Classic Trucks! Builds

Want more content like this?

Join the PowerNation Email NewsletterEpisode Transcript

Today on trucks, it's big power upgrades. As Stacy shows you how to get more power from your turbocharged power stroke by using a kit called the power pack. Now that's powerful stuff

and then we'll send you back to school and show you the best place on the planet to learn the ins and outs of diesel engines. That's all today on trucks.

Hey, welcome to the shop. You know, the world of trucks is really diverse. You've got your street trucks and your four wheel drive stuff, then you have your slammers and your hot rods that this show is not about those. This is about the big boys, the guys that use diesel trucks because they really do

ha and hauling and they really need all the power that they can get. So

today we're gonna take this brand new F 250 with the Ford power stroke.

We're gonna show you how to get some serious performance gains and not hurt the truck and keep it in a reasonable budget. So if you're into diesels, you're gonna like this

in the late fifties and the early 19 sixties, a young hot roder by the name of gay banks began modifying various cars and trucks to not only go faster on the street and impress the girls but also run flat out on the Bonneville Salt Flats. It started, uh, about 1954.

Uh,

my dad, uh, bought a model a, a 31 Ford for 35 bucks.

And for the next two years I did everything I could possibly do to that car.

So, with a growing reputation, it was long before this enterprising youngster opened his own shop to supply racing engines for customers.

At the beginning, I called the business CP Auto and Marine because I was earning money to go to Cal Polly.

I wanted to learn how you design the stuff I was bolting on.

Along about this time, Gayle began to experiment with a fairly new technology to the automotive and truck world and that was the turbo charger.

Along about the late sixties,

I designed a, a twin turbo system for the big block Chevy and then later the small block Chevy. For the next couple of decades, Gle

Banks continued to refine and expand the use of turbos in cars,

trucks,

and even boats.

And at the same time, he built a state of the art facility to manufacture performance parts.

Through our consulting work. Through the years, we came to know what's required

to have oe durability.

We bring that and our air flow knowledge from racing to the truck business today.

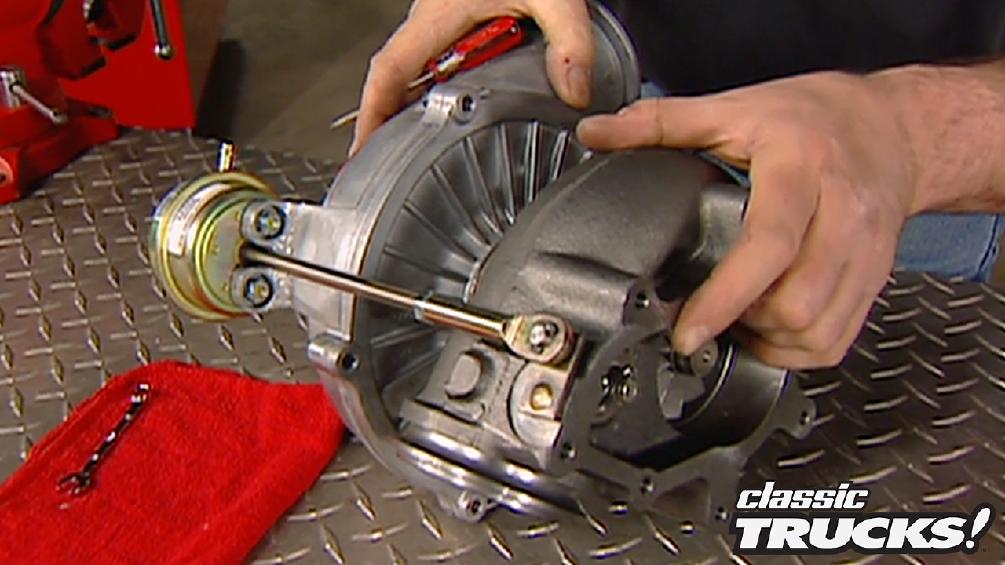

Now Gil Banks went into business in 1960. That's over 40 years that he's been supplying quality high performance parts and diesels are their specialty. Now, this system consists of a new housing

actuator

and compressor wheel for the turbo.

