BEAST PUT DOWN OVER 450 HORSEPOWER AND JUST NORTH OF 430 POUND FEET OF TORQUE.

[ ENGINE REVVING ]

(IAN)>> ENGINE POWER'S PROJECT CAR WAS A STICK, BUT OUR BRONCO, IT'S GONNA BE AN AUTOMATIC. SO THE SIX SPEED TRANS, ALONG WITH THE PRESSURE PLATE, CLUTCH, AND FLYWHEEL, HAVE TO GO.

[ DRILL SPINNING ]

(IAN)>> USING AN ENGINE SLING, I POSITION THE COYOTE ONTO THE FRAME TABLE AND LEVEL IT UP USING A SCISSOR JACK ON THE FRONT BALANCER. I'VE PUSHED THE ENTIRE MOTOR AN INCH AND A HALF

TOWARDS THE PASSENGER SIDE OF THE RIG. THAT'LL GIVE ME MORE ROOM FOR MY FEET INSIDE THE PASSENGER COMPARTMENT AND BETTER ANGLE FOR MY DRIVE LINE AS IT COMES OUT OF THE TRANSFER CASE UP INTO OUR NINE INCH CENTER SECTION THAT'S GONNA BE PART OF OUR INDEPENDENT FRONT SUSPENSION. NOW THE MOTOR ITSELF WILL BE SOLID MOUNTED INTO THIS RIG. SO NOW I'M JUST GONNA BUILD SOME MOUNTS FOR THE BLOCK THAT'LL TIE INTO THE LOWER BELLY PAN, AND THEN IN BETWEEN THE MOTOR AND TRANSMISSION I'M GONNA USE

THIS MOTOR PLATE THAT I PICKED UP FROM SUMMIT RACING. THE MID PLATE NEEDS TO BE TRIMMED AROUND A COUPLE OF SENSORS BUT ONCE CLEARANCED, IT BOLTS

RIGHT INTO POSITION. [ SAW CUTTING ]

(IAN)>> THE ENGINE MOUNTING PLATES ARE MADE FROM SOME THREESIXTEENTHS INCH STEEL AND CUT ON THE EDWARDS IRON WORKER WITH THE MOUNTING HOLES PUNCHED AS WELL. THEN IT'S BOLTED INTO THE BLOCK. INCH AND THREE QUARTER DOM IS THEN CUT... [ SAW CUTTING ] ...NOTCHED... [ DRILL SPINNING ] ...AND TACK WELDED INTO POSITION ALONG WITH A SECONDARY SUPPORT TUBE FOR EXTRA STRENGTH. AND WITH THAT PROJECT BUCKIN' BRONCO HAS A POWER PLANT WORTHY OF THIS MONSTER CHASSIS.

Show Full Transcript

AND WE INTRODUCE A WEST COAST KID TO EAST COAST ROCK BOUNCING.

(IAN)>> WE'RE KICKING THINGS OFF TODAY WITH PROJECT DISCOUNT DATSUN. NOW WE HAVE MADE A LOT OF HEADWAY ON OUR LITTLE MINI TRUCK THAT WE'RE CONVERTING INTO A $10,000 DOLLAR HARDCORE CRAWLER. WE'VE ALREADY LINKED THE BACK END OF THE TRUCK, CUT

IT UP, AND PUT IN A TUBE CHASSIS ON THE BACK, ADDED SOME 42 INCH TALL TIRES ON SOME BEADLOCKS, AND REBUILT A TRANSFER CASE TO CONVERT IT OVER TO FOUR WHEEL DRIVE. I'M SURE YOU'VE FIGURED OUT BY NOW THAT I'VE ONLY BEEN WORKING ON THE BACK HALF OF THE TRUCK, AND THAT IS BECAUSE ON THE FRONT END WE'RE GONNA NEED SOME TYPE OF CUSTOM AXLE BECAUSE THE DROP OF OUR

TRANSFER CASE IS ON THE PASSENGER SIDE AND I WANT TO USE A HIGH PINION FORD. BUT CAN YOU BUILD A CUSTOM AXLE ON THE CHEAP? WELL YOU CAN, YOU JUST BUILD IT A LITTLE BIT DIFFERENT.

TO START THE AXLE NEEDS TO BE STRIPPED OF ALL OF ITS FACTORY BRACKETS.

THE BEST JOB FOR THIS IS THE GOOD OLE OXY FUEL TORCH.

