Classic Trucks! Builds

Want more content like this?

Join the PowerNation Email NewsletterEpisode Transcript

Hey, welcome to drugs.

I've got a great show for you today. Is this cool or what?

Now we got some four wheel drive stuff, got some classic truck stuff, even have a really sweet bike. But before I get sidetracked, let me show you the first thing that we're gonna work on today,

gonna take care of some of the details on project Crazy Horse.

As you can see, this thing is almost finished. It's almost ready to take down the trail.

But after today, it's gonna be even closer. The first thing we're gonna put on it

are these James Duff tubular prerunner bumpers. Now, these not only look good,

these are a true off road bumper, so they are very strong.

Now, this powder coating, we sent them off to a place called color coded to have that done

because powder coating is a lot stronger than paint

to install the bumper, slide in the frame supports,

followed by the bumper

and then finally just bolt them on

while I'm back here with the tailgate off. It's a good time to do something about a spare tire.

You've got a couple choices here, bumper

or bed

and either one can be a little bit of a challenge if you're using a 35 inch or bigger tire.

Now, since our bumper doesn't have any place to mount a tire,

we're gonna put it in the bed because that looks really cool on these half cabs. And also this little Bronco bed is perfect for carrying all your four wheel drive gear.

So to mount the tire in,

we went to a place called RJ R products. Got this tire mount.

It's a lightweight design but still very strong

and it will allow you to mount big diameter tires. Now, of course, it comes with all the bracketry and hardware to put it in.

Now,

this will not only allow you to pull out the tire in just seconds,

but it'll also allow you to pull out the whole mound in just seconds. If you wanna use this bed for something else,

first decide where you want to mount the thing by centering it up in the bed,

then mark your holes for your mounting plates

and then drill your holes.

Now, with the brackets bolted on,

this is how the mount slides into it.

Finally just mount your tire.

Now, I told you that looked good in the Bronco gives it just a little bit of desert racer feel Parnelli would be proud. Now, while I'm back here in the bed, I have something else I need to put in here a battery

or two

since the engine compartment on most vehicles is a little tight.

It's always nice to be able to relocate the battery and get it out of there in the bed of that. Bronco is gonna be a perfect spot. Also,

if you do any kind of off roading,

having dual batteries is a really good idea, especially if you use a winch or any kind of off road lights.

So I put together a system, let's check it out.

First thing we're gonna do is put in a couple of optima yellow top deep cycle batteries because of their quick recovery time. These have 950 cranking amps each.

You got the option of side or top posts

and the optima is sealed so you can literally mount this thing in any position with no problem to connect those two batteries. We're gonna use a dual battery kit that we got from wild horses and it includes cables and wiring and hardware and relays and switches.

Everything that you're gonna need to hook up a dual battery system and get the most benefit out of it.

Now, you don't wanna just mount these batteries out in the weather, you wanna put them in something.

So for that went to Mr Gasket, got a couple of these battery boxes

and these will not only protect the battery,

but they also come with cables and hardware and all kinds of stuff to help you hook it up. Matter of fact, putting this whole system in is as simple as bolding in the box

and making your connections.

Now that we know where the spare tire is going to go,

we can mount the battery boxes around it

up against the bulkhead

is the perfect place.

Ok. Now it's time to deal with some questions you might have about a dual battery set up. Now, in this application,

I'm gonna run them in parallel. Now what this means is the positive of one battery will connect to the positive of the other.

The negative will go to the negative. This will double your amps but still keep everything 12 volt.

Now, if you hook them up in series, here's what you have negative out.

This positive connects to this negative, then you have your positive out.

This gives you 24 volt

and will burn down all your 12 volt accessories and probably your wiring harness. Yeah, you don't wanna do that. So

make sure that you're hooking up in parallel unless you're specifically building a rig

to handle a 24 volt system.

All right, with all this talk about batteries, let's move up here to the front and see why I'm gonna need all that extra power.