You've got the auto mind engine calibration module,

new inlet tubes

connectors and clamps for the transmission. You've got a command module and a transmission controller. Of course, those have their own harnesses and we'll tell you what those do when we put them in.

You also get new gauges and a gauge pod mounts on your A pillar.

You have a high flow air filter and of course

a new inner cooler, but that's not all. We also got a full stainless steel exhaust system that's four inches in diameter.

Four inches is the size of the sewer pipe in your house. Now, these are all pre bent,

have a high flow muffler

and you've got a polished end. Now,

I know this looks like a huge intimidating pile of parts, but this is not that hard to put in and I'm gonna prove it to you.

So let's get started.

All right. The first thing you need to do

is to get that old exhaust system out of there.

The tailpipe, the muffler, the whole shooting match. Now, about 95% of all diesels don't have a catalytic converter. So if your truck didn't come with one, well, you don't have to put one in,

but unfortunately, if your truck came with it.

I know it's got to go back in. Now, once you have the exhaust out of the way, it's time to go up on top and deal with the turbo.

Ok. The toughest part about getting the turbo out

is just getting to it. Now, don't be shy. You need to roll up your sleeves and actually get up in here, you'll never reach it.

Now, once you have all your inlet and outlet tubes undone the wiring harness, all you have to do is unbolt it from the engine

and take it out.

Come on, come out of there.

Uh

One way that banks is able to keep the cost down is instead of sending you a brand new turbo, very expensive.

They give you the parts to upgrade your stock one. Now it's very simple.

Just set the turbo in ice

and remove the turbine housing. Be careful that you don't damage the blades.

Reposition the turbo in the vice,

then remove the compressor housing,

remove the compressor impeller

and replace it with the new one

six

reinstall, the housing,

then reposition the turbo

in the vice.

Now we're ready for that new turbine housing and it slides right in place

of where that old one went. Now, make sure that you don't damage the impeller blades

bolted on.

Yeah.

Finally we'll put on the bank's big head actuator

and that will finish off the turbo.

All right, what we've done here is increase our air flow and our efficiency of the turbo by putting on this housing and that new impeller inside the compressor. Now, these things flow about 20 P SS I stock. This one now flows 32 P si

but it's just as reliable as your stock piece. Now, the big head actuator controls your waist gate holds it closed longer. So you develop peak boost sooner, which means great throttle response. Now, the best part is putting this thing in

is as easy as just bolting it back in place.

All right, that takes care of the turbo.

Next comes the exhaust break. We're gonna deal with that after our own break. Stay with us

up. Next. Stacy is showing us how the exhaust brake works before going down under to install a new exhaust system along with some transmission helpers.

Welcome back to trucks. We are right in the middle of doing some serious upgrades on our new Ford F 250 power stroke and the system we're using is gale banks power pack system. Now, we've already got the new inner cooler in

the turbo is back on everything bolted in. No surprises. If you look real close, you can see that I've already got there

exhaust brake installed because it bolts right to the turbo. Now, if you're not familiar with the operation of an exhaust brake, well, come on over here. Let me explain it to you.

Now, using exhaust pressure as a supplemental form of breaking. Well, that's been around a long time, but the bank's break takes it one step further. Now, the housing is cast in a nice smooth band

and the butterfly sits a lot lower than a normal exhaust brake. This gives you 30% better flow when the brake is off and that's really nice.

Now, when the brake is on

the butterfly closes and gives you the back pressure, you need to slow everything down, very similar to compression braking when you shift down a gear. Now, the brake itself is wonderful, but to get the full benefit out of it,

we also got the smart lock transmission controller

and what this does is lock up the torque converter and increase line pressure. So you have a direct connection between the engine and the rear wheels. No slippage.