IT MAKES QUICK WORK OF THIS RUSTY AXLE.

THE SHORT SIDE TUBE IS THEN CUT OFF THE AXLE USING THE PLASMA CUTTER. IT'S GROUND FLAT WITH A BEVEL AROUND THE OUTER EDGE OF THE TUBE. WE'RE BUILDING A CUSTOM WIDTH FRONT AXLE FOR A COUPLE OF DIFFERENT REASONS. THE 14 BOLT THAT'S IN THE BACK OF OUR PROJECT IS NOT A FULL WIDTH 14 BOLT. IT'S OUT OF A DUAL REAR WHEEL CAB AND CHASSIS TRUCK. NOW THEY ARE ABOUT FOUR INCHES NARROWER THAN A FULL WIDTH AXLE, AND THAT'S WHAT THIS FRONT SUPERDUTY 60 IS. IT'S FULL WIDTH, RIGHT AROUND 67 INCHES. THE OTHER PROBLEM IS THE SAMURAI TRANSFER CASE I'M USING TO TURN THIS TRUCK INTO A FOUR WHEEL DRIVE,

THE DROP IS ON THE OPPOSITE SIDE, AND THESE

BIG FORD SUPERDUTY HIGH PINION 60'S, THEY'RE

WHAT'S CALLED A DRIVER'S SIDE DROP. SO THE PUMPKIN IS ON THE DRIVER'S SIDE OF THE TRUCK. I BASICALLY NEED TO MOVE IT OVER TO THE PASSENGER SIDE OF THE TRUCK. THAT MEANS THAT THE LONG TUBE NEEDS TO BE ON THIS SIDE AND THE SHORT TUBE NEEDS TO BE ON THIS SIDE. NOW THE CORRECT WAY TO DO THIS WOULD BE TO DRILL OUT

ALL THE SPOT WELDS, PRESS THE TUBES OUT OF THE HOUSING, REPLACE THEM WITH SOME BRAND NEW BEEFY HALF INCH WALLED DOM, UPGRADE TO SOME KINGPIN KNUCKLES, A WHOLE NEW BRAKE SYSTEM, AND THEN INSTALL A LOCKER AND GEAR SET. BASICALLY BUILD A BOMBPROOF TRAIL AXLE, BUT THAT WILL BASICALLY DECIMATE THE BUDGET THAT WE HAVE FOR THIS TRUCK. I'M GONNA RETAIN THE MAJORITY OF THE STOCK COMPONENTS, AND I AM GONNA NARROW THIS AXLE USING A SYSTEM CALLED SLEEVE AND TRUSS. BECAUSE WE'RE WORKING ON A BUDGET, I NEED TO MAKE SURE THAT THE NEW HOUSING WORKS WITH A SET OF OFF

THE SHELF AXLE SHAFTS. SO I AM MEASURING INTO THE FACTORY DIFFERENTIAL TO DETERMINE THE LOCATION OF THE LOWER BALL JOINT. THE LONG SIDE AXLE WILL BE 34.5 FIVE INCHES LONG, AND KNOWING THIS MEANS THAT I NEED TO ADD 24 AND A HALF INCHES TO THE DRIVER'S SIDE OF THE HOUSING.

THIS IS WHAT I WILL CUT OFF OF THE EXISTING LONG SIDE TUBE.

WITH THE INNER "C" REMOVED FROM THE KNUCKLE, THE

ORIGINAL AXLE SHAFT IS CUT AND THEN HAMMERED OUT. THE SHORT SIDE AXLE WILL BE ONLY 16 INCHES LONG. SO I WILL GRIND WHAT IS LEFT OF THE ORIGINAL LONG SIDE AXLE TUBE FOR THE STOCK INNER "C" TO SLIDE OVER.

NOW THIS FIRST STEP IN CHANGING THE DROP OF THE FRONT AXLE WAS OBVIOUSLY PRETTY EASY.