Obviously, this is a winch bumper.

So let's talk winches. I got this baby from mile marker and it is a hoss. It's a 12,000 pound electric winch

has a powerful 5.5 horsepower motor line holding brake power in and out 38 inch cable. Yeah, this is the good stuff comes with accessories, roller, fairly

remote

and for a few dollars more, you can get this wireless remote system so you can control the winch with the push of a button.

No wire, hook up pretty slick. But the best part about this is this is a true 12,000 pound winch. It will bolt into the same spot of the smaller 9000 pound winch and it's only about 20 pounds heavier

installation is as simple as Bolton on the winch, the fair lead

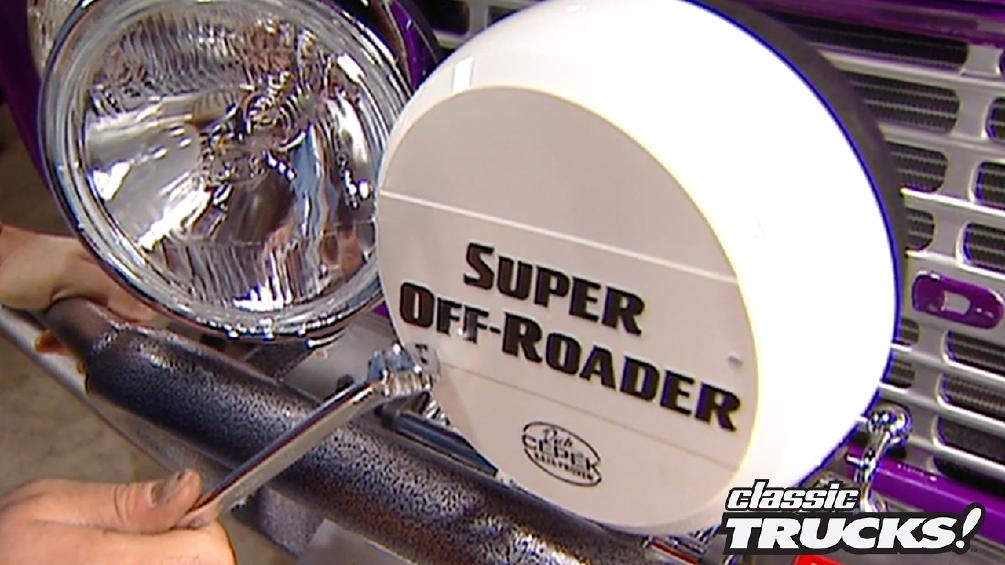

and making your electrical connections. Now, there is one other thing I'm gonna put on up here and it's gonna suck some power too. And that's these off road lights.

Now, these big old boys are from extreme suspensions

and they are basically a redesign of the old DX C

PC C 900 Super off Roaders.

Now, they feature

100 and 30 watt halogen bulb

that kicks out 310,000 candle power. Now, they have a dual design lens that not only throws a light long, like miles long,

but also throws it wide. So you see what's around you now to hook these up. I also got one of their dual relays and dual switch kits because using the relay is the only way to hook these kind of lights up properly.

Well, that finishes off what I wanted to do on the front, the lights, the winch the bumper

and the rear, the spare tire, the batteries, the bumper.

Now, obviously, I've got a few more things to do on here. I've got wiring to put in and glass and the roof needs to go on, but

I'll take care of that later because after the break, I'm gonna show you what to do when those new parts you're putting on aren't quite fitting the way you want them to.

Sometimes you need to persuade them a little bit.

Welcome back. You know, some of the comments that I get when I'm out at shows or wherever is

man, you make this stuff look easy. It just falls into place and

you must have a lot of people helping you. Right.

Well, the answer is no, no and no, no, it's not that easy.

No, it doesn't just fall into place and no, there's not a lot of people helping me, just me and a TV crew.