That's what you need with an exhaust brake. Now, you can see by the wiring harness, you got about five connections on each end and that's all there is to it.

Ok. Now it's time to go back under the truck

and finish some things up.

First, we need to mount the vacuum pump for the exhaust break. Now, all you have to do

is mark and drill your holes according to the instructions,

then just bolt it on

and make your connections.

Another component that we're gonna mount over here on the passenger side underneath the truck is the trans command transmission control module. Now, unlike the smart lock that works in conjunction with the exhaust brake.

Well, this actually increases line pressure when you're under acceleration.

That way, when you stomp down on all that new horsepower, your tranny doesn't slip now. Only Gail Banks has this and it's really important because if you build an engine like that

and you don't upgrade the tranny,

you're gonna burn it up.

Oh, that's expensive

while I'm under here. It's the perfect time to deal with this new exhaust system. Now, like I said before, it's all pre vent,

all the hangers are welded on. So it will literally

just slide into place. Make sure you got on a good set of gloves because these pipes will cut you.

Now, once you have the turbine outlet pipe on,

just slide on the intermediate pipes,

followed by this big old dyno Flow muffler,

the tailpipe and of course, the tip,

the tip should sit about two inches below the fender. So you have room for expansion. Now how far the tip sticks out is entirely up to you?

But a good look is out about as far as the tire.

Now, once you have everything positioned, go ahead and tighten all your clamps starting in the front.

All right.

That takes care of the hookups underneath

the exhaust system and yet another segment of the show. Now, after the break, we're gonna finish the hookups up in the cab,

then we're gonna turn the key on this thing and see if any of this makes any difference.

I think you're gonna be surprised.

Next, the gauges go in and we're going to put this baby to the test

and later it's diesel 101. As we take a tour of Wyoming Tech diesel program

just can't get enough of trucks. Check us out online at TRUCKS, tv.com.

Welcome back. We are on the final leg of doing some upgrades on a Ford power stroke on this brand new F 250. Now, we've already upgraded the turbo, the inter cooler and the transmission

we put on an exhaust brake. Now, all we have to do is make some connections and that means going in the cab.

First thing we're gonna do is deal with these auxiliary gauges and we got transmission temperature turbo boost and exhaust temperature and they slide into this little plastic pod.

Now, the pod mounts to your factory trim piece using these plastic rivets.

Then it all just pops back into place. All you have to do is make your connections to your wires

and you're ready to roll.

Now we're ready to mount the switch that activates the exhaust brake. Now, the bank's engineers found the perfect place right here on the dash next to the steering column. All you have to do is cut out the template that comes in your instructions, set it in place and drill your hole.

Now, all you have to do is make your connections to the idle validation switch down here on the pedal

to your supplied relays, then go under the hood, connect to the brake switch on the master cylinder,

the actuator control valve and then finally down to the vacuum pump on the frame.

While I'm in here, I'm gonna go ahead and mount this smart lock transmission controller

and it sticks right to this junction box that runs underneath the steering column. Now, it's held in place with some adhesive tape that comes with the kit

and all you have to do is plug in your harness

and run the harness through the firewall and make your connections. It's that easy.

Next, we're going to deal with the auto

Mind engine calibration module. All you have to do is remove the computer from the left kick panel.

Now, once you have it all disassembled, remove the plug from the back of the computer

plug in the bank's auto.

Mind,

it's a good idea to use a piece of tape to hold this thing in place,

then slide the whole thing back into the retainer.

And remember you're gonna have to cut off some of this plastic here so that auto mine will stick up out of there,

then

just reinstall it.

Now, I know you're dying to know some numbers on this thing. So here's what we got.

The bank's power pack kit will take your stock power stroke from around 200 horsepower to over 300 horsepower. It'll also increase your foot pounds of torque to over 675.

That's nice. You'll also expect to get a little better gas mileage about three miles to the gallon provided you can stay out of the pedal. Yeah, right

now all these numbers are great, but the real test comes out on the road. So

it's time to put this thing of the test.