I NOW HAVE THE PINION ON THE PASSENGER SIDE OF THE TRUCK BY MAKING THE LONG SIDE AXLE TUBE A LOT SHORTER. SIMPLY MOVED THE INNER "C" FURTHER DOWN THE TUBE. BUT MAKING THE SHORT SIDE AXLE TUBE LONGER, THAT'S WHERE THINGS GET A LITTLE BIT MORE DIFFICULT. NOW WHEN YOU'RE WORKING ON A BUDGET, IT STARTS BY CUTTING A SLEEVE TO FIT INSIDE THE HOUSING. [ GRINDER SPINNING ]

[ WELDER CRACKLING ] [ GRINDER SPINNING ]

(IAN)>> THE MAIN PURPOSE OF THE SLEEVE IS JUST TO ALIGN THE TWO AXLE TUBES. NOW IT DOES GIVE A LITTLE BIT MORE STRENGTH TO THE BUTT JOINT THAT I'M GONNA BE WELDING IN PLACE HERE, BUT WE DO NEED TO ADD A LITTLE BIT MORE. IF YOU REMEMBER, WHEN WE GOT OUR FOUR LINK KITS FROM BARNES FOUR WHEEL DRIVE, THEY SENT US TRUSSES FOR BOTH AXLES, AND THAT IS WHERE THE REAL STRENGTH WILL COME INTO PLAY ON THIS AXLE.

THIS TRUSS WILL NOT ONLY BRIDGE THE GAP OVER THE CENTER SECTION, BASICALLY ATTACHING BOTH TUBES TOGETHER, BUT THE TRUSS ITSELF WILL ACTUALLY COVER UP THE FINISH WELDED JOINT, GIVING IT EVEN MORE STRENGTH. ONCE ALL THIS WELDING IS DONE I HAVE FLIPPED THE DRIVER'S SIDE TO THE PASSENGER SIDE DROP ON THE

AXLE AND NARROWED IT THREE INCHES TO MATCH THE REAR. WITH THE SLEEVE IN PLACE, THIS JOINT NEEDS A MULTIPASS WELD.

THE ROOT WILL LOCK THE SLEEVE INTO PLACE AND THE COVER PASSES WILL FINISH OUT THE JOINT AND IT IS GROUND SMOOTH. [ WELDER CRACKLING ]

(ANNOUNCER)>> UP NEXT, OUR DATSUN GETS FULL HYDRAULIC STEERING, GEARS, AND A LOCKED DIFF.

(IAN)>> ANOTHER WAY TO STRENGTHEN UP THAT FRONT AXLE IS TO ADD A TUBE TRUSS ACROSS THE FRONT OF IT. NOW THAT TUBE TRUSS IS USED TO MOUNT A FULL HYDRAULIC STEERING SYSTEM. NOW YES, THIS IS NOT CHEAP, BUT WE HAVE ROOM IN OUR BUDGET FOR IT AND IT'S THE RIGHT DECISION TO MAKE WITH A 42 INCH TALL TIRE. NOW THE KIT THAT I HAVE CHOSEN FOR DISCOUNT DATSUN IS A COMPLETE KIT FROM TRAIL GEAR OFF ROAD. IT COMES WITH THE RAM, ORBITAL VALVE, EVEN A PUMP, AND ALL THE HEIM JOINTS AND ALL THE

FITTINGS AND EVERYTHING TO MAKE IT WORK.

BUT WHAT'S REALLY COOL IS THEY ALSO INCLUDE A PIECE OF TUBING TO WELD ONTO THE FRONT AXLE AS WELL AS THE PADS TO MOUNT THE RAM. SO YOU'RE NOT ON THE HOOK TO FABRICATE ANYTHING. IT BASICALLY COMES READY TO GO. THIS TUBE WILL BRIDGE ACROSS THE CENTER SECTION, CONNECT OUR TWO AXLE TUBES TOGETHER MAKING OUR AXLE EVEN STRONGER. THE TUBE IS A UNIVERSAL LENGTH AND NEEDS TO BE SHORTENED TO FIT THE AXLE. [ SAW CUTTING ]

(IAN)>> WITH IT CUT TO THE CORRECT LENGTH, IT IS THEN GROUND TO FIT THE PROFILE OF THE AXLE TUBE AND TACKED INTO PLACE. [ GRINDER SPINNING ]