The reason I tell you this is because one thing I like to do on the show here is show you some of the problems that come up when you're building a rig and how to deal with them.

That's why they call it, do it yourself. Sometimes you have to make it work. Got a prime example here for you. Follow me.

OK? You may remember on crazy horse that this B and M shifter is exactly what I wanted to make this thing really shift, right?

Unfortunately, this is the only handle available with that shifter for that transmission.

And since this is a custom application, well, it's not in the most ideal spot. It's a little forward up toward the dash. A

little bit of a reach. It'd be much better if it was right back here because

you wanna be able to come right off of the steering wheel. Boom, right down onto the shifter.

So,

what are you gonna do?

Well, you could heat it and bend it, but you've already got to bend here. That would have to be straightened. Uh

There's a better way to do it.

I went out and got this chrome hurst handle

and it will put the shifter exactly where it needs to be. So

I cut off this stub off of an old her shifter. Now, all I have to do is set it in place

and make a cut mark,

then cut off the old B and M handle

and drew up the end.

Now weld the new stub onto the shaft. Now, this is one area that I prefer the tig welder because of the small precise welds, great strength and penetration, but

a mile

work too

with your welding done. Go ahead and paint the part. So it doesn't rust

and then bolt on the shifter and then put on the handle. Now, here's what we've got,

have our performance shifter.

Now we have an arm that comes up exactly where we wanted it.

That is sweet. Now, we're gonna finish it off with one of these low car boots and that will be that.

Now, this was pretty easy. This didn't take very long and hopefully this shows you that you don't have to settle for what comes out of the box, if it's not right, take a little bit of time, make it fit your application perfectly.

Now, we're gonna do something a little different. This project is for you classic truck guys.

One thing that makes a classic or older truck unique is that most of them have that gorgeous wood bed in the back.

Now, if you like trucks, eventually, you're gonna wanna build them with a wooden bed

and you're gonna wanna know how to put a good finish on it. Now, some of you might be thinking, well, how hard is that?

You go down to Home Depot and buy some stain and brush it on. Right.

Right. And that'll last you about two months. No. If you want to look like this and handle the weather,

there's a lot more to it than that. And I'm gonna walk you through the steps first. You need to start with some good materials, both wood

and coatings. So we went to Bruce

Hoy's wood and parts

because they specialize in wood bed kits.

We got some of these really nice oak planks to demonstrate on

and we got some stain and sealer and then for our final finish, we got some spar varnish. Of course, we have various brushes and sandpaper and materials to help in the process.

The first step

is working the raw wood. Now, this stuff comes from Bruce Hokey already machine sanded, but

it doesn't mean it's ready for stain.

So the first thing you wanna do

is come in

and slightly round off all these sharp edges. Now, I'm using some 120 grit

and a backing pad.

And what this will do

is keep the finish from getting too thin on a sharp corner. Now, once those are right, we'll take the 120 grit

and we'll work the face, the sides and the back

and then once you have those, how you want them,

we'll take a tack cloth, wipe it all down, get the dust and particles off, then you're ready to put some stain on, which is what we're gonna do

after the break.

Just can't get enough of trucks. Check us out online at trucks, tv.com.

Welcome back.

We are in the process of showing you how to put a nice quality finish

on the wood bed in your truck.

And we're using products from Bruce

Hoy's wood and parts.

Now, we've got the wood all sanded down nice and smooth.

Now it is time for the finish. And the first step of that is the stain.

Now we're gonna put this on using nice long strokes,

making sure it stays all uniform

and this product will do a couple of different things. It's gonna seal the wood

and of course, it's gonna stain it a nice golden oak color.

Once your stain is dry, you're ready to move on to your varnish.

Couple of things here, you wanna make sure that you do all of the wood, not just the top, need to do the sides, the bottom, the ends, everything

because if you don't,

that's where moisture will get in and that will cause your wood to split and crack on you. Now, a nice trick to doing both sides is to run some screws or nails down into your saw horses, then finish the backside,

roll the board over

and now you can do the face and not have to worry about rubbing the finish off the bottom.