Yeah, we'll see what this thing will pull.

Keep coming.

Oh.

Oh,

that's

not.

Oh,

all I can say is, wow, you need to feel this. Now, I may not have mentioned, but this is Gail's own personal truck.

And it says a lot when a guy believes enough in his products to let him be installed on his own brand new truck, especially when he knows how hard I'm going to be on it to see if I can find a weak spot. I'll tell you what I haven't found any, but I guess that's to be expected because gay's got a reputation to uphold. But then again,

so do I so gail this one's for you

after the break. We're going to a school where the classroom smells like diesel and the students love it. It's Wyoming Tech and we'll take you there.

Welcome back to the truck shop. Now, I know that there's a lot of you, especially after seeing the Gay Banks project

that would really like to learn more about diesel engines. Heck, there are a lot of opportunities out there for qualified diesel mechanics. So the question is,

where do you go to learn? Well, I just happen to know of a place in Wyoming. That'll teach you everything you need to know to get you started.

Check this out

the diesel technology program. Wyotech is a six month intensive program, teaching the ins and outs of some of the most popular engines in the business. You got Cummins, Detroit, diesel Caterpillar and others. And the best part is you have a state of the art diesel shop that has the latest equipment. That way the graduates are ready for the real world. We do a lot of diagnostic testing, hooking up computers, PC

and data links to see what, what is wrong with the engine.

We have little boxes along the side, like right over here,

they'll flip the switches on the instructor will

and then you'll have to go through the computer and find out what they, what

was the problem? What they flipped over?

I mean, you do get tested over pretty well.

The instructors use a real hands on approach to teaching the students

in all aspects of the industry, including refrigeration,

Adras brake and electrical system.

Very good,

good

job.

Wyotech

keeps things interesting by inviting professionals from the industry to give lectures and have question and answer sessions with the students about the different careers that are out there waiting for them.

Now, guest speaker, Mike Ryan is a guy who's made a living playing with trucks

that all started with an interest in going fast.

I've had a interesting performance since I was a kid. I guess I go karts and mini bikes and

fixed all the lawn mowers in the neighborhood, kind of thing to support

building go karts. And what have you

after being a mechanic for a few years, Mike started working in the movie stunt business

and with some friends, we raced motorcycles up the hill climb at Pike's peak.

So I went to Pike's peak in 95 on a motorcycle and raced it for two years.

And a guy showed up from New York with a semi truck and did an exhibition run, which just knocked me out. Most of my

career in the stun business has been involved around race cars or semi trucks. And so the idea of racing a semi truck

just kind of stuck. He brought his heavily modified semi truck to show the Wyotech students

that there are other job options out there for a graduate of the diesel program, for instance,

and

experience mechanic could work on the Mercedes V6 twin turbo

that puts out 1250 horsepower to a ZF automatic transmission.

He's won the Pikes peak race four times in his red truck and has even attempted land speed records at the Bonneville Salt Flats going 225 miles an hour

in a semi truck

at

225 in the,

in the century class.

I think that's a pretty amazing

engineering technological feat in itself. I mean, that's the same body

that's sitting right here with my over the road freight liner

um with very few modifications uh because the rules don't allow it in a modified class.

Um So it's pretty incredible that that thing would go 225 or that shape would go 225

mi

has found even more ways to work in the truck business. He also recreates road accidents for analysis in the insurance business.

Now, this is a job he doesn't recommend for just anybody,

but he does recommend going to Wild Tech because you can get so many skills in a short period of time.

Eventually I kind of learned and picked it up a little bit here and a little bit there, but never ever was certified in any way. So

I'm pretty impressed that somebody could come into a school like this for a few months

and walk out really knowing something that kind of took me a few years to,

I don't know that my knowledge will ever

match up to what you get in in six months.

Another thing that Wyotech does is hold career fairs at the school every three months here. Employers from around the globe, set up information booths and talk to the students about job possibilities

on site. Interviews are scheduled to give upcoming graduates

a lot of choices in the career they want

and this benefits the employers too. By getting high quality trained technicians right out of school.