(IAN)>> THE FACTORY KNUCKLE IS THEN INSTALLED TO DETERMINE THE LENGTH OF THE TIE ROD. AND WITH THE HEIM JOINTS IN PLACE ON THE RAM AND THE STEERING KNUCKLE, THE TIE ROD IS CUT FROM SOME QUARTER INCH WALL DOM. THE REASON I ONLY TACK WELDED ON OUR FULL HYDRAULIC STEERING RAM MOUNT IS BECAUSE I NEED TO MAKE SURE I CAN STILL GET THE DIFF COVER OFF AS WELL AS GET THE DIFFERENTIAL CARRIER OUT OF THE AXLE IN ORDER TO SERVICE IT. THAT'S WHY I WAIT UNTIL THE VERY END TO UPGRADE OUR RING AND PINION AS WELL AS LOCK UP THIS AXLE. NOW WHEN YOU'RE BUILDING AN AXLE ON A BUDGET LIKE WE ARE YOU'RE GONNA HAVE TO GO AT IT A

LITTLE BIT DIFFERENTLY. TRY TO REUSE AS MANY OF THE STOCK PARTS AS YOU CAN. I CAN REUSE MY OUTER STUBS. I HAVE ONE INNER SHAFT THAT IS THE CORRECT LENGTH. I DID NEED TO BUY A SINGLE SHORT SIDE AXLE SHAFT FROM YUKON BECAUSE I DIDN'T HAVE ANYTHING LAYING AROUND THE SHOP.

ALSO WHEN YOU'RE INSTALLING YOUR RING AND PINION, DON'T GO FOR THE FULL BLOWN INSTALL KIT. GET WHAT'S CALLED THE MINI INSTALL KIT. THIS IS JUST ENOUGH PARTS TO INSTALL A RING AND

PINION IN THE AXLE. YOU'LL HAVE TO REUSE THE MAJORITY OF YOUR BEARINGS. IF WHEN YOU'RE IN THE AXLE YOU FIND A BAD BEARING, JUST REPLACE THE SINGLE ONE. ALSO PLAN FOR A COUPLE OF SPARE PARTS. I CAN REUSE ALL MY OUTER SHAFTS BUT I DID GET ONE SINGLE CHROMOLY OUTER SHAFT THAT I'LL CARRY IN THE TRUCK AS A SPARE. THIS IS GONNA BE THE ONE FAILURE POINT ON OUR AXLE. I FULLY EXPECT THE STOCK SHAFTS TO BREAK AT SOME TIME. SO I'LL ONLY UPGRADE THEM TO CHROMOLY WHEN IT'S REQUIRED, AND BY CARRY ONE IN THE TRUCK I'LL BE ABLE TO GET OFF THE TRAIL.

I CHOSE A PRETTY DEEP GEAR RATIO FOR PROJECT DISCOUNT DATSUN. THAT'S BECAUSE I'M GONNA NEED ALL THE HELP I CAN GET TO TURN OUR 42 INCH TALL TIRES. I CHOSE A 5.38 TO ONE FROM YUKON GEAR AND AXLE. NOW WE'LL INSTALL THOSE IN BOTH THE REAR 14 BOLT AND OUR FRONT DANA 60. NOW IF PRICE WAS NO OBJECT I'D ALSO PICK UP A COUPLE

OF LOCKERS WHEN I GOT THOSE GEARS. MAYBE A ZIP LOCKER FOR THE BACK AND MAYBE A GRIZZLY LOCKER FOR THE FRONT. WHO KNOWS, BUT I'M PINCHING MY PENNIES. SO WE HAVE TO DO SOMETHING A LITTLE BIT DIFFERENTLY. I'M GOING TO WELD UP THE DIFFERENTIALS IN THIS AXLE, AND WHEN YOU SEE HOW THAT WORKS YOU'LL

UNDERSTAND WHY IT CREATES A LOCKER. WHEN YOU DRIVE AN OPEN CARRIER ON THE STREET, WHEN YOU DRIVE AROUND A CORNER, THE TIRES MOVE

INDEPENDENT OF EACH OTHER. NOW WHAT A LOCKER DOES IS IT WILL SENSE WHEEL SPEED.

SO IF ONE TIRE GETS OFF THE GROUND, IT'LL SENSE THAT TIRE SPINNING IN THE AIR AND WILL LOCK THE AXLE TOGETHER.