Now, the first coat of varnish is gonna be thinned about 25%

to help it penetrate a little quicker and a little easier.

Once it's completely dry, move on to a second coat of thin varnish.

This ensures proper penetration and sealing in the wood.

When that's dry,

lightly sand, the wood with the grain to remove any dust or imperfections,

then you're ready for your first full varnish coat.

All right. A couple of things about spar varnish. Number one is self leveling. So

don't overwork the finish trying to get all the brush strokes out of there. It'll take care of that for you.

Also. Number two, once you have the finish on,

run the length of the board using long even strokes. This will remove any kind of splotches that you might have gotten in there where the brush start and stop. And finally, and this is the biggie,

make sure that each coat is cured before you put on the next one. Now, just because it's dry to the touch, doesn't mean that it's cured the stuff dries from the inside out. And if you slap on another coat

before that one's dry,

well, now you're gonna end up with a finish that never completely dries underneath and that's gonna give you problems down the road.

So don't be in a hurry here.

Moving on. We put on a 2nd and 3rd full varnish coat to give us the protection and the finish we want.

Now make sure you lightly sand between each coat to knock down any high spots or imperfections

and that is it? Oh,

now there are some variations to this. You can use urethane or even automotive clears instead of varnish, but the steps are gonna be pretty much the same.

And if you follow these steps correctly,

well, you're gonna have a bed that not only looks awesome but it's also pretty much weatherproof. Now, you can take this even one step further. You can wet sand it with 1200 grit, sandpaper

and buff it out like you would a car paint job and that will really blow your mind.

Now, upkeep very simple. All you have to do is hit it with a coat of wax periodically and you're gonna have a bed that will last a long, long time

trucks

when things don't go as planned,

when you're ready to go racing and you're all excited and the adrenaline's pumping and the crowd is screaming,

just don't forget to make sure you've got enough gas in the tank to finish the race.

This is the legendary Walker Evans losing a wheel in competition,

but it doesn't really slow him down. He just heads back to the pits to get another one as only Walker Evans can.

Oh, yeah.

The only problem this guy is having is throttle control.

Whoa, a little too fast here

and, well, you know, a little too slow here.

Oh

my

God.

If you're working on an older Chevy street truck, I'm talking from 1960 all the way to 1987.

Eventually you're gonna wanna upgrade your brakes and I have got something to show you here. This is from bear racing. This is called the GT plus brake system.

Now, for the front, you get big thick drilled and slotted 13 and a quarter inch rotors.

The calipers are a dual piston aluminum caliper. You have performance pads inside there

and it's all assembled onto a spindle. So literally, you just bolt this on your ball joints and you go.

Now the rear is just as impressive.

You have a 13 quarter inch rotor back here. A little thinner than the front,

single piston calipers. And of course, you get all the bracketry and the hoses and the hardware to bolt this in.

If you're serious about stopping your truck, this will get the job done.

It look good doing it too.

And bear brakes is the only place to get it. Now for your four wheel drive guys, there's no doubt that the Hummer H two is a cool rig

expensive but cool. However, in stock form,

uh, they were a little lacking in the balls department and the guys at Skyjacker thought exactly the same thing

and they came out with a 5.5 inch lift for the Hummer H two

to give it more

oom

since the two suspension is fairly simple, fairly straightforward.

So was the kid from Skyjacker in spite of all these parts that you see here on the table, let me walk you through it real quick. First four new shocks then in the rear

you get new lower links, the big hem

joint at one end,

then you have the bracket to mount those.

Then you get drop brackets for your upper links

and you get drop brackets for your torsion bar cross member.

These cool looking things are aluminum spacers for your rear airbags.