Pretty much if they, if they pass here, technically they can, they can handle the job that I have to offer coming in the big,

big facility like ours. Uh you know, the,

the students have to be well motivated and no discipline.

And, and I think well

tech does a real good job of that.

The thing we like the most is quality of student that graduates from here

working with diesel engines can be a well paying rewarding job and heck you get to play with tools and trucks all the time

and of course, getting the best training

is essential for success. A Wyotech can give you the skills that you need and keep it fun no matter what field you go into

Wyotech in my mind represents

an opportunity that I'm not aware of anywhere else in the country

where you could learn how to do this stuff, right. Do it efficiently and make a profit at it and serve the truck industry,

uh which definitely needs some help

next week on trucks.

It's the start of project Copperhead as Stacy begins bolt the suspension onto the frame of a cool 1967 C and Chevy

and we'll get some hammer time with professor Hammer himself. Ron Coll.

That's all next week on trucks.

Trucks is an RTM production.

Show Full Transcript

and then we'll send you back to school and show you the best place on the planet to learn the ins and outs of diesel engines. That's all today on trucks.

Hey, welcome to the shop. You know, the world of trucks is really diverse. You've got your street trucks and your four wheel drive stuff, then you have your slammers and your hot rods that this show is not about those. This is about the big boys, the guys that use diesel trucks because they really do

ha and hauling and they really need all the power that they can get. So

today we're gonna take this brand new F 250 with the Ford power stroke.

We're gonna show you how to get some serious performance gains and not hurt the truck and keep it in a reasonable budget. So if you're into diesels, you're gonna like this

in the late fifties and the early 19 sixties, a young hot roder by the name of gay banks began modifying various cars and trucks to not only go faster on the street and impress the girls but also run flat out on the Bonneville Salt Flats. It started, uh, about 1954.

Uh,

my dad, uh, bought a model a, a 31 Ford for 35 bucks.

And for the next two years I did everything I could possibly do to that car.

So, with a growing reputation, it was long before this enterprising youngster opened his own shop to supply racing engines for customers.

At the beginning, I called the business CP Auto and Marine because I was earning money to go to Cal Polly.

I wanted to learn how you design the stuff I was bolting on.

Along about this time, Gayle began to experiment with a fairly new technology to the automotive and truck world and that was the turbo charger.

Along about the late sixties,

I designed a, a twin turbo system for the big block Chevy and then later the small block Chevy. For the next couple of decades, Gle

Banks continued to refine and expand the use of turbos in cars,

trucks,

and even boats.

And at the same time, he built a state of the art facility to manufacture performance parts.

Through our consulting work. Through the years, we came to know what's required

to have oe durability.

We bring that and our air flow knowledge from racing to the truck business today.

Now Gil Banks went into business in 1960. That's over 40 years that he's been supplying quality high performance parts and diesels are their specialty. Now, this system consists of a new housing

actuator

and compressor wheel for the turbo.

You've got the auto mind engine calibration module,

new inlet tubes

connectors and clamps for the transmission. You've got a command module and a transmission controller. Of course, those have their own harnesses and we'll tell you what those do when we put them in.

You also get new gauges and a gauge pod mounts on your A pillar.

You have a high flow air filter and of course

a new inner cooler, but that's not all. We also got a full stainless steel exhaust system that's four inches in diameter.

Four inches is the size of the sewer pipe in your house. Now, these are all pre bent,

have a high flow muffler

and you've got a polished end. Now,

I know this looks like a huge intimidating pile of parts, but this is not that hard to put in and I'm gonna prove it to you.

So let's get started.

All right. The first thing you need to do

is to get that old exhaust system out of there.

The tailpipe, the muffler, the whole shooting match. Now, about 95% of all diesels don't have a catalytic converter. So if your truck didn't come with one, well, you don't have to put one in,

but unfortunately, if your truck came with it.