IF YOU DON'T HAVE A LOCKER, IF YOU HAVE AN OPEN DIFFERENTIAL LIKE THIS, WHEN ONE TIRE GETS OFF THE GROUND YOU'RE NOT GOING ANYWHERE BECAUSE THAT SPIDER GEAR IS JUST GONNA SIT THERE AND SPIN. WHAT I'M GONNA DO IS WELD ALL THESE SPIDER GEARS TOGETHER AND PREVENT THEM FROM TURNING. IT'LL BASICALLY TURN OUR AXLES INTO SPOOLS FRONT AND REAR. NOW THIS IS OBVIOUSLY FOR OFF ROAD USE ONLY AND ONLY WHEN YOU'RE WORKING ON A BUDGET. LATER ON IF WE GET SOME MORE MONEY FOR THIS PROJECT THE BEST DECISION WOULD BE TO REPLACE THESE WITH SOME TYPE OF LOCKER. BUT FOR NOW WELDED DIFF, IT'S THE WAY TO GO. [ DRILL SPINNING ]

(IAN)>> TO WELD UP THE SPIDERS IN THESE DIFFERENTIALS I'M SWITCHING THE REBEL WELDER OVER TO STICK WELDING AND USING A 70-14 ROD IN THE ARC STINGER. [ WELDER CRACKLING ]

(IAN)>> THEN ALL WE HAVE LEFT TO DO IS INSTALL THE NEW GEARS AND DROP THE CARRIERS BACK INTO THE

HOUSING, AND THEN THESE AXLES WILL BE FINISHED. SO HOW MUCH DAMAGE DID WE DO TO OUR BUDGET TODAY? THE FULL HYDRO STEERING KIT WAS $1,300 BUCKS. OUR SINGLE NEW INNER AXLE, $130. RING AND PINION FRONT AND REAR, $550, AND OUR SPARE SINGLE CHROMOLY OUTER STUB, THAT WAS ANOTHER $150 BUCKS. WE SPENT $150 DOLLARS ON INSTALL KITS AND I UPGRADED THE YOKE ON THE DANA 60 FOR $175. AND I'LL BE FINISHING OFF THESE AXLES WITH A SET OF YUKON HEAVY DUTY DRIVE FLANGES AT JUST UNDER $270 DOLLARS. THE LOCKERS, THOSE WERE FREE, BRINGING TODAY'S TOTAL TO $2,725 BUCKS. A STEAL FOR A CUSTOM FRONT AXLE AND A REGEARED

REAR FULLY LOCKED.

(ANNOUNCER)>> COMING UP, SPEND A DAY ON THE TRAIL AT ONE OF OUR FAVORITE OFF ROAD PARKS.

(IAN)>> FOR THE PAST EIGHT YEARS ONE OF OUR FAVORITE PLACES TO GO WHEELING HAS BEEN WOOLEY'S OFF ROAD IN LYNNVILLE, TENNESSEE.

WITH A WIDE VARIETY OF TERRAIN AND TRAILS IT'S THE IDEAL PLACE TO PUT OUR PROJECTS THROUGH THE PACES. FROM DIRT CHEAP BUDGET BUILDS TO FULLY BLOWN TUBE BUGGIES. WE'VE DROPPED ALL KINDS OF RIGS ONTO THE TRAIL AND HAD A BLAST DOING IT. FROM THE BEGINNING THE OWNERS OF WOOLEY'S OFF ROAD WANTED TO BUILD A FOREST FULL OF EXCITING AND CHALLENGING TRAILS, BUT THEIR FIRST IDEA WAS QUITE DIFFERENT THAN THE PARK WE KNOW AND LOVE TODAY.

(VAN)>> MY DAD'S ALWAYS WANTED TO INVITE HORSE RIDERS HERE AND DO TRAIL RIDES AND I THOUGHT, YEAH, THEY ONLY COME OUT A COUPLE TIMES A YEAR, AND I SEE THESE PEOPLE ON FOUR WHEELS AND DIRT BIKES. WE ALWAYS LIKE TO DO THAT TOO. WE RODE OURS ALL THE TIME AND I NOTICED PEOPLE LOADING THEM UP AND GOING SOMEWHERE EVERY WEEKEND. SO WE DECIDED WE'D GO WITH THAT INSTEAD OF HORSES.

(IAN)>> FORTUNATELY FOR WHEELS WOOLEY'S EQUESTRIAN PARK BECAME WOOLEY'S OFF ROAD PARK. 500 ACRES OF PRIME TRAILS, A WEEKEND GETAWAY LESS THAN AN HOUR FROM NASHVILLE, TENNESSEE,

AND HUNTSVILLE, ALABAMA.