Then on the front,

new steering knuckles and everything that you're gonna need to lift that independent front suspension

and all these parts made out of heavy gauge steel, powder coated red

and to protect the front suspension. You got these heavy duty skid plates. Now, if you want your H two to really stand out in the crowd, have some, uh,

skyjackers got the deal. Now, like I said before, one of the best things about owning a truck is having the bed to carry junk in. Now, like I've also said before, one of the worst things about the bed is loading stuff into it. Especially heavy things like welders and a TV S and motorcycles. Yeah. You know what I'm talking about?

Well, hold on to your shorts because a mead

deck has got the answer in what they call the super deck. Now, this is a lift platform that slides into your existing bed in just a couple hours, no modifications to the bed and with the push of a button and some high speed photography,

a hydraulic ram lifts the deck and allows you to load things into the bed you never dreamed of.

Now, the super deck is available in steel or aluminum like we've got, but the only place you can get one is a mer

deck. Now about this bike. Yeah, that's a little 60 horse Ford flathead V8 power in this thing.

And I was gonna take you for a spin. But, oh man, we're out of time but we'll take care of that next week. We'll see you then.

Show Full Transcript

I've got a great show for you today. Is this cool or what?

Now we got some four wheel drive stuff, got some classic truck stuff, even have a really sweet bike. But before I get sidetracked, let me show you the first thing that we're gonna work on today,

gonna take care of some of the details on project Crazy Horse.

As you can see, this thing is almost finished. It's almost ready to take down the trail.

But after today, it's gonna be even closer. The first thing we're gonna put on it

are these James Duff tubular prerunner bumpers. Now, these not only look good,

these are a true off road bumper, so they are very strong.

Now, this powder coating, we sent them off to a place called color coded to have that done

because powder coating is a lot stronger than paint

to install the bumper, slide in the frame supports,

followed by the bumper

and then finally just bolt them on

while I'm back here with the tailgate off. It's a good time to do something about a spare tire.

You've got a couple choices here, bumper

or bed

and either one can be a little bit of a challenge if you're using a 35 inch or bigger tire.

Now, since our bumper doesn't have any place to mount a tire,

we're gonna put it in the bed because that looks really cool on these half cabs. And also this little Bronco bed is perfect for carrying all your four wheel drive gear.

So to mount the tire in,

we went to a place called RJ R products. Got this tire mount.

It's a lightweight design but still very strong

and it will allow you to mount big diameter tires. Now, of course, it comes with all the bracketry and hardware to put it in.

Now,

this will not only allow you to pull out the tire in just seconds,

but it'll also allow you to pull out the whole mound in just seconds. If you wanna use this bed for something else,

first decide where you want to mount the thing by centering it up in the bed,

then mark your holes for your mounting plates

and then drill your holes.

Now, with the brackets bolted on,

this is how the mount slides into it.

Finally just mount your tire.

Now, I told you that looked good in the Bronco gives it just a little bit of desert racer feel Parnelli would be proud. Now, while I'm back here in the bed, I have something else I need to put in here a battery

or two

since the engine compartment on most vehicles is a little tight.

It's always nice to be able to relocate the battery and get it out of there in the bed of that. Bronco is gonna be a perfect spot. Also,

if you do any kind of off roading,

having dual batteries is a really good idea, especially if you use a winch or any kind of off road lights.

So I put together a system, let's check it out.

First thing we're gonna do is put in a couple of optima yellow top deep cycle batteries because of their quick recovery time. These have 950 cranking amps each.

You got the option of side or top posts

and the optima is sealed so you can literally mount this thing in any position with no problem to connect those two batteries. We're gonna use a dual battery kit that we got from wild horses and it includes cables and wiring and hardware and relays and switches.

Everything that you're gonna need to hook up a dual battery system and get the most benefit out of it.

Now, you don't wanna just mount these batteries out in the weather, you wanna put them in something.

So for that went to Mr Gasket, got a couple of these battery boxes

and these will not only protect the battery,

but they also come with cables and hardware and all kinds of stuff to help you hook it up. Matter of fact, putting this whole system in is as simple as bolding in the box

and making your connections.