I know it's got to go back in. Now, once you have the exhaust out of the way, it's time to go up on top and deal with the turbo.

Ok. The toughest part about getting the turbo out

is just getting to it. Now, don't be shy. You need to roll up your sleeves and actually get up in here, you'll never reach it.

Now, once you have all your inlet and outlet tubes undone the wiring harness, all you have to do is unbolt it from the engine

and take it out.

Come on, come out of there.

Uh

One way that banks is able to keep the cost down is instead of sending you a brand new turbo, very expensive.

They give you the parts to upgrade your stock one. Now it's very simple.

Just set the turbo in ice

and remove the turbine housing. Be careful that you don't damage the blades.

Reposition the turbo in the vice,

then remove the compressor housing,

remove the compressor impeller

and replace it with the new one

six

reinstall, the housing,

then reposition the turbo

in the vice.

Now we're ready for that new turbine housing and it slides right in place

of where that old one went. Now, make sure that you don't damage the impeller blades

bolted on.

Yeah.

Finally we'll put on the bank's big head actuator

and that will finish off the turbo.

All right, what we've done here is increase our air flow and our efficiency of the turbo by putting on this housing and that new impeller inside the compressor. Now, these things flow about 20 P SS I stock. This one now flows 32 P si

but it's just as reliable as your stock piece. Now, the big head actuator controls your waist gate holds it closed longer. So you develop peak boost sooner, which means great throttle response. Now, the best part is putting this thing in

is as easy as just bolting it back in place.

All right, that takes care of the turbo.

Next comes the exhaust break. We're gonna deal with that after our own break. Stay with us

up. Next. Stacy is showing us how the exhaust brake works before going down under to install a new exhaust system along with some transmission helpers.

Welcome back to trucks. We are right in the middle of doing some serious upgrades on our new Ford F 250 power stroke and the system we're using is gale banks power pack system. Now, we've already got the new inner cooler in

the turbo is back on everything bolted in. No surprises. If you look real close, you can see that I've already got there

exhaust brake installed because it bolts right to the turbo. Now, if you're not familiar with the operation of an exhaust brake, well, come on over here. Let me explain it to you.

Now, using exhaust pressure as a supplemental form of breaking. Well, that's been around a long time, but the bank's break takes it one step further. Now, the housing is cast in a nice smooth band

and the butterfly sits a lot lower than a normal exhaust brake. This gives you 30% better flow when the brake is off and that's really nice.

Now, when the brake is on

the butterfly closes and gives you the back pressure, you need to slow everything down, very similar to compression braking when you shift down a gear. Now, the brake itself is wonderful, but to get the full benefit out of it,

we also got the smart lock transmission controller

and what this does is lock up the torque converter and increase line pressure. So you have a direct connection between the engine and the rear wheels. No slippage.

That's what you need with an exhaust brake. Now, you can see by the wiring harness, you got about five connections on each end and that's all there is to it.

Ok. Now it's time to go back under the truck

and finish some things up.

First, we need to mount the vacuum pump for the exhaust break. Now, all you have to do

is mark and drill your holes according to the instructions,

then just bolt it on

and make your connections.

Another component that we're gonna mount over here on the passenger side underneath the truck is the trans command transmission control module. Now, unlike the smart lock that works in conjunction with the exhaust brake.

Well, this actually increases line pressure when you're under acceleration.

That way, when you stomp down on all that new horsepower, your tranny doesn't slip now. Only Gail Banks has this and it's really important because if you build an engine like that

and you don't upgrade the tranny,

you're gonna burn it up.

Oh, that's expensive

while I'm under here. It's the perfect time to deal with this new exhaust system. Now, like I said before, it's all pre vent,

all the hangers are welded on. So it will literally

just slide into place. Make sure you got on a good set of gloves because these pipes will cut you.