(VON)>> MOST TRAILS STARTED OUT AS LOGGING TRAILS. WE DRAGGED LOGS OUT OF THE WOODS WITH A SKIDDER, AND THAT'S HOW MOST OF THE TRAILS STARTED. AND THEN WE CLEANED THEM UP A LITTLE BIT WITH A CHAINSAW, AND THEN THERE WERE A FEW WE ACTUALLY MADE WITH JEEPS.

(IAN)>> IF YOU'RE TRAVELING LONG DISTANCE, WOOLEY'S AND THE SURROUNDING AREA HAVE PLENTY OF AMENITIES. ON SIDE THERE'S PRIMITIVE CAMPING, RESTROOMS, AND A SNACK BAR. NEARBY ARE SEVERAL HOTELS, RESTAURANTS, AND A FULL SERVICE CAMP GROUND. THERE'S ALSO PLENTY OF OPTIONS FOR ALL KINDS OF RIGS.

(VON)>> AND WE GET TO SEE A LOT OF ROCK CRAWLERS AND ROCK BOUNCERS. WE SEE A LOT OF SIDE BY SIDES AND ATV'S. SO THERE'S A WIDE RANGE OF VEHICLES, AND THEY ALL HAVE A GOOD TIME.

(IAN)>> THE TRAILS HERE RANGE FROM MODERATE RUNS

TO SERIOUS HILL CLIMBS, BUT WOOLEY'S IS RESPONDING

TO REQUESTS FOR MORE ENTRY LEVEL OPTIONS FOR NEW AND YOUNGER RIDERS.

(VON)>> WE'RE GONNA BUILD SOME EASIER AREAS, AND

I'VE GOT A FIELD ACROSS THE ROAD FROM THE BUILDING HERE, AND I'M JUST GONNA BUILD A LITTLE OBSTACLE COURSE IN THERE FOR BEGINNERS.

(IAN)>> TODAY WE'RE RIDING WITH A BUNCH OF FELLOW WHEELERS FROM THE MIDDLE TENNESSEE AREA, AS WELL AS NICK BARTON AND HIS FAMILY. THEY LIVE IN SACRAMENTO, AND ARE MAKING THEIR FIRST WHEELING TRIP OUT EAST.

(NICK)>> IT'S AWESOME! IT'S A TOTALLY DIFFERENT TERRAIN. ROCKS ARE DIFFERENT, REALLY SLICK, DON'T REALLY HOOK UP THAT GOOD IN SOME SPOTS, BUT OVERALL IT WAS A GOOD TIME.

(IAN)>> NICK'S REGULAR TRAIL RIG IS A '94 TOYOTA PICK UP. WE DECIDED TO GIVE HIM SOME SEAT TIME IN A FULL BLOWN TUBE BUGGY.

(NICK)>> YOU CAN SEE A LOT BETTER WHERE YOU'RE GOING INSTEAD OF BEING IN A CAB TRUCK, AND IT'S A LITTLE BIT EASIER TO POINT IN THE DIRECTION YOU WANT TO GO. AND OVERALL REALLY GOOD MACHINE.

(IAN)>> AND SINCE NICK TRAVELED ALL THE WAY ACROSS THE COUNTRY TO GO WHEELING WITH US, WE WANTED HIM TO EXPERIENCE THE ULTIMATE IN EAST COAST EXCITEMENT, ROCK BOUNCING. SO RICHIE KEITH, ONE OF THE PREMIER RACERS IN THE SPORT, BROUGHT OUT HIS RIG "PLOW BOY" AND AN EXTRA HELMET. FOR NICK, IT'S AN EXPERIENCE HE'LL NEVER FORGET.

(NICK)>> NUTS, IT WAS SUCH AN ADRENALINE RUSH. I MEAN JUST THAT FIRST HILL JUST BOUNCING OFF THOSE ROCKS. JUST LIKE I COULD FEEL MY HEAD SHAKING AROUND, AND IT WAS CRAZY. JUST LIKE THE MUD FLYING OFF THE TIRES. IT WAS AN EXPERIENCE LIKE NO OTHER, AND I'M GLAD

THAT I GOT TO EXPERIENCE THAT.

(IAN)>> SO THE NEXT TIME YOU'RE PLANNING A WHEELING TRIP, NO MATTER WHAT KIND OF RIG YOU'VE GOT, WOOLEY'S HAS A TRAIL FOR YOU. [ ENGINE REVVING ]

(ANNOUNCER)>> UP NEXT, IT'S BASED ON THE CLASSIC '66 BRONCO, BUT OUR DESERT RACER WILL HAVE PLENTY OF MODERN MUSCLE UNDER THE HOOD.