Now that we know where the spare tire is going to go,

we can mount the battery boxes around it

up against the bulkhead

is the perfect place.

Ok. Now it's time to deal with some questions you might have about a dual battery set up. Now, in this application,

I'm gonna run them in parallel. Now what this means is the positive of one battery will connect to the positive of the other.

The negative will go to the negative. This will double your amps but still keep everything 12 volt.

Now, if you hook them up in series, here's what you have negative out.

This positive connects to this negative, then you have your positive out.

This gives you 24 volt

and will burn down all your 12 volt accessories and probably your wiring harness. Yeah, you don't wanna do that. So

make sure that you're hooking up in parallel unless you're specifically building a rig

to handle a 24 volt system.

All right, with all this talk about batteries, let's move up here to the front and see why I'm gonna need all that extra power.

Obviously, this is a winch bumper.

So let's talk winches. I got this baby from mile marker and it is a hoss. It's a 12,000 pound electric winch

has a powerful 5.5 horsepower motor line holding brake power in and out 38 inch cable. Yeah, this is the good stuff comes with accessories, roller, fairly

remote

and for a few dollars more, you can get this wireless remote system so you can control the winch with the push of a button.

No wire, hook up pretty slick. But the best part about this is this is a true 12,000 pound winch. It will bolt into the same spot of the smaller 9000 pound winch and it's only about 20 pounds heavier

installation is as simple as Bolton on the winch, the fair lead

and making your electrical connections. Now, there is one other thing I'm gonna put on up here and it's gonna suck some power too. And that's these off road lights.

Now, these big old boys are from extreme suspensions

and they are basically a redesign of the old DX C

PC C 900 Super off Roaders.

Now, they feature

100 and 30 watt halogen bulb

that kicks out 310,000 candle power. Now, they have a dual design lens that not only throws a light long, like miles long,

but also throws it wide. So you see what's around you now to hook these up. I also got one of their dual relays and dual switch kits because using the relay is the only way to hook these kind of lights up properly.

Well, that finishes off what I wanted to do on the front, the lights, the winch the bumper

and the rear, the spare tire, the batteries, the bumper.

Now, obviously, I've got a few more things to do on here. I've got wiring to put in and glass and the roof needs to go on, but

I'll take care of that later because after the break, I'm gonna show you what to do when those new parts you're putting on aren't quite fitting the way you want them to.

Sometimes you need to persuade them a little bit.

Welcome back. You know, some of the comments that I get when I'm out at shows or wherever is

man, you make this stuff look easy. It just falls into place and

you must have a lot of people helping you. Right.

Well, the answer is no, no and no, no, it's not that easy.

No, it doesn't just fall into place and no, there's not a lot of people helping me, just me and a TV crew.

The reason I tell you this is because one thing I like to do on the show here is show you some of the problems that come up when you're building a rig and how to deal with them.

That's why they call it, do it yourself. Sometimes you have to make it work. Got a prime example here for you. Follow me.

OK? You may remember on crazy horse that this B and M shifter is exactly what I wanted to make this thing really shift, right?

Unfortunately, this is the only handle available with that shifter for that transmission.

And since this is a custom application, well, it's not in the most ideal spot. It's a little forward up toward the dash. A

little bit of a reach. It'd be much better if it was right back here because

you wanna be able to come right off of the steering wheel. Boom, right down onto the shifter.

So,

what are you gonna do?

Well, you could heat it and bend it, but you've already got to bend here. That would have to be straightened. Uh

There's a better way to do it.

I went out and got this chrome hurst handle

and it will put the shifter exactly where it needs to be. So

I cut off this stub off of an old her shifter. Now, all I have to do is set it in place

and make a cut mark,

then cut off the old B and M handle

and drew up the end.