Now, once you have the turbine outlet pipe on,

just slide on the intermediate pipes,

followed by this big old dyno Flow muffler,

the tailpipe and of course, the tip,

the tip should sit about two inches below the fender. So you have room for expansion. Now how far the tip sticks out is entirely up to you?

But a good look is out about as far as the tire.

Now, once you have everything positioned, go ahead and tighten all your clamps starting in the front.

All right.

That takes care of the hookups underneath

the exhaust system and yet another segment of the show. Now, after the break, we're gonna finish the hookups up in the cab,

then we're gonna turn the key on this thing and see if any of this makes any difference.

I think you're gonna be surprised.

Next, the gauges go in and we're going to put this baby to the test

and later it's diesel 101. As we take a tour of Wyoming Tech diesel program

just can't get enough of trucks. Check us out online at TRUCKS, tv.com.

Welcome back. We are on the final leg of doing some upgrades on a Ford power stroke on this brand new F 250. Now, we've already upgraded the turbo, the inter cooler and the transmission

we put on an exhaust brake. Now, all we have to do is make some connections and that means going in the cab.

First thing we're gonna do is deal with these auxiliary gauges and we got transmission temperature turbo boost and exhaust temperature and they slide into this little plastic pod.

Now, the pod mounts to your factory trim piece using these plastic rivets.

Then it all just pops back into place. All you have to do is make your connections to your wires

and you're ready to roll.

Now we're ready to mount the switch that activates the exhaust brake. Now, the bank's engineers found the perfect place right here on the dash next to the steering column. All you have to do is cut out the template that comes in your instructions, set it in place and drill your hole.

Now, all you have to do is make your connections to the idle validation switch down here on the pedal

to your supplied relays, then go under the hood, connect to the brake switch on the master cylinder,

the actuator control valve and then finally down to the vacuum pump on the frame.

While I'm in here, I'm gonna go ahead and mount this smart lock transmission controller

and it sticks right to this junction box that runs underneath the steering column. Now, it's held in place with some adhesive tape that comes with the kit

and all you have to do is plug in your harness

and run the harness through the firewall and make your connections. It's that easy.

Next, we're going to deal with the auto

Mind engine calibration module. All you have to do is remove the computer from the left kick panel.

Now, once you have it all disassembled, remove the plug from the back of the computer

plug in the bank's auto.

Mind,

it's a good idea to use a piece of tape to hold this thing in place,

then slide the whole thing back into the retainer.

And remember you're gonna have to cut off some of this plastic here so that auto mine will stick up out of there,

then

just reinstall it.

Now, I know you're dying to know some numbers on this thing. So here's what we got.

The bank's power pack kit will take your stock power stroke from around 200 horsepower to over 300 horsepower. It'll also increase your foot pounds of torque to over 675.

That's nice. You'll also expect to get a little better gas mileage about three miles to the gallon provided you can stay out of the pedal. Yeah, right

now all these numbers are great, but the real test comes out on the road. So

it's time to put this thing of the test.

Yeah, we'll see what this thing will pull.

Keep coming.

Oh.

Oh,

that's

not.

Oh,

all I can say is, wow, you need to feel this. Now, I may not have mentioned, but this is Gail's own personal truck.

And it says a lot when a guy believes enough in his products to let him be installed on his own brand new truck, especially when he knows how hard I'm going to be on it to see if I can find a weak spot. I'll tell you what I haven't found any, but I guess that's to be expected because gay's got a reputation to uphold. But then again,

so do I so gail this one's for you

after the break. We're going to a school where the classroom smells like diesel and the students love it. It's Wyoming Tech and we'll take you there.

Welcome back to the truck shop. Now, I know that there's a lot of you, especially after seeing the Gay Banks project

that would really like to learn more about diesel engines. Heck, there are a lot of opportunities out there for qualified diesel mechanics. So the question is,

where do you go to learn? Well, I just happen to know of a place in Wyoming. That'll teach you everything you need to know to get you started.