(IAN)>> THERE'S BEEN A LOT OF SPECULATION ABOUT WHAT ENGINE I PLAN TO PUT INSIDE OUR TUBE CHASSIS '66 BRONCO. WE WANTED TO HAVE LOTS OF POWER BECAUSE WE'RE BASICALLY BUILDING AN ULTRA FOUR RACE CAR WITH CLASSIC STYLING. WE WANTED IT TO BE A MODERN ENGINE SO IT'S LIGHTWEIGHT WITH A MODERN EFI SYSTEM INSIDE OF IT. NOW MOST PEOPLE WOULD THINK, WELL THE EASIEST SOLUTION THERE IS GONNA BE SOME TYPE OF LS BASED ENGINE, AND THAT IS VERY POPULAR IN ULTRA FOUR RACING BUT COME ON! THIS IS A '66 BRONCO, IT NEEDS FORD POWER, AND WHAT BETTER THAN A FORD PERFORMANCE PARTS ALUMINATOR COYOTE BASED ENGINE.

THIS IS NOT A BRAND NEW CRATE ENGINE, BUT AN ENGINE THAT WAS ORIGINALLY INSTALLED INTO AN ENGINE POWER FOX BODY MUSTANG PROJECT. THEY PULLED IT OUT FOR AN ENGINE SWAP AND I SNAGGED IT. THIS ALUMINATOR IS THE LOW COMPRESSION SUPERCHARGER READY VERSION WITH HBEAM CONNECTING RODS, ARP BOLTS, AND FORGED PISTONS. ON OUR ENGINE DYNO THIS BEAST PUT DOWN OVER 450 HORSEPOWER AND JUST NORTH OF 430 POUND FEET OF TORQUE.

[ ENGINE REVVING ]

(IAN)>> ENGINE POWER'S PROJECT CAR WAS A STICK, BUT OUR BRONCO, IT'S GONNA BE AN AUTOMATIC. SO THE SIX SPEED TRANS, ALONG WITH THE PRESSURE PLATE, CLUTCH, AND FLYWHEEL, HAVE TO GO.

[ DRILL SPINNING ]

(IAN)>> USING AN ENGINE SLING, I POSITION THE COYOTE ONTO THE FRAME TABLE AND LEVEL IT UP USING A SCISSOR JACK ON THE FRONT BALANCER. I'VE PUSHED THE ENTIRE MOTOR AN INCH AND A HALF

TOWARDS THE PASSENGER SIDE OF THE RIG. THAT'LL GIVE ME MORE ROOM FOR MY FEET INSIDE THE PASSENGER COMPARTMENT AND BETTER ANGLE FOR MY DRIVE LINE AS IT COMES OUT OF THE TRANSFER CASE UP INTO OUR NINE INCH CENTER SECTION THAT'S GONNA BE PART OF OUR INDEPENDENT FRONT SUSPENSION. NOW THE MOTOR ITSELF WILL BE SOLID MOUNTED INTO THIS RIG. SO NOW I'M JUST GONNA BUILD SOME MOUNTS FOR THE BLOCK THAT'LL TIE INTO THE LOWER BELLY PAN, AND THEN IN BETWEEN THE MOTOR AND TRANSMISSION I'M GONNA USE

THIS MOTOR PLATE THAT I PICKED UP FROM SUMMIT RACING. THE MID PLATE NEEDS TO BE TRIMMED AROUND A COUPLE OF SENSORS BUT ONCE CLEARANCED, IT BOLTS

RIGHT INTO POSITION. [ SAW CUTTING ]

(IAN)>> THE ENGINE MOUNTING PLATES ARE MADE FROM SOME THREESIXTEENTHS INCH STEEL AND CUT ON THE EDWARDS IRON WORKER WITH THE MOUNTING HOLES PUNCHED AS WELL. THEN IT'S BOLTED INTO THE BLOCK. INCH AND THREE QUARTER DOM IS THEN CUT... [ SAW CUTTING ] ...NOTCHED... [ DRILL SPINNING ] ...AND TACK WELDED INTO POSITION ALONG WITH A SECONDARY SUPPORT TUBE FOR EXTRA STRENGTH. AND WITH THAT PROJECT BUCKIN' BRONCO HAS A POWER PLANT WORTHY OF THIS MONSTER CHASSIS.