Now weld the new stub onto the shaft. Now, this is one area that I prefer the tig welder because of the small precise welds, great strength and penetration, but

a mile

work too

with your welding done. Go ahead and paint the part. So it doesn't rust

and then bolt on the shifter and then put on the handle. Now, here's what we've got,

have our performance shifter.

Now we have an arm that comes up exactly where we wanted it.

That is sweet. Now, we're gonna finish it off with one of these low car boots and that will be that.

Now, this was pretty easy. This didn't take very long and hopefully this shows you that you don't have to settle for what comes out of the box, if it's not right, take a little bit of time, make it fit your application perfectly.

Now, we're gonna do something a little different. This project is for you classic truck guys.

One thing that makes a classic or older truck unique is that most of them have that gorgeous wood bed in the back.

Now, if you like trucks, eventually, you're gonna wanna build them with a wooden bed

and you're gonna wanna know how to put a good finish on it. Now, some of you might be thinking, well, how hard is that?

You go down to Home Depot and buy some stain and brush it on. Right.

Right. And that'll last you about two months. No. If you want to look like this and handle the weather,

there's a lot more to it than that. And I'm gonna walk you through the steps first. You need to start with some good materials, both wood

and coatings. So we went to Bruce

Hoy's wood and parts

because they specialize in wood bed kits.

We got some of these really nice oak planks to demonstrate on

and we got some stain and sealer and then for our final finish, we got some spar varnish. Of course, we have various brushes and sandpaper and materials to help in the process.

The first step

is working the raw wood. Now, this stuff comes from Bruce Hokey already machine sanded, but

it doesn't mean it's ready for stain.

So the first thing you wanna do

is come in

and slightly round off all these sharp edges. Now, I'm using some 120 grit

and a backing pad.

And what this will do

is keep the finish from getting too thin on a sharp corner. Now, once those are right, we'll take the 120 grit

and we'll work the face, the sides and the back

and then once you have those, how you want them,

we'll take a tack cloth, wipe it all down, get the dust and particles off, then you're ready to put some stain on, which is what we're gonna do

after the break.

Just can't get enough of trucks. Check us out online at trucks, tv.com.

Welcome back.

We are in the process of showing you how to put a nice quality finish

on the wood bed in your truck.

And we're using products from Bruce

Hoy's wood and parts.

Now, we've got the wood all sanded down nice and smooth.

Now it is time for the finish. And the first step of that is the stain.

Now we're gonna put this on using nice long strokes,

making sure it stays all uniform

and this product will do a couple of different things. It's gonna seal the wood

and of course, it's gonna stain it a nice golden oak color.

Once your stain is dry, you're ready to move on to your varnish.

Couple of things here, you wanna make sure that you do all of the wood, not just the top, need to do the sides, the bottom, the ends, everything

because if you don't,

that's where moisture will get in and that will cause your wood to split and crack on you. Now, a nice trick to doing both sides is to run some screws or nails down into your saw horses, then finish the backside,

roll the board over

and now you can do the face and not have to worry about rubbing the finish off the bottom.

Now, the first coat of varnish is gonna be thinned about 25%

to help it penetrate a little quicker and a little easier.

Once it's completely dry, move on to a second coat of thin varnish.

This ensures proper penetration and sealing in the wood.

When that's dry,

lightly sand, the wood with the grain to remove any dust or imperfections,

then you're ready for your first full varnish coat.

All right. A couple of things about spar varnish. Number one is self leveling. So

don't overwork the finish trying to get all the brush strokes out of there. It'll take care of that for you.

Also. Number two, once you have the finish on,

run the length of the board using long even strokes. This will remove any kind of splotches that you might have gotten in there where the brush start and stop. And finally, and this is the biggie,

make sure that each coat is cured before you put on the next one. Now, just because it's dry to the touch, doesn't mean that it's cured the stuff dries from the inside out. And if you slap on another coat

before that one's dry,

well, now you're gonna end up with a finish that never completely dries underneath and that's gonna give you problems down the road.