Check this out

the diesel technology program. Wyotech is a six month intensive program, teaching the ins and outs of some of the most popular engines in the business. You got Cummins, Detroit, diesel Caterpillar and others. And the best part is you have a state of the art diesel shop that has the latest equipment. That way the graduates are ready for the real world. We do a lot of diagnostic testing, hooking up computers, PC

and data links to see what, what is wrong with the engine.

We have little boxes along the side, like right over here,

they'll flip the switches on the instructor will

and then you'll have to go through the computer and find out what they, what

was the problem? What they flipped over?

I mean, you do get tested over pretty well.

The instructors use a real hands on approach to teaching the students

in all aspects of the industry, including refrigeration,

Adras brake and electrical system.

Very good,

good

job.

Wyotech

keeps things interesting by inviting professionals from the industry to give lectures and have question and answer sessions with the students about the different careers that are out there waiting for them.

Now, guest speaker, Mike Ryan is a guy who's made a living playing with trucks

that all started with an interest in going fast.

I've had a interesting performance since I was a kid. I guess I go karts and mini bikes and

fixed all the lawn mowers in the neighborhood, kind of thing to support

building go karts. And what have you

after being a mechanic for a few years, Mike started working in the movie stunt business

and with some friends, we raced motorcycles up the hill climb at Pike's peak.

So I went to Pike's peak in 95 on a motorcycle and raced it for two years.

And a guy showed up from New York with a semi truck and did an exhibition run, which just knocked me out. Most of my

career in the stun business has been involved around race cars or semi trucks. And so the idea of racing a semi truck

just kind of stuck. He brought his heavily modified semi truck to show the Wyotech students

that there are other job options out there for a graduate of the diesel program, for instance,

and

experience mechanic could work on the Mercedes V6 twin turbo

that puts out 1250 horsepower to a ZF automatic transmission.

He's won the Pikes peak race four times in his red truck and has even attempted land speed records at the Bonneville Salt Flats going 225 miles an hour

in a semi truck

at

225 in the,

in the century class.

I think that's a pretty amazing

engineering technological feat in itself. I mean, that's the same body

that's sitting right here with my over the road freight liner

um with very few modifications uh because the rules don't allow it in a modified class.

Um So it's pretty incredible that that thing would go 225 or that shape would go 225

mi

has found even more ways to work in the truck business. He also recreates road accidents for analysis in the insurance business.

Now, this is a job he doesn't recommend for just anybody,

but he does recommend going to Wild Tech because you can get so many skills in a short period of time.

Eventually I kind of learned and picked it up a little bit here and a little bit there, but never ever was certified in any way. So

I'm pretty impressed that somebody could come into a school like this for a few months

and walk out really knowing something that kind of took me a few years to,

I don't know that my knowledge will ever

match up to what you get in in six months.

Another thing that Wyotech does is hold career fairs at the school every three months here. Employers from around the globe, set up information booths and talk to the students about job possibilities

on site. Interviews are scheduled to give upcoming graduates

a lot of choices in the career they want

and this benefits the employers too. By getting high quality trained technicians right out of school.

Pretty much if they, if they pass here, technically they can, they can handle the job that I have to offer coming in the big,

big facility like ours. Uh you know, the,

the students have to be well motivated and no discipline.

And, and I think well

tech does a real good job of that.

The thing we like the most is quality of student that graduates from here

working with diesel engines can be a well paying rewarding job and heck you get to play with tools and trucks all the time

and of course, getting the best training

is essential for success. A Wyotech can give you the skills that you need and keep it fun no matter what field you go into

Wyotech in my mind represents

an opportunity that I'm not aware of anywhere else in the country

where you could learn how to do this stuff, right. Do it efficiently and make a profit at it and serve the truck industry,

uh which definitely needs some help

next week on trucks.

It's the start of project Copperhead as Stacy begins bolt the suspension onto the frame of a cool 1967 C and Chevy

and we'll get some hammer time with professor Hammer himself. Ron Coll.

That's all next week on trucks.

Trucks is an RTM production.