So don't be in a hurry here.

Moving on. We put on a 2nd and 3rd full varnish coat to give us the protection and the finish we want.

Now make sure you lightly sand between each coat to knock down any high spots or imperfections

and that is it? Oh,

now there are some variations to this. You can use urethane or even automotive clears instead of varnish, but the steps are gonna be pretty much the same.

And if you follow these steps correctly,

well, you're gonna have a bed that not only looks awesome but it's also pretty much weatherproof. Now, you can take this even one step further. You can wet sand it with 1200 grit, sandpaper

and buff it out like you would a car paint job and that will really blow your mind.

Now, upkeep very simple. All you have to do is hit it with a coat of wax periodically and you're gonna have a bed that will last a long, long time

trucks

when things don't go as planned,

when you're ready to go racing and you're all excited and the adrenaline's pumping and the crowd is screaming,

just don't forget to make sure you've got enough gas in the tank to finish the race.

This is the legendary Walker Evans losing a wheel in competition,

but it doesn't really slow him down. He just heads back to the pits to get another one as only Walker Evans can.

Oh, yeah.

The only problem this guy is having is throttle control.

Whoa, a little too fast here

and, well, you know, a little too slow here.

Oh

my

God.

If you're working on an older Chevy street truck, I'm talking from 1960 all the way to 1987.

Eventually you're gonna wanna upgrade your brakes and I have got something to show you here. This is from bear racing. This is called the GT plus brake system.

Now, for the front, you get big thick drilled and slotted 13 and a quarter inch rotors.

The calipers are a dual piston aluminum caliper. You have performance pads inside there

and it's all assembled onto a spindle. So literally, you just bolt this on your ball joints and you go.

Now the rear is just as impressive.

You have a 13 quarter inch rotor back here. A little thinner than the front,

single piston calipers. And of course, you get all the bracketry and the hoses and the hardware to bolt this in.

If you're serious about stopping your truck, this will get the job done.

It look good doing it too.

And bear brakes is the only place to get it. Now for your four wheel drive guys, there's no doubt that the Hummer H two is a cool rig

expensive but cool. However, in stock form,

uh, they were a little lacking in the balls department and the guys at Skyjacker thought exactly the same thing

and they came out with a 5.5 inch lift for the Hummer H two

to give it more

oom

since the two suspension is fairly simple, fairly straightforward.

So was the kid from Skyjacker in spite of all these parts that you see here on the table, let me walk you through it real quick. First four new shocks then in the rear

you get new lower links, the big hem

joint at one end,

then you have the bracket to mount those.

Then you get drop brackets for your upper links

and you get drop brackets for your torsion bar cross member.

These cool looking things are aluminum spacers for your rear airbags.

Then on the front,

new steering knuckles and everything that you're gonna need to lift that independent front suspension

and all these parts made out of heavy gauge steel, powder coated red

and to protect the front suspension. You got these heavy duty skid plates. Now, if you want your H two to really stand out in the crowd, have some, uh,

skyjackers got the deal. Now, like I said before, one of the best things about owning a truck is having the bed to carry junk in. Now, like I've also said before, one of the worst things about the bed is loading stuff into it. Especially heavy things like welders and a TV S and motorcycles. Yeah. You know what I'm talking about?

Well, hold on to your shorts because a mead

deck has got the answer in what they call the super deck. Now, this is a lift platform that slides into your existing bed in just a couple hours, no modifications to the bed and with the push of a button and some high speed photography,

a hydraulic ram lifts the deck and allows you to load things into the bed you never dreamed of.

Now, the super deck is available in steel or aluminum like we've got, but the only place you can get one is a mer

deck. Now about this bike. Yeah, that's a little 60 horse Ford flathead V8 power in this thing.

And I was gonna take you for a spin. But, oh man, we're out of time but we'll take care of that next week. We'll see you